Field Evaluation of Synthetic Polymer Rubber Gel through Filler Content and Oil Leakage Mass Measurement

Abstract

:1. Introduction

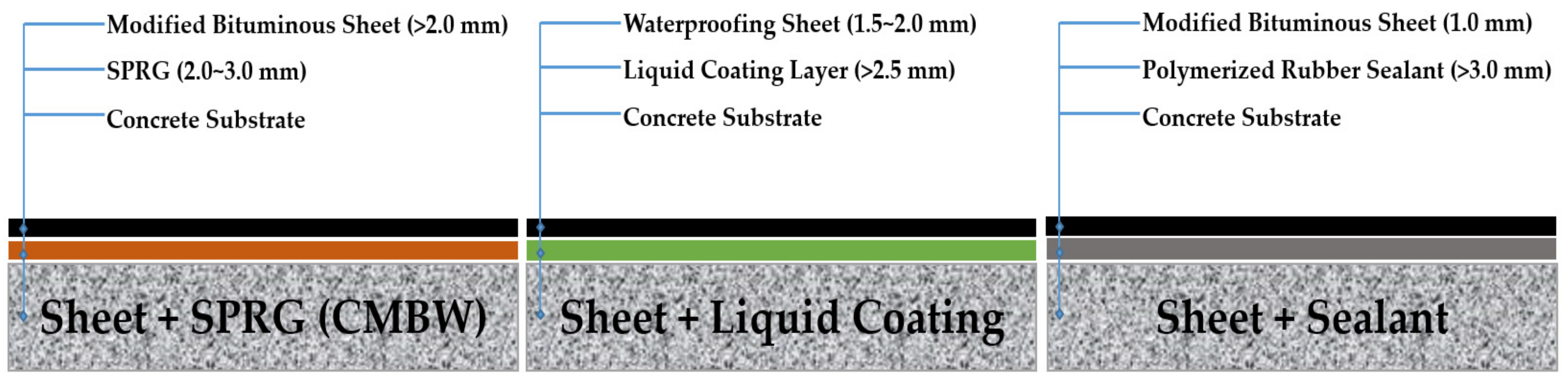

1.1. Research Background and Objectives

1.2. Problems Concerning CMBW System Application as Waterproofing in Concrete Structures

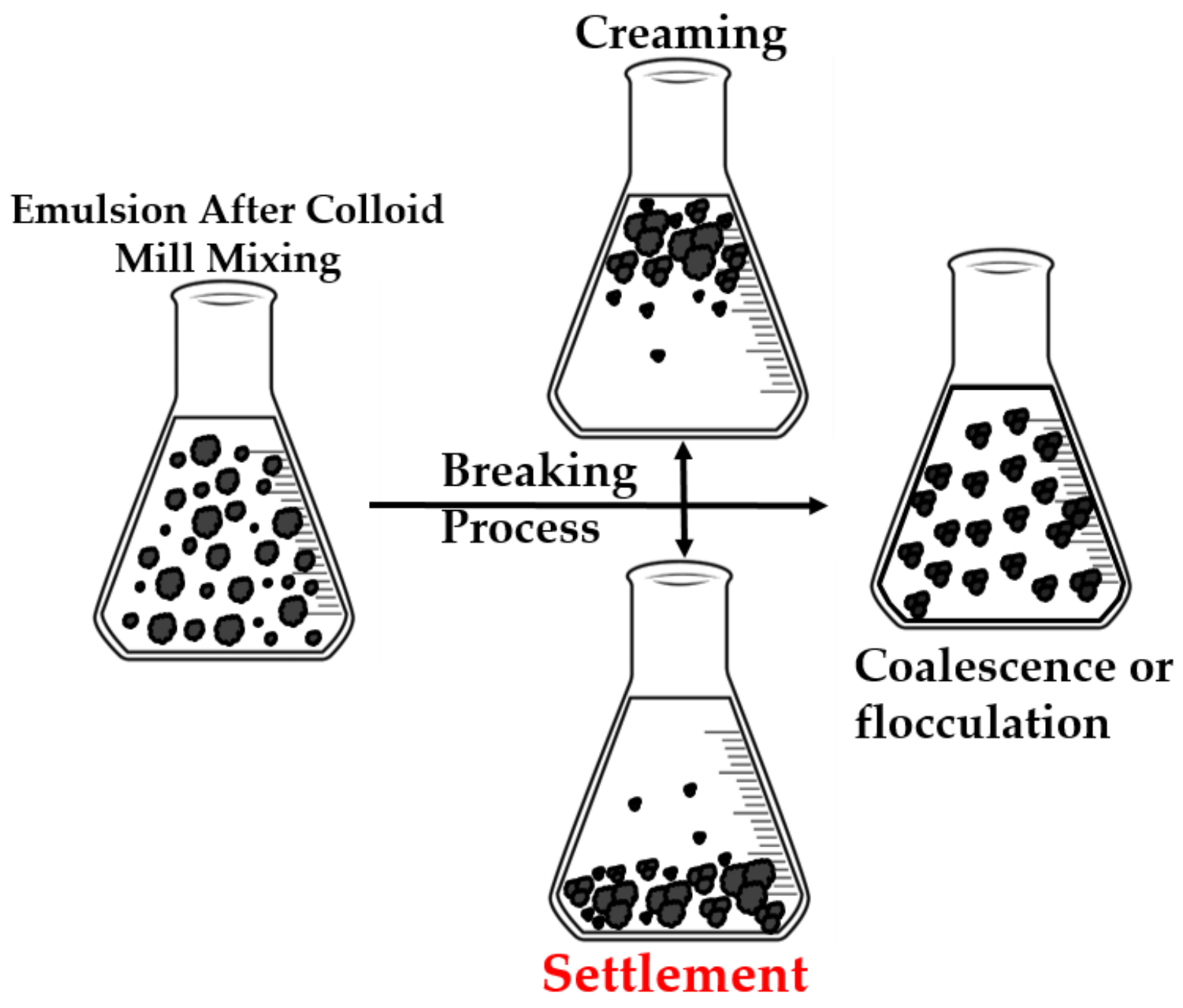

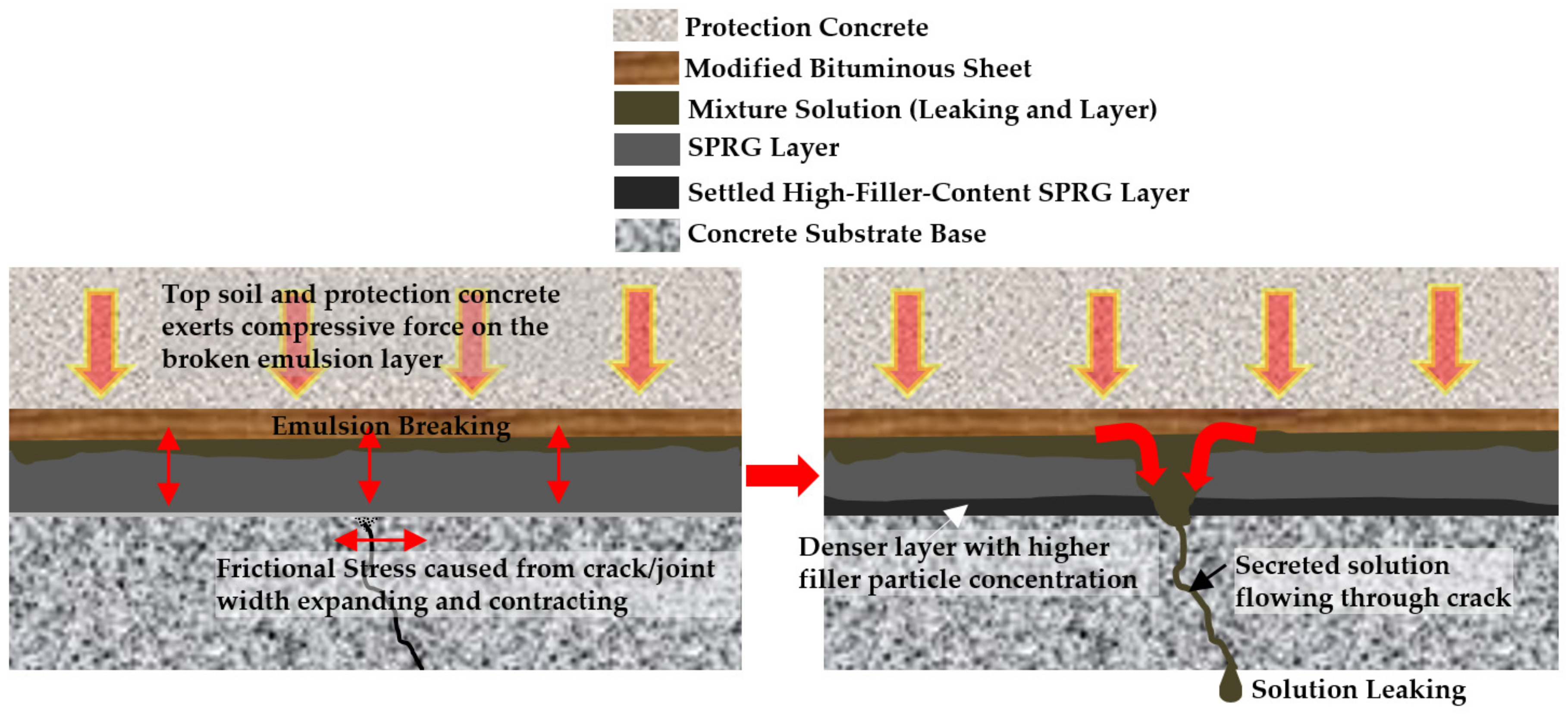

2. Oil Leakage Mechanism of SPRG in CMBW Systems

2.1. Oil Leakage Phenomenon of SPRG Used as Waterproofing in Concrete Structures

2.2. Existing Standard Evaluation Methods and Limitations

3. Materials: SPRG in a Composite Modified Bituminous Waterproofing (CMBW) System

4. Preparation of Test Specimens for the New Proposed Evaluation Method

5. Testing Methods for the New Proposed Evaluation Method (Demonstration)

5.1. Total Oil Leakage Mass Measurement

5.2. Filler Content of Oil Leakage Measurement

- Fc: the percentage of the measured filler content;

- W1: the mass of the ceramic collecting board;

- W2: the mass of the ceramic collecting board and the procured oil leakage specimen;

- W3: the mass of the ceramic collecting board after placement in a high-temperature electric furnace.

5.3. Evaluation Criteria

5.3.1. Leakage Duration (Collective Number of Leakage Day Intervals)

- t1: the collective number of days when leakage was detected;

- t2: the collective number of days when leakage was not detected;

- t3: the predetermined period for the evaluation (for the demonstration, 28 days was selected).

5.3.2. Cumulative Leakage Mass

- mi: the amount of leaked oil from the SPRG in specific daily interval i;

- l: the cumulative amount of leaked oil at the end of the predetermined testing period (for the demonstration, 28 days was selected).

5.3.3. Average Filler Content Measurement of Leaked Samples

- h: average of the respective filler content percentages of oil leak samples during the testing period;

- p: filler content percentage of the original sample (provided in Table 2);

- fa: average percentage difference of the filler content of the oil layer and the original filler content over the evaluation period.

5.3.4. Average Filler Content at Initial Leakage (IL) Day

- r: filler content percentage of the oil leak sample in the IL day interval;

- p: filler content percentage of the original sample (provided in Table 2);

- fi: estimated percentage of the minimum filler content of the oil layer in the SPRG to achieve the rheological state to leak through the concrete cracks.

6. Evaluation Results

6.1. Evaluation of Oil Leakage Mass and Duration (Number of Leakage Day Intervals)

6.2. Overall Average and IL Day Filler Content Measurement

6.3. SPRG Filler Content Settlement Ratio Calculation

- fa: estimated percentage of the minimum filler content of the oil layer in the SPRG to achieve the required rheological state to leak through the concrete cracks;

- fi: average percentage difference of the filler content of the oil layer and the original filler content over the evaluation period;

- fd: average filler content ratio discrepancy between average leaked oil sample filler content over the evaluation period and the IL day oil sample filler content.

6.4. Comprehensive Results for Comparative Evaluation

7. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Abbreviations

| ASTM | American Standard of Testing and Materials |

| SPRG | Synthetic Polymerized Rubber Gels |

| BS | British Standards |

| CMBW | Composite Modified Bituminous Waterproofing |

| FC | Filler Content |

| IL | Initial Leakage |

| KS | Korean Industrial Standards |

| LH | KOREA LAND & HOUSING CORPORATION |

References

- Seo, W.I.; Kim, S.Y.; Kwak, G.S.; Oh, S.G. A Study on Complex Waterproofing Method Using Part of Joint Water-Tightness Improved Sheet; The Korea Institute of Building Construction: Seoul, Korea, 2004; Volume 7, pp. 1–6. [Google Scholar]

- Chang, S.J. Advanced Technology of Waterproofing. J. Arch. Inst. Korea 2005, 49, 57–60. [Google Scholar]

- Zakari, N.; Muhammad-Keyvanfar, A.; Muhd-Zaimi-Abd, M.; Shafaghat, A.; Mirza, J. Waterproof Performance of Concrete: A Critical Review on Implemented Approaches. Constr. Build. Mater. 2015, 101 Pt 1, 80–90. [Google Scholar]

- Elsawy, M.M.; Taher, M.S.; Ebraheme, A.A.; Farag, R.K.; Saleh, A.M.M. Improvement Performance of Soft Bitumen for Coating Applications. Constr. Build. Mater. 2016, 128, 47–56. [Google Scholar] [CrossRef]

- Oh, S.K.; Shim, J.S. Maintenance for Leakage due to Cracking in Concrete Structures-Guidelines for Repair of Water-Leakage Cracks in Concrete Structures. J. Korea Concr. Inst. 2011, 23, 47–52. [Google Scholar]

- Ahn, D.S. A Study on the Physical Properties Change of Synthetic Rubber Polymer Gel by Using Stirring Screw Mixer. Master’s Thesis, Seoul National University of Science and Technology, Seoul, Korea, 2015. [Google Scholar]

- Song, J.Y.; Oh, K.H.; Kim, B.I.; Oh, S.K. Performance Evaluation of Waterproofing Membrane Systems Subject to the Concrete Joint Load Behavior of Below-Grade Concrete Structures. Appl. Sci. 2017, 7, 1147. [Google Scholar] [CrossRef]

- Cuadri, A.A.; Carrera, V.; Izquierdo, M.A.; García-Morales, M.; Navarro, F.J. Bitumen Modifiers for Reduced Temperature Bitumens: A Comparative Analysis between Three Polymeric and Non-polymeric Additives. Constr. Build. Mater. 2014, 51, 82–88. [Google Scholar] [CrossRef]

- Isacsson, U. A Compilation of Laboratory Methods for Studying Stability of Bitumen Emulsions. Mater. Struct. 1985, 18, 228–236. [Google Scholar] [CrossRef]

- Palade, L.; Attane, P.; Camaro, S. Linear Viscoeslastic Behavior of Asphalt and Asphalt based Mastic. Rheol. Acta 2000, 39, 180–190. [Google Scholar] [CrossRef]

- Deckard, C.; Hagerty, P.D. Rethinking Waterproofing for Subsurface Structures. In Forensic Engineering 2009: Pathology of the Built Environment, 1st ed.; Chen, S.-E., de Leon, A.D., Dolhon, A.M., Drerup, M.J., Parfitt, M.K., Eds.; American Society of Civil Engineers (ASCE): Washington, DC, USA, 2009; pp. 298–307. [Google Scholar]

- Oba, K.; Hugener, M. Characterization of Polymer Modified Bituminous Roofing Membranes using Chromatography. Mater. Struct. 1995, 28, 534–544. [Google Scholar] [CrossRef]

- Long, Y.; Dabros, T.; Hamza, H. Stability and Settling Characteristics of Solvent-diluted Bitumen Emulsions. Fuel 2002, 81, 1945–1952. [Google Scholar] [CrossRef]

- Oh, S.K.; Lee, J.Y.; Choi, S.M. An Experimental Study on the Highly Adhesive Composite Waterproofing Sheet using Reclaimed Rubber. J. Arch. Inst. Korea 2014, 16, 279–284. [Google Scholar]

- ASTM D2170/D2170M-10. Standard Test Method for Kinematic Viscosity of Asphalts (Bitumens); ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, J.S.; Park, J.S.; Kim, D.B.; Park, W.G. A Research on Property Evaluation of Polymer-Modified Bitumen Waterproofing Sheet According to using Solven. J. Korean Recycled Constr. Resour. Inst. 2015, 15, 394–396. [Google Scholar]

| Composition | Component Types | Specific Gravity (g/mL) | Remarks | |

|---|---|---|---|---|

| Solids | Rubber and Bitumen | Binders (Bitumen) | 1.03 | Organic additives |

| Process oil (liquid type) | 0.977 | |||

| Natural rubber latex | 0.921 | |||

| Fillers | Calcium carbonate compound (powder type) | 2.71 | Inorganic additives (fillers) | |

| Natural minerals (powder type) | 2.12 | |||

| Other additives | 1.02 | |||

| Solvent | Emulsion solvent base, and other additives to stabilize emulsion | 9.3~1.00 | Water, chemical agents, etc. | |

| Sample | Viscosity (cps) (20 °C, Sp. 6) | Composition (%) | ||

|---|---|---|---|---|

| Solids | Water Content | |||

| Filler Content (p) *1 | Rubber and Bitumen | Water and Chemical Additives | ||

| A | 346,000 | 25.8 | 52.2 | 22 |

| B | 430,333 | 22.7 | 55.1 | 22.2 |

| C | 346,000 | 25.5 | 51.2 | 23.3 |

| D | 954,000 | 27.4 | 58.7 | 13.9 |

| E | 718,000 | 25.8 | 55.8 | 18.4 |

| F | 822,000 | 28.3 | 61 | 10.7 |

| G | 393,000 | 24.6 | 48 | 27.4 |

| H | 480,000 | 27.1 | 47.7 | 25.2 |

| Specimen Composition | Description | Illustration |

|---|---|---|

| Ceramic Collecting Board | Flat ceramic board (300 × 300 × 5 mm) |  |

| Protection Concrete Layer | Concrete slab (300 × 300 × 40 mm, W/C ratio: 0.55, 20 kg) |  |

| Waterproofing membrane (CMBW) | 1. 0.3 kg/m2 bitumen primer 2. 2 mm (150 g) SPRG 3. Modified bitumen sheet (300 × 300 × 1 mm) |  |

| Concrete Substrate (with Crack or Joint) | Two concrete substrate parts (150 × 300 × 15 mm for each part, W/C ratio: 0.55) |  |

| Frame | Consists of a base plate (300 × 300 × 60 mm) and a vertical plate manufactured using an acryl panel |  |

| Completed Specimen | Specimen mounted on stands over the ceramic collecting board, ready for testing |  |

| Procedure | Illustration and Description | ||

|---|---|---|---|

| Base Structure |  |  |  |

| Explanation | Acrylic frame | Concrete substrate base (with joint) | Primer installation |

| CMBW Structure |  |  |  |

| Explanation | SPRG installation | Modified bituminous sheet placement | Protection concrete casting |

| Days | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | Mass (g) | Avg. (l) *1 (g) | No. Days (t1) *2 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample | |||||||||||||||||||||||||||||

| A | 1 | X | X | 0.35 | 0.21 | 1.25 | 2.16 | 1.37 | X | 1.23 | 1.65 | X | 1.73 | 0.91 | 1.18 | 3.71 | 1.32 | 1.86 | 2.57 | X | 1.13 | X | X | X | X | X | 22.68 | 15 | |

| 2 | X | X | 0.21 | 1.82 | 0.91 | 1.39 | 2.11 | 1.78 | 2.52 | 3.15 | 1.21 | 0.87 | 1.62 | 0.72 | X | 0.54 | 0.38 | X | 0.52 | 0.17 | X | X | X | X | X | 19.92 | 20.65 | 16 | |

| 3 | X | X | X | 0.51 | 0.79 | 1.21 | 3.27 | 2.46 | 1.56 | 2.13 | 1.39 | 2.52 | X | 1.57 | X | X | 0.54 | 0.38 | 0.88 | X | X | 0.13 | X | X | X | 19.34 | 14 | ||

| B | 1 | X | 0.69 | 0.42 | 0.73 | 0.35 | 0.47 | X | X | 0.52 | X | 0.72 | 0.33 | X | 0.81 | 0.85 | 0.93 | 0.62 | 0.43 | X | X | X | X | X | X | X | 7.87 | 13 | |

| 2 | X | 0.32 | X | 0.27 | 0.61 | 0.33 | 0.84 | 0.16 | X | X | 0.63 | X | 1.27 | 2.65 | 1.97 | 0.63 | X | X | X | X | X | X | X | X | X | 9.68 | 9.12 | 11 | |

| 3 | X | 0.75 | 0.29 | 0.53 | 0.45 | X | 0.48 | 0.39 | X | 0.78 | 1.23 | 0.74 | X | 0.45 | 1.67 | 1.02 | 0.28 | 0.44 | 0.31 | X | X | X | X | X | X | 9.81 | 15 | ||

| C | 1 | X | X | X | X | X | 0.63 | 1.34 | 0.97 | 1.25 | X | 1.03 | 0.82 | 0.76 | X | 1.56 | 1.12 | 0.57 | X | 0.83 | X | 0.68 | X | X | X | X | 11.56 | 12 | |

| 2 | X | X | X | X | X | X | 0.51 | X | 0.36 | 2.16 | 1.43 | X | 0.26 | 0.64 | 0.57 | 1.35 | 1.86 | 1.67 | 0.95 | 0.77 | X | X | X | X | X | 12.53 | 12.67 | 12 | |

| 3 | X | X | X | X | X | 0.44 | X | 1.67 | 2.13 | 1.26 | 2.07 | 0.35 | 0.75 | 1.62 | X | 0.63 | 0.21 | 0.76 | 0.59 | 0.47 | 0.66 | 0.31 | X | X | X | 13.92 | 15 | ||

| D | 1 | X | X | X | X | X | X | 0.21 | 0.59 | X | 0.63 | 0.87 | 1.82 | X | 1.25 | 2.64 | 1.17 | 0.16 | 2.63 | X | 0.84 | 2.47 | 1.13 | X | X | 0.21 | 16.62 | 14 | |

| 2 | X | X | X | X | X | X | X | 0.38 | 0.14 | 0.82 | 1.35 | 1.58 | 1.16 | 0.71 | X | 1.89 | 2.32 | 0.93 | 0.45 | 1.12 | X | X | X | 0.13 | X | 12.98 | 13.59 | 13 | |

| 3 | X | X | X | X | X | X | X | X | 0.16 | 0.74 | 0.37 | X | 1.07 | 1.35 | 2.22 | 1.17 | 0.65 | 0.46 | 1.23 | 1.51 | 0.24 | X | X | X | X | 11.17 | 12 | ||

| E | 1 | X | X | X | 1.02 | 0.36 | X | 0.52 | X | 0.27 | X | 0.57 | X | X | 0.33 | 0.68 | X | X | X | 0.26 | 0.19 | X | 0.35 | X | X | X | 4.55 | 10 | |

| 2 | X | 0.42 | X | 1.23 | X | 0.12 | X | 0.74 | X | 0.52 | 0.17 | X | 0.58 | X | 0.64 | 0.29 | X | 0.17 | X | X | 0.45 | 0.36 | X | 0.27 | X | 5.96 | 5.64 | 13 | |

| 3 | X | X | X | X | 0.68 | X | 0.74 | X | 0.83 | 0.26 | X | X | 0.57 | 0.62 | X | 0.79 | 1.42 | 0.32 | X | X | 0.18 | X | X | X | X | 6.41 | 10 | ||

| F | 1 | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | No Leak | ||

| 2 | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | No Leak | N/L | ||

| 3 | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | No Leak | |||

| G | 1 | X | X | 0.28 | 0.22 | 0.84 | X | X | 0.42 | 1.35 | X | 0.27 | 0.49 | X | 0.87 | 1.25 | 1.07 | 1.15 | 0.27 | 1.32 | 1.27 | 0.34 | 0.25 | X | X | X | 11.66 | 16 | |

| 2 | X | X | X | 0.36 | X | 0.72 | 0.51 | X | 0.23 | 0.53 | X | 0.36 | 0.57 | 1.03 | 1.26 | 1.56 | 1.08 | 1.01 | 0.67 | 0.51 | X | 0.12 | X | X | X | 10.52 | 11.83 | 15 | |

| 3 | X | X | 0.53 | X | 0.14 | 0.42 | X | 0.78 | X | 1.11 | X | 0.82 | 0.44 | 1.42 | 1.75 | 0.58 | 0.73 | 1.64 | 0.73 | 1.28 | 0.34 | 0.61 | X | X | X | 13.32 | 16 | ||

| H | 1 | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | No Leak | ||

| 2 | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | No Leak | N/L | ||

| 3 | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | No Leak | |||

| Days | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | FC *1 Avg. (h) *2 (%) | IL *3 FC (r) *4 (%) | Days (t1 avg.) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample | ||||||||||||||||||||||||||||

| A | x | x | 15.2 | 15.6 | 15.1 | 14.3 | 15.2 | 14.6 | 15.2 | 13.2 | 12.7 | 14.9 | 12.5 | 11.2 | 12.5 | 11.8 | 11.1 | 10.5 | 12.5 | 11.2 | x | 11.5 | x | x | x | 13.2 | 15.2 | 15 |

| B | x | 16.1 | 15.2 | 15.6 | 15.1 | 16.2 | 14.2 | 13.6 | 12.2 | 13.6 | 12.5 | 12.8 | 12.1 | 13.2 | 12.3 | 13.2 | 11.5 | 12.5 | 13.3 | x | x | x | x | x | x | 13.6 | 16.1 | 13 |

| C | x | x | x | x | x | 11.5 | 12.2 | 12.7 | 10.8 | 11.1 | 13.2 | 14.6 | 12.5 | 11.8 | 10.5 | 12.5 | 12.6 | 12.3 | 11.5 | 11.6 | 10.6 | 12.6 | x | x | x | 12.1 | 11.5 | 13 |

| D | x | x | x | x | x | x | 9.7 | 10.3 | 11.2 | 9.2 | 9.5 | 9.6 | 11.5 | 11 | 10.6 | 9.6 | 9.2 | 10.7 | 11.2 | 8.5 | 9.2 | 9.3 | x | 10.6 | 9.2 | 10.1 | 9.7 | 13 |

| E | x | 13.9 | x | 13.2 | 13.5 | 14.6 | 13.2 | 13.5 | 14.6 | 13.2 | 12.6 | x | 12.4 | 12.8 | 13.6 | 13.4 | 14.1 | 12.2 | 13.1 | 11.3 | 12.5 | 11.2 | x | 11.8 | x | 12.7 | 13.9 | 11 |

| F | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | No Leak | No Leak | No Leak |

| G | x | x | 11.8 | 11.6 | 10.4 | 11.7 | 11.9 | 10.2 | 13.2 | 10.4 | 13.8 | 11.5 | 11.3 | 11.4 | 13.6 | 12.5 | 11.4 | 11.3 | 11.8 | 10.3 | 10.5 | 11.3 | x | x | 11.6 | 11.8 | 15.6 | |

| H | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x | No Leak | No Leak | No Leak |

| Samples | Average Filler Content (h) (%) | IL Day Filler Content (r) (%) | Average Filler Content % Difference (fa) (Leaked Oil/Normal Sample) (%) | Average Filler Content % Difference (fi) (IL Day Sample/Normal Sample) (%) |

|---|---|---|---|---|

| A | 13.2 | 15.2 | 51.1 | 58.9 |

| B | 13.6 | 16.1 | 59.9 | 70.9 |

| C | 12.1 | 11.5 | 47.5 | 45.1 |

| D | 10.1 | 9.7 | 36.9 | 35.4 |

| E | 12.7 | 13.9 | 49.2 | 53.8 |

| F | No Leak | No Leak | No Leak | No Leak |

| G | 11.6 | 11.8 | 42.8 | 43.5 |

| H | No Leak | No Leak | No Leak | No Leak |

| Sample Types | Avg. Leak Mass (Avg. l) (g) | Period of Leak (Avg. t1) (Days) | Average Filler Content % Difference (fa) (%) | Discrepancy Obtained by the Equation fa – fi = fd (%) |

|---|---|---|---|---|

| A | 20.65 | 15 | 51.1 | (−) 7.8 |

| B | 9.12 | 13 | 59.9 | (−) 11 |

| C | 12.67 | 13 | 47.5 | (+) 2.4 |

| D | 13.59 | 13 | 36.9 | (+) 1.9 |

| E | 5.64 | 11 | 49.2 | (−) 4.6 |

| F | No Leak | No Leak | No Leak | No Leak |

| G | 11.83 | 15.6 | 42.8 | (−) 0.7 |

| H | No Leak | No Leak | No Leak | No Leak |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.-s.; Kim, D.-b.; Oh, K.-h.; Oh, S.-k. Field Evaluation of Synthetic Polymer Rubber Gel through Filler Content and Oil Leakage Mass Measurement. Appl. Sci. 2018, 8, 896. https://doi.org/10.3390/app8060896

Park J-s, Kim D-b, Oh K-h, Oh S-k. Field Evaluation of Synthetic Polymer Rubber Gel through Filler Content and Oil Leakage Mass Measurement. Applied Sciences. 2018; 8(6):896. https://doi.org/10.3390/app8060896

Chicago/Turabian StylePark, Jin-sang, Dong-bum Kim, Kyu-hwan Oh, and Sang-keun Oh. 2018. "Field Evaluation of Synthetic Polymer Rubber Gel through Filler Content and Oil Leakage Mass Measurement" Applied Sciences 8, no. 6: 896. https://doi.org/10.3390/app8060896

APA StylePark, J.-s., Kim, D.-b., Oh, K.-h., & Oh, S.-k. (2018). Field Evaluation of Synthetic Polymer Rubber Gel through Filler Content and Oil Leakage Mass Measurement. Applied Sciences, 8(6), 896. https://doi.org/10.3390/app8060896