Effects of Water Reducing Admixture on Rheological Properties, Fiber Distribution, and Mechanical Behavior of UHPFRC

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Mixture Proportions

2.2. Rheological Tests

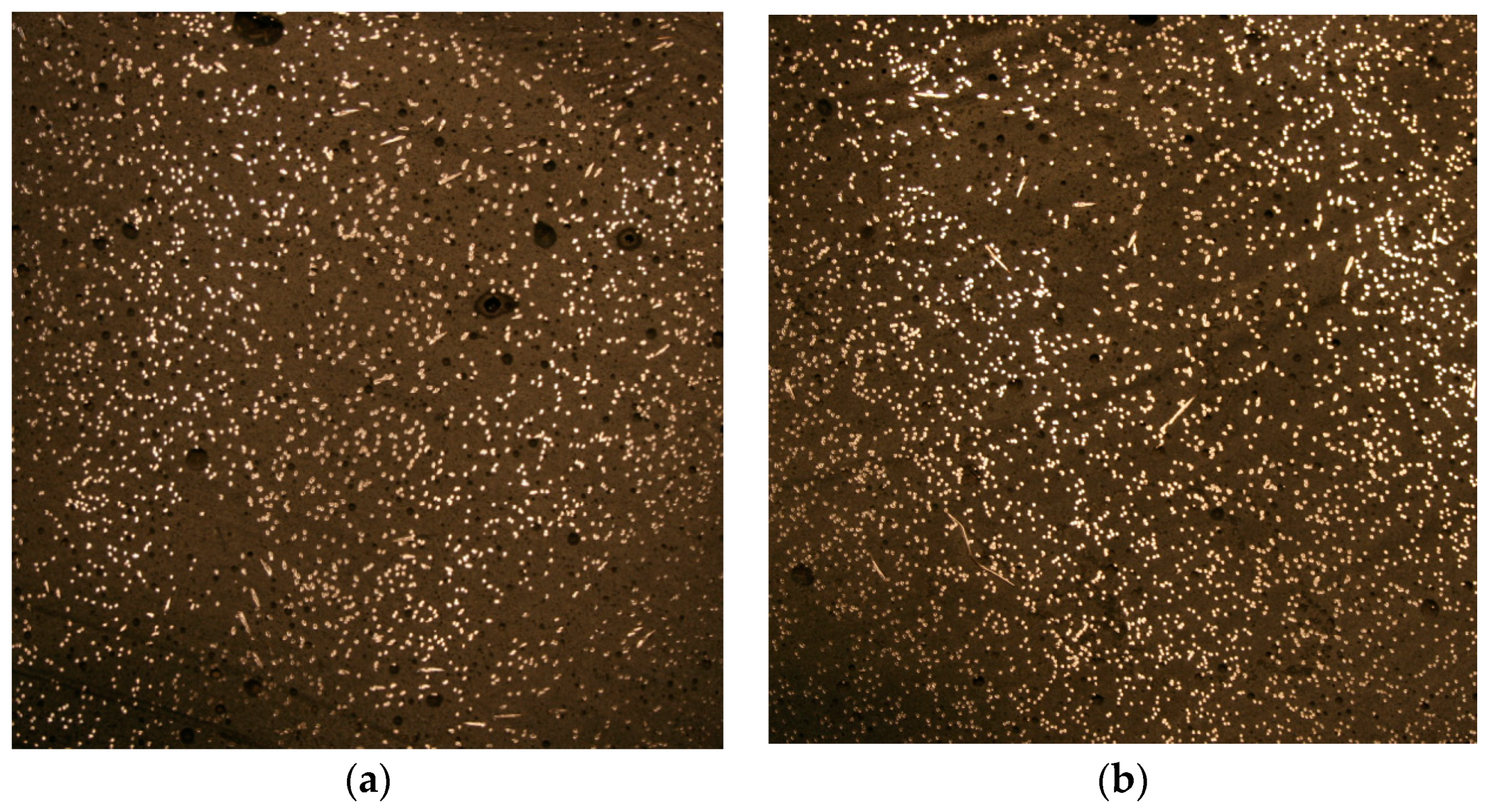

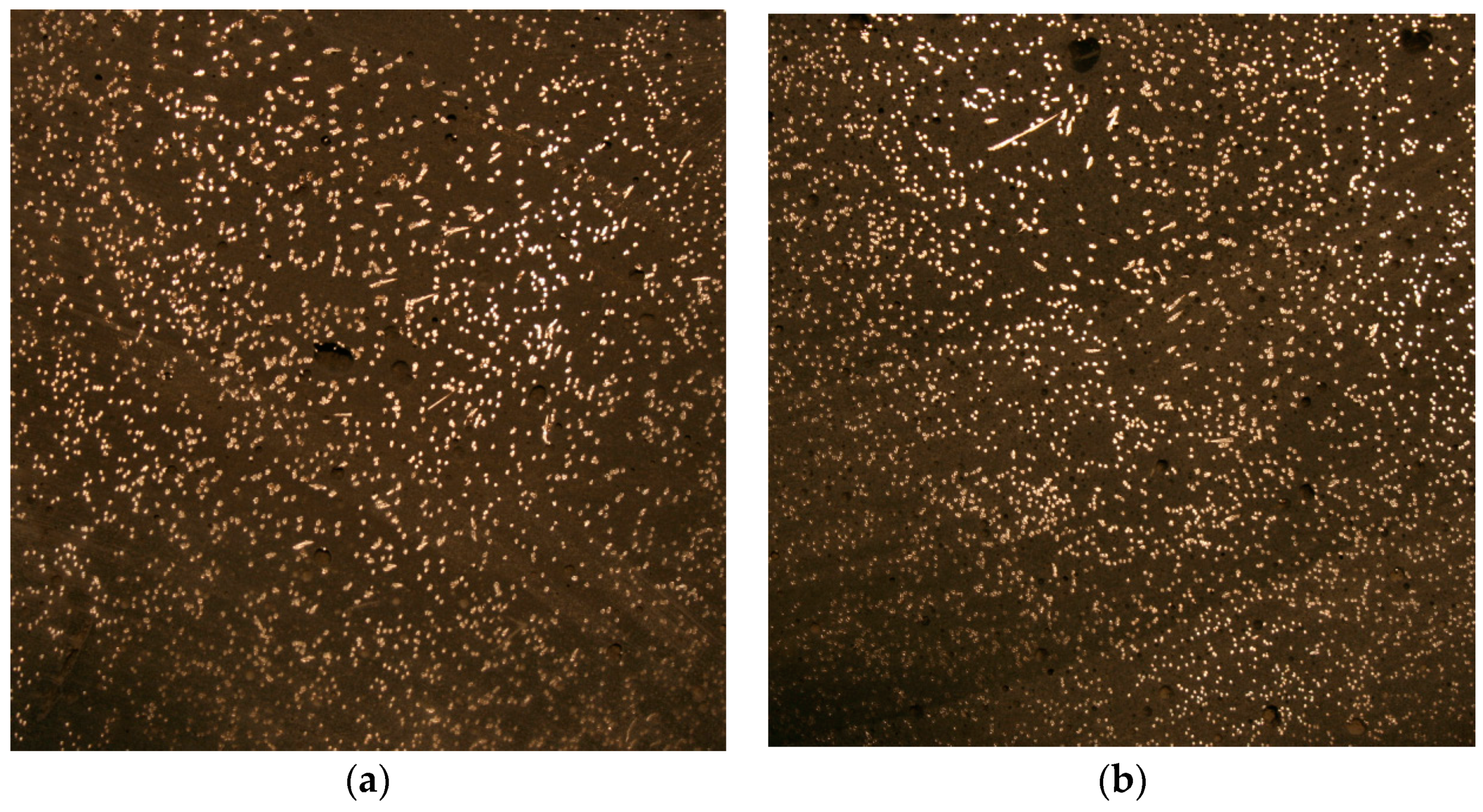

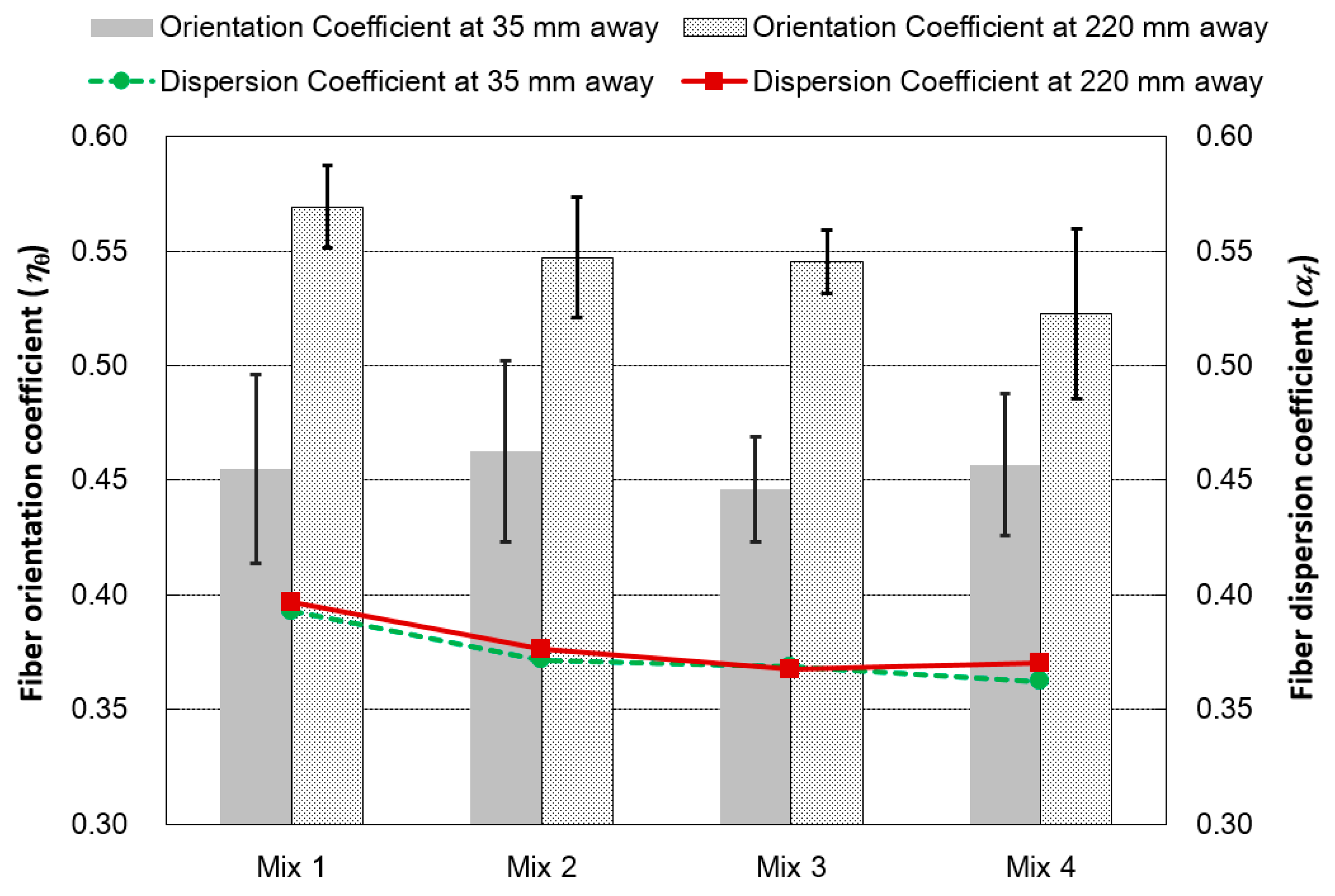

2.4. Fiber Distribution Evaluation

3. Results and Discussion

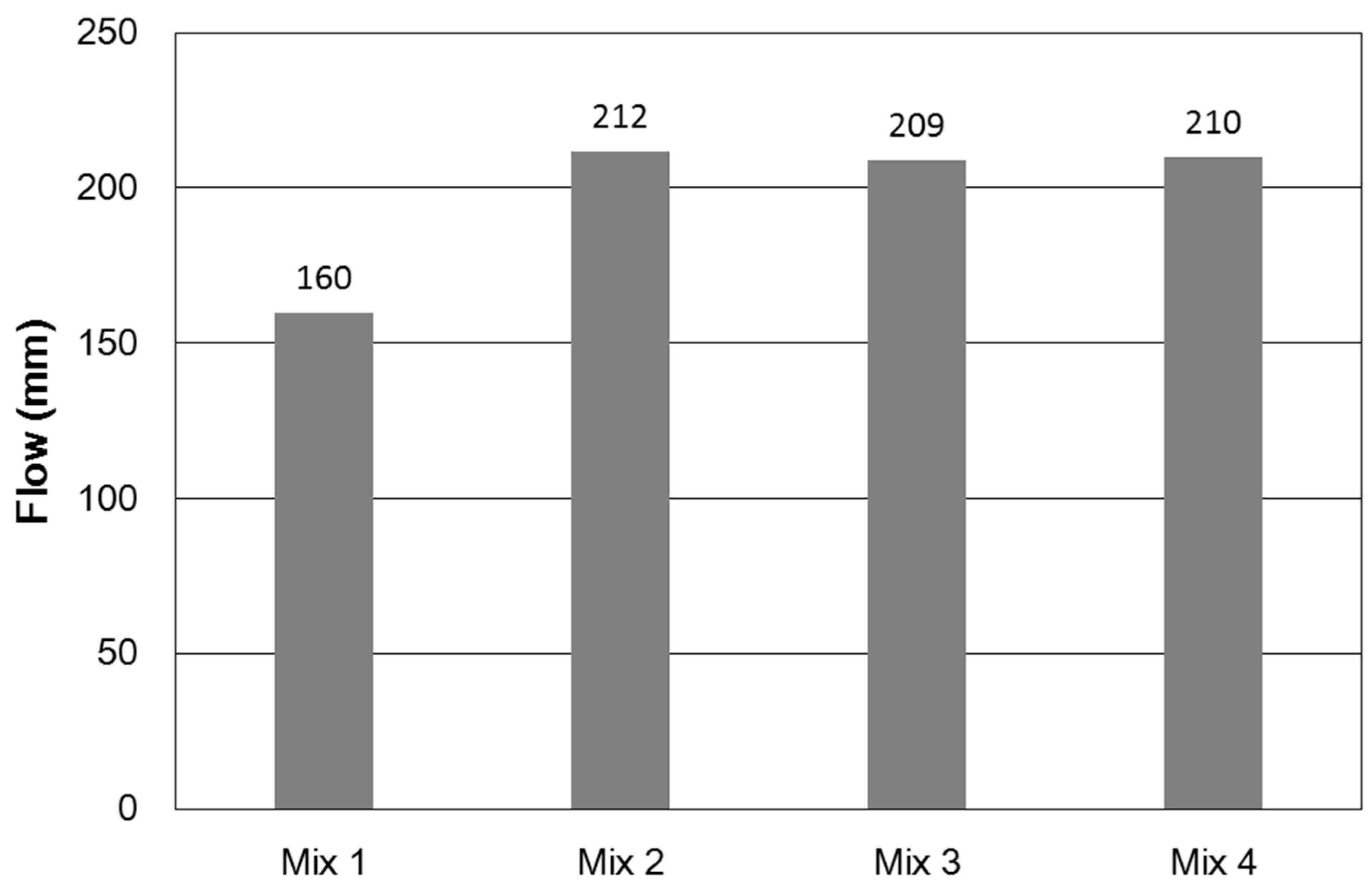

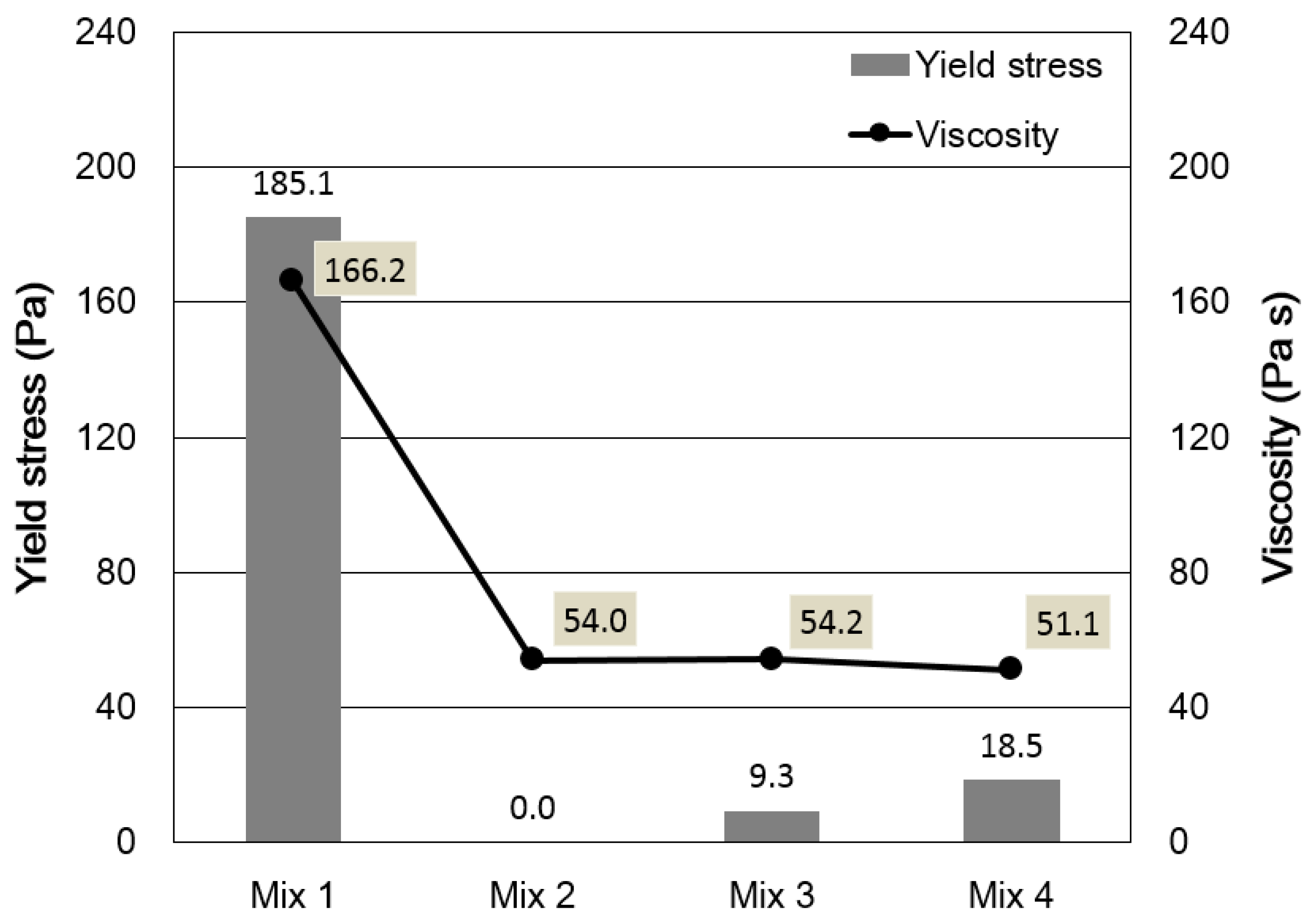

3.1. Rheological Properties

3.2. Compressive Strength

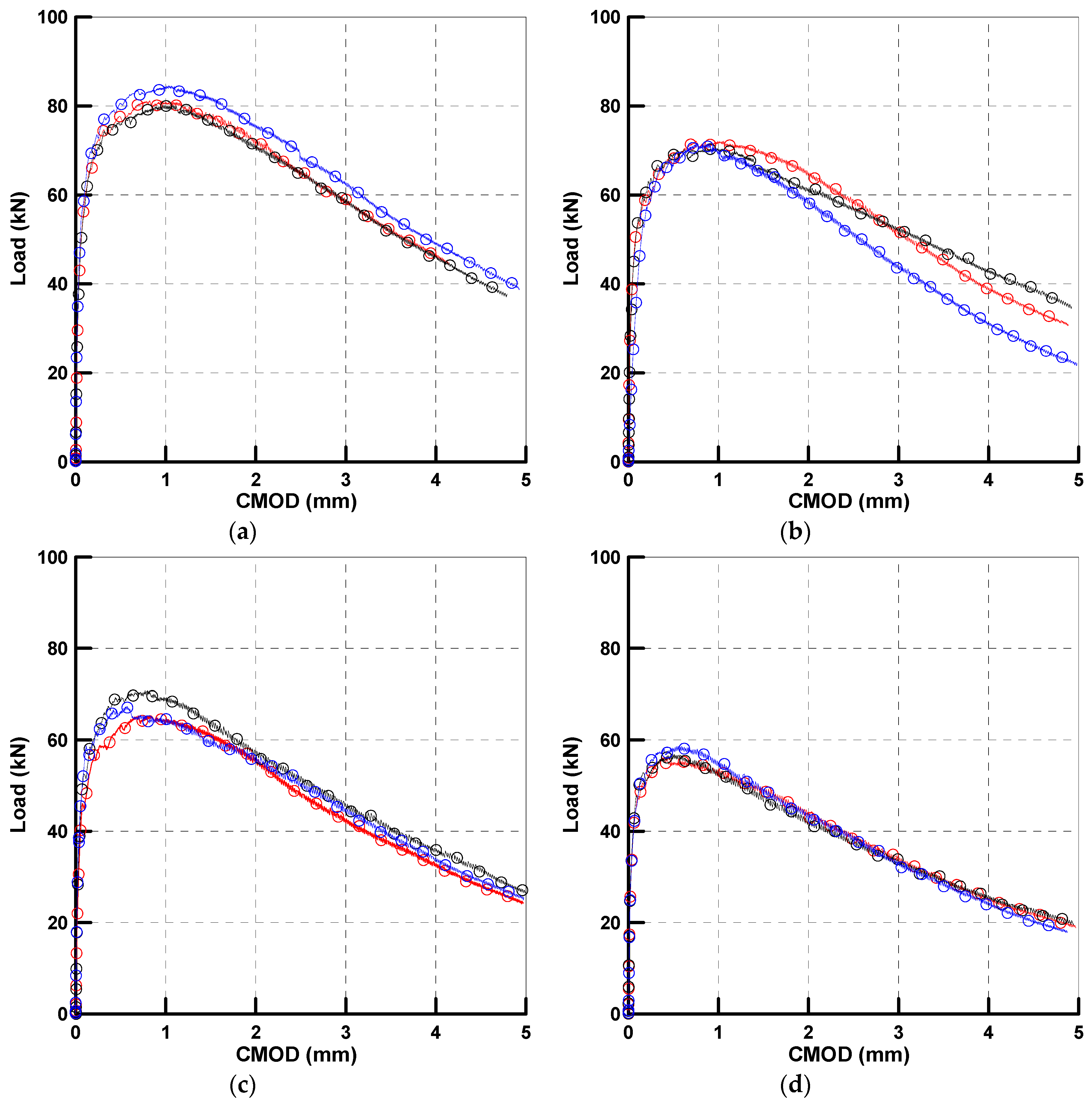

3.3. Flexural Behavior

3.4. Fiber Distribution

4. Conclusions

- The flowability and rheological properties were measured for the fresh UHPFRC, and the results revealed that the positive effect of increasing the amount of WRA on the flowability as well as the rheological properties of fresh UHPFRC could be achieved only with an amount less than a threshold, and a higher amount of WRA exceeding the threshold contributed little to improving the flowability and the rheological properties.

- The compressive strength test results revealed that adding WRA up to a certain amount did not adversely affect the compressive strength while providing a beneficial effect on the workability, whereas an excessive amount of WRA had a negative influence on the compressive strength of UHPFRC.

- The flexural performance showed that the flexural strength and the CMOD at peak load decreased as the amount of WRA increased. Through the comparison between the tendency of the compressive strength and flexural strength, it could be surmised that the flexural strength due to the amount of WRA might be influenced by the fiber distribution.

- A quantitative investigation using the image analysis of the fiber distribution proved that the flexural behaviors with four different mixtures depended in part on the compressive strengths of the matrices and in part on the fiber orientation distributions due to the rheological properties. Furthermore, it was observed that the effect of the rheological property on the fiber orientation is more significant than that on the fiber dispersion.

Author Contributions

Funding

Conflicts of Interest

References

- Joshaghani, A.; Balapour, M.; Ramezanianpour, A.A. Effect of controlled environmental conditions on mechanical, microstructural and durability properties of cement mortar. Constr. Build. Mater. 2018, 164, 134–149. [Google Scholar] [CrossRef]

- Ramezanianpour, A.; Malhotra, V. Effect of curing on the compressive strength, resistance to chloride-ion penetration and porosity of concretes incorporating slag, fly ash or silica fume. Cem. Concr. Compos. 1995, 17, 125–133. [Google Scholar] [CrossRef]

- Sánchez, I.; Antón, C.; De Vera, G.; Ortega, J.M.; Climent, M. Moisture distribution in partially saturated concrete studied by impedance spectroscopy. J. Nondestruct. Eval. 2013, 32, 362–371. [Google Scholar] [CrossRef]

- Williams, M.; Ortega, J.M.; Sánchez, I.; Cabeza, M.; Climent, M.Á. Non-destructive study of the microstructural effects of sodium and magnesium sulphate attack on mortars containing silica fume using impedance spectroscopy. Appl. Sci. 2017, 7, 648. [Google Scholar] [CrossRef]

- Romualdi, J.P.; Batson, G.B. Mechanics of crack arrest in concrete. J. Eng. Mech. Div. 1963, 89, 147–168. [Google Scholar]

- Zollo, R.F. Fiber-reinforced concrete: An overview after 30 years of development. Cem. Concr. Compos. 1997, 19, 107–122. [Google Scholar] [CrossRef]

- Song, P.; Hwang, S. Mechanical properties of high-strength steel fiber-reinforced concrete. Constr. Build. Mater. 2004, 18, 669–673. [Google Scholar] [CrossRef]

- De la Rosa, Á.; Poveda, E.; Ruiz, G.; Cifuentes, H. Proportioning of self-compacting steel-fiber reinforced concrete mixes based on target plastic viscosity and compressive strength: Mix-design procedure & experimental validation. Constr. Build. Mater. 2018, 189, 409–419. [Google Scholar]

- Banthia, N.; Sappakittipakorn, M. Toughness enhancement in steel fiber reinforced concrete through fiber hybridization. Cem. Concr. Res. 2007, 37, 1366–1372. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M.H. Reactive powder concretes with high ductility and 200–800 mpa compressive strength. Spec. Publ. 1994, 144, 507–518. [Google Scholar]

- Rossi, P. Ultra high performance concretes. Concr. Int. 2008, 30, 31–34. [Google Scholar]

- Yoo, D.-Y.; Yoon, Y.-S. A review on structural behavior, design, and application of ultra-high-performance fiber-reinforced concrete. Int. J. Concr. Struct. Mater. 2016, 10, 125–142. [Google Scholar] [CrossRef]

- Bonneau, O.; Lachemi, M.; Dallaire, E.; Dugat, J.; Aitcin, P.-C. Mechanical properties and durability of two industrial reactive powder concretes. Mater. J. 1997, 94, 286–290. [Google Scholar]

- Graybeal, B.; Davis, M. Cylinder or cube: Strength testing of 80 to 200 MPa (11.6 to 29 ksi) ultra-high-performance fiber-reinforced concrete. Mater. J. 2008, 105, 603–609. [Google Scholar]

- Jungwirth, J.; Muttoni, A. Structural behavior of tension members in ultra high performance concrete. In Proceedings of the International Symposium on Ultra High Performance Concrete, Kassel, Germany, 13–15 September 2004. [Google Scholar]

- Kang, S.-T.; Choi, J.-I.; Koh, K.-T.; Lee, K.S.; Lee, B.Y. Hybrid effects of steel fiber and microfiber on the tensile behavior of ultra-high performance concrete. Compos. Struct. 2016, 145, 37–42. [Google Scholar] [CrossRef]

- Kang, S.-T.; Lee, K.-S.; Choi, J.-I.; Lee, Y.; Felekoğlu, B.; Lee, B.Y. Control of tensile behavior of ultra-high performance concrete through artificial flaws and fiber hybridization. Int. J. Concr. Struct. Mater. 2016, 10, 33–41. [Google Scholar] [CrossRef]

- Bencardino, F.; Rizzuti, L.; Spadea, G.; Swamy, R. Experimental evaluation of fiber reinforced concrete fracture properties. Compos. Part B Eng. 2010, 41, 17–24. [Google Scholar] [CrossRef]

- Ferrara, L.; Di Prisco, M.; Lamperti, M. Identification of the stress-crack opening behavior of HPFRCC: The role of flow-induced fiber orientation. In Proceedings of the FraMCoS; Korea Concrete Institute: Seoul, Korea, 2010; pp. 1541–1550. [Google Scholar]

- Markovi, I. High-Performance Hybrid-Fibre Concrete-Development and Utilization. Ph.D. Thesis, Universiteit van Belgrado, Belgrade, Serbia, 2006; pp. 90–92. [Google Scholar]

- Rizzuti, L.; Bencardino, F. Effects of fibre volume fraction on the compressive and flexural experimental behaviour of sfrc. Contemp. Eng. Sci. 2014, 7, 379–390. [Google Scholar] [CrossRef]

- Swamy, R.; Mangat, P.; Rao, C.K. The mechanics of fiber reinforcement of cement matrices. Speci. Publ. 1974, 44, 1–28. [Google Scholar]

- Ezeldin, A.S.; Balaguru, P.N. Normal-and high-strength fiber-reinforced concrete under compression. J. Mater. Civ. Eng. 1992, 4, 415–429. [Google Scholar] [CrossRef]

- Huang, C.; Zhao, G. Properties of steel fibre reinforced concrete containing larger coarse aggregate. Cem. Concr. Compos. 1995, 17, 199–206. [Google Scholar] [CrossRef]

- Jang, S.-J.; Yun, H.-D. Combined effects of steel fiber and coarse aggregate size on the compressive and flexural toughness of high-strength concrete. Compos. Struct. 2018, 185, 203–211. [Google Scholar] [CrossRef]

- Armelin, H.S.; Banthia, N. Predicting the flexural postcracking performance of steel fiber reinforced concrete from the pullout of single fibers. Mater. J. 1997, 94, 18–31. [Google Scholar]

- Mandel, J.A.; Wei, S.; Said, S. Studies of the properties of the fiber-matrix interface in steel fiber reinforced mortar. Mater. J. 1987, 84, 101–109. [Google Scholar]

- Stang, H.; Shah, S. Failure of fibre-reinforced composites by pull-out fracture. J. Mater. Sci. 1986, 21, 953–957. [Google Scholar] [CrossRef]

- Mai, Y. Strength and fracture properties of asbestos-cement mortar composites. J. Mater. Sci. 1979, 14, 2091–2102. [Google Scholar] [CrossRef]

- Naaman, A.E. A Statistical Theory of Strength for Fiber Reinforced Concrete; Massachusetts Institute of Technology: Cambridge, MA, USA, 1972. [Google Scholar]

- Naaman, A.E. High performance fiber reinforced cement composites. In High-Performance Construction Materials: Science and Applications; World Scientific: Singapore, 2008; pp. 91–153. [Google Scholar]

- Barnett, S.J.; Lataste, J.-F.; Parry, T.; Millard, S.G.; Soutsos, M.N. Assessment of fibre orientation in ultra high performance fibre reinforced concrete and its effect on flexural strength. Mater. Struct. 2010, 43, 1009–1023. [Google Scholar] [CrossRef]

- Ferrara, L.; Ozyurt, N.; Di Prisco, M. High mechanical performance of fibre reinforced cementitious composites: The role of “casting-flow induced” fibre orientation. Mater. Struct. 2011, 44, 109–128. [Google Scholar] [CrossRef]

- Kang, S.T.; Lee, B.Y.; Kim, J.-K.; Kim, Y.Y. The effect of fibre distribution characteristics on the flexural strength of steel fibre-reinforced ultra high strength concrete. Constr. Build. Mater. 2011, 25, 2450–2457. [Google Scholar] [CrossRef]

- Kang, S.-T.; Kim, J.-K. The relation between fiber orientation and tensile behavior in an ultra high performance fiber reinforced cementitious composites (uhpfrcc). Cem. Concr. Res. 2011, 41, 1001–1014. [Google Scholar] [CrossRef]

- Şanal, İ.; Zihnioğlu, N.Ö. To what extent does the fiber orientation affect mechanical performance? Constr. Build. Mater. 2013, 44, 671–681. [Google Scholar] [CrossRef]

- Abbas, S.; Nehdi, M.; Saleem, M. Ultra-high performance concrete: Mechanical performance, durability, sustainability and implementation challenges. Int. J. Concr. Struct. Mater. 2016, 10, 271–295. [Google Scholar] [CrossRef]

- Li, P.; Yu, Q.; Brouwers, H. Effect of pce-type superplasticizer on early-age behaviour of ultra-high performance concrete (uhpc). Constr. Build. Mater. 2017, 153, 740–750. [Google Scholar] [CrossRef]

- Ozyurt, N.; Mason, T.O.; Shah, S.P. Correlation of fiber dispersion, rheology and mechanical performance of frcs. Cem. Concr. Compos. 2007, 29, 70–79. [Google Scholar] [CrossRef]

- Stähli, P.; Custer, R.; van Mier, J.G. On flow properties, fibre distribution, fibre orientation and flexural behaviour of frc. Mater. Struct. 2008, 41, 189–196. [Google Scholar] [CrossRef]

- Wang, R.; Gao, X.; Huang, H.; Han, G. Influence of rheological properties of cement mortar on steel fiber distribution in uhpc. Constr. Build. Mater. 2017, 144, 65–73. [Google Scholar] [CrossRef]

- Standard Test Method for Flow of Hydraulic Cement Mortar. 2007. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/C1437-07.htm (accessed on 15 January 2016).

- De Larrard, F.; Sedran, T. Mixture-proportioning of high-performance concrete. Cem. Concr. Res. 2002, 32, 1699–1704. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Papthanasiou, T.; Guell, D.C. Flow-Induced Alignment in Composite Materials; Elsevier: Amsterdam, The Netherlands, 1997. [Google Scholar]

- Takano, M. Viscosity Effect on Flow Orientation of Short Fibers; Monsanto Research Corp.: St Louis, MO, USA, 1973. [Google Scholar]

- Piggott, M.R. Short fibre polymer composites: A fracture-based theory of fibre reinforcement. J. Compos. Mater. 1994, 28, 588–606. [Google Scholar] [CrossRef]

- Park, J.J.; Kang, S.T.; Koh, K.T.; Kim, S.W. Influence of the ingredients on the compressive strength of uhpc as a fundamental study to optimize the mixing proportion. In Proceedings of the Second International Symposium on Ultra High Performance Concrete, Kassel, Germany, 5–7 March 2008; pp. 105–112. [Google Scholar]

- Reda, M.; Shrive, N.; Gillott, J. Microstructural investigation of innovative uhpc. Cem. Concr. Res. 1999, 29, 323–329. [Google Scholar] [CrossRef]

- Schmidt, M.; Fehling, E. Ultra-high-performance concrete: Research, development and application in europe. ACI Spec. Publ. 2005, 228, 51–78. [Google Scholar]

- Folgar, F.; Tucker, C.L., III. Orientation behavior of fibers in concentrated suspensions. J. Reinf. Plast. Compos. 1984, 3, 98–119. [Google Scholar] [CrossRef]

| Mixture | Unit Weight (kg/m3) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cement | Silica Fume | Filler | Sand | Water | Admixtures | Anti-Foamer | Steel Fiber | |||

| WRA * | EA ** | SRA *** | ||||||||

| Mix 1 | 771 | 193 | 231 | 848 | 165 | 30.8 | 57.8 | 7.70 | 1.40 | 156 |

| Mix 2 | 160 | 46.3 | ||||||||

| Mix 3 | 156 | 61.7 | ||||||||

| Mix 4 | 151 | 77.1 | ||||||||

| Mixture | Peak Load (kN) | Flexural Strength (MPa) | Deflection at Peak Load (mm) | CMOD at Peak Load (mm) |

|---|---|---|---|---|

| Mix 1 | 81.97 ± 2.31 | 45.54 ± 1.29 | 0.81 ± 0.05 | 0.94 ± 0.11 |

| Mix 2 | 71.42 ± 0.86 | 39.68 ± 0.48 | 0.87 ± 0.26 | 0.85 ± 0.12 |

| Mix 3 | 67.83 ± 2.77 | 37.68 ± 1.54 | 0.84 ± 0.34 | 0.73 ± 0.14 |

| Mix 4 | 57.28 ± 1.17 | 31.82 ± 0.65 | 0.66 ± 0.09 | 0.48 ± 0.09 |

| Properties | WRA | Flow | Plastic Viscosity | Yield Stress | Compressive Strength | Flexural Strength | ||

|---|---|---|---|---|---|---|---|---|

| WRA | 1 | - | - | - | - | - | - | - |

| Flow | 0.75 | 1 | - | - | - | - | - | - |

| Plastic viscosity | −0.79 | −1.00 | 1 | - | - | - | - | - |

| Yield stress | −0.72 | −1.00 | 0.99 | 1 | - | - | - | - |

| Compressive strength | −0.88 | −0.39 | 0.43 | 0.34 | 1 | - | - | - |

| Flexural strength | −0.98 | −0.79 | 0.82 | 0.76 | 0.87 | 1 | - | - |

| −0.87 | −0.95 | 0.97 | 0.95 | 0.52 | 0.86 | 1 | - | |

| −0.96 | −0.80 | 0.82 | 0.76 | 0.86 | 0.99 | 0.83 | 1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, S.-T.; Kim, J.H.; Lee, B.Y. Effects of Water Reducing Admixture on Rheological Properties, Fiber Distribution, and Mechanical Behavior of UHPFRC. Appl. Sci. 2019, 9, 29. https://doi.org/10.3390/app9010029

Kang S-T, Kim JH, Lee BY. Effects of Water Reducing Admixture on Rheological Properties, Fiber Distribution, and Mechanical Behavior of UHPFRC. Applied Sciences. 2019; 9(1):29. https://doi.org/10.3390/app9010029

Chicago/Turabian StyleKang, Su-Tae, Jae Hong Kim, and Bang Yeon Lee. 2019. "Effects of Water Reducing Admixture on Rheological Properties, Fiber Distribution, and Mechanical Behavior of UHPFRC" Applied Sciences 9, no. 1: 29. https://doi.org/10.3390/app9010029

APA StyleKang, S.-T., Kim, J. H., & Lee, B. Y. (2019). Effects of Water Reducing Admixture on Rheological Properties, Fiber Distribution, and Mechanical Behavior of UHPFRC. Applied Sciences, 9(1), 29. https://doi.org/10.3390/app9010029