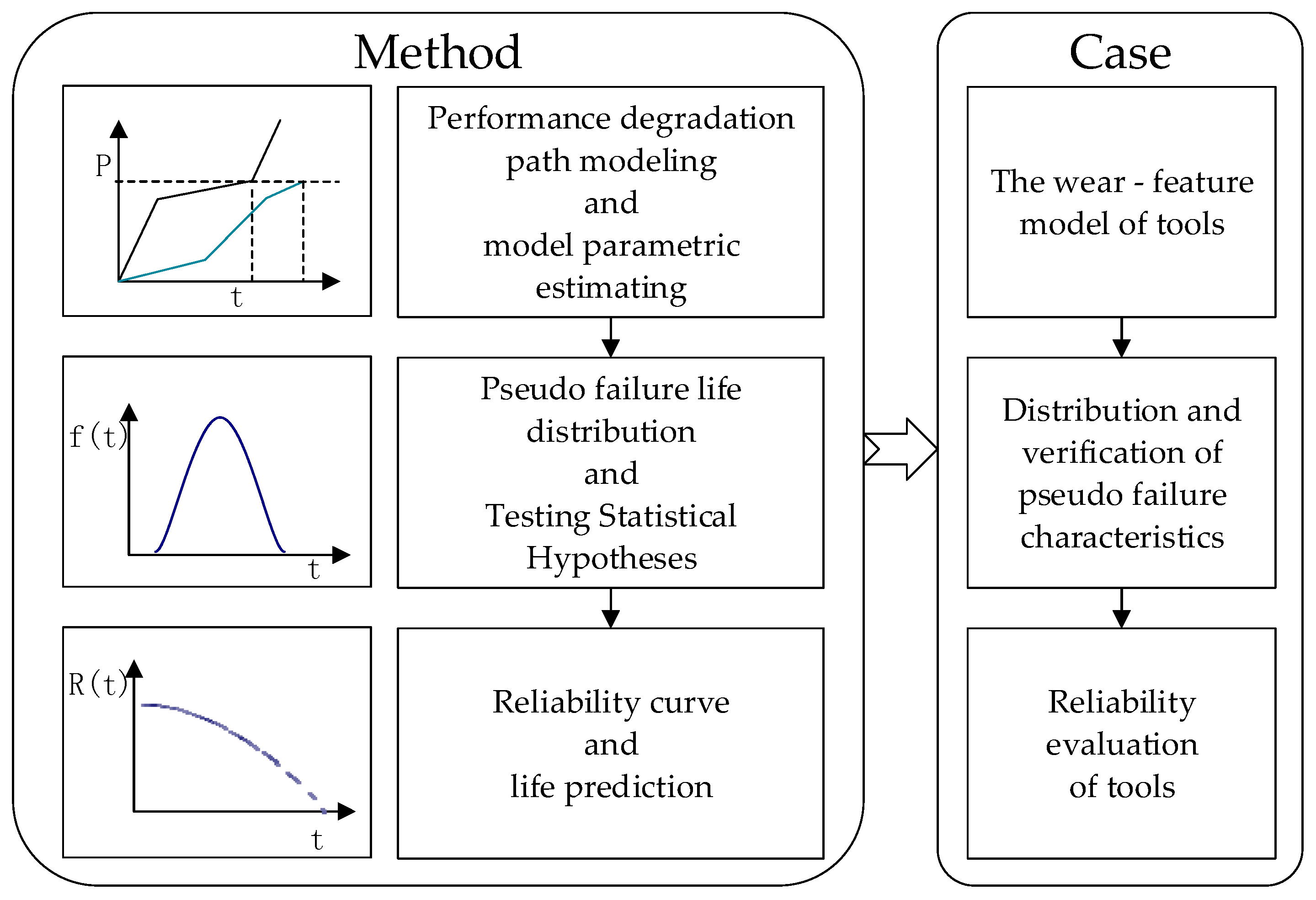

2.1. Method Flowchart

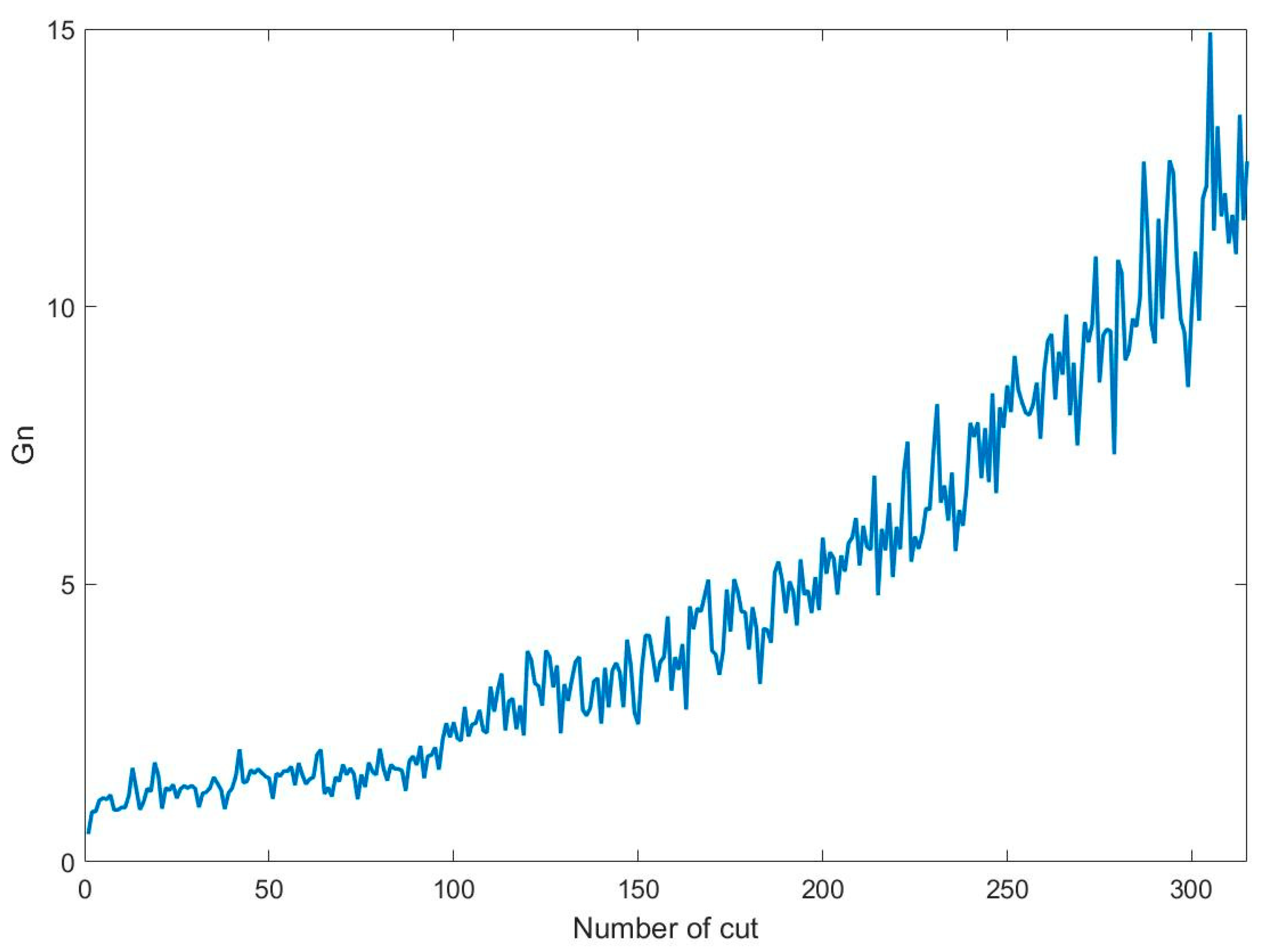

In this paper, the features of monitored vibration signals were extracted and the performance degradation data was applied to reliability assessment for mechanical equipment. The process of method is shown in

Figure 1.

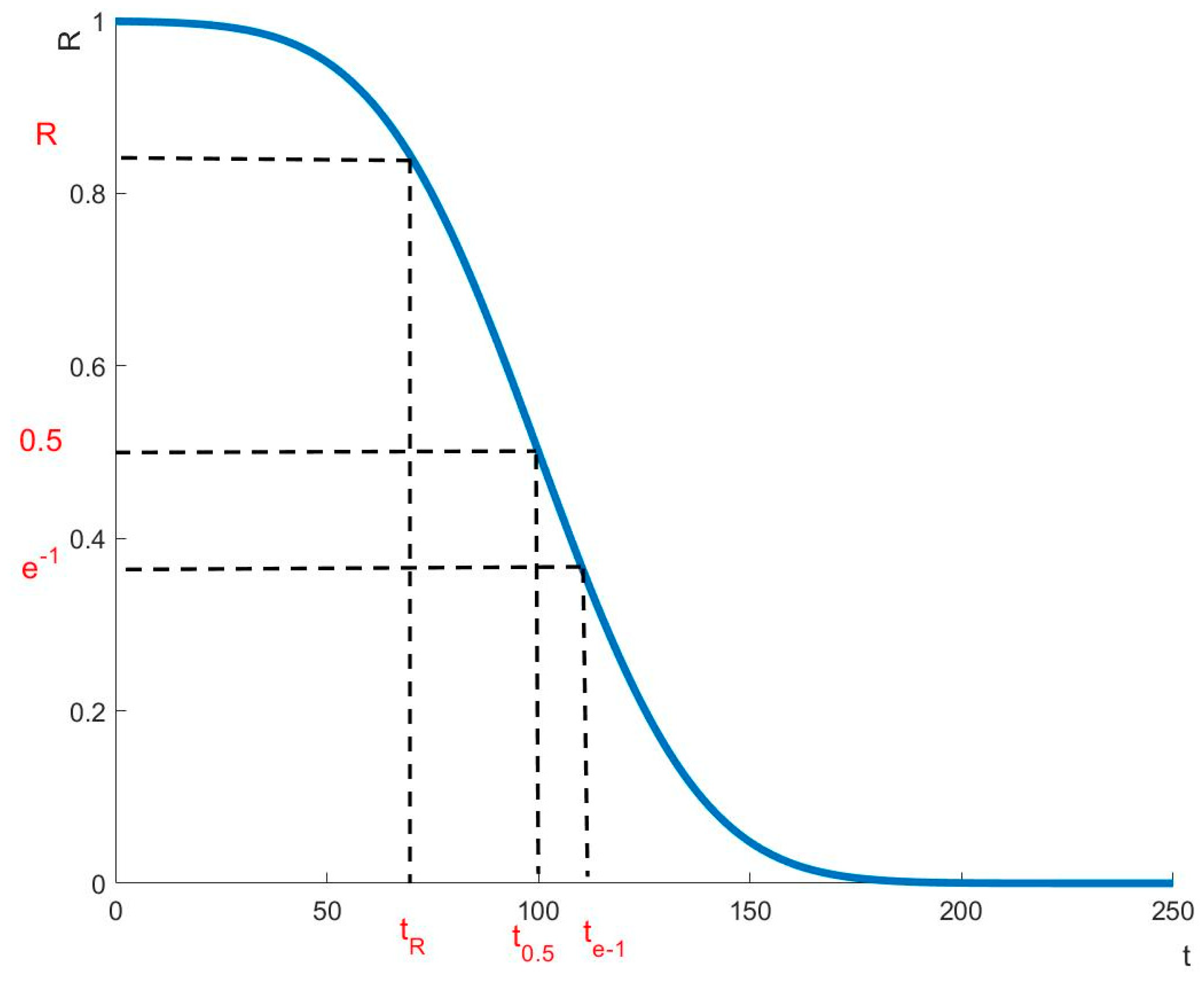

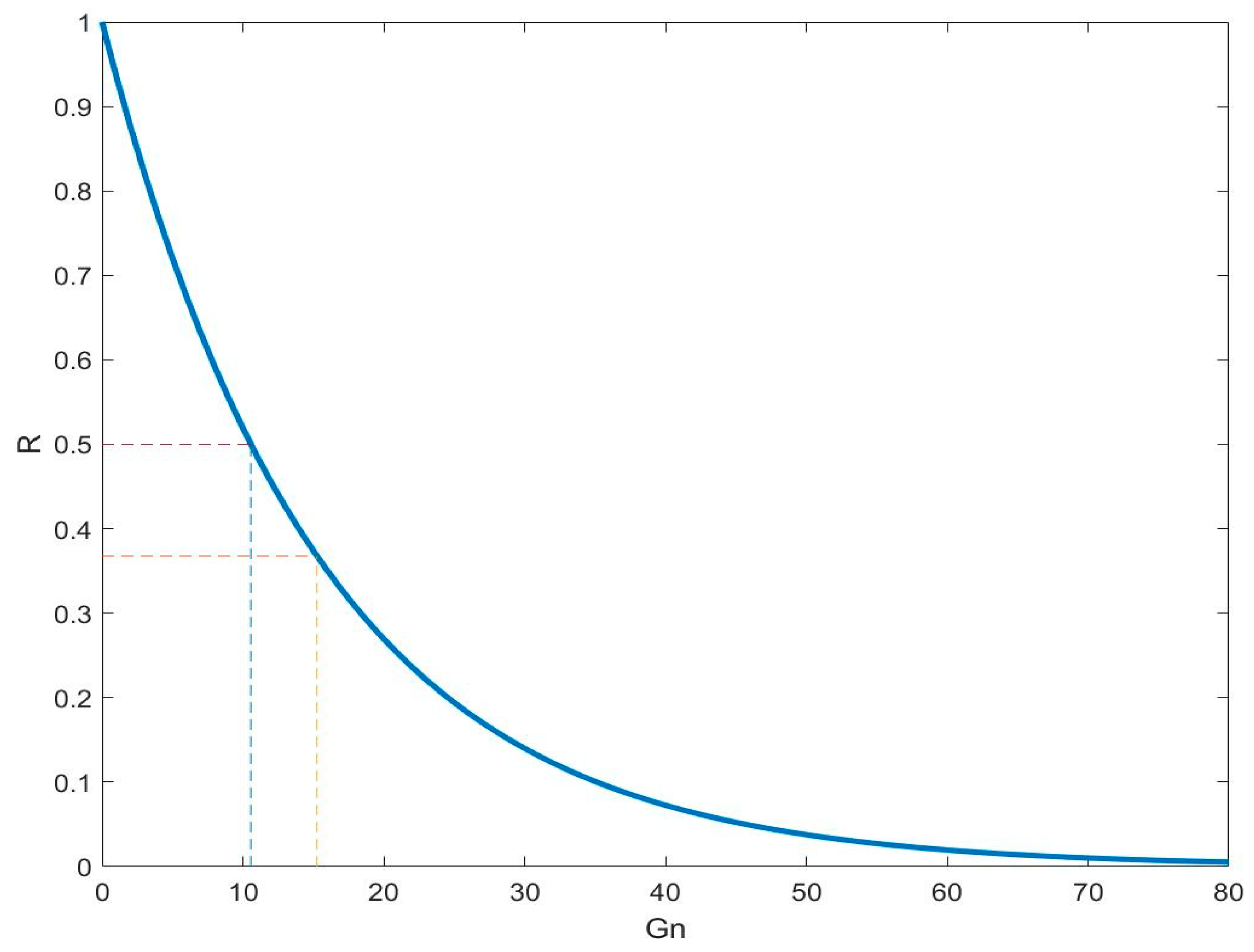

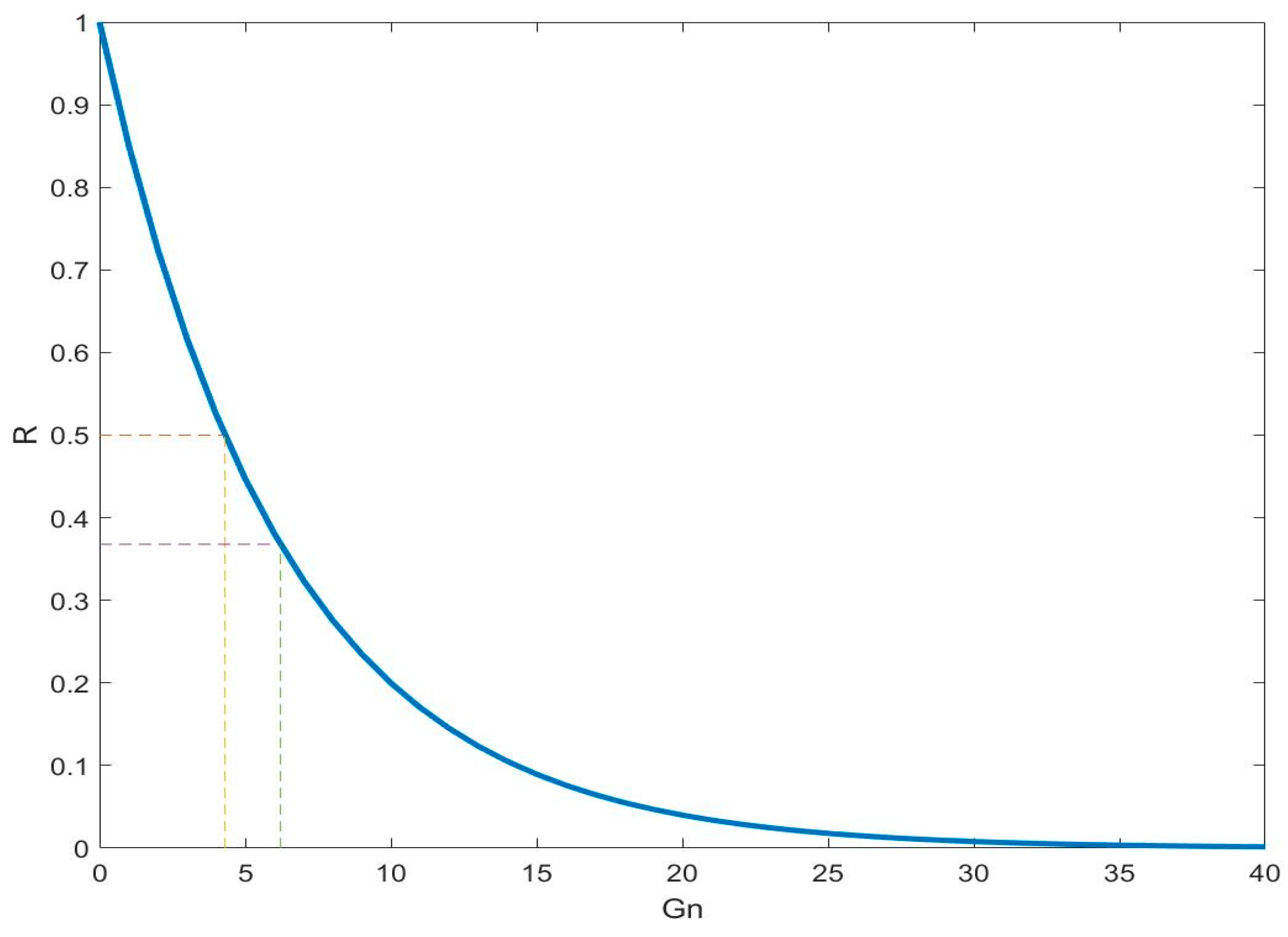

There are three main parts, i.e., performance degradation path modeling and model parametric estimating, pseudo failure life distribution and Testing Statistical Hypotheses, and reliability curve and life prediction. The first part is the performance degradation path modeling and model parametric estimating, where the performance degradation data of samples are known to fit the degradation path using the features extracted from processing signals, and the model parameters that reflect the degradation paths of different samples are calculated. The second part is pseudo failure life distribution and Testing Statistical Hypotheses. Pseudo failure characteristics (PFCs) are collected based on threshold values and the performance degradation model, and the distribution of the feature is extracted and verified by Testing Statistical Hypotheses. The third part is reliability curve and life prediction, i.e., the reliability curve is plotted, and the characteristics of different reliability can be obtained. In the end, an example for tool analysis is investigated in this research to verify the effectiveness of the method.

2.2. Basic Concepts of Performance Degradation

In the reliability degradation test, it is difficult to continuously monitor the degradation process of product performance, so the performance characteristics of the product can be tested regularly in the test process. The amount of performance degradation recorded, contains a lot of useful information about product performance degradation and reliability [

19,

20].

For some products with obvious performance degradation characteristics, the degradation mechanism is easy to understand, so product reliability can be directly derived by using the relationship between degradation characteristics and time [

21]. For products with performance degradation characteristics that are not obvious, the quantitative relationship of the degradation model cannot be directly expressed, and analysis methods and techniques such as regression analysis are needed. In many cases, the degradation model of products is often a nonlinear function of the parameters, and the calculation of the parameters of such models is often very large.

Assuming that the regression paths of the samples satisfy the model, the times at which the different samples reach the failure threshold can be deduced. Since these times are not the actual failure times of the samples, using them to evaluate product reliability is needed, so it is called pseudo failure life time. The life time of each sample can be predicted, that is, the life distribution of the product.

Relative to the failure time data, the reliability of the product performance degradation data contains more information. In addition, through the product performance degradation information, reliability analysis can be time and cost effective. Reliability analysis based on performance degradation data will be one of the methods used to evaluate the reliability of high reliability and long-life products.

The use of degradation data, instead of failure time data, for product reliability life assessment has the following advantages:

(1) For many products, degradation is a natural attribute and its performance data can be monitored to obtain degradation data regardless of failure;

(2) Degraded data can be applied in cases where there are only a few or zero failures, which can provide more information than failure time data;

(3) The degraded data can provide more accurate life estimation, than the accelerated life test with little or no failure. In other words, for products with zero failure, useful reliability inferences can be obtained using degraded data.

If degradation performance reaches a critical level, which can be defined as the failure threshold Df, the failure will occur, then the product fault time T can be defined as the time that actual degradation path D(t) reached the critical degradation level Df. The degradation paths of different products are random, and the time of the degradation critical level will be also different from one product to another product, so the random distribution can be used to describe the degradation and to establish the model. Then this model can reflect the model parameters. Therefore, the product failure time distribution can be derived by the degenerate data model, describing the relationship between D(t) and Df.