Acoustic Emission Method for Locating and Identifying Active Destructive Processes in Operating Facilities

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

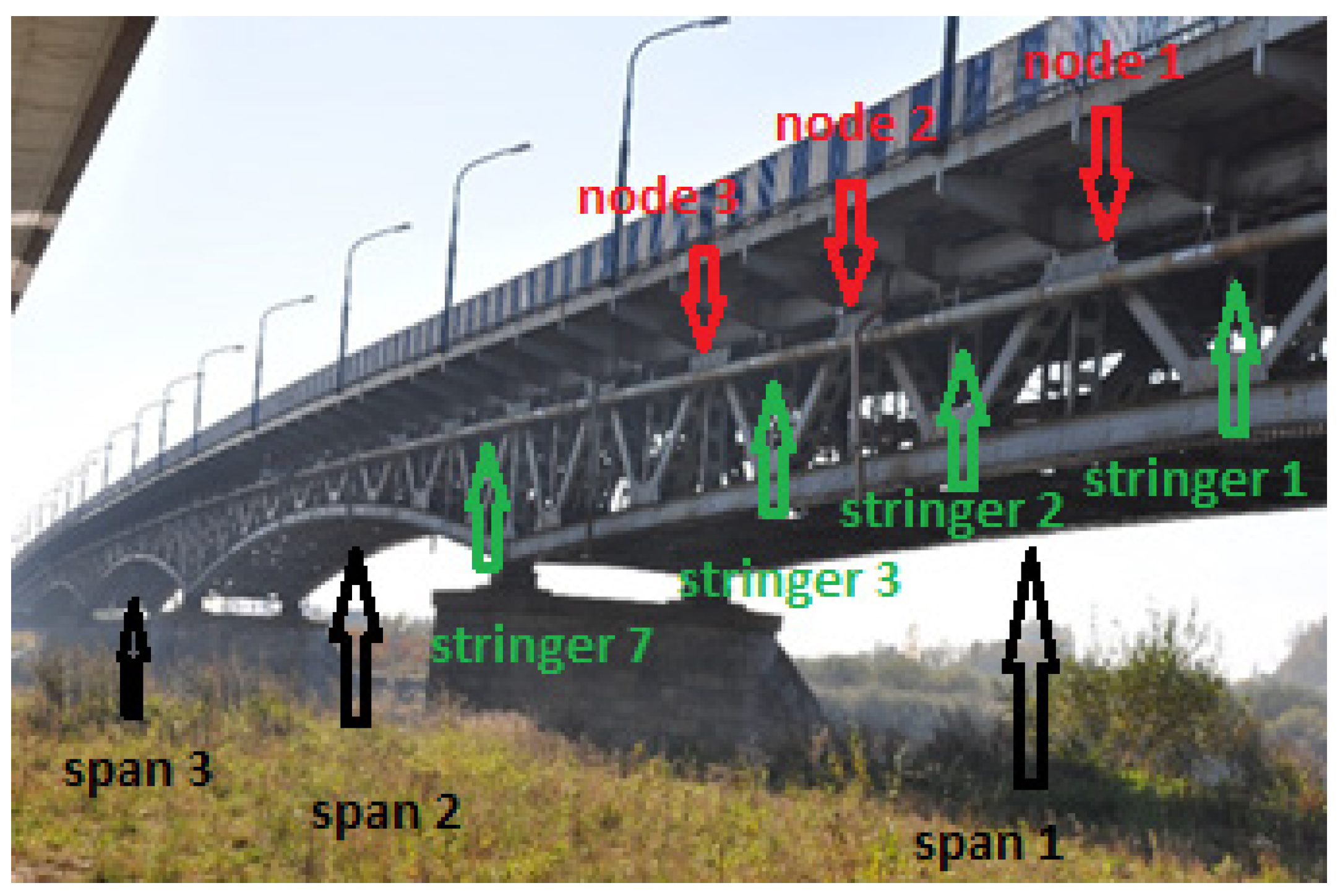

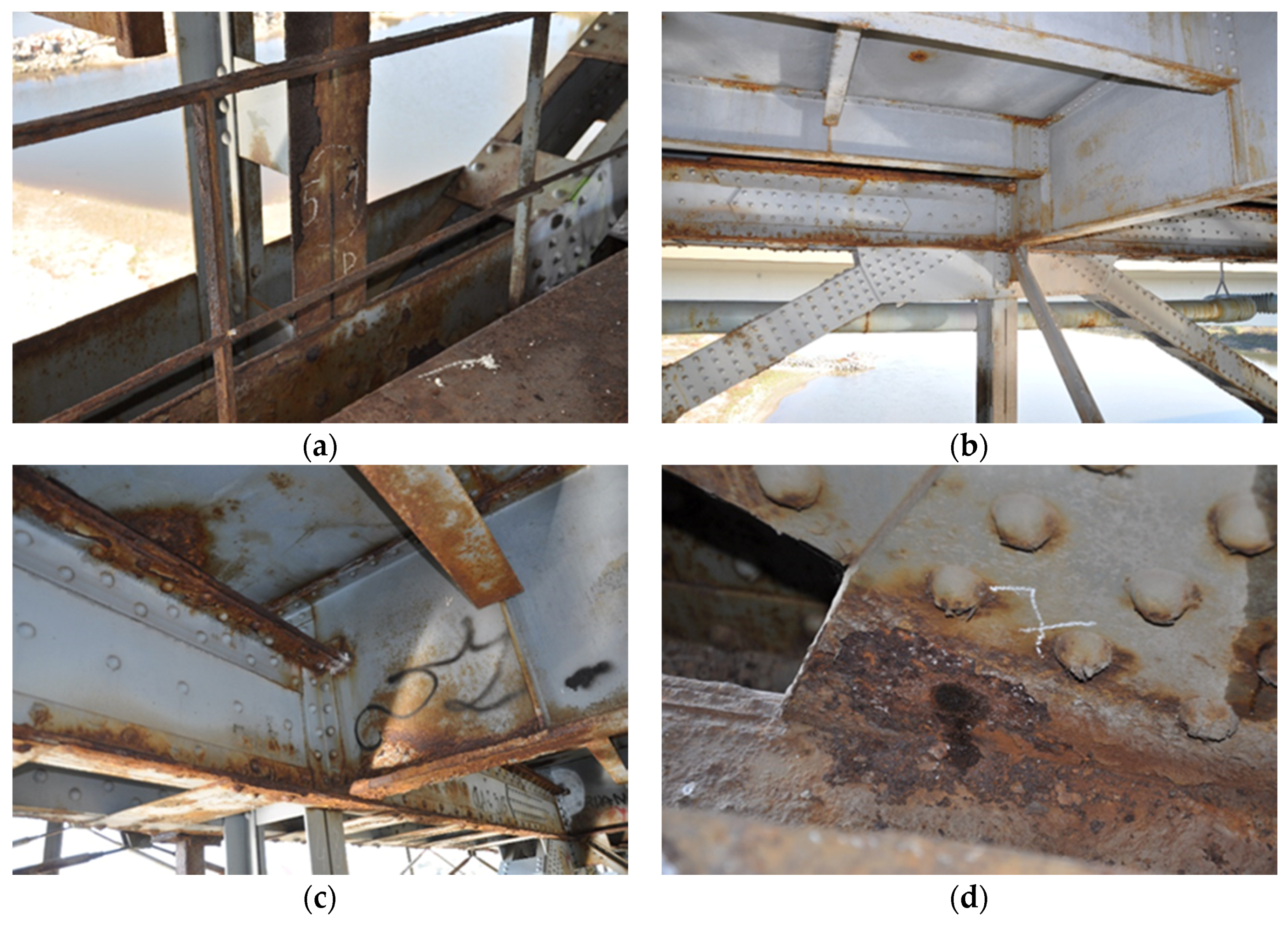

2.1.1. Steel Bridge

2.1.2. Steel Columns

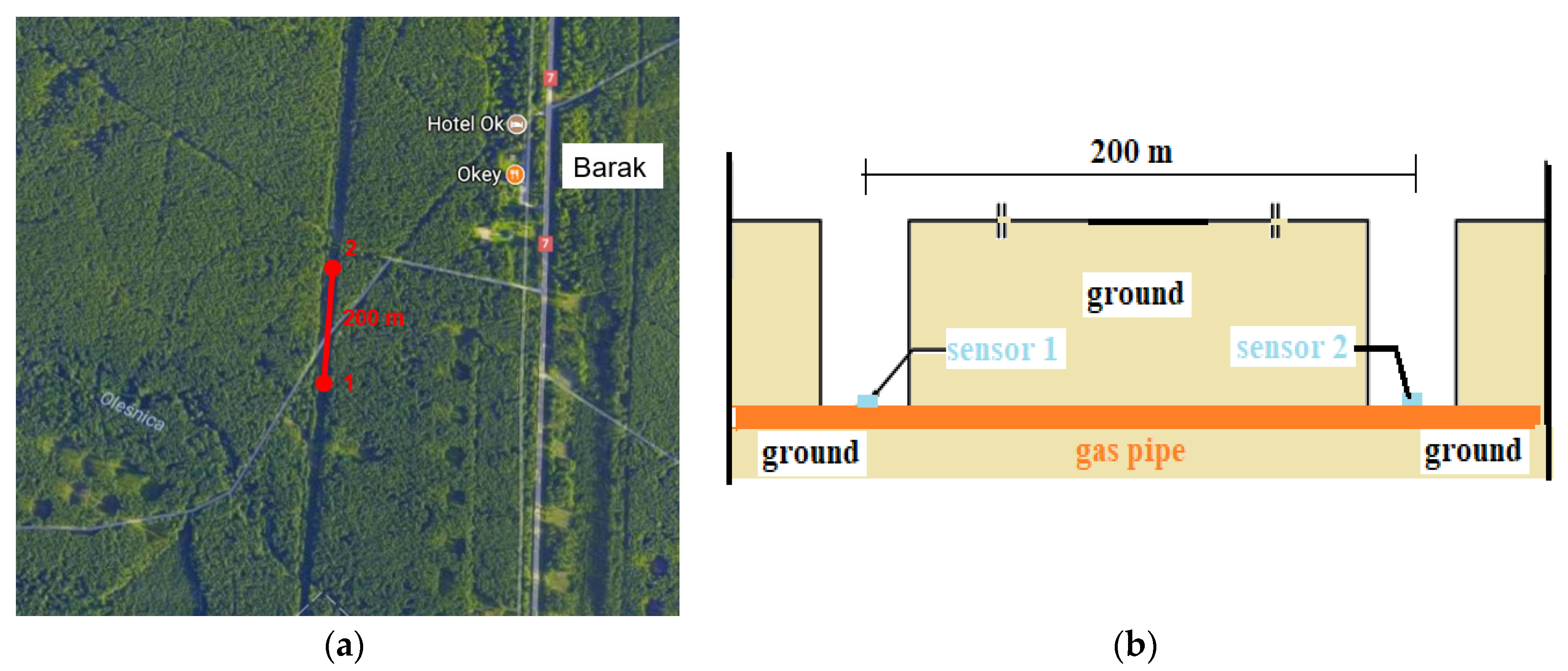

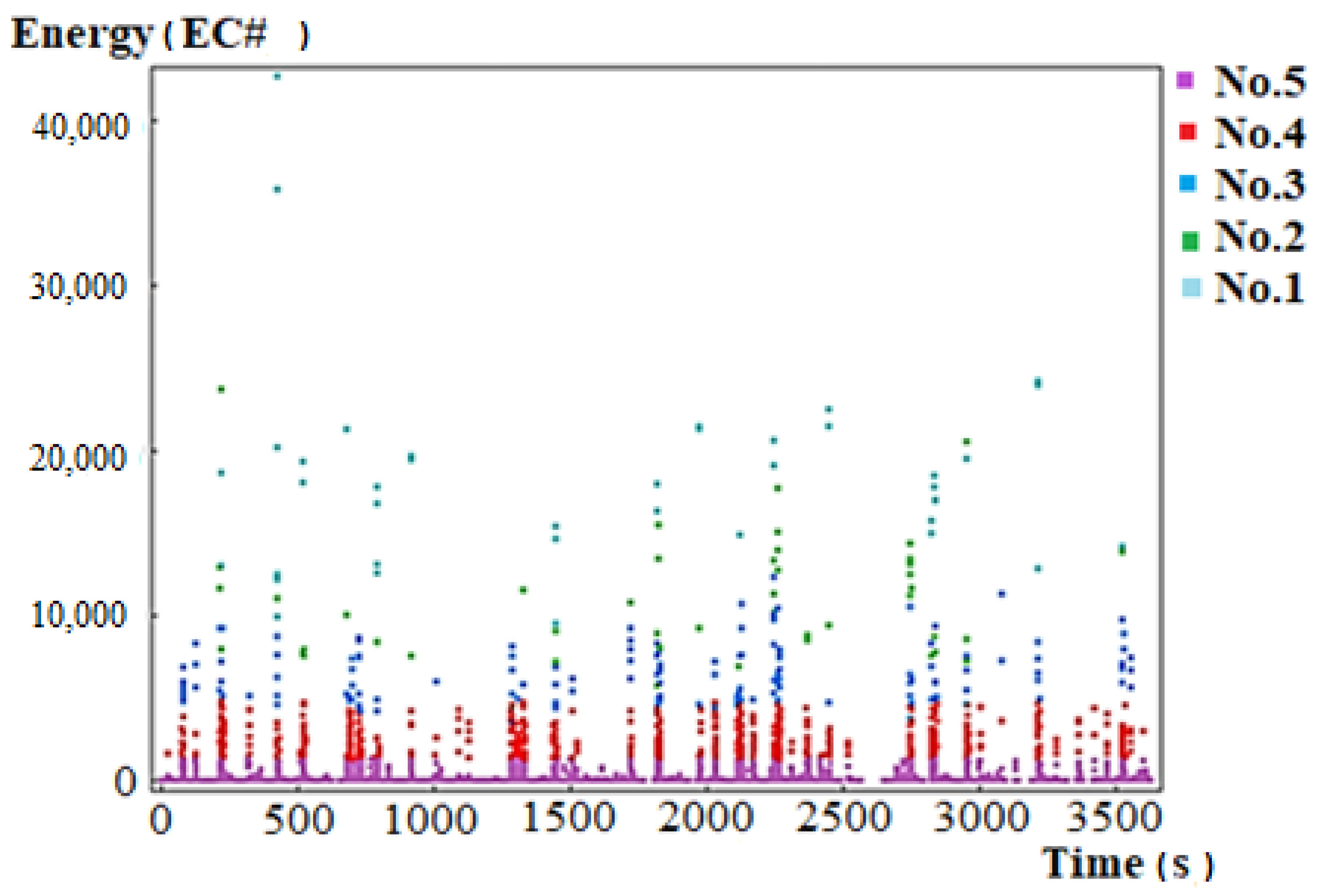

2.1.3. Gas Pipeline

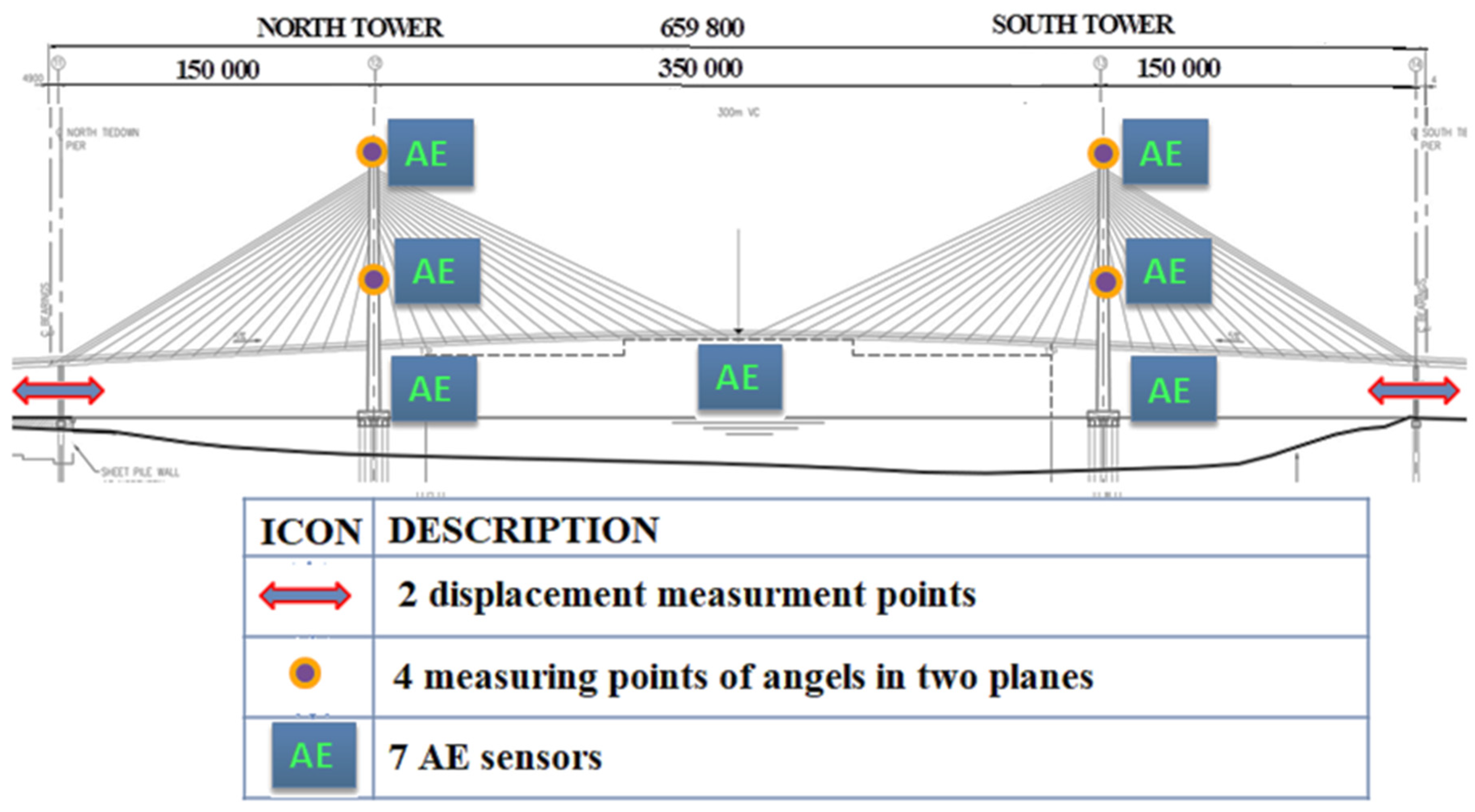

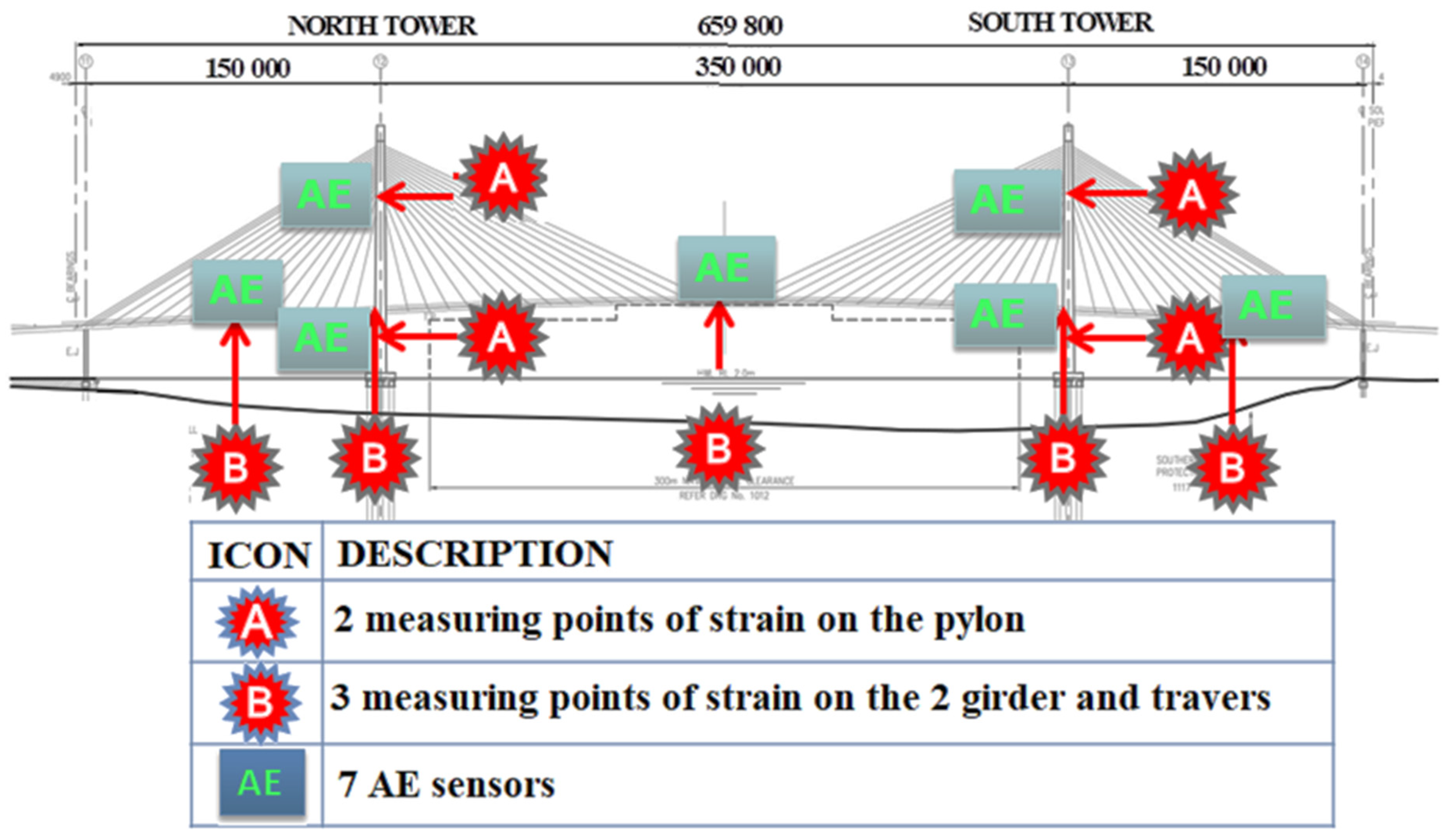

2.1.4. My Thuan Bridge

2.2. Methods

- look for active damage processes (progressing under service conditions) in the structure;

- identify and locate the damage;

- estimate the risk potential of the damage;

- determine the extent of the risk posed to the safety of the facility under routine operation.

- microcracks;

- friction between crack surfaces;

- formation and development of cracks in concrete;

- cracking at the concrete–reinforcement interface;

- concrete crumbling;

- friction at the concrete–reinforcement interface;

- corrosion;

- plastic deformation and cracking of cables and other reinforcements.

- generating signals in the laboratory while destroying specially designed specimens (bars, cubes, rolls) in a specific way,

- comparison of signals received from the specimens with the signals generated during the destruction of model beams (reinforced concrete and pre-tensioned concrete),

- verification of reference signals based on the monitoring results obtained for various types and lengths of prestressed concrete girders loaded to failure,

- final verification of selected elements of the bridge during its normal operation.

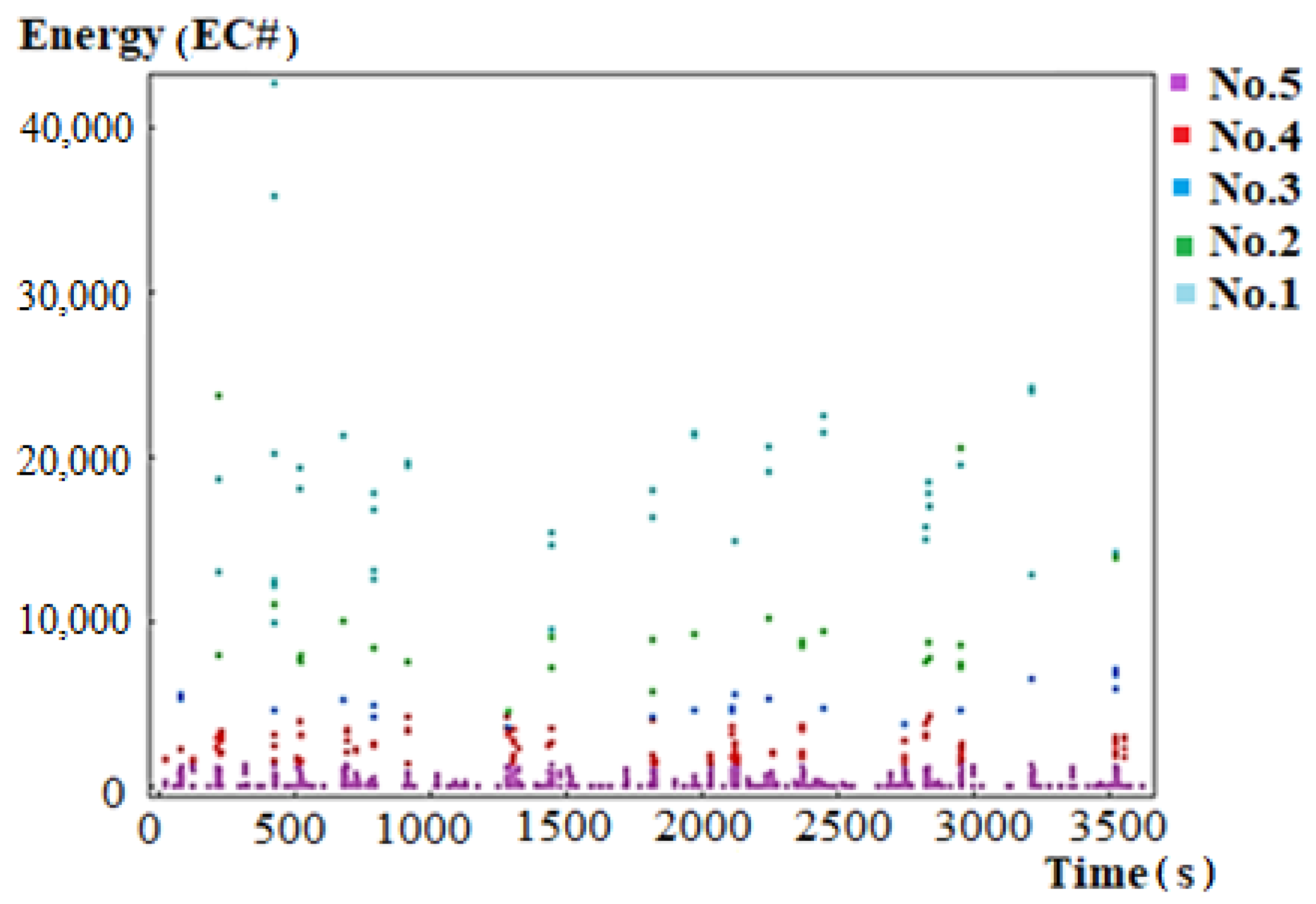

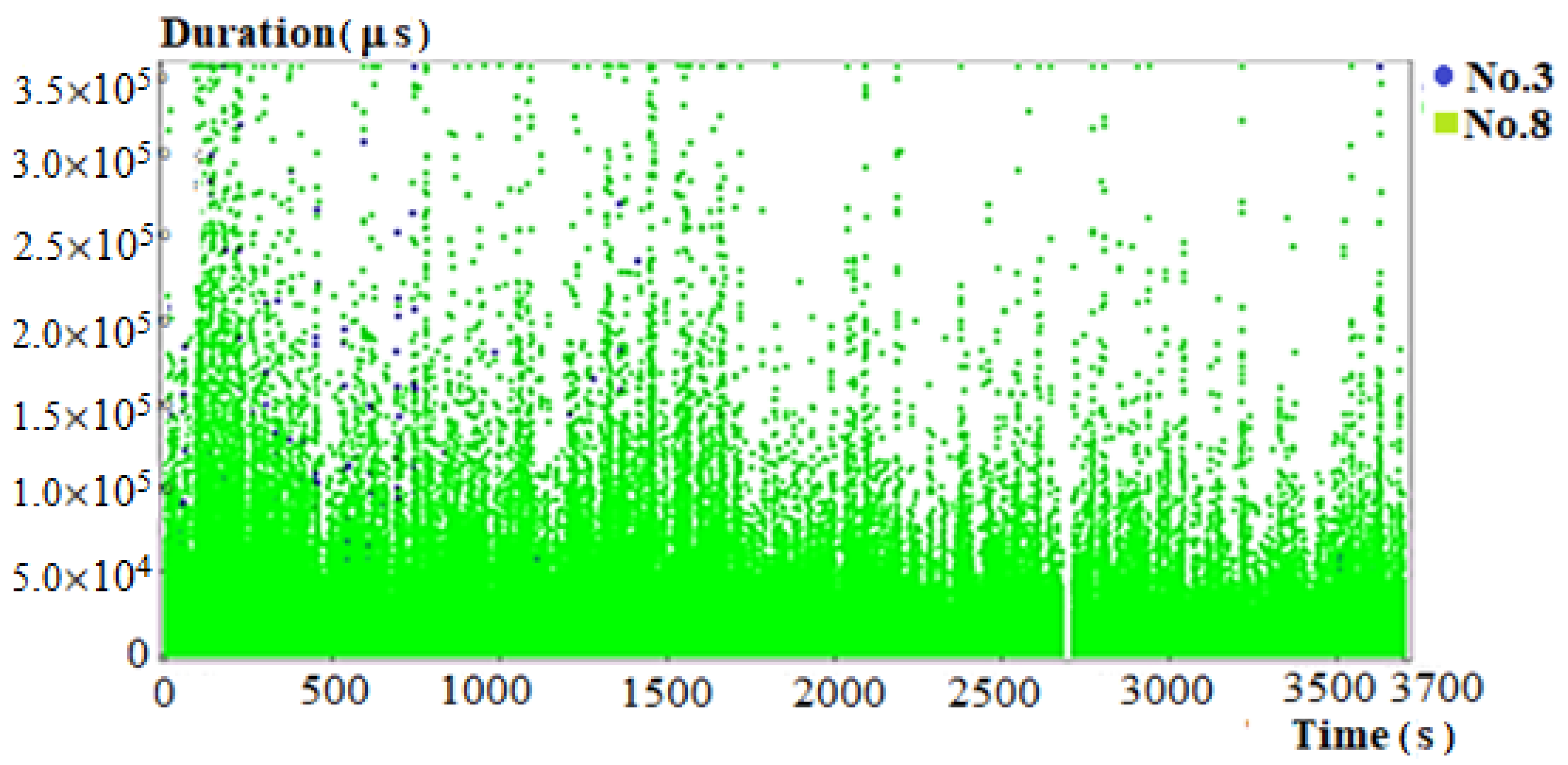

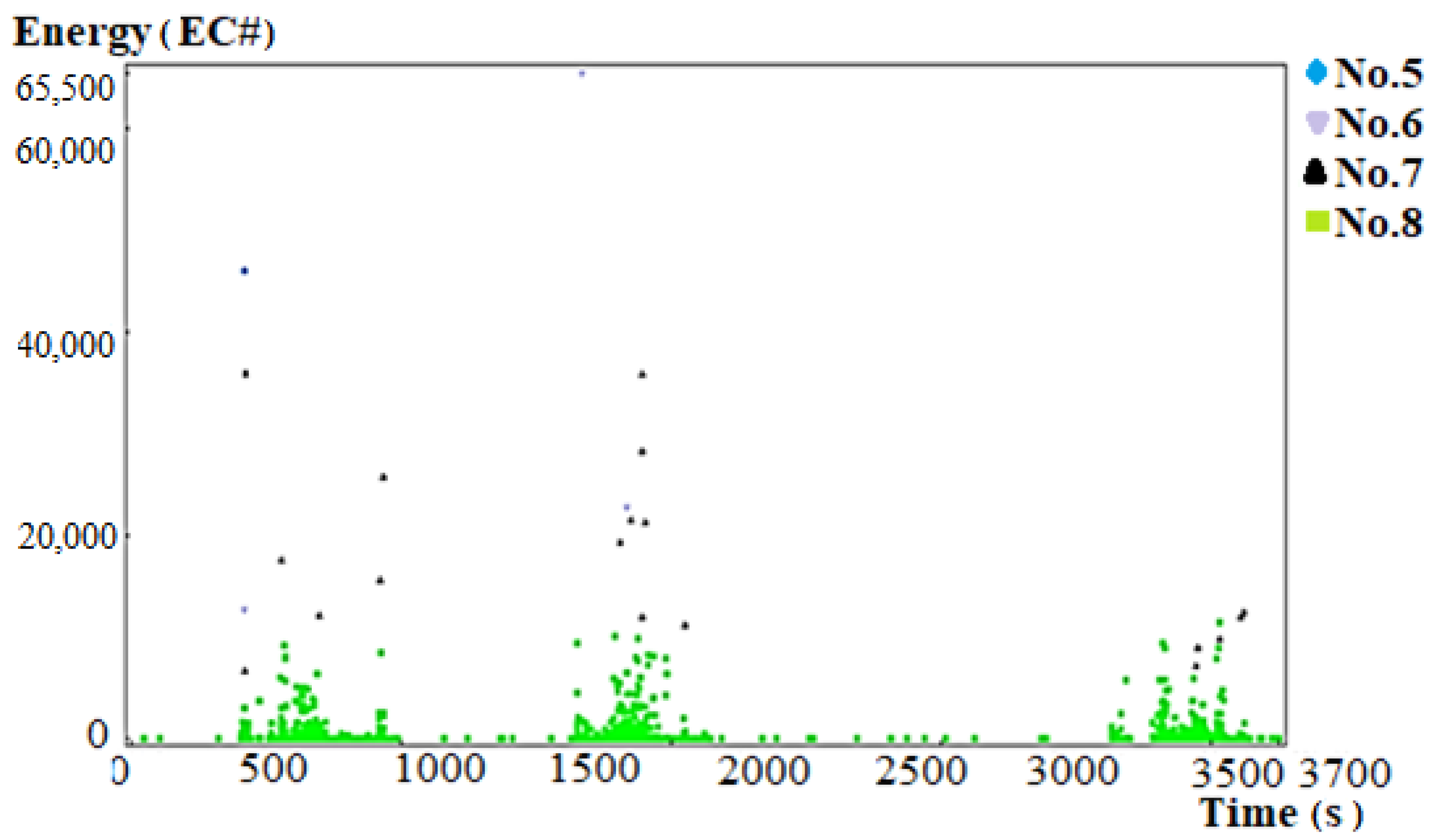

2.2.1. Acoustic Emission Evaluation of Steel Structures

- No.4—yielding of steel at the crack tip;

- No.3—crack initiation;

- No.2—crack propagation.

- No.1—rupture;

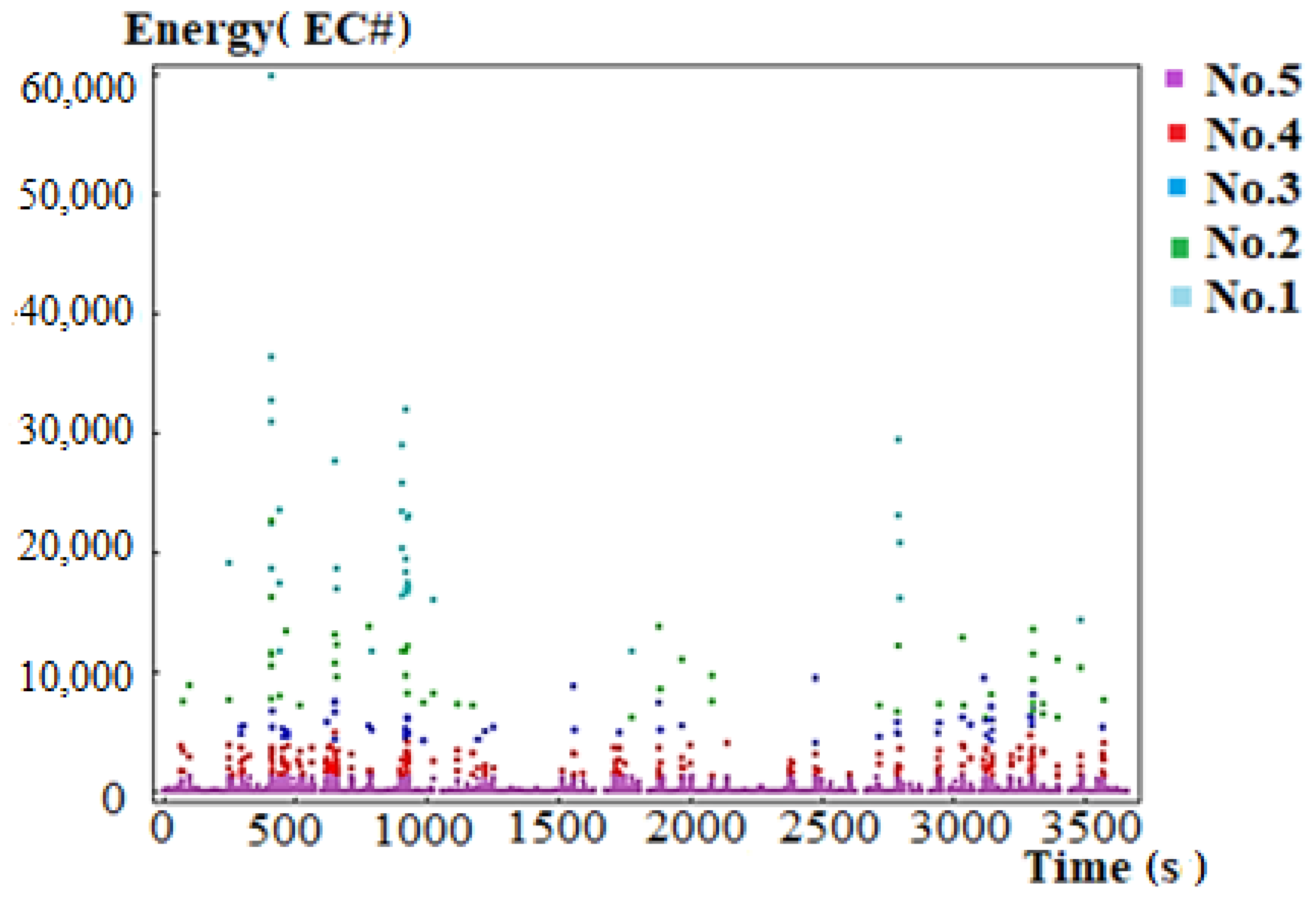

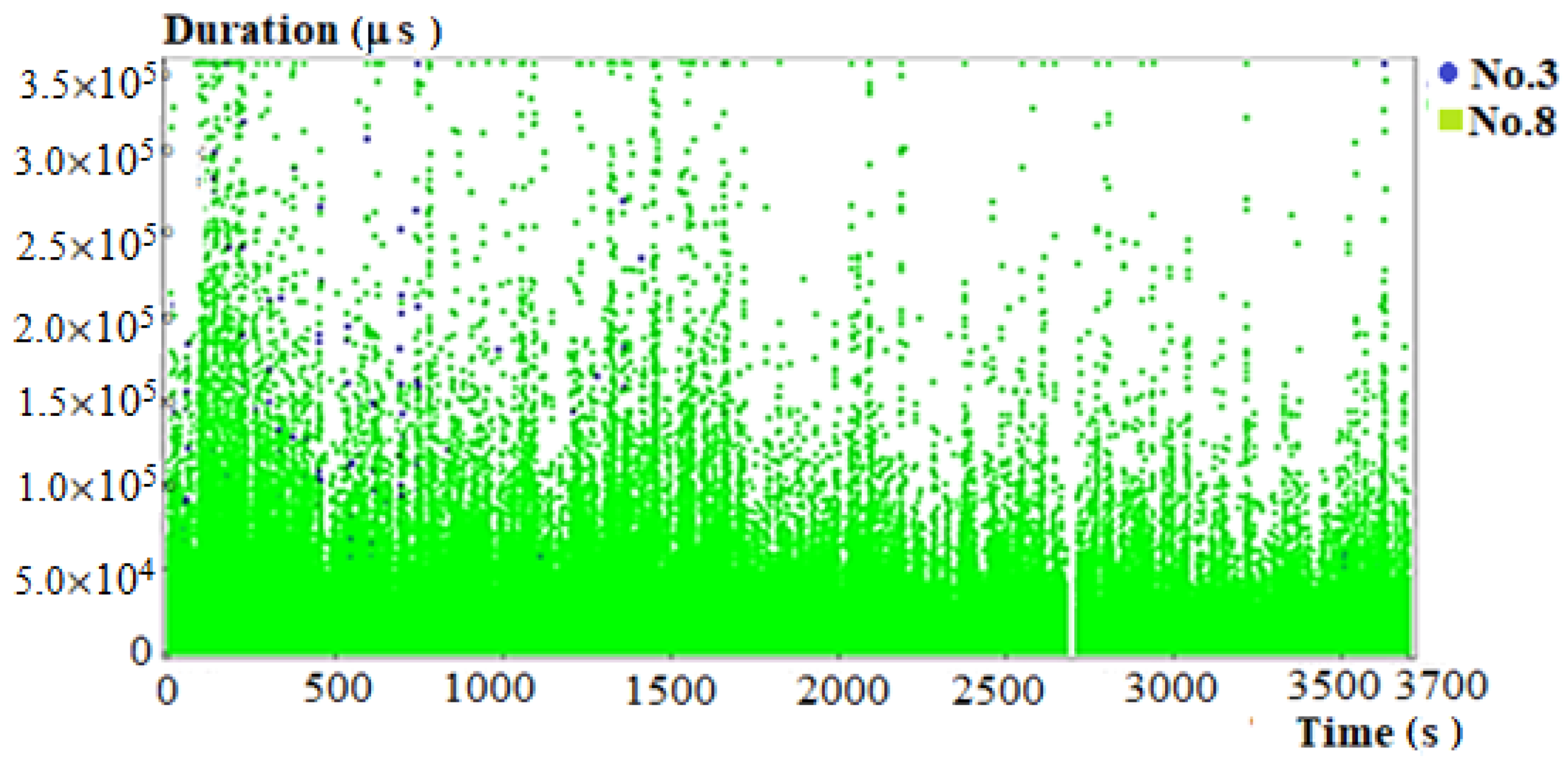

- No.2—friction;

- No.3—crack propagation;

- No.4—crack initiation;

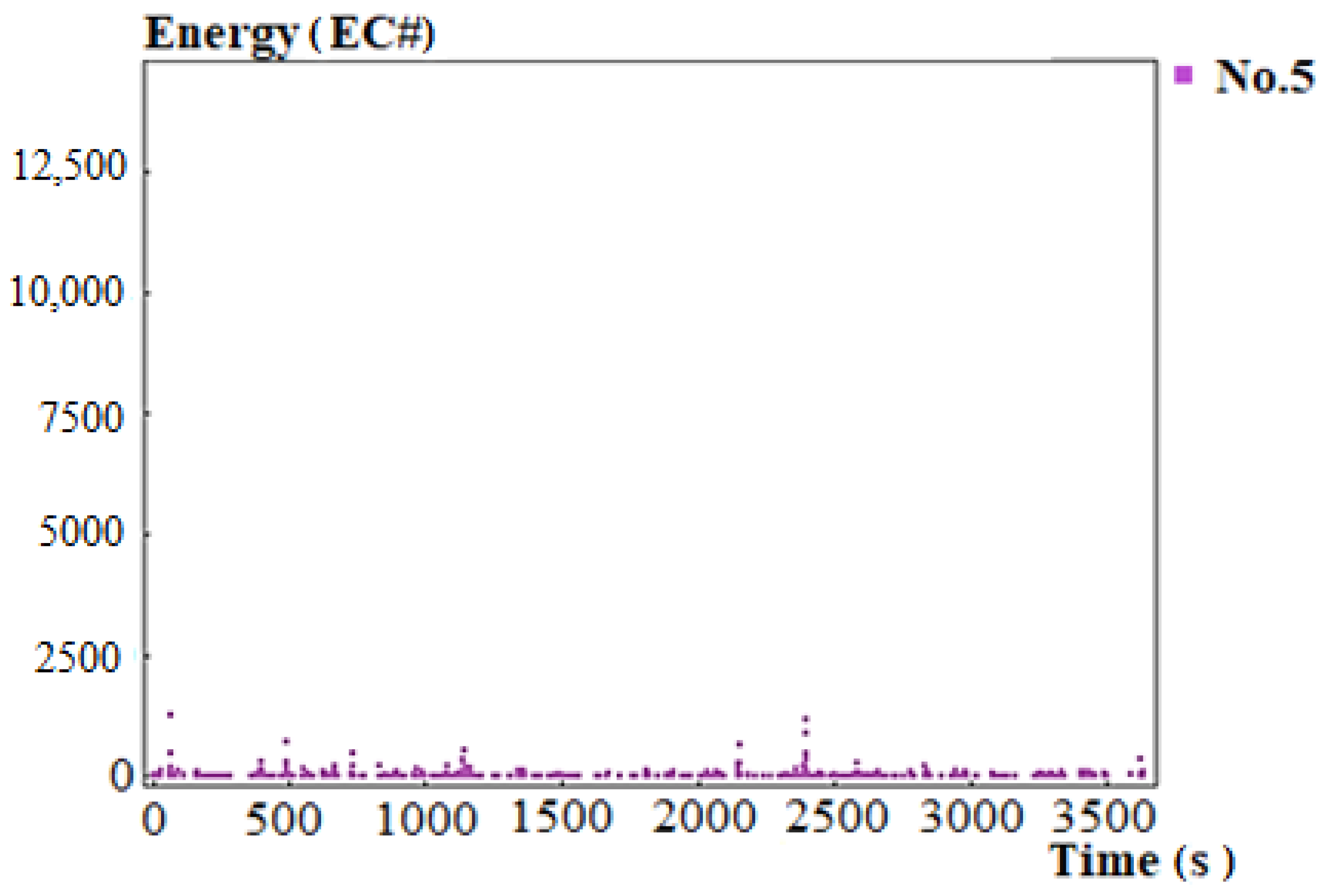

- No.5—perforation/deformation;

- No.6—material losses;

- No.7—surface corrosion;

- No.8—work in the elastic range.

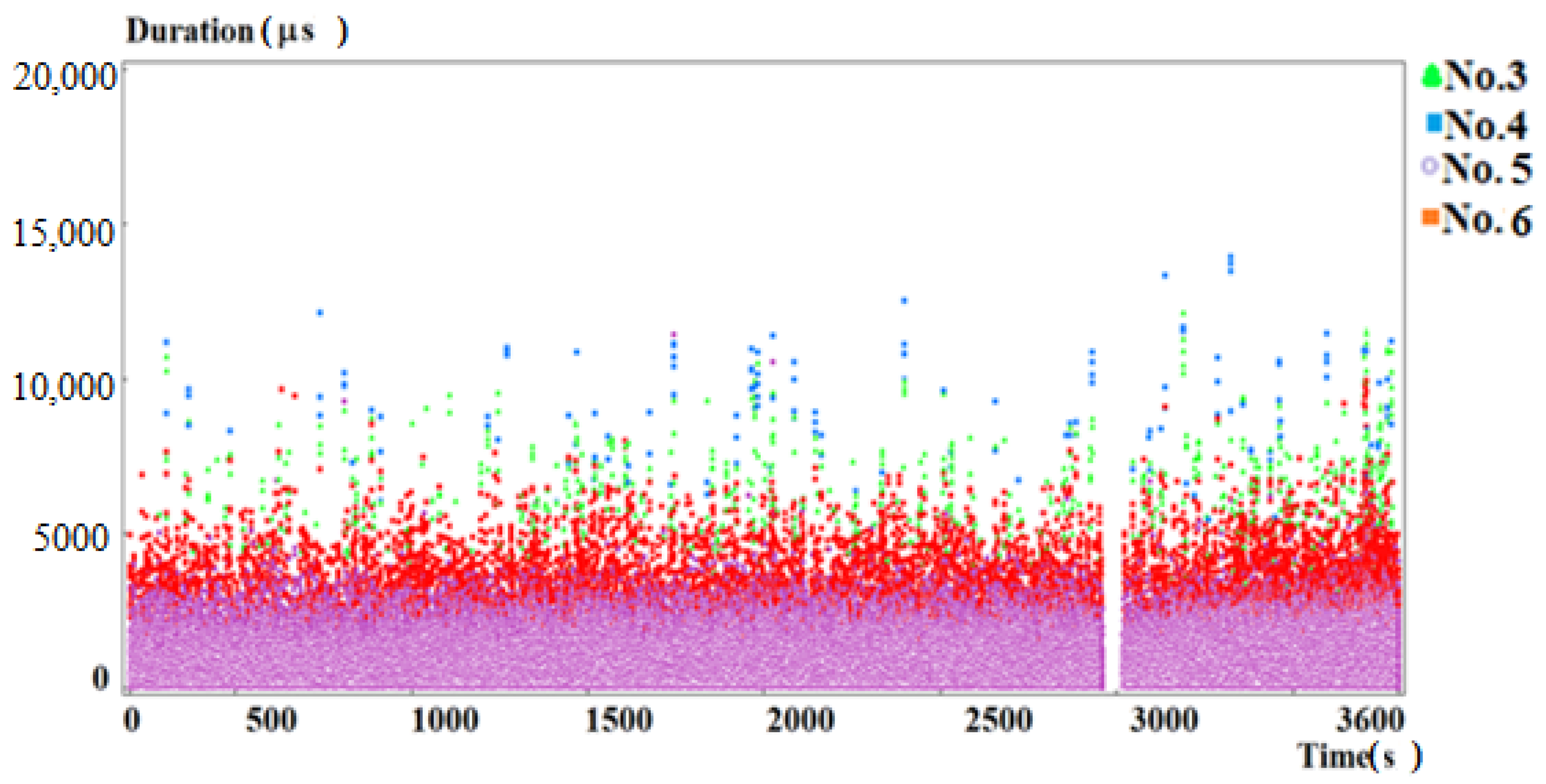

2.2.2. Acoustic Emission Evaluation of Gas Pipelines

2.2.3. Acoustic Emission Evaluation of Reinforced Concrete Structures; Classes, Symbols, and Risk Codes for Reinforced Concrete Structures

- Class No.1 Crack formation in the paste;

- Class No.2 Crack formation at the paste—aggregate boundary;

- Class No.3 Microcrack formation;

- Class No.4 Crack growth;

- Class No.5 Loss of adhesion around the cracks;

- Class No.6 Buckling of compressed bars/crushing of compressed concrete/rupture of rebar.

- Classes No.6 and No.5—safe behavior of the structure;

- Class No.4—warning;

- Class No.3—threat to durability;

- Class No.2—threat to load carrying capacity;

- Class No.1—loss of safety.

3. Results and Discussion

3.1. Steel Bridge

3.2. Steel Columns

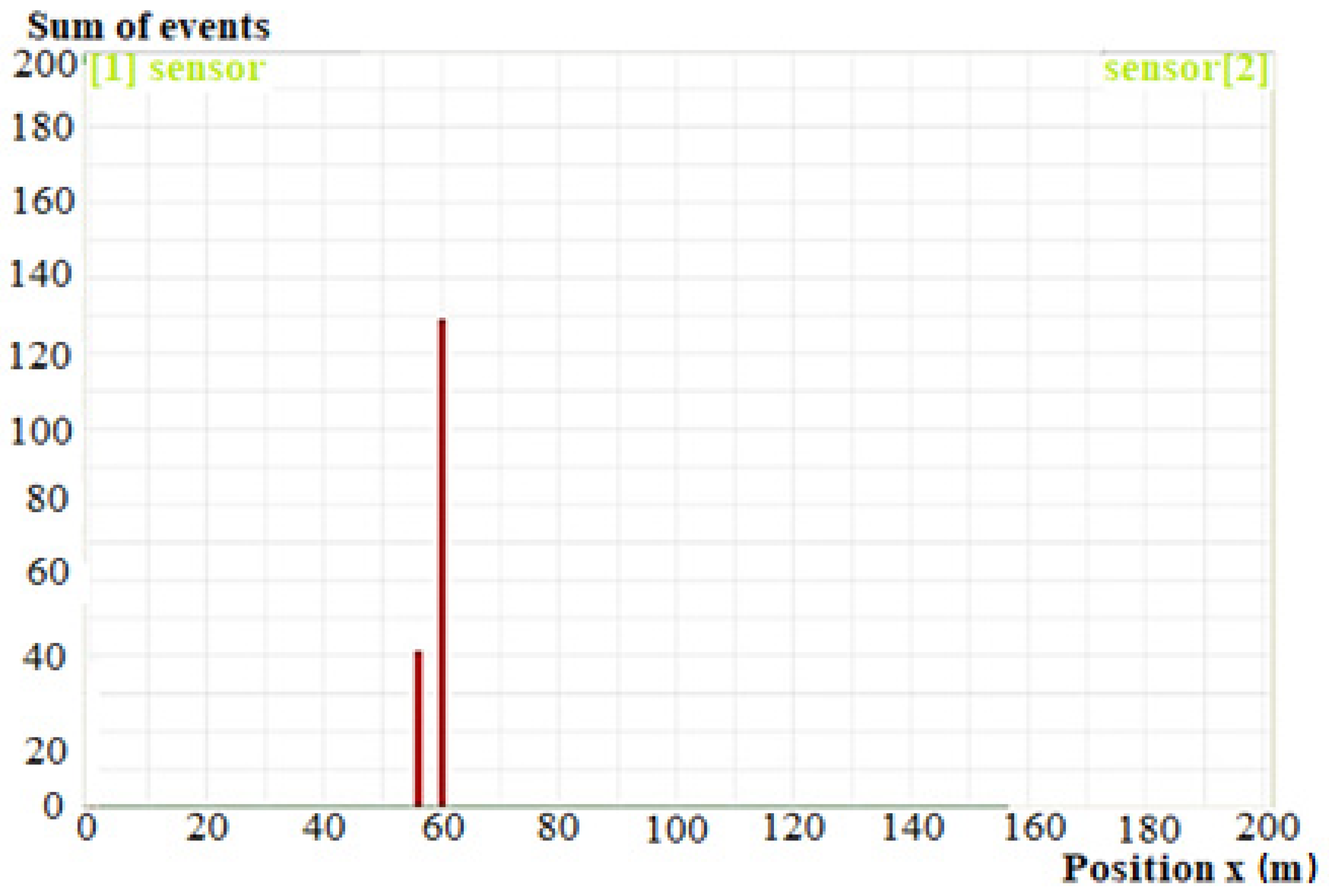

3.3. Gas Pipeline

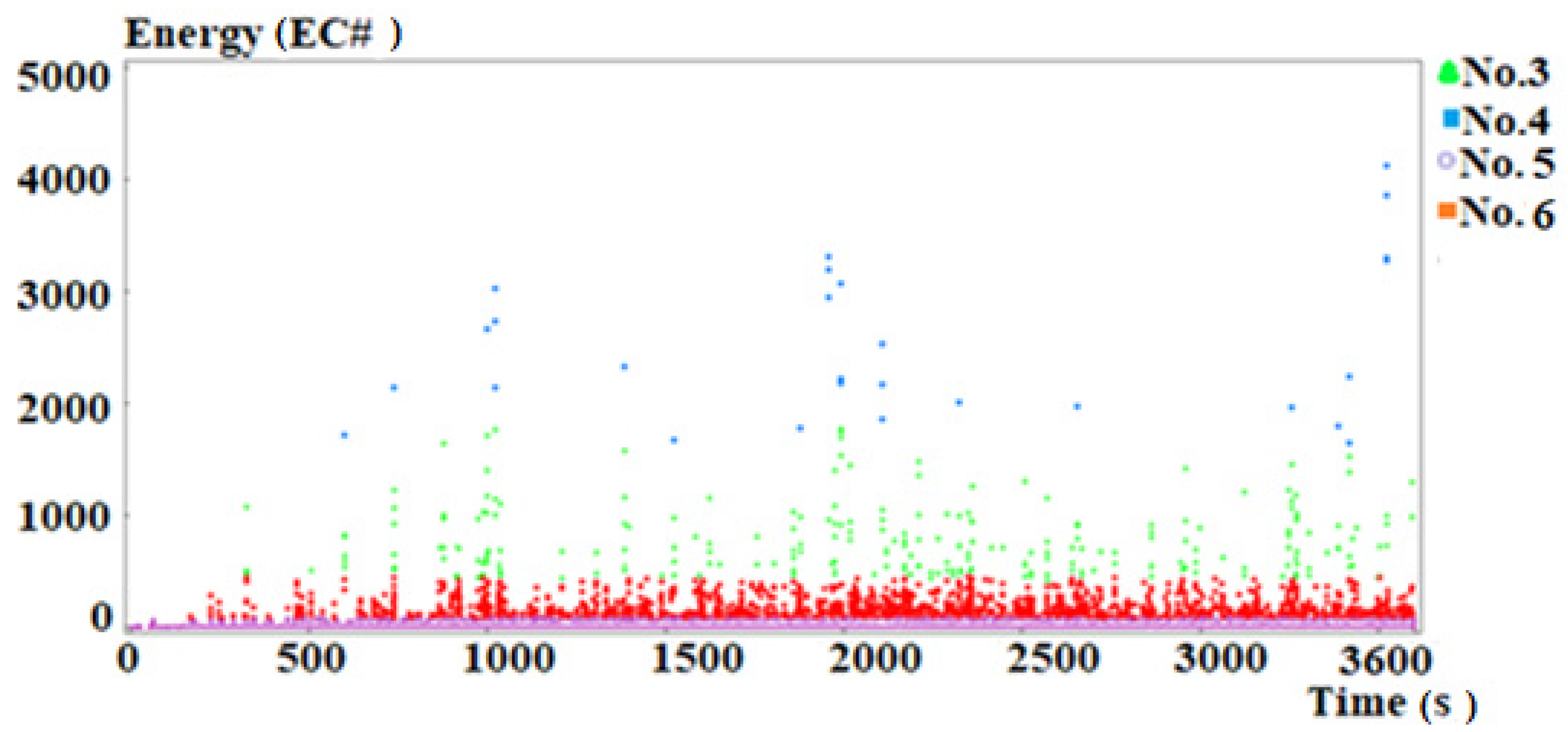

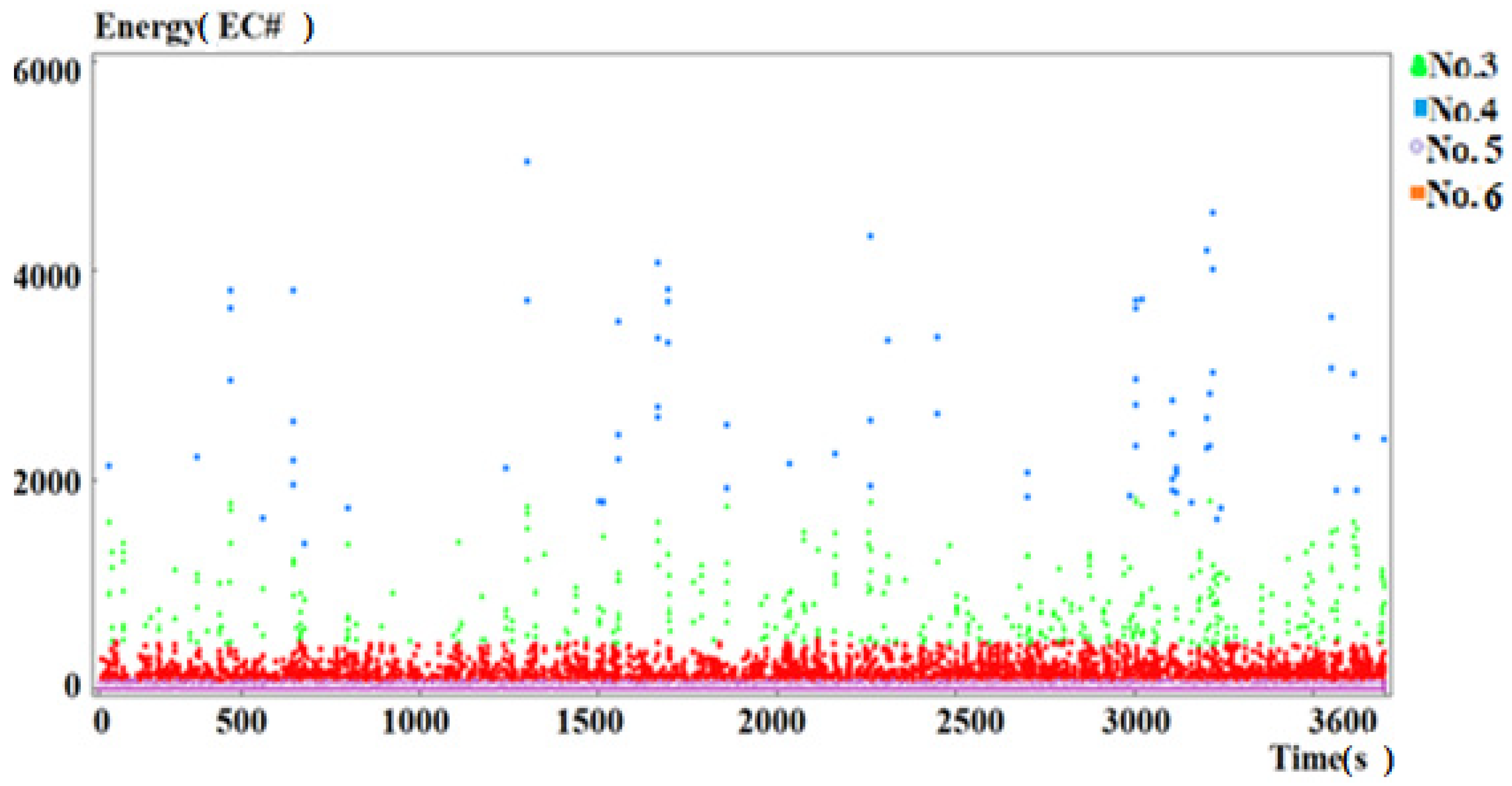

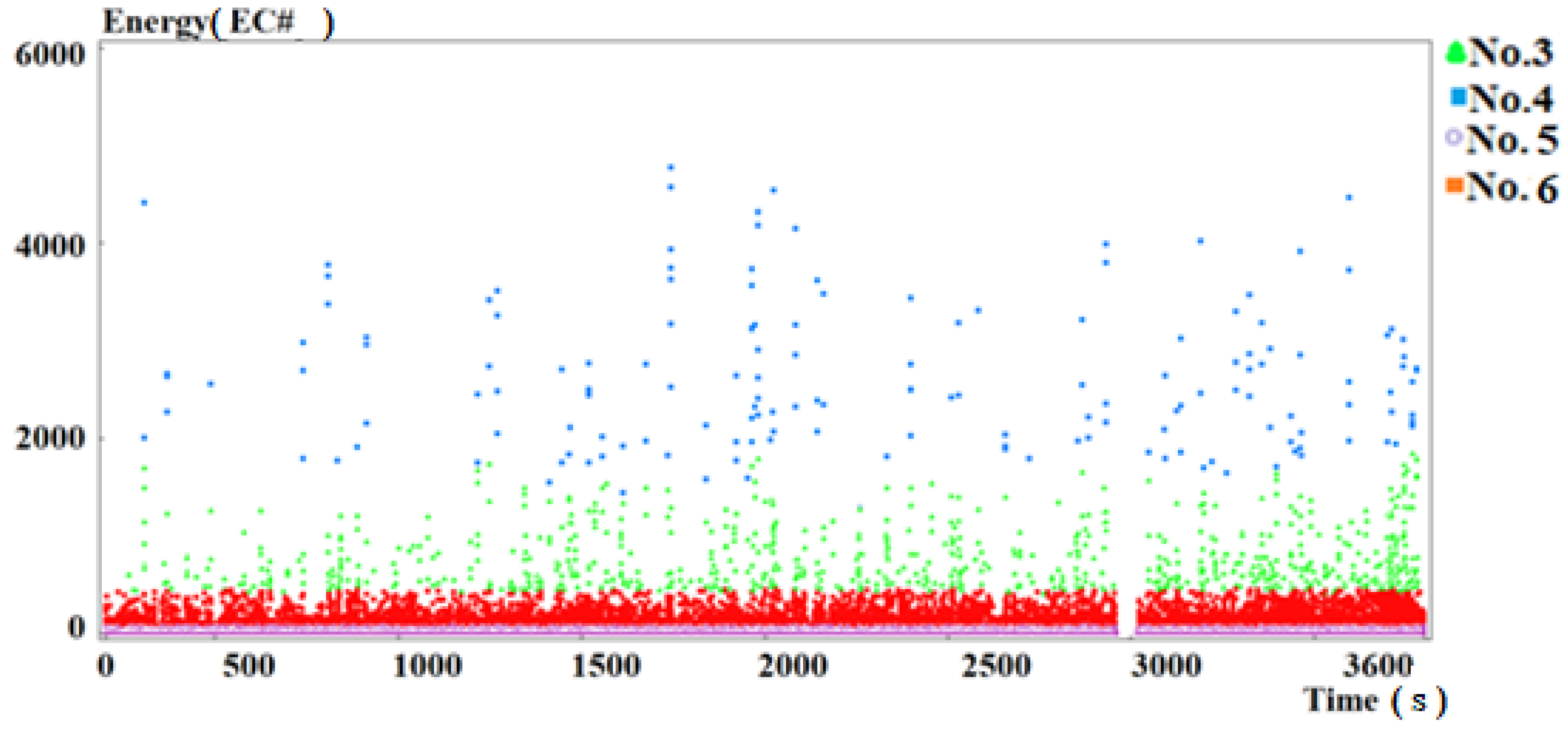

3.4. My Thuan Bridge

4. Conclusions

- the assessment of the health of a structure and identification of potential risks;

- the monitoring of the dynamics of destructive processes;

- the support in decision-making process concerning the risk management;

- the assessment of the repair work quality and outcome;

- the assessment of non-standard vehicle traffic.

5. Patents

Funding

Conflicts of Interest

References

- Ono, K. Application of Acoustic Emission for Structure Diagnosis. Diagnostics 2011, 2, 3–18. [Google Scholar]

- Marsh, B.K.; Nixon, P.J. Assuring performance of concrete structures through a durability audit. Int. Conf. Concrete in the Service of Mankind. In Appropriate Concrete Technology, Proceedings of the Concrete in the Service of Mankind, Dundee, UK, 24–26 June 1996; CRC Press: Boca Raton, FL, USA, 1996; pp. 49–59. [Google Scholar]

- Guide for Service Life Design of Buildings: Part 1—General Principles; ISO Draft No. 2; International Standard Organization: Geneva, Switzerland, 1995.

- Service Life Design ACI 365 (1R-00); State-of-the-Art-Report; ACI: Farmington Hills, MI, USA, 2000.

- BRITE/EURAM (Basic Research in Industrial Technologies/European Research in Advanced Materials) Program; DuraCrete 1996–99, DuraNet 1998–01, Darts 1997–2004.

- Niraki, T. Service life design. Constr. Build. Mater. 1996, 10, 403–406. [Google Scholar] [CrossRef]

- Houston, J.T.; Atimtay, E.; Ferguson, P.M. Corrosion of Reinforcing Steel Embedded in Structural Concrete; Research Report 112-1F; Center for Highway Research: Austin, TX, USA, 1972. [Google Scholar]

- Yuyama, S.; Okamoto, T.; Shigeiski, M.; Ohtsu, M.; Kishi, T. A Proposed Standard for Evaluating Integrity of Reinforced Concrete Beams by Acoustic Emission: Standard and Technology Update; American Society for Testing and Matrials: West Conshohocken, PA, USA, 1999. [Google Scholar]

- Lawson, R.M. Sustainability of Steel in Housing and Residential Buildings (P370); The Steel Construction Institute: Ascot, UK, 2007. [Google Scholar]

- Lawson, R.M.; Francis, K. Energy Efficient Housing Using Light Steel Framing (P367); The Steel Construction Institute: Ascot, UK, 2007. [Google Scholar]

- Lu, Y.; Michael, J. A methodology for structural health monitoring with diffuse ultrasonic waves in the presence of temperature variations. Ultrasonics 2005, 43, 717–731. [Google Scholar] [CrossRef] [PubMed]

- Su, Z.; Ye, L.; Lu, Y. Guided Lamb waves for identification of damage in composite structures: A review. J. Sound Vib. 2006, 295, 753–780. [Google Scholar] [CrossRef]

- Ebrahimkhanlou, A.; Salamone, S. Single-Sensor Acoustic Emission Source Localization in Plate-Like Structures Using Deep Learning. Aerospace 2018, 5, 50. [Google Scholar] [CrossRef]

- Ebrahimkhanlou, A.; Salamone, S. A probabilistic framework for single-sensor acoustic emission source localization in thin metallic plates. Smart Mater. Struct. 2017, 26, 095026. [Google Scholar] [CrossRef]

- Ebrahimkhanlou, A.; Salamone, S. Acoustic emission source localization in thin metallic plates: A single-sensor approach based on multimodal edge reflections. Ultrasonics 2017, 78, 134–145. [Google Scholar] [CrossRef] [PubMed]

- Carpinteri, A.; Lacidogna, G.; Puzzi, S. From criticality to final collapse: Evolution of the ‘‘b-value” from 1.5 to 1.0. Chaos Solitons Fractals 2009, 4, 843–853. [Google Scholar] [CrossRef]

- Carpinteri, A.; Corrado, M.; Lacidogna, G. Three different approaches for damage domain characterization in disordered materials: Fractal energy density, b-value statistics, renormalization group theory. Mech. Mater. 2012, 53, 15–28. [Google Scholar] [CrossRef]

- Balageas, J.; Fritzen, C.; Guemes, A. Structural Health Monitoring Systems; ISTE: Washington, DC, USA, 2006. [Google Scholar]

- Adams, D. Health Monitoring of Structural Materials and Components; Wiley: New York, NY, USA, 2007. [Google Scholar]

- Swamy, R.N. Durability of Rebars in Concrete. Spec. Publ. 1992, 131, 67–98. [Google Scholar]

- Vennesland, O.; Gjorv, O.E. Effect of Cracks in Submerged Concrete Sea Structures on Steel Corrosion. Mater. Perform. 1981, 20, 49–51. [Google Scholar]

- Alampalli, S.; Ettouney, M. Results of workshop on structural health monitoring in bridge security. In Proceedings of the 3rd International Conference on Structural Health Monitoring of Intelligent Infrastructure, Vancouver, BC, Canada, 14–16 November 2007; pp. 13–16. [Google Scholar]

- Inaudi, D. Structural Health Monitoring of bridges: General Issues and Applications. Struct. Health Monitor. Civ. Infrastruct. Syst. 2009, 339–370. [Google Scholar]

- Zhou, H.F.; Ni, Y.Q.; Ko, J.M. Structural Damage Alarming Using Auto-Associative Neural Network Technique: Exploration of Environment-Tolerant Capacity and Setup of Alarming Threshold. Mech. Syst. Signal Process. 2011, 25, 1508–1526. [Google Scholar] [CrossRef]

- Olaszek, P.; Świt, G.; Casas, J.R. On-site assessment of bridges supported by acoustic emission. Proc. Inst. Civ. Eng. Bridge Eng. 2016, 169, 81–92. [Google Scholar] [CrossRef]

- Świt, G.; Adamczak, A.; Krampikowska, A. Wavelet Analysis of Acoustic Emissions during Tensile Test of Carbon Fibre Reinforced Polymer Composites. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245. [Google Scholar] [CrossRef]

- Świt, G.; Adamczak, A.; Krampikowska, A. Time-frequency analysis of acoustic emission signals generated by the Glass Fibre Reinforced Polymer Composites during the tensile test. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251, 1–8. [Google Scholar] [CrossRef]

- Goszczyńska, B.; Świt, G.; Trąmpczyński, W.; Krampikowska, A. Application of the Acoustic Emission Method of identification and location of destructive processes to the monitoring concrete bridges. In Proceedings of the 7th International Conference on Bridge Maintenance, Safety and Management (IABMAS), Shanghai, China, 7–11 July 2014; pp. 688–694. [Google Scholar]

- Świt, G.; Krampikowska, A. Influence of the Number of Acoustic Emission Descriptors on the Accuracy of Destructive Process Identification in Concrete Structures. In Proceedings of the 2016 Prognostics and System Health Management Conference, Chengdu, China, 19–21 October 2016; pp. 6–11. [Google Scholar]

- Świt, G.; Krampikowska, A.; Chinh, L.M. A Prototype System for Acoustic Emission-Based Structural Health Monitoring of My Thuan Bridge. In Proceedings of the 2016 Prognostics and System Health Management Conference, Chengdu, China, 19–21 October 2016; pp. 624–630. [Google Scholar]

- Chinh, L.M.; Adamczak, A.; Krampikowska, A.; Świt, G. Dragon bridge—The world largest dragon-shaped (ARCH) steel bridge as element of smart city. In Proceedings of the International Conference on the Sustainable Energy and Environment Development (SEED 2016), Krakow, Poland, 17–19 May 2016; Volume 10, pp. 1–5. [Google Scholar]

- Świt, G.; Krampikowska, A.; Chinh, L.M.; Adamczak, A. Nhat Tan Bridge—THE Biggest Cable-Stayed Bridge in Vietnam. Procedia Eng. 2016, 161, 666–673. [Google Scholar] [CrossRef]

- Olaszek, P.; Świt, G.; Casas, J.R. Proof load testing supported by acoustic emission. An example of application. In Bridge Maintenance, Safety, Management and Life-Cycle Optimization, Proceedings of the Fifth International IABMAS Conference, Philadelphia, PA, USA, 11–15 July 2010; CRC Press: Boca Raton, FL, USA, 2010; pp. 472–479. [Google Scholar]

- Deraemaeker, A.; Reynders, E.; De Roeck, G.; Kullaa, J. Vibration—Based structural health monitoring using output-only measurements under changing environment. Mech. Syst. Signal Process. 2008, 22, 34–56. [Google Scholar] [CrossRef]

- Wong, K.Y. Design of a Structural Health Monitoring System for Long-Span Bridges. Struct. Infrastruct. Eng. 2007, 3, 169–185. [Google Scholar] [CrossRef]

- Catbas, F.N. Structural Health Monitoring: Applications and Data Analysis. In Structural Health Monitoring of Civil Infrastructure Systems; Woodhead Publishing: Cambridge, UK, 2009. [Google Scholar]

- Goszczyńska, B.; Świt, G.; Trąmpczyński, W. Application of the IADP acoustic emission method to automatic control of traffic on reinforced concrete bridges to ensure their safe operation. Arch. Civ. Mech. Eng. 2016, 16, 867–875. [Google Scholar] [CrossRef]

- Świt, G. Evaluation of compliance changes in concrete beams reinforced by glass fiber reinforced plastics using acoustic emission. J. Mater. Civ. Eng. 2004, 16, 414–418. [Google Scholar] [CrossRef]

- Goszczyńska, B.; Świt, G.; Trąmpczyński, W. Analysis of the microcracking process with the Acoustic Emission method with respect to the service life of reinforced concrete structures with the example of the RC beams. Bull. Pol. Acad. Sci. Tech. Sci. 2015, 63, 55–65. [Google Scholar] [CrossRef]

| Colour |  |  |  |  |  |

|---|---|---|---|---|---|

| Class | No.1 | No.2 | No.3 | No.4 | No.5 |

| Risk code | 0 | 1 | 2 | 3 | 4 |

| Risk | Very high | High | Medium | Low | No risk |

| Colour |  |  |  |  |  |  |  |  |

|---|---|---|---|---|---|---|---|---|

| Class | No.1 | No.2 | No.3 | No.4 | No.5 | No.6 | No.7 | No.8 |

| Risk code | 0 | 1 | 1 | 2 | 3 | 3 | 4 | 5 |

| Risk | Very high | High | High | Mid-to-high | Medium | Medium | Low | No risk |

| Colour |  |  |  |  |  |  |  |  |

|---|---|---|---|---|---|---|---|---|

| Class | No.1 | No.2 | No.3 | No.4 | No.5 | No.6 | No.7 | No.8 |

| Code | 0 | 1 | 1 | 2 | 2 | 3 | 4 | 5 |

| Risk | Very high | High | High | Mid-to-high | Mid-to-high | Medium | Low | No risk |

| Colour |  |  |  |  |  |  |

|---|---|---|---|---|---|---|

| Class | No.1 | No.2 | No.3 | No.4 | No.5 | No.6 |

| Code | 0 | 1 | 2 | 3 | 4 | 5 |

| Risk | Very high | High | Medium | Medium | Low | No risk |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Świt, G. Acoustic Emission Method for Locating and Identifying Active Destructive Processes in Operating Facilities. Appl. Sci. 2018, 8, 1295. https://doi.org/10.3390/app8081295

Świt G. Acoustic Emission Method for Locating and Identifying Active Destructive Processes in Operating Facilities. Applied Sciences. 2018; 8(8):1295. https://doi.org/10.3390/app8081295

Chicago/Turabian StyleŚwit, Grzegorz. 2018. "Acoustic Emission Method for Locating and Identifying Active Destructive Processes in Operating Facilities" Applied Sciences 8, no. 8: 1295. https://doi.org/10.3390/app8081295

APA StyleŚwit, G. (2018). Acoustic Emission Method for Locating and Identifying Active Destructive Processes in Operating Facilities. Applied Sciences, 8(8), 1295. https://doi.org/10.3390/app8081295