Durability of Subsea Tunnels under the Coupled Action of Stress and Chloride Ions

Abstract

1. Introduction

2. Chloride Ion Transfer Equation under the Coupled Action of Convection and Diffusion

2.1. Diffusion Coefficient of Chloride Ions, D

2.2. Convection Velocity

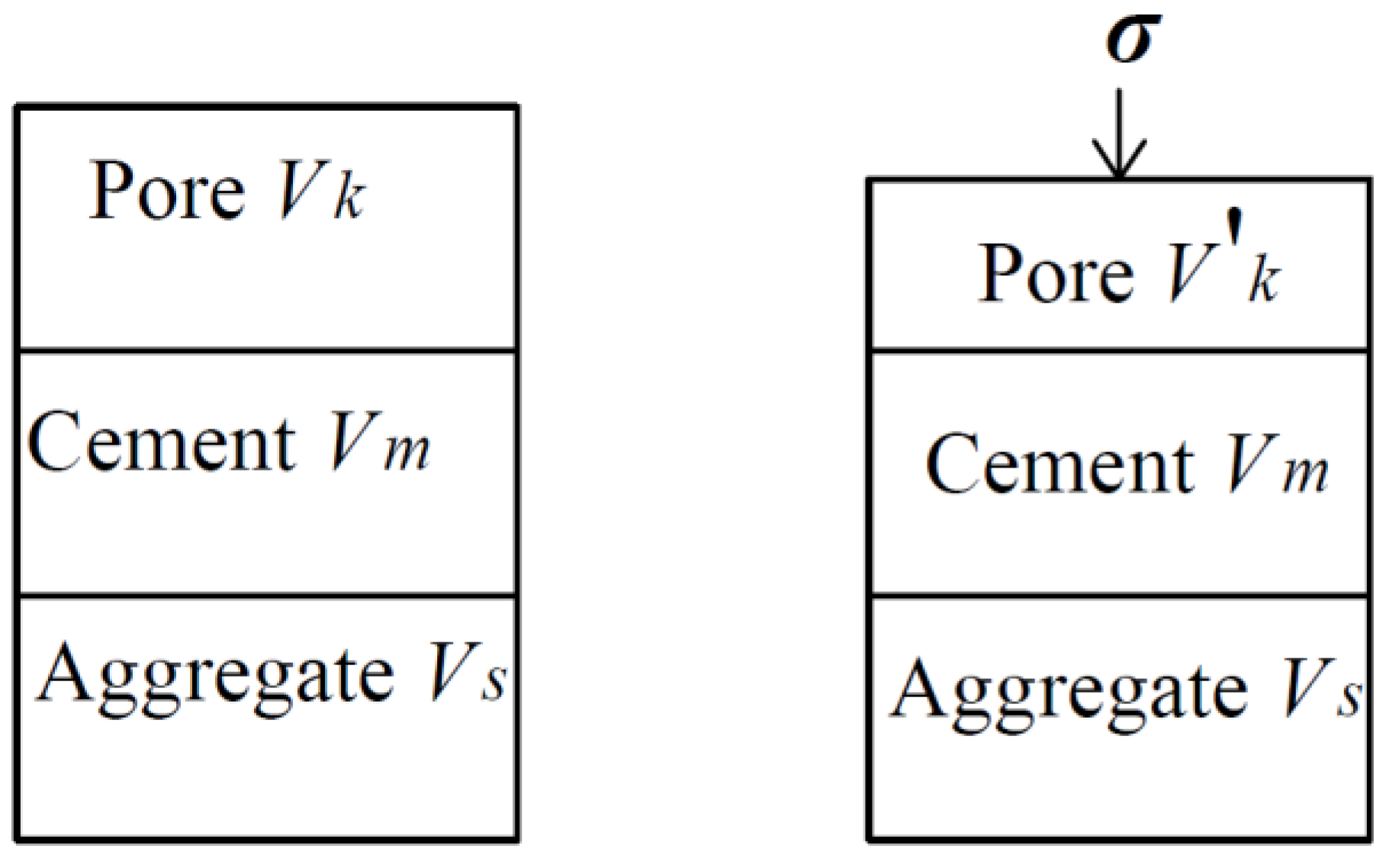

3. Effect of Stress on Chloride Ions Transfer

3.1. The Coefficient under the Influence of Stress

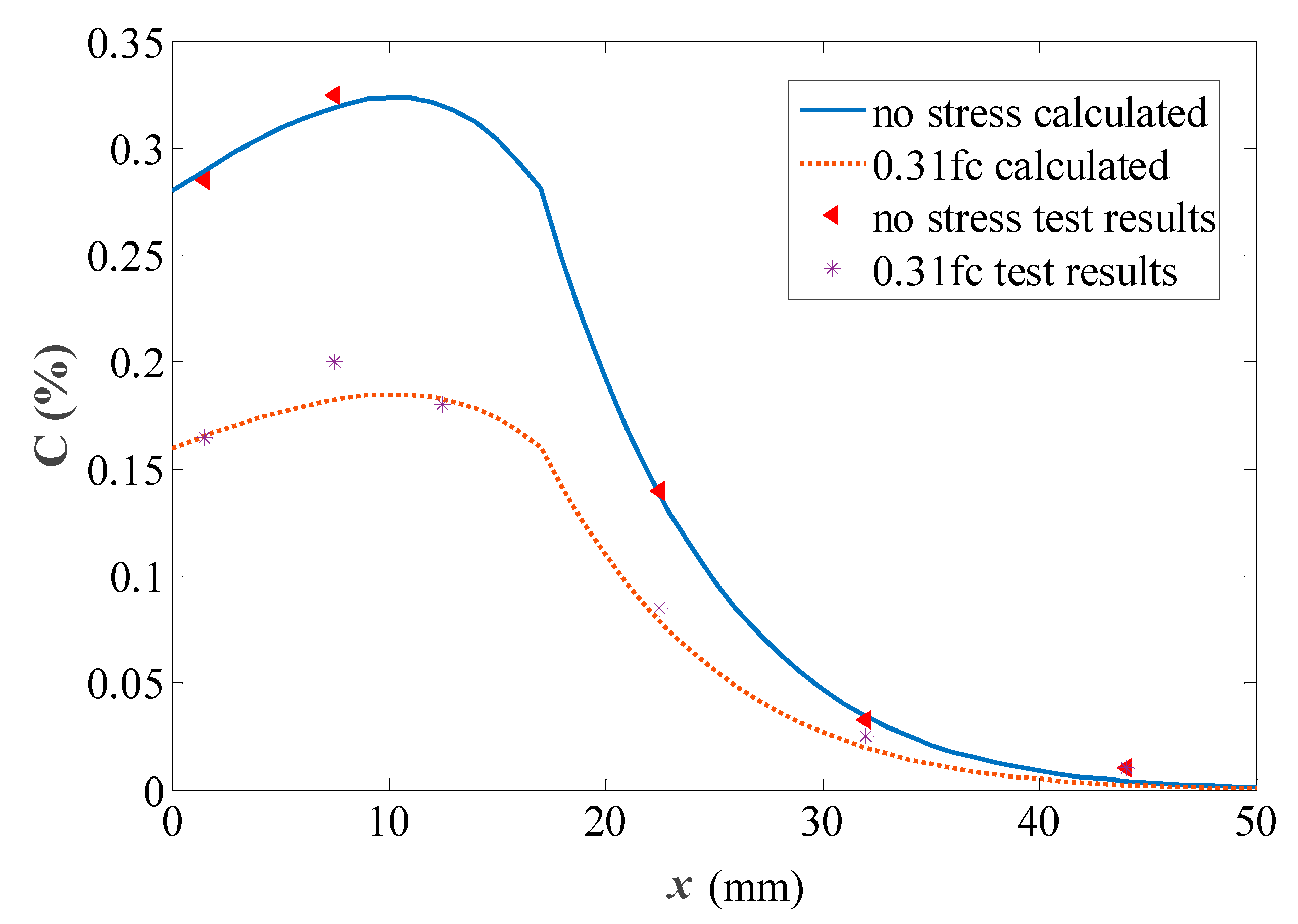

3.2. Experimental Verification

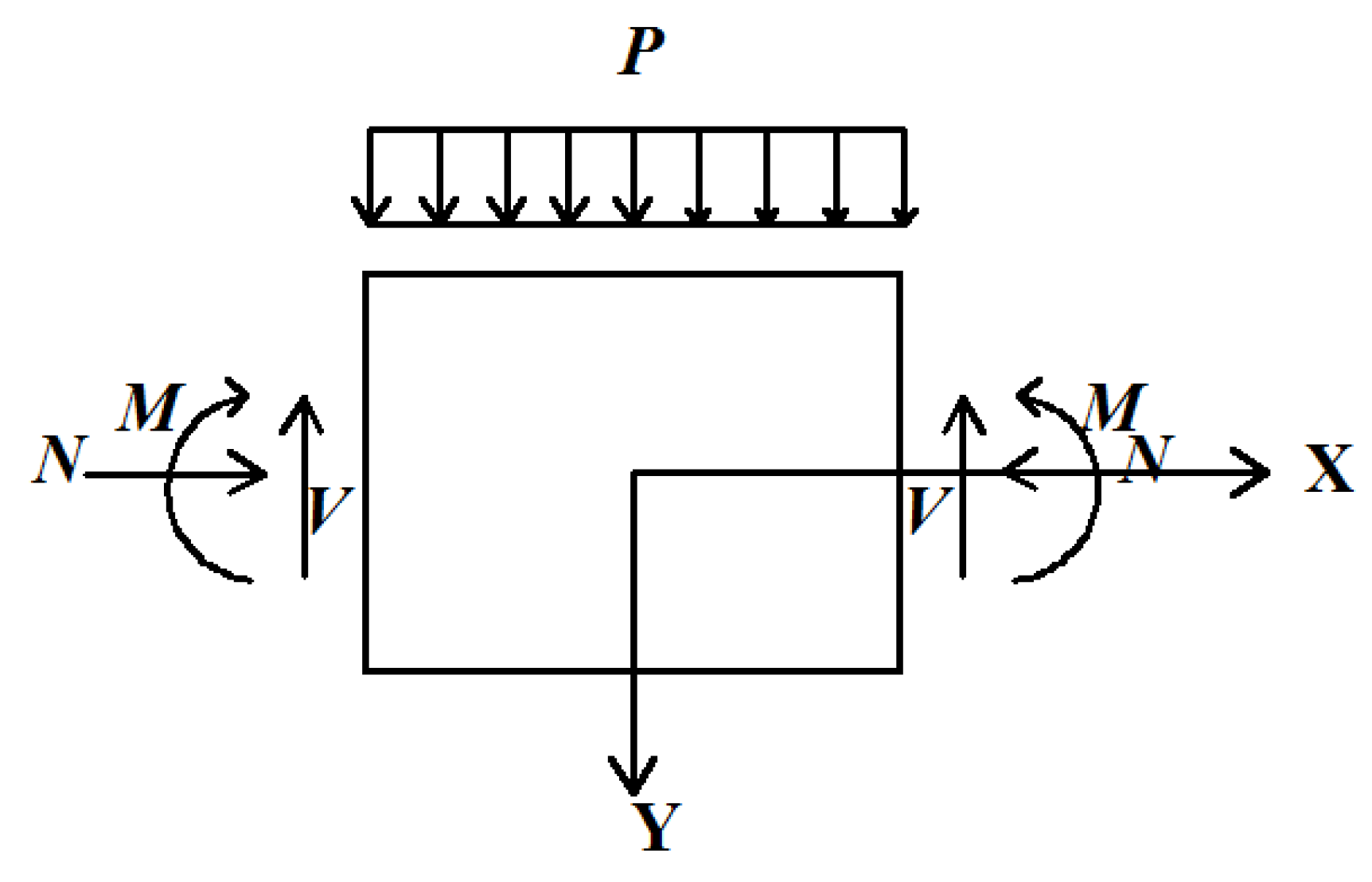

3.3. The Stress of a Section of a Subsea Tunnel’s Lining

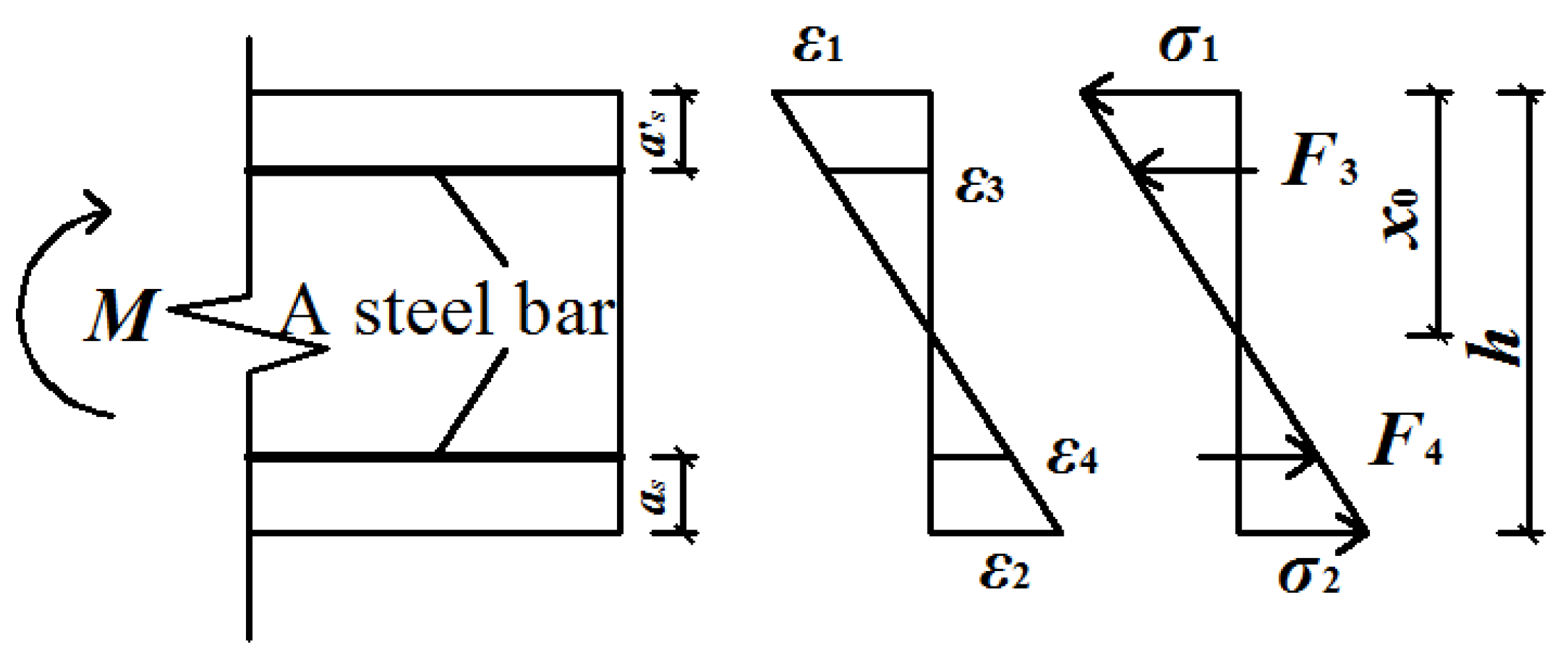

3.3.1. Normal Stresses of the Lining Section Corresponding to Bending Moment

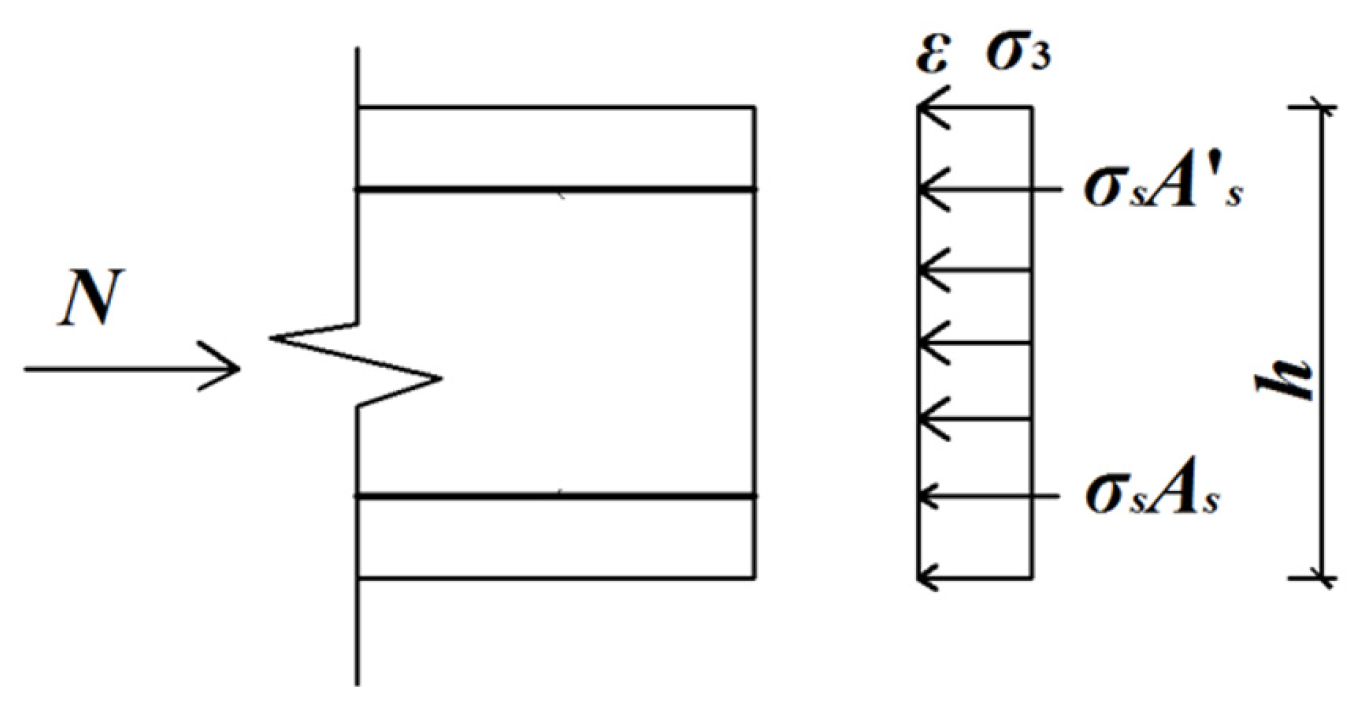

3.3.2. The Compressive Stress of the Lining Section Corresponding to the Axial Force

3.3.3. The Total Stress of the Lining Section

3.3.4. Normal Stress of the Lining Section Caused by the Surrounding Water and Soil Pressure

4. Service Life of Subsea Tunnels Based on the Reliability Theory

5. Engineering Application

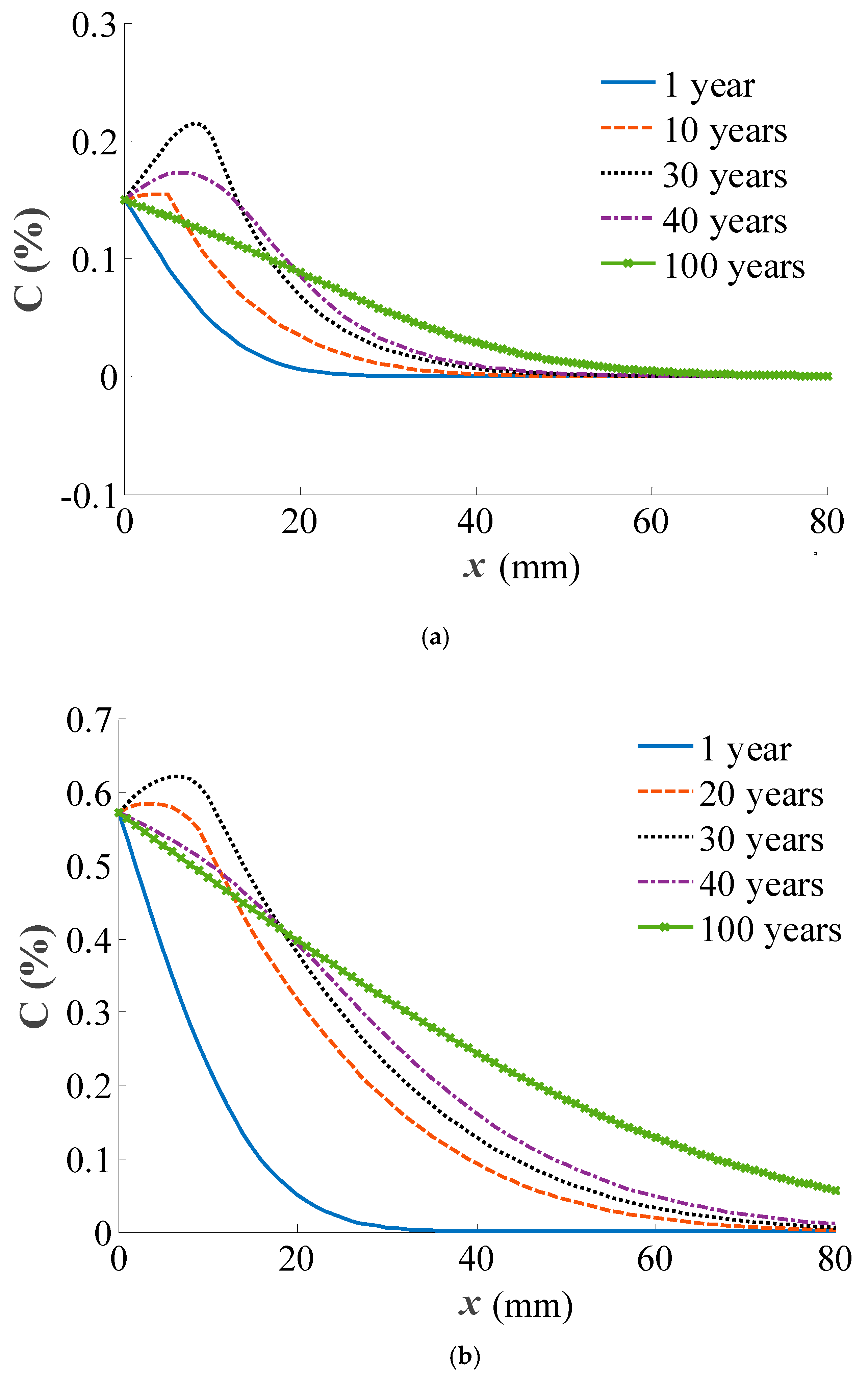

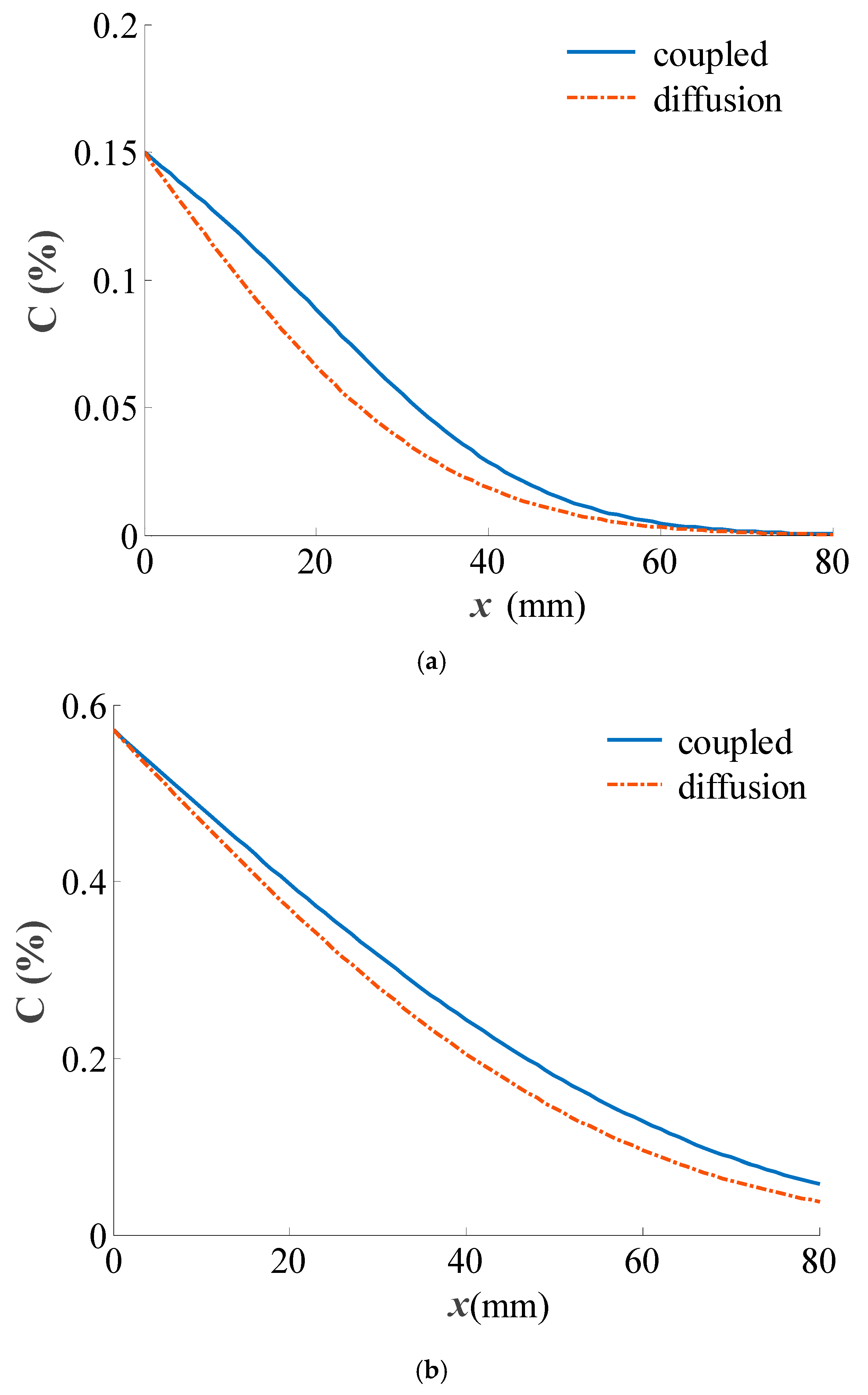

5.1. Chloride Ion Concentration Distribution

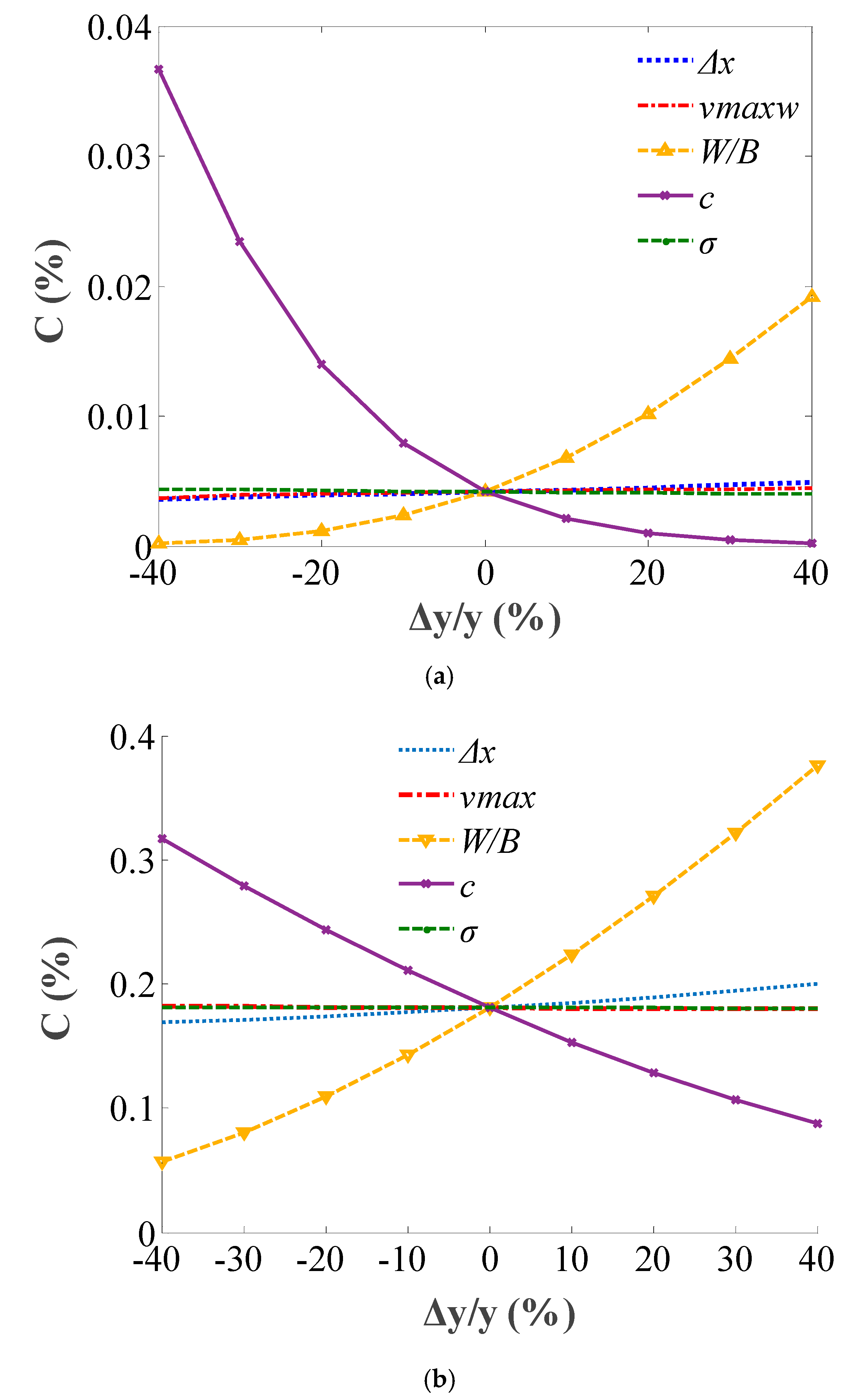

5.2. Sensitivity of Chloride Ion Concentration Under the Coupled Effect

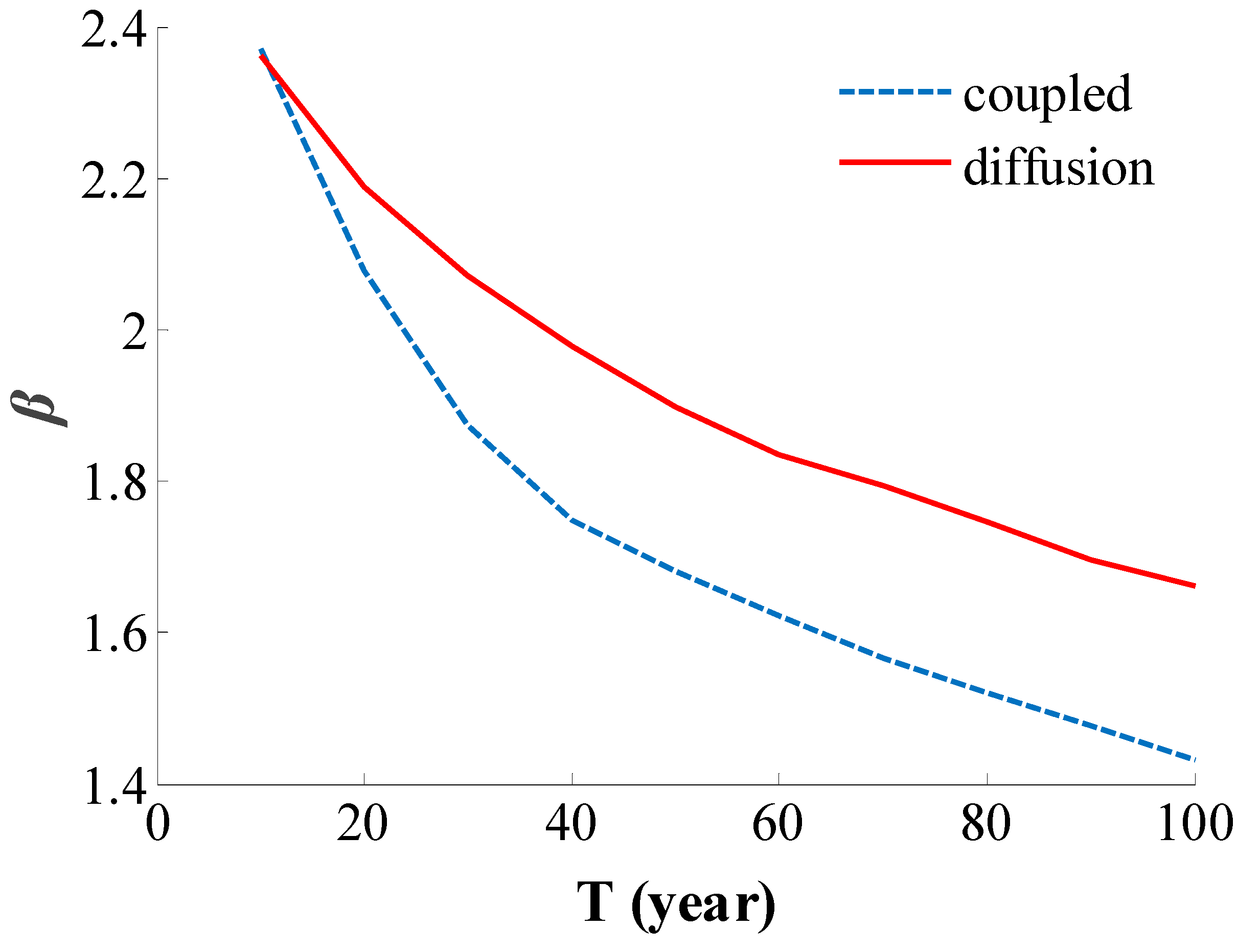

5.3. Service Life

6. Conclusions

- (1)

- Under the influence of the coupled effect of diffusion and convection, diffusion played a major role in the early period, convection was the main effect during the middle period, and during the late period, diffusion was again responsible for the majority of the effect.

- (2)

- For the durability design of subsea tunnels, the coupled effect should be considered. It is safer to calculate the chloride ion concentration and predict the service life based on the coupled effect of diffusion and convection.

- (3)

- To improve the service life of subsea tunnels, the water-binder ratio should be reduced and/or the thickness of the protective cover should be increased.

- (4)

- The influence of stress on the convection was not considered, which can be studied by means of experiments and numerical simulation in future research.

Author Contributions

Funding

Conflicts of Interest

References

- Eisenstein, Z.D. Large undersea tunnels and the progress of tunneling technology. Tunn. Undergr. Space Technol. 1994, 19, 283–292. [Google Scholar] [CrossRef]

- Odgard, A.; David, G.; Rostam, B.S. Design of the store belt railway tunnel. Tunn. Undergr. Space Technol. 1994, 19, 293–307. [Google Scholar] [CrossRef]

- Li, S.C.; Xu, B.S.; Li, S.C. Lining structure type of subsea tunnel and its support parameters optimizing. Chin. J. Rock Mech. Eng. 2005, 24, 3894–3902. [Google Scholar]

- Jin, W.L.; Yuan, Y.S.; Wei, J.; Wang, H.L. Design Method for the Durability of Concrete Structure under Chloride Environment; Science Press: Beijing, China, 2011. [Google Scholar]

- Bazant, Z.P. Physical model for steel corrosion in concrete sea structures-theory. J. Struct. Div. 1979, 105, 1137–1153. [Google Scholar]

- Glasser, F.P.; Marchand, J.; Samson, E. Durability of concrete-degradation phenomena involving detrimental chemical reactions. Cem. Concr. Res. 2008, 38, 226–246. [Google Scholar] [CrossRef]

- Zhang, Y.F. Study on the Durability Evaluation of Lining Structure in Sea Area during Subway Operation Period. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2018. [Google Scholar]

- Zhao, T.J.; Jiang, F.X. Durability of Subsea Tunnels; China Communications Press: Beijing, China, 2010. [Google Scholar]

- Jin, Z.; Zhao, T.; Hou, B. Service Life Prediction of Lining Concrete for Jiaozhou Bay Subsea Tunnel. Archit. Environ. Eng. 2009, 31, 86–91. [Google Scholar]

- Qu, L.; Jin, Z.; Zhao, T.; Li, Q. Study on durability parameter design of subsea tunnel reinforced concrete based on chloride corrosion. Chin. J. Rock Mech. Eng. 2007, 26, 2333–2340. [Google Scholar]

- DuraCrete. Chloride ingress initiation of corrosion. In General Guidelines for Durability Design and Redesign; Probabilistic Performance Based Durability Design of Concrete Structure; CUR: Gouda, The Netherlands, 2000; pp. 32–38. [Google Scholar]

- Yang, L. Investigation of Moisture and Chloride Ion Transport Inunsaturated Concrete. Ph.D. Thesis, Southeast University, Nanjing, China, 2017. [Google Scholar]

- Zhang, Y.; Li, X.; Yu, G. Chloride transport in undersea concrete tunnel. Adv. Mater. Sci. Eng. 2016, 2016, 1–10. [Google Scholar] [CrossRef]

- Liu, S.; Sun, Q.; Feng, K.; He, C. Research on chloride ion erosion and migration in segment joints of undersea shield tunnels. Mod. Tunn. Technol. 2016, 53, 100–107. [Google Scholar]

- Liu, Q.; Huang, M.; Jin, F. Study on durability and service life of concrete structure of coastal tunnel. J. Beijing Jiaotong Univ. 2018, 42, 1–8. [Google Scholar]

- Lei, M.F. Research on Calculation Methods of Life-Cycle Structure Performance of Shield Tunnel in Aggressive Environment. Ph.D. Thesis, Central South University, Changsha, China, 2013. [Google Scholar]

- Liu, S.; He, C.; Feng, K.; An, Z. Research on corrosion deterioration and failure process of shield tunnel segments under loads. China Civ. Eng. J. 2018, 51, 120–128. [Google Scholar]

- Song, Y.S. Study on Shield Segment Concrete Durability of Resistance to Chloride Ion and Service Life Prediction. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2015. [Google Scholar]

- Fang, S. The Reliability Analysis Based on Durability Performance Degradation about the Existing Tunnel Lining Structure. Master’s Thesis, Shijiazhuang tiedao University, Shijiazhuang, China, 2018. [Google Scholar]

- Li, Q.; Yu, H.F.; Ma, H.Y.; Chen, S.D.; Liu, S.G. Test on Durability of Shield Tunnel Concrete Segment under Coupling Multi-Factors. Open Civ. Eng. J. 2014, 8, 451–457. [Google Scholar] [CrossRef]

- Yue, Z.W.; Li, J.P.; Yang, B. Calculation of chloride ions transportation in concrete considering convection. J. Tongji Univ. Nat. Sci. 2015, 43, 60–66. [Google Scholar]

- Bentz, E.C.; Thomas, M.D.A. Computer program for prediction the service life and life-cycle costs of reinforced concrete exposed to chlorides. In Life-365 Manual; SFA: Edison, NJ, USA, 2013. [Google Scholar]

- Zhao, Q.L.; Zhang, Y.Z. Concentration distribution of chloride ion under the influence of the convection-diffusion coupling. Adv. Mater. Sci. Eng. 2017, 2017, 207698. [Google Scholar] [CrossRef]

- Liu, L.; Chen, H.; Sun, W.; Ye, G. Microstructure-based modeling of the diffusivity of cement paste with micro-cracks. Constr. Build. Mater. 2013, 38, 1107–1116. [Google Scholar] [CrossRef]

- Hoseini, M.; Bindiganavile, V.; Banthia, N. The effect of mechanical stress on permeability of concrete: A review. Cem. Concr. Compos. 2009, 31, 213–220. [Google Scholar] [CrossRef]

- Djerbi, T.A.; Bonnet, S.; Khelidj, A.; Baroghel-Bouny, V. Effect of uniaxial compressive loading on gas permeability and chloride diffusion coefficient of concrete and their relationship. Cem. Concr. Res. 2013, 52, 131–139. [Google Scholar] [CrossRef]

- Choinska, M.; Khelidj, A.; Chatzigeorgiou, G.; Pijaudier-Cabot, G. Effects and interactions of temperature and stress-level related damage on permeability of concrete. Cem. Concr. Res. 2007, 37, 79–88. [Google Scholar] [CrossRef]

- Luo, D.; Niu, D.; Su, L. Research progress on durability of stressed concrete under environmental actions. Eng. Mech. 2019, 36, 1–14. [Google Scholar]

- Dong, J. Cracking and Spalling of Reinforced Concrete Structures under Simultaneous Loading and Chloride Penetration. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2018. [Google Scholar]

- Jin, L.; Zhang, R.B.; Du, X.L. Multi-scale analysis for the chloride diffusivity in concrete subjected to low-level stress. Eng. Mech. 2017, 34, 84–92. [Google Scholar]

- Bernard, F.; Kamali-Bernard, S. Numerical study of ITZ contribution on mechanical behavior and diffusivity of mortars. Comput. Mater. Sci. 2015, 102, 250–257. [Google Scholar] [CrossRef]

- Du, X.; Jin, L.; Zhang, R. Chloride diffusivity in saturated cement paste subjected to external mechanical loadings. Ocean Eng. 2015, 95, 1–10. [Google Scholar] [CrossRef]

- Bentz, D.P.; Garboczi, E.J. Percolation of phases in a three-dimensional cement paste microstructure modal. Cem. Concr. Res. 1991, 21, 325–344. [Google Scholar] [CrossRef]

- Du, X.; Jin, L.; Ma, G. A meso-scale numerical method for the simulation of chloride diffusivity in concrete. Finite Elem. Anal. Des. 2014, 85, 87–100. [Google Scholar] [CrossRef]

- Zhang, W.P.; Zhang, Q.Z.; Gu, X.L.; Zhong, L.J.; Huang, Q.H. Effects of environmental conditions and stress level on chloride ion transport in concrete. J. Jiangsu Univ. Nat. Sci. Ed. 2013, 34, 101–106. [Google Scholar]

- Siemes, A.J.M.; Rostam, S. Durable Safety and Serviceability—A Performance Based Design Format. Basis of Design and Actions on Structures-Background and Application of Eurocode 1. IABSE Report 74. In Proceedings of the IABSE Colloquium, Delft, The Netherlands, 27–29 March 1996. [Google Scholar]

| Variable | Mean Value | Coefficient of Variable | Type of Probability Distribution |

|---|---|---|---|

| fc (kN/m2) | 39,500 | 0.11 | Normal distribution |

| ft (kN/m2) | 3220 | 0.11 | Normal distribution |

| As (m2) | 0.011 (0.023) | 0.01 | Normal distribution |

| D0 (m2/year) | 1.61 × 10−4 | 0.7 | Logarithmic normal distribution |

| Cs (%) | 0.57 (0.15) | 0.5 | Logarithmic normal distribution |

| Ccr (%) | 0.46 (0.065) | 0.2 | Logarithmic normal distribution |

| C (m) | 0.05 (0.06) | 0.3 | Normal distribution |

| Density of concrete (kN/m3) | 26.5 | 0.07 | Normal distribution |

| Density of soil (kN/m3) | 17.11 | 0.01 | Normal distribution |

| The buried depth of the top of lining (m) | 49.5 | 0.05 | Normal distribution |

| Coefficient of static earth pressure | 0.06 | 0.15 | Normal distribution |

| Coefficient of strata resistance | 300,000 | 0.15 | Logarithmic normal distribution |

| Water depth (m) | 50 | 0.05 | Normal distribution |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Q.; Lu, L. Durability of Subsea Tunnels under the Coupled Action of Stress and Chloride Ions. Appl. Sci. 2019, 9, 1984. https://doi.org/10.3390/app9101984

Zhao Q, Lu L. Durability of Subsea Tunnels under the Coupled Action of Stress and Chloride Ions. Applied Sciences. 2019; 9(10):1984. https://doi.org/10.3390/app9101984

Chicago/Turabian StyleZhao, Qingli, and Limin Lu. 2019. "Durability of Subsea Tunnels under the Coupled Action of Stress and Chloride Ions" Applied Sciences 9, no. 10: 1984. https://doi.org/10.3390/app9101984

APA StyleZhao, Q., & Lu, L. (2019). Durability of Subsea Tunnels under the Coupled Action of Stress and Chloride Ions. Applied Sciences, 9(10), 1984. https://doi.org/10.3390/app9101984