Part Qualification Methodology for Composite Aircraft Components Using Acoustic Emission Monitoring

Abstract

1. Introduction

2. Technical Approach

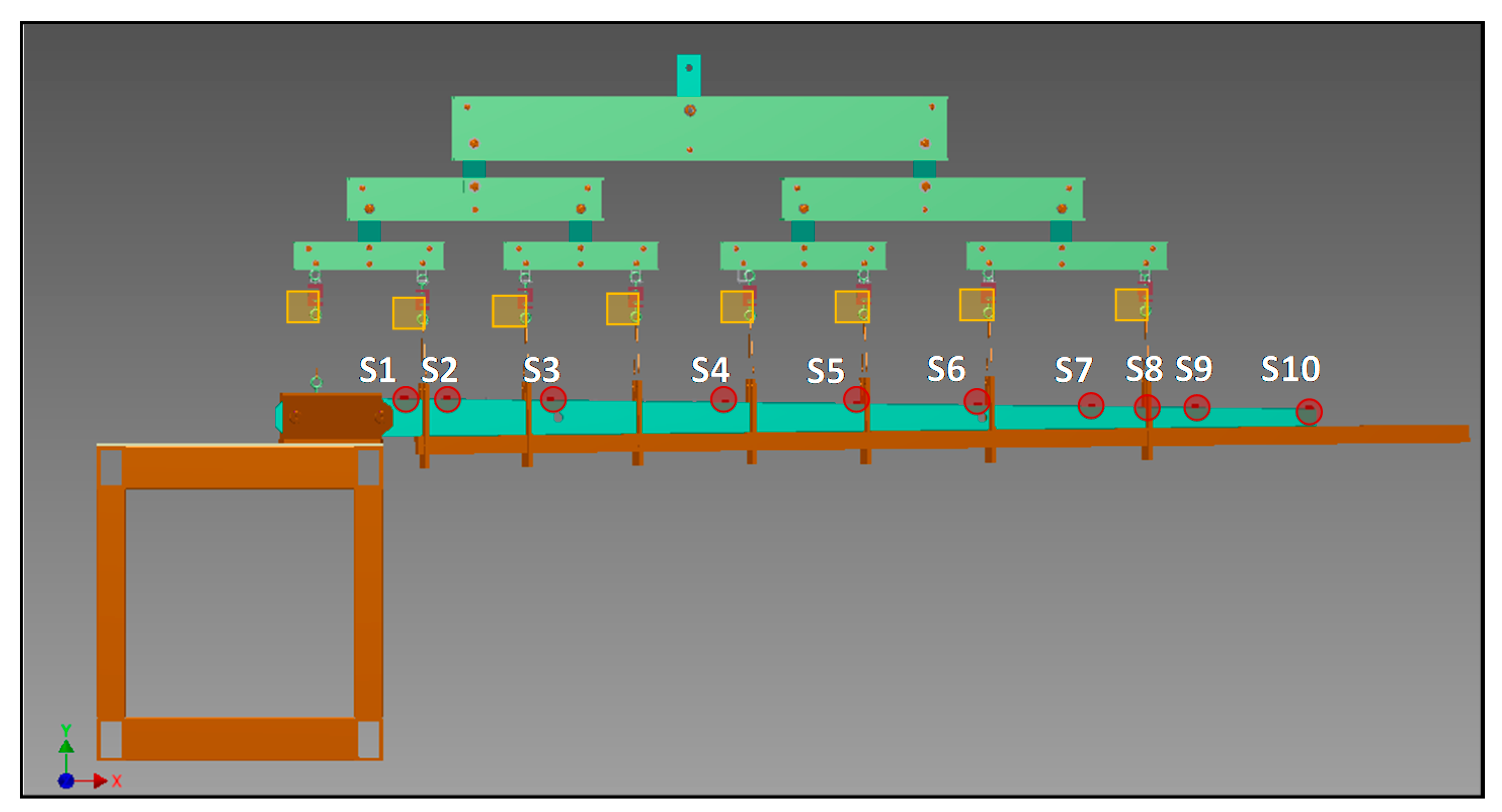

2.1. Experimental Setup

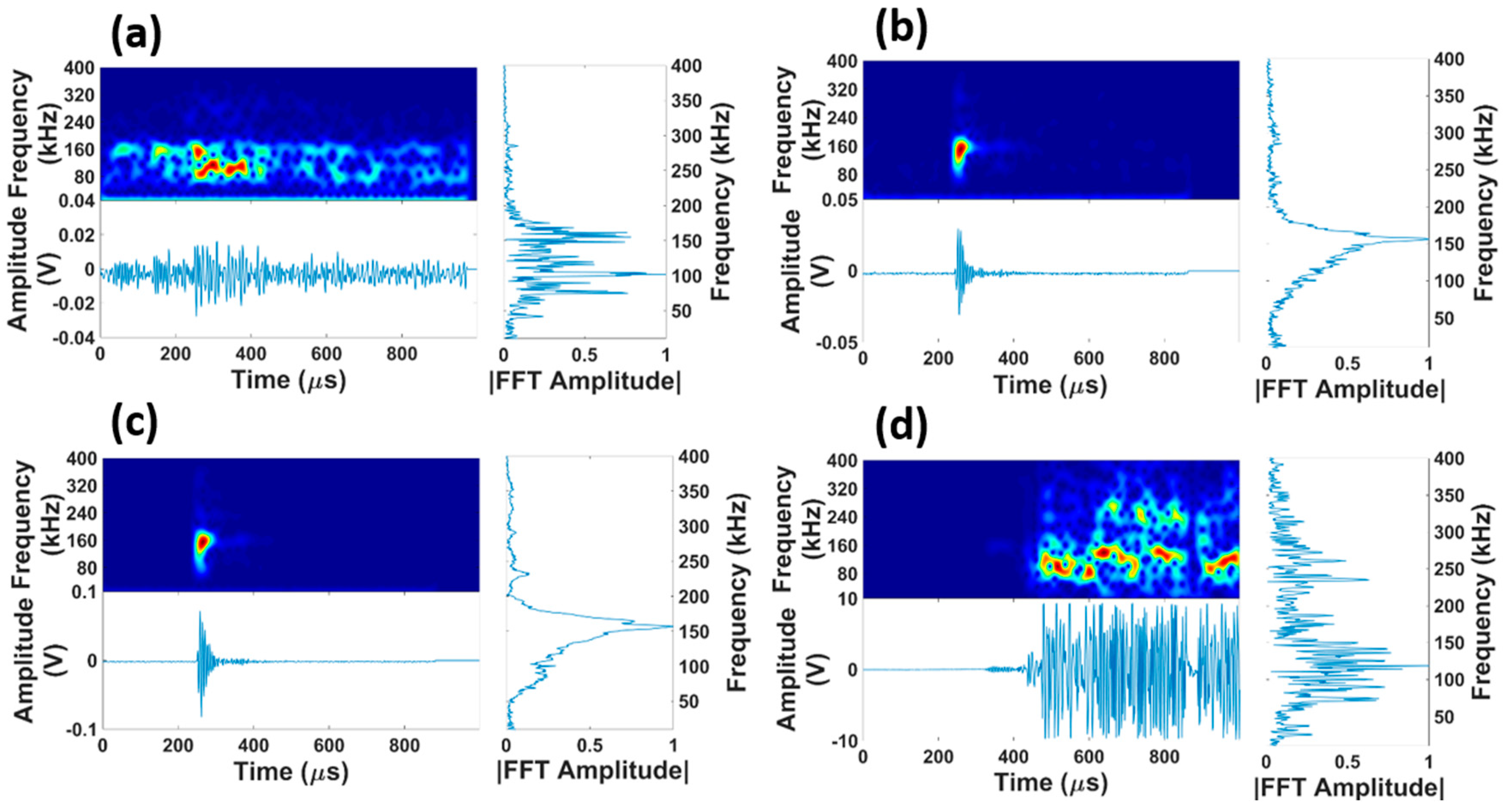

2.2. Data Acquisition and Processesing

3. Results and Discussion

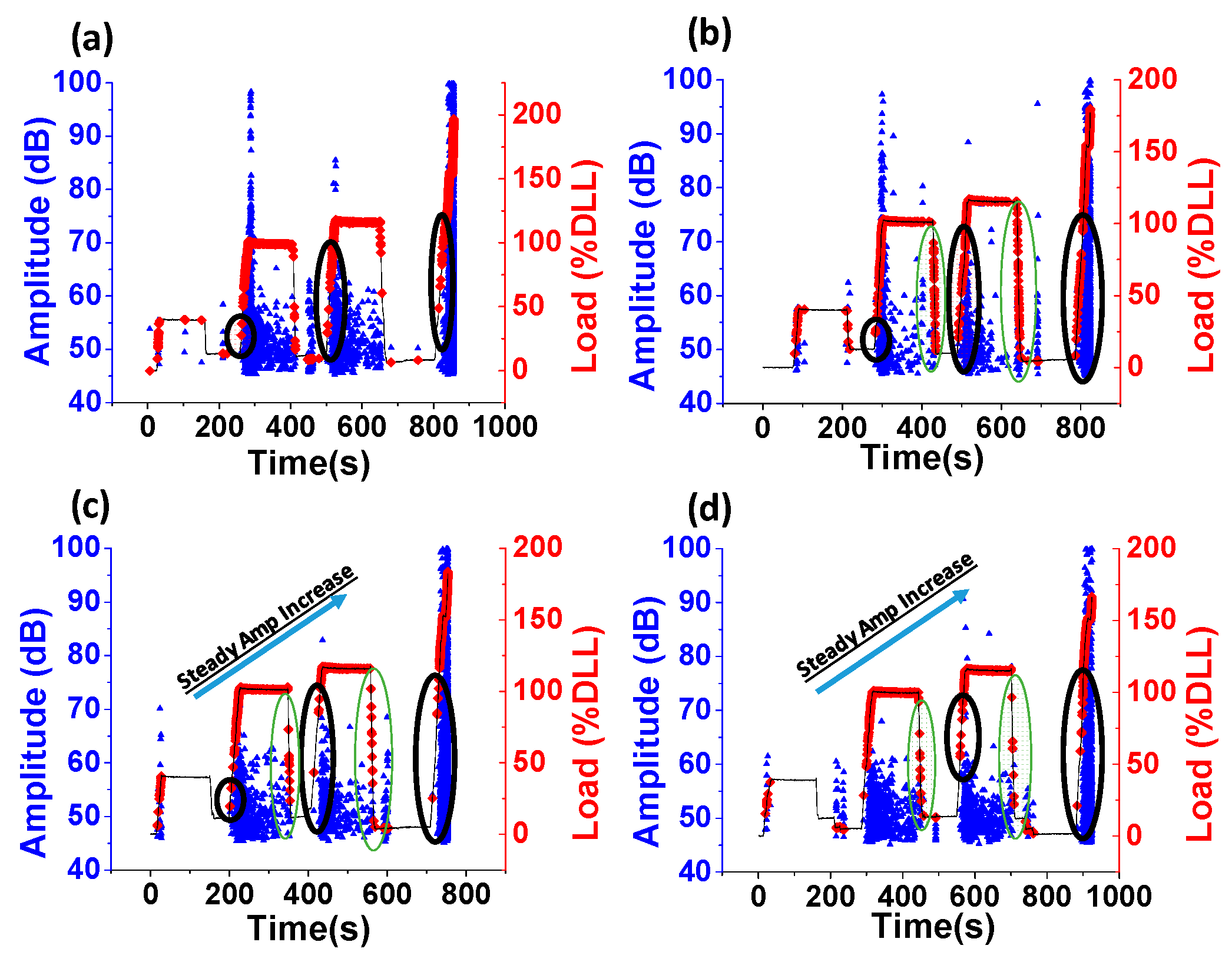

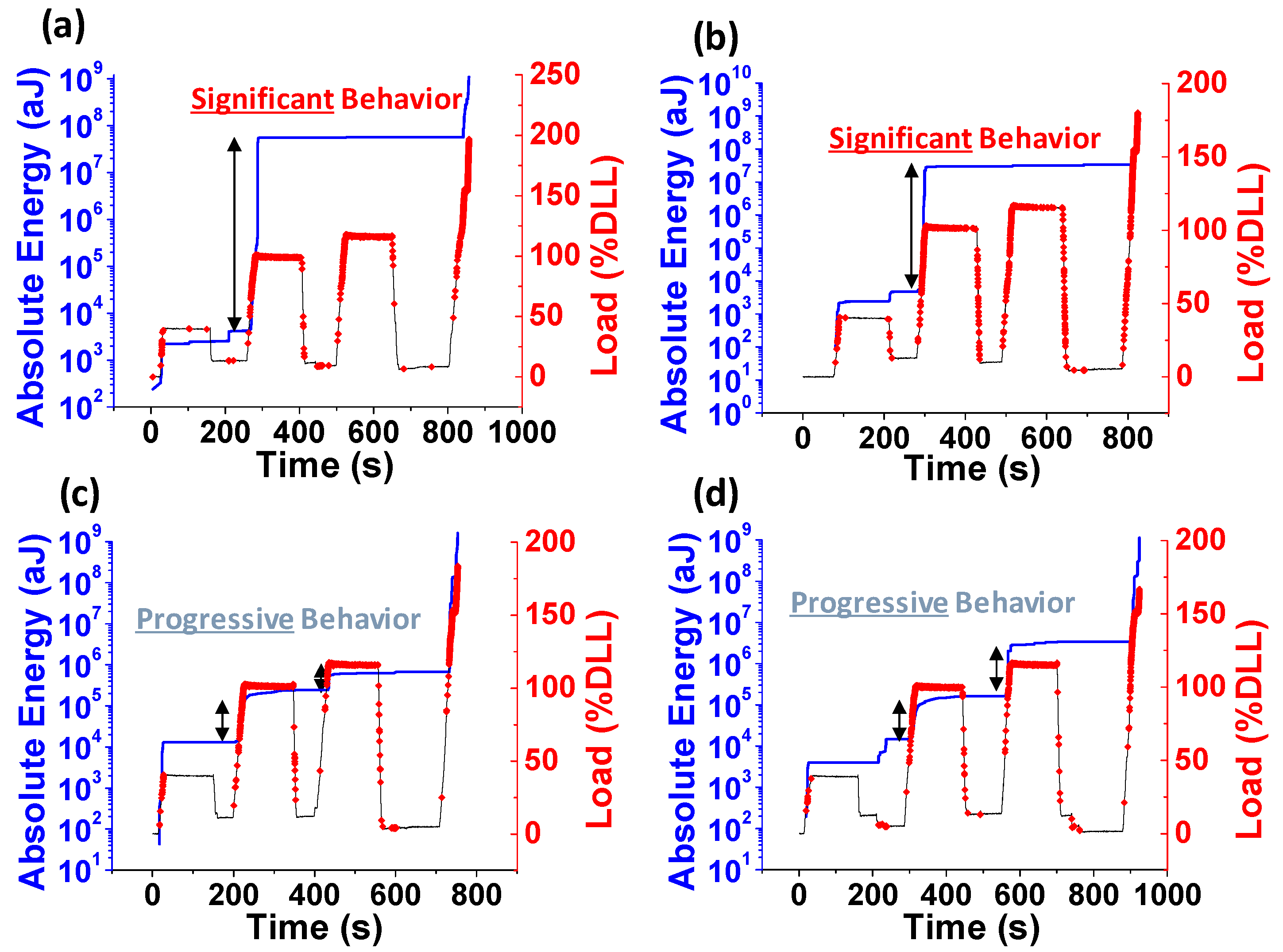

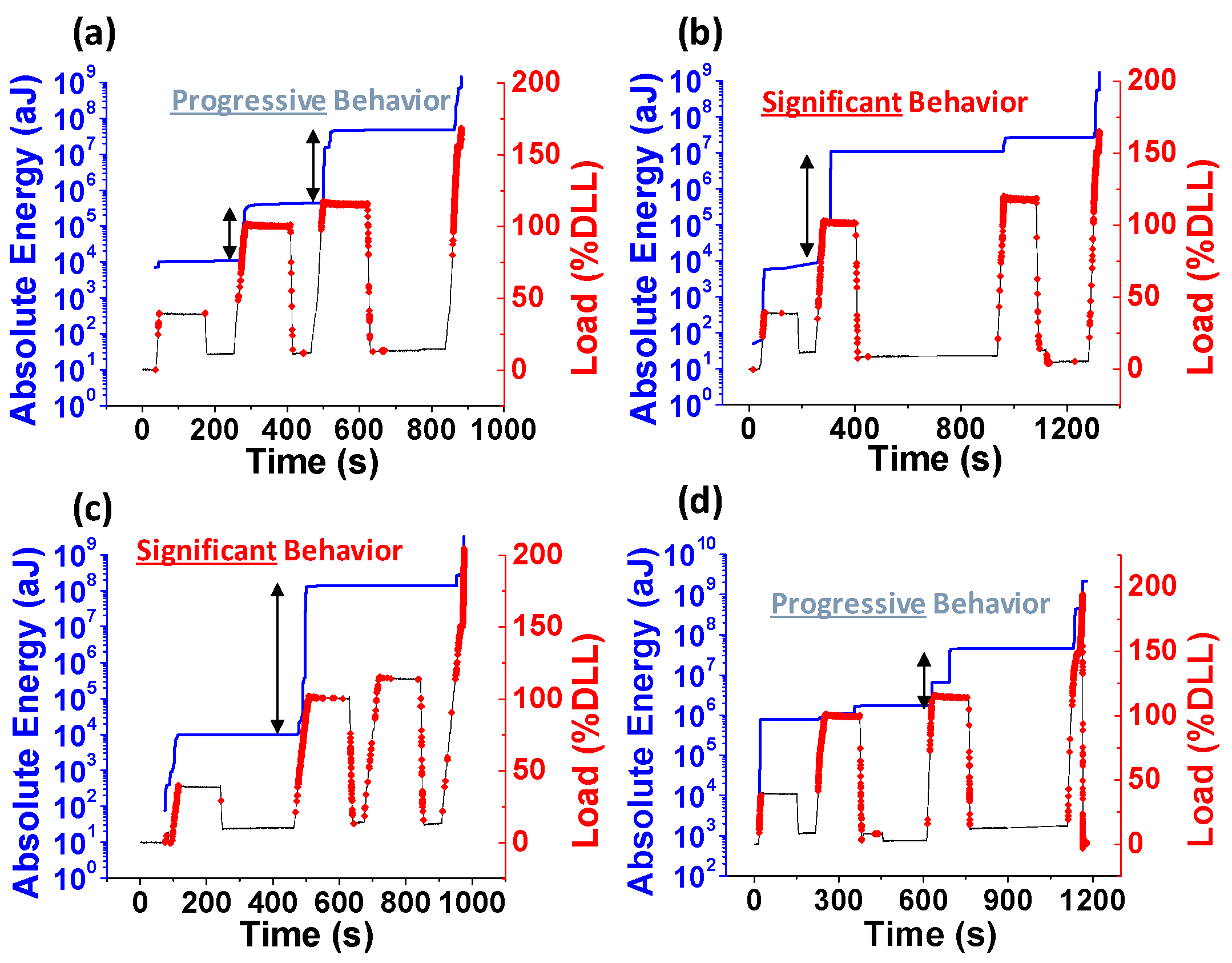

3.1. Progressive Damage Characterization

3.2. Identification of Probable Damage Regions

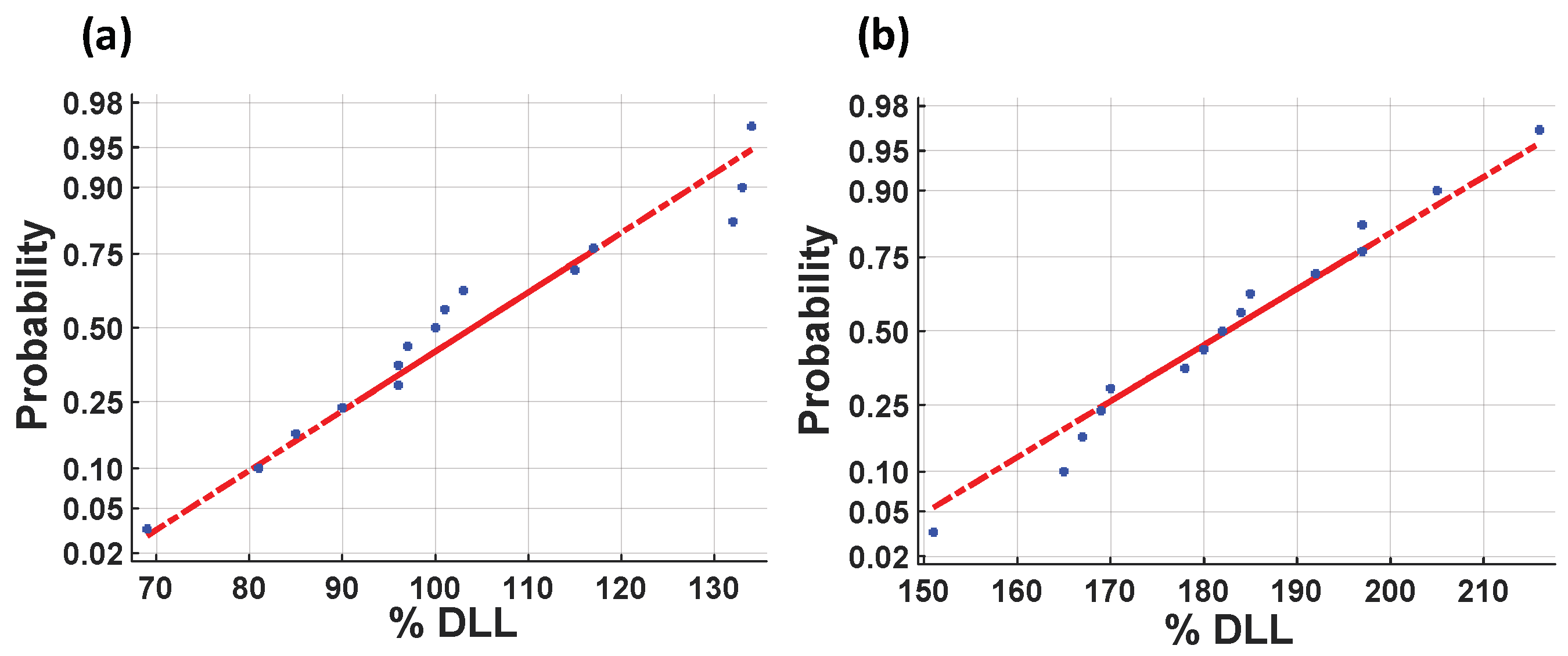

3.3. Ultimate Failure Load Prognosis

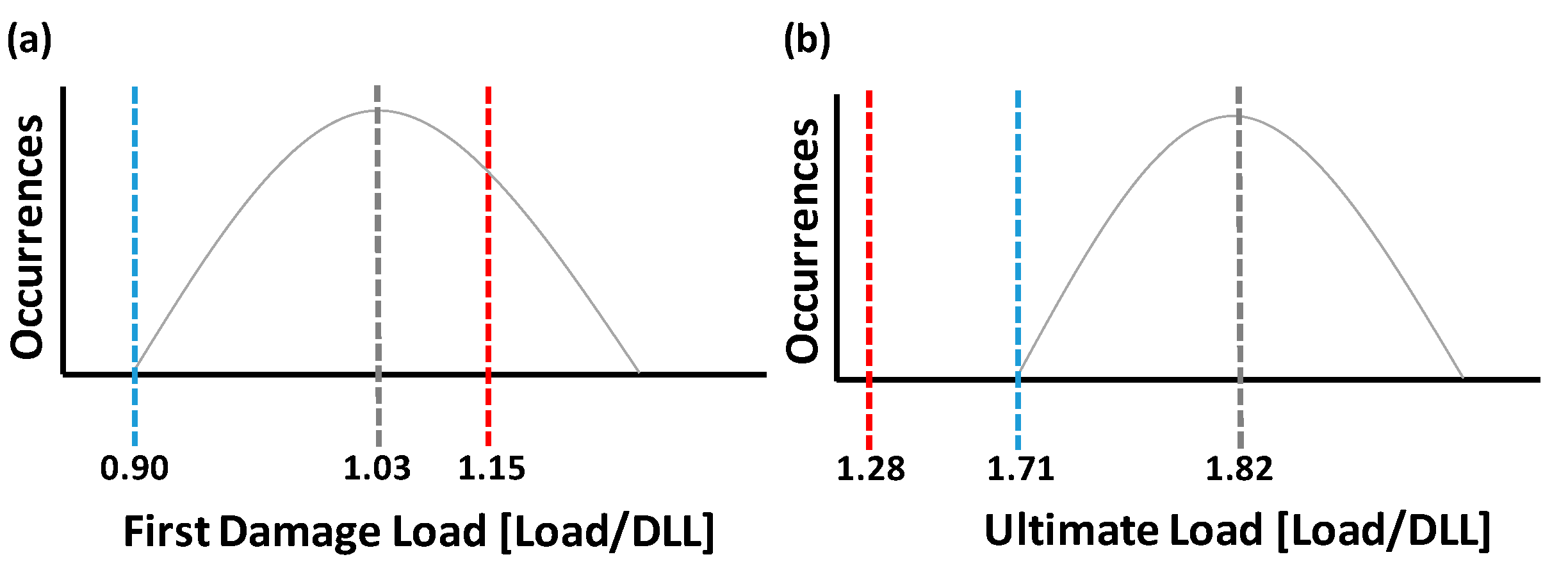

3.4. Statistical Static Strength Assessment

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- U.S. Naval Air Systems Command. Airplane Strength and Rigidity: Ground Tests. In MIL-A-8867C(AS); U.S. Department of Defense: Washington, DC, USA, 1987. [Google Scholar]

- U.S. Federal Aviation Administration. Subchapter C—AIRCRAFT. In U.S. Code of Federal Regulation; Volume 14—Aeronautics and Space; Office of the Federal Register: Washington, DC, USA, 2018. [Google Scholar]

- SAE International. Polymer Matrix Composites: Materials, Usage, Design, and Analysis. In Composite Materials Handbook; Volume 3 Revision G R-424; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- SAE International. Polymer Matrix Composites: Guidelines for Characterization of Structural Materials. In Composite Materials Handbook; Volume 1 Revision G R-422; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- U.S. Fire Administration. Airframe Guide for Certification of Part 23 Airplanes; U.S. Fire Administration: Frederick County, MD, USA, 2007.

- U.S. Fire Administration. Damage Tolerance and Fatigue Evaluation of Structure; U.S. Fire Administration: Frederick County, MD, USA, 2011.

- U.S. Fire Administration. Proof of Structure; U.S. Fire Administration: Frederick County, MD, USA, 2014.

- U.S. Fire Administration. Quality System for the Manufacture of Composite Structures; U.S. Fire Administration: Frederick County, MD, USA, 2010.

- U.S. Fire Administration. Acceptance Guidance on Material Procurement and Process Specifications for Polymer Matrix Composite Systems; U.S. Fire Administration: Frederick County, MD, USA, 2003.

- Hamstad, M. Acceptance Testing Of Graphite/Epoxy Composite Parts Using An Acoustic Emission Monitoring Technique. NDT Int. 1982, 15, 307–314. [Google Scholar] [CrossRef]

- Oster, R. Non-Destructive Testing Methodologies on Helicopter Fiber Composite Components Challenges Today and in the Future. In Proceedings of the 18th World Conference on Nondestructive Testing, Durban, South Africa, 16–20 April 2012; pp. 16–20. [Google Scholar]

- Swindell, P.; Doyle, J.; Roach, D. Integration Of Structural Health Monitoring Solutions Onto Commercial Aircraft via The Federal Aviation Administration Structural Health Monitoring Research Program. In Proceedings of the AIP Conference, Atlanta, GA, USA, 17–22 July 2016; Volume 1806, p. 070001. [Google Scholar]

- Shull, P.J. Nondestructive Evaluation: Theory, Techniques, and Applications; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Pollock, A.A. Acoustic Emission from Solids Undergoing Deformation. Ph.D. Thesis, University of London, London, UK, 1970. [Google Scholar]

- Ono, K. Acoustic Emission in Materials Research—A Review. J. Acoust. Emiss. 2011, 29, 284–308. [Google Scholar]

- Moore, P.O. (Ed.) Fundamentals of Acoustic Emission Testing. In Nondestructive Testing Handbook, 3rd ed.; Volume 6 Acoustic Emission Testing; American Society for Nondestructive Testing: Columbus, OH, USA, 2005. [Google Scholar]

- Mo, C.; Wisner, B.; Cabal, M.; Hazeli, K.; Ramesh, K.; El Kadiri, H.; Al-Samman, T.; Molodov, K.D.; Molodov, D.A.; Kontsos, A. Acoustic emission of deformation twinning in magnesium. Materials 2016, 9, 662. [Google Scholar] [CrossRef] [PubMed]

- Wisner, B.; Cabal, M.; Vanniamparambil, P.; Hochhalter, J.; Leser, W.; Kontsos, A. In situ microscopic investigation to validate acoustic emission monitoring. Exp. Mech. 2015, 55, 1705–1715. [Google Scholar] [CrossRef]

- Wisner, B.; Kontsos, A. In situ monitoring of particle fracture in aluminium alloys. Fatigue Fract. Eng. Mater. Struct. 2017, 41, 581–596. [Google Scholar] [CrossRef]

- Wisner, B.; Kontsos, A. Investigation of particle fracture during fatigue of aluminum 2024. Int. J. Fatigue 2018, 111, 33–43. [Google Scholar] [CrossRef]

- Castaneda, N.; Wisner, B.; Cuadra, J.; Amini, S.; Kontsos, A. Investigation of the Z-binder role in progressive damage of 3D woven composites. Compos. Part A Appl. Sci. Manuf. 2017, 98, 76–89. [Google Scholar] [CrossRef]

- Cuadra, J.; Vanniamparambil, P.A.; Hazeli, K.; Bartoli, I.; Kontsos, A. Damage quantification in polymer composites using a hybrid NDT approach. Compos. Sci. Technol. 2013, 83, 11–21. [Google Scholar] [CrossRef]

- Vanniamparambil, P.A.; Bartoli, I.; Hazeli, K.; Cuadra, J.; Schwartz, E.; Saralaya, R.; Kontsos, A. An integrated structural health monitoring approach for crack growth monitoring. J. Intell. Mater. Syst. Struct. 2012, 23, 1563–1573. [Google Scholar] [CrossRef]

- Vanniamparambil, P.A.; Khan, F.; Hazeli, K.; Cuadra, J.; Schwartz, E.; Kontsos, A.; Bartoli, I. Novel optico-acoustic nondestructive testing for wire break detection in cables. Struct. Control. Health Monit. 2013, 20, 1339–1350. [Google Scholar] [CrossRef]

- Khan, F.; Rajaram, S.; Vanniamparambil, P.A.; Bolhassani, M.; Hamid, A.; Kontsos, A.; Bartoli, I. Multi-sensing NDT for damage assessment of concrete masonry walls. Struct. Control. Health Monit. 2015, 22, 449–462. [Google Scholar] [CrossRef]

- Salamone, S.; Bartoli, I.; Phillips, R.; Nucera, C.; di Scalea, F. Health monitoring of prestressing tendons in posttensioned concrete bridges. Transp. Res. Rec. J. Transp. Res. Board 2011, 2220, 21–27. [Google Scholar] [CrossRef]

- Vanniamparambil, P.A.; Bolhassani, M.; Carmi, R.; Khan, F.; Bartoli, I.; Moon, F.L.; Hamid, A.; Kontsos, A. A data fusion approach for progressive damage quantification in reinforced concrete masonry walls. Smart Mater. Struct. 2013, 23, 015007. [Google Scholar] [CrossRef]

- Baxevanakis, K.P.; Wisner, B.; Schlenker, S.; Baid, H.; Kontsos, A. Data-Driven Damage Model Based on Nondestructive Evaluation. J. Nondestruct. Eval. Diagn. Progn. Eng. Syst. 2018, 1, 031007. [Google Scholar] [CrossRef]

- Cuadra, J.; Vanniamparambil, P.; Servansky, D.; Bartoli, I.; Kontsos, A. Acoustic emission source modeling using a data-driven approach. J. Sound Vib. 2015, 341, 222–236. [Google Scholar] [CrossRef]

- Mazur, K.; Wisner, B.; Kontsos, A. Fatigue Damage Assessment Leveraging Nondestructive Evaluation Data. JOM 2018, 70, 1182–1189. [Google Scholar] [CrossRef]

- Wisner, B.; Mazur, K.; Perumal, V.; Baxevanakis, K.; An, L.; Feng, G.; Kontsos, A. Acoustic emission signal processing framework to identify fracture in aluminum alloys. Eng. Fract. Mech. 2018, in press. [Google Scholar] [CrossRef]

- Zárate, B.A.; Caicedo, J.M.; Yu, J.; Ziehl, P. Probabilistic prognosis of fatigue crack growth using acoustic emission data. J. Eng. Mech. 2012, 138, 1101–1111. [Google Scholar] [CrossRef]

- Ono, K. Application of acoustic emission for structure diagnosis. Diagnostyka 2011, 2, 3–18. [Google Scholar]

- Anay, R.; Cortez, T.M.; Jáuregui, D.V.; ElBatanouny, M.K.; Ziehl, P. On-site acoustic-emission monitoring for assessment of a prestressed concrete double-tee-beam bridge without plans. J. Perform. Constr. Facil. 2015, 30, 04015062. [Google Scholar] [CrossRef]

- De Santis, S.; Tomor, A.K. Laboratory and field studies on the use of acoustic emission for masonry bridges. NDT E Int. 2013, 55, 64–74. [Google Scholar] [CrossRef]

- Golaski, L.; Gebski, P.; Ono, K. Diagnostics of reinforced concrete bridges by acoustic emission. J. Acoust. Emiss. 2002, 20, 83–89. [Google Scholar]

- Pollock, A.; Smith, B. Stress-wave-emission monitoring of a military bridge. Non-Destr. Test. 1972, 5, 348–353. [Google Scholar] [CrossRef]

- Blanch, M.; Dutton, A. Acoustic emission monitoring of field tests of an operating wind turbine. In Key Engineering Materials; Trans Tech Publ: Princeton, NJ, USA, 2003; pp. 475–482. [Google Scholar]

- Han, B.-H.; Yoon, D.-J.; Huh, Y.-H.; Lee, Y.-S. Damage assessment of wind turbine blade under static loading test using acoustic emission. J. Intell. Mater. Syst. Struct. 2014, 25, 621–630. [Google Scholar] [CrossRef]

- Paquette, J.; Van Dam, J.; Hughes, S. Structural testing of 9m carbon fiber wind turbine research blades. In Proceedings of the 45th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 8–11 January 2007; p. 816. [Google Scholar]

- Sutherland, H.; Beattie, A.; Hansche, B.; Musial, W.; Allread, J.; Johnson, J.; Summers, M. The Application of Non-Destructive Techniques to the Testing of a Wind Turbine Blade; Sandia National Labs.: Albuquerque, NM, USA, 1994. [Google Scholar]

- Moore, P.O. (Ed.) Aerospace Applications of Acoustic Emission Testing. In Nondestructive Testing Handbook, 3rd ed.; Volume 6 Acoustic Emission Testing; American Society for Nondestructive Testing: Columbus, OH, USA, 2005. [Google Scholar]

- Holford, K.M.; Pullin, R.; Evans, S.L.; Eaton, M.J.; Hensman, J.; Worden, K. Acoustic emission for monitoring aircraft structures. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2009, 223, 525–532. [Google Scholar] [CrossRef]

- Vanniamparambil, P.A.; Carmi, R.; Khan, F.; Cuadra, J.; Bartoli, I.; Kontsos, A. An active–passive acoustics approach for bond-line condition monitoring in aerospace skin stiffener panels. Aerosp. Sci. Technol. 2015, 43, 289–300. [Google Scholar] [CrossRef]

- Prosser, W.H.; Gorman, M.R.; Madaras, E.I. Acoustic Emission Detection of Impact Damage on Space Shuttle Structures; NASA: Washington, DC, USA, 2004. [Google Scholar]

- Staszewski, W.; Mahzan, S.; Traynor, R. Health monitoring of aerospace composite structures—Active and passive approach. Compos. Sci. Technol. 2009, 69, 1678–1685. [Google Scholar] [CrossRef]

- Awerbuch, J.; Leone, F.A., Jr.; Ozevin, D.; Tan, T.-M. On the applicability of acoustic emission to identify modes of damage in full-scale composite fuselage structures. J. Compos. Mater. 2016, 50, 447–469. [Google Scholar] [CrossRef]

- Weis, M.; Cejpek, J.; Juračka, J. Acoustic Emission Localization in Testing of Composite Structures. In Applied Mechanics and Materials; Trans Tech Publ: Princeton, NJ, USA, 2016; pp. 405–411. [Google Scholar]

- Haile, M.A.; Bordick, N.E.; Riddick, J.C. Distributed acoustic emission sensing for large complex air structures. Struct. Health Monit. 2018, 17, 624–634. [Google Scholar] [CrossRef]

- Cawley, P. Structural health monitoring: Closing the gap between research and industrial deployment. Struct. Health Monit. 2018. [Google Scholar] [CrossRef]

- Brunner, A.J. Identification of damage mechanisms in fiber-reinforced polymer-matrix composites with Acoustic Emission and the challenge of assessing structural integrity and service-life. Constr. Build. Mater. 2018, 173, 629–637. [Google Scholar] [CrossRef]

- Moore, P.O. (Ed.) Acoustic Emission Signal Processing. In Nondestructive Testing Handbook, 3rd ed.; Volume 6 Acoustic Emission Testing; American Society for Nondestructive Testing: Columbus, OH, USA, 2005. [Google Scholar]

- Tensi, H.M. The Kaiser-effect and its scientific background. J. Acoust. Emiss. 2004, 22, s1–s16. [Google Scholar]

- Waller, J.; Andrade, E.; Saulsberry, R. Use of acoustic emission to monitor progressive damage accumulation in Kevlar® 49 composites. In Proceedings of the AIP Conference, Kingston, RI, USA, 26–31 July 2009; Volume 1211, p. 1111. [Google Scholar]

- Fowler, T.J. Acoustic emission of fiber reinforced plastics. J. Tech. Counc. ASCE 1979, 105, 281–289. [Google Scholar]

- Behnia, A.; Chai, H.K.; Shiotani, T. Advanced structural health monitoring of concrete structures with the aid of acoustic emission. Constr. Build. Mater. 2014, 65, 282–302. [Google Scholar] [CrossRef]

- Ono, K.; Gallego, A. Research and applications of AE on advanced composites. J. Acoust. Emiss 2012, 30, 180–229. [Google Scholar]

- Loutas, T.; Kostopoulos, V. Health monitoring of carbon/carbon, woven reinforced composites. Damage assessment by using advanced signal processing techniques. Part I: Acoustic emission monitoring and damage mechanisms evolution. Compos. Sci. Technol. 2009, 69, 265–272. [Google Scholar]

- Djabali, A.; Toubal, L.; Zitoune, R.; Rechak, S. An experimental investigation of the mechanical behavior and damage of thick laminated carbon/epoxy composite. Compos. Struct. 2018, 184, 178–190. [Google Scholar] [CrossRef]

- Joosse, P.; Blanch, M.; Dutton, A.; Kouroussis, D.; Philippidis, T.; Vionis, P. Acoustic emission monitoring of small wind turbine blades. J. Sol. Energy Eng. 2002, 124, 446–454. [Google Scholar] [CrossRef]

- Lilliefors, H.W. On the Kolmogorov-Smirnov test for normality with mean and variance unknown. J. Am. Stat. Assoc. 1967, 62, 399–402. [Google Scholar] [CrossRef]

| Test ID | Acoustic Emission Sensor ID and Location (in) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 | S9 | S10 | |

| 1 | - | - | - | - | - | - | - | - | - | - |

| 2 | 3 | 9 | 23.5 | 36 | 48 | 66.5 | 83.5 | 99.5 | 114 | 130 |

| 3 | 1 | 6 | 25 | 41.5 | 56.5 | 73 | 83.5 | - | 112.5 | - |

| 4 | 2 | 6 | 25 | 42 | 57 | 74 | 93.5 | - | 114 | - |

| 5 | 1 | 7 | 23.5 | 38 | 55 | 70 | 86 | - | 101 | - |

| 6 | 1 | 7 | 24 | 39.5 | 55 | 69 | 84 | - | 100 | - |

| 7 | 1.5 | 6 | 25.5 | 40.5 | 56.5 | 74 | 93 | - | 112.5 | - |

| 8 | 2 | 6.5 | 26 | 41.5 | 56 | 72.5 | 93 | - | 113.5 | - |

| 9 | 1 | 6 | 27 | 43 | 61 | 76 | 93 | - | 113.5 | - |

| 10 | 1.5 | 6.5 | 24.5 | 40.5 | 56.5 | 73.5 | 93.5 | - | 113.5 | - |

| 11 | 1 | 6 | 26 | 41.5 | 57 | 72 | 88 | - | 105.5 | - |

| 12 | 1 | 6.5 | 25.5 | 40.5 | 57 | 73.65 | 90.5 | - | 112.5 | - |

| 13 | 1 | 6.75 | 23.5 | 38 | 55 | 70 | 86 | - | 101 | - |

| 14 | 2 | 6.5 | 25.5 | 41 | 56.5 | 79 | 91 | - | 111.5 | - |

| 15 | 3 | 13.5 | 26 | 36 | 48 | 66.5 | 83.5 | 99.5 | 114 | 130 |

| 16 | 1.5 | 7.25 | 25 | 40.5 | 56 | 70 | 86 | - | 101 | - |

| File Name | Felicity Ratio | |||

|---|---|---|---|---|

| Load 2 | Load 3 | Load 4 | Average | |

| 1 | N/A | N/A | N/A | N/A |

| 2 | 1.08 | 0.93 | 0.87 | 0.96 |

| 3 | 1.09 | 0.73 | 0.86 | 0.89 |

| 4 | 1.25 | 0.91 | 0.83 | 1.00 |

| 5 | 1.46 | 0.96 | 0.75 | 1.06 |

| 6 | 1.15 | 0.91 | 0.89 | 0.98 |

| 7 | 1.28 | 1.03 | 0.99 | 1.10 |

| 8 | 0.59 | 0.51 | 0.42 | 0.51 |

| 9 | 1.13 | 0.61 | 0.56 | 0.77 |

| 10 | 1.15 | 1.00 | 0.72 | 0.96 |

| 11 | 1.06 | 0.82 | 0.80 | 0.94 |

| 12 | 1.32 | 0.99 | 0.94 | 1.08 |

| 13 | 1.08 | 0.72 | 0.93 | 0.91 |

| 14 | 1.27 | 0.72 | 0.82 | 0.94 |

| 15 | 0.97 | 1.02 | 0.99 | 0.99 |

| 16 | 0.73 | 1.08 | 1.00 | 0.94 |

| File Name | Ultimate Crane Load [%DLL] | Target Load [%DLL] o First Damage Signal | Estimated Load [lbf] @ 1st Damage Signal | Cumulative AE Behavior | Critical Region |

|---|---|---|---|---|---|

| 1 | N/A | 115 | N/A | Significant | S1 (N/A) |

| 2 | 151 | 100 | 90 | Significant | S3, S5, S6, S19 (15,23.5,48,66.5 in) |

| 3 | 165 | 100 | 103 | Significant | S2 (6 in) |

| 4 | 167 | 150 | 133 | Progressive | S2 (6 in) |

| 5 | 169 | 115 | 117 | Progressive | S2 (7 in) |

| 6 | 170 | 100 | 69 | Significant | S2 (7 in) |

| 7 | 178 | 100 | 101 | Significant | S2 (6 in) |

| 8 | 180 | 100 | 85 | Significant | S2 (6.5 in) |

| 9 | 182 | 100 | 97 | Significant | S2 (6 in) |

| 10 | 184 | 150 | 132 | Progressive | S2 (6.5 in) |

| 11 | 185 | 100 | 96 | Significant | S2 (6 in) |

| 12 | 192 | 100 | 96 | Significant | S2, S4 (6.5&40.5 in) |

| 13 | 197 | 115 | 115 | Progressive | S2 (6.75 in) |

| 14 | 197 | 100 | 100 | Significant | S2 (6.5 in) |

| 15 | 205 | 100 | 81 | Significant | S4 (36 in) |

| 16 | 216 | 150 | 134 | Progressive | S2 (7.25) |

| Crane-Load @ 1st Damage Signal | Ultimate Crane-Load | |

|---|---|---|

| Mean [Load/DLL] | 1.03 | 1.82 |

| StDev [Load/DLL] | 0.19 | 0.17 |

| Spread [Load/DLL] | 0.65 | 0.65 |

| 99% LCL [Load/DLL] | 0.90 | 1.71 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Esola, S.; Wisner, B.J.; Vanniamparambil, P.A.; Geriguis, J.; Kontsos, A. Part Qualification Methodology for Composite Aircraft Components Using Acoustic Emission Monitoring. Appl. Sci. 2018, 8, 1490. https://doi.org/10.3390/app8091490

Esola S, Wisner BJ, Vanniamparambil PA, Geriguis J, Kontsos A. Part Qualification Methodology for Composite Aircraft Components Using Acoustic Emission Monitoring. Applied Sciences. 2018; 8(9):1490. https://doi.org/10.3390/app8091490

Chicago/Turabian StyleEsola, Shane, Brian J. Wisner, Prashanth Abraham Vanniamparambil, John Geriguis, and Antonios Kontsos. 2018. "Part Qualification Methodology for Composite Aircraft Components Using Acoustic Emission Monitoring" Applied Sciences 8, no. 9: 1490. https://doi.org/10.3390/app8091490

APA StyleEsola, S., Wisner, B. J., Vanniamparambil, P. A., Geriguis, J., & Kontsos, A. (2018). Part Qualification Methodology for Composite Aircraft Components Using Acoustic Emission Monitoring. Applied Sciences, 8(9), 1490. https://doi.org/10.3390/app8091490