1. Introduction

The electric wheel dump truck is used for several hundred tons of transportation in large open pit sites. There are a large number of curves on the mine surface, so that the steering is frequently needed [

1,

2]. The welded A-type frame is considered as one of the bearing components in the steering system, and thus its fatigue reliability is of pivotal performance to guarantee the safe operation of the vehicle [

3]. When the structural fatigue reliability is calculated as the traditional linear cumulative damage theory, the accumulated fatigue damage that is caused by high stress level over fatigue limit is only taken into account, while the one that is produced by low stress level below fatigue limit is often ignored. However, there is fuzziness in whether the stress near fatigue limit results in damage, and some research suggests that the low stress level slightly below fatigue limit also yields fatigue damage [

4,

5]. Therefore, exploring structural fatigue reliability based on fuzzy theory is more effective than the traditional linear cumulative damage theory.

With the increasingly harsh service environment of mechanical equipment, more and more scholars focus on the fatigue reliability of bearing components. Li et al. [

4] proposed a failure-based reliability estimation method while using the multi-source information compound to predict the reliability of turbine blades of aero engines. Case studies of reliability assessment under fuzzy stress with and without strength were implemented based on dynamic stress-strength interference model by taking types of cycles into account. Zhu et al. [

5] presented a novel linear damage accumulation rule by use of fuzzy sets theory, which was in consideration of both the damage and strengthening of low amplitude loads, as well as the sequence effects of different loads. Zhang et al. [

6] suggested a kind of Bayesian approach to ascertain a fatigue lifetime reliability model of ship structure taking advantage of small sample experimental data. The empirical distribution was obtained from the fuzzy synthesis judgment, and by likelihood function characterized the sample information. Combining empirical information with sample information, the Bayesian approach was utilized to determine the posterior probability distribution. However, even though the fuzzy theory was widely employed to estimate the engineering structure reliability by determining the distribution of random stress and strength, the effects on fatigue reliability evolution that are caused by the uncertainties of design variables were still not included. Liu et al. [

7] evaluated the fatigue strength of welded structures with welding defects using fuzzy sets theory, when considering the interrelations among the category, dimension, location, and the interaction of defects. Based on the fuzzy theory and reliability design rules, Zhu et al. [

8] constructed the fuzzy reliability mathematical model for the fatigue strength of the V-belt. The fuzzy reliability design method with coexisting random variables and fuzzy variables was discussed. These researches that are mentioned above mainly depended on the traditional fuzzy membership function to characterize fuzzy extent, such as normal distribution, parabolic distribution, et al. However, the characteristic parameters that were needed in these models could be only ascertained by a large number of sample data, which was not suitable to describe the distribution of random variable having limited sample data. Wang et al. [

9] proposed a fatigue reliability analysis and optimization method based on the three degrees of freedom flexible micro-positioning stage to determine the fatigue strength of the hinges by considering various influencing factors. Subsequently, the genetic algorithm was utilized to conduct on fatigue reliability optimization. Jiang et al. [

10] analyzed the structural reliability under both static and fatigue load, and then the optimal design with different variables was carried out by making use of an improved genetic algorithm. However, this work characterized the randomness of variables utilizing the traditional distribution function, and the fatigue reliability performance function could be directly obtained. As for engineering structures, in fact, the fatigue reliability performance function was difficult to ascertain on the basis of limited samples.

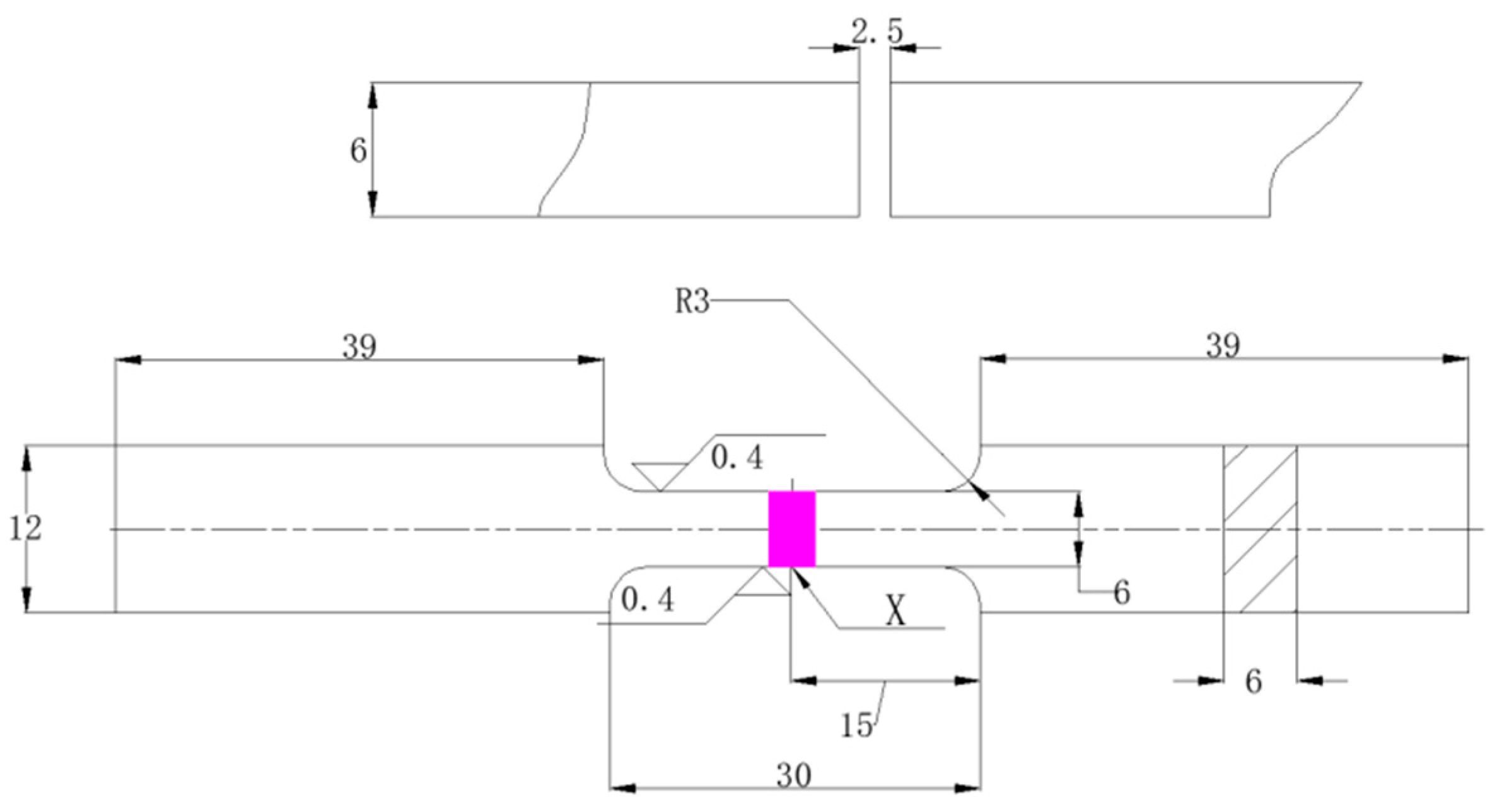

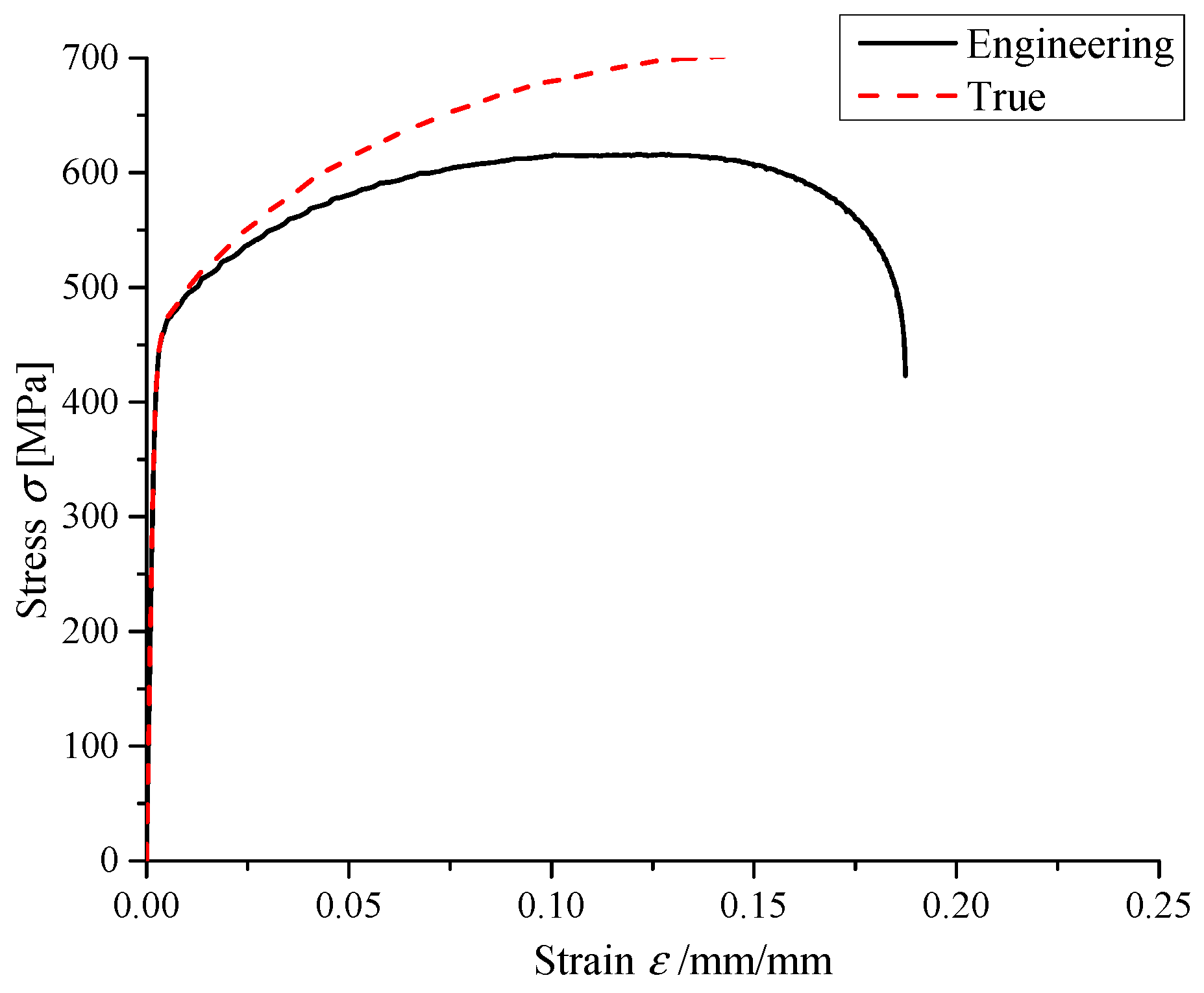

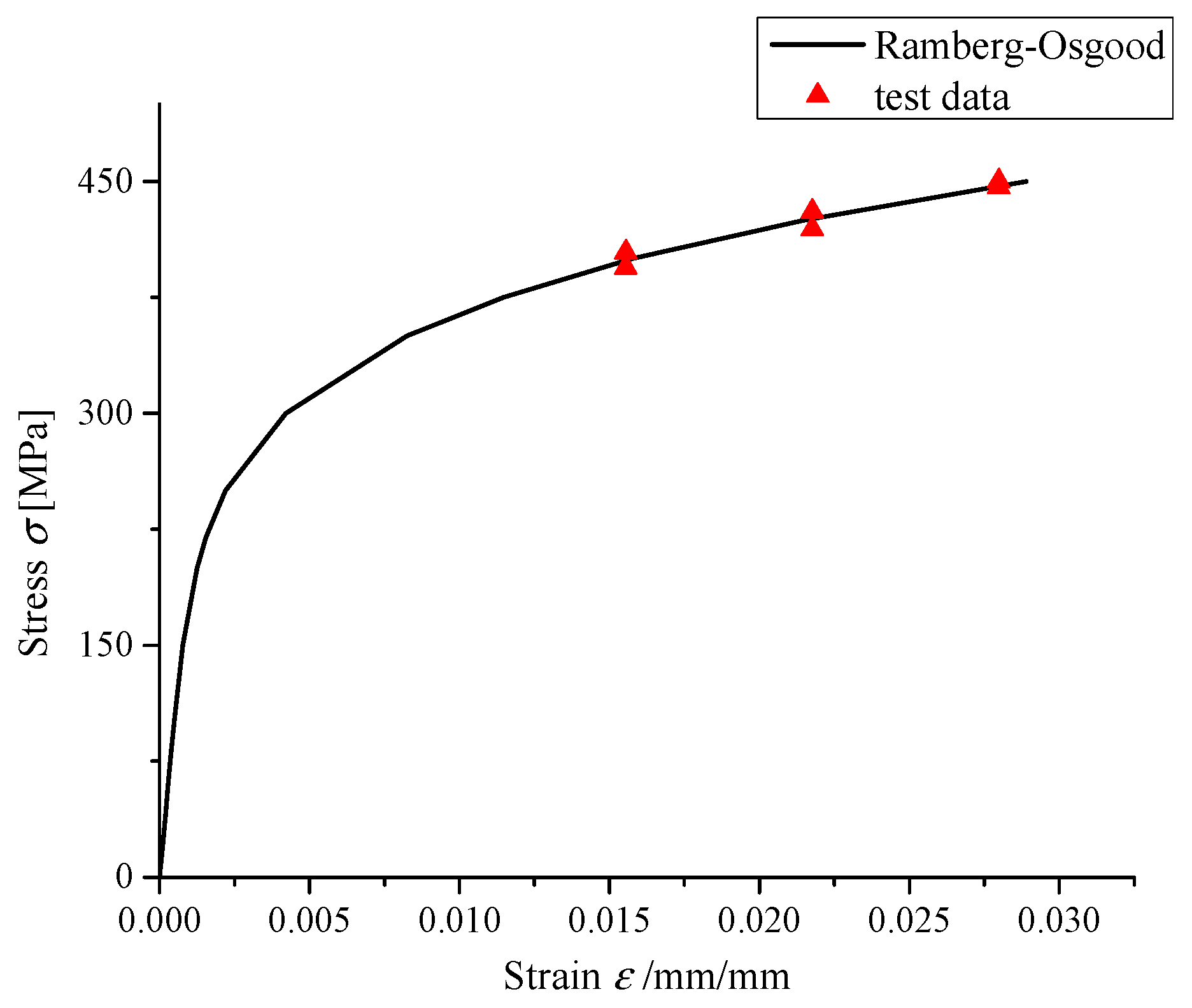

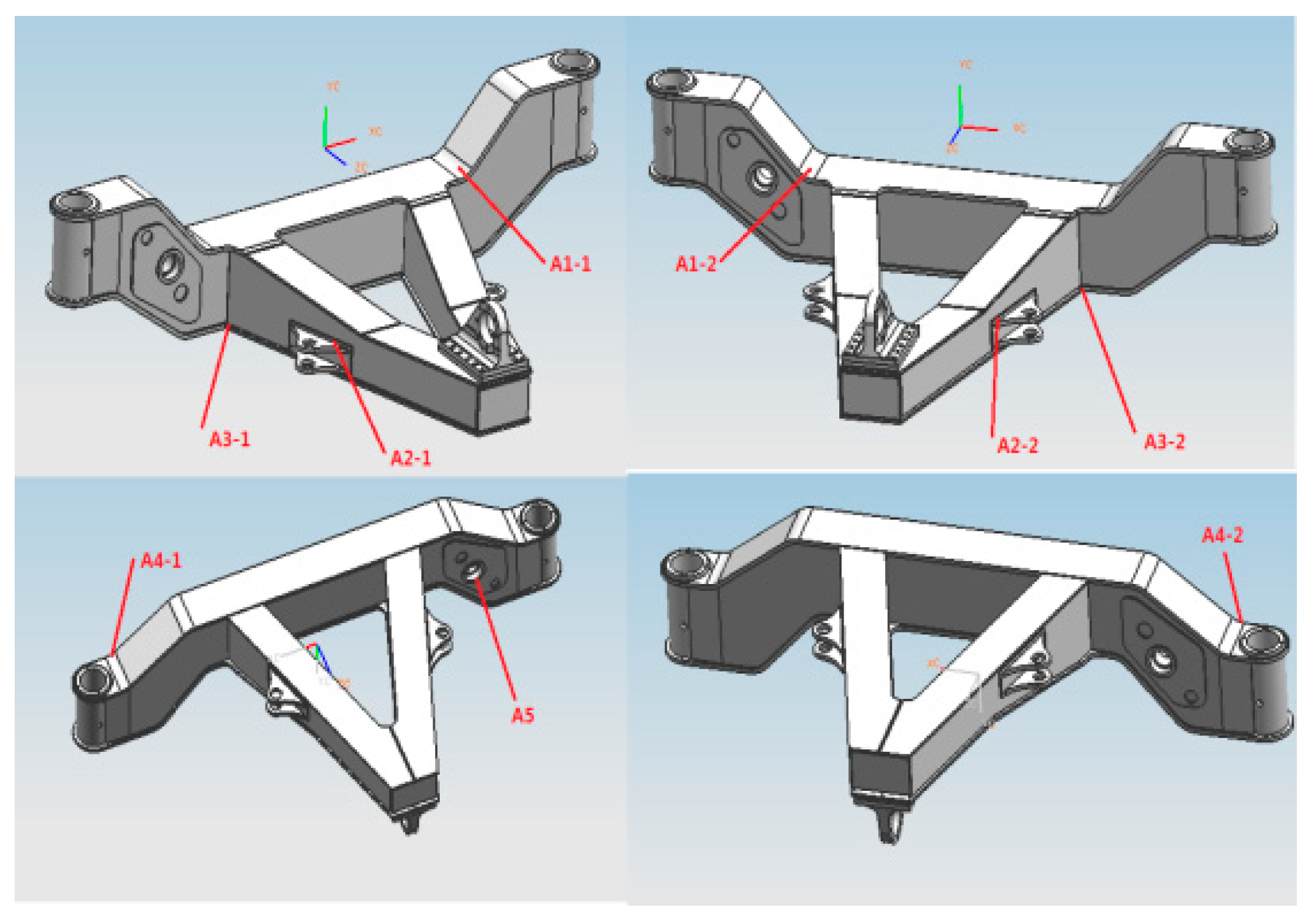

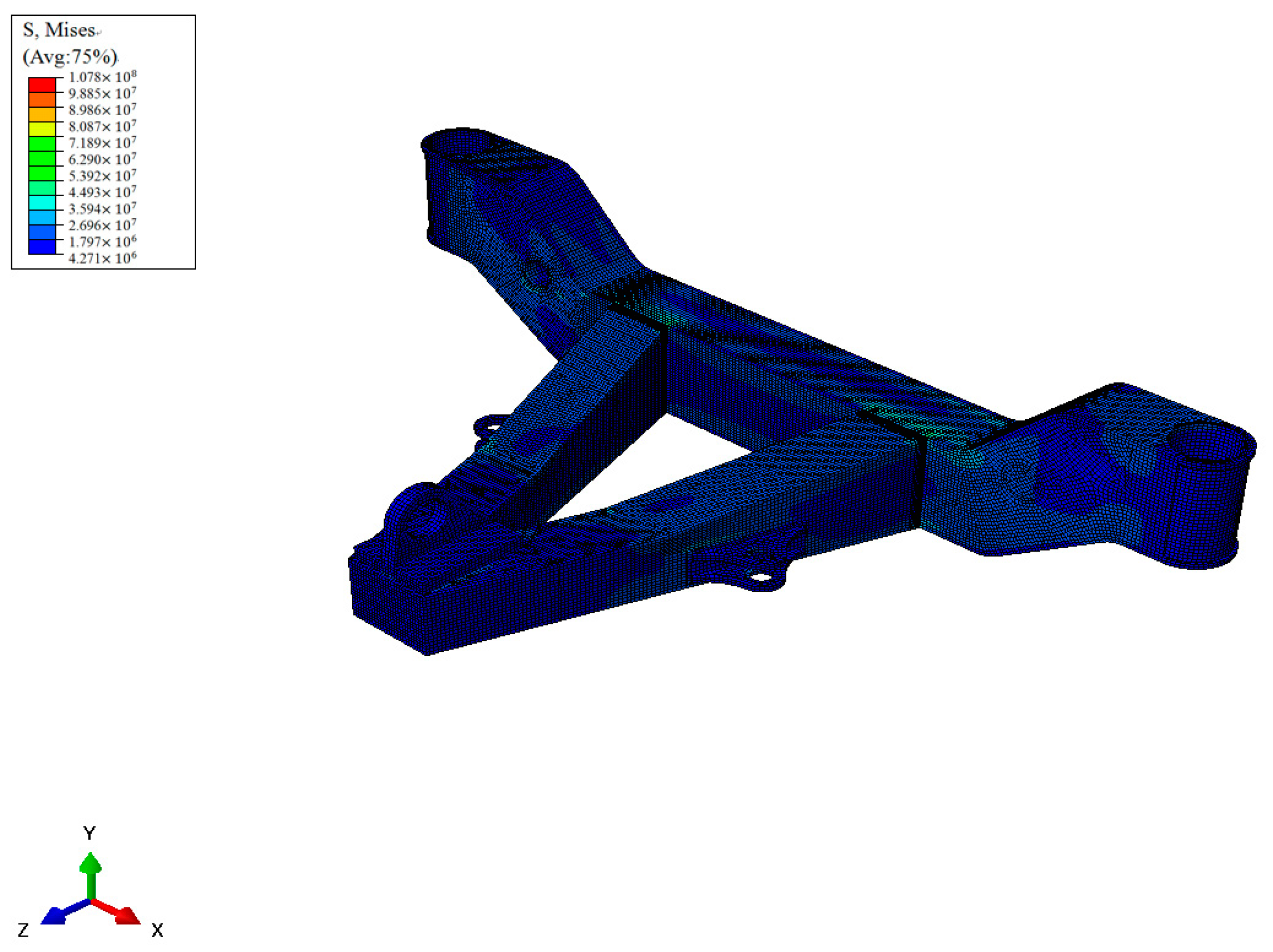

Plate high-strength steel with different thicknesses welded this A-type frame [

11]. In the manufacturing stage, the material properties of the weld metal are scattered, which is caused by man-made factors. In addition, the dimension of A-type frame is usually obtained from the traditional experience, which could be different from the “ideal” structure. The steering loads at its connection sites should be random during the in-service stage, because the excitation source is stochastic. These parameters are all relative with the structural fatigue reliability. According to the traditional stress-strength interface model [

12,

13,

14], only stress and strength are directly considered as random variables to evaluate fuzzy fatigue reliability, which is unreasonable to ignore the uncertainties of dimension, material properties, and loads. More importantly, the common fuzzy fatigue reliability analysis is based on the traditional membership function, such as normal distribution, parabolic distribution, et al. However, a large number of sample data is needed to ascertain the characteristic parameters of traditional membership function, so that the calculated fuzzy fatigue reliability that is based on this method has certain errors for engineering structures without enough samples. The performance function used for calculating fatigue reliability is also not easy to determine on account of a small amount of sample data. Therefore, the multi-source uncertainties were taken into account to analyze the fuzzy fatigue reliability of welded A-type frame to accurately establish the membership function and performance function.

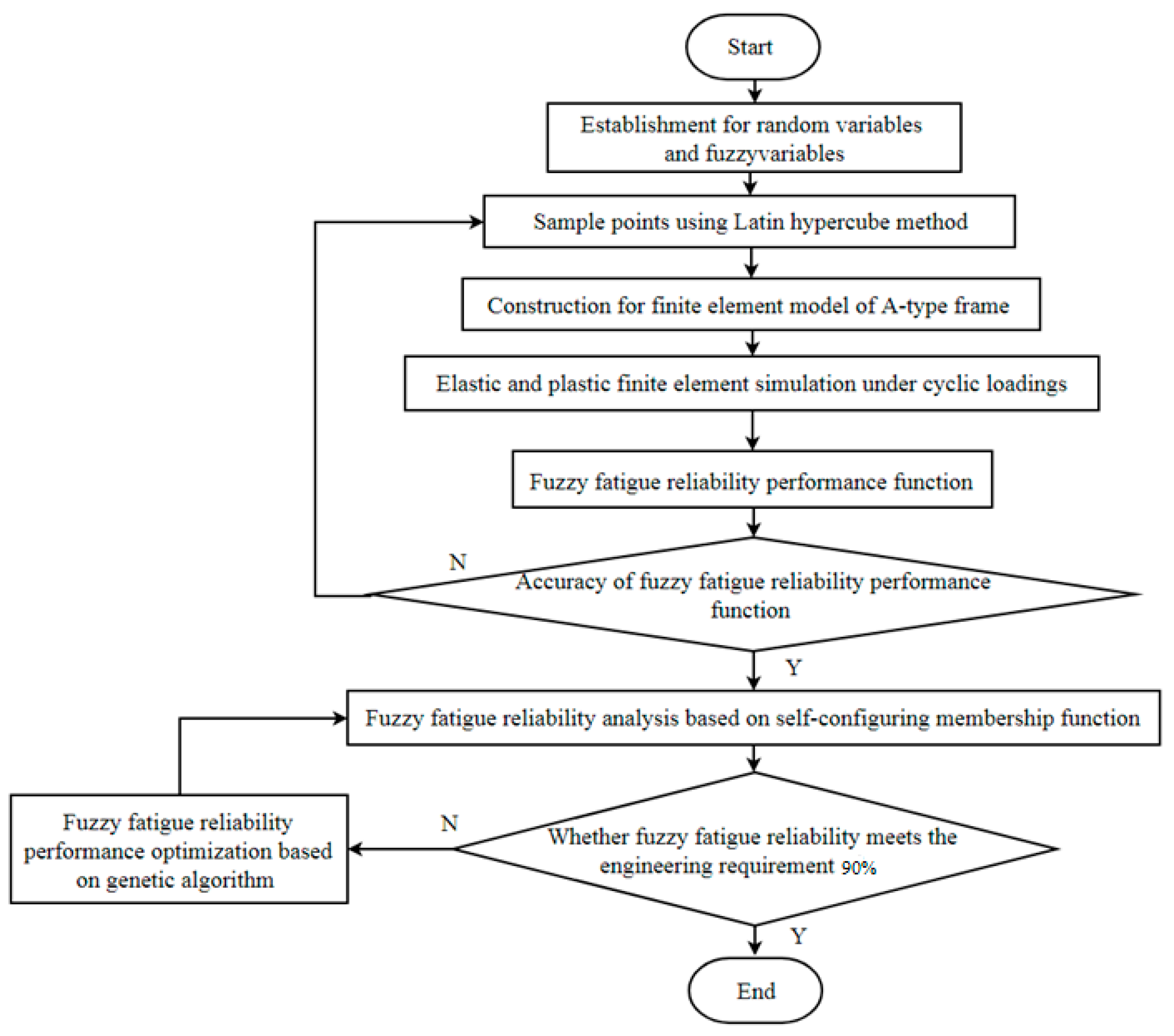

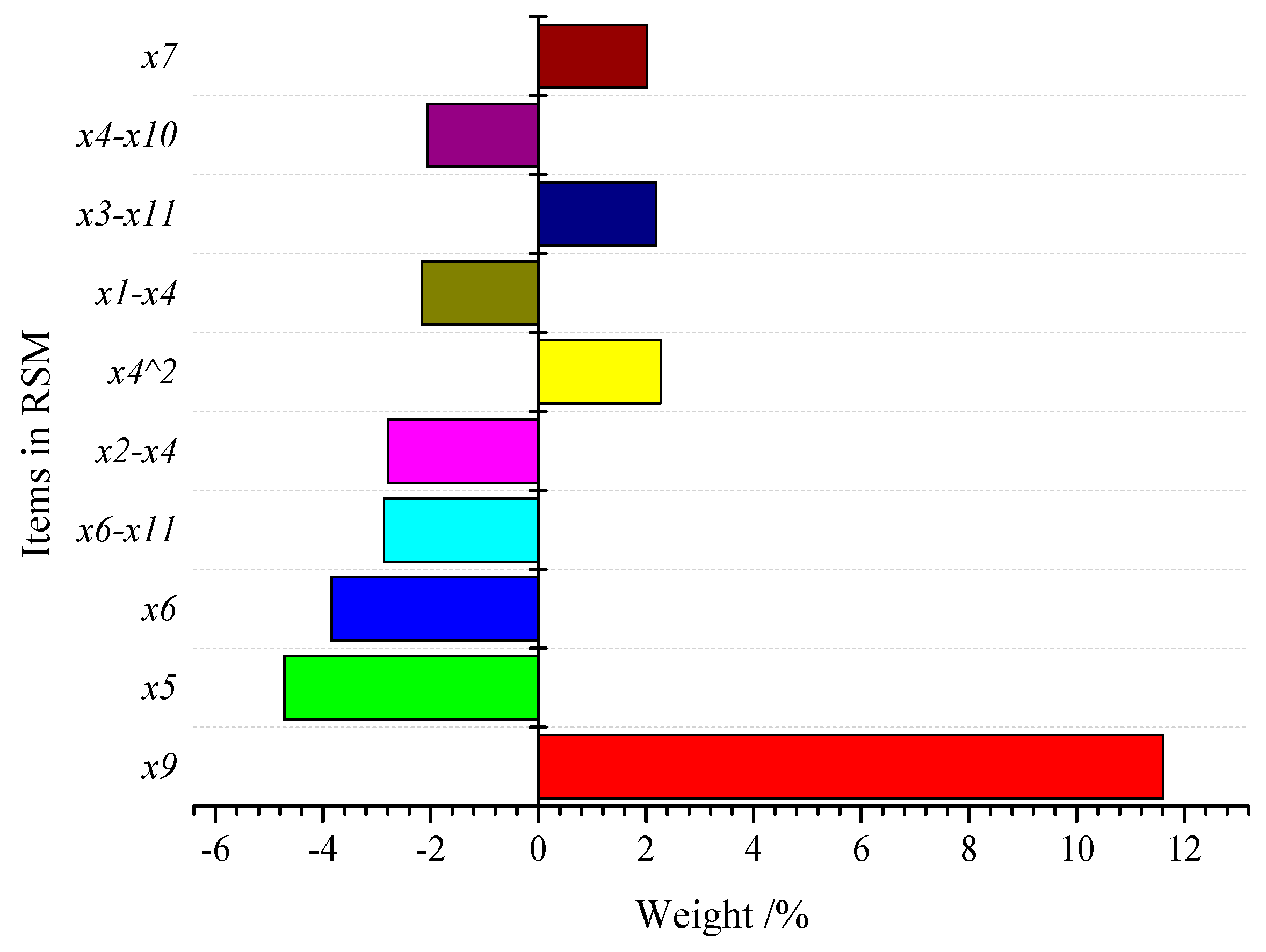

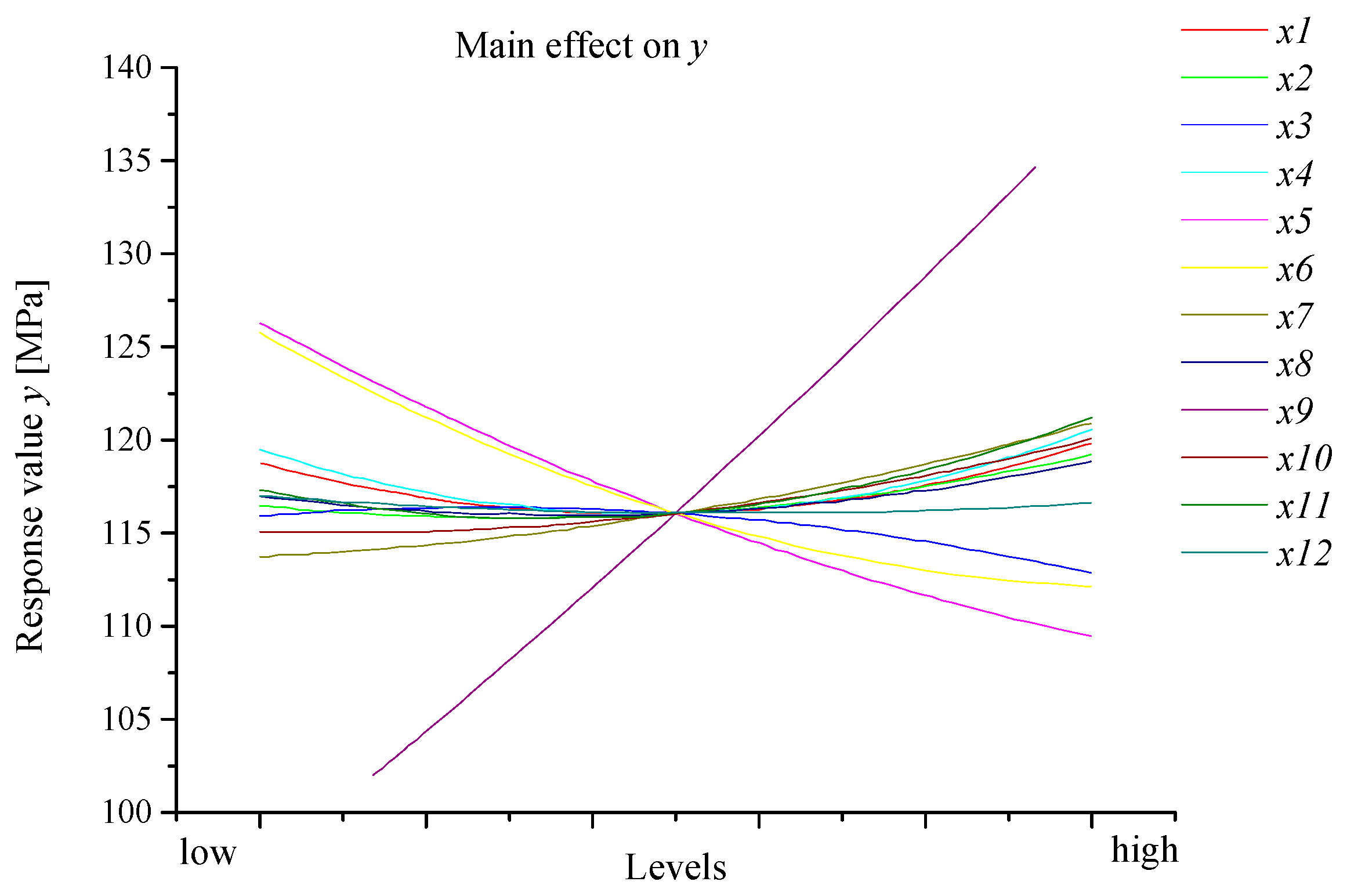

In this paper, a new membership function was constructed based on the limited sample data, whose accuracy was testified by experimental data. According to the fuzzy theory, the failure probability formula was deduced. Subsequently, the response surface method was employed to establish fuzzy fatigue reliability performance function, while considering the uncertainties of dimension, material properties, and loads. The fuzzy fatigue reliability of the welded A-type frame was evaluated by the self-configuring membership function, and the optimal design for improving fatigue reliability was conducted through the genetic algorithm.

6. Conclusions

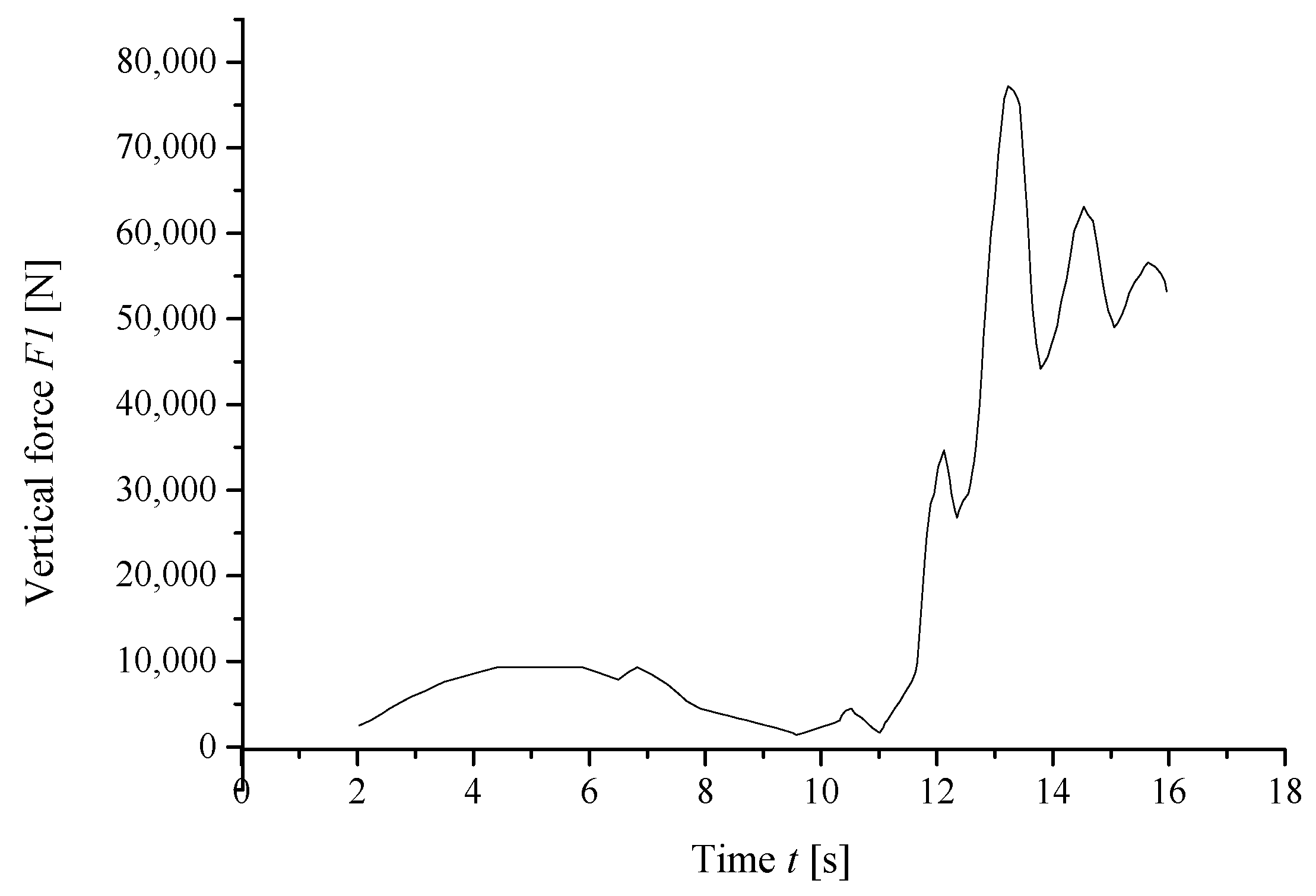

In this paper, based on the fuzzy theory, a novel membership function was constructed and verified through the experimental data. Subsequently, the material properties, dimensions, and loads of welded A-type frame were considered as random variables, and the fatigue limit of the welded A-type frame was taken as a fuzzy variable. By taking advantage of Latin hypercube method, the samples were obtained and fitted to build the fuzzy fatigue reliability performance function. Based on the suggested membership function, the fuzzy fatigue reliability of the welded A-type frame under conditions of downhill and turning braking with full load. When the fuzzy fatigue reliability was found to be less than the engineering requirement, the optimal design for improving the reliability based on genetic algorithm was conducted. Here are some specific conclusions:

Based on the fuzzy theory, a novel membership function was presented to characterize the distribution feature of fuzziness for this welded A-type frame. It was more accurate to obtain the ambiguity that was caused by the fatigue damage.

The multi-source uncertainties from the material properties, dimensions, and loads of welded A-type frame were fully taken into account. A fuzzy fatigue reliability calculation method was proposed based on the self-configuring membership function.

The fuzzy fatigue reliability of welded A-type frame under conditions of downhill and turning braking with full load was found to be 69.47%. It was far less than the engineering requirement. Based on the genetic algorithm, it was improved to 95.12%.

According to the optimized results, the quality of weld seam had to be ascertained in order to ensure the enough fuzzy fatigue reliability of welded A-type frame. In addition, the driving speed under this severe condition had to be reduced.