Wind Turbine Generator Efficiency Based on Powertrain Combination and Annual Power Generation Prediction

Abstract

:Featured Application

Abstract

1. Introduction

1.1. Research Background

1.2. Requirement for Analysis Technology

1.3. Aim of this Study

2. Methods

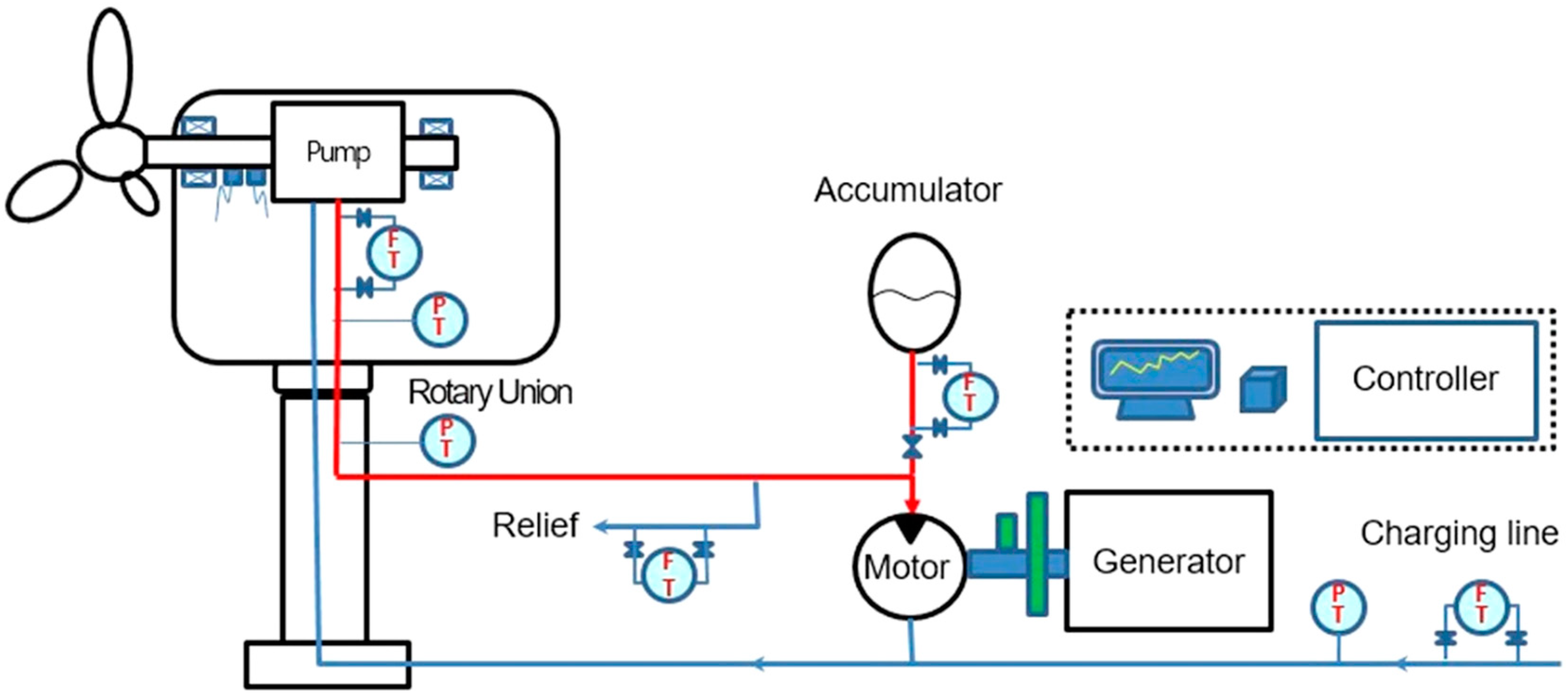

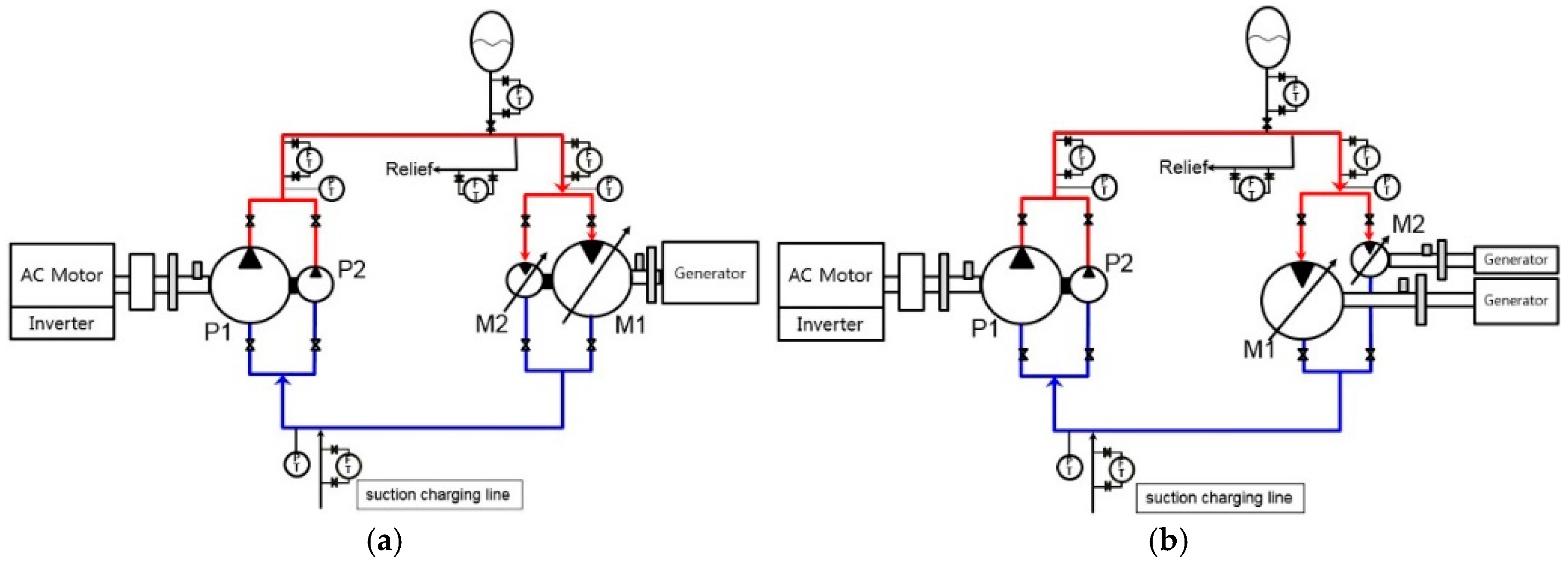

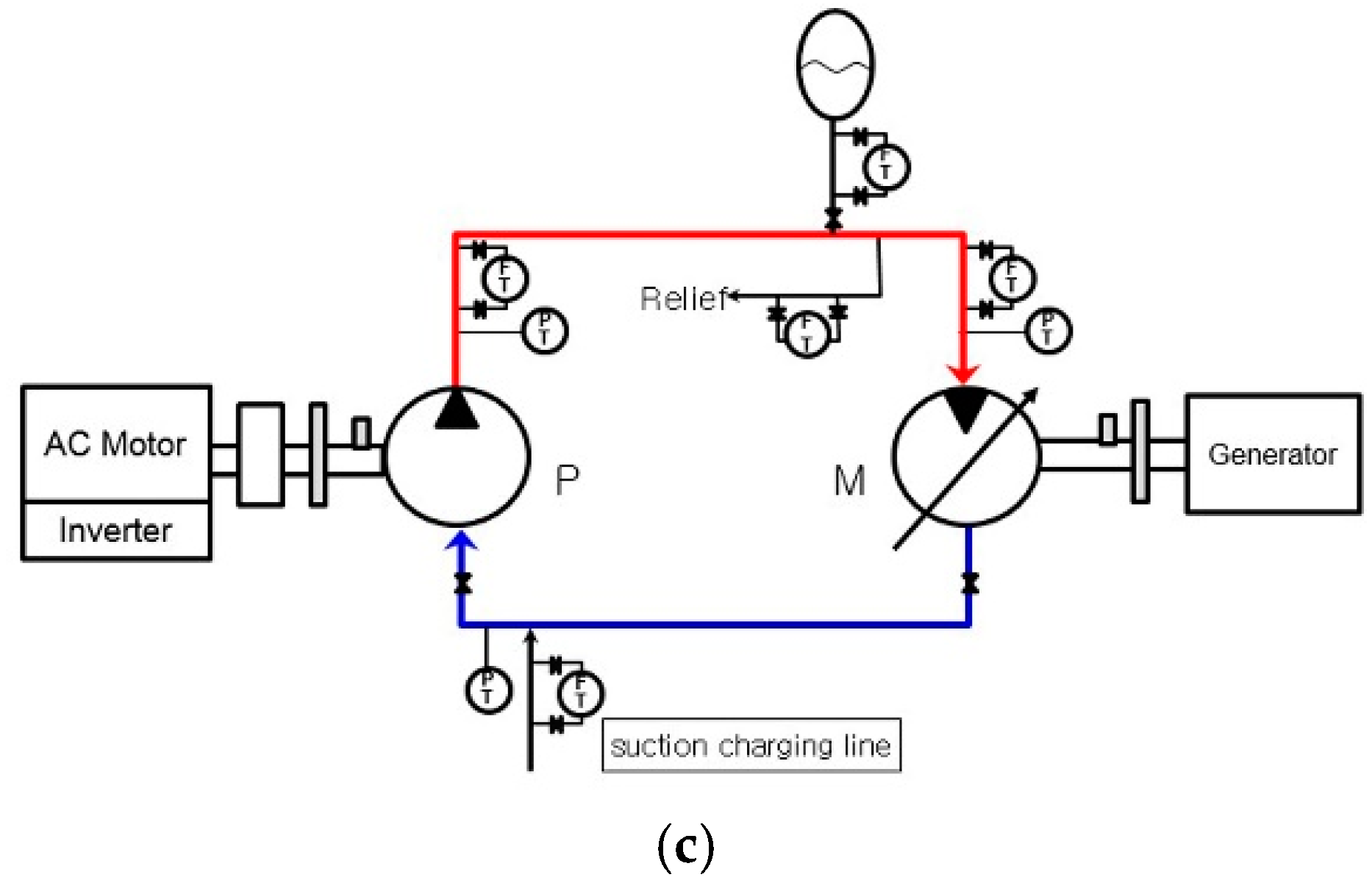

2.1. Wind Turbine Generator System Configuration

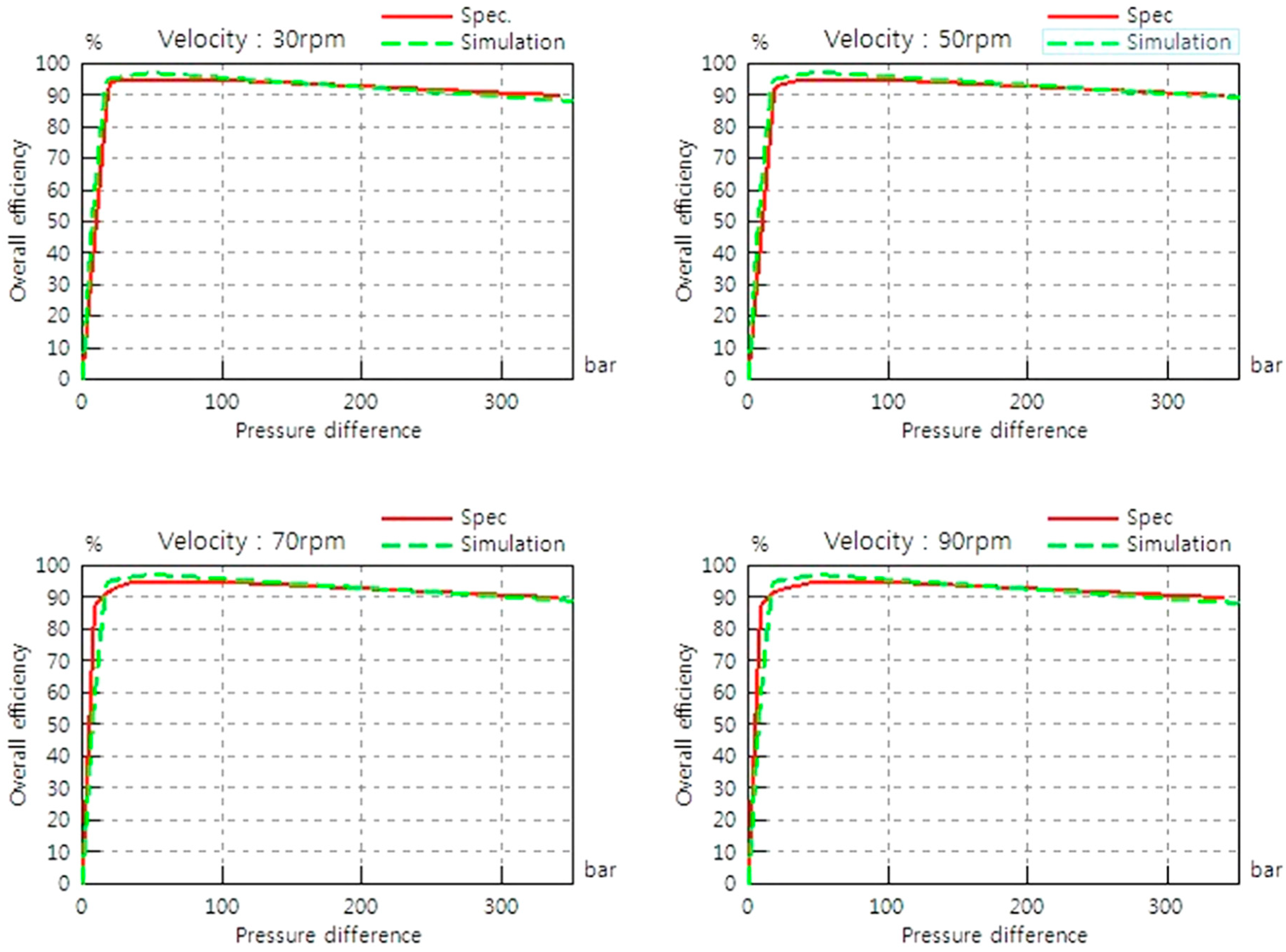

2.2. Component Test to Verify the Analysis Model

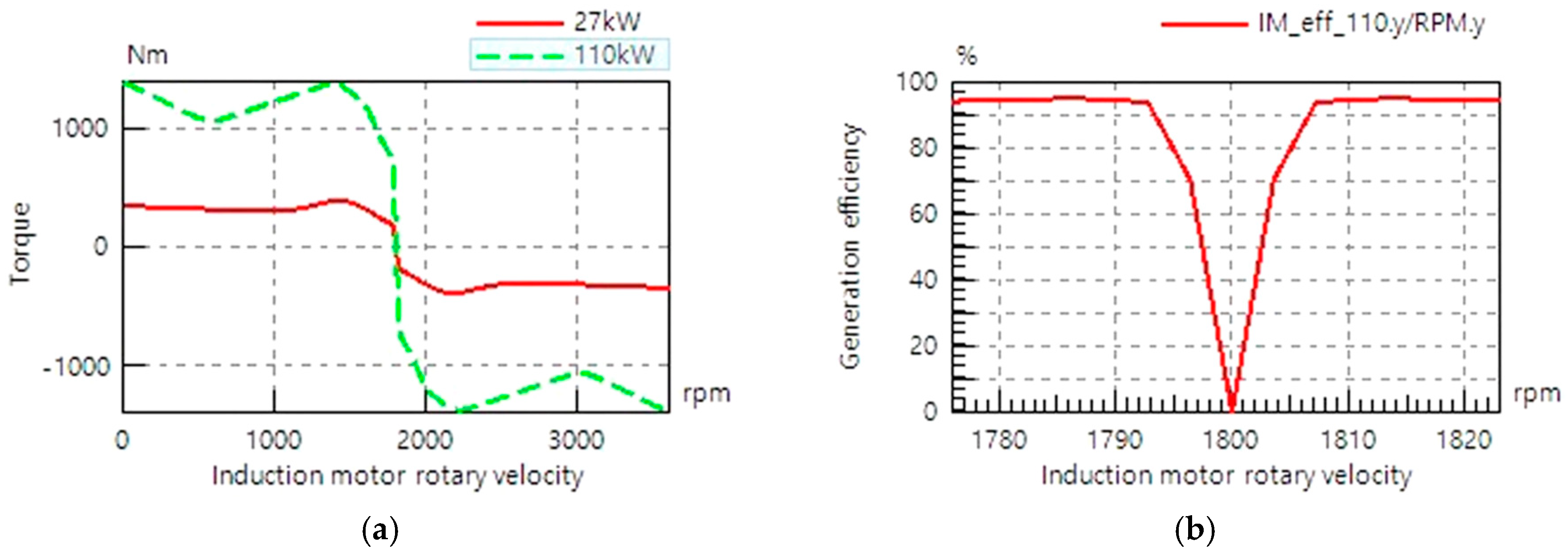

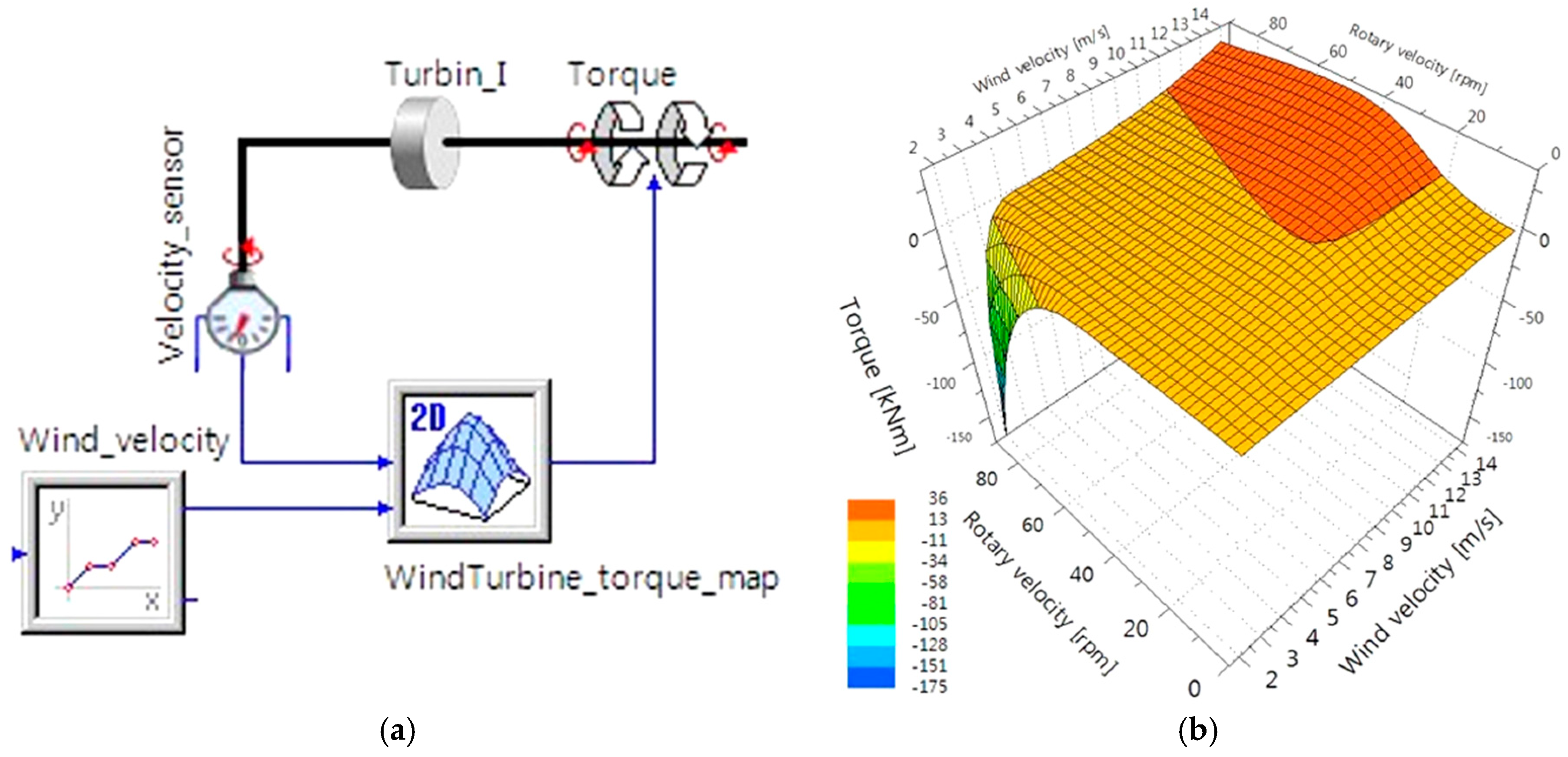

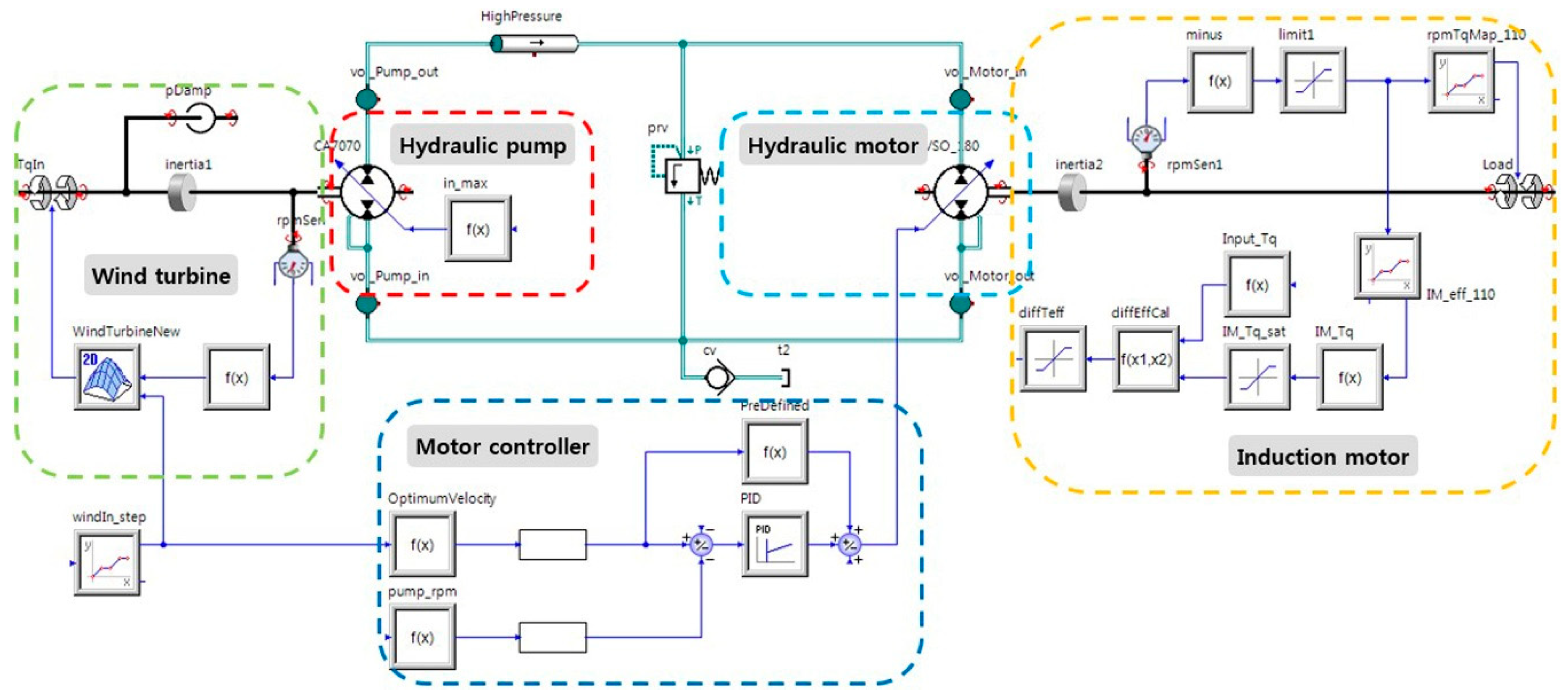

2.3. Analysis Model Development

3. Results

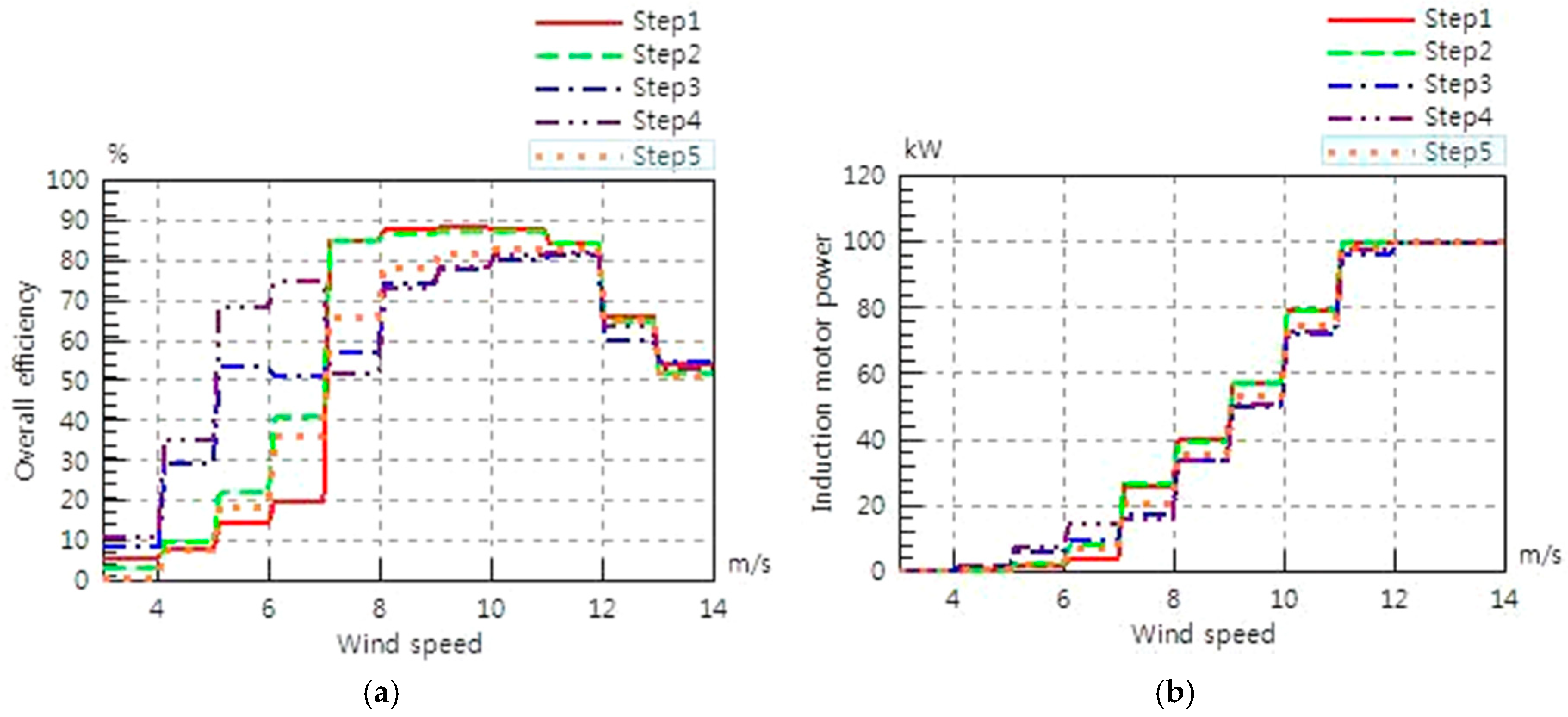

3.1. System Efficiency Analysis

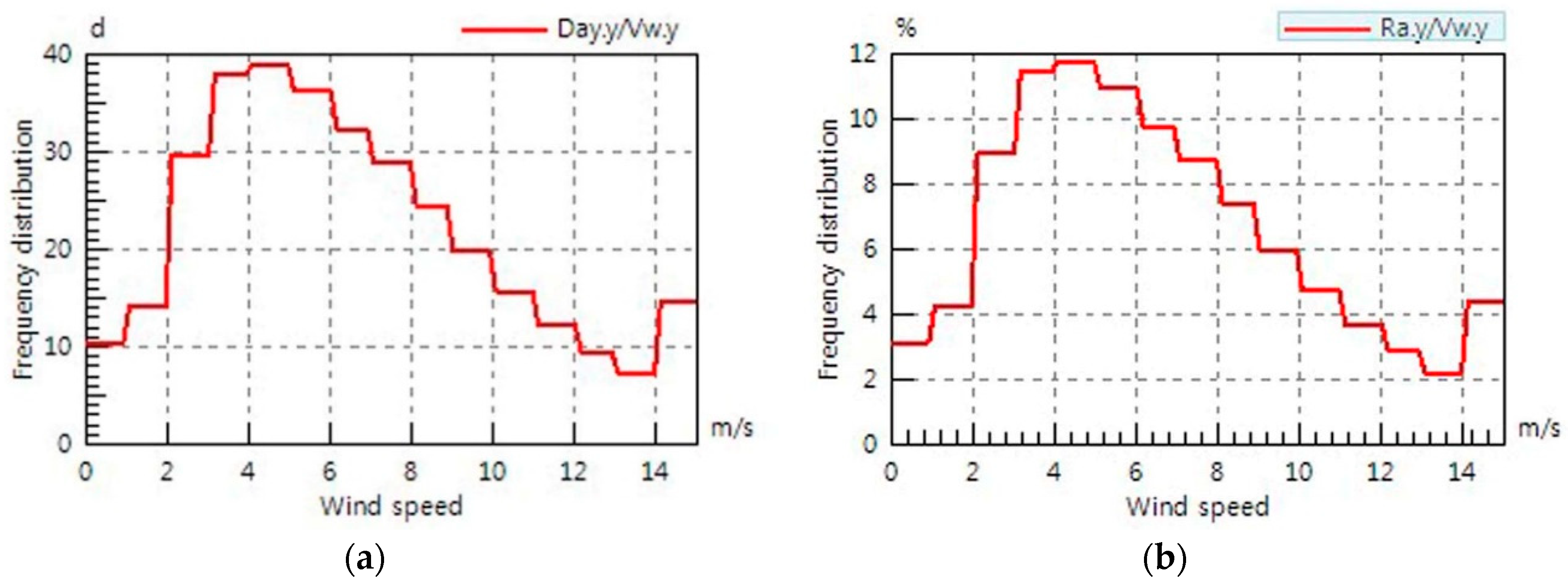

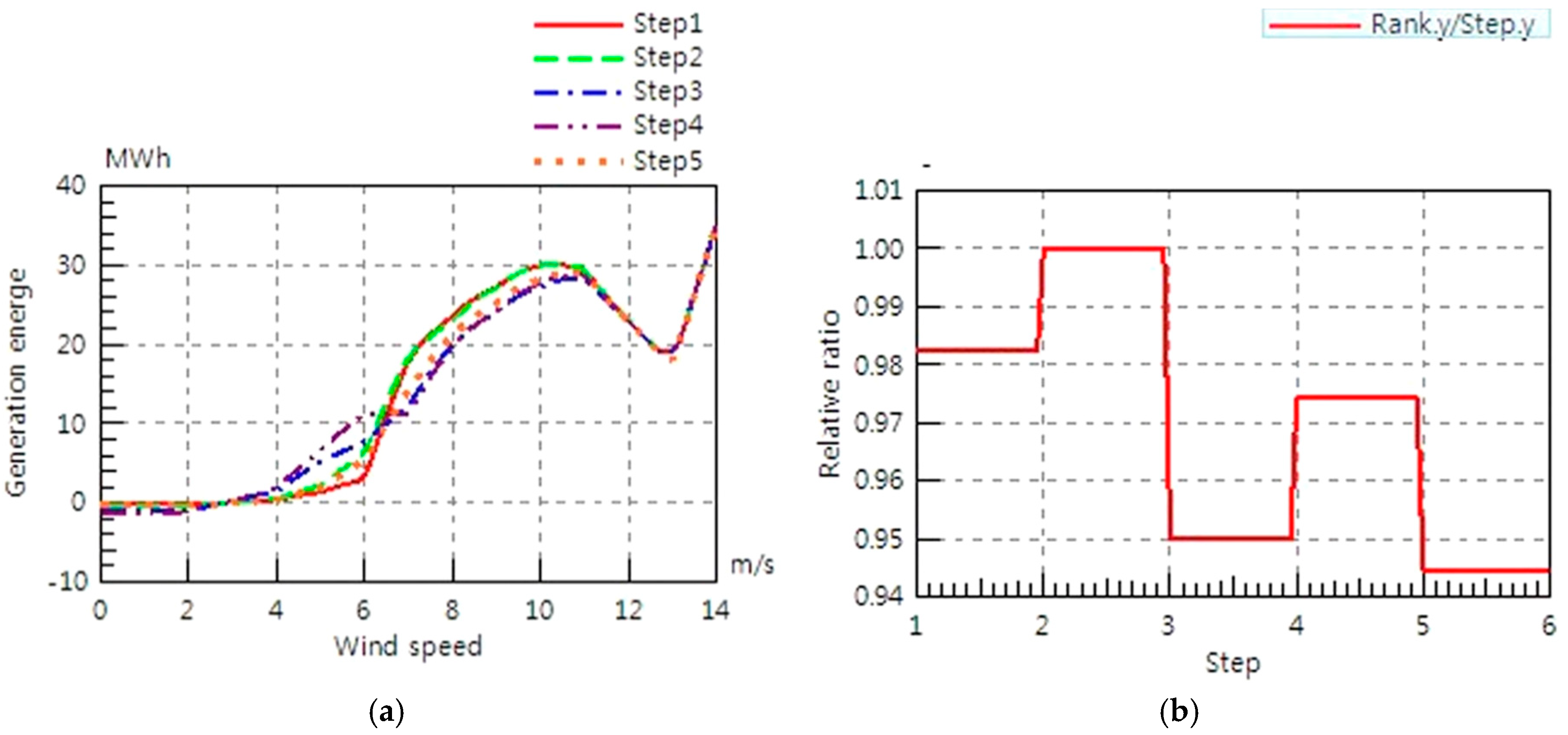

3.2. Annual Power Generation Prediction

4. Conclusions

- The overall efficiency was examined by testing the performances of a hydraulic pump and a hydraulic motor with hydrostatic transmission, which were the key components of wind turbine generators. In particular, it was confirmed that the overall efficiency decreased with the capacity of the hydraulic motor.

- The serial combination of generators exhibited a higher power generation efficiency when the wind speed was higher than 7 m/s, while the parallel combination showed a higher power generation efficiency when the wind speed was lower than 7 m/s.

- The analysis of e annual power generation energy, which considered the regional characteristics, showed that step 2, which was a combination of the parallel hydraulic motor and serial generator, was the optimal combination and step 5, which was the combination of the large-capacity pump and motor, was the worst combination.

- It was confirmed that power generation efficiency declined sharply when the wind speed exceeded 10–11 m/s, because the maximum power generation capacity of the induction motor was limited. This indicated that the maximum power generation capacity needed to be determined, considering the regional characteristics for designing a wind turbine generator.

- It was possible to predict system performance before the system construction and to systematically and specifically approach problems that may have arisen after the system construction using a simulation model.

- The system performance could be analyzed using an analysis model for designing the controller and blade of a wind turbine generator. This would save the time and cost that were required for research and development.

- The major disadvantage of using a simulation in the concept design stage, was that it could not perform the performance test on all of the components. Therefore, the performance tests on all of the components are required.

- The system will be assembled based on the results of this study, and a full system performance test will be performed. In addition, the verification of the full analytical model will be required before applying it to the various fields that use analytical models.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Höhn, B.R. Future transmissions for wind turbines. Appl. Mech. Mater. 2011, 86, 18–25. [Google Scholar] [CrossRef]

- Jones, J.A.; Bruce, A.; Lam, A.S. Advanced performance hydraulic wind energy. In Proceedings of the 5th IEEE Green Technologies Conference, Denver, CO, USA, 4–5 April 2013. [Google Scholar]

- Fan, Y.; Mu, A.; Ma, T. Study on the application of energy storage system in offshore wind turbine with hydraulic transmission. Energy Convers. Manag. 2016, 110, 338–346. [Google Scholar] [CrossRef]

- Thomsen, K.E.; Dahlhaug, O.G.; Niss, M.O.K.; Haugset, S.K. Technological advances in hydraulic drive trains for wind turbines. Energy Procedia 2012, 24, 76–82. [Google Scholar] [CrossRef]

- Spinato, F.; Tavner, P.J.; Van Bussel, G.J.W.; Koutoulakos, E. Reliability of wind turbine subassemblies. IET Rene. Power Gener. 2009, 3, 1–15. [Google Scholar] [CrossRef]

- Jensen, B.B.; Mijatovic, N.; Abrahamsen, A.B. Development of superconducting wind turbine generators. J. Renew. Sustain. Energy 2013, 5. [Google Scholar] [CrossRef]

- Skaare, B.; Hörnsten, B.; Nielsen, F.G. Modeling, simulation and control of a wind turbine with a hydraulic transmission system. Wind Energy 2013, 16, 1259–1276. [Google Scholar] [CrossRef]

- Muljadi, E.; Butterfield, C.P.; Chacon, J.; Romanowitz, H. Power quality aspects in a wind power plant. In Proceedings of the IEEE Power Engineering Society General Meeting, Montreal, QC, Canada, 18–22 June 2006. [Google Scholar]

- Chen, W.; Gao, F.; Meng, X.; Ren, A.; Zhou, S. An offshore hydraulic wind turbine generator with variable-diameter rotor: Design, modeling and experiment. Proc. IMechE Part M 2017, 231, 521–532. [Google Scholar] [CrossRef]

- Qin, C.; Innes-Wimsatt, E.; Loth, E. Hydraulic-electric hybrid wind turbines: Tower mass saving and energy storage capacity. Renew. Energy 2016, 99, 69–79. [Google Scholar] [CrossRef]

- Polinder, H.; Ferreira, J.A.; Jensen, B.B.; Abrahamsen, A.B.; Atallah, K.; McMahon, R.A. Trends in wind turbine generator systesms. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 174–185. [Google Scholar] [CrossRef]

- Silva, P.; Giuffrida, A.; Fergnani, N.; Macchi, E.; Cantù, M.; Suffredini, R.; Schiavetti, M.; Gigliucci, G. Performance prediction of a multi-MW wind turbine adopting an advanced hydrostatic transmission. Energy 2014, 64, 450–461. [Google Scholar] [CrossRef]

- Dolan, B.; Aschemann, H. Control of a wind turbine with a hydrostatic transmission—An extended linearisation approach. In Proceedings of the 17th International Conference on Methods & Models in Automation & Robotics (MMAR), Miedzyzdrojie, Poland, 27–30 August 2012. [Google Scholar]

- Izadian, A.; Hamzehlouia, S.; Deldar, M.; Anwar, S. A Hydraulic wind power transfer system: Operation and modeling. IEEE Trans. Sustain. Energy 2014, 5, 457–465. [Google Scholar] [CrossRef]

- Mortensen, K.A.; Henriksen, K.H. Efficiency Analysis of a Radial Piston Pump Applied in a 5MW Wind Turbine with Hydraulic Transmission. Master’s Thesis, Aalborg University, Aalborg, Denmark, 31 May 2011. [Google Scholar]

- Barthelmie, R.J.; Hansen, K.; Frandsen, S.T.; Rathmann, O.; Schepers, J.G.; Schlez, W.; Phillips, J.; Rados, K.; Zervos, A.; Politis, E.S.; et al. Modelling and measuring flow and wind turbine wakes in large wind farms offshore. Wind Energy 2009, 12, 431–444. [Google Scholar] [CrossRef]

- Nelson, B.; Kouh, J.S. The aerodynamic analysis of a rotating wind turbine by viscous-coupled 3D panel method. Appl. Sci. 2017, 7, 551. [Google Scholar] [CrossRef]

| No. | Pump1 | Pump2 | Motor1 | Motor2 | Induction Motor |

|---|---|---|---|---|---|

| 1 | 3771 cc/rev | 1256 cc/rev | 180 cc/rev | 40 cc/rev | 110 kW |

| 2 | 2512 cc/rev | 2512 cc/rev | 180 cc/rev | 71 cc/rev | 110 kW |

| 3 | 3771 cc/rev | 1256 cc/rev | 180 cc/rev | 40 cc/rev | 110 kW + 27 kW |

| 4 | 2512 cc/rev | 2512 cc/rev | 180 cc/rev | 71 cc/rev | 110 kW + 27 kW |

| 5 | 4400 cc/rev | - | 180 cc/rev | - | 110 kW |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.; Park, B.; Jang, J. Wind Turbine Generator Efficiency Based on Powertrain Combination and Annual Power Generation Prediction. Appl. Sci. 2018, 8, 858. https://doi.org/10.3390/app8060858

Kim D, Park B, Jang J. Wind Turbine Generator Efficiency Based on Powertrain Combination and Annual Power Generation Prediction. Applied Sciences. 2018; 8(6):858. https://doi.org/10.3390/app8060858

Chicago/Turabian StyleKim, Dongmyung, Byeongcheol Park, and Joosup Jang. 2018. "Wind Turbine Generator Efficiency Based on Powertrain Combination and Annual Power Generation Prediction" Applied Sciences 8, no. 6: 858. https://doi.org/10.3390/app8060858

APA StyleKim, D., Park, B., & Jang, J. (2018). Wind Turbine Generator Efficiency Based on Powertrain Combination and Annual Power Generation Prediction. Applied Sciences, 8(6), 858. https://doi.org/10.3390/app8060858