Simulation Analysis and Experimental Study of the Cooker Hoods of High-Rise Residential Buildings

Abstract

:1. Introduction

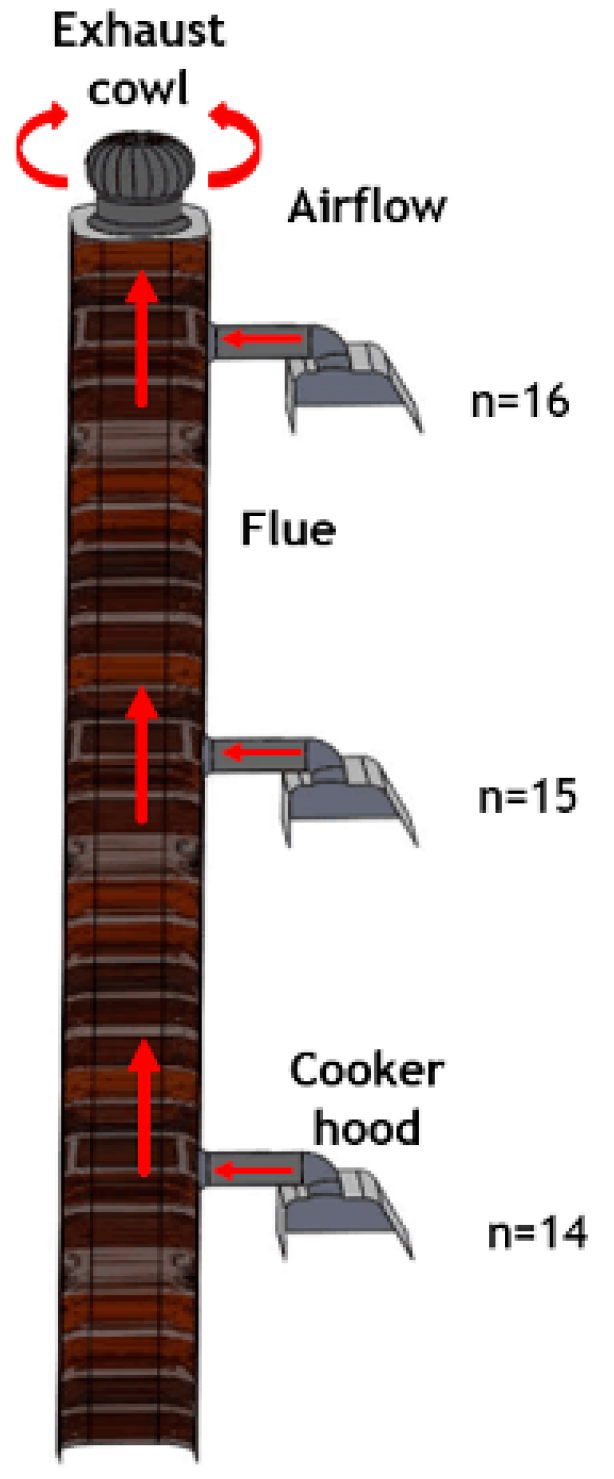

2. Simulation of Centralized Flue System in High-Rise Residential Buildings

2.1. Simulation Theory of Centralized Flue System

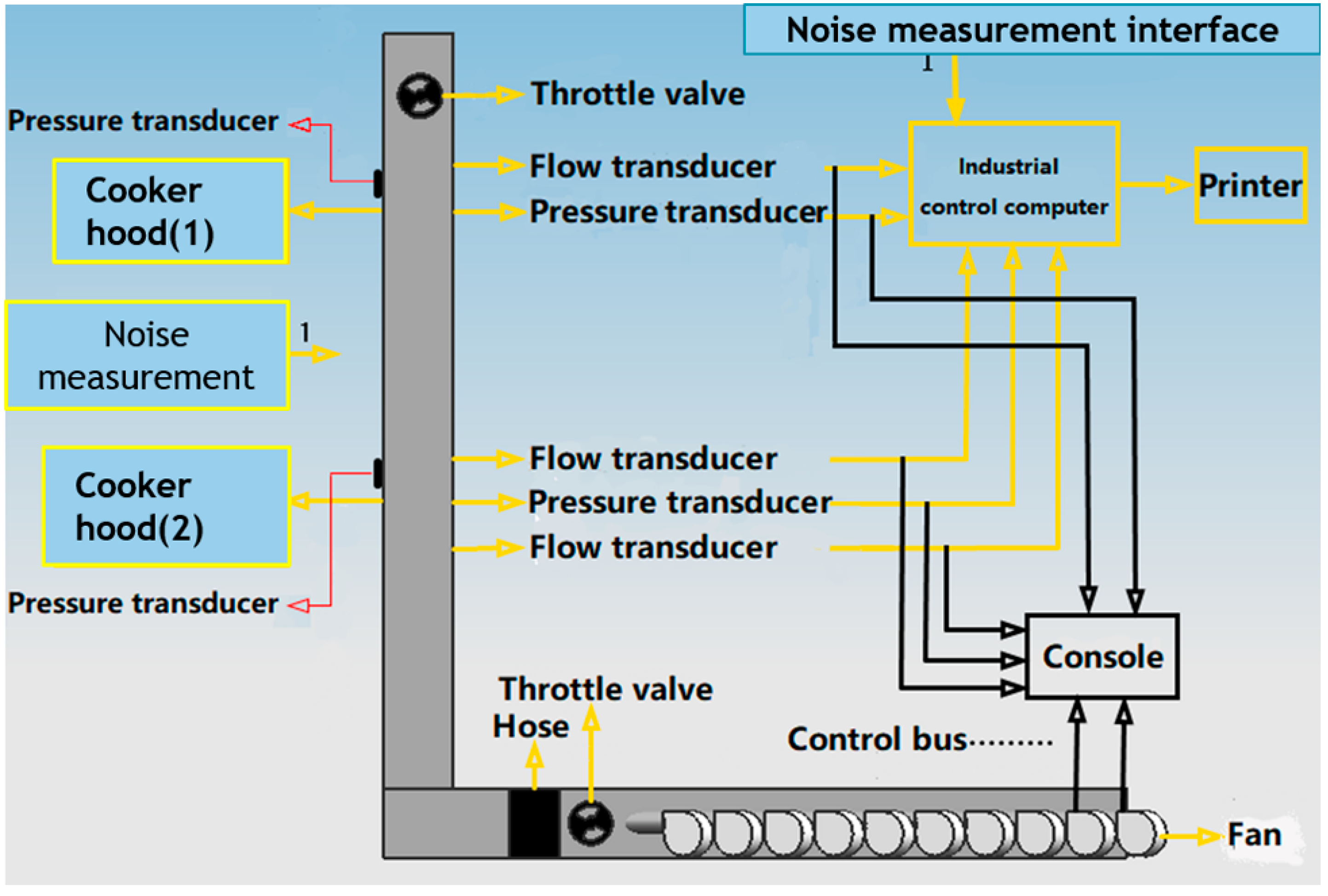

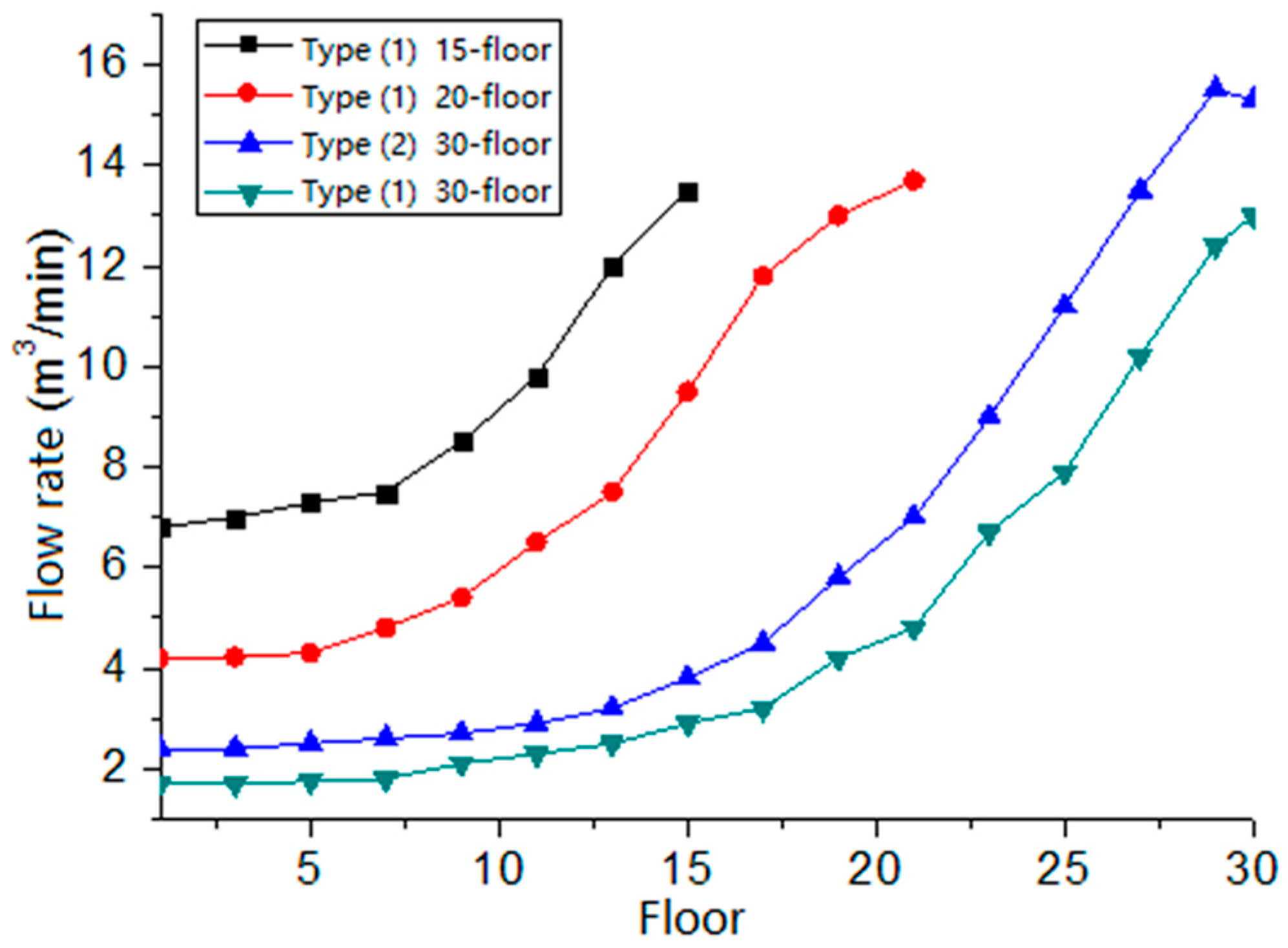

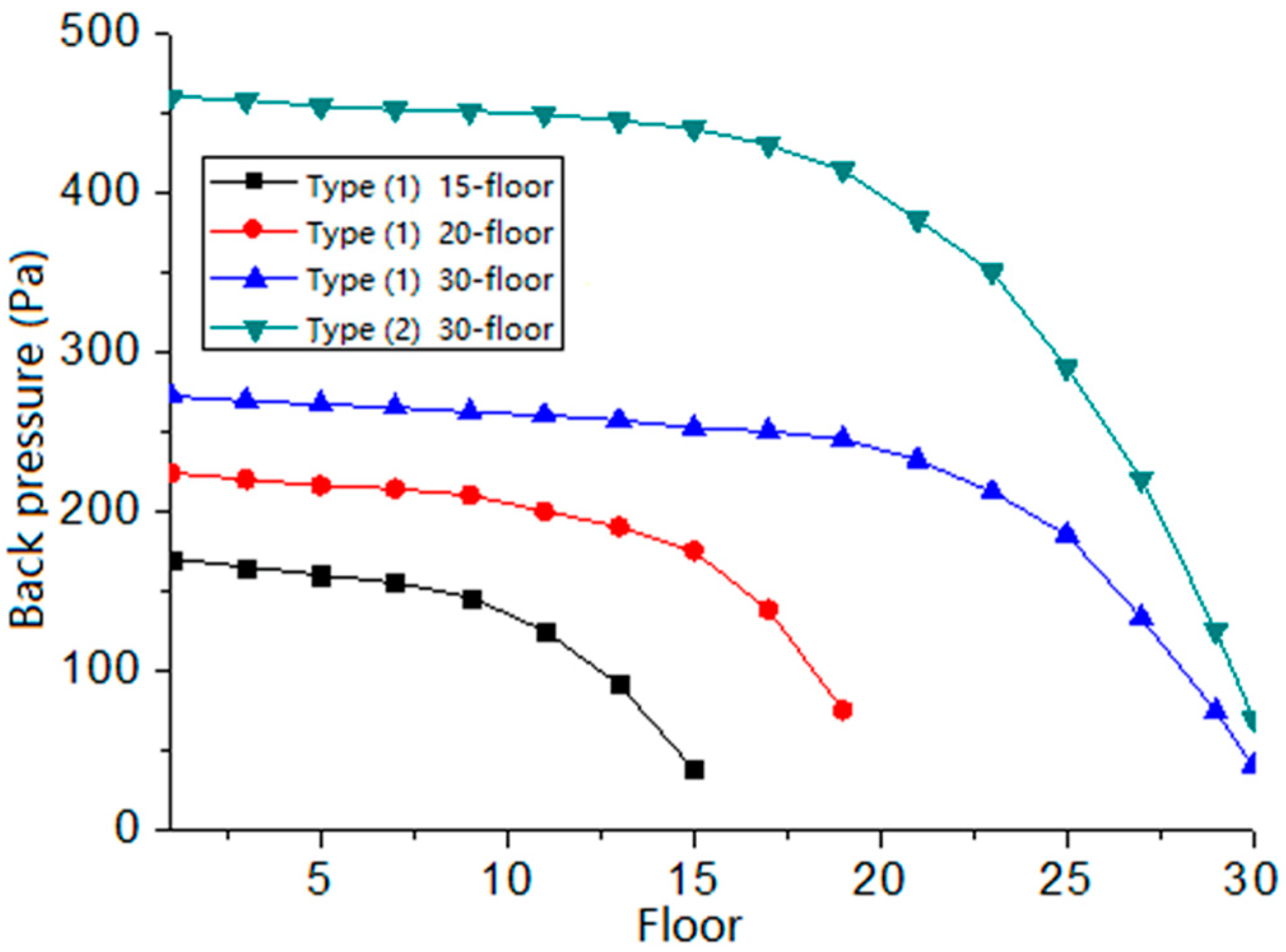

2.2. Simulation of Centralized Flue System

2.3. Performance Parameters of Range Hoods

3. Exterior Flow Field of Cooker Hood

3.1. Analysis Theory of Exterior Flow Field

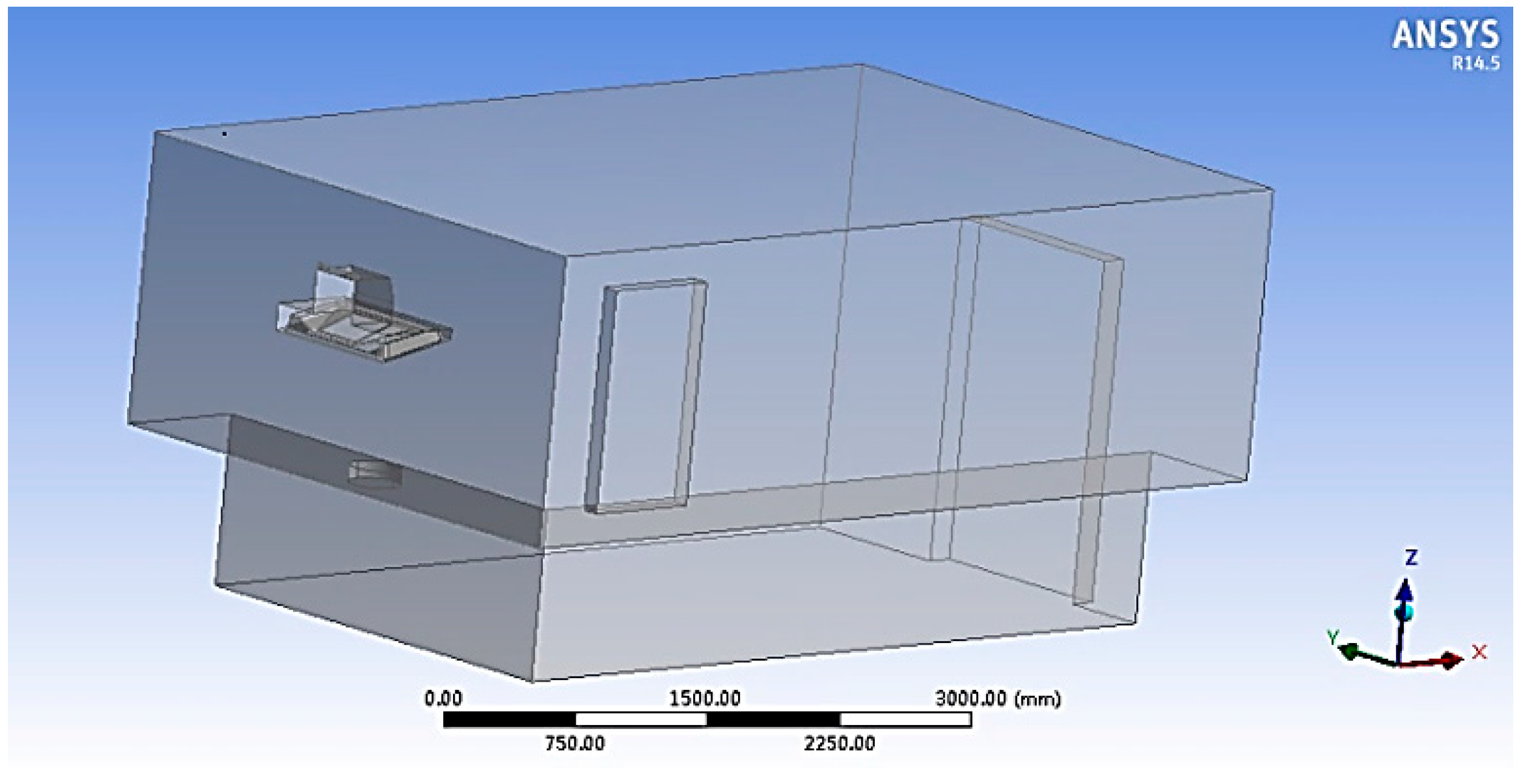

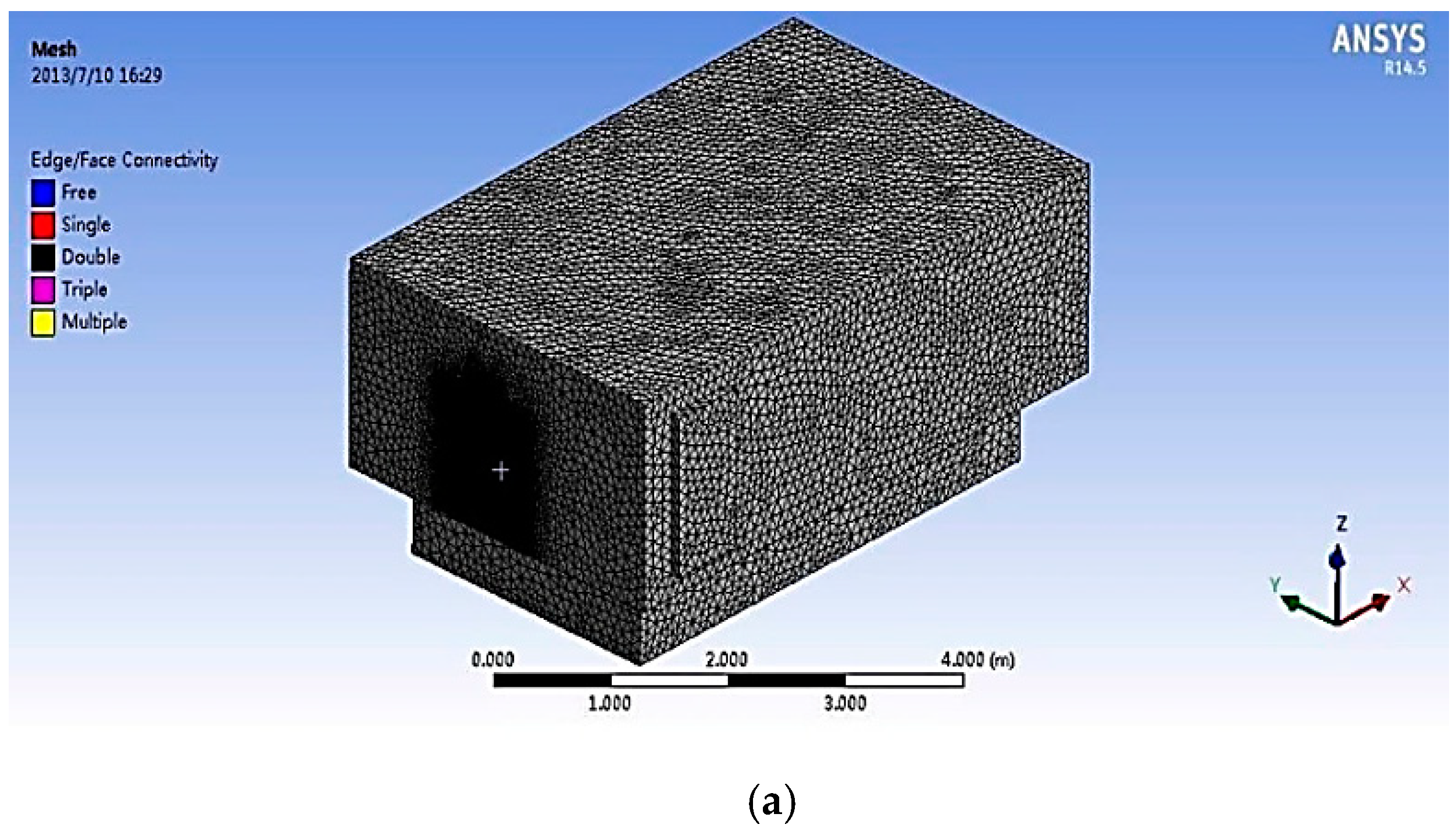

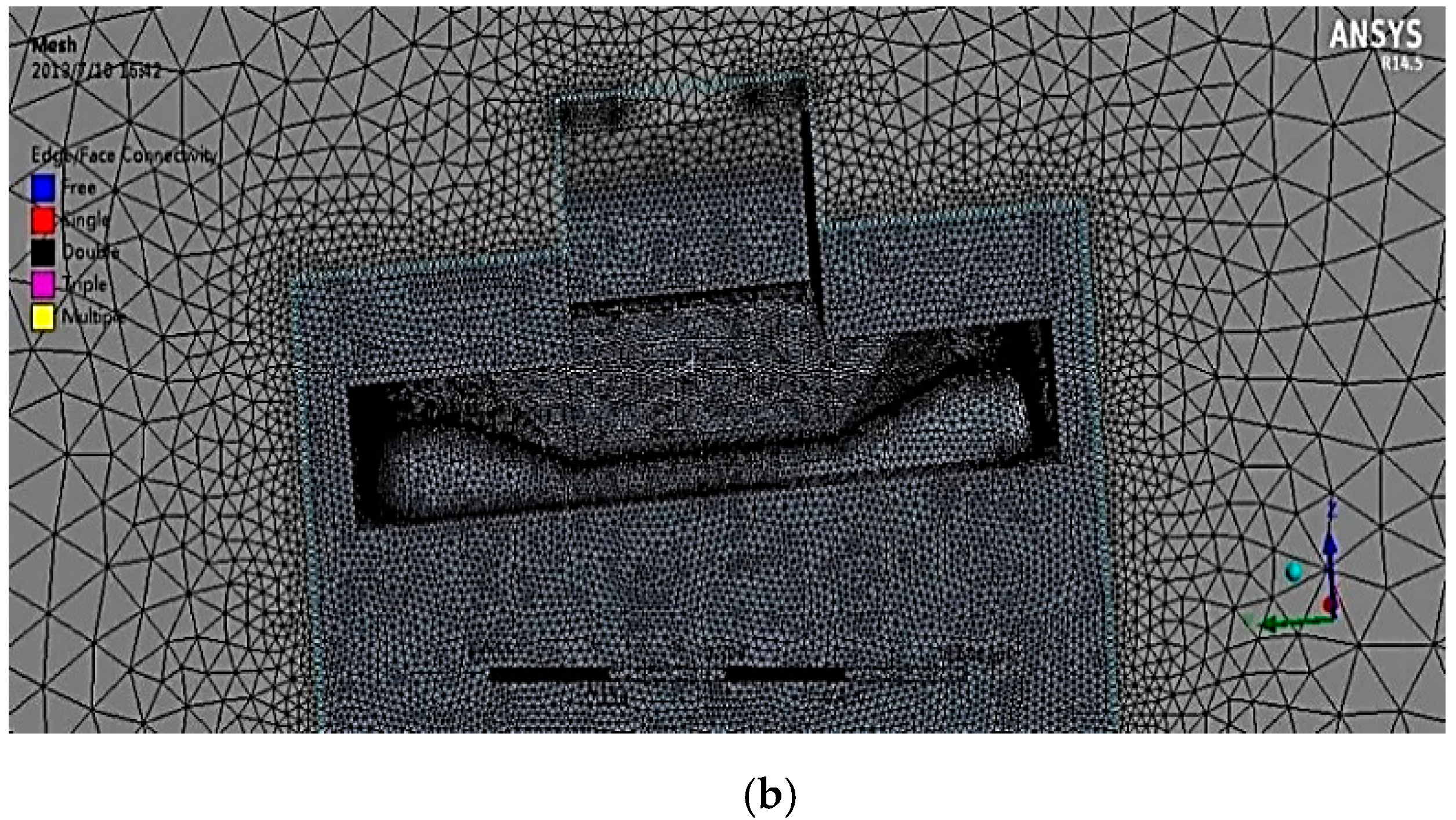

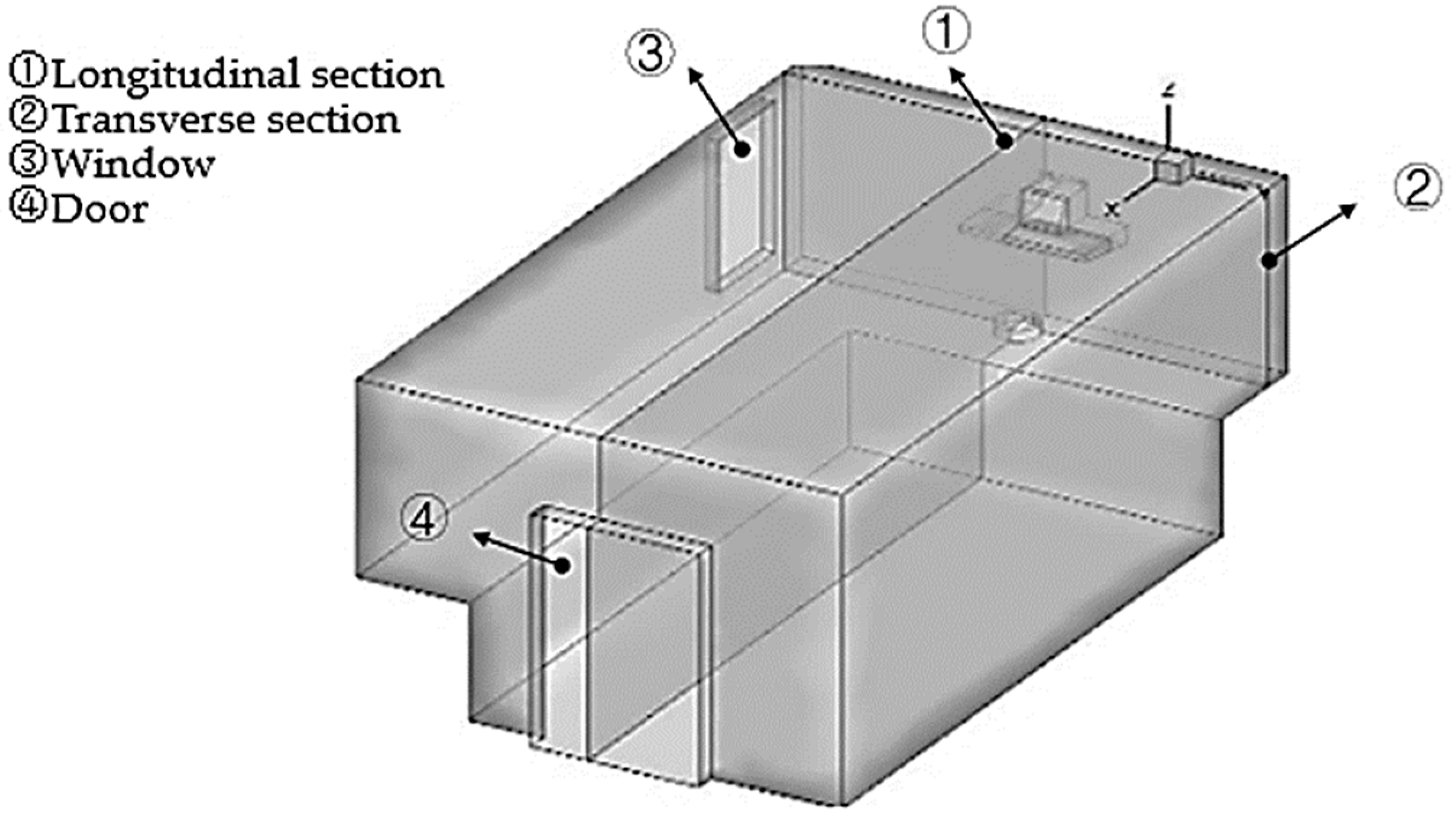

3.2. Simulation Model of Exterior Flow Field

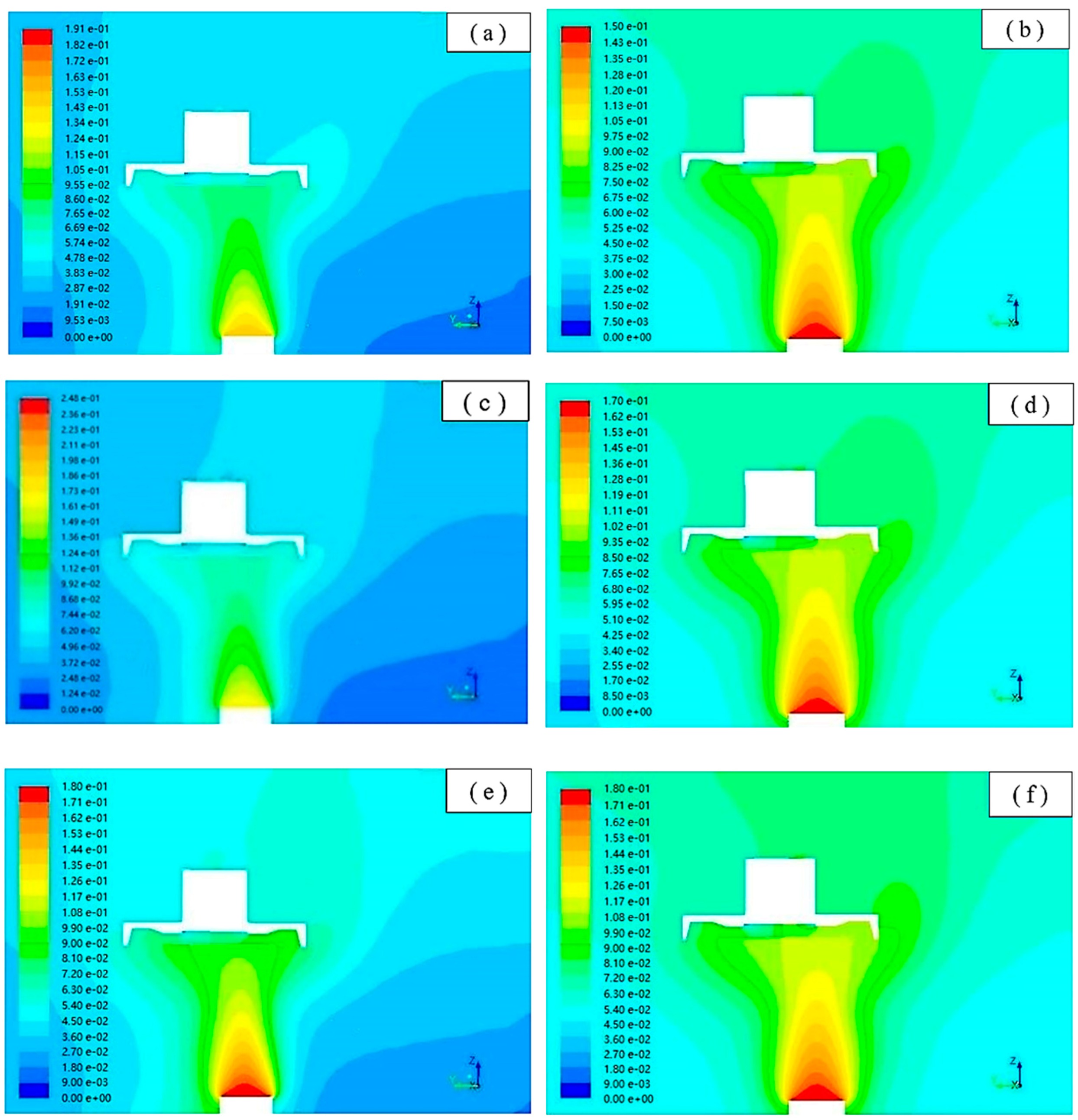

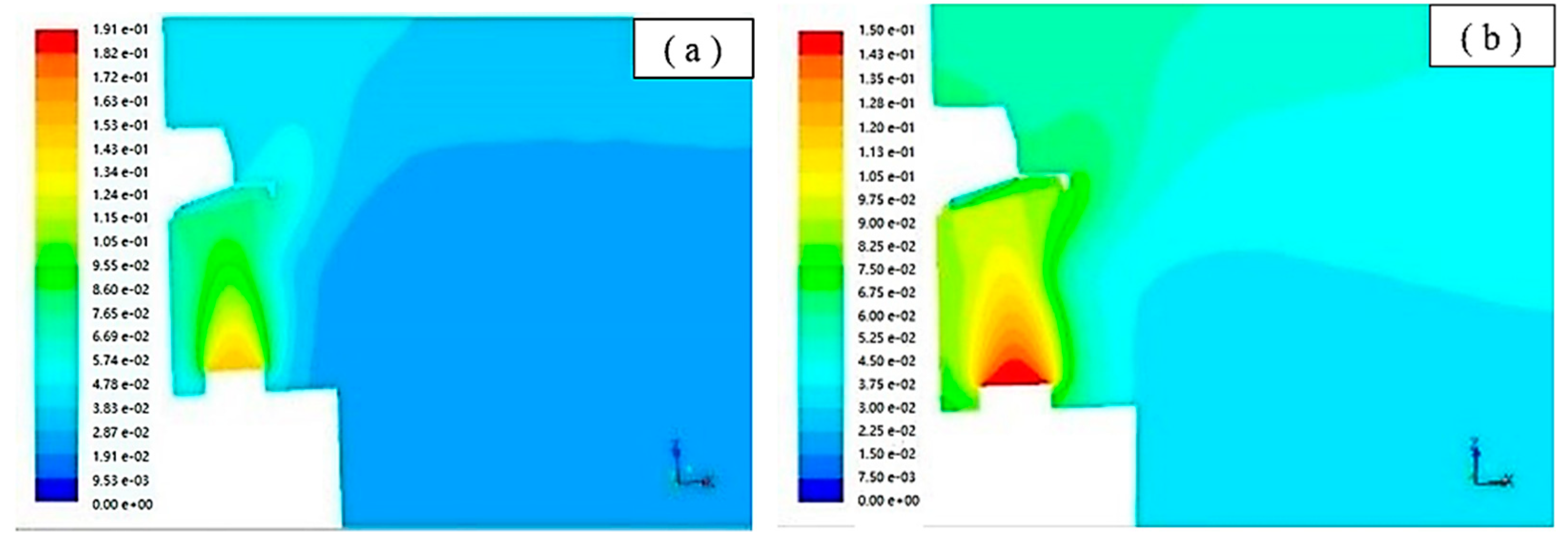

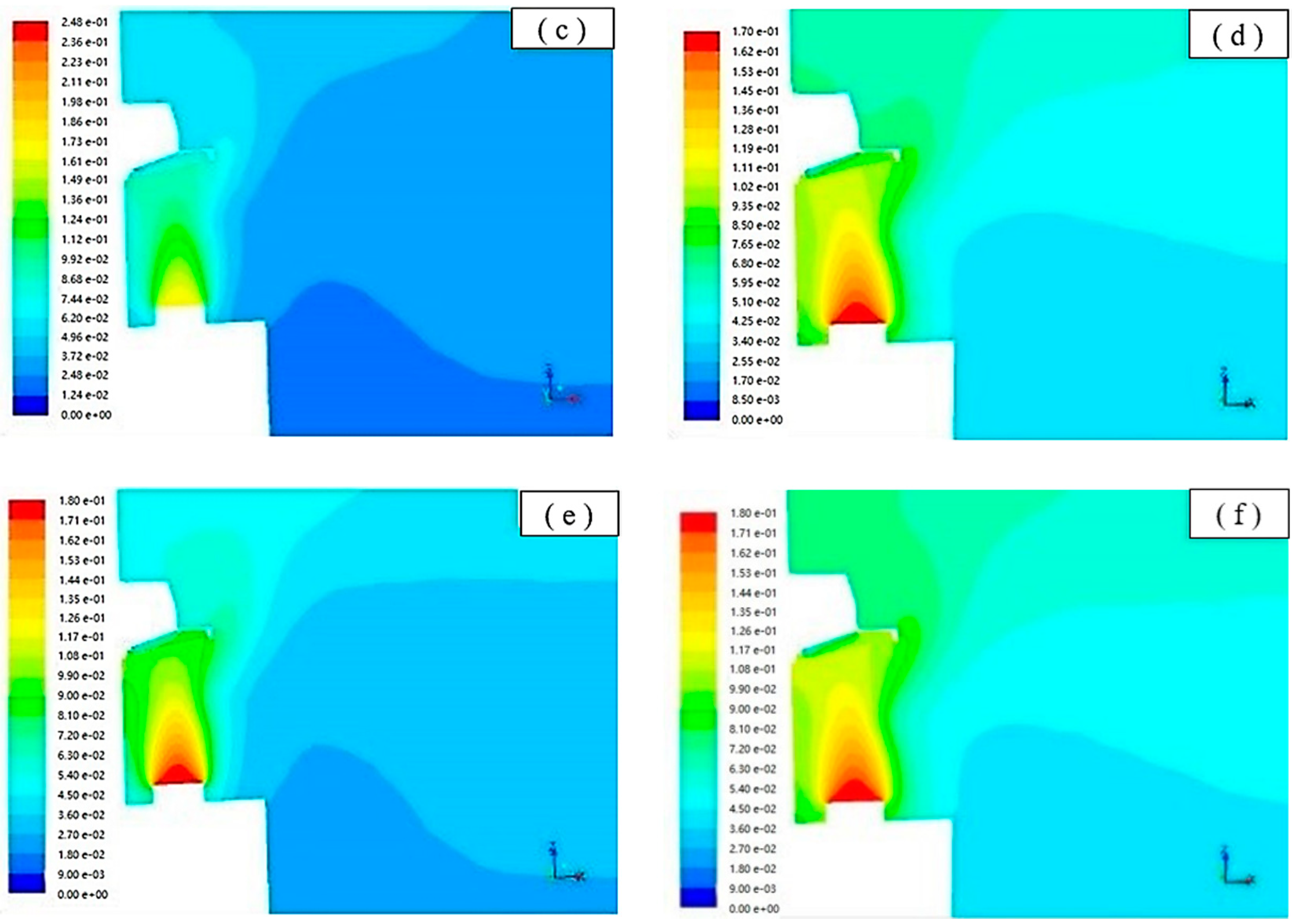

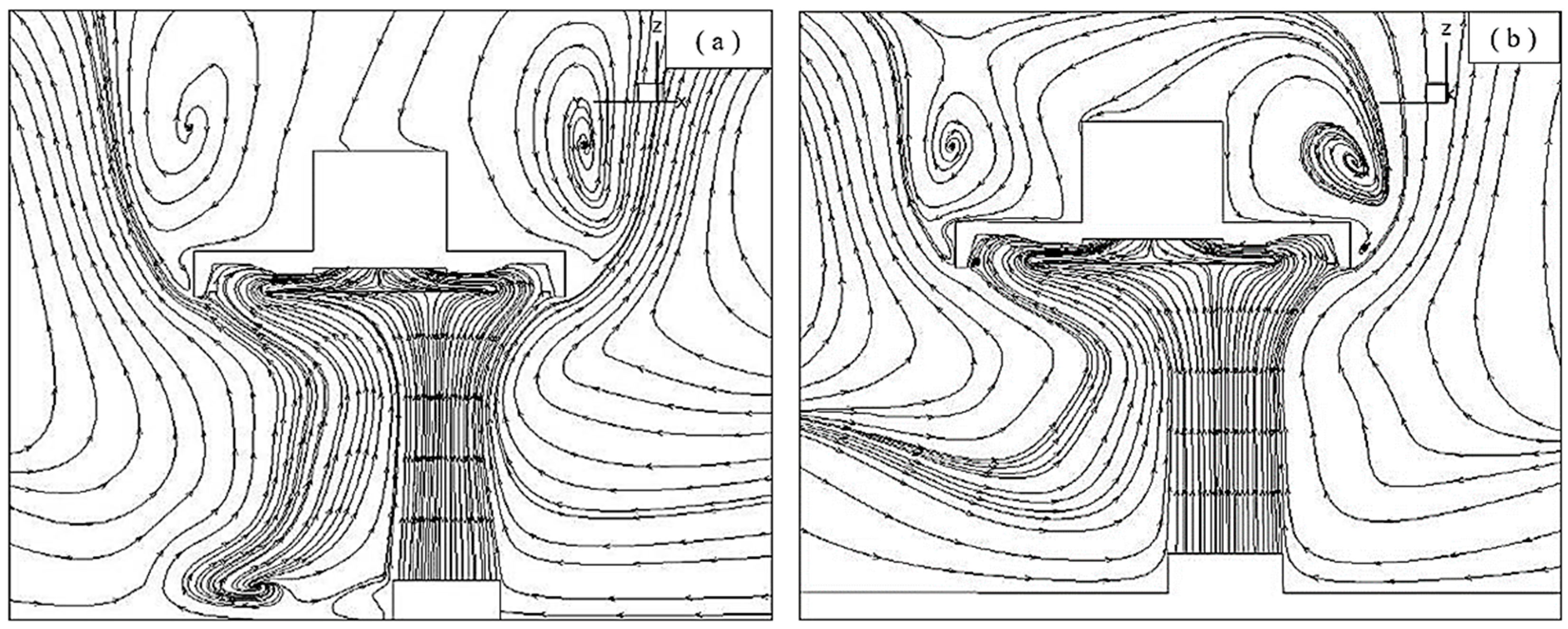

4. Results and Discussion

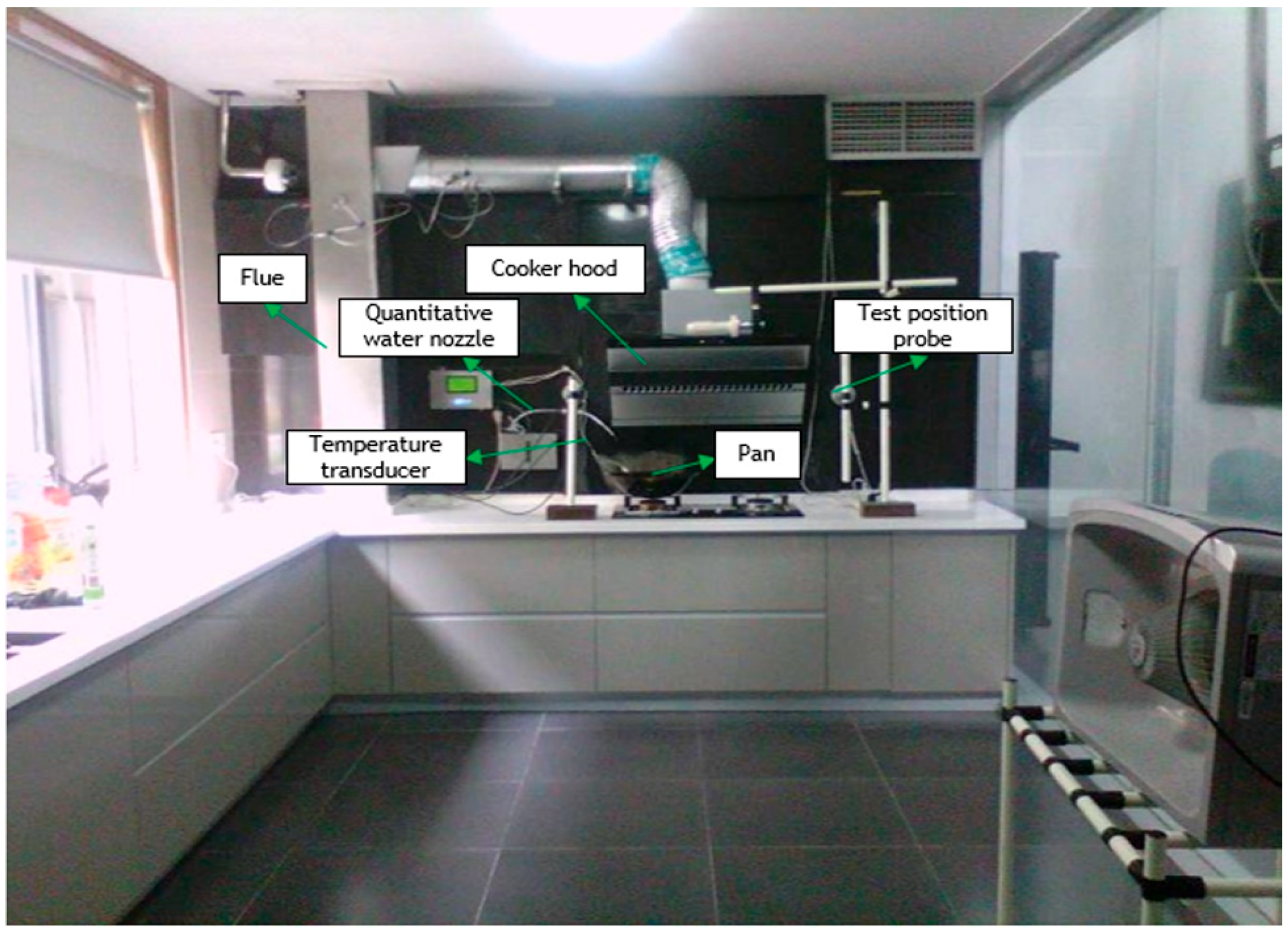

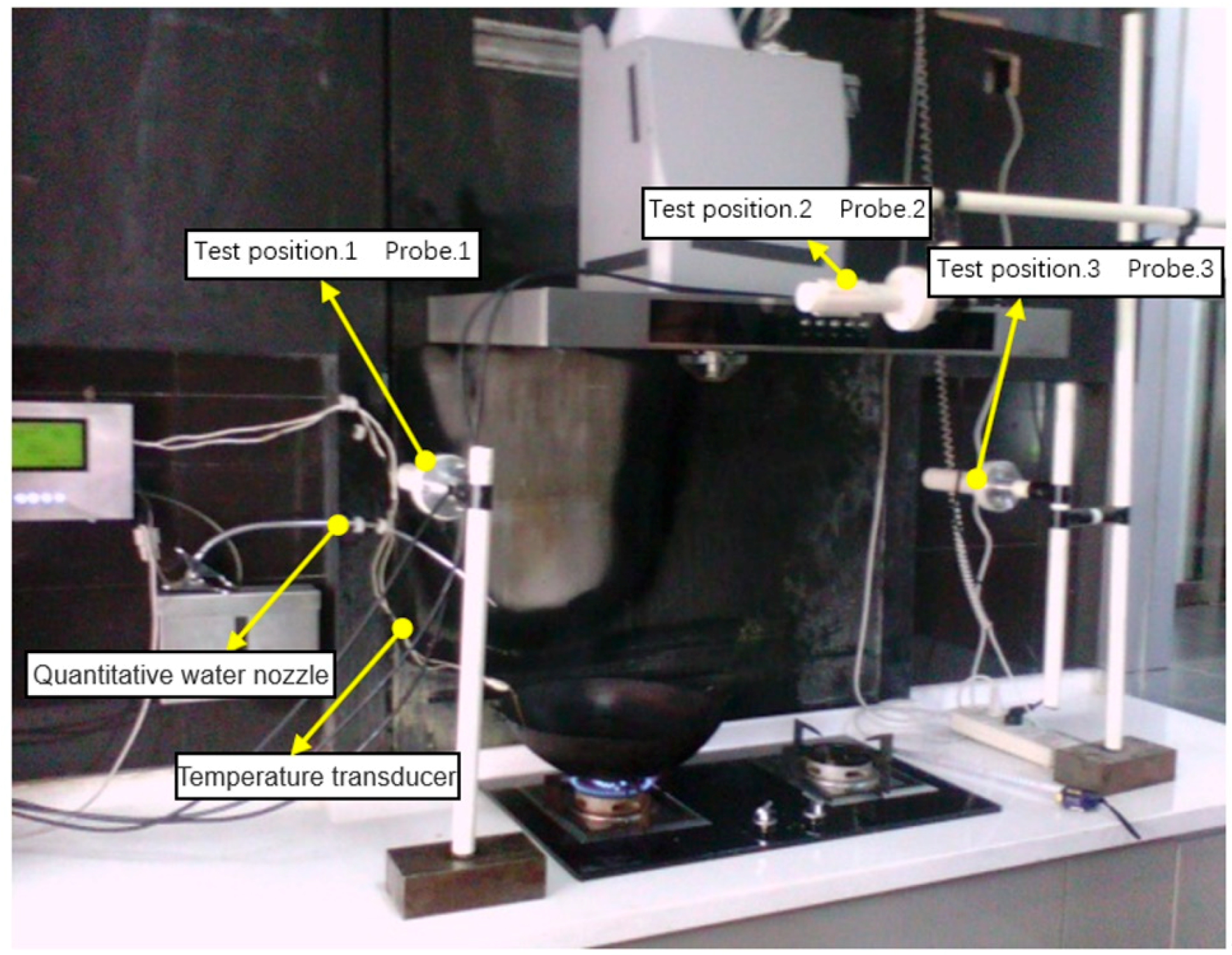

5. Experiment

6. Conclusions

- (1)

- The effects of different operation rates and different installation floors are considered in this study, and a calculation model for the centralized flue system of high-rise residential buildings is proposed. The correlation of the back pressure and flow rate of cooker hoods with the installation floors is obtained by the model, and it provides a feasible theoretical method for the performance design of cooker hoods and the user selection of cooker hoods.

- (2)

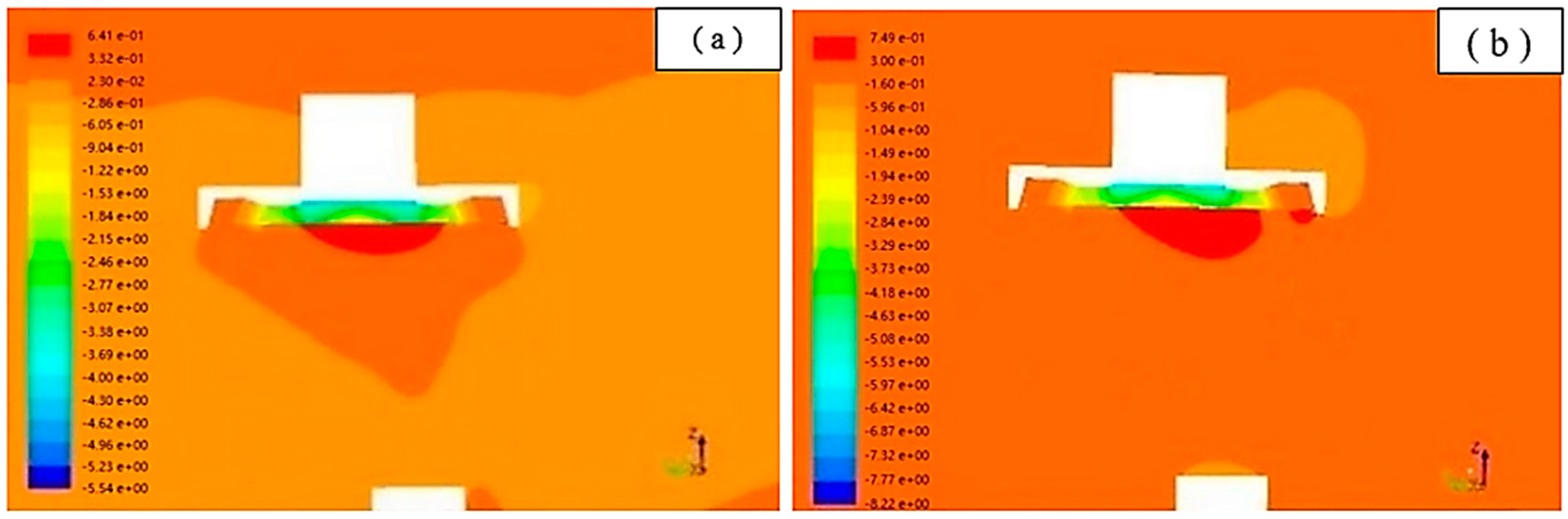

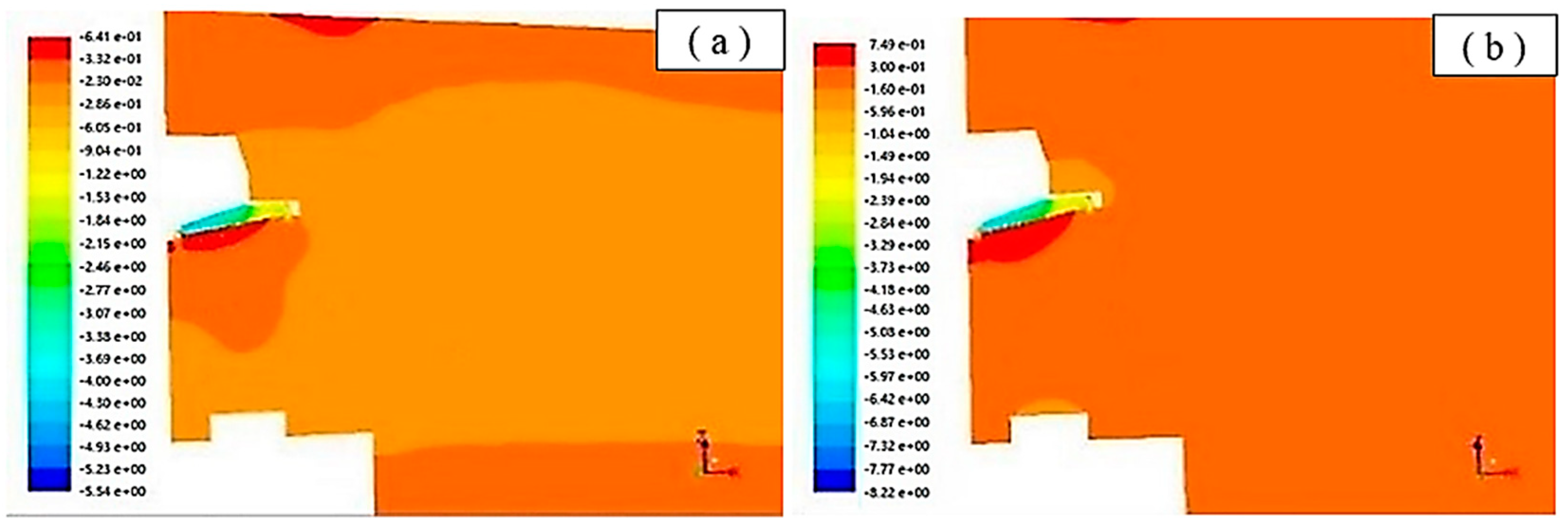

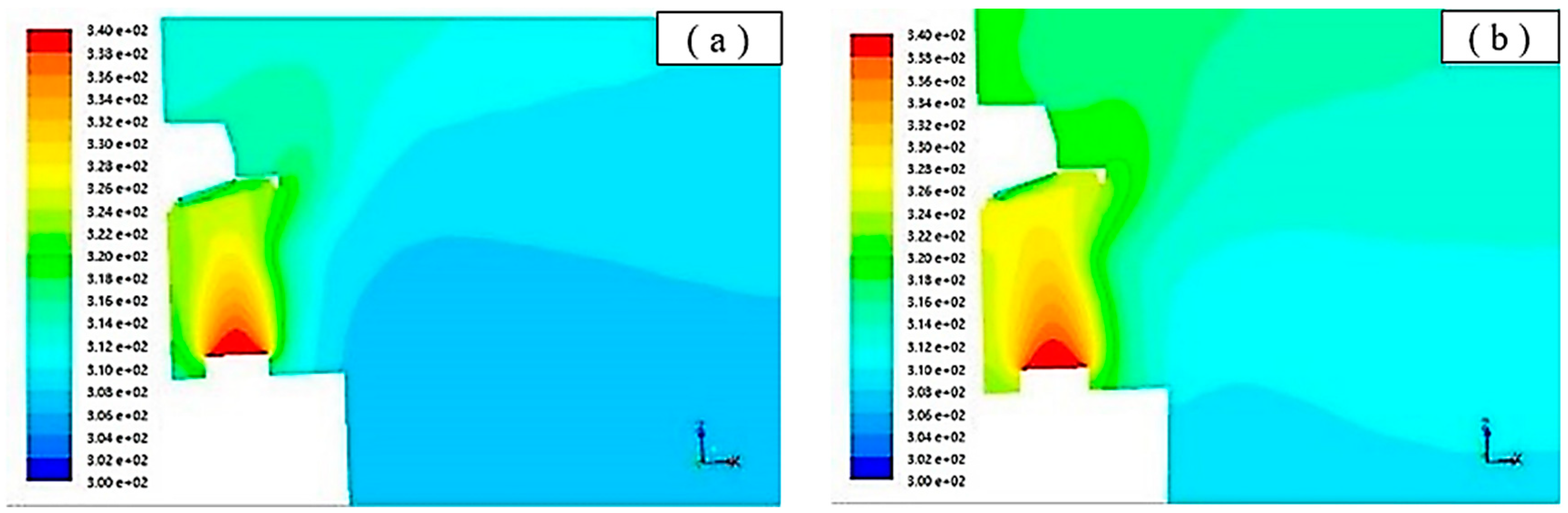

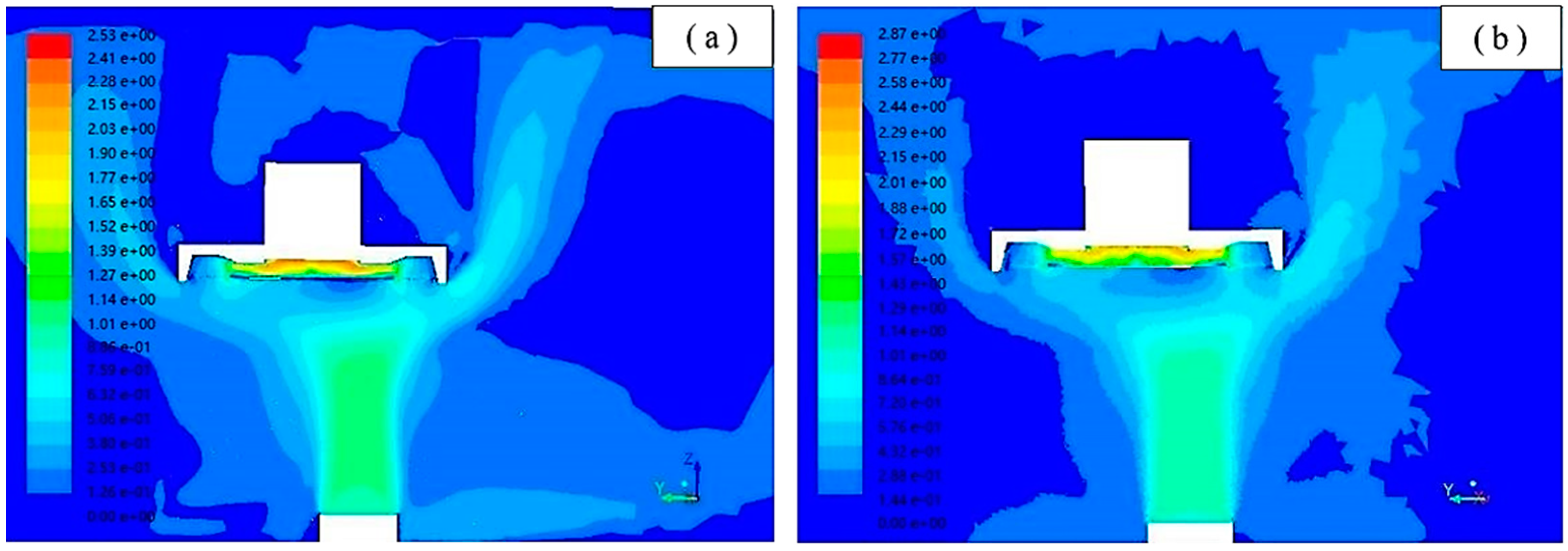

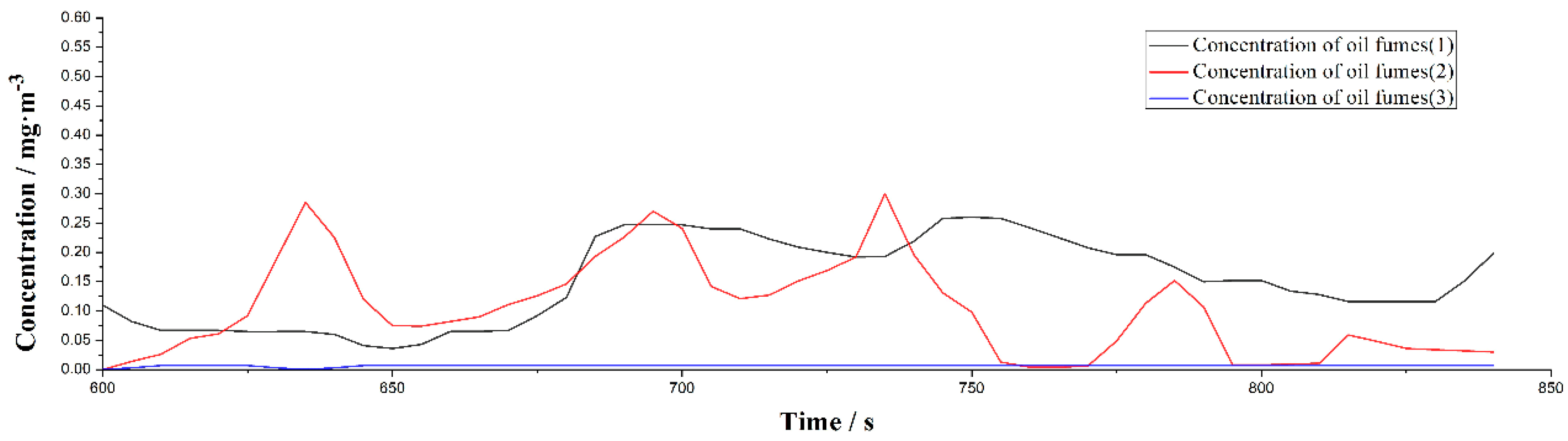

- Based on the simulation environment of high-rise residential buildings with centralized flue systems, the simulation model of exterior flow field for cooker hoods was built to analyze the diffusion characteristics of cooking oil fumes. The escape path, temperature distribution, pressure distribution, and the concentration distribution of oil fumes in kitchens were obtained. The simulation results show that the escape path of oil fumes mainly concentrates on the sides of the cookers and the front sides of the cooker hoods, and the maximum concentrations of escaping oil fumes are and , respectively. When the window is closed, the highest temperature in the main escape region above the cooker hood is 315 K. When the window is opened, the temperature is reduced by 5 K, due to the fact that the air flow is usually more conducive to the emission of oil fumes, fumes escape less, and the temperature is lower.

- (3)

- The results calculated by the simulation model of the cooker hood based on the simulation environment of high-rise residential building agree well with the experiment data. Comparing the simulation analysis with the test results from the experimental test results, the peak value of the maximum concentration on the right side is 0.26 , and the maximum peak value of the front side oil smoke concentration is 0.30 , so the front side error is only 5% minimum, and on the right side the maximum error is not more than 12%. The simulation model proposed in this paper can better analyze the diffusion characteristics of cooking oil fumes in kitchens of high-rise residential buildings with cooker hoods. This method provides a useful reference for kitchen design, performance improvements of cooker hoods, and the relationships between the living environments and cooker hoods.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Wang, K.X.; Zhu, X.D. The constituents in cooking-oil smoke and their analysis of methods. Shanghai Environ. Sci. 1999, 18, 526–528. [Google Scholar]

- Song, R.J.; Wang, G.F.; Wang, B. Chemical composition analysis and identification of cooking oil smoke. Chin. J. Public Health Eng. 1996, 5, 7–11. [Google Scholar]

- De Gennaro, G.; Dambruoso, P.R.; Di Gilio, A.; Di Palma, V.; Marzocca, A.; Tutino, M. Discontinuous and continuous indoor air quality monitoring in homes with fireplaces or wood stoves as heating system. Int. J. Environ. Res. Public Health 2015, 13, 78. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.Z.; Wang, J.; Jiang, B.H. Prelimilary exploration of features and sources of PAHs pollution in air of kitchen. China Environ. Sci. 2002, 22, 142–145. [Google Scholar]

- Rbeumer, R.; Kusumaningru, H. Kitchen hygiene in daily life. Int. Biodeterior. Biodegrad. 2003, 51, 299–302. [Google Scholar] [CrossRef]

- Shun, C.L.; Wai, M.L.; Lo, Y.C. Indoor air quality at restaurants with different styles of cooking in metropolitan Hong Kong. Sci. Total Environ. 2001, 279, 181–193. [Google Scholar]

- Wang, X.X. Research on Design Method of the Central Exhaust System for Residential Kitchen in High-Rise Buildings; Tongji University: Shanghai, China, 2006. [Google Scholar]

- Li, M.F.; Peng, X.Y.; Yao, L. Effect of different working modes of range hood on environmental characteristics of kitchen. Power Gener. Air Cond. 2010, 31, 55–58. [Google Scholar]

- Feng, M.; Wang, Y.R.; Wang, Y.C.; Wang, P.C.; Tang, A.L. Experimental study on branch set up check valve of centralized exhaust system in high-rise residential buildings. China House Facil. 2010, 4, 60–63. [Google Scholar]

- Liu, N. Ordinary high-rise residential kitchen computer simulation in central exhaust system. Refrigeration Air Cond. 2009, 5, 119–126. [Google Scholar]

- Zhu, P.G.; Zhu, M.L.; Cai, H. Numerical simulation and test on smoke of residential kitchen. J. PLA Univ. Sci. Technol. 2006, 7, 153–156. [Google Scholar]

- Yu, M.C.; Zhang, D.C. Numerical simulation of fume concentration in indoor kitchens. J. Xiangtan Norm. Univ. 2008, 30, 72–75. [Google Scholar]

- Li, S.D.; Xu, J.B.; Mo, S.P.; Li, W.H.; Gao, J.J.; Cao, Y.Q.; Chen, Y.F. Particle size distribution and diffusion for simulated cooking fume. Environ. Sci. 2017, 38, 32–40. [Google Scholar]

- Yao, X.; Chen, M.; Fan, Z.Y.; Chen, M.X.; Shi, J.W.; Shang guan, W.F.; Cao, Y.Q.; Zhang, X.D. Pollution from cooking emission and progress in its control technology. Chem. Ind. Eng. 2015, 32, 53–58. [Google Scholar]

- Chen, F.; Zhou, B.; Liu, J.X.; Xue, K.; Xu, Y.; Tang, X.Y. Auxiliary effect of slot air curtain on pollution control performance of kitchen range hood. China Environ. Sci. 2016, 36, 709–718. [Google Scholar]

- Fu, W.J.; Li, J.; Wang, H.J. Optimization design of kitchen hood system based on simulation analysis. Comput. Simul. 2013, 30, 229–233. [Google Scholar]

- Shi, M.X.; Wang, H.Q.; Wang, Z.Y.; Chen, Y. Experimental research on new design for wind-curta in lampblack presser. J. Hunan Univ. Technol. 2008, 22, 20–23. [Google Scholar]

- Zhang, J.Y. Studies on the Characteristic of Smoke Movement and Smoke Control in Shaft of High-Rise Buildings; University of Science and Technology of China: Hefei, China, 2006. [Google Scholar]

- Zhang, D.Y.; Zhao, F.F.; Li, Y.; Li, P.Y.; Zeng, Q.F.; Dong, G.N. Study on tribological properties of multi-layer surface texture on Babbitt alloys surface. Appl. Surf. Sci. 2016, 390, 540–549. [Google Scholar] [CrossRef]

| Components Window State | Acetaldehyde | Acetic Acid | Water Vapor | Mixed Gas | ||||

|---|---|---|---|---|---|---|---|---|

| Open | Close | Open | Close | Open | Close | Open | Close | |

| Right | 0.047 | 0.068 | 0.070 | 0.090 | 0.062 | 0.089 | 0.179 | 0.247 |

| Front | 0.064 | 0.075 | 0.075 | 0.094 | 0.081 | 0.096 | 0.220 | 0.265 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.-C.; Wang, T.; Liu, X.-Q.; Zhu, Y.-D.; Yang, Y.-X. Simulation Analysis and Experimental Study of the Cooker Hoods of High-Rise Residential Buildings. Appl. Sci. 2018, 8, 777. https://doi.org/10.3390/app8050777

Zhang Y-C, Wang T, Liu X-Q, Zhu Y-D, Yang Y-X. Simulation Analysis and Experimental Study of the Cooker Hoods of High-Rise Residential Buildings. Applied Sciences. 2018; 8(5):777. https://doi.org/10.3390/app8050777

Chicago/Turabian StyleZhang, Yan-Chao, Ting Wang, Xun-Qian Liu, Yong-Ding Zhu, and Yun-Xia Yang. 2018. "Simulation Analysis and Experimental Study of the Cooker Hoods of High-Rise Residential Buildings" Applied Sciences 8, no. 5: 777. https://doi.org/10.3390/app8050777

APA StyleZhang, Y.-C., Wang, T., Liu, X.-Q., Zhu, Y.-D., & Yang, Y.-X. (2018). Simulation Analysis and Experimental Study of the Cooker Hoods of High-Rise Residential Buildings. Applied Sciences, 8(5), 777. https://doi.org/10.3390/app8050777