Research on Stagger Coupling Mode of Pulse Duration and Tool Vibration in Electrochemical Machining

Abstract

:1. Introduction

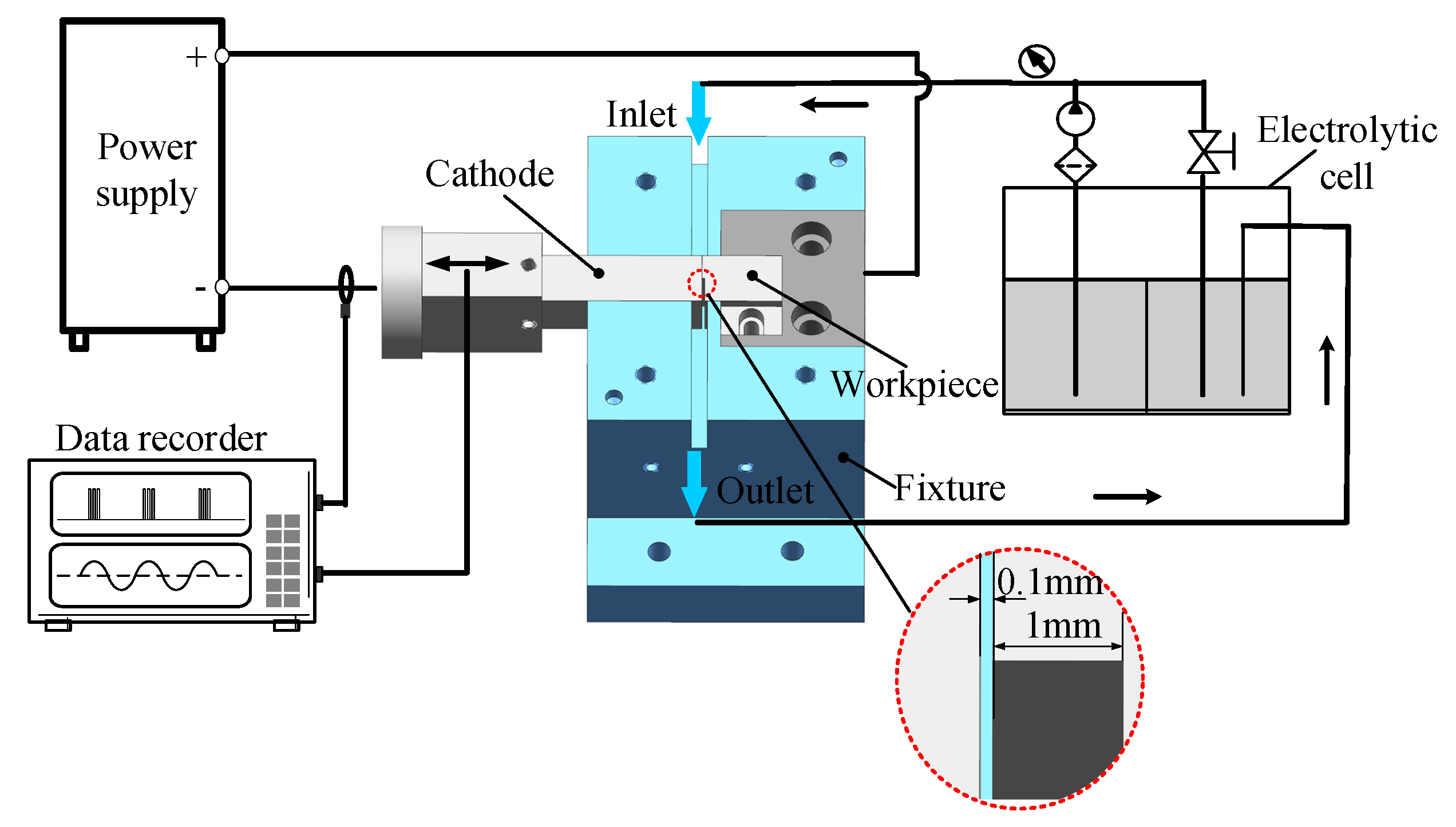

2. Analysis of the Simulation of a Dynamic PVECM Process

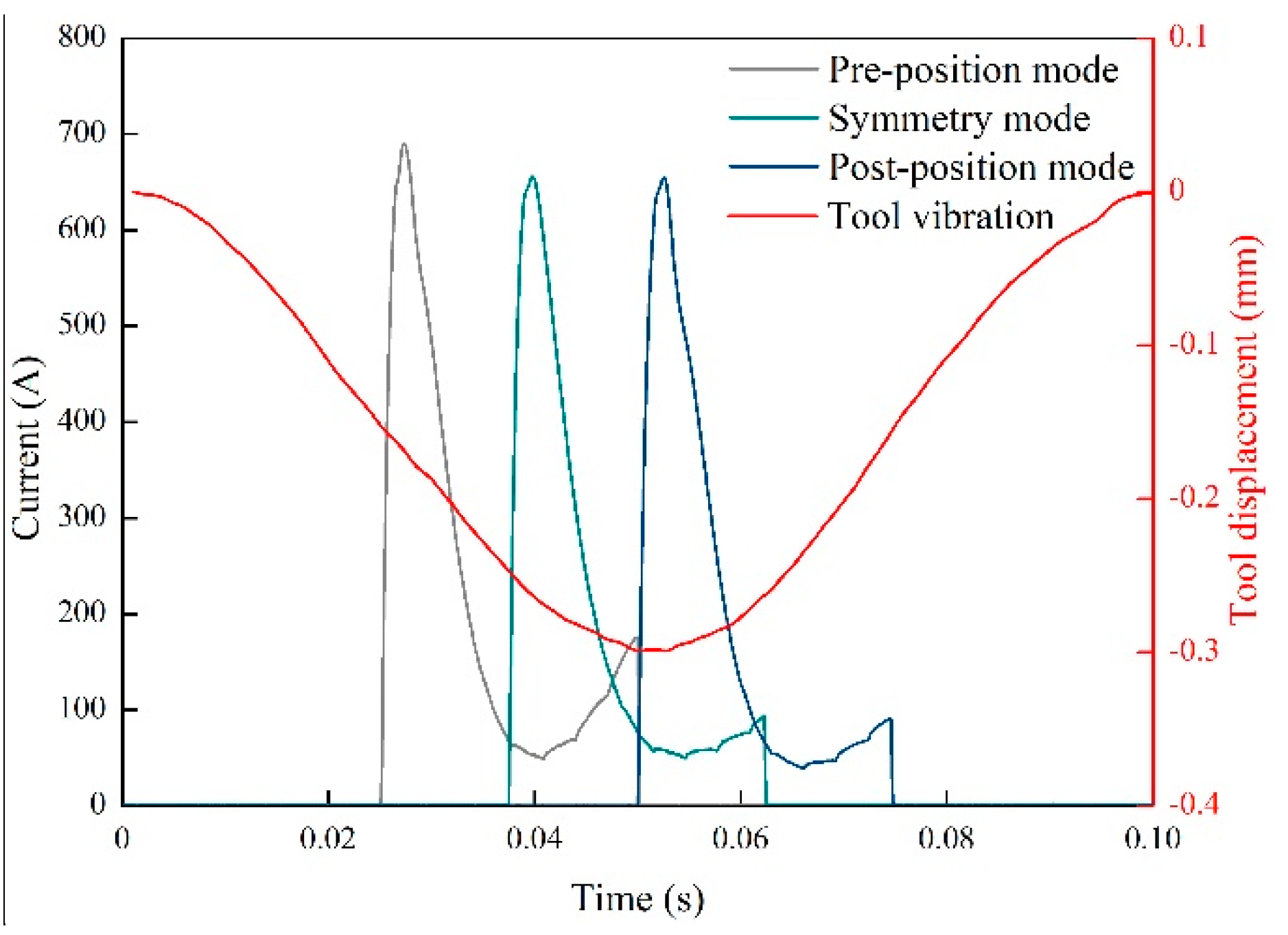

2.1. Traditional Coupling Mode

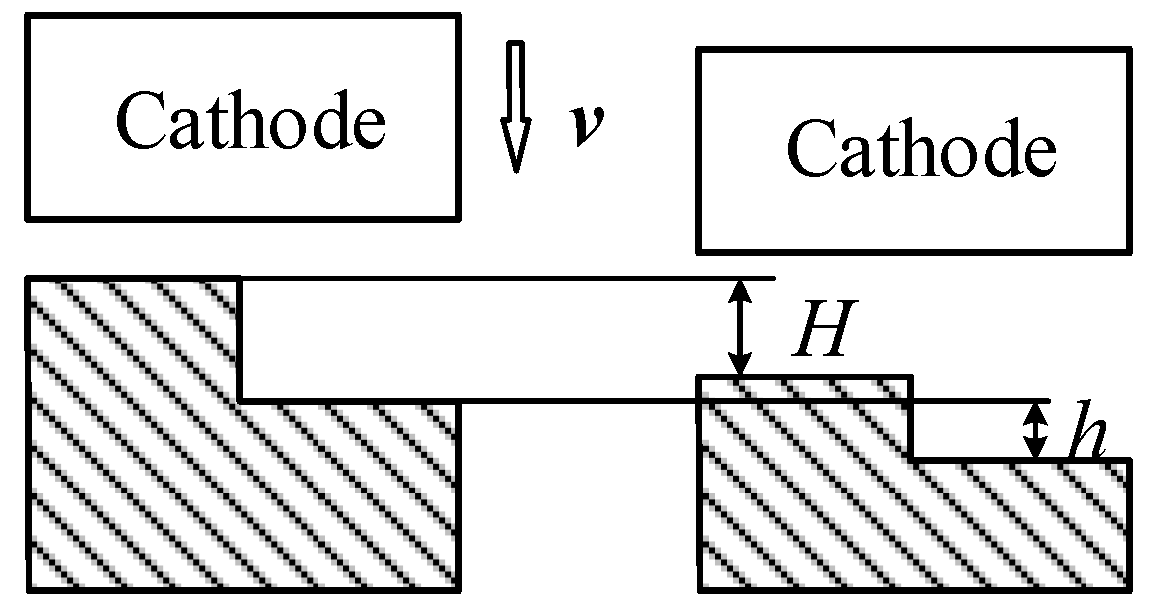

2.2. Physical Model

- The bubbles are evenly distributed in the liquid phase, and no mass transfer occurs between gas and liquid.

- The cathode and workpiece surfaces are electric equipotential surfaces.

- The current efficiency η = 100%.

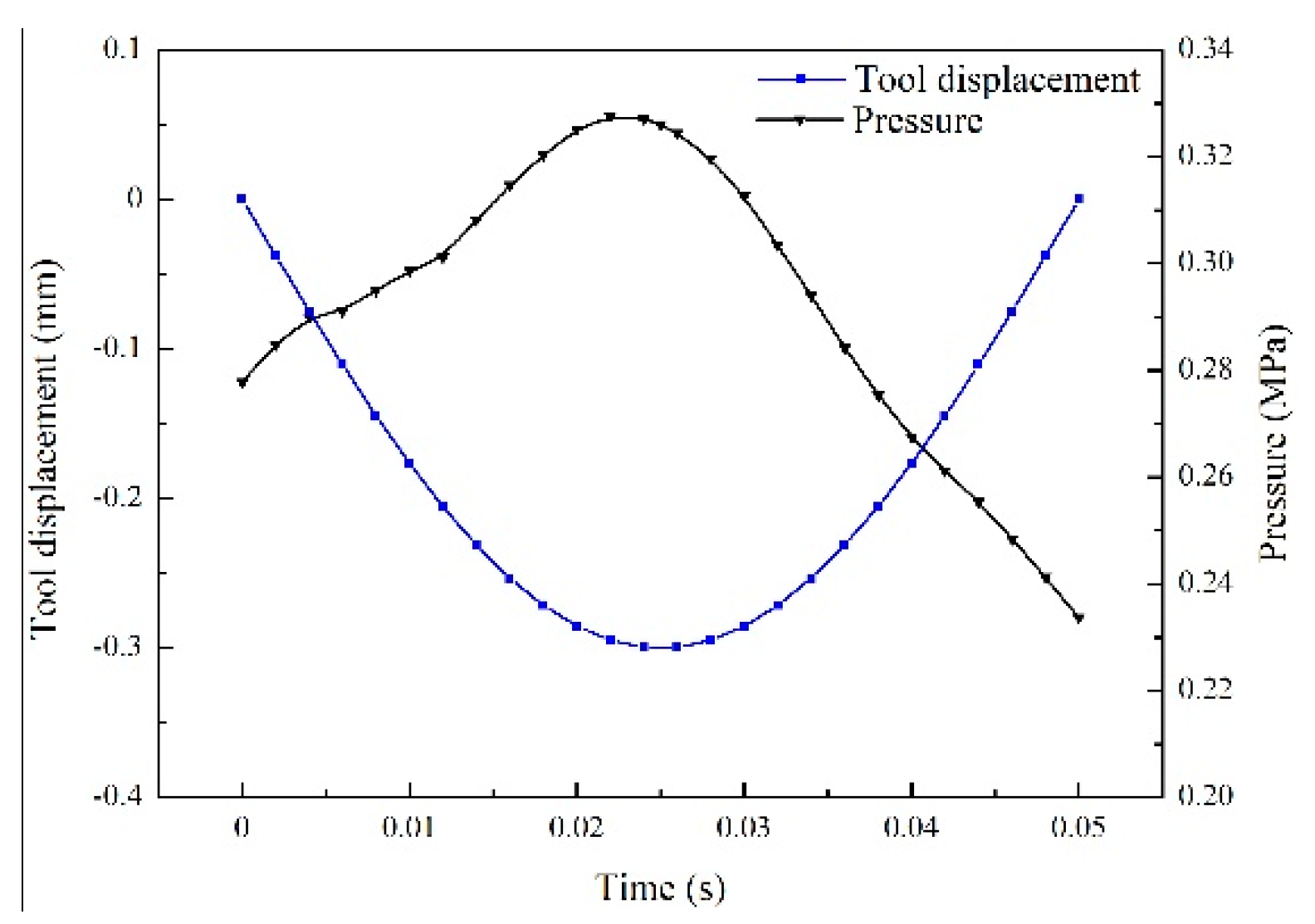

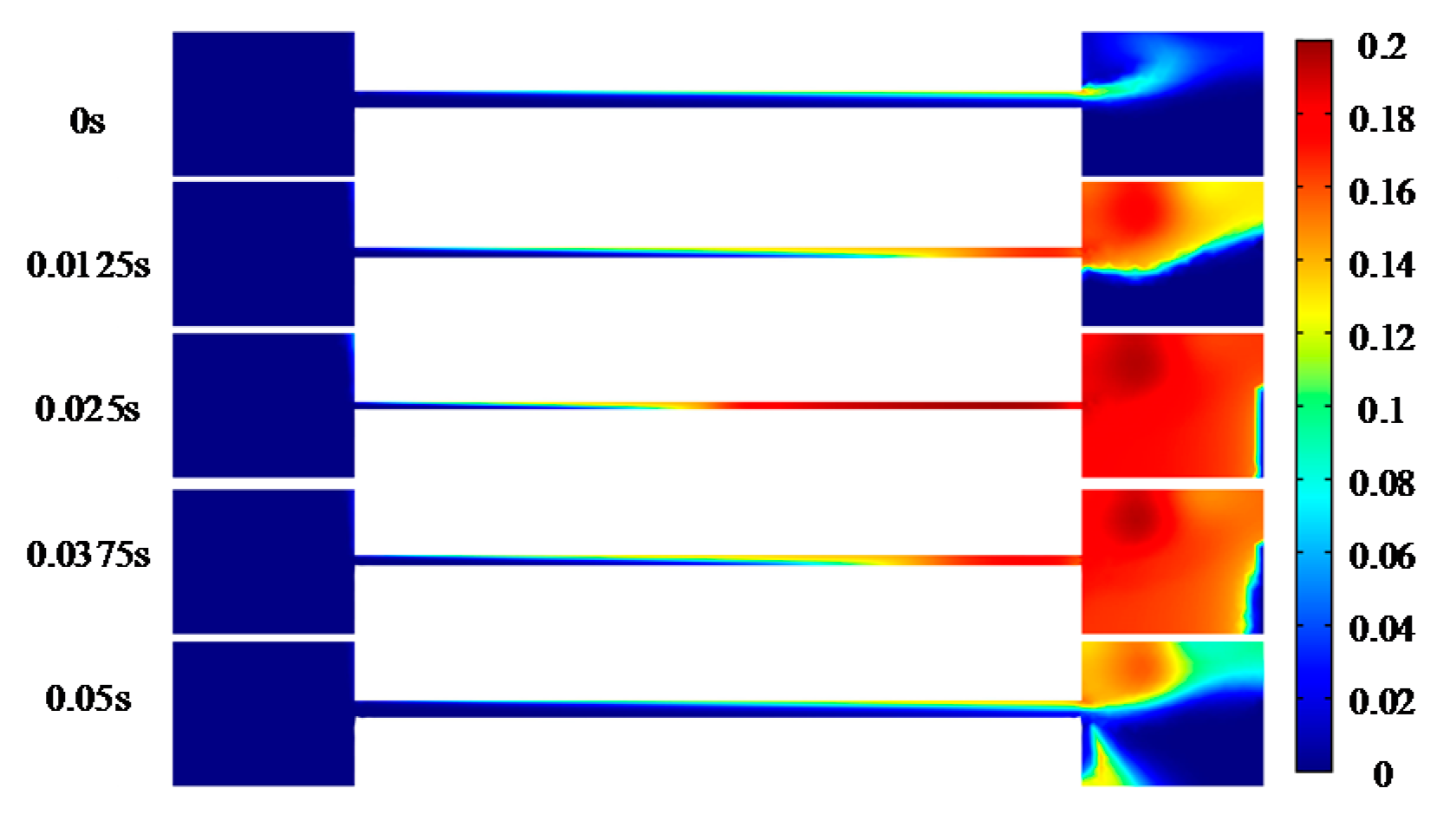

2.3. Variation of Electrolyte Pressure and Gas Void Fraction

3. Experimental Procedures

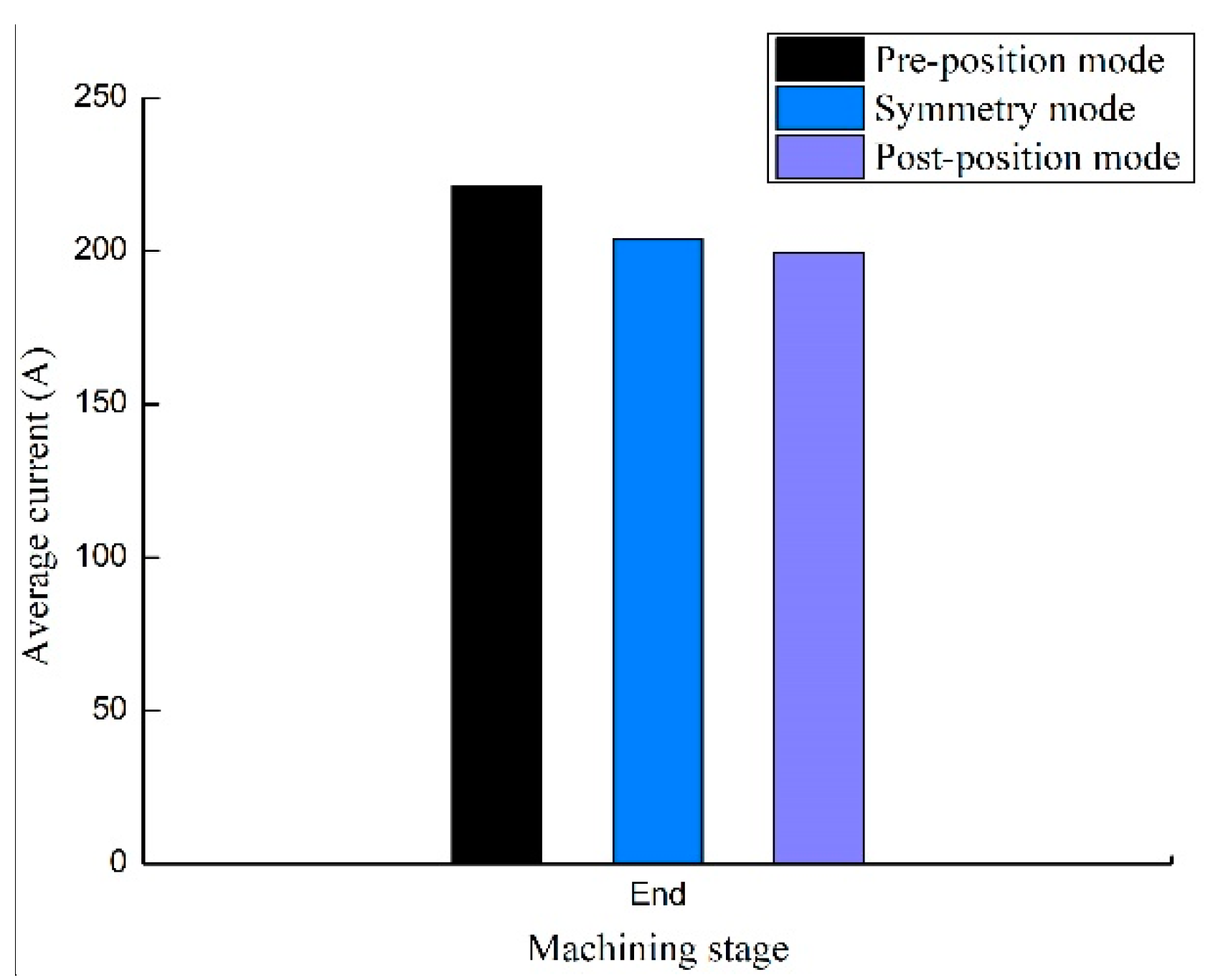

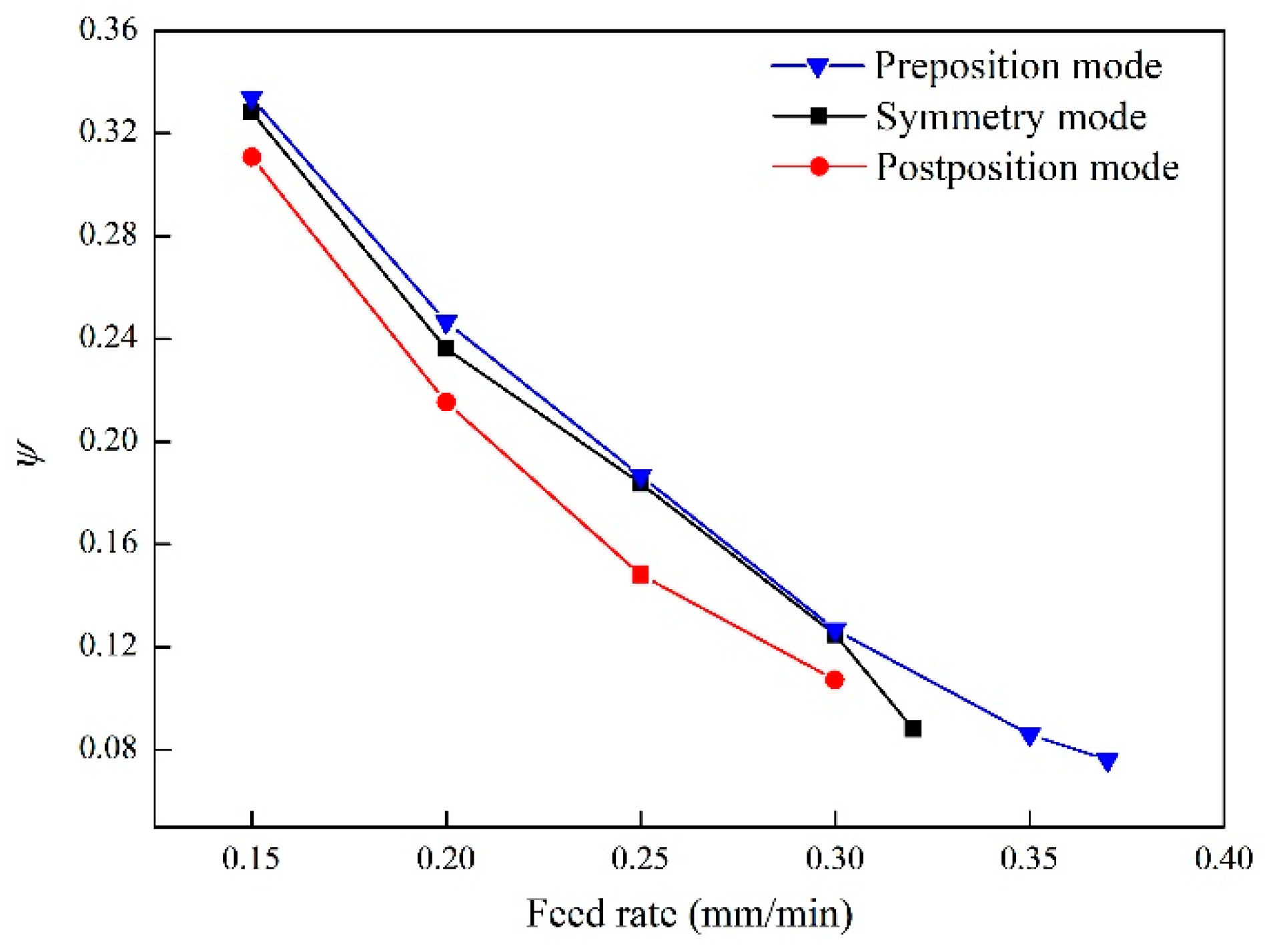

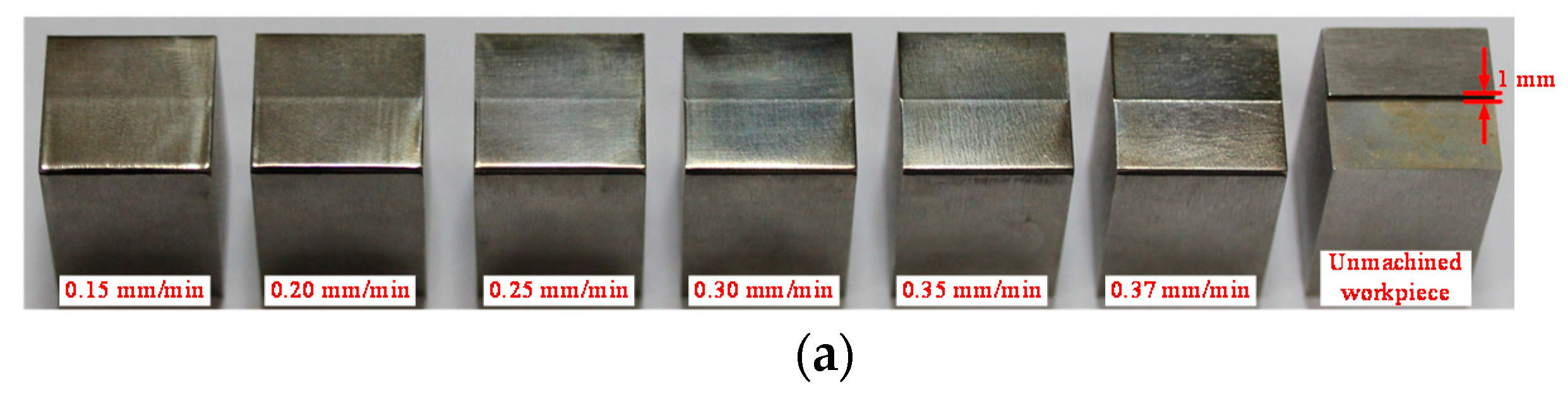

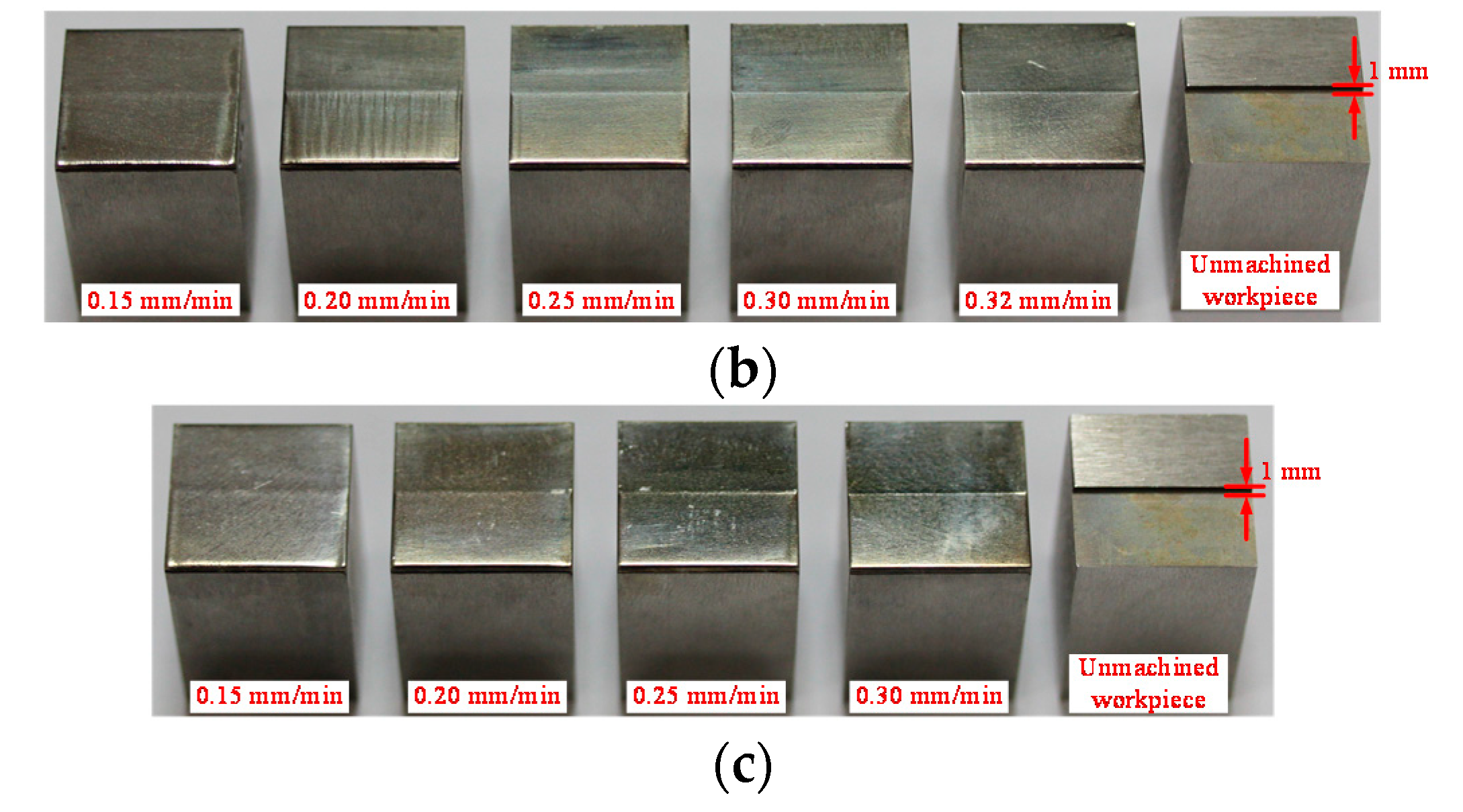

4. Results and Discussion

5. Conclusions

- As the inter-electrode gap narrows, the electrolyte pressure and gas void fraction differ from those as the gap widens. In the pre-position coupling mode, the fluid conditions are better than in the post-position coupling mode.

- In each coupling mode, decreases with increasing feed rate. A higher feed rate corresponds to a better machining localization.

- At a given feed rate, the post-position coupling mode offers a better machining localization than either the pre-position coupling mode or the symmetry coupling mode.

- The best machining localization and highest feed rate are obtained by the pre-position coupling mode, closely followed by the symmetry coupling mode and the post-position coupling mode.

Author Contributions

Funding

Conflicts of Interest

References

- Rajurkar, K.P.; Zhu, D.; Mcgeough, J.A.; Kozak, J.; Silva, A.D. New developments in electro-chemical machining. CIRP Ann.Manuf. Technol. 1999, 48, 567–579. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, J.; Xu, Q.; Gong, T.; Zhu, D.; Qu, N. The tool design and experiments on electrochemical machining of a blisk using multiple tube electrodes. Int. J. Adv. Manuf. Technol. 2015, 79, 531–539. [Google Scholar] [CrossRef]

- Zhu, D.; Zhu, D.; Xu, Z. Optimal design of the sheet cathode using w-shaped electrolyte flow mode in ecm. Int. J. Adv. Manuf. Technol. 2012, 62, 147–156. [Google Scholar] [CrossRef]

- Qu, N.S.; Xu, Z.Y. Improving machining accuracy of electrochemical machining blade by optimization of cathode feeding directions. Int. J. Adv. Manuf. Technol. 2013, 68, 1565–1572. [Google Scholar] [CrossRef]

- Rajurkar, K.P.; Zhu, D. Improvement of electrochemical machining accuracy by using orbital electrode movement. CIRP Ann.Manuf. Technol. 1999, 48, 139–142. [Google Scholar] [CrossRef]

- Bhattacharyya, B.; Munda, J. Experimental investigation on the influence of electrochemical machining parameters on machining rate and accuracy in micromachining domain. Int. J. Mach. Tools Manuf. 2003, 43, 1301–1310. [Google Scholar] [CrossRef]

- Demyantseva, N.G.; Kuzmin, S.M.; Balmasov, A.V. Evaluation of shaping accuracy upon electrochemical machining of metals. Surf. Eng. Appl. Electrochem. 2012, 48, 230–233. [Google Scholar] [CrossRef]

- Zhu, D.; Xu, H.Y. Improvement of electrochemical machining accuracy by using dual pole tool. J. Mater. Process. Technol. 2002, 129, 15–18. [Google Scholar] [CrossRef]

- Ebeid, S.J.; Hewidy, M.S.; El-Taweel, T.A.; Youssef, A.H. Towards higher accuracy for ecm hybridized with low-frequency vibrations using the response surface methodology. J. Mater. Process. Technol. 2004, 149, 432–438. [Google Scholar] [CrossRef]

- Hewidy, M.S.; Ebeid, S.J.; El-Taweel, T.A.; Youssef, A.H. Modelling the performance of ecm assisted by low frequency vibrations. J. Mater. Process. Technol. 2007, 189, 466–472. [Google Scholar] [CrossRef]

- Liu, J.; Jiang, X.; Zhu, D. Electrochemical machining of multiple slots with low-frequency tool vibrations. Procedia Cirp 2016, 42, 799–803. [Google Scholar]

- Natsu, W.; Nakayama, H.; Yu, Z. Improvement of ecm characteristics by applying ultrasonic vibration. Int. J. Precis. Eng. Manuf. 2012, 13, 1131–1136. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, X.; Yang, Z.; Lü, Y.; He, Y. Experimental research on the optimization of precision electrochemical machining feed mode of diamond-hole grille. Int. J. Adv. Manuf. Technol. 2017, 91, 147–153. [Google Scholar] [CrossRef]

- Pan, Y.; Xu, L. Vibration analysis and experiments on electrochemical micro-machining using cathode vibration feed system. Int. J. Precis. Eng. Manuf. 2015, 16, 143–149. [Google Scholar] [CrossRef]

- Yang, I.; Min, S.P.; Chu, C.N. Micro ecm with ultrasonic vibrations using a semi-cylindrical tool. Int. J. Precis. Eng. Manuf. 2009, 10, 5–10. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, Y.; Deng, Y.; Wei, H.; Zhou, C.; Liu, J.; Luo, H. The tool design and experiments on pulse electrochemical machining of micro channel arrays on metallic bipolar plate using multifunctional cathode. Int. J. Adv. Manuf. Technol. 2016, 89, 407–416. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, J.; Zhang, X.; Yang, Z.; Gan, W.; Tian, Z. Electrochemical machining of a narrow slit by cathodic compound feeding. Int. J. Adv. Manuf. Technol. 2017, 90, 971–978. [Google Scholar]

- Bhattacharyya, B.; Malapati, M.; Munda, J.; Sarkar, A. Influence of tool vibration on machining performance in electrochemical micro-machining of copper. Int. J. Mach. Tools Manuf. 2007, 47, 335–342. [Google Scholar] [CrossRef]

- Ruszaj, A.; Zybura, M.; Żurek, R.; Skrabalak, G. Some aspects of the electrochemical machining process supported by electrode ultrasonic vibrations optimization. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2003, 217, 1365–1371. [Google Scholar] [CrossRef]

- Fang, X.; Qu, N.; Zhang, Y.; Xu, Z.; Zhu, D. Improvement of hole exit accuracy in electrochemical drilling by applying a potential difference between an auxiliary electrode and the anode. J. Mater. Process. Technol. 2014, 214, 556–564. [Google Scholar] [CrossRef]

- Roušar, I. Choked two-phase flow during electrochemical machining. J. Appl. Electrochem. 1987, 17, 1304–1314. [Google Scholar] [CrossRef]

- Tijum, R.V.; Pajak, P.T. Simulation of production processes using the multiphysics approach: The electrochemical machining process. Am. J. Phys. Med. Rehabilitation 2012, 84, 287–293. [Google Scholar]

- Rajurkar, K.P.; Wei, B.; Kozak, J.; Mcgeough, J.A. Modelling and monitoring interelectrode gap in pulse electrochemical machining. CIRP Ann.Manuf. Technol. 2015, 44, 177–180. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Applied voltage (V) | 20 |

| Electrolyte conductivity | 16.1 S/m at 30 °C |

| Electrolyte inlet pressure (MPa) | 0.6 |

| Electrolyte outlet pressure (MPa) | 0.1 |

| Initial gap (mm) | 0.1 |

| Vibration frequency (Hz) | 10 |

| Vibration amplitude (mm) | 0.3 |

| Coefficient m | 1.5 |

| Conditions | Value |

|---|---|

| Electrolyte | NaNO3 |

| Electrolyte conductivity | 16.1 S/m at 30 °C |

| Voltage (V) | 20 |

| Electrolyte inlet pressure (MPa) | 0.6 |

| Electrolyte outlet pressure (MPa) | 0.1 |

| Electrolyte temperature (°C) | 30 ± 1 |

| Initial gap (mm) | 0.1 |

| Amount of feed (mm) | 1 |

| Vibration frequency (Hz) | 10 |

| Vibration amplitude (mm) | 0.3 |

| Duty cycle | 25% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, X.; Liu, J.; Zhu, D.; Wang, M.; Qu, N. Research on Stagger Coupling Mode of Pulse Duration and Tool Vibration in Electrochemical Machining. Appl. Sci. 2018, 8, 1296. https://doi.org/10.3390/app8081296

Jiang X, Liu J, Zhu D, Wang M, Qu N. Research on Stagger Coupling Mode of Pulse Duration and Tool Vibration in Electrochemical Machining. Applied Sciences. 2018; 8(8):1296. https://doi.org/10.3390/app8081296

Chicago/Turabian StyleJiang, Xiaochen, Jia Liu, Di Zhu, Mingming Wang, and Ningsong Qu. 2018. "Research on Stagger Coupling Mode of Pulse Duration and Tool Vibration in Electrochemical Machining" Applied Sciences 8, no. 8: 1296. https://doi.org/10.3390/app8081296

APA StyleJiang, X., Liu, J., Zhu, D., Wang, M., & Qu, N. (2018). Research on Stagger Coupling Mode of Pulse Duration and Tool Vibration in Electrochemical Machining. Applied Sciences, 8(8), 1296. https://doi.org/10.3390/app8081296