3.1. Laser Interference Lithography Fabrication

Laser interference lithography was used to fabricate hexagonal arranged hole-like patterns in SU-8-2. These structures were achieved by irradiating a spin-coated layer of non-polymerized SU-8. To obtain the hole-like patters, two exposure steps were applied with a rotation of 60° between them. On the positions corresponding to the interference maxima, the SU-8 material starts to polymerize forming the periodic structure. By varying the laser fluence between 1–8 mJ/cm², the amount of polymerized material can be controlled and thus the diameter of the produced holes. In the case of small spatial periods, lower fluences are required to avoid the full polymerization of the SU-8 layer.

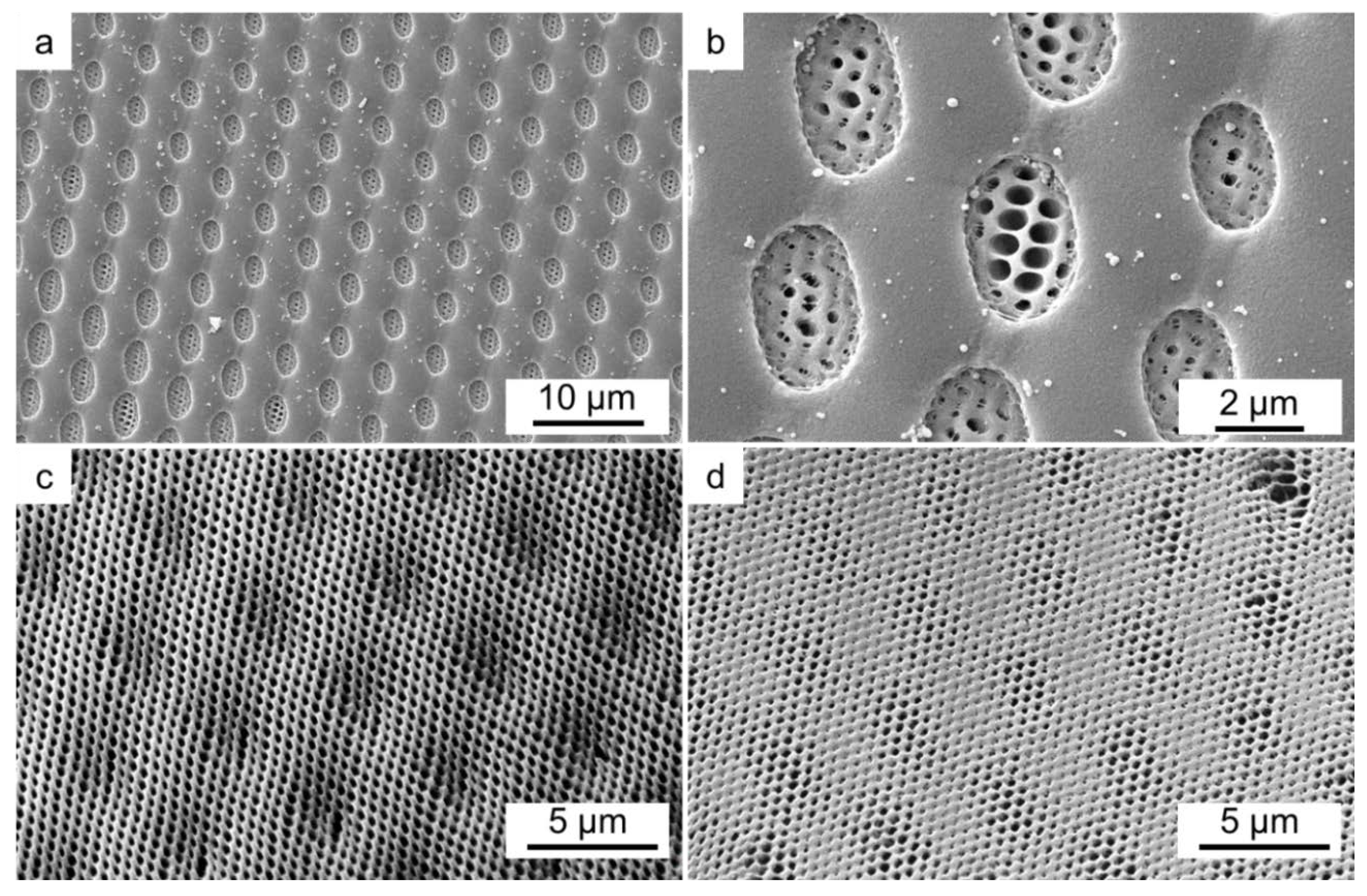

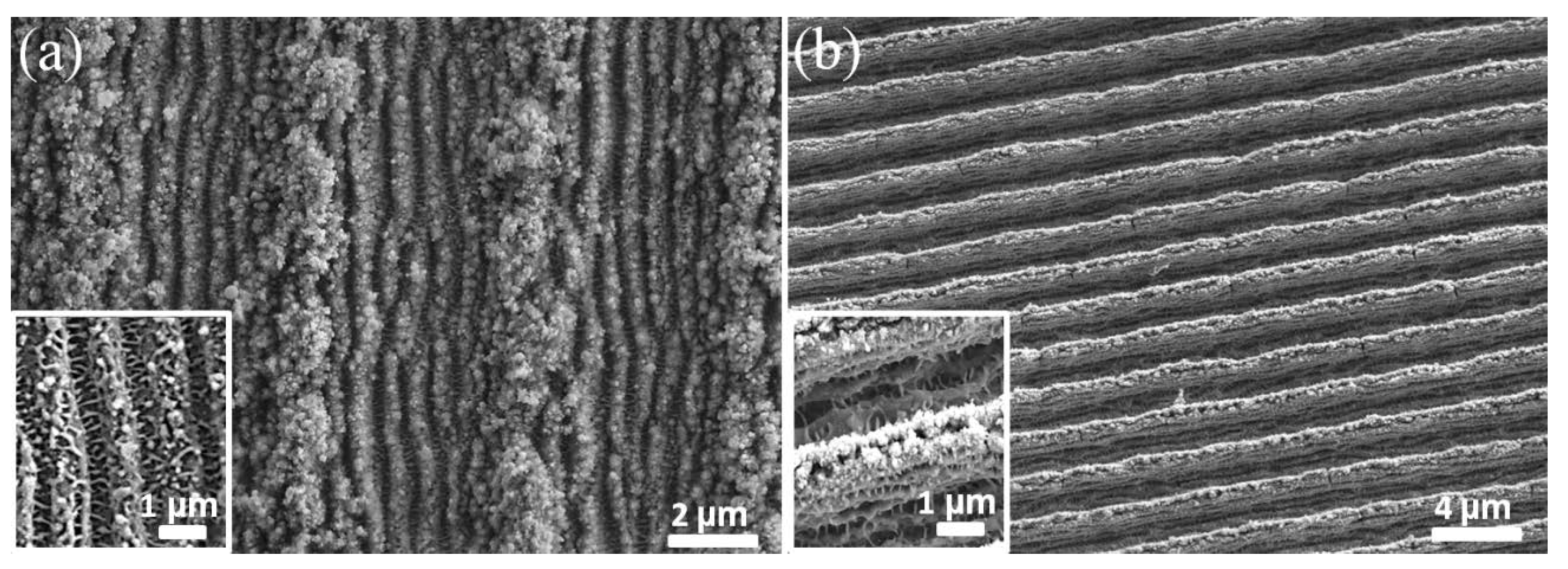

This first study permitted to determine the most adequate fluences for the fabrication of the biomimetic hierarchical surface structures. In this case, fluences of 7.5 mJ/cm² and 4 mJ/cm² for the 5 µm and 0.5 µm patterns were used, respectively. Scanning electron microscope images of resulting two-level hierarchical patterns fabricated using three different strategies are shown in

Figure 1.

Figure 1a,b shows a hexagonal hole-like structure with a 0.5 µm spatial period covered with a 5.0 µm hole-like structure. This strategy for fabricating hierarchical structures has been developed before as reported in [

27]. First, a single-scale pattern with 0.5 µm spatial period was applied on a silicon wafer as described in the experimental section. After the hard baking step, the patterned wafer was spin coated again and the exposure setup was changed to fabricate a 5 µm hole-like pattern. Finally, the wafer was baked, developed, rinsed and hard baked again to finish the second layer. It is visible in

Figure 1a that the 5.0 µm hole-like pattern dominates the surface topography. Only within the holes of the large-scale structure, the small-scale structure is visible. In addition, since two layers of the resist were applied, the 0.5 µm geometry can be observed below the large pattern.

In

Figure 1c, hierarchical patterns fabricated with a similar strategy are shown. In this case, the largest periodic pattern was fabricated first. Then, the pre-patterned substrate with the 5.0 µm structure was covered with a second layer of SU-8 which was later exposed to the interference patterns with the 0.5 µm spatial period geometry. As it can be seen in the image, the small-scale structure dominates the surface, since it covers the whole surface of the 5 µm pattern. The difference to a single-scale pattern is that the 0.5 µm pattern topography is now modulated with the 5 µm topography lying underneath. Consequently, the small-scale pattern is on different height levels at different lateral positions.

Finally, a second strategy for the production of multi-scale patterns was used. Here, a single layer of SU-8 was exposed first with the 5 µm spatial period setup and later with the 0.5 µm spatial period setup. Between the irradiation steps any other treatment was performed. As it can be seen in

Figure 1d, the small-scale structure of 0.5 µm spatial period is visible mainly at the regions corresponding to the interference minima positions of the larger 5.0 µm pattern. It is also evident from the image that both geometries are at the same level, since only one layer of the resist was applied. Compared to the previous described strategy, the small-scale structures dominates in this case, probably because the laser exposure dose which corresponds to the large patterns was not high enough to totally polymerized the used SU-8 layer.

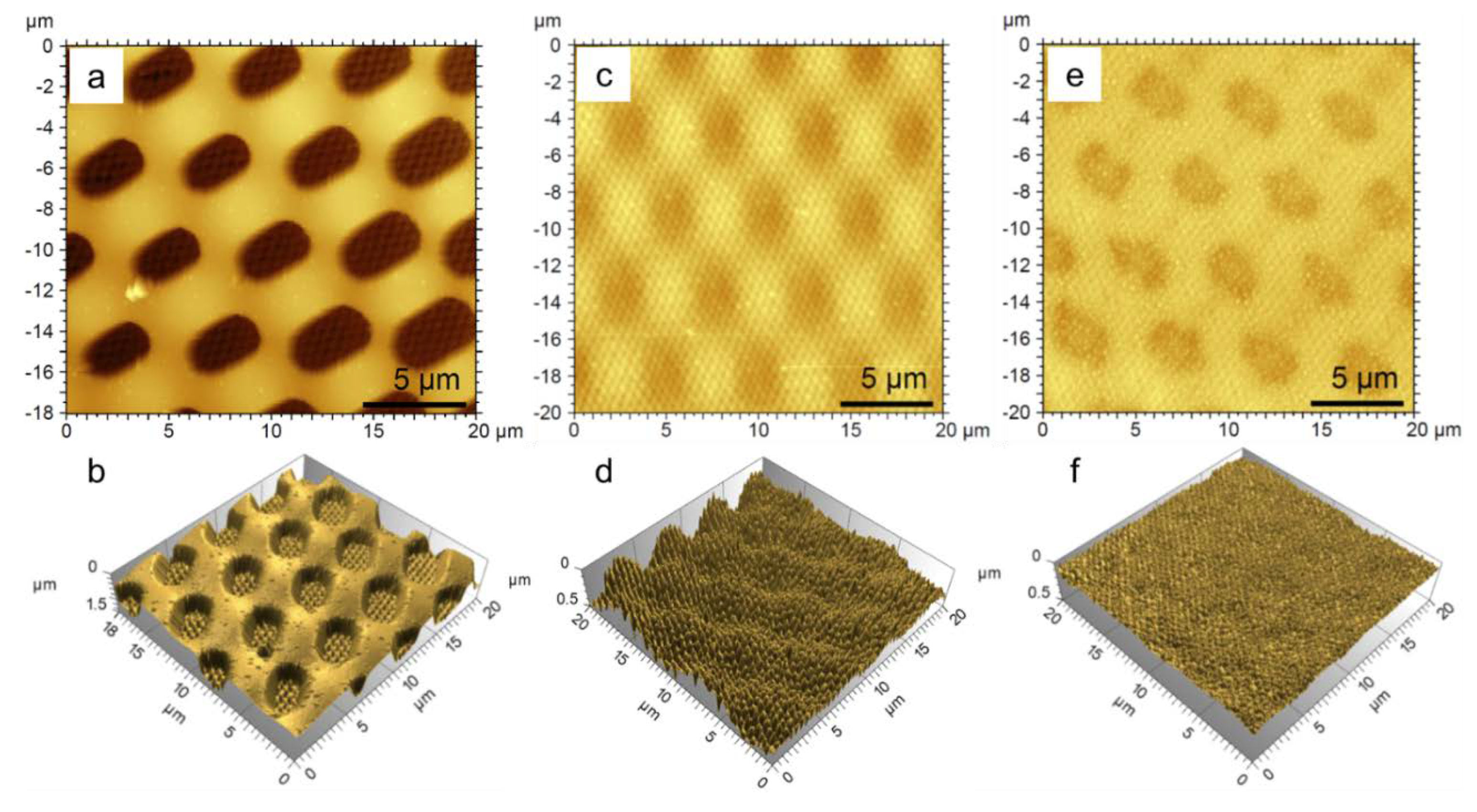

In addition to SEM images, the surface topography of the fabricated patterns was characterized using AFM. The results are shown in

Figure 2. From

Figure 2a,b, the structure height of the 5 µm on 0.5 µm hierarchical patterns using the first strategy can be measured (two layer of resist, lower layer with the smaller 0.5 µm hole-like pattern). The overall structure height is in average 0.83 ± 0.14 µm, which corresponds to the sum of the average heights of the structures in each single layer. Considering that each individual layer of the resist had a thickness of ~0.72 µm and that the height of the 5.0 µm pattern was 0.73 µm, it can be assumed either that in the case of the small pattern part of the material was partially polymerized at the interference minima positions or that the thickness of each layer was different. The figure also demonstrates that the large-scale pattern dominates the surface. The small-scale structure can be seen only in the holes of the large-scale structure and is located on a lower height level. The results on the surface topography of the strategy consisting on utilizing also two layers of resist, but with the lower layer corresponding to the larger 5.0 µm hole-like pattern are shown in

Figure 2c,d. In this case, the overall structure depth was 0.30 ± 0.07 µm, which is close to the height of the small-scale structure (0.18 ± 0.06 µm). As explained before, the differences can be attributed to the reason, that for the small-scaled pattern, the resist is also polymerized partially at the interference minima positions.

Finally,

Figure 2e,f shows AFM measurements of the hierarchical pattern fabricated in a single layer of the SU-8 resist. The average structure height was only 0.08 ± 0.01 µm. In this pattern, the 0.5 µm structure height was ~0.03 ± 0.01 µm while the structure height of the 5 µm pattern (measured as an envelope on top of the 0.5 µm structure) was 0.05 ± 0.01 µm. Thus, the overall height is the sum of the envelope of the large pattern and the height of the small-scale pattern. Nevertheless, the depth is not comparable to other structures obtained from this exposure setup. This process could be improved, by reducing the exposure dose used for both patterns.

3.2. Direct Laser Interference Patterning of Dielectric Polymers

A possible processing strategy in DLIP is to employ a pixel-wise structuring, that means making use of slightly focused interfering beams and irradiating areas with an interference area with dimensions ranging from tens to a few hundreds of µm [

25,

28,

29]. It has been also demonstrated that under specific conditions polymers can be structured by DLIP obtaining unusual ablation profiles [

28]. This is the case of transparent polycarbonate, which for low special periods and high laser fluence, shows a high amount of unselectively ablated material in the upper part of the treated DLIP pixel volume, creating a concave-like shape. If this phenomenon is controlled, hierarchical structures can be realized by correctly distributing the amount of energy on the material’s surface [

30].

Preliminary investigations aiming to explore the behavior of PC under high pulse-overlap structuring has been carried out by irradiating polycarbonate sheets with a UV (266 nm) laser, a spatial period of 2.0 µm and a pulse-overlap varying from 90% to 99.57%, with a beam size of ~20 µm. The results were analyzed by monitoring how the non-structured depth changes with the pulse-overlap, aiming to investigate the saturation depth of the method. The large-periodicity depth increases linearly with the number of laser pulses up to approximately 200 pulses, corresponding to 22 µm in depth. On the other hand, the height of the upper interference-generated structures remains constant after 100 pulses, reaching the value of about 1.2 µm, due to saturation effects associated with the plasma formation during the ablation process [

30].

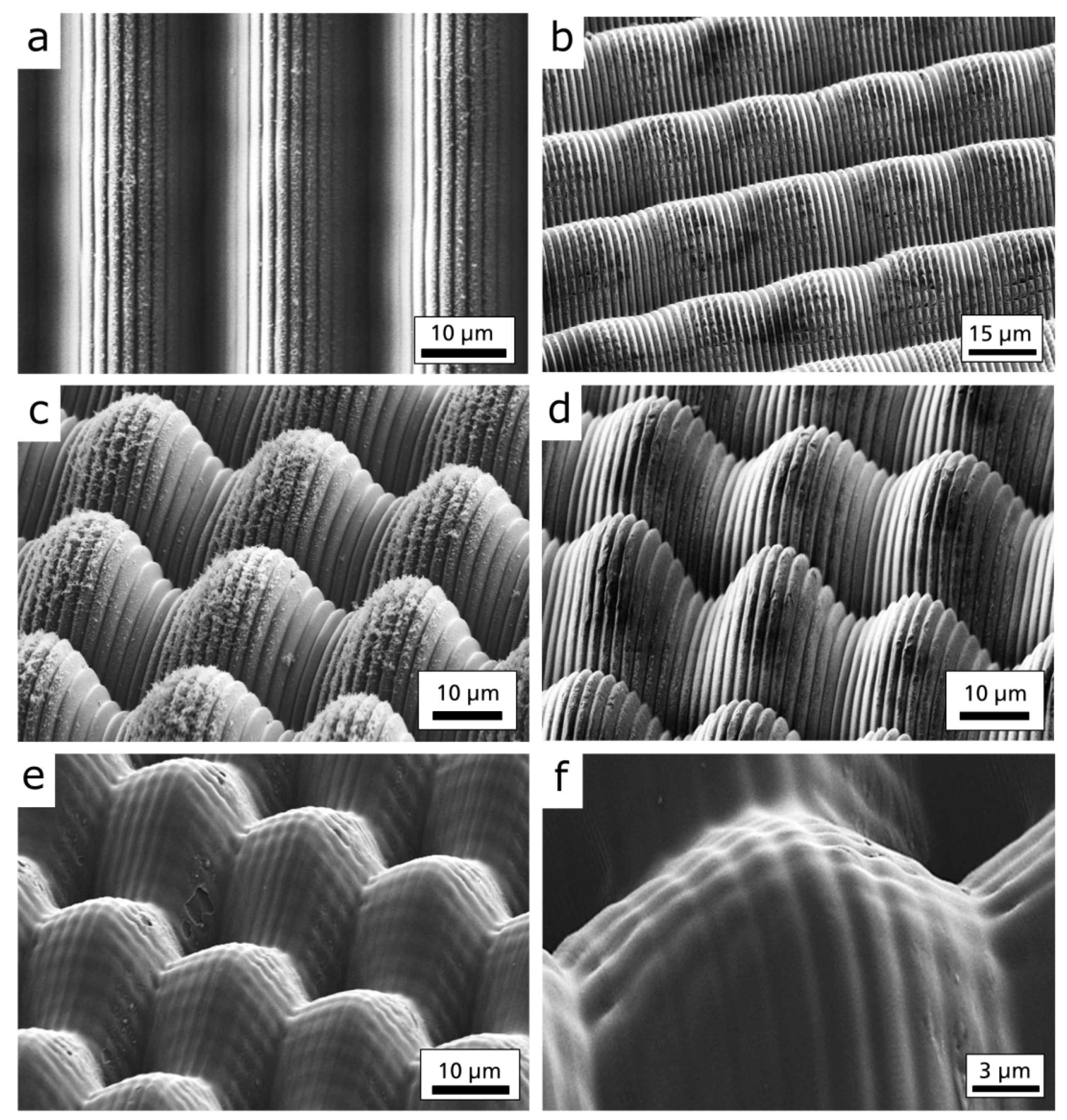

An example of the structures produced with this method is presented in

Figure 3a, where an overlap corresponding to 194 pulses per pixel area with a fluence of 1.63 J/cm² was employed (5.4 × 10

8 W/cm²) [

30]. As it can be noticed, the upper part of the structures consists of DLIP line-like structures, which due to the high overlap have a strong modulation of the depth in the horizontal direction (perpendicular to the pattern). The shape of these structures resembles the multi-level structure of the rice leaf, in which the grooves act as a major role in the anisotropic spreading of the water droplet along the lines.

If a second irradiation is performed after the first structuring on the 90° rotated sample, pillars-like structures with rectangular symmetry can be obtained and its dual-scale geometry can be varied through the laser fluence of the second process. An example of the results for a double-irradiation DLIP is presented in

Figure 3b–d, where the first structuring process has been carried out with 1.48 J/cm² and a structure period of 2 µm, with an overlap variation corresponding to 90 pulses per pixel. If the same pulse-overlap is employed after a 90° rotation, but using a fluence of 0.51 mJ/cm², the result is a hierarchical structure with lines perpendicularly orientated line-like structures (

Figure 3b). In this case, the second irradiation has erased the first DLIP-lines, but the large-period lines have not been strongly affected.

Figure 3c,d shows instead hierarchical structures consisting of lines on pillar-like structures, obtained with a second irradiation fluence of 1.63 mJ/cm². In this case the second irradiation has not only erased the first DLIP structures, but also ablated the large-periodicity structures, leaving pillars in the lower hierarchy level. It is worth noticing that the high-overlap structuring produces a high amount of polymeric particles which re-arrange and deposit on the pillars crests (where the Gaussian-beam distribution is lower,

Figure 3c). After an ultra-sound bath in ethanol (1 h) no particle is visible on the resulting structures (

Figure 3d).

Although the fabrication of hierarchical structures was possible, it is worth mentioning that through the double-irradiation method is not possible to create well-balanced structures (DLIP pillars on large pillars) within two irradiation steps. Another strategy to fabricate balanced hierarchical structures consists on performing the structuring process with a pulse-based method. This consists in moving the sample using the translational stages to a certain position and then irradiating it with a certain number of laser pulses. After that, the sample is moved in X and Y to a new position and this procedure is repeated until the surface is totally treated. Since the structuring of polycarbonate presents a Gaussian unselective ablation for every pulse, for high number of pulses this method can produce an alternation of valleys and heights in both directions and hierarchical structures can be fabricated in a single-step process. Choosing correctly the pixel distance and the number of pulses, hierarchical structures consisting of line-like structures on the top of pillars can be fabricated in a single step process, similar to the ones presented in

Figure 3d. Consequently, a second structuring process can be performed by irradiating orthogonally to the first DLIP lines with a low-overlap scan-based process, which can selectively ablate only this pattern, creating balanced pillars on the top of large pillars (

Figure 3e). The peak-to-valley height of the small-scale pillars is around 0.7 µm, sensibly lower than the one reached in the scan-based process (1.0 µm), leading to a smoother hierarchical topography (

Figure 3f). This behavior can be explained by taking into account that two processes concur in the creation of the pillars, while only a single process is sufficient to fabricate the upper line-like structures.

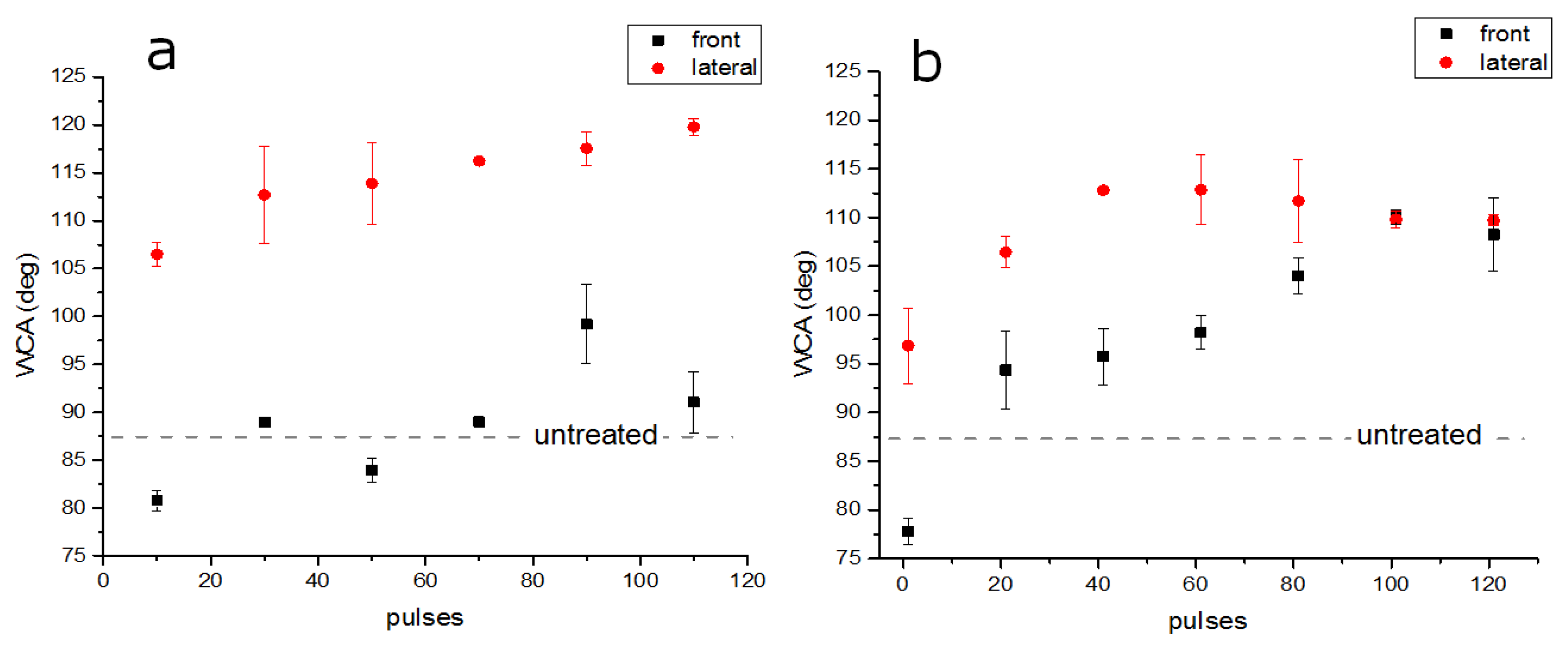

The change in the topography, structure geometry and orientation resulted to have an effect on the wettability response of the treated polycarbonate samples. For this purpose, the water contact angle (WCA) has been measured in orthogonal directions, corresponding to the direction parallel (front) and perpendicular (lateral) to the DLIP lines of the structures. The results, correlated with the pulse overlap of the structures, are presented in

Figure 4, reporting the results for the structures presented in

Figure 1d,e, respectively.

As can be seen, in the case of anisotropic structures (

Figure 4a) the WCA in both directions increase with the number of pulses, since the structure depth increases as well. However a strong difference (~20°) can be appreciated between the WCA values measured in the front and lateral direction. This can be ascribed to the strong anisotropy of the structures realized with this method. On the other hand, when the structures are sufficiently balanced in both directions, the hydrophobicity increases with the structure depth and the WCA values are comparable in both directions (

Figure 4b). As a result of the different high-rate irradiation processes, the structuring has made possible to change the polycarbonate wettability, increasing the static contact angle from 87.8° ± 0.4° to 117.6° ± 1.8°, without significantly change the surface chemistry [

30]. Moreover, due to the different structure geometries obtained, different wetting regimes and preferential wetting directions were possible.

3.3. Direct Laser Interference Patterning of Metallic Substrates

DLIP has shown to be an outstanding technology for the processing of metallic surfaces. In the past, this technology has been applied a wide number of materials including aluminum, stainless steel, copper and titanium between others using nanosecond and picosecond pulsed laser systems [

31,

32,

33,

34,

35].

Depending on the parameters used to irradiate the materials, very different surface topologies can be obtained. For instance, the pulse-to-pulse overlap has shown to have significant effect on the height of the produced patterns. This effect is shown exemplary in

Figure 5, for the case of line-like periodic arrays produced in ferritic steel and Ti6Al4V using high pulse-to-pulse overlaps in

Figure 5a,b, respectively. For the irradiation process, a picosecond pulsed laser system (10 ps) was used and the overlapping angle was varied to obtain 5.2 µm and 2.9 µm periods for

Figure 5a,b, respectively. For both materials, a pulse-to-pulse overlap value of 99% was used as well as a laser fluence of 1.42 J/cm². In addition to the very well defined periodic line-like patterns, additional repetitive features can be observed on both materials. The nanostructures mostly visible at the interference maxima positions of the DLIP structures consist of periodical features which can be classified as to different types of laser-induced periodic surface structures (LIPSS) [

36]. The features observed parallel to the DLIP structures correspond to low spatial frequency LIPSS (LSFL) with a spatial period of approximately 800 nm, which is similar to the used laser wavelength (1064 nm). In addition, also high spatial frequency LIPSS (HSFL) can be observed (see inset in

Figure 5a), but in this case they are perpendicular to the DLIP structures with a spatial period of approximately 200 nm. The same features could be observed in the irradiated Ti6Al4V (see inset in

Figure 5b) with similar feature sizes. The orientation of both LSFL and HSFL are related to the direction of the polarization of the laser radiation. While the LSFL are in general oriented perpendicular to the beam polarization, the HSFL are parallel oriented which is in good agreement with the literature [

37].

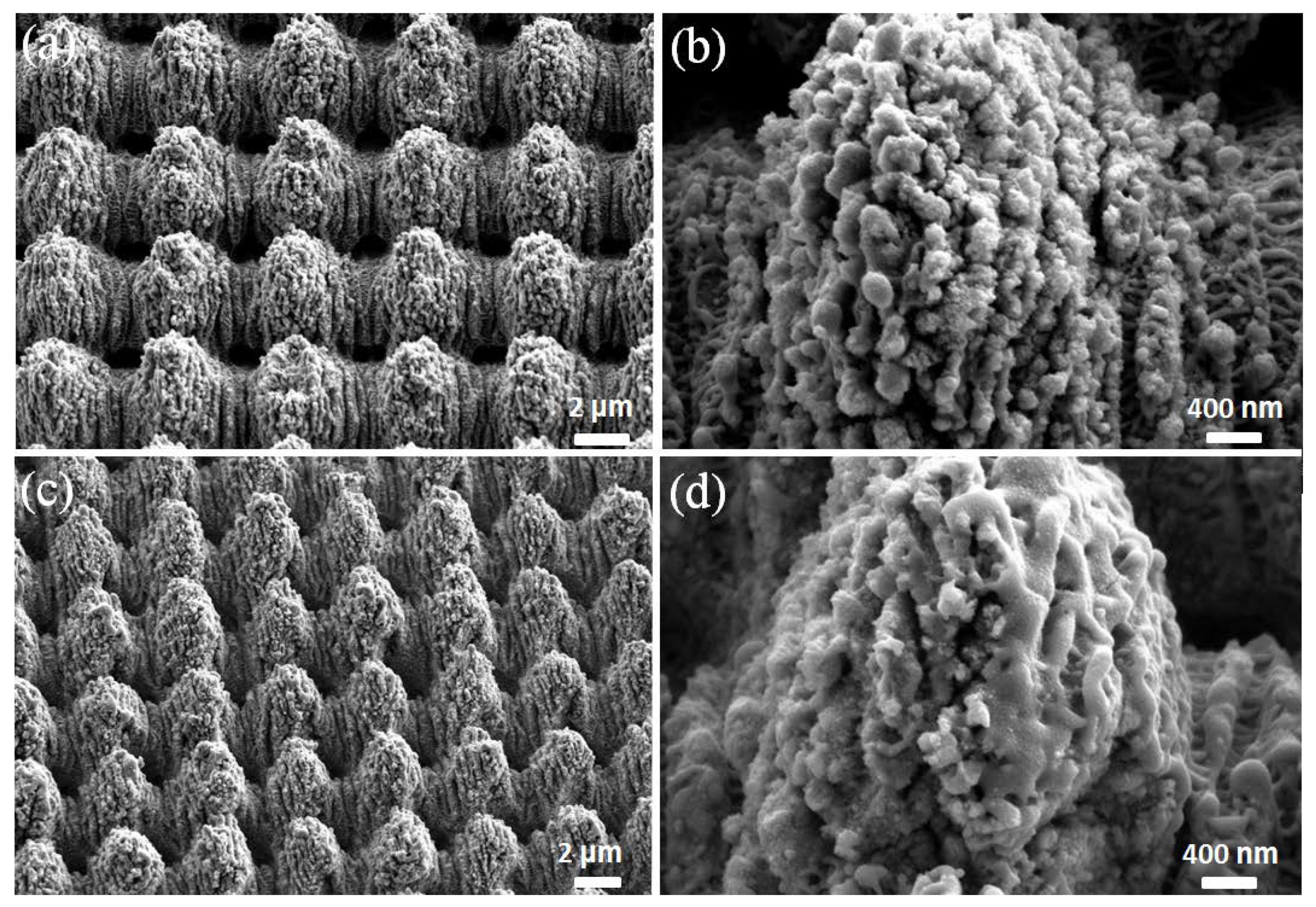

In addition to line-like patterns, using two-beam DLIP, also pillar like patterns can be produced, using the procedure previously described for the polymer materials. Examples of these structures are shown in

Figure 6 on ferritic steel and Ti6Al4V, using picosecond (10 ps) IR (1064 nm) radiation. Additional information about the methodology employed can be found in [

37]. Also in this case, the pulse-to-pulse overlap was set to 99%. The spatial period for both materials was 5.2 µm and a laser fluence of 1.42 J/cm² was used. The used spatial period is similar to the feature sizes observed in the Colocasia esculenta surface, with super-hydrophobic properties [

38]. The DLIP treatment at the mentioned conditions allowed achieving depths of 5.0 ± 0.5 µm and 4.2 ± 0.3 µm on ferritic steel and Ti6AlV4, respectively. Consequently, aspect ratios (ratio between structure depth and spatial period) of 0.96 and 0.80 were achieved, for a total cumulative fluence of 284 J/cm². The last value clearly shows the high amount of energy per unit of area that is required for fabricating high-aspect ratio patterns using ps-laser sources. However, they are comparable with other experiments in the literature for instance involving direct laser writing, where cumulated fluences up to ~400J/cm² have been reported for producing patterns with relative high aspect ratios (~1–2) [

15]. Similarly, cone-like or spike-like geometries (corresponding to LIPSS morphologies) with high aspect ratio also required of high cumulated fluence vales (e.g., 300 pulses with ~1 J/cm² = 300 J/cm², for steel) [

18]. Like in the line-like patterns, also LSFL and HSFL were observed, but because of their orientation it can be assumed that they were fabricated during the second irradiation step.

Finally, water contact angle (WCA) measurements of the produced pillar-like patterns were performed. In the case of the ferritic steel substrate, a WCA of 5° was measured directly after the laser process denoting a hydrophilic character of the surface. For the Ti6Al4V material, a similar behavior was observed, with a WCA of 30°. However, after 30 days, the WCA significantly increased for both surfaces up to 120° and 76° for the ferritic steel and Ti6Al4V, respectively. This increase has been observed not only for DLIP but also other laser based processing methods and has been explained in relation with an increasing amount of carbon in the processed surface when exposed in normal environment conditions [

39]. In other materials such stainless steel, contact angles over 160° could be obtained denoting also the importance of the material and thus the surface chemistry [

37].

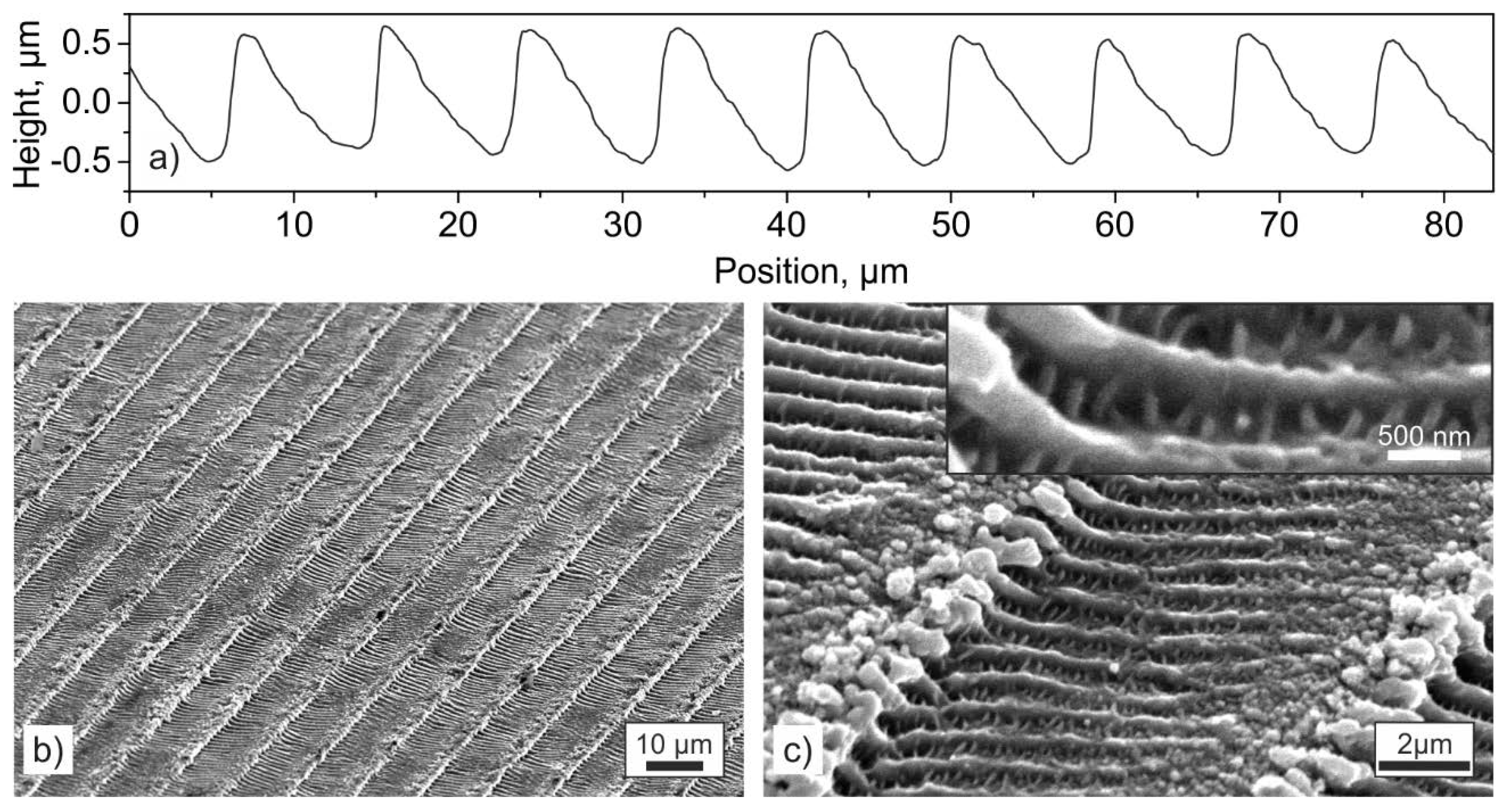

The relatively long depth of interference field provides the ability to structure not only rough surfaces but also the tilted surface that result in the structure with asymmetrical topography. An example of such structure formed by DLIP on ferritic steel is showed in

Figure 7b. The structure was formed by scanning the 2 beam interference spot of 83 µm in diameter across the tilted by 45° surface and keeping the overlap of 97% between the spots. The picosecond laser emitting pulses of 70 ps at 1 kHz repetition rate with the fluence of 0.87 J/cm² was applied in this case.

The topography cross-section of the fabricated structure measured with confocal microscope is plotted in

Figure 7a. It can be seen, that the resultant structure contains periodic line-like grooves formed of inclined planes. The plane inclination angle of 7° was measured (note that the scales in

Figure 7a are different). As can be seen from the magnified SEM image of the single inclined plane (

Figure 7c) the formation of the previously mentioned LIPSS oriented perpendicularly to the direction of the structure is observed on top of those planes. The measured period of these LIPSS was in this case ~886 ± 50 nm, which is close to the used laser wavelength of 1064 nm and therefore corresponds to the low spatial frequency LIPSS (LSFL). The high spatial frequency LIPSS (HSFL) with the period of 180 ± 30 nm was also found in between the grooves of the LSFL (see inset of

Figure 7c).

Taking into account all different scale structures formed in this case, the overall morphology of such multiscale-structure can be attributed to the hierarchical structure with asymmetrical topography. The resultant asymmetry of the topography alters the isotropy of the induced functional properties, conferring them directional properties, which, for example, can be used to transport water droplets and soft materials, control liquid spreading, provide directional adhesion and exhibit directional friction [

40].

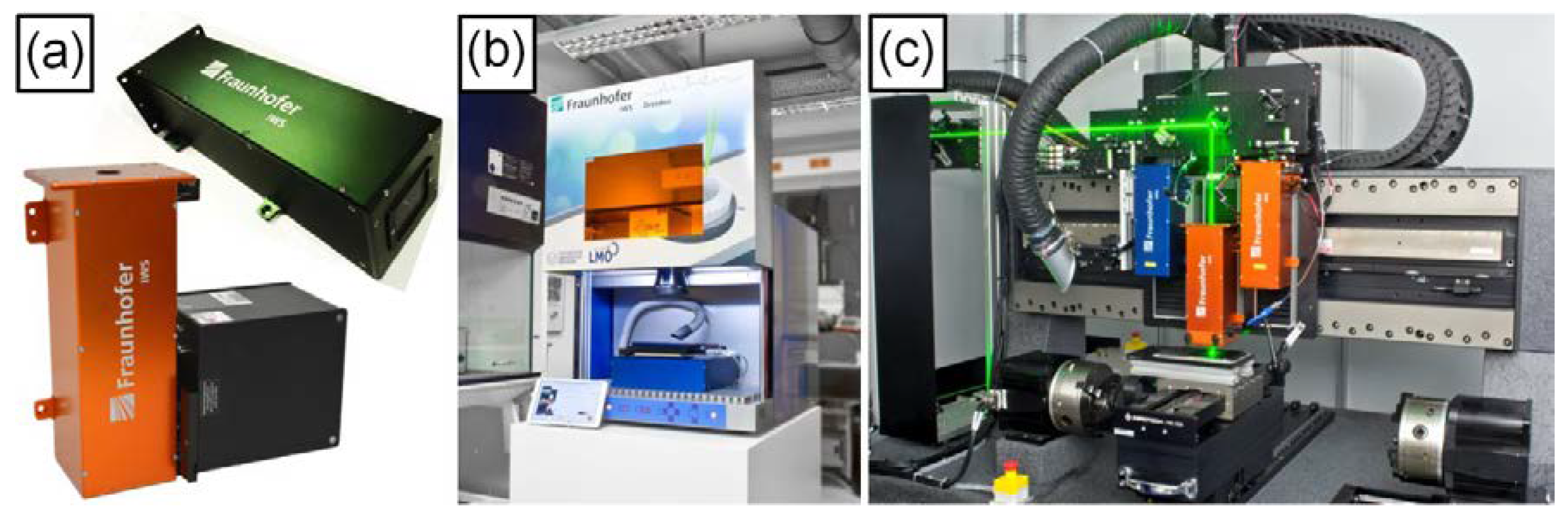

3.4. Industrial System for Direct Laser Interference Patterning

In order to meet particular requirements of industrial environments, different concepts for interference structuring have been developed (see

Figure 8a). The high-throughput DLIP module consist on optical system with a cylindrical telescope to expand the laser beam only in one direction, followed by an arrangement for beam splitting and alignment (patented by Fraunhofer IWS, Dresden). Later, a cylindrical lens is used for compressing the laser sub-beams, also only in one direction (details about this optical setup have been published elsewhere [

41]). In this way, the module realizes beam shaping to a long drawn line in the focused area, where the interference pattern is obtained. Forming the interfering beams into the shape of long lines has advantages in achieving maximum process speeds. For instance, using a Q-switched slab-type solid-state laser, throughputs up to ~1 m²/min have been already achieved [

25]. While conventional laser processing generates only one feature for each single pulse, DLIP allows the simultaneous fabrication of several hundred of features utilizing one single laser pulse. For example, in [

25] 682 features were produced per single laser spot. For producing this amount of features using DLW (for example at 300 kHz repetition rate), to achieve feature densities y of ~10

9 m

−2, a maximum processing speed of 0.04 m²/min can be achieved using DLW. These speeds are about 10 to 50 times slower, compared to high-speed DLIP. Clearly, the use of laser systems operating in the MHz range could solve this problem. However, linear speeds over the limits of galvanometer scanners are required (>10 m/s) and simultaneously, the spot diameter over the work piece must be at least 8–10 µm to be comparable with high-speed DLIP. Polygon-scanners are today capable to offer scanning speeds even over 100 m/s. However, their resolution is limited to 24–45 µm (for IR radiation) [

42].

Other DLIP optical modules that have been developed enable an individualized control of structure properties (e.g., topographical structure geometry and period). These modules permit an automatized variation of the spatial period and geometry, and thus can be used to fabricate decorative elements.

In recent years, various DLIP systems have been developed. In addition to the DLIP-µFAB system (first prototype developed in 2013), a DLIP galvanometer scanning system was also recently constructed (

Figure 8a). In this way, a significant improvement of the process speed due to the low inertia of the galvanometer mirrors compared to translational stages can be obtained. The scanner-based DLIP optical head permits to reach throughputs of several cm² per min (e.g., 12 and 60 cm²/min for 2 and 10 KHz repetition rates). Furthermore, these optical heads have been already integrated into prototype system (DLIP-cube) as shown in

Figure 8b. For the case when larger parts must be treated, a special DLIP system (developed at the TU-Dresden, Dresden, Germany) can be also used (

Figure 8c). This system permits to treat cylindrical parts up to 600 mm in length and 300 mm in diameter. The system can be equipped with both ns and ps-laser systems and similarly like in the DLIP-μFAB system, different optical heads can be utilized. Further information about the 3D-DLIP system has been published elsewhere [

43].