Double Low-Rank and Sparse Decomposition for Surface Defect Segmentation of Steel Sheet

Abstract

:Featured Application

Abstract

1. Introduction

2. Related Work

3. Double Low-Rank and Sparse Decomposition Model

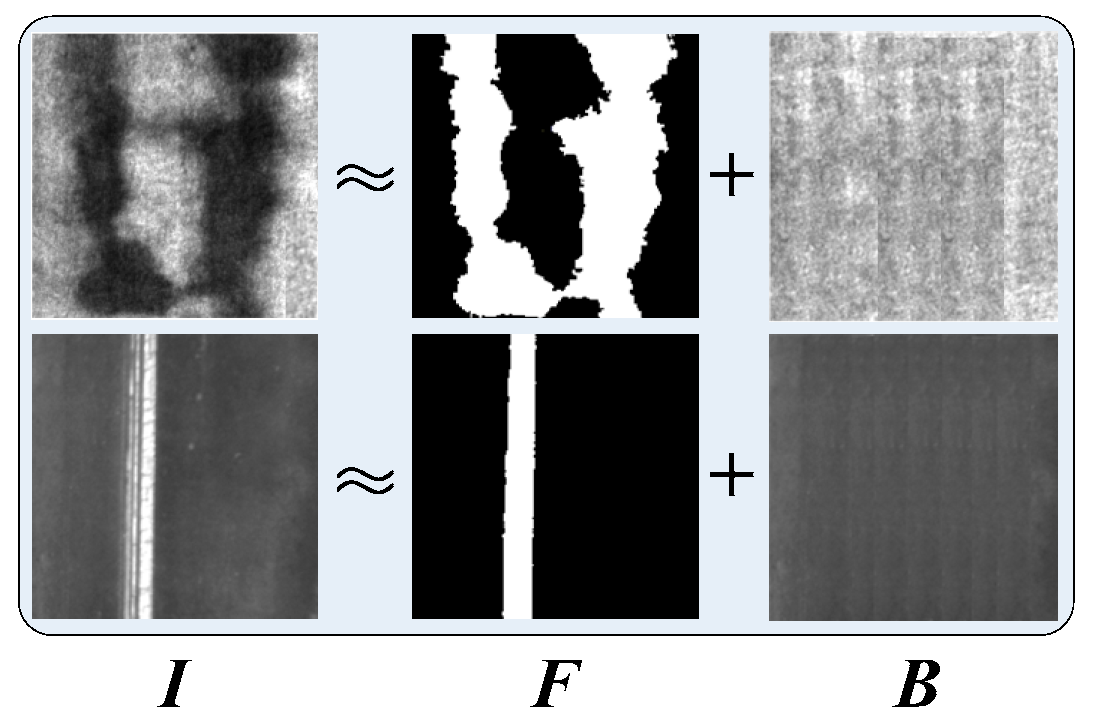

3.1. Problem Formulation

3.2. Optimization

| Algorithm 1 Solving DLRSD via ADM |

| Input: Data matrix , parameters , , and |

| Output: The optimal solution and |

| 1: Initializing |

| , , , , , |

| While OR , , |

| 2: Updating |

| 3: Updating |

| 4: Updating |

| 5: Updating |

| 6: Updating , and |

| 7: Updating |

| 8: Iteration |

| End While |

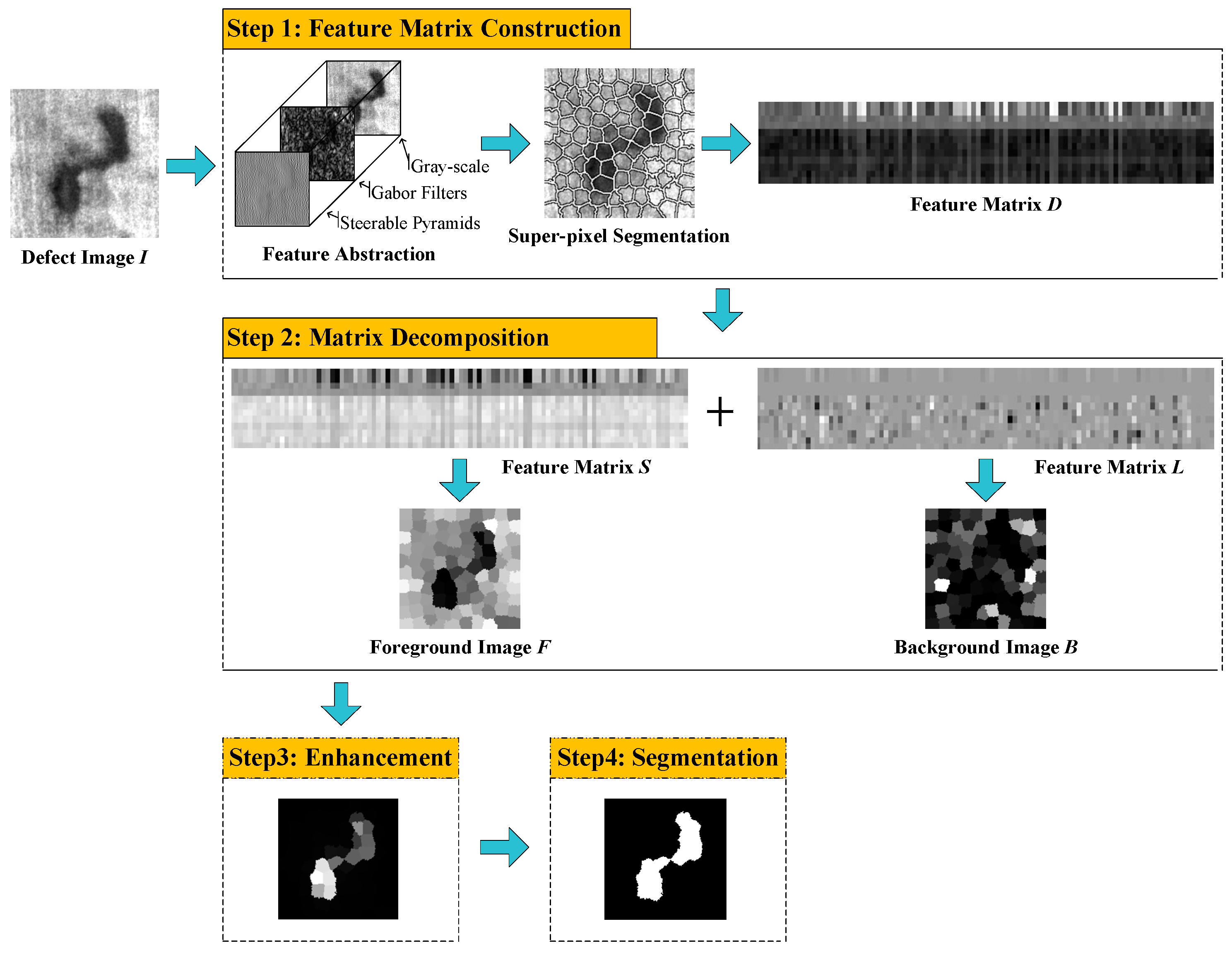

4. DLRSD-Based Surface Defect Segmentation

4.1. Feature Matrix Construction

4.2. Matrix Decomposition

4.3. Enhancement

4.4. Segmentation

| Algorithm 2 DLRSD-based defect segmentation |

| Input: Surface defect image Output: Binary segmentation image |

| 1: Construct the feature matrix 2: Run Algorithm 1 to get the defect foreground feature matrix 3: Enhance defect foreground image 4: Segment enhanced by Otsu’s method |

5. Experiment

5.1. Experimental Setup

5.1.1. Parameters Settings

5.1.2. Evaluation Metrics

5.2. Experimental Results Analysis

5.2.1. Analysis of Computational Complexity

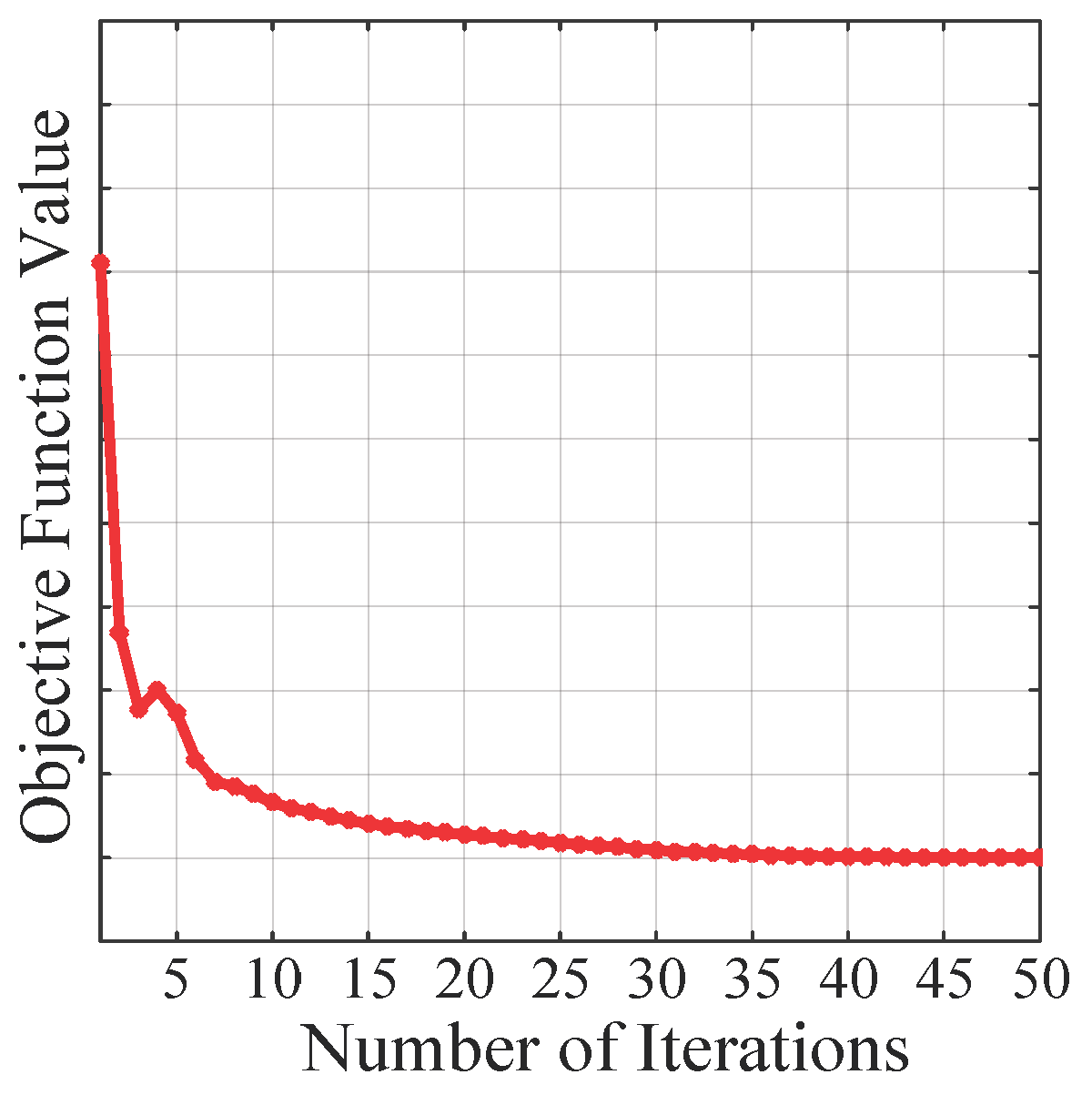

5.2.2. Analysis of Convergence

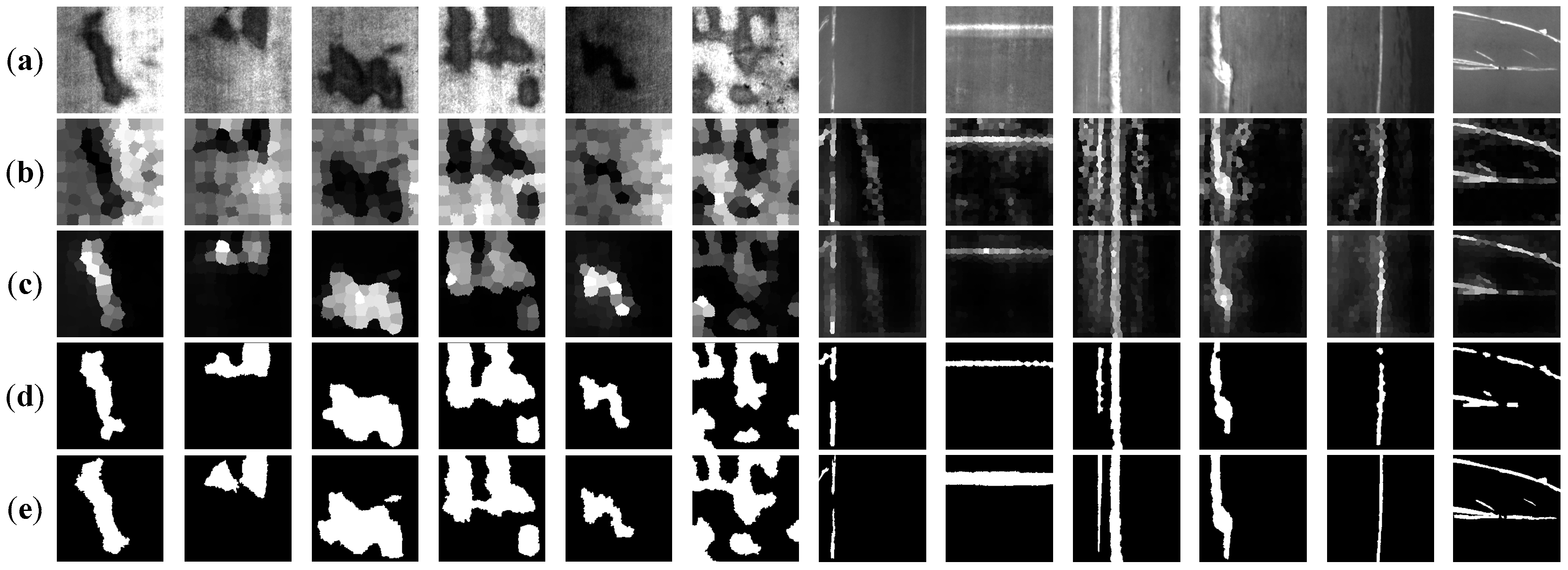

5.2.3. Analysis of Segmentation Results

5.2.4. Analysis of Robustness to Noise

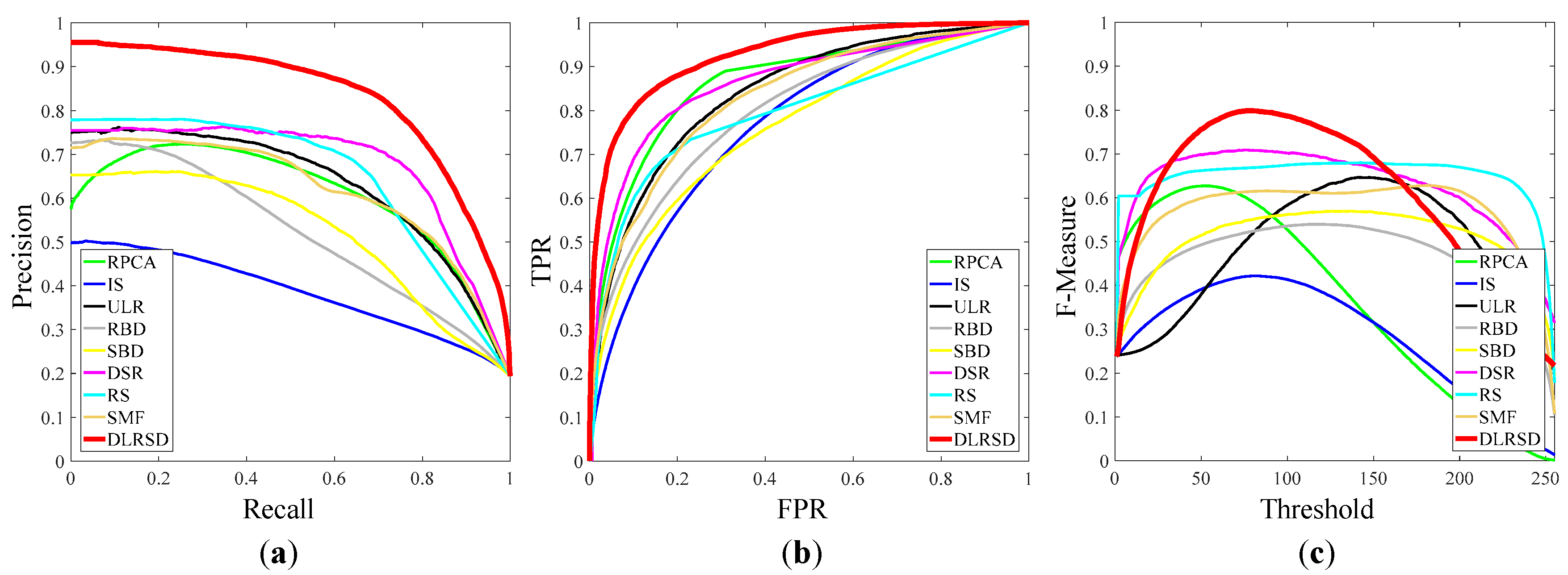

5.3. Comparison with State-of-the-Art Methods

5.3.1. Qualitative Comparison

5.3.2. Quantitative Comparison

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hanbaya, K.; Talub, M.F.; Özgüvenc, Ö.F. Fabric defect detection systems and methods-a systematic literature review. OPTIK 2016, 127, 11960–11973. [Google Scholar] [CrossRef]

- Neogi, N.; Mohanta, D.K.; Dutta, P.K. Review of vision-based steel surface inspection systems. EURASIP J. Image Video Process. 2014, 2014, 1–19. [Google Scholar] [CrossRef]

- Yun, J.P.; Kim, D.; Kim, K.H.; Lee, S.J.; Park, C.H.; Kim, S.W. Vision-based surface defect inspection for thick steel plates. Opt. Eng. 2017, 56, 1–12. [Google Scholar] [CrossRef]

- Madrigal, C.A.; Branch, J.W.; Restrepo, A.; Mery, D. A method for automatic surface inspection using a model-based 3D descriptor. Sensors 2017, 17, 2262. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.P.; Li, Q.W.; Zhou, Y.Q.; He, F.J.; Xi, S.Y. A surface defects inspection method based on multidirectional gray-level fluctuation. Int. J. Adv. Robot. Syst. 2017, 14, 1–7. [Google Scholar] [CrossRef]

- Aiger, D.; Talbot, H. The phase only transform for unsupervised surface defect detection. In Proceedings of the 2010 IEEE Computer Society Conference on Computer Vision and Pattern Recognition, San Francisco, CA, USA, 13–18 June 2010; pp. 295–302. [Google Scholar] [CrossRef]

- Choi, D.C.; Jeon, Y.J.; Kim, S.H.; Moon, S.; Yun, J.P.; Kim, S.W. Detection of pinholes in steel slabs using Gabor filter combination and morphological features. ISIJ Int. 2017, 57, 1045–1053. [Google Scholar] [CrossRef]

- Jeon, Y.J.; Choi, D.C.; Lee, S.J.; Yun, J.P.; Kim, S.W. Defect detection for corner cracks in steel billets using a wavelet reconstruction method. J. Opt. Soc. Am. A 2014, 31, 227–237. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Wang, H.Y.; Chen, H.Y.; Qu, E.Q.; Tian, Y.; Sun, H.X. Steel surface defect detection using a new Haar-Weibull-Variance model in unsupervised manner. IEEE Trans. Instrum. Meas. 2017, 66, 2585–2596. [Google Scholar] [CrossRef]

- Guan, S.Q. Strip steel defect detection based on saliency map construction using Gaussian pyramid decomposition. ISIJ Int. 2015, 55, 1950–1955. [Google Scholar] [CrossRef]

- Li, P.; Liang, J.L.; Shen, X.B.; Zhao, M.H.; Sui, L.S. Textile fabric defect detection based on low-rank representation. Multimed. Tools Appl. 2017, 1–26. [Google Scholar] [CrossRef]

- Zhao, Y.J.; Yan, Y.H.; Song, K.C. Vision-based automatic detection of steel surface defects in the cold rolling process: Considering the influence of industrial liquids and surface textures. Int. J. Adv. Manuf. Technol. 2017, 90, 1665–1678. [Google Scholar] [CrossRef]

- Hou, X.D.; Harel, J.; Koch, C. Image signature: Highlighting sparse salient regions. IEEE Trans. Pattern Anal. Mach. Intell. 2012, 34, 194–201. [Google Scholar] [CrossRef]

- Perazzi, F.; Krahenbuhl, P.; Pritch, Y.; Hornung, A. Saliency filters: Contrast based filtering for salient region detection. In Proceedings of the 2012 IEEE Conference on Computer Vision and Pattern Recognition, Providence, RI, USA, 16–21 June 2012; pp. 733–740. [Google Scholar] [CrossRef]

- Shi, J.P.; Yan, Q.; Xu, L.; Jia, J.Y. Hierarchical image saliency detection on extended CSSD. IEEE Trans. Pattern Anal. Mach. Intell. 2016, 38, 717–729. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.H.; Yang, C.; Lu, H.C.; Ruan, X.; Yang, M.H. Ranking saliency. IEEE Trans. Pattern Anal. Mach. Intell. 2017, 39, 1892–1904. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.Q.; Zhang, L.; Zhao, W.D.; Liu, X.H.; Chen, Y.F.; Wang, Z.C. Salient object detection using coarse-to-fine processing. J. Opt. Soc. Am. A 2017, 34, 370–383. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.M.; Yang, M.H. Top-down visual saliency via joint CRF and dictionary learning. IEEE Trans. Pattern Anal. Mach. Intell. 2017, 39, 576–588. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.D.; Jiang, H.Z.; Yuan, Z.J.; Cheng, M.M.; Hu, X.W.; Zheng, N.N. Salient object detection: A discriminative regional feature integration approach. Int. J. Comput. Vis. 2017, 123, 251–268. [Google Scholar] [CrossRef]

- Peng, Q.M.; Cheung, Y.M.; You, X.G.; Tang, Y.Y. A hybrid of local and global saliencies for detecting image salient region and appearance. IEEE Trans. Syst. Man Cybern. Soc. 2017, 47, 86–97. [Google Scholar] [CrossRef]

- Yan, J.C.; Zhu, M.Y.; Liu, H.X.; Liu, Y.C. Visual saliency detection via sparsity pursuit. IEEE Signal Process. Lett. 2010, 17, 739–742. [Google Scholar] [CrossRef]

- Zou, W.B.; Liu, Z.; Kpalma, K.; Ronsin, J.; Zhao, Y.; Komodakis, N. Unsupervised joint salient region detection and object segmentation. IEEE Trans. Image Process. 2015, 24, 3858–3873. [Google Scholar] [CrossRef] [PubMed]

- Shen, X.H.; Wu, Y. A unified approach to salient object detection via low rank matrix recovery. In Proceedings of the 2012 IEEE Conference on Computer Vision and Pattern Recognition, Providence, RI, USA, 16–21 June 2012; pp. 853–860. [Google Scholar] [CrossRef]

- Peng, H.W.; Li, B.; Ling, H.B.; Hu, W.M.; Xiong, W.H.; Maybank, S.J. Salient object detection via structured matrix decomposition. IEEE Trans. Pattern Anal. Mach. Intell. 2017, 39, 818–832. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.L.; He, Z.X.; Xu, C.; Zhang, X.J.; Zou, W.B.; Baciu, G. Diversity induced matrix decomposition model for salient object detection. Pattern Recogn. 2017, 66, 253–267. [Google Scholar] [CrossRef]

- Cai, D.; He, X.F.; Han, J.W.; Huang, T.S. Graph regularized non-negative matrix factorization for data representation. IEEE Trans. Pattern Anal. Mach. Intell. 2011, 33, 1548–1560. [Google Scholar] [CrossRef] [PubMed]

- Bruckstein, A.M.; Donoho, D.L.; Elad, M. From sparse solutions of systems of equations to sparse modeling of signals and images. SIAM Rev. 2009, 51, 34–81. [Google Scholar] [CrossRef]

- Candès, E.J.; Li, X.D.; Ma, Y.; Wright, J. Robust principal component analysis. J. ACM 2011, 58, 1–37. [Google Scholar] [CrossRef]

- Lin, Z.C.; Chen, M.M.; Ma, Y. The Augmented Lagrange Multiplier Method for Exact Recovery of Corrupted Low-Rank Matrices; University of Illinois Urbana-Champaign Technical Report; UILU-ENG-09-2215; University of Illinois Urbana-Champaign: Champaign, IL, USA, 2009. [Google Scholar]

- Achanta, R.; Shaji, A.; Smith, K.; Lucchi, A.; Fua, P.; Susstrunk, S. SLIC superpixels compared to state-of-the-art superpixel methods. IEEE Trans. Pattern Anal. Mach. Intell. 2012, 34, 2274–2282. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.J.; Liang, S.; Wei, Y.C.; Sun, J. Saliency optimization from robust background detection. In Proceedings of the 2014 IEEE Conference on Computer Vision and Pattern Recognition, Columbus, OH, USA, 23–28 June 2014; pp. 2814–2821. [Google Scholar] [CrossRef]

- Zhao, T.; Li, L.; Ding, X.H.; Huang, Y.; Zeng, D.L. Saliency detection with spaces of background-based distribution. IEEE Signal Process. Lett. 2016, 23, 683–687. [Google Scholar] [CrossRef]

- Lu, H.C.; Li, X.H.; Zhang, L.H.; Ruan, X.; Yang, M.H. Dense and sparse reconstruction error based saliency descriptor. IEEE Trans. Image Process. 2016, 25, 1592–1603. [Google Scholar] [CrossRef] [PubMed]

| SNR | No Noise | 22 dB | 18 dB | 14 dB | 10 dB | |

|---|---|---|---|---|---|---|

| Index | ||||||

| AUC | 0.8350 | 0.8216 | 0.7922 | 0.7414 | 0.6918 | |

| MAE | 0.1584 | 0.1638 | 0.1837 | 0.2114 | 0.2384 | |

| Index | AUC | Fζ | MAE | Time (s) | |

|---|---|---|---|---|---|

| Method | |||||

| RPCA [28] | 0.7636 | 0.3633 | 0.1860 | 0.1982 | |

| IS [13] | 0.7140 | 0.2814 | 0.2485 | 0.0032 | |

| ULR [23] | 0.7843 | 0.4780 | 0.2976 | 4.5504 | |

| RBD [31] | 0.7125 | 0.4607 | 0.2090 | 0.0331 | |

| SBD [32] | 0.6907 | 0.5038 | 0.2390 | 0.6619 | |

| DSR [33] | 0.7786 | 0.6264 | 0.1626 | 1.1797 | |

| RS [16] | 0.7469 | 0.6454 | 0.1758 | 0.1281 | |

| SMF [24] | 0.7497 | 0.5655 | 0.2085 | 0.4615 | |

| Ours | 0.8350 | 0.6060 | 0.1584 | 0.1713 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, S.; Wu, S.; Liu, H.; Lu, Y.; Hu, N. Double Low-Rank and Sparse Decomposition for Surface Defect Segmentation of Steel Sheet. Appl. Sci. 2018, 8, 1628. https://doi.org/10.3390/app8091628

Zhou S, Wu S, Liu H, Lu Y, Hu N. Double Low-Rank and Sparse Decomposition for Surface Defect Segmentation of Steel Sheet. Applied Sciences. 2018; 8(9):1628. https://doi.org/10.3390/app8091628

Chicago/Turabian StyleZhou, Shiyang, Shiqian Wu, Huaiguang Liu, Yang Lu, and Nianzong Hu. 2018. "Double Low-Rank and Sparse Decomposition for Surface Defect Segmentation of Steel Sheet" Applied Sciences 8, no. 9: 1628. https://doi.org/10.3390/app8091628

APA StyleZhou, S., Wu, S., Liu, H., Lu, Y., & Hu, N. (2018). Double Low-Rank and Sparse Decomposition for Surface Defect Segmentation of Steel Sheet. Applied Sciences, 8(9), 1628. https://doi.org/10.3390/app8091628