Abstract

This experimental investigation focused on the mechanical and damping properties of raw and alkali treated flax fibers reinforced cementitious composites. The objective of this study was to research the influence of flax fiber for the damping properties of cementitious composites. The mechanical strengths were obtained using compressive and flexural tests and damping properties were measured using a dynamic mechanical analysis. Structural modifications to the treated flax fibers were analyzed using scanning electronic microscopy and mercury intrusion porosimetry. Results showed that cement compressive strength was decreased, and flexural strength was increased by the addition of untreated flax fibers. Alkali treatment improved the mechanical strength of flax reinforced cement. The addition of flax fibers improved cement damping properties, and the damping effect of untreated flax fibers was greater than that of alkali treated fibers. The loss tangent of the cementitious composites reinforced with raw and alkali treated flax fibers at an amount of 1 wt % of cement was improved by 45.83% and 37.5% at 20 Hz, respectively. The damping properties of flax fiber was attributed to friction between elementary fibers and between adjacent fiber cell walls and slipping between the fiber and matrix. Callouses, pectin, and lignocellulose in untreated flax fiber contributed to damping and their removal by alkali treatment was the main reason why untreated flax fibers had a greater damping effect as compared to alkali-modified flax fibers.

1. Introduction

The energy-efficient building and green building are conducive to solve the global energy predicament and achieve CO2 emission reduction targets [1]. Currently, building energy consumption was expected to grow with the increasing of urbanization. With growing interest in energy conservation and emission reduction, interest in the use of renewable energy sources and biologically based materials in building engineering is also increasing. For example, the use of plant fibers as fiber reinforcement for conventional building materials is of interest due to their low environmental footprint, biodegradability, relatively good specific mechanical properties, and the fact that they are less harmful to people as compared to synthetic fibers. The lower density and intrinsic damping properties of plant fibers are also of interest, notably in sports equipment and building materials with a thermal or damping requirement [2].

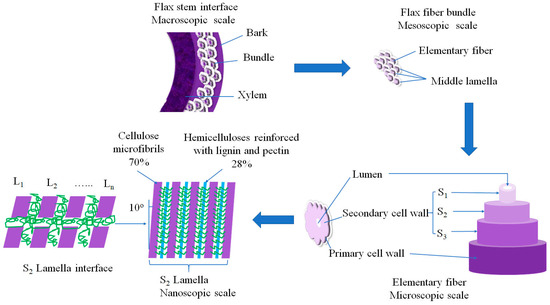

Flax fiber is highly regarded as a construction material in China due to its high yield, environmental characteristics, and end-of-life incineration energy recovery. In flax fibers, semicrystalline cellulose microfibrils are embedded in pectin in a hemicellulose matrix [3], forming cell walls that enclose a lumen to comprise the fiber microstructure. In turn, these elementary fibers are bundled with a lignin matrix and twisted together to form the structural fiber [4]. This structure gives the flax fibers intrinsic damping performance, which is of key interest in the study of the seismic performance of cement matrix composites. Here, we build on existing research by studying the effect of flax fibers on cementitious composites.

Considerable research has been conducted to develop the use of flax fibers in construction. This research has uncovered many urgent issues regarding the use of flax fibers in reinforced cement matrix composites. Firstly, the hydrophilic nature and lumen microstructure of flax fibers cause them to absorb water [5], competing with cement particles with respect to water demand. This characteristic impacts cement hydration and the bond between the fiber and the matrix [5]. Secondly, pectins from flax fibers can interact with the calcium ions of the cementitious matrix to produce a chelating effect [3], prolonging the initial setting time of the mixture [6]. Thirdly, cement hydration producing calcium hydroxide is likely to deposit on the single fiber wall of the fiber bundle or the interlayer of fiber wall, increasing the crystallinity of the plant fibers and decreasing their ductility [7]. To alleviate the impact of flax fibers on the performance of cementitious composites, studies have investigated preliminary flax fiber treatments prior to its use in the cement matrix. For example, Page [8] found that shorter flax fibers can reduce the damaging influence of the fibers on fresh concrete workability and reduce the “wall effect” that can form balls during mixing. Further research determined that combined use of flax fiber with other artificially synthesized fibers can ensure the benefits of flax fiber use while eliminating many of its deleterious effects [8,9]. Rueppel [10] found that flax fibers and continuous carbon fibers improved the damping behavior of polymers without decreasing the elastic modulus. Wang [11] grafted nano-TiO2 onto flax fibers to study its effects on the mechanical properties of epoxy plates and found that flax fiber significantly enhanced flexural properties in the presence of the nano-TiO2. Flax fibers and carbon nanotubes were found to improve the damping properties of epoxy composites, attributed to internal sliding friction within flax fibers and the stick-slip action of the carbon nanotubes [12]. Surface modification methods have been employed to change the effect of flax fibers and alter the interface between the fiber and matrix. For example, treatment with boiling water can remove multi-carbohydrate materials, such as pectin, that impact the cement setting time [6]; however, this method cannot decease the hygroscopicity of the flax fibers. Alkali-soaked treatments for plant fibers can remove multi-carbohydrate materials that roughen the surface of the fiber, improving the bonding of the fiber in the matrix, and enhancing the mechanical properties of the composite material [1,7,13]. Waterproofing processes, including silane treatments [11], polymer coatings [13], and cement grout coating [6], can change the hygroscopicity of flax fibers by adding some hydrophobic materials to the fiber surface, reducing the deleterious impacts of flax fiber hygroscopicity on composite material performance.

In this study, we investigate the effect of flax fibers on the damping properties of cement pastes. By improving the damping properties of building materials, engineered structures can be made more resistant to dynamic loading events through the dissipation of strain energy. Alkali treatments are applied to flax fibers and the mechanical and damping properties of these treated fibers in cement paste are evaluated. Furthermore, the microscopic pore structure of flax fibers in reinforced cement composites is investigated using mercury intrusion porosimetry (MIP) and composite microstructure is investigated using scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS).

2. Material and Methods

2.1. Materials

Type I Portland cement meeting the ASTMC150/150 M standard obtained from the China United Cement Corp. (Beijing, China) was used in this study. Flax fiber was purchased from the Harbin Linen Textile Co., Ltd. (Harbin, China) and the long flax fibers were chopped into 5 mm lengths. Analysis of 30 flax fiber samples showed an average diameter of 20.68 5 μm (measured by microscope (Olympus Corporation, Tokyo, Japan) and a density of 1.35 g/cm3 (measured by a hydrometer (Tianchang Jigao Experimental Equipment Co., Ltd., Anhui, China)). PCA®IVether based polycarboxylate superplasticizer (SP) was procured from the Jiangsu Subote New Material Co. Ltd. (Jiangsu, China). Liquid tributyl phosphate (TBP) defoamer was used to eliminate air bubbles formed during the mixing process.

2.2. Surface Treatment of Flax Fibers

The flax fiber was soaked with 6 wt %. NaOH aqueous solution for 24 h, treated in an ultrasonic bath (300 w, 40 °C) for 20 min, and then washed with distilled water for one hour. The treated flax fiber was oven dried at 50 °C for 24 h.

2.3. Sample Preparations

Original and alkali treated flax fibers were added to the cement mixture at weight fractions of 0 wt %, 0.5 wt %, and 1 wt %. The water/cement ratio of the different groups was 0.2. Superplasticizer and liquid tributyl phosphate were added at 0.4% and 0.13% of the mass fraction of cement, respectively. The plain cement paste, untreated flax fiber, and modified flax fiber reinforced cement pastes were designated as C, F, and MF, respectively. Each treatment group with different concentrations of flax fibers were referred to as C0, F0.5, F1, MF0.5, and MF1.

Untreated and treated fibers were mixed with the cement for 10 min to ensure that fibers were uniformly distributed within the cement. Water, water reducer, and defoamer were then mixed thoroughly with the fiber mixture for 20 min. The fresh paste was cast in 40 mm 40 mm 160 mm molds for evaluation of mechanical properties, and 60 mm 12 mm 4 mm molds for evaluation of damping properties. Specimens were demolded after 48 h and placed in a curing chamber at a temperature of 20 °C and relative humidity of 95%. Specimens were cured for a total of 28 days.

2.4. Mechanical Testing

Evaluation of cement mechanical properties was conducted after 3 days, 7 days, and 28 days of curing according to ASTM C 348 and ASTM C 349, for flexural and compressive strength testing, respectively. Three specimens were used for flexural strength testing, after this test the six specimens remaining were used for compressive strength evaluation.

2.5. Dynamic Mechanical Analysis

Dynamic mechanical analysis (DMA) was carried out on TA Instruments DMA Q800 equipment operating in a three-point bending mode at 25 °C with a span of 50 mm. A sinusoidal stress wave with frequencies varying from 0.1–20 Hz was used. A strain control measuring mode was chosen to apply the deforming load to the sample, which responded with a similar stress wave provided the material remained within its elastic limits. Scans were conducted using a fixed displacement amplitude of 10 µm to avoid the presence of multiple vibration modes. The loss tangent was an important parameter representing the damping performance of the material.

2.6. Microstructure Analysis

After mechanical testing, fragments of diameter 3–5 mm were collected by forceps and stored in ethanol to prevent further hydration. Prior to scanning electron microscope (SEM) and mercury intrusion porosimetry (MIP) testing, samples were removed from the ethanol and dried under a vacuum at 60 °C. Morphology was investigated using the SEM (VEGA3, TESCAN Co., Brno, Czech), with accelerated voltages of 200–30,000 V, and thin-window energy dispersive spectroscopy (EDS (AMETEK, Inc., Philadelphia, USA)) to analyze composite components. All cement samples were coated with gold to enhance their conductivity. Pore structure and pore size distribution were investigated using MIP (AutoPore IV 9500, Micromeritics Instrument Corporation, Norcross, Georgia, USA). Samples were collected after the 28 days compressive strength tests.

3. Results and Discussion

3.1. Microstructure and Components

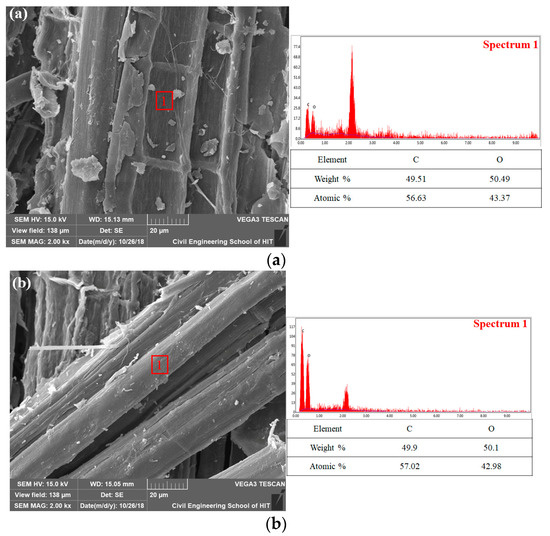

Figure 1 shows the morphologies of the original and alkali-modified flax fibers. It is apparent that the alkali-modified flax fiber surface (Figure 1b) is cleaner as compared to the original flax fiber (Figure 1a) because the alkali has removed carbohydrate substances from the fiber. EDS results show that the main components of flax fiber are carbon and oxygen, and alkali treatment did not change the composition of the flax fiber.

Figure 1.

SEM/energy dispersive spectroscopy (EDS) image of (a) original flax fiber and (b) alkali modified flax fiber at 2000.

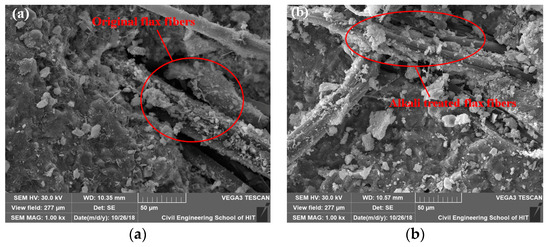

Figure 2a,b show the microstructure of the cementitious composites after 28 days of curing for F0.5 and MF0.5. It is apparent that the flax fiber produces some pores in the matrix, and the incorporation of flax fibers into cement hydrates creates multi-phase boundaries and multiform interfaces.

Figure 2.

SEM image of cement paste with 0.5 wt %. (a) Original flax fiber (F0.5) and (b) alkali modified flax fiber (MF0.5) at 1000.

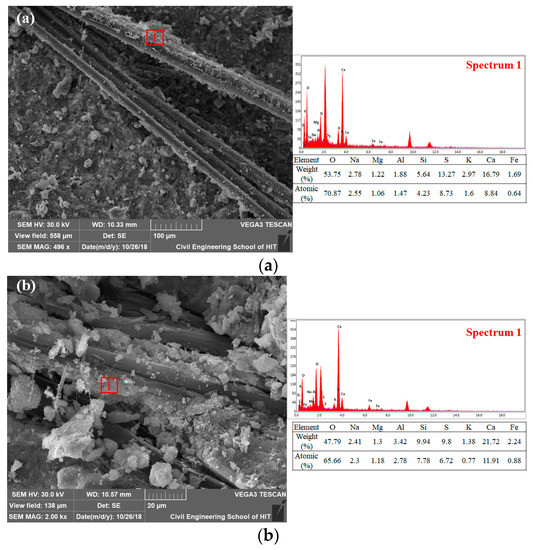

Comparisons of Figure 2a,b illustrate that alkali modified flax fibers adhered better to the matrix as compared to the untreated fibers. Untreated flax fibers showed many impurities on the fiber surface (Figure 1a) while the cellulose of alkali modified flax fibers was directly exposed, improving the anchoring force of the flax fiber in the cement matrix and thus improving the fiber-matrix adhesion. Alkali treatment changed the chemical composition of the fiber by removing amorphous constituents (pectin, hemicelluloses, etc.), thereby increasing fiber crystallinity and roughness [14]. Consequently, alkali treated flax fiber enhances the adhesion and compatibility between the fiber and cement-based matrix. This compatibility, leading to a homogeneous distribution of the reinforcing fibers, is the predominant factor influencing the mechanical properties of the composites [15]. Cement hydration products are more apparent on the alkali modified flax fiber (Figure 3b) as compared to the untreated fiber (Figure 3b). These results indicate that alkali treatment improved the adhesion between the flax fibers and cementitious matrix.

Figure 3.

SEM/EDS images of flax fiber surface in (a) F0.5 at about 500 and (b) MF0.5 at 2000.

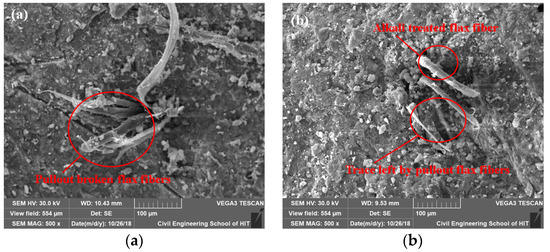

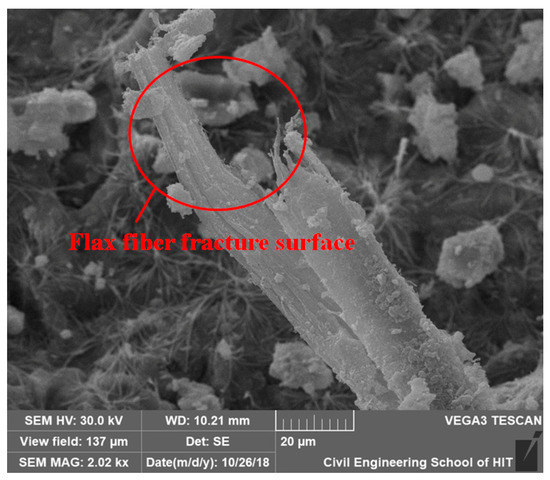

Figure 4 shows SEM images of the fracture surface of the cured F0.5 and MF0.5 specimens. It is apparent that some fibers are embedded in the cement hydrate with the opposite ends free. Untreated flax fibers were pulled off during the mechanical test (Figure 4a), and the traces left by pulled out alkali-treated flax fibers (Figure 4b) suggest that the flax fibers contributed to the cement paste damage process.

Figure 4.

SEM image of the fracture surface of (a) F0.5 and (b) MF0.5 at 500 .

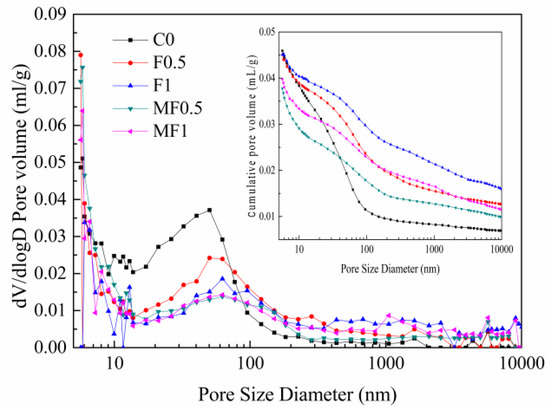

3.2. Pore Size Distribution

Porosity parameters are important to determine the strength and durability of cement composites. Figure 5 shows the pore size distribution and variation of dV/dlogV with pore diameter of the cement specimens. Table 1 details the classification of the pores and Table 2 shows the proportion by volume of pore structures in the cement specimens. Results suggest that the flax fiber increased macropores (50–10,000 nm) and voids and microcracks (>10,000 nm) in the cement composites. Macropores increased from 27.01% in C0 to 40.64% and 38.81% in F1 and MF1, respectively. The increase is attributed to trapped air in the composite and increased porosity at the interfacial transition zone (ITZ) between the flax fibers and the matrix [16]. This suggests that the porosity increase at the ITZ was mainly due to the porous features of flax fiber, which leads to air import by the addition of fibers into the mixture.

Figure 5.

Pore size distribution of cement specimens.

Table 1.

Classifications of pores in cement pastes.

Table 2.

Proportion by volume of pore structures in cement specimens.

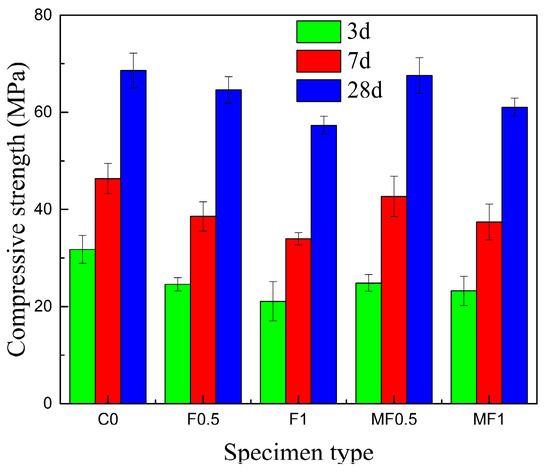

3.3. Mechanical Properties

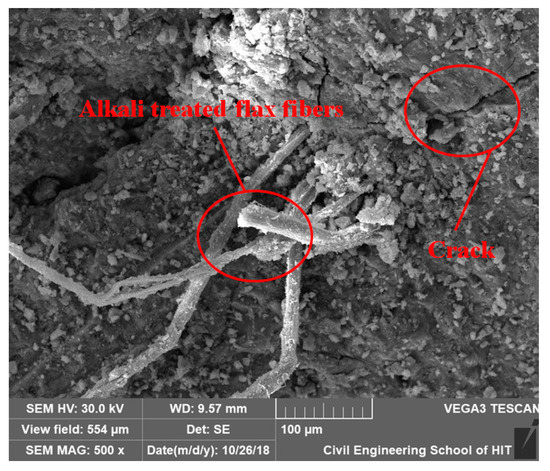

The compressive strengths of the cement specimens are shown in Figure 6. The addition of flax fibers reduced the compressive strength of the cement in all cases. However, the loss of compressive strength reduces as curing age increases; F0.5 compressive strength was reduced by 22.6%, 16.82%, and 5.8% as compared to C0 at curing ages of 3 days, 7 days, and 28 days, respectively. MF0.5 demonstrates that the alkali treatment somewhat offsets the compressive strength reduction caused by flax fiber, with reductions of 21.78%, 7.89%, and 1.46% as compared to C0 at curing ages of 3 days, 7 days, and 28 days, respectively. Notwithstanding, concrete compressive strength decreased with increasing fiber content, even with alkali pretreatment. This was attributed to the presence of the lumen and pore in the wall of the flax fibers, and the fact that flax fibers display obvious hydrophilicity, this essential characteristic induced a stiff fight on the water demand between the flax fibers and cement particles in the mixing step. Hence, the fibers content clearly affect the water availability during cement hydration [17]. Moreover, water was released from the fiber towards the end of cement hydration, producing a water-cement ratio gradient near the fiber (the water-cement ratio near the fiber was higher). The higher water-cement ratio increased the porosity of the composite and thus reduced adhesion between the fiber and matrix. Furthermore, flax fibers have lower rigidity as compared to conventional fibers, reducing dispersion during mixing and promoting the formation of balls [18]. Some carbohydrates in the flax fiber (e.g., pectin) disturb the hydration reaction of the cement and delay the initial setting time of cement composites [7]. Alkali treatment dissolves the pectin and other impurities from the flax fiber, improving the progress of hydration [7]. As shown in Figure 6, increased flax fiber content decreased the compressive strength of cement specimens due to the undispersed fiber producing microfractures within the matrix (Figure 7).

Figure 6.

Compressive strength of cement specimens for different curing ages.

Figure 7.

SEM image of F1 showing microfractures at 500.

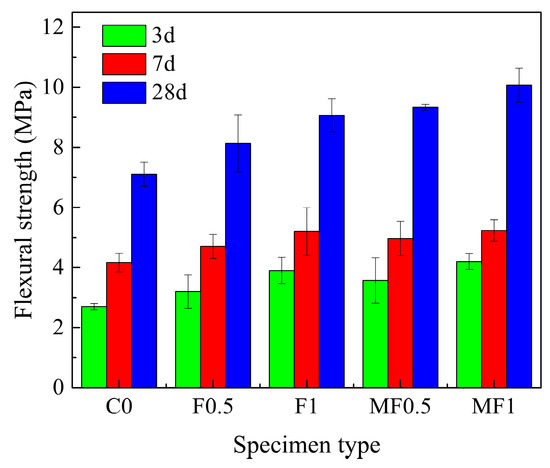

The flexural strengths of the cement specimens are shown in Figure 8. It is apparent that the flexural strengths of F0.5, F1, MF0.5, and MF1 were higher as compared to the control specimen, and strength increased with flax fiber content. Alkali-modified flax fibers appeared to further improve the flexural strength as compared to untreated fibers. After 28 days of curing, MF1 flexural strength was 10.47% stronger as compared to F1, and 41.7% stronger as compared to C0. This could be attributed to the alkali treatment increasing the roughness of the fiber surface by dissolving and removing impurities. A rougher surface would provide better adhesion between the fiber and matrix, and thus increase the flexural strength of the cement composite. Moreover, the alkali treatment results in an improvement in the flax fiber tensile strength by removing impurities and increasing density [7].

Figure 8.

Flexural strength of cement specimens for different curing ages.

3.4. Damping Properties

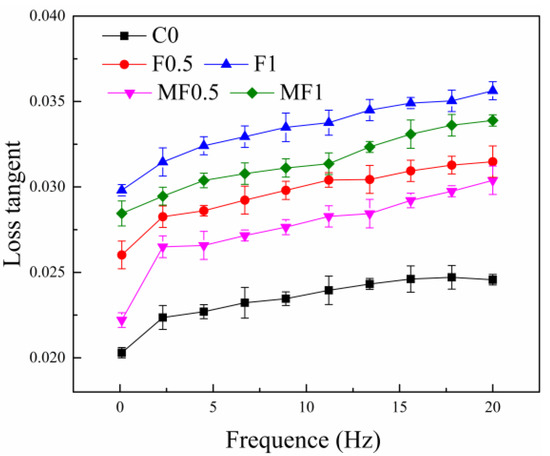

Figure 9 shows cement specimen loss tangents at 0.1–20 Hz. The loss tangent increased for all specimens as the frequency increased. Loss tangents were higher for specimens with added flax fiber as compared to C0, and increasing the fiber content resulted in a greater improvement in the loss tangent, indicating that the addition of flax fiber improved cement damping properties. F0.5 and F1 improved the loss tangent by 29.17% and 45.83%, respectively, relative to C0 at 20 Hz, and MF0.5 and MF1 improved the loss tangent by 25% and 37.5%, respectively, relative to C0 at the same frequency. The loss tangent of alkali-modified flax fiber reinforced cement pastes was lower as compared to that of raw flax fiber reinforced cement pastes. In other words, alkali treatment decreased the damping properties of flax fiber in the cement composites.

Figure 9.

Loss tangent of the cement specimens for different frequencies.

Improved damping by the addition of flax fibers could be attributed to the following:

- (1)

- The components of flax fiber include a type of polymer possessing viscoelastic properties; the incorporation of viscoelastic material in cement could improve its damping properties.

- (2)

- A single flax fiber is normally comprised of a bundle of elementary fibers and each elementary fiber is made up of a fiber cell wall layer (S1, S2, and S3; Figure 10 and Figure 11). The S2 layer consists of numerous cellulose microfibril that contribute to the mechanical properties of flax fibers. Vibration damping in flax fibers is attributed to the friction between elementary fibers and between adjacent fiber cell walls in fiber bundles [19]. Moreover, the flax fiber produces a relative displacement within the cementitious matrix, causing sliding friction, which dissipates energy under external loads.

Figure 10. SEM image of a flax fiber fracture surface at about 2000.

Figure 10. SEM image of a flax fiber fracture surface at about 2000. Figure 11. Structural diagram of a flax fiber.

Figure 11. Structural diagram of a flax fiber. - (3)

- In the S2 layer system, the cellulose, pectin, and lignocellulose form a sandwich structure. During loading transfer processes, the complete system produces a constrained damping in the untreated flax fiber reinforced cement composite. However, alkali treatment removes the pectin and lignocellulose from the flax fiber. This removal is the likely reason why the damping properties of alkali-modified flax fibers are lower as compared to those of raw flax fibers.

- (4)

- The lumen of the elementary flax fiber may also contribute to its damping properties [20].

4. Conclusions

This study presented the results of the analysis of the damping properties of cement pastes reinforced with different quantities (0 wt %, 0.5 wt %, and 1 wt %.) of untreated and alkali-modified flax fibers. Our conclusions are summarized as follows:

- (1)

- Alkali treatment roughened the surface and increased the crystallinity of the flax fiber, improving adhesion between the cementitious matrix and fiber by removing amorphous components.

- (2)

- Flax fiber increased the population of macropores and voids and microcracks in cement composites, which are the main causes for the decrease in compressive strength in flax fiber reinforced cement composites.

- (3)

- The addition of flax fibers reduced the compressive strength and increased the flexural strength of the cement composite regardless of whether the flax fibers were treated or not. Alkali treatment somewhat offset this reduction in compressive strength. Compared with the untreated flax fiber, alkali treated flax fibers at an amount of 1 wt % of cement improved the compressive and flexural properties of composites, i.e., 4.55% and 11.3% growth in the compressive and flexural strength, respectively.

- (4)

- The incorporation of flax fibers was an effective method to enhance cement damping properties. The loss tangent of the cementitious composites reinforced with raw and alkali treated flax fibers at an amount of 1 wt % of cement was improved by 45.83% and 37.5% at 20 Hz, respectively, that is due to the friction in the internal structure of the flax fiber, and slipping between the fiber and matrix. The damping effect was greater in untreated flax fibers when compared to alkali-modified flax fibers due to constraints on the damping system caused by the removal of pectin and lignocellulose in treated fibers.

There is still a lot of controversy about the durability of the flax fiber in cementitious matrix. Some literature indicated that the plant fibers can deteriorate due to the mineralization in the alkaline environment of cementitious matrices, but there is no direct evidence that the plant fibers impregnated by mineral species can cause the loss of mechanical properties in fibers. Many researchers suggested that the mineralization may not cause any reduction in the mechanical performance but merely fill the empty spaces inside the cell lumen and wall of the plant fibers [21]. Moreover, some researchers have suggested that the reason of the mechanical strength of plant fibers was decreased was due to the degradation at the fiber-matrix interface produced by biodeterioration [22]. To control composite degradation by alkaline attack, some researchers found that surface pretreatment of plant fibers can be effectively alleviated the degradation of plant fibers [13]. Nevertheless, as mentioned earlier, there are many questions about the application of flax fibers in cementitious composites, but due to its environmental friendliness, economy, and other advantages, it still has high research value. In order to further study the effect of flax fibers for the cementitious composites, we will complete the follow-up work:

- (1)

- Study the effect of flax fibers for the cementitious composite in longer curing ages and different curing environment.

- (2)

- Seek a suitable fiber surface treatment to improve the bonding between the fiber and the matrix, thereby improve the durability of the flax fiber in the cementitious composites.

Author Contributions

Methodology, X.Z.; Experiment, P.L. and P.Y.; Writing, P.L., X.Z. and P.Y.; Supervision, X.Z., Z.W. and S.S.

Funding

This research was funded by the Chinese National Key Research and Development Program of China, Program No. 2018YFC0705703, the Chinese National Natural Science Foundation, Project designations: 51525802 and 51778183.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Perremans, I.V.D.; Dupont-Gillain, C.; Van Vuure, A.W. Investigation of the tensile behavior of treated flax fibre bio-composites at ambient humidity. Compos. Sci. Technol. 2018, 159, 119–126. [Google Scholar] [CrossRef]

- Duc, F.; Bourban, P.E.; Månson, J.A.E. The role of twist and crimp on the vibration behaviour of flax fibre composites. Compos. Sci. Technol. 2014, 102, 94–99. [Google Scholar] [CrossRef]

- Oksman, K.; Mathew, A.P.; Långström, R.; Nyström, B.; Joseph, K. The influence of fibre microstructure on fibre breakage and mechanical properties of natural fibre reinforced polypropylene. Compos. Sci. Technol. 2009, 69, 1847–1853. [Google Scholar] [CrossRef]

- Madsen, B.; Aslan, M.; Lilholt, H. Fractographic observations of the microstructural characteristics of flax fibre composites. Compos. Sci. Technol. 2016, 123, 151–162. [Google Scholar] [CrossRef]

- Thuault, A.; Eve, S.; Blond, D.; Bréard, J.; Gomina, M. Effects of the hygrothermal environment on the mechanical properties of flax fibres. J. Compos. Mater. 2013, 48, 1699–1707. [Google Scholar] [CrossRef]

- Chafei Sawsen, K.F.; Mohamed, B.; Moussa, G. Effect of flax fibers treatments on the rheological and the mechanical behavior of a cement composite. Constr. Build. Mater. 2015, 79, 229–235. [Google Scholar] [CrossRef]

- Chafei Sawsen, K.F.; Mohamed, B.; Moussa, G. Optimizing the formulation of flax fiber-reinforced cement composites. Constr. Build. Mater. 2014, 54, 659–664. [Google Scholar] [CrossRef]

- El Hadi Saidane, D.S.; Assarar, M.; Ayad, R. Damage mechanisms assessment of hybrid flax-glass fibre composites. Compos. Struct. 2017, 174, 1–11. [Google Scholar] [CrossRef]

- Mustapha Assarar, W.Z.; Sabhi, H.; Ayad, R.; Berthelot, J. Evaluation of the damping of hybrid carbon–flax reinforced composites. Compos. Struct. 2015, 132, 148–154. [Google Scholar] [CrossRef]

- Rueppel, J.R.B.M.; Dransfeld, C.; Fischer, C. Masania Damping of carbon fibre and flax fibre angle-ply composite laminates. Compos. Sci. Technol. 2017, 146, 1–9. [Google Scholar] [CrossRef]

- Wang, H.; Xian, G.; Li, H. Grafting of nano-TiO2 onto flax fibers and the enhancement of the mechanical properties of the flax fiber and flax fiber epoxy composite. Compos. Part A 2015, 76, 172–180. [Google Scholar] [CrossRef]

- Li, Y.; Cai, S.; Huang, X. Multi-scaled enhancement of damping property for carbon fiber reinforced composites. Compos. Sci. Technol. 2017, 143, 89–97. [Google Scholar] [CrossRef]

- Chakraborty, S.; Kundu, S.P.; Roy, A.; Adhikari, B.; Majumder, S.B. Polymer modified jute fibre as reinforcing agent controlling the physical and mechanical characteristics of cement mortar. Constr. Build. Mater. 2013, 49, 214–222. [Google Scholar] [CrossRef]

- Roy, A.; Chakraborty, S.; Kundu, S.P.; Basak, R.K.; Majumder, S.B.; Adhikari, B. Improvement in mechanical properties of jute fibres through mild alkali treatment as demonstrated by utilisation of the Weibull distribution model. Bioresour. Technol. 2012, 107, 222–228. [Google Scholar] [CrossRef] [PubMed]

- Jarabo, R.; Fuente, E.; Monte, M.C.; Savastano, H.; Mutjé, P.; Negro, C. Use of cellulose fibers from hemp core in fiber-cement production. Effect on flocculation, retention, drainage and product properties. Ind. Crops Prod. 2012, 39, 89–96. [Google Scholar] [CrossRef]

- Page, J.; Khadraoui, F.; Boutouil, M.; Gomina, M. Multi-physical properties of a structural concrete incorporating short flax fibers. Constr. Build. Mater. 2017, 140, 344–353. [Google Scholar] [CrossRef]

- Tung, L.H.; Khadraoui, F.; Boutouil, M.; Moussa, G. Mechanical properties of flax fibre reinforced cement composites. In Proceedings of the ICTACE, Chennai, India, 19–20 February 2011. [Google Scholar]

- Arnon Bentur, S.M. Fibre Reinforced Cementitious Composites; Taylor & Francis: London, UK; New York, NY, USA, 2007. [Google Scholar]

- Saw, S.K.; Sarkhel, G.; Choudhury, A. Preparation and characterization of chemically modified Jute-Coir hybrid fiber reinforced epoxy novolac composites. J. Appl. Polym. Sci. 2012, 125, 3038–3049. [Google Scholar] [CrossRef]

- Chen, C.; Li, Y.; Yu, T. Interlaminar toughening in flax fiber-reinforced composites interleaved with carbon nanotube buckypaper. J. Reinf. Plast. Compos. 2014, 33, 1859–1868. [Google Scholar] [CrossRef]

- John, V.M.; Cincotto, M.A.; Sjöström, C.; Agopyan, V.; Oliveira, C.T.A. Durability of slag mortar reinforced with coconut fibre. Cem. Concr. Compos. 2005, 27, 565–574. [Google Scholar] [CrossRef]

- Savastano, H., Jr.; Agopyan, V. Transition zone studies of vegetable fibre-cement paste composites. Cem. Concr. Compos. 1999, 21, 49–57. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).