Fabrication of Metallic Glass Layers on Al Alloys with Improved Corrosion Resistance and Micro-Hardness by Pulsed Electrical Discharge Treatment

Abstract

1. Introduction

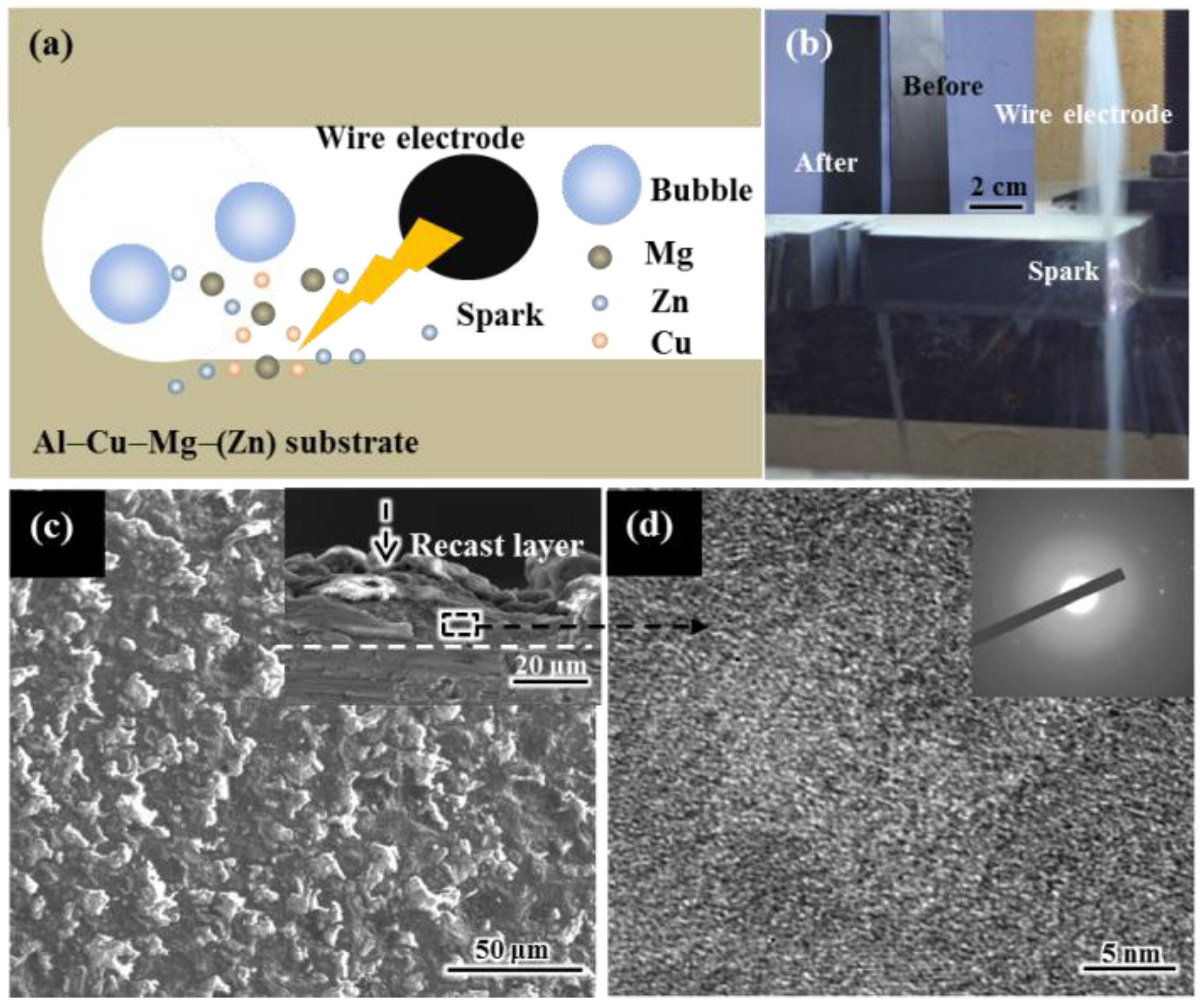

2. Experimental

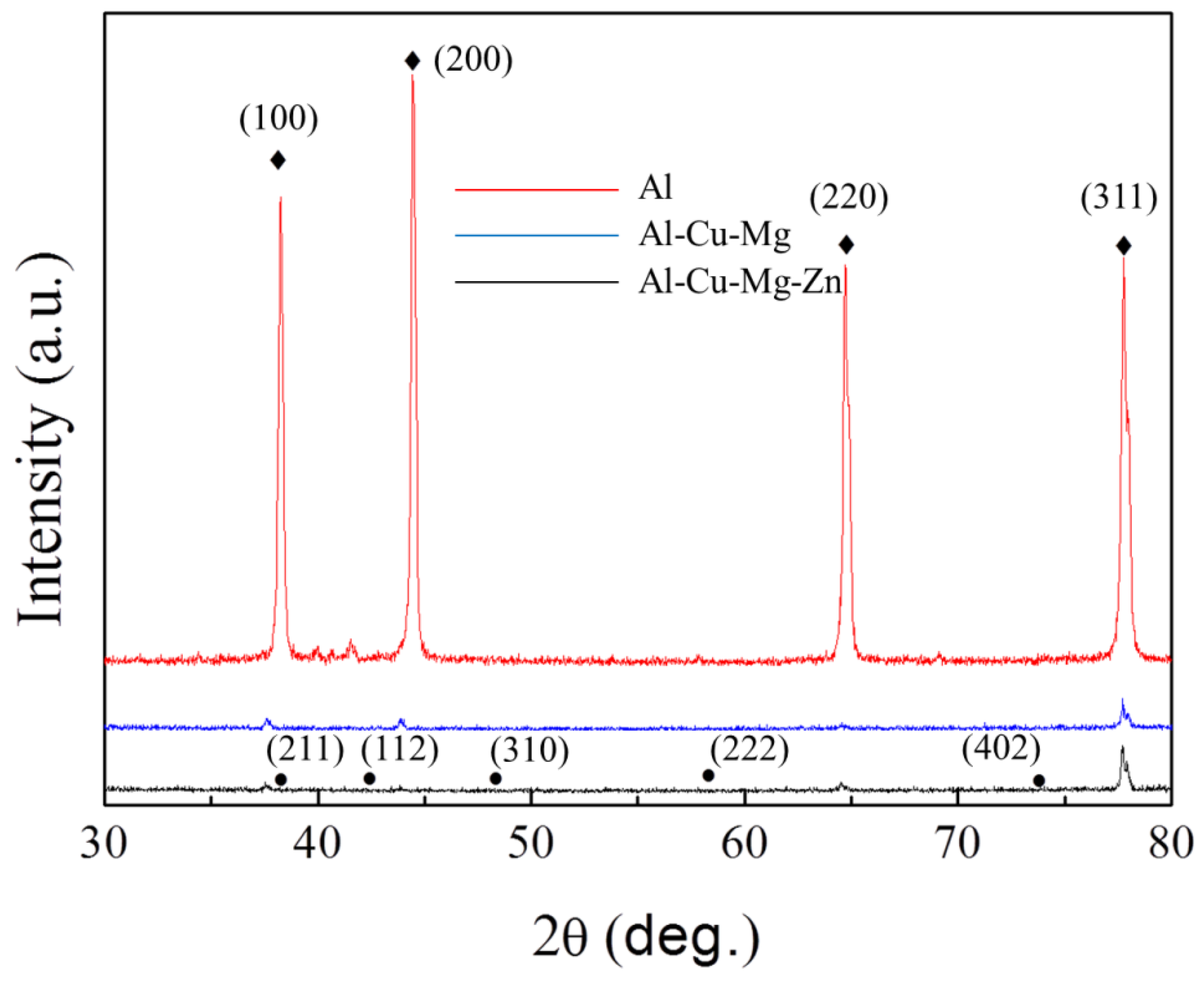

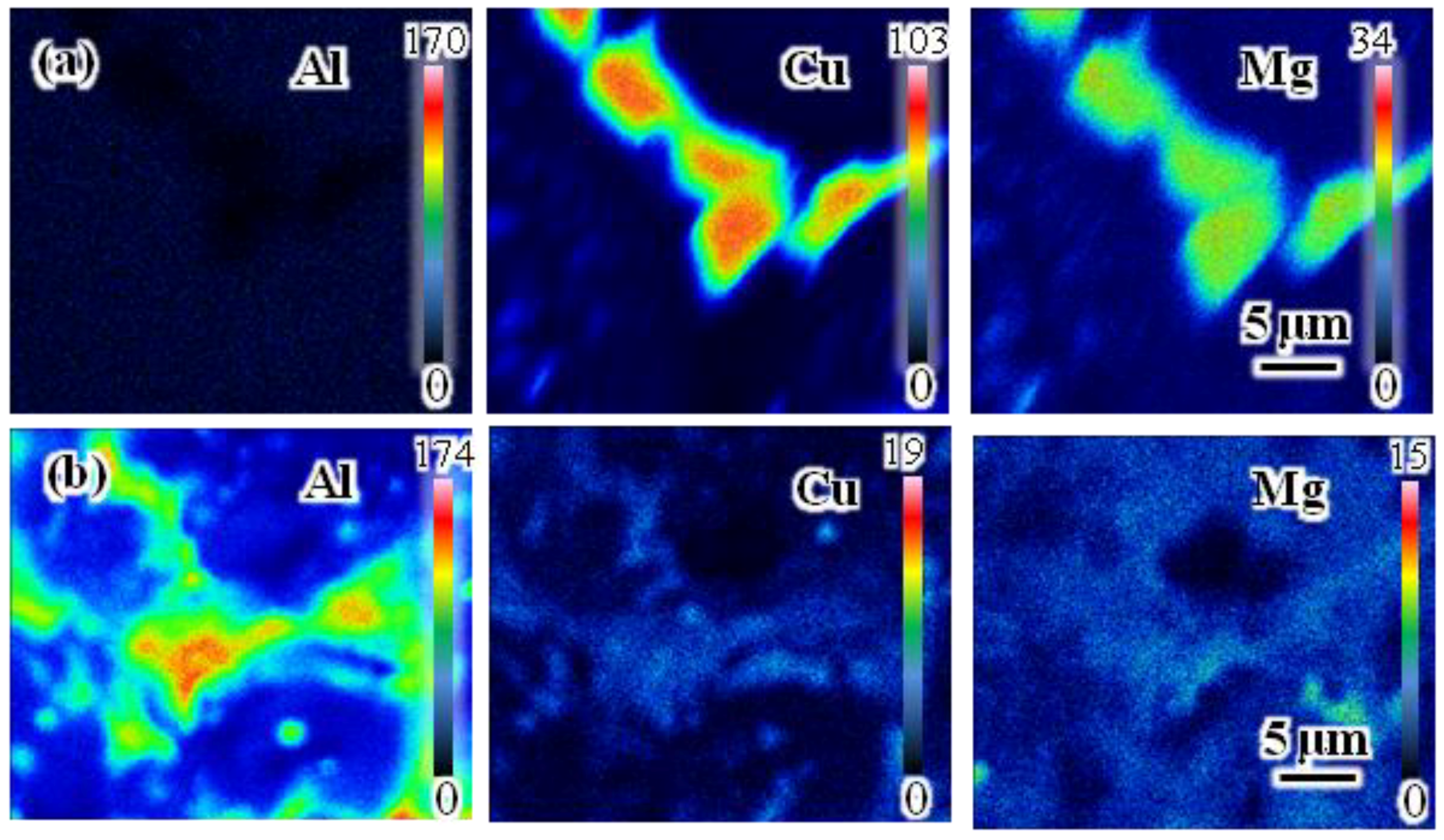

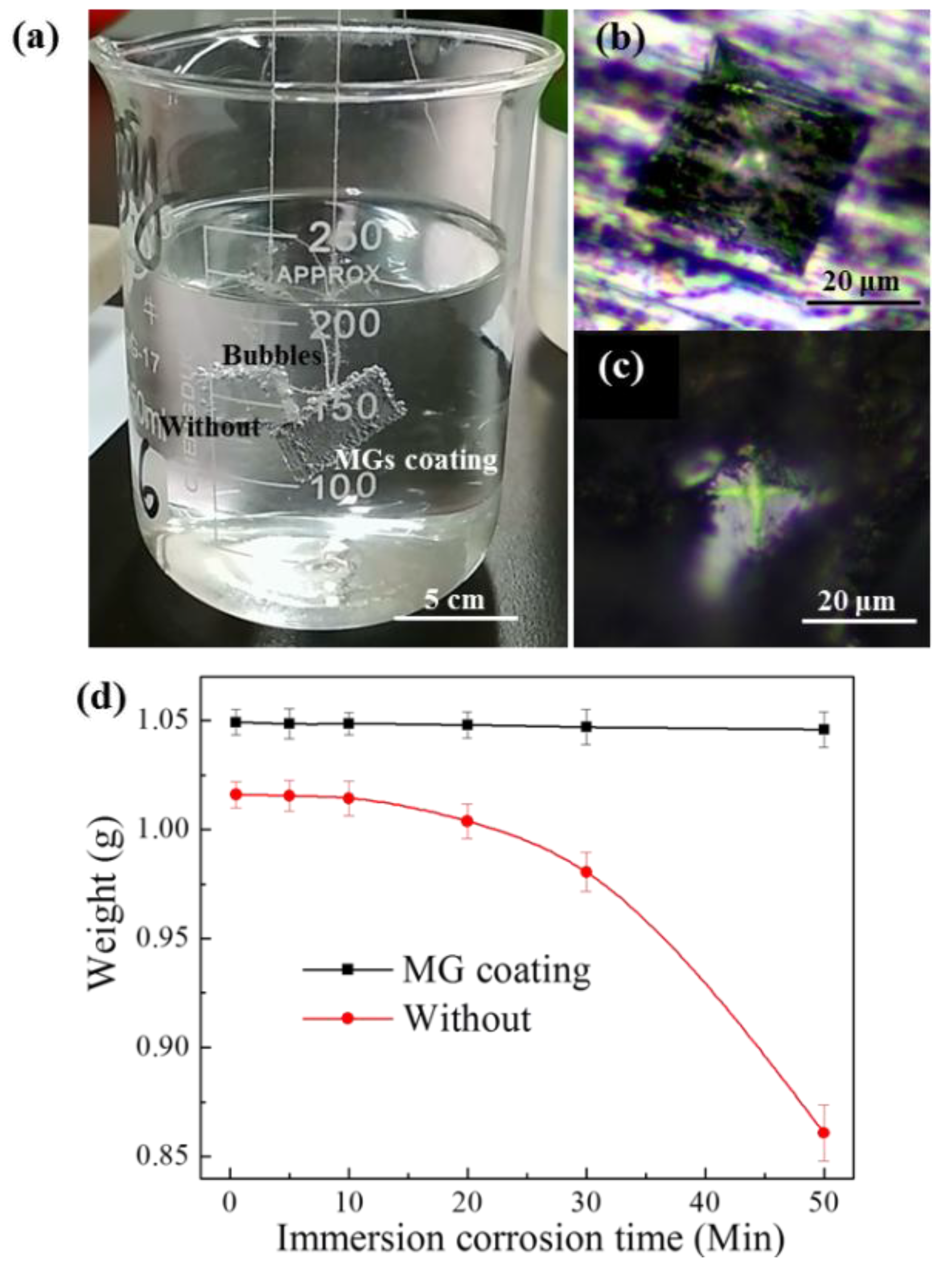

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ghahremaninezhad, A.; Dolati, A. A study on electrochemical growth behavior of the Co–Ni alloy nanowires in anodic aluminum oxide template. J. Alloys Compd. 2009, 480, 275–278. [Google Scholar] [CrossRef]

- Singh, S.S.; Schwartzstein, C.; Williams, J.J.; Zhao, X.H.; DeCarlo, F.; Chawala, N.; Singh, S.S.; Schwartzstein, C.; Williams, J.J. 3D microstructural characterization and mechanical properties of constituent particles in Al 7075 alloys using X-ray synchrotron tomography and nanoindentation. J. Alloys Compd. 2014, 602, 163–174. [Google Scholar] [CrossRef]

- Li, L.L.; Whitman, B.W.; Munson, C.A.; Estrada, R.; Matzdorf, C.A.; Swain, G.M. Structure and Corrosion Performance of a Non-Chromium Process (NCP) Zr/Zn Pretreatment Conversion Coating on Aluminum Alloys. J. Electrochem. Soc. 2016, 163, C718–C728. [Google Scholar] [CrossRef]

- Zheng, S.L.; Li, C.; Fu, Q.T.; Li, M.; Hu, W.; Wang, Q.; Du, M.P.; Liu, X.C.; Chen, Z. Fabrication of self-cleaning superhydrophobic surface on aluminum alloys with excellent corrosion resistance. Surf. Coat. Tech. 2015, 276, 341–348. [Google Scholar] [CrossRef]

- Wu, G.; Liu, Y.; Liu, C.; Tang, Q.H.; Miao, X.S.; Lu, J. Novel multilayer structure design of metallic glass film deposited Mg alloy with superior mechanical properties and corrosion resistance. Intermetallics 2015, 62, 22–26. [Google Scholar] [CrossRef]

- Lin, C.J.; Spaepen, F. Fe-B glasses formed by picosecond pulsed laser quenching. Appl. Phys. Lett. 1982, 41, 721–723. [Google Scholar] [CrossRef]

- Shi, W.T.; Liu, Z.D.; Qiu, M.B.; Tian, Z.J. Wire tension in high-speed wire electrical discharge machining. Int. J. Adv. Manuf. Tech. 2016, 82, 379–389. [Google Scholar]

- Zuo, L.; Pang, S.J.; Zou, S.F.; Li, H.F.; Zhang, T. Surface vitrification of alloys by pulsed electrical discharge treatment. J. Alloys Compd. 2017, 707, 148–154. [Google Scholar] [CrossRef]

- Proskurovsky, D.I.; Rotshtein, V.P.; Ozur, G.E.; Markov, A.B.; Nazarov, D.S.; Shulov, V.A.; Ivanov, F.Y.; Buchheit, R.G. Pulsed electron-beam technology for surface modification of metallic materials. J. Vac. Sci. Technol. A 1998, 16, 2480–2488. [Google Scholar] [CrossRef]

- Lukes, P.; Locke, B.R. Plasmachemical oxidation processes in a hybrid gas–liquid electrical discharge reactor. J. Phys. D Appl. Phys. 2005, 38, 4074–4081. [Google Scholar] [CrossRef]

- Bae, W.G.; Song, K.Y.; Rahmawan, Y.; Chu, C.N.; Kim, D.; Chung, D.K.; Suh, K.Y. Fabrication and analysis of functionalized metallic surface. ACS Appl. Mater. Inter. 2012, 4, 3685–3691. [Google Scholar] [CrossRef] [PubMed]

- Köster, U. Surface crystallization of metallic glasses. Mat. Sci. Eng. 1998, 97, 233–239. [Google Scholar] [CrossRef]

- Pang, S.J.; Zhang, T.; Asami, K.; Inoue, A. Synthesis of Fe–Cr–Mo–C–B–P bulk metallic glasses with high corrosion resistance. Acta Mater. 2002, 50, 489–497. [Google Scholar] [CrossRef]

- Tosun, N.; Cogun, C. An investigation on wire wear in WEDM. J. Mater. Process. Tech. 2003, 134, 273–278. [Google Scholar] [CrossRef]

- Woloszko, J.; Stalder, K.R.; Brown, I.G. Plasma characteristics of repetitively-pulsed electrical discharges in saline solutions used for surgical procedures. IEEE Trans. Plasma Sci. 2002, 30, 1376–1383. [Google Scholar] [CrossRef]

- Dai, H.; Wang, T.Y.; Li, M.C. Spotlight on ultrasonic fracture behaviour of nanowires: Their size-dependent effect and prospect for controllable functional modification. RSC Adv. 2016, 6, 72080–72085. [Google Scholar] [CrossRef]

- Jia, M.; Zheng, Z.; Gong, Z. Microstructure evolution of the 1469 Al–Cu–Li–Sc alloy during homogenization. J. Alloys Compd. 2014, 614, 131–139. [Google Scholar] [CrossRef]

- Deng, Y.; Yin, Z.; Cong, F. Intermetallic phase evolution of 7050 aluminum alloy during homogenization. Intermetallics 2012, 26, 114–121. [Google Scholar] [CrossRef]

- Grosse, A.V. The temperature range of liquid metals and an estimate of their critical constants. J. Inorg. Nucl. Chem. 1961, 22, 23–31. [Google Scholar] [CrossRef]

| Alloys | Zn (at. %) | Mg (at. %) | Cu (at. %) | Al |

|---|---|---|---|---|

| Al-Cu-Mg | - | 1.6 | 1.66 | Balance |

| Al-Cu-Mg-Zn | 2.88 | 1.75 | 1.11 | Balance |

| Elements | Zn (°C) | Mg (°C) | Cu (°C) | Al (°C) |

|---|---|---|---|---|

| Melting point | 419 | 650 | 1083 | 660 |

| Boiling point | 907 | 1108 | 2580 | 2500 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, H.; Sun, J.; Li, Z.; Zhao, J.; Yu, X.; Fang, H.; Chen, J. Fabrication of Metallic Glass Layers on Al Alloys with Improved Corrosion Resistance and Micro-Hardness by Pulsed Electrical Discharge Treatment. Appl. Sci. 2018, 8, 956. https://doi.org/10.3390/app8060956

Dai H, Sun J, Li Z, Zhao J, Yu X, Fang H, Chen J. Fabrication of Metallic Glass Layers on Al Alloys with Improved Corrosion Resistance and Micro-Hardness by Pulsed Electrical Discharge Treatment. Applied Sciences. 2018; 8(6):956. https://doi.org/10.3390/app8060956

Chicago/Turabian StyleDai, Han, Jie Sun, Zhutie Li, Junfeng Zhao, Xinxiang Yu, Hongjie Fang, and Junhao Chen. 2018. "Fabrication of Metallic Glass Layers on Al Alloys with Improved Corrosion Resistance and Micro-Hardness by Pulsed Electrical Discharge Treatment" Applied Sciences 8, no. 6: 956. https://doi.org/10.3390/app8060956

APA StyleDai, H., Sun, J., Li, Z., Zhao, J., Yu, X., Fang, H., & Chen, J. (2018). Fabrication of Metallic Glass Layers on Al Alloys with Improved Corrosion Resistance and Micro-Hardness by Pulsed Electrical Discharge Treatment. Applied Sciences, 8(6), 956. https://doi.org/10.3390/app8060956