Cavity Design in Woodpile Based 3D Photonic Crystals

Abstract

1. Introduction

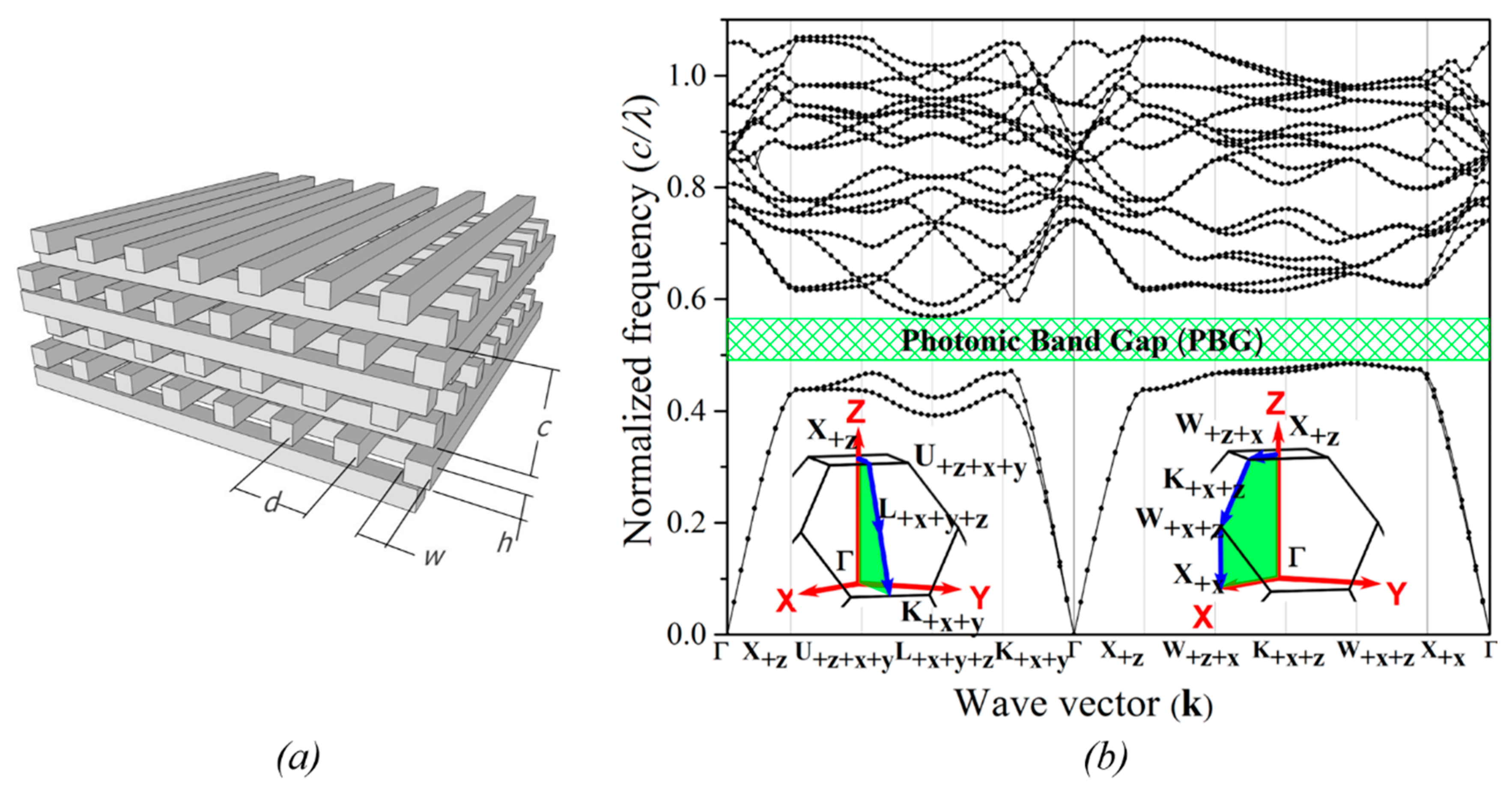

2. Calculation Methods

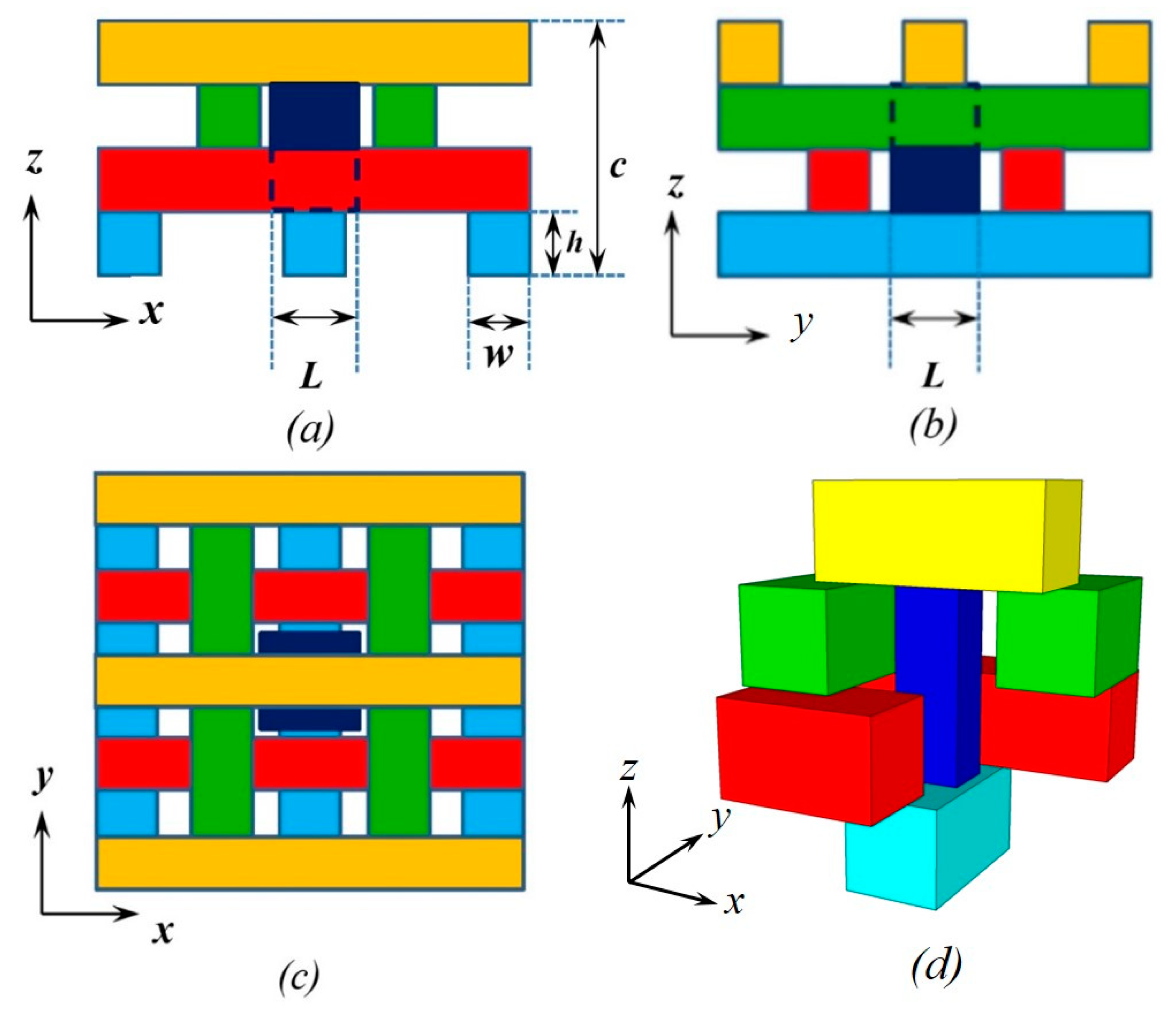

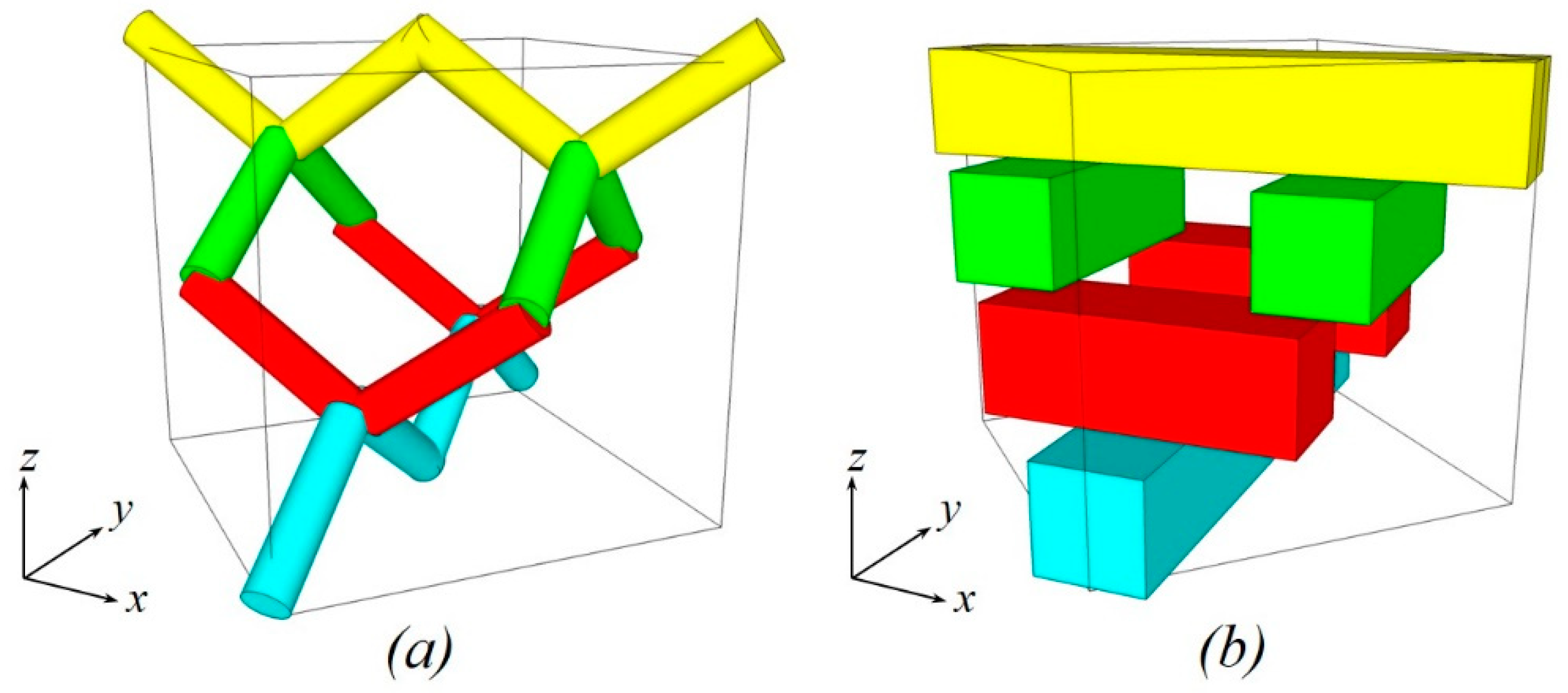

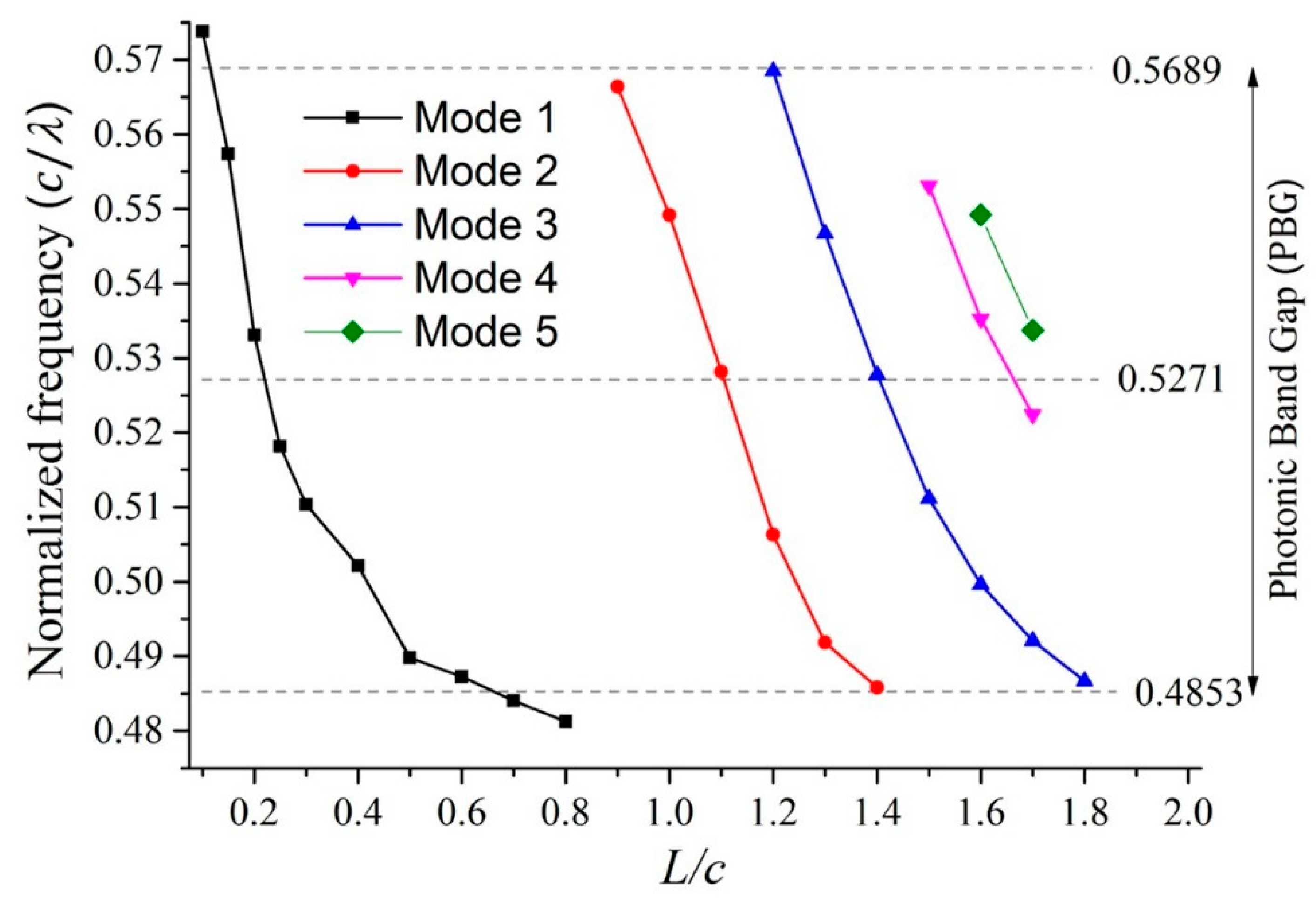

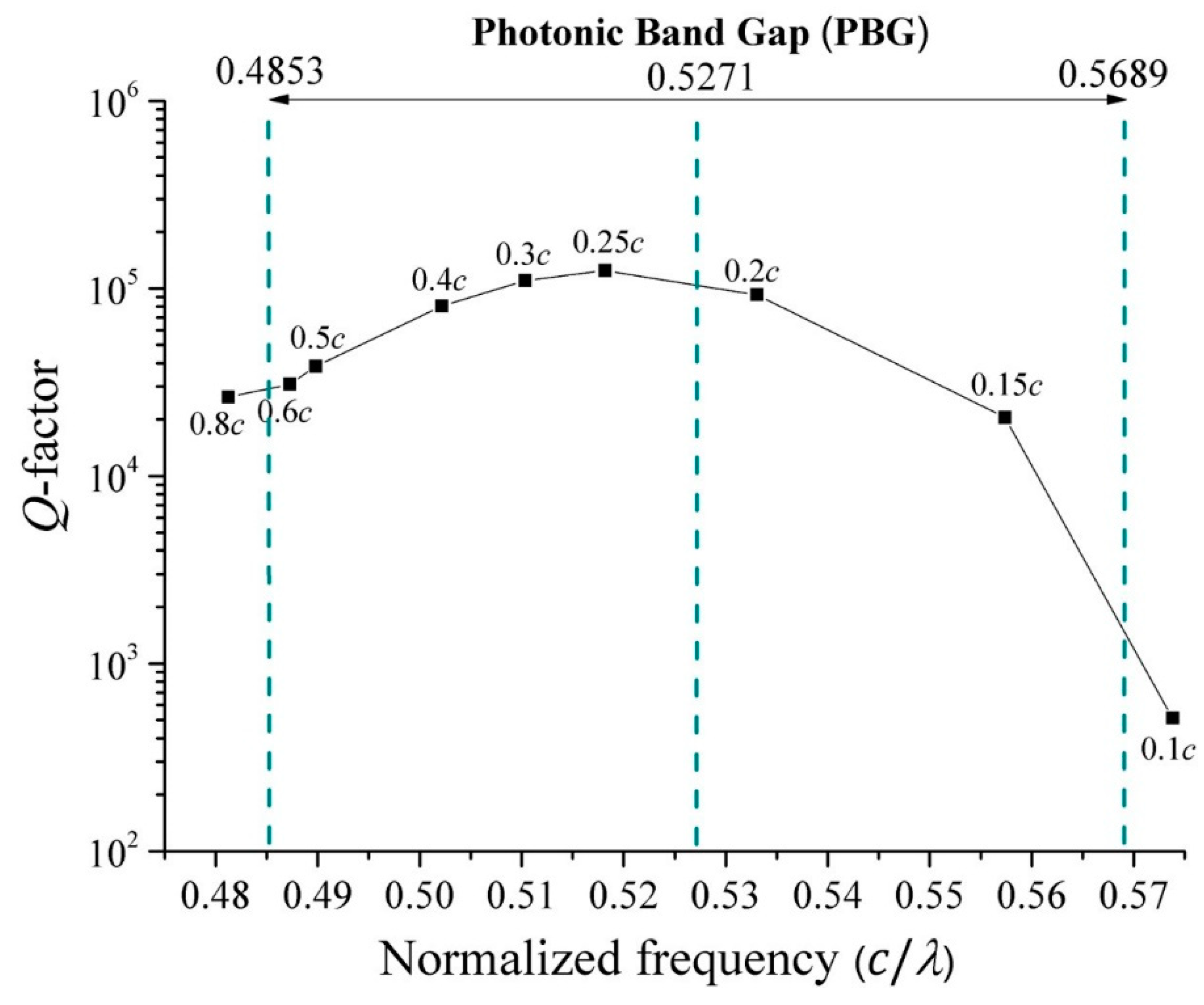

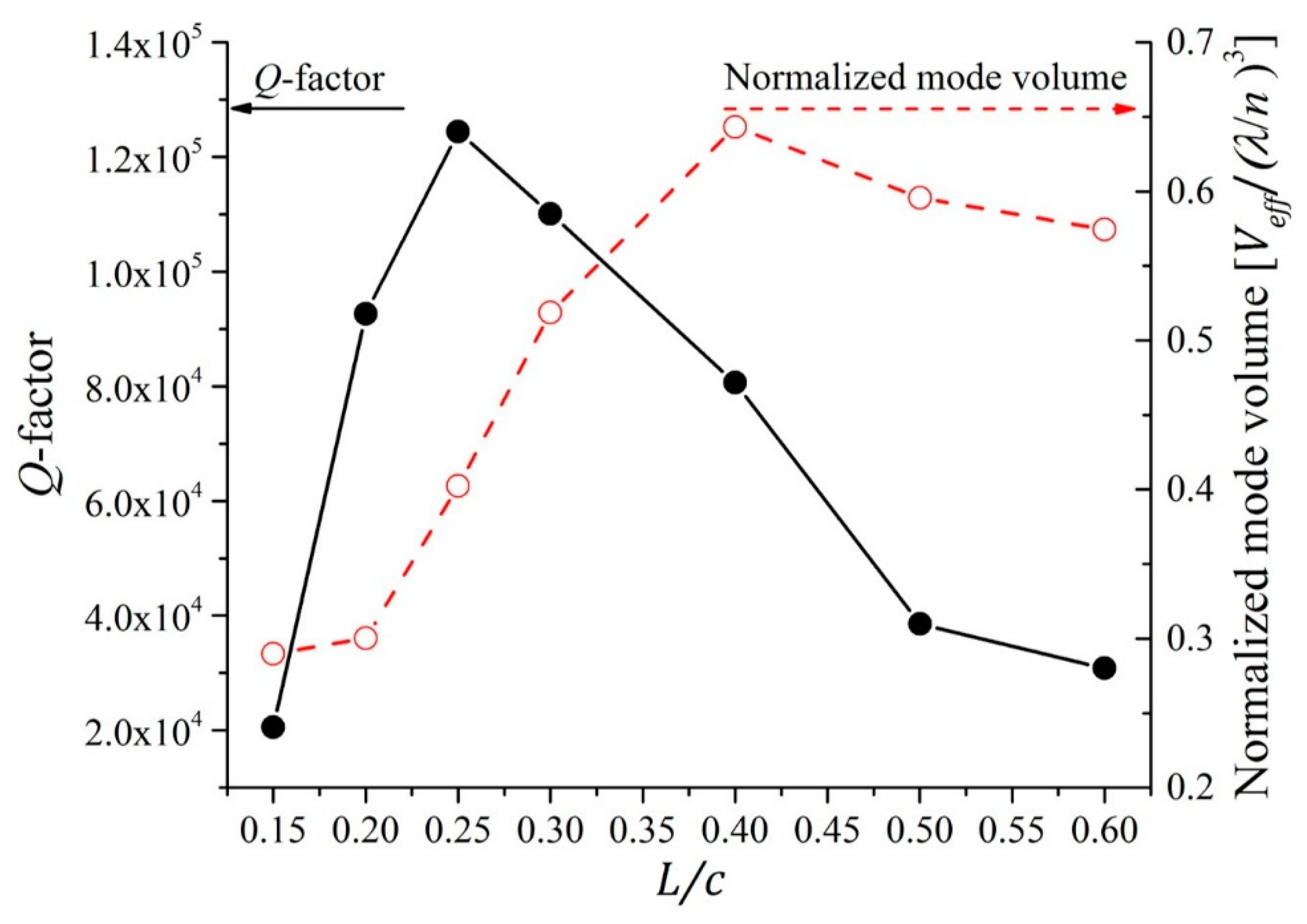

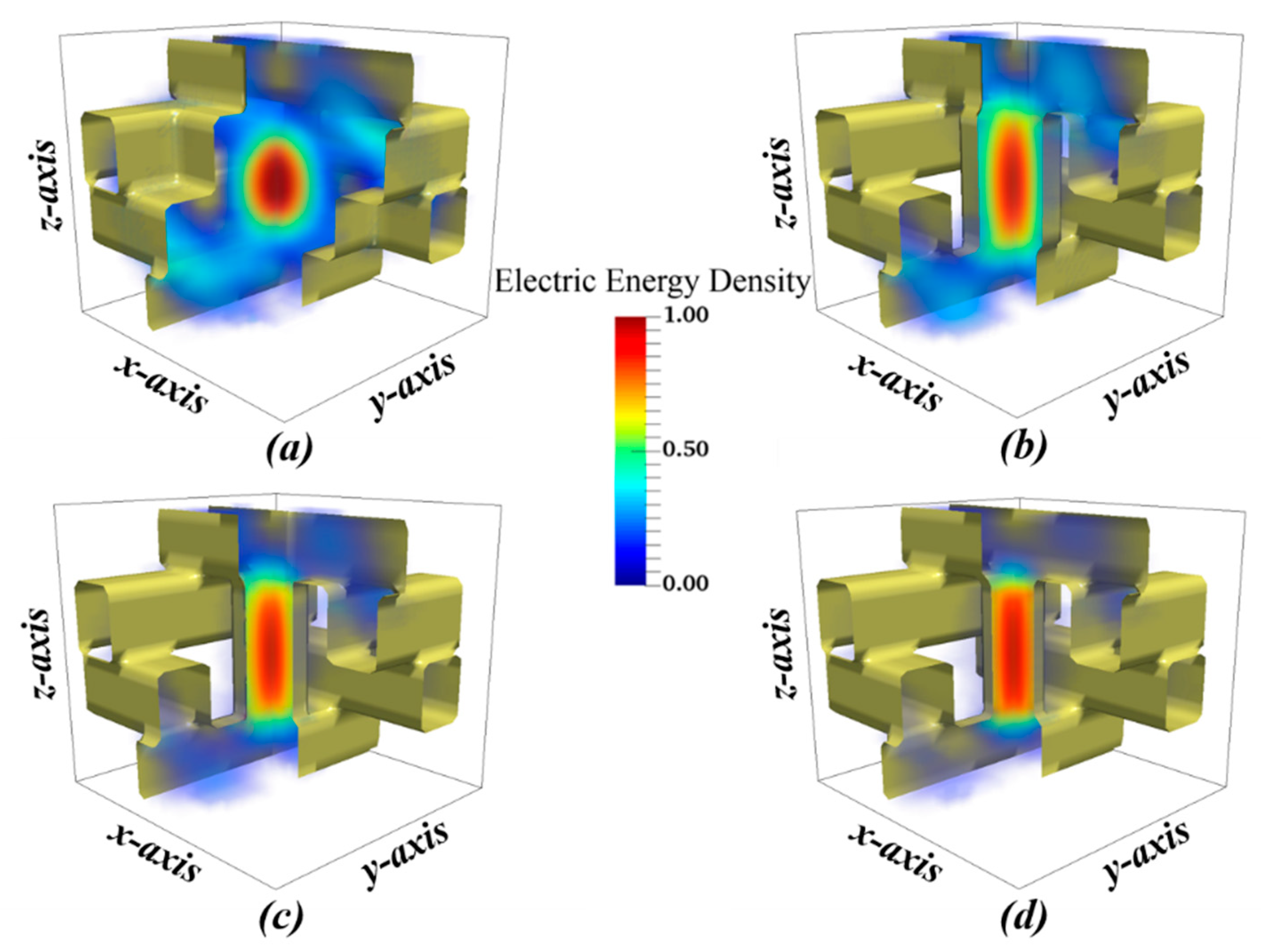

3. Woodpile Parameters and Cavity Design

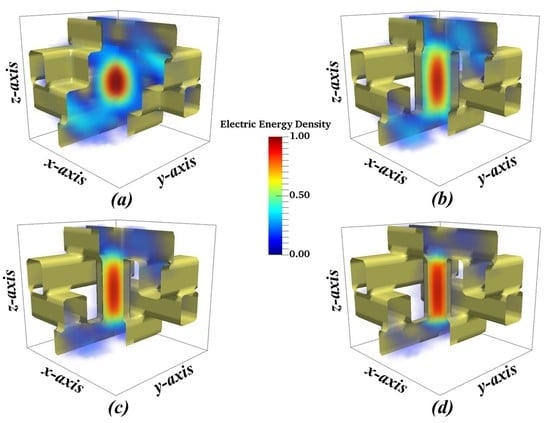

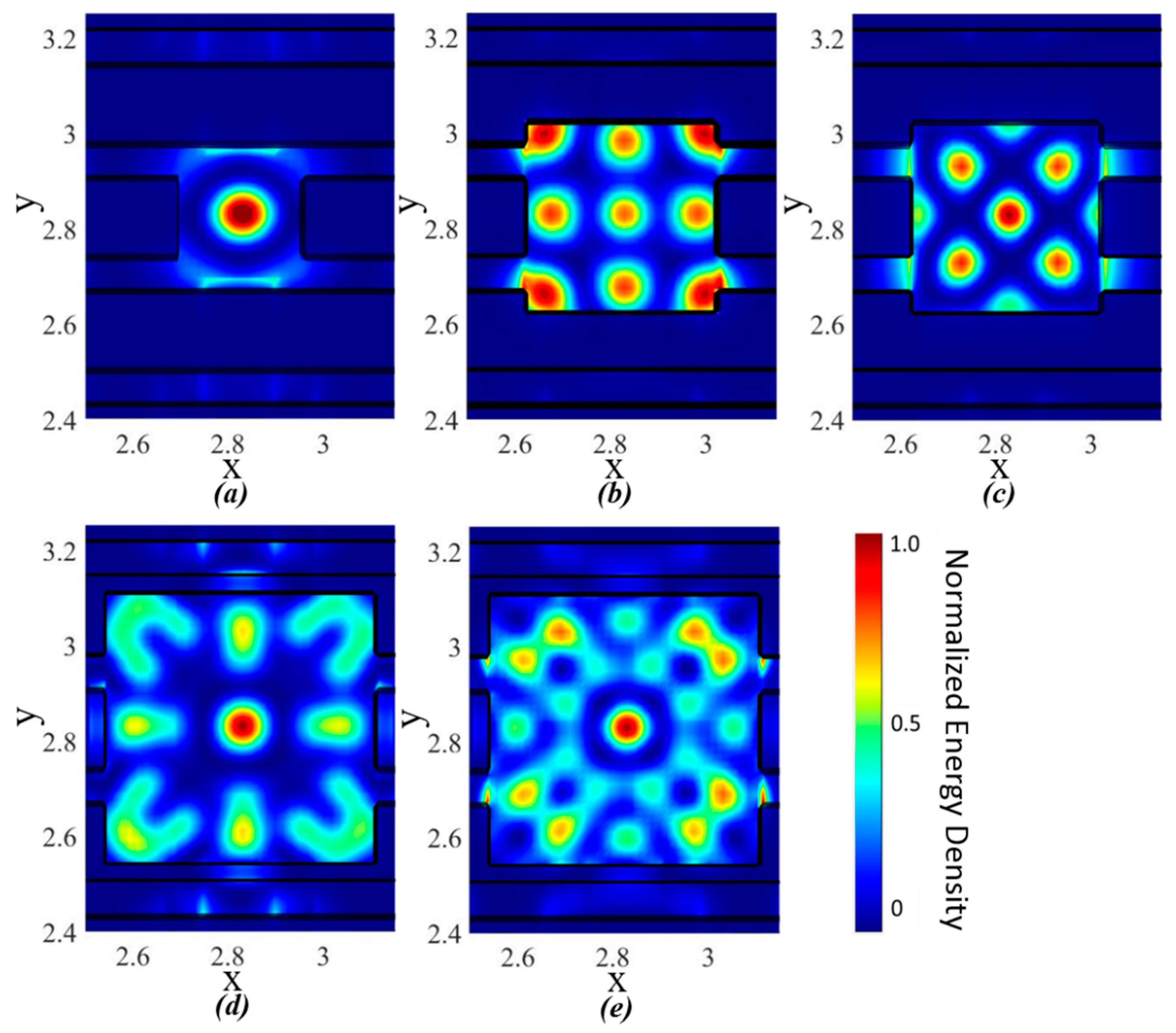

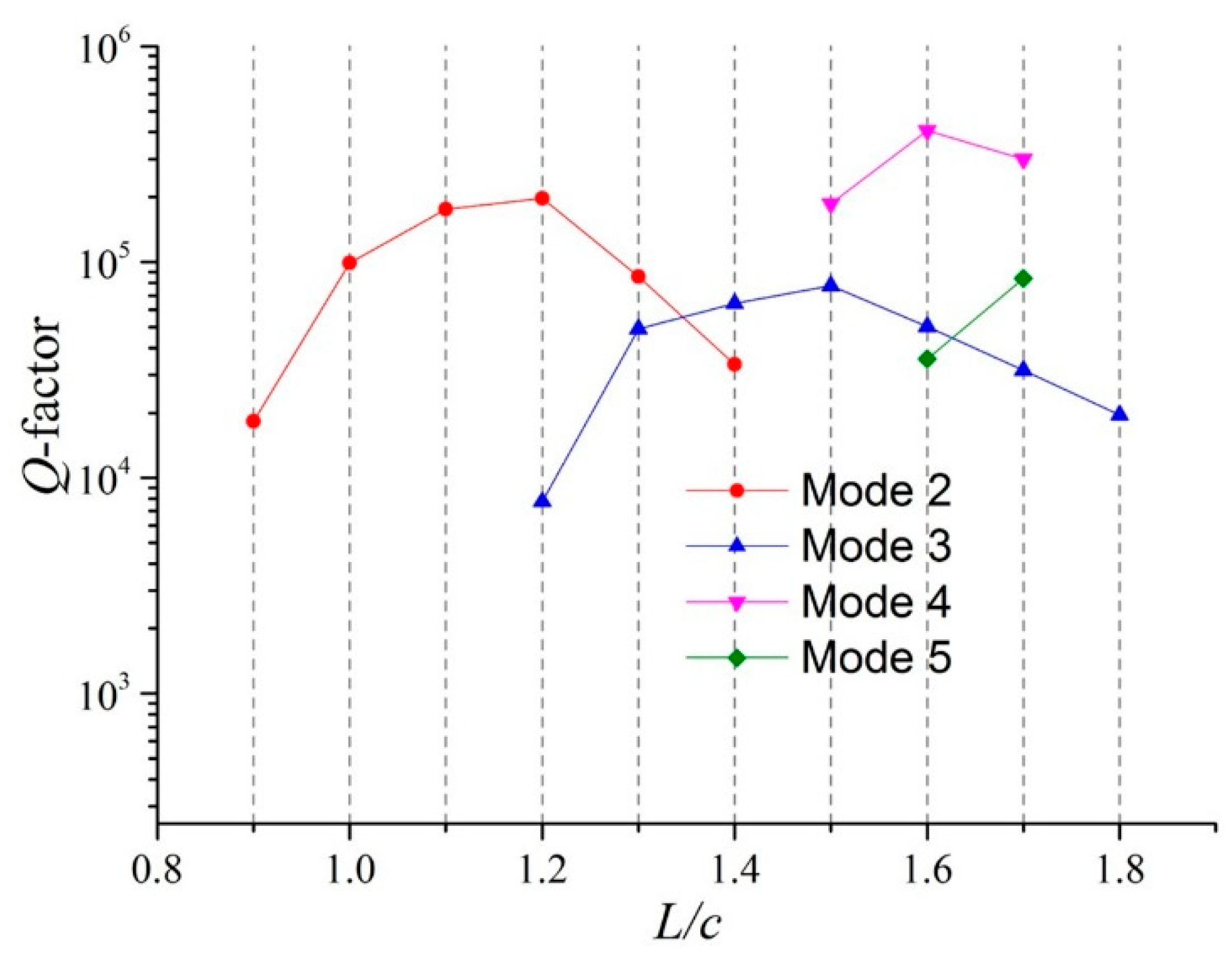

4. Numerical Results

5. Discussion and Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Joannopoulos, J.D.; Johnson, S.G.; Winn, J.N.; Meade, R.D. Photonic Crystals: Molding the Flow of Light, 2nd ed.; Princeton University Press: Princeton, NJ, USA, 2008. [Google Scholar]

- Yablonovitch, E. Inhibited Spontaneous Emission in Solid-State Physics and Electronics. Phys. Rev. Lett. 1987, 58, 2059–2062. [Google Scholar] [CrossRef] [PubMed]

- John, S. Strong localization of photons in certain disordered dielectric superlattices. Phys. Rev. Lett. 1987, 58, 2486–2489. [Google Scholar] [CrossRef] [PubMed]

- Yablonovitch, E.; Gmitter, T.J. Photonic band structure: The face-centered-cubic case. Phys. Rev. Lett. 1989, 63, 1950–1953. [Google Scholar] [CrossRef] [PubMed]

- Datta, S.; Chan, C.T.; Ho, K.M.; Soukoulis, C.M. Photonic Band Gaps in Experimentally Realizable Periodic Dielectric Structures. Europhys. Lett. 1991, 16, 563–568. [Google Scholar]

- Datta, S.; Chan, C.T.; Ho, K.M.; Soukoulis, C.M. Photonic bandgaps in periodic dielectric structures: The scalar-wave approximation. Phys. Rev. B 1992, 46, 10650. [Google Scholar] [CrossRef]

- Chan, C.T.; Datta, S.; Ho, K.M.; Soukoulis, C.M. A7 structure: A family of photonic crystals. Phys. Rev. B 1994, 50, 1988–1991. [Google Scholar] [CrossRef]

- Maldovan, M.; Thomas, E.L. Diamond-structured photonic crystals. Nat. Mater. 2004, 3, 593–600. [Google Scholar] [CrossRef] [PubMed]

- Yablonovitch, E.; Gmitter, T.J.; Leung, K.M. Photonic band structure: The face-centered-cubic case employing nonspherical atoms. Phys. Rev. Lett. 1991, 67, 2295–2298. [Google Scholar] [CrossRef] [PubMed]

- Ho, K.M.; Chan, C.T.; Soukoulis, C.M.; Biswas, R.; Sigalas, M. Photonic band gaps in three dimensions: New layer-by-layer periodic structures. Solid State Commun. 1994, 89, 413–416. [Google Scholar] [CrossRef]

- Chutinan, A.; John, S. Light localization for broadband integrated optics in three dimensions. Phys. Rev. B 2005, 72, 161316(R). [Google Scholar] [CrossRef]

- Chutinan, A.; John, S. 3+1 dimensional integrated optics with localized light in a photonic band gap. Opt. Express 2006, 14, 1266. [Google Scholar] [CrossRef] [PubMed]

- Ishizaki, K.; Koumura, M.; Suzuki, K.; Gondaira, K.; Noda, S. Realization of three-dimensional guiding of photons in photonic crystals. Nat. Photonics 2013, 7, 133–137. [Google Scholar] [CrossRef]

- Gondaira, K.; Ishizaki, K.; Kitano, K.; Asano, T.; Noda, S. Control of radiation angle by introducing symmetric end structure to oblique waveguide in three-dimensional photonic crystal. Opt. Express 2016, 24, 13518. [Google Scholar] [CrossRef] [PubMed]

- Braun, P.V.; Rinne, S.A.; García-Santamaría, F. Introducing defects in 3D photonic crystals: State of the art. Adv. Mater. 2006, 18, 2665–2678. [Google Scholar] [CrossRef]

- Okano, M.; Chutinan, A.; Noda, S. Analysis and design of single-defect cavities in a three-dimensional photonic crystal. Phys. Rev. B 2002, 66, 165211. [Google Scholar] [CrossRef]

- Ho, Y.-L.D.; Ivanov, P.S.; Engin, E.; Nicol, M.F.J.; Taverne, M.P.C.; Cryan, M.J.; Craddock, I.J.; Railton, C.J.; Rarity, J.G. FDTD Simulation of Inverse Three-Dimensional Face-centered Cubic Photonic Crystal Cavities. IEEE J. Quantum Electron 2011, 47, 1480–1492. [Google Scholar] [CrossRef]

- Imagawa, S.; Edagawa, K.; Notomi, M. Strong light confinement in a photonic amorphous diamond structure. Appl. Phys. Lett. 2012, 100, 151103. [Google Scholar] [CrossRef]

- Tajiri, T.; Takahashi, S.; Tandaechanurat, A.; Iwamoto, S.; Arakawa, Y. Design of a three-dimensional photonic crystal nanocavity in a <110>-layered diamond structure. Jpn. J. Appl. Phys. 2014, 53, 04EG08. [Google Scholar] [CrossRef]

- Taverne, M.P.C.; Ho, Y.-L.D.; Rarity, J.G. Investigation of defect cavities formed in three-dimensional woodpile photonic crystals. J. Opt. Soc. Am. B 2015, 32, 639. [Google Scholar] [CrossRef]

- Taverne, M.P.C.; Ho, Y.-L.D.; Zheng, X.; Liu, S.; Chen, L.-F.; Lopez-Garcia, M.; Rarity, J.G. Investigation of Defect Cavities Formed in Inverse Three-Dimensional Rod-Connected Diamond Photonic Crystals. Europhys. Lett. 2016, 116, 64007. [Google Scholar] [CrossRef]

- Woldering, L.A.; Mosk, A.P.; Vos, W.L. Design of a three-dimensional photonic band gap cavity in a diamondlike inverse woodpile photonic crystal. Phys. Rev. B 2014, 90. [Google Scholar] [CrossRef]

- Nomura, M.; Iwamoto, S.; Kumagai, N.; Arakawa, Y. Ultralow threshold photonic crystal nanocavity laser. Phys. E 2008, 40, 1800–1803. [Google Scholar] [CrossRef]

- Matsuo, S.; Shinya, A.; Kakitsuka, T.; Nozaki, K.; Segawa, T.; Sato, T.; Kawaguchi, Y.; Notomi, M. High-speed ultracompact buried heterostructure photonic-crystal laser with 13 fJ of energy consumed per bit transmitted. Nat. Photonics 2010, 4, 648–654. [Google Scholar] [CrossRef]

- Cao, D.; Tandaechanurat, A.; Nakayama, S.; Ishida, S.; Iwamoto, S.; Arakawa, Y. Silicon-based three-dimensional photonic crystal nanocavity laser with InAs quantum-dot gain. Appl. Phys. Lett. 2012, 101, 191107. [Google Scholar] [CrossRef]

- Lončar, M.; Yoshie, T.; Scherer, A.; Gogna, P.; Qiu, Y. Low threshold photonic crystal laser. Appl. Phys. Lett. 2002, 81, 2680–2682. [Google Scholar] [CrossRef]

- Loncar, M.; Scherer, A.; Qiu, Y.M. Photonic crystal laser sources for chemical detection. Appl. Phys. Lett. 2003, 82, 4648–4650. [Google Scholar] [CrossRef]

- Chow, E.; Grot, A.; Mirkarimi, L.W.; Sigalas, M.; Girolami, G. Ultracompact biochemical sensor built with two-dimensional photonic crystal microcavity. Opt. Lett. 2004, 29, 1093. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.R.; Fauchet, P.M. Nanoscale microcavity sensor for single particle detection. Opt. Lett. 2007, 32, 3284. [Google Scholar] [CrossRef] [PubMed]

- Baba, T. Photonic Crystal Nanolaser Biosensors. MRS Commun. 2015, 5, 1. [Google Scholar] [CrossRef]

- Johnson, P.M.; Koenderink, A.F.; Vos, W.L. Ultrafast switching of photonic density of states in photonic crystals. Phys. Rev. B 2002, 66, 081102. [Google Scholar] [CrossRef]

- Nozaki, K.; Tanabe, T.; Shinya, A.; Matsuo, S.; Sato, T.; Taniyama, H.; Notomi, M. Sub-femtojoule all-optical switching using a photonic crystal nanocavity. Nat. Photonics 2010, 4, 477–483. [Google Scholar] [CrossRef]

- Volz, T.; Reinhard, A.; Winger, M.; Badolato, A.; Hennessy, K.J.; Hu, E.L.; Imamoğlu, A. Ultrafast all-optical switching by single photons. Nat. Photonics 2012, 6, 605–611. [Google Scholar] [CrossRef]

- Chen, W.; Beck, K.M.; Bücker, R.; Gullans, M.; Lukin, M.D.; Tanji-Suzuki, H.; Vuletic, V. All-optical switch and transistor gated by one stored photon. Science 2013, 341, 768–770. [Google Scholar] [CrossRef] [PubMed]

- Fushman, I.; Englund, D.; Faraon, A.; Stoltz, N.; Petroff, P.; Vučković, J. Controlled phase shifts with a single quantum dot. Science 2008, 320, 769–772. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.-F.; Gao, J.; Zou, X.-B.; McMillan, J.F.; Yang, X.; Chen, Y.-L.; Han, Z.-F.; Guo, G.-C.; Wong, C.W. Coupled quantum electrodynamics in photonic crystal cavities towards controlled phase gate operations. New J. Phys. 2008, 10, 123013. [Google Scholar] [CrossRef]

- Young, A.; Hu, C.Y.; Marseglia, L.; Harrison, J.P.; O’Brien, J.L.; Rarity, J.G. Cavity enhanced spin measurement of the ground state spin of an NV center in diamond. New J. Phys. 2009, 11, 013007. [Google Scholar] [CrossRef]

- Lodahl, P.; Mahmoodian, S.; Stobbe, S. Interfacing single photons and single quantum dots with photonic nanostructures. Rev. Mod. Phys. 2015, 87, 347–400. [Google Scholar] [CrossRef]

- Sánchez, A.; Porta, A.V.; Orozco, S. Photonic band-gap and defect modes of a one-dimensional photonic crystal under localized compression. J. Appl. Phys. 2017, 121. [Google Scholar] [CrossRef]

- Chen, C.-P.; Tetsuo, A.; Stephen, G.; Trevor, M.B.; Phillip, S. A Novel Photonic Crystal Band-pass Filter Using Degenerate Modes of A Point-defect Microcavity for Terahertz Communication Systems. Microw. Opt. Technol. Lett. 2014, 56, 792–797. [Google Scholar] [CrossRef]

- Chen, C.; Li, X.; Li, H.; Xu, K.; Wu, J.; Lin, J. Bandpass filters based on phase-shifted photonic crystal waveguide gratings. Opt. Soc. Am. 2007, 15, 237–241. [Google Scholar] [CrossRef]

- Costa, R.; Melloni, A.; Martinelli, M. Bandpass resonant filters in photonic-crystal waveguides. IEEE Photonics Technol. Lett. 2003, 15, 401–403. [Google Scholar] [CrossRef]

- Maruo, S.; Nakamura, O.; Kawata, S. Three-dimensional microfabrication with two-photon-absorbed photopolymerization. Opt. Lett. 1997, 22, 132. [Google Scholar] [CrossRef] [PubMed]

- Hermatschweiler, M.; Ledermann, A.; Ozin, G.A.; Wegener, M.; von Freymann, G. Fabrication of Silicon Inverse Woodpile Photonic Crystals. Adv. Funct. Mater. 2007, 17, 2273–2277. [Google Scholar] [CrossRef]

- T´etreault, N.; von Freymann, G.; Deubel, M.; Hermatschweiler, M.; P´erez-Willard, F.; John, S.; Wegener, M.; Ozin, G.A. New route to three-dimensional photonic bandgap materials: Silicon double inversion of polymer templates. Adv. Mater. 2006, 18, 457–460. [Google Scholar]

- Staude, I.; Thiel, M.; Essig, S.; Wolff, C.; Busch, K.; von Freymann, G.; Wegener, M. Fabrication and characterization of silicon woodpile photonic crystals with a complete bandgap at telecom wavelengths. Opt. Lett. 2010, 35, 1094. [Google Scholar] [CrossRef] [PubMed]

- Staude, I.; von Freymann, G.; Essig, S.; Busch, K.; Wegener, M. Waveguides in three-dimensional photonicbandgap materials by direct laser writing and silicon double inversion. Opt. Lett. 2011, 36, 67. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.-F.; Taverne, M.P.C.; Zheng, X.; Oulton, R.; Lin, J.-D.; Lopez-Garcia, M.; Ho, Y.-L.D.; Rarity, J.G. Evidence of Near-Infrared Partial Photonic Bandgap in Polymeric Rod-connected Diamond Structure. Opt. Express 2015, 23, 26565. [Google Scholar] [CrossRef] [PubMed]

- Ishizaki, K.; Noda, S. Manipulation of photons at the surface of three-dimensional photonic crystals. Nature 2009, 460, 367–370. [Google Scholar] [CrossRef] [PubMed]

- Ogawa, S.; Imada, M.; Yoshimoto, S.; Okano, M.; Noda, S. Control of light emission by 3D photonic crystals. Science 2004, 305, 227–229. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Huang, Y. Mode characteristics and directional emission for square microcavity lasers. J. Phys. D Appl. Phys. 2016, 49, 253001. [Google Scholar] [CrossRef]

- Johnson, S.G.; Joannopoulos, J. Block-iterative frequency domain methods for Maxwell’s equations in a planewave basis. Opt. Express 2001, 8, 173. [Google Scholar] [CrossRef] [PubMed]

- Railton, C.; Hilton, G. The analysis of medium-sized arrays of complex elements using a combination of FDTD and reaction matching. IEEE Trans. Antennas Propag. 1999, 47, 707. [Google Scholar] [CrossRef]

- Mandelshtam, V.A.; Taylor, H.S. Harmonic inversion of time signals and its applications. J. Chem. Phys. 1997, 107, 6756–6769. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, X.; Taverne, M.P.C.; Ho, Y.-L.D.; Rarity, J.G. Cavity Design in Woodpile Based 3D Photonic Crystals. Appl. Sci. 2018, 8, 1087. https://doi.org/10.3390/app8071087

Zheng X, Taverne MPC, Ho Y-LD, Rarity JG. Cavity Design in Woodpile Based 3D Photonic Crystals. Applied Sciences. 2018; 8(7):1087. https://doi.org/10.3390/app8071087

Chicago/Turabian StyleZheng, Xu, Mike P. C. Taverne, Ying-Lung D. Ho, and John G. Rarity. 2018. "Cavity Design in Woodpile Based 3D Photonic Crystals" Applied Sciences 8, no. 7: 1087. https://doi.org/10.3390/app8071087

APA StyleZheng, X., Taverne, M. P. C., Ho, Y.-L. D., & Rarity, J. G. (2018). Cavity Design in Woodpile Based 3D Photonic Crystals. Applied Sciences, 8(7), 1087. https://doi.org/10.3390/app8071087