Evaluation of Fe-Based Shape Memory Alloy (Fe-SMA) as Strengthening Material for Reinforced Concrete Structures

Abstract

1. Introduction

2. Experimental Program

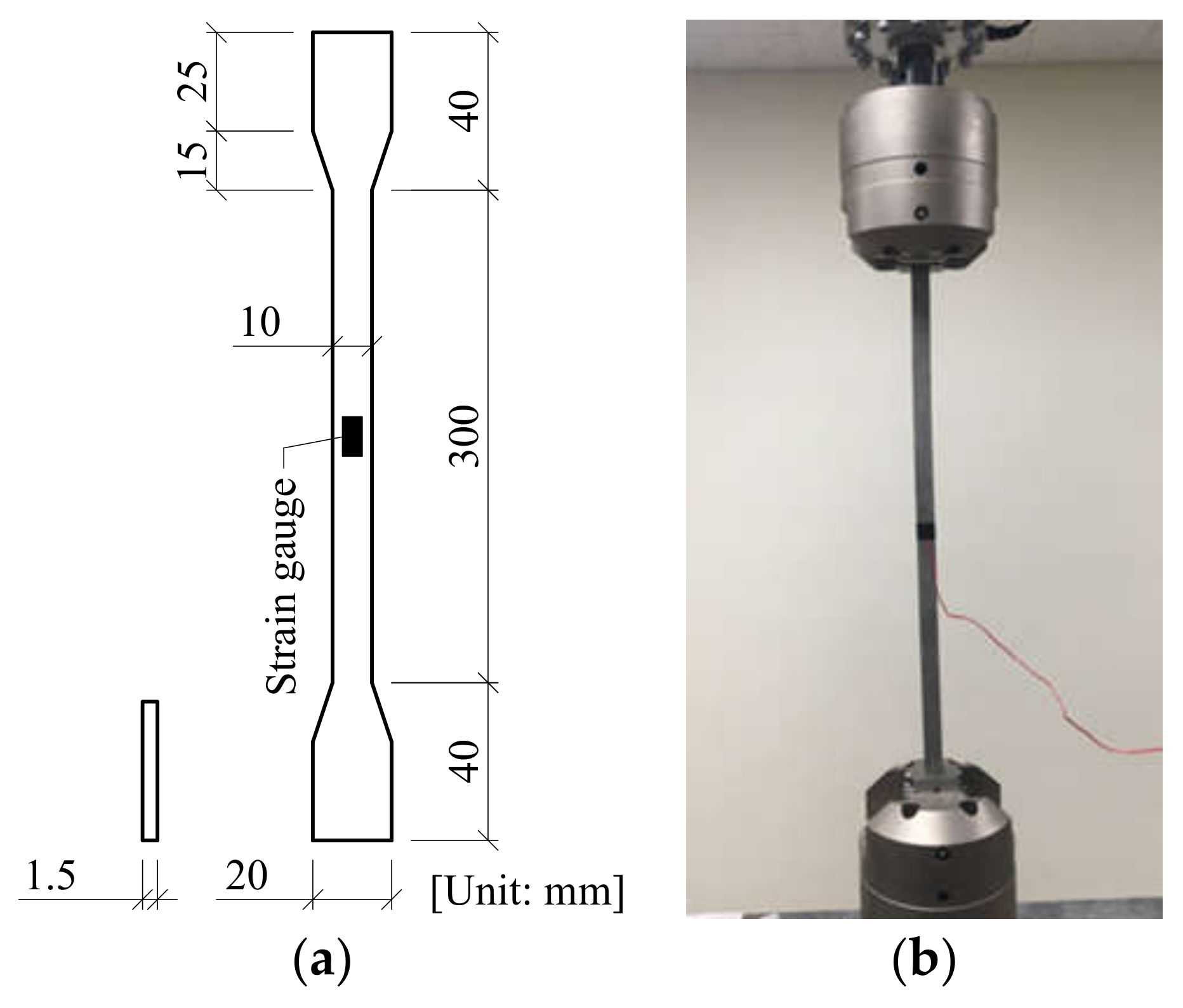

2.1. Fe-SMAs

2.2. Pre-Straining of Fe-SMA

2.3. Recovery Stress Test of Fe-SMA

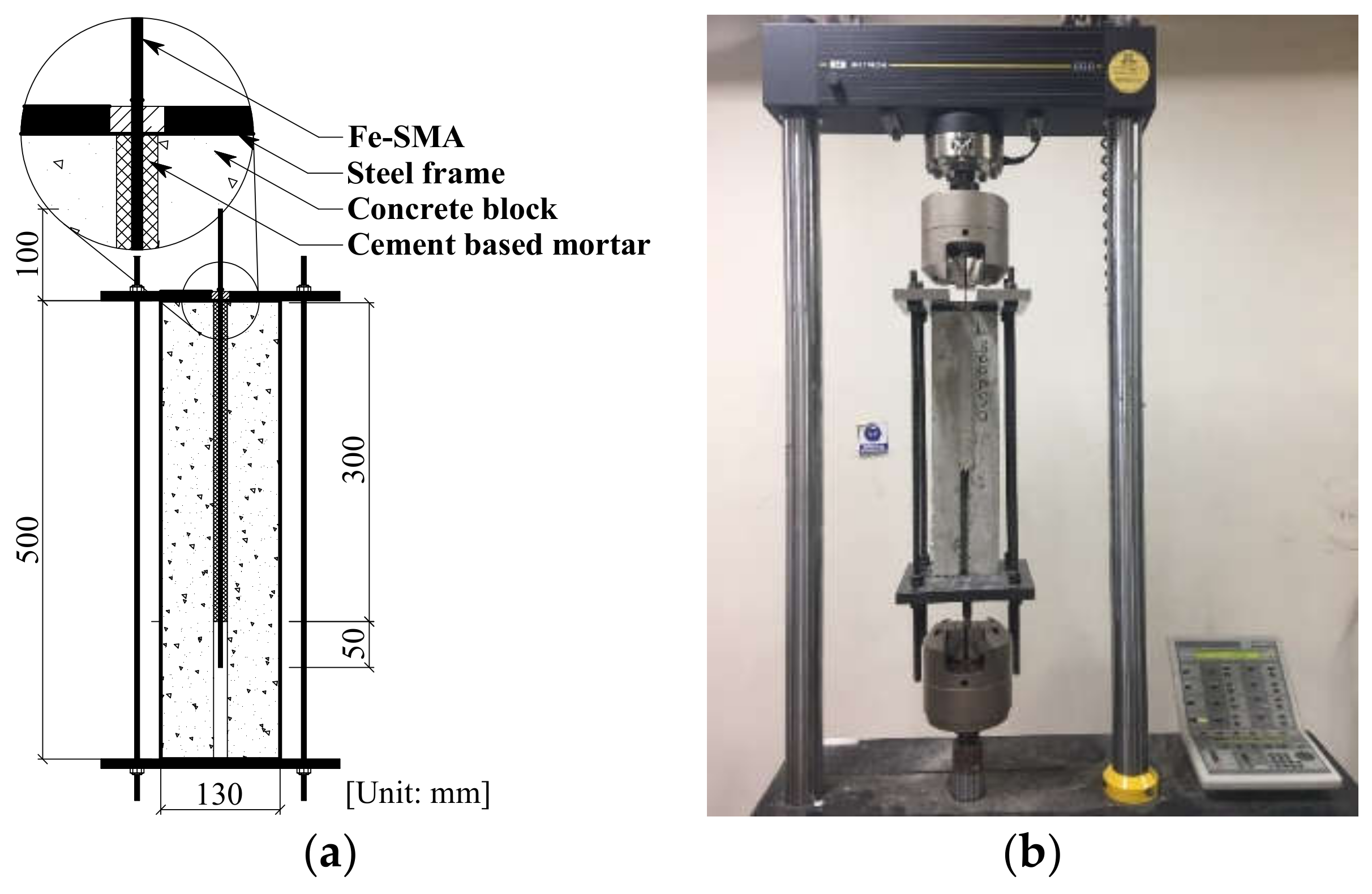

2.4. Bonding Test of Fe-SMA

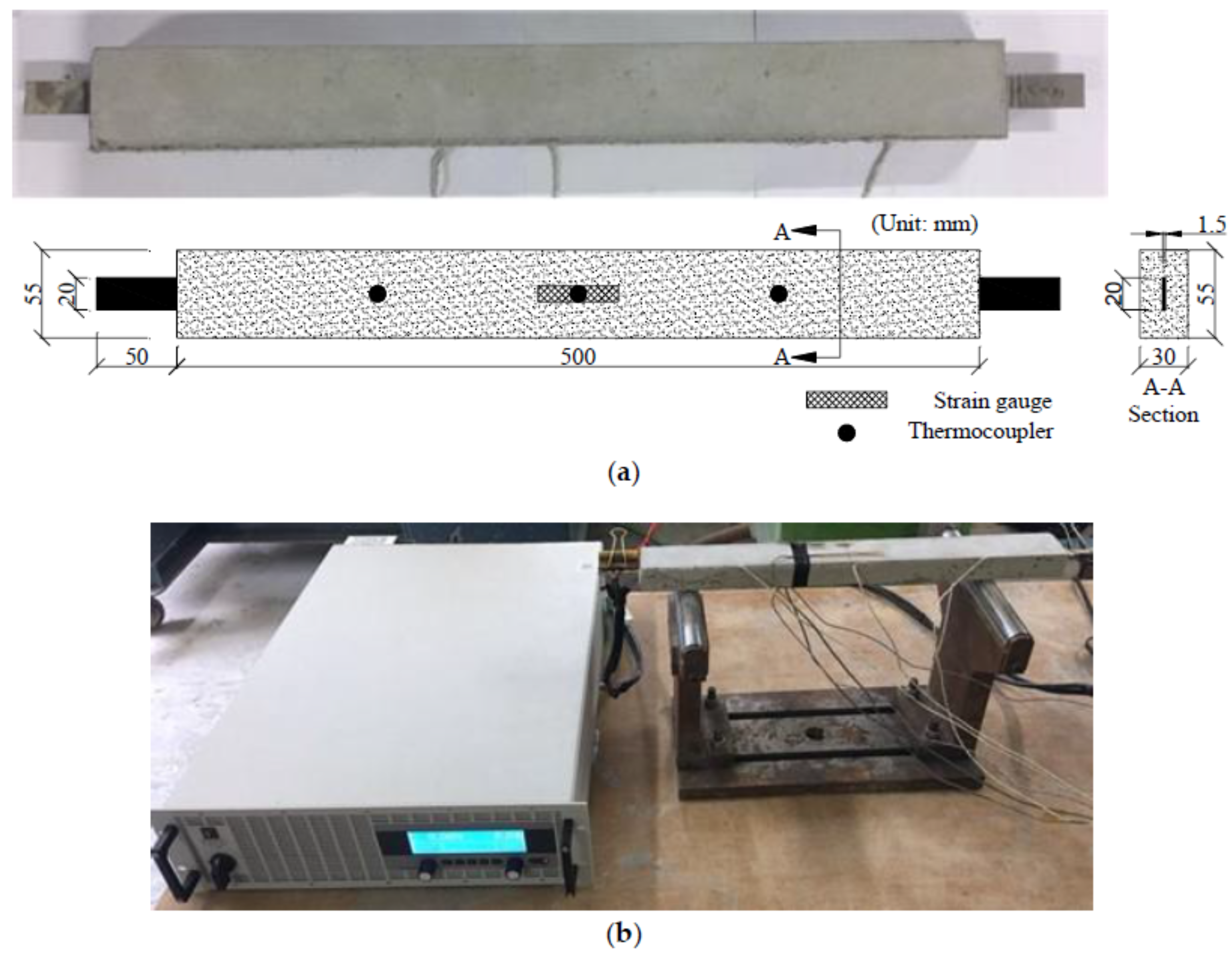

2.5. Recovery Stress Transfer Test

3. Results and Discussion

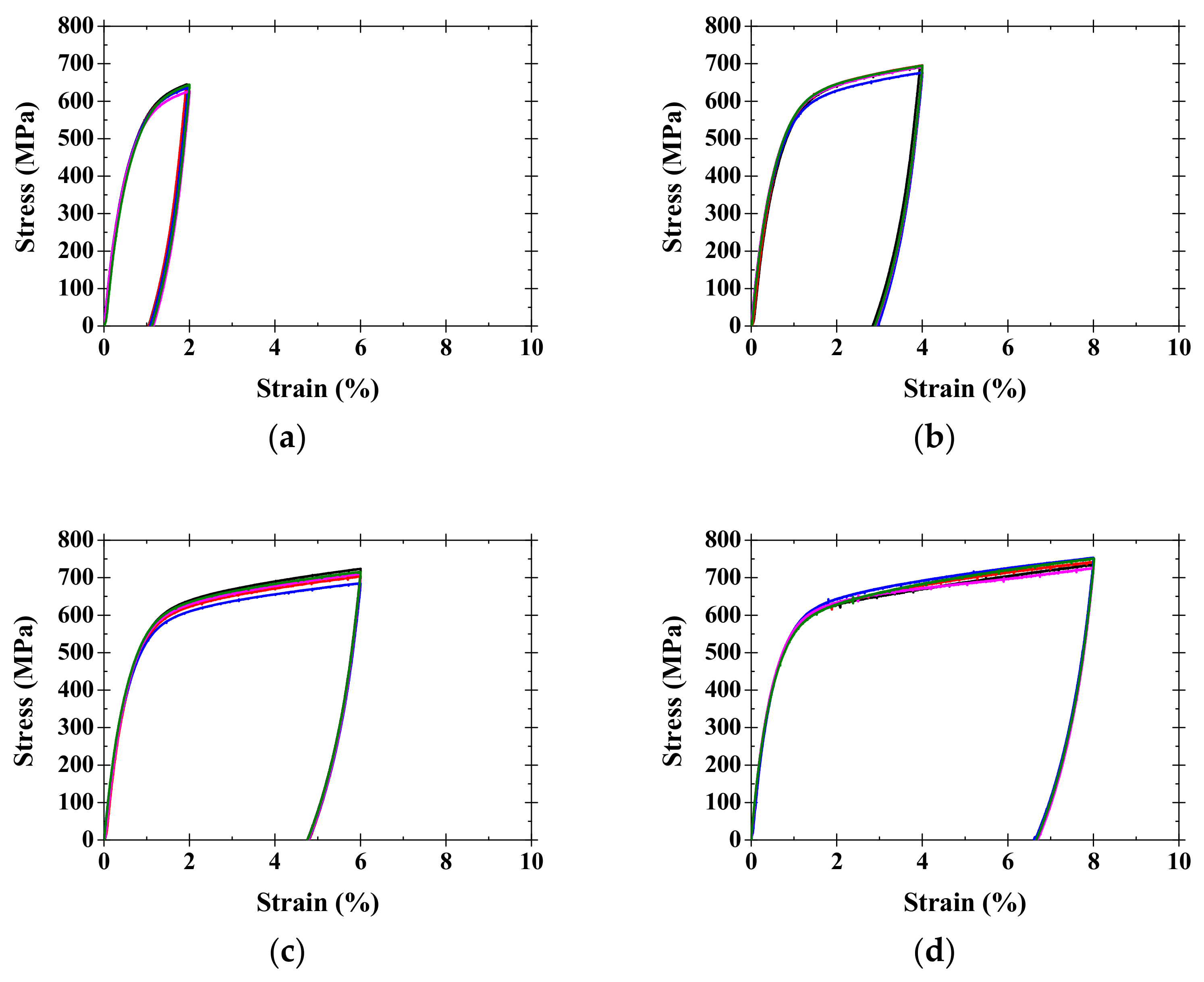

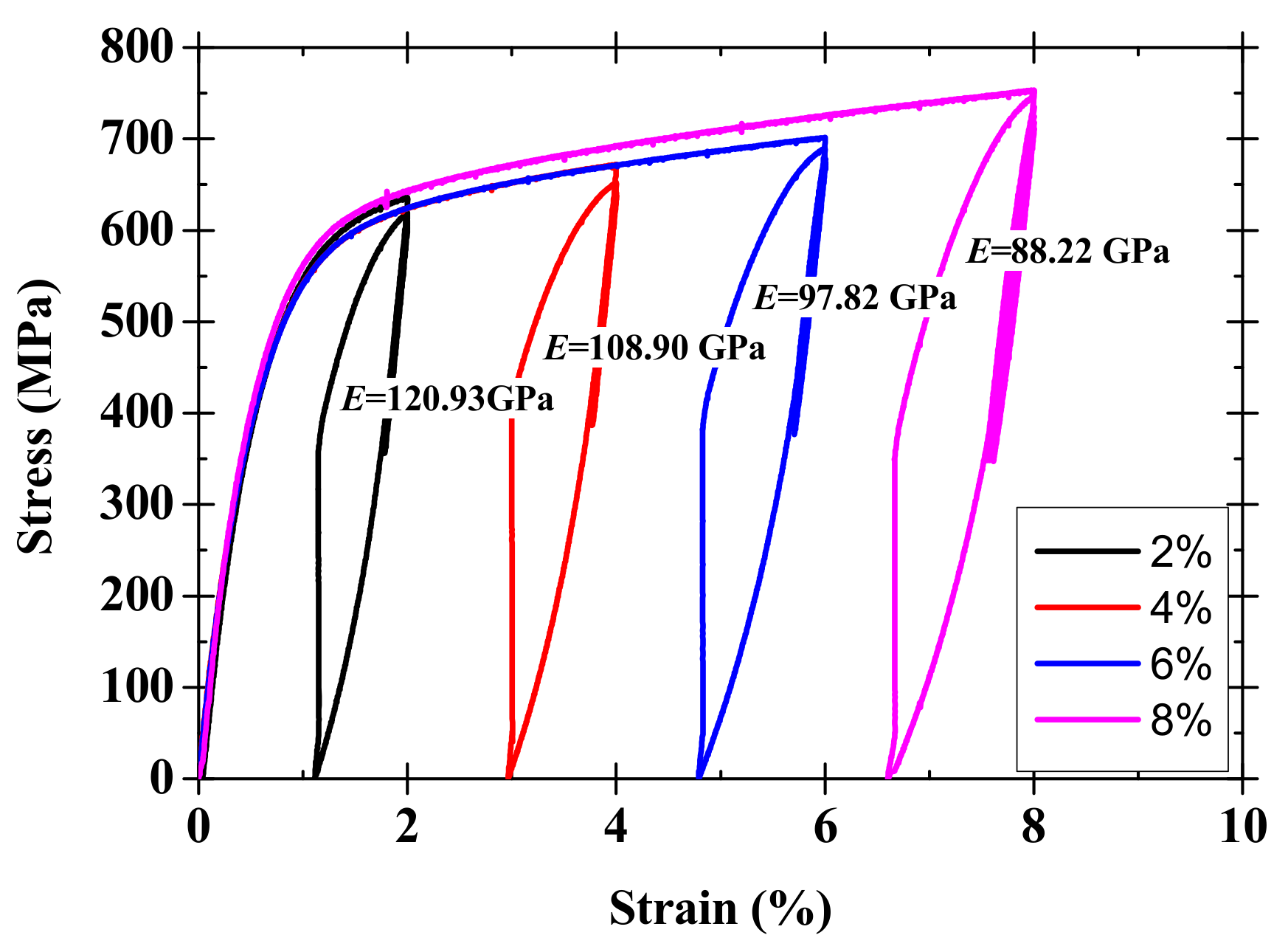

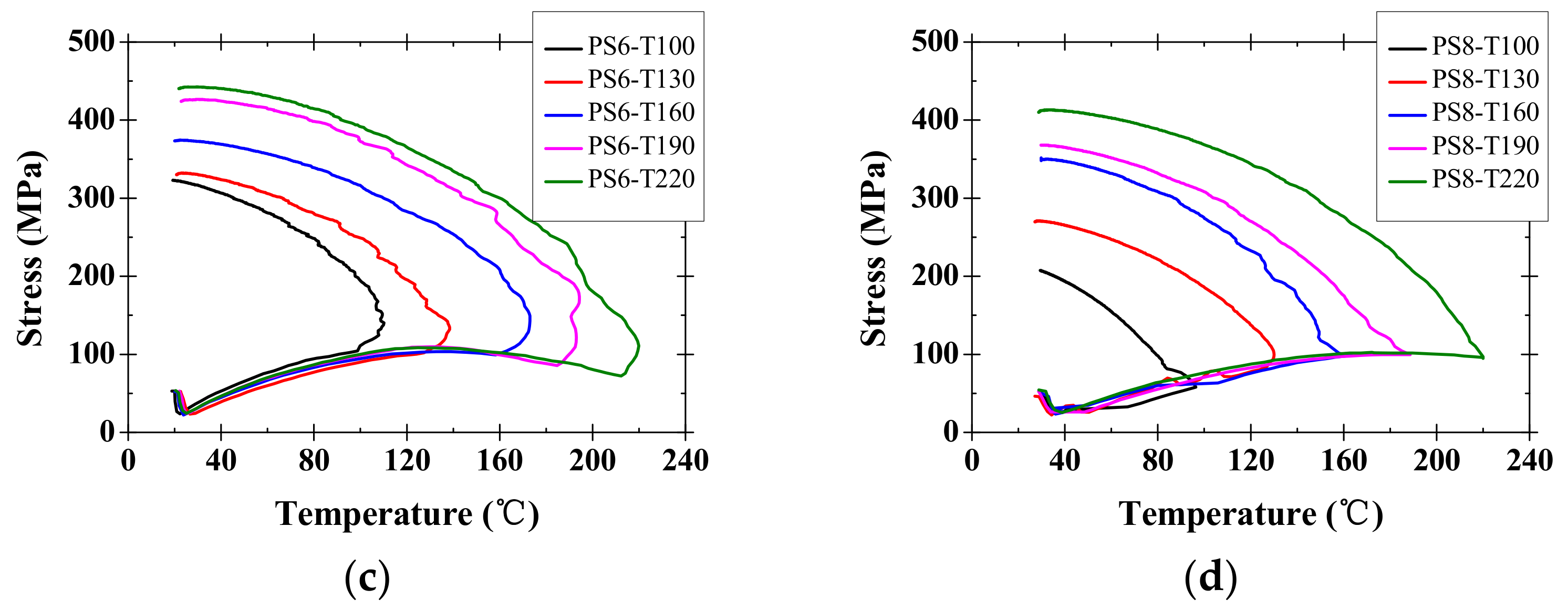

3.1. Pre-Straining of Fe-SMA

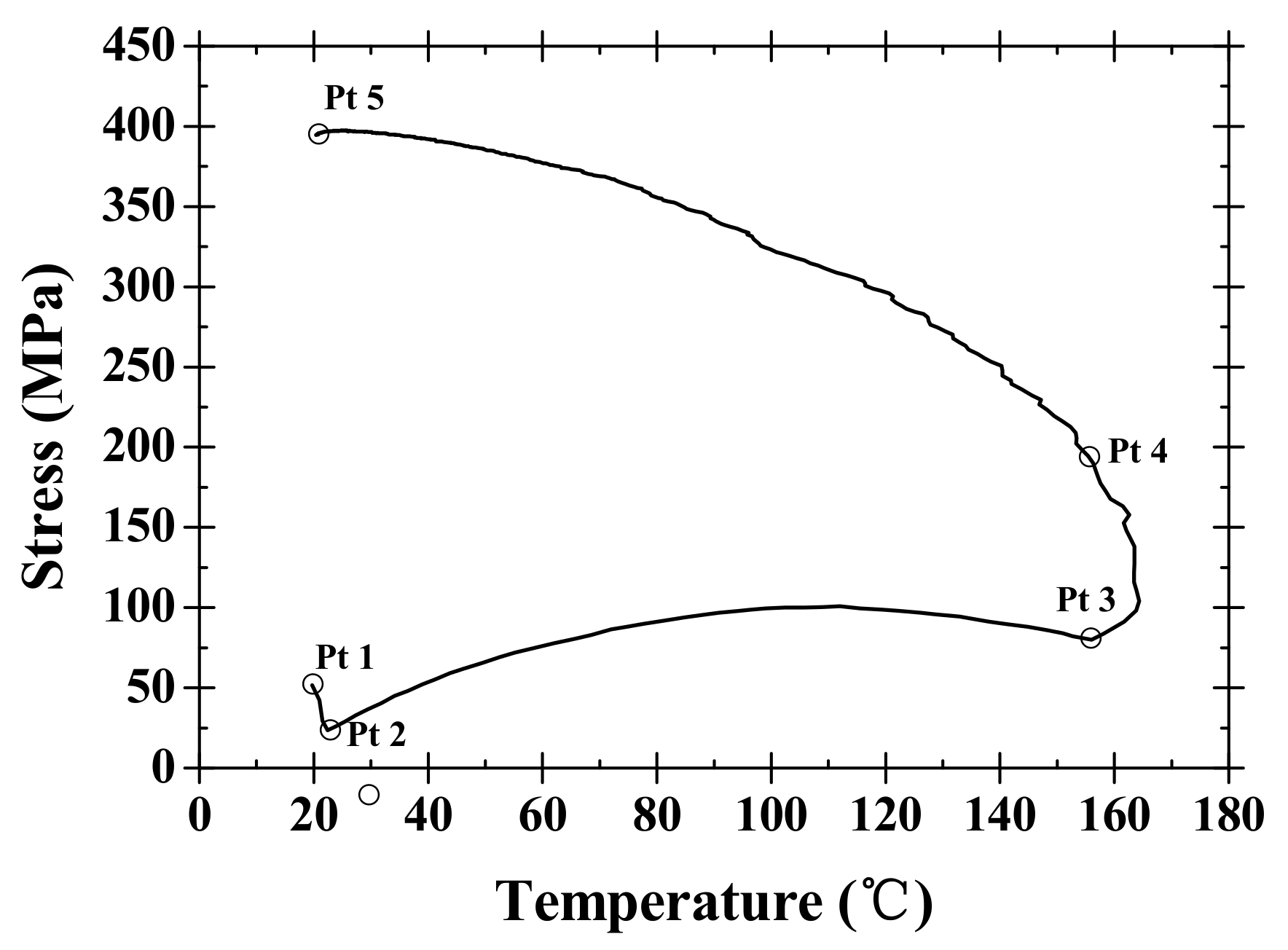

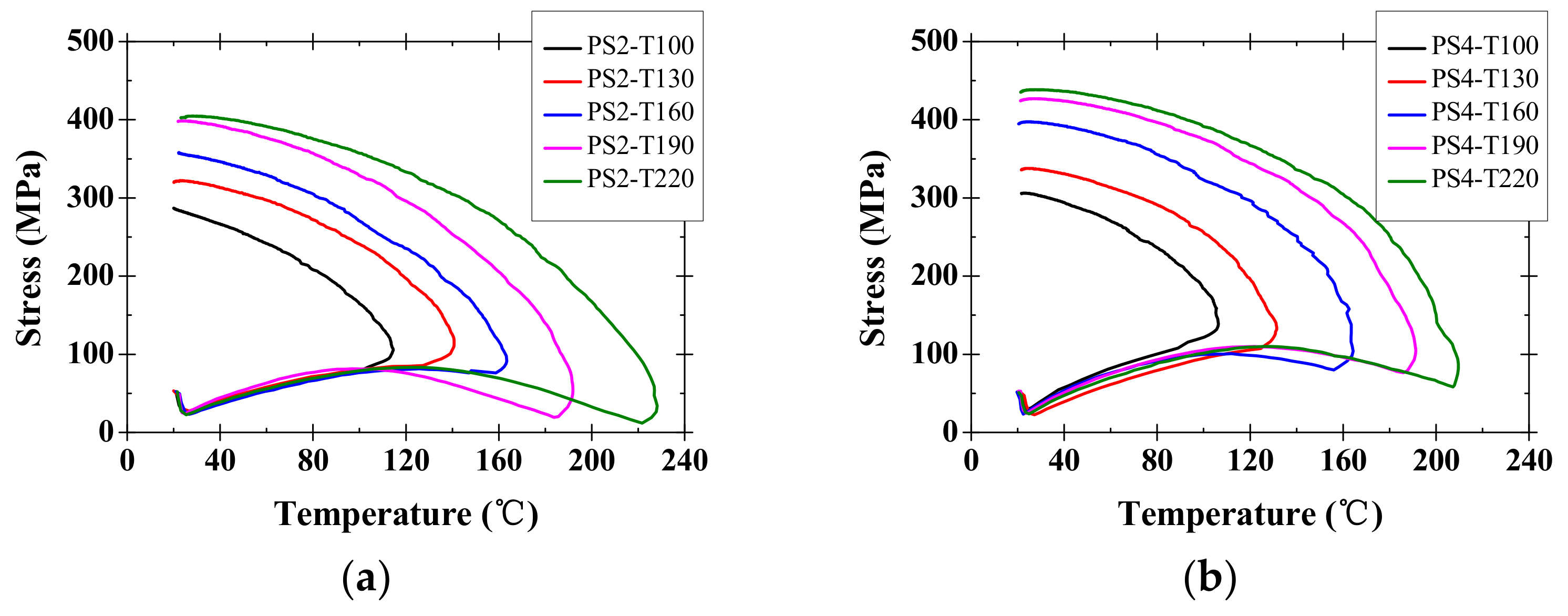

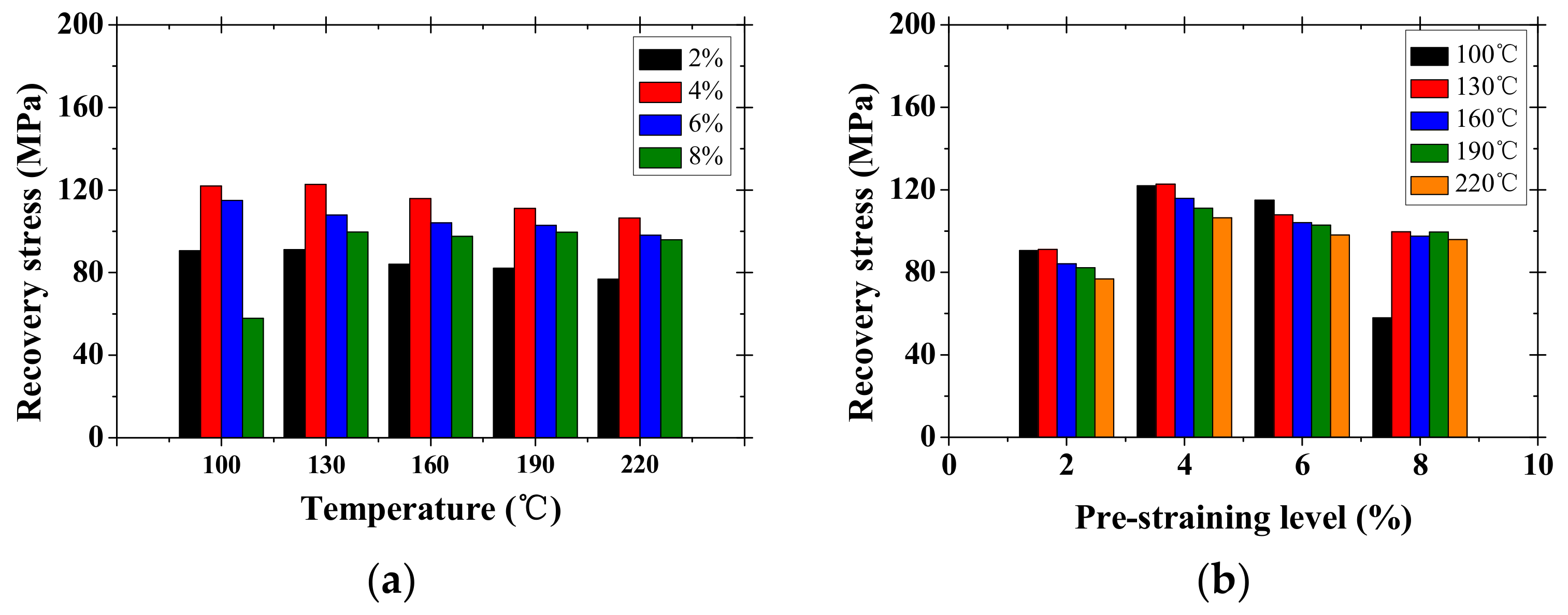

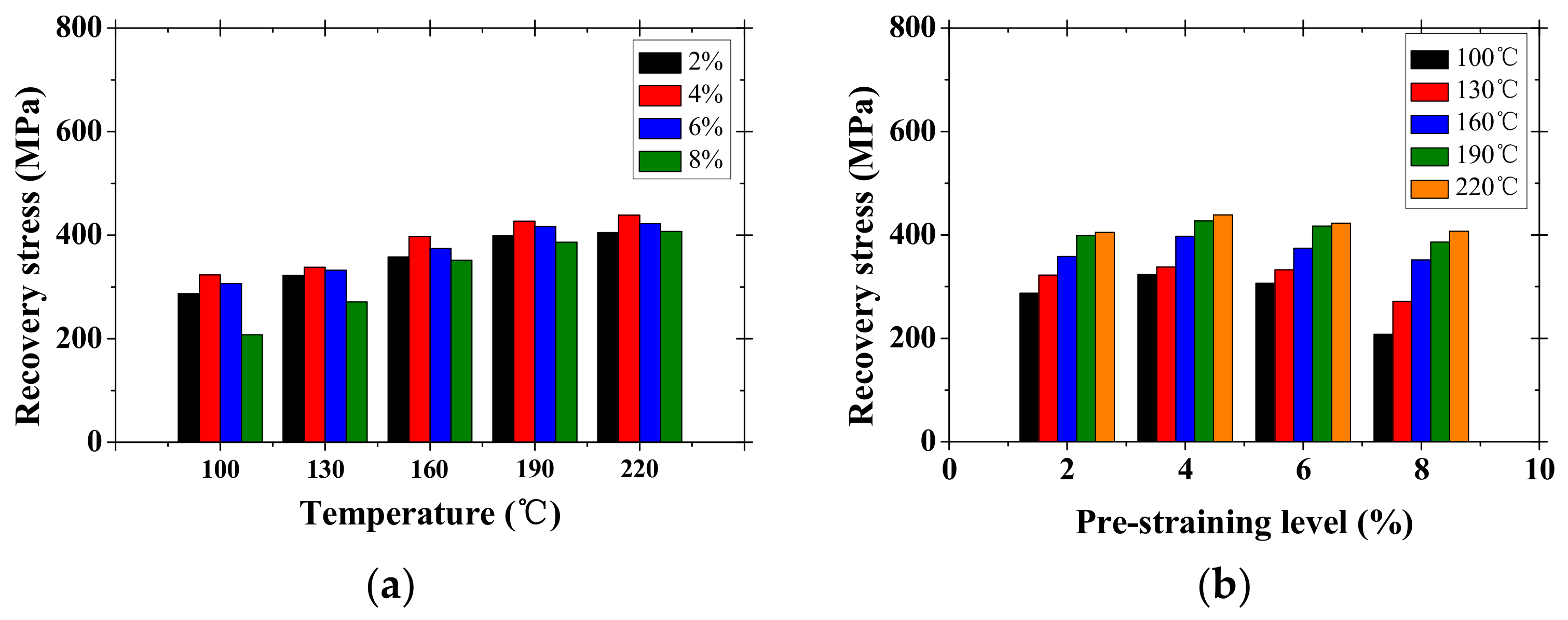

3.2. Recovery Stress Test of Fe-SMA

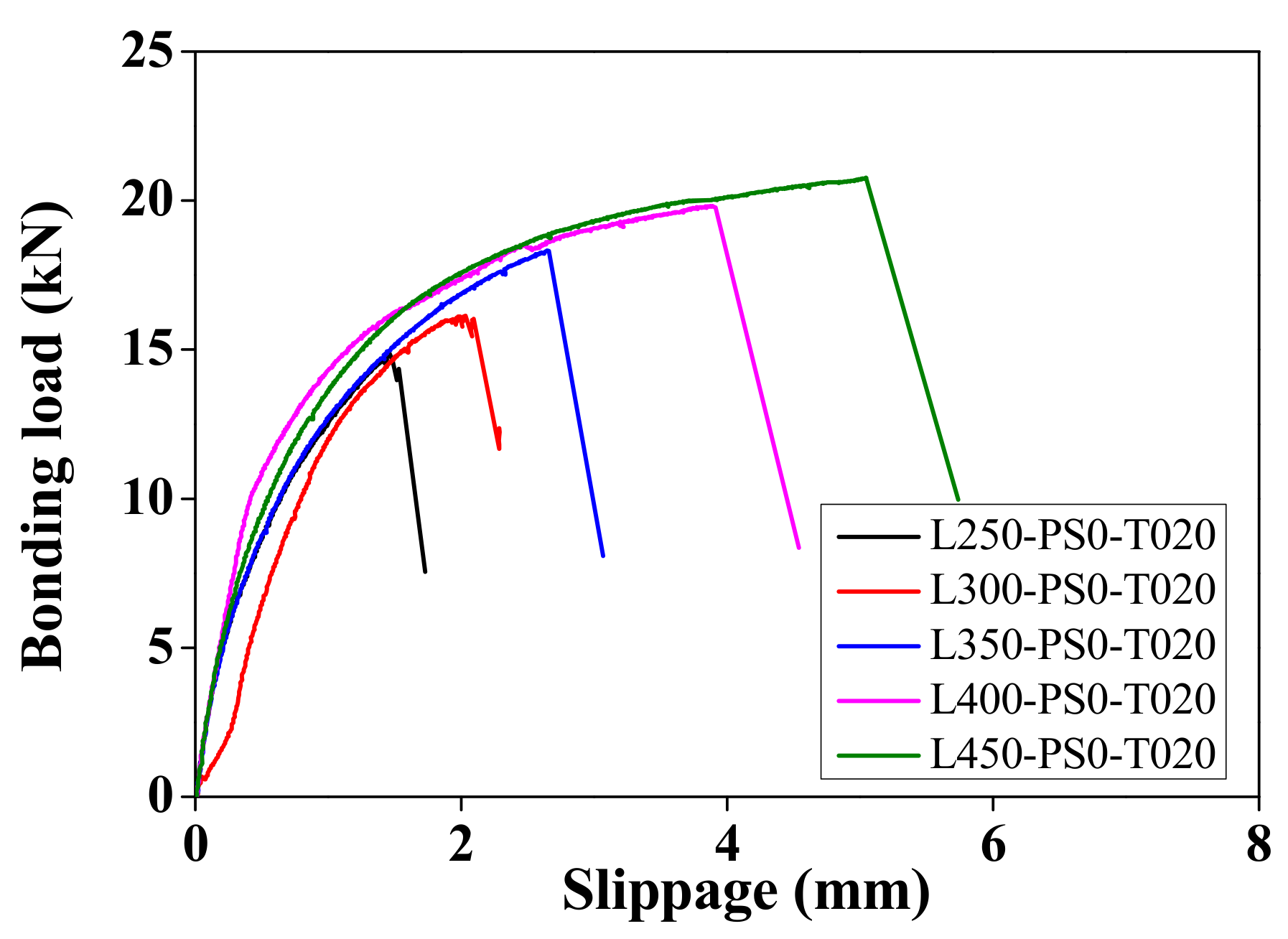

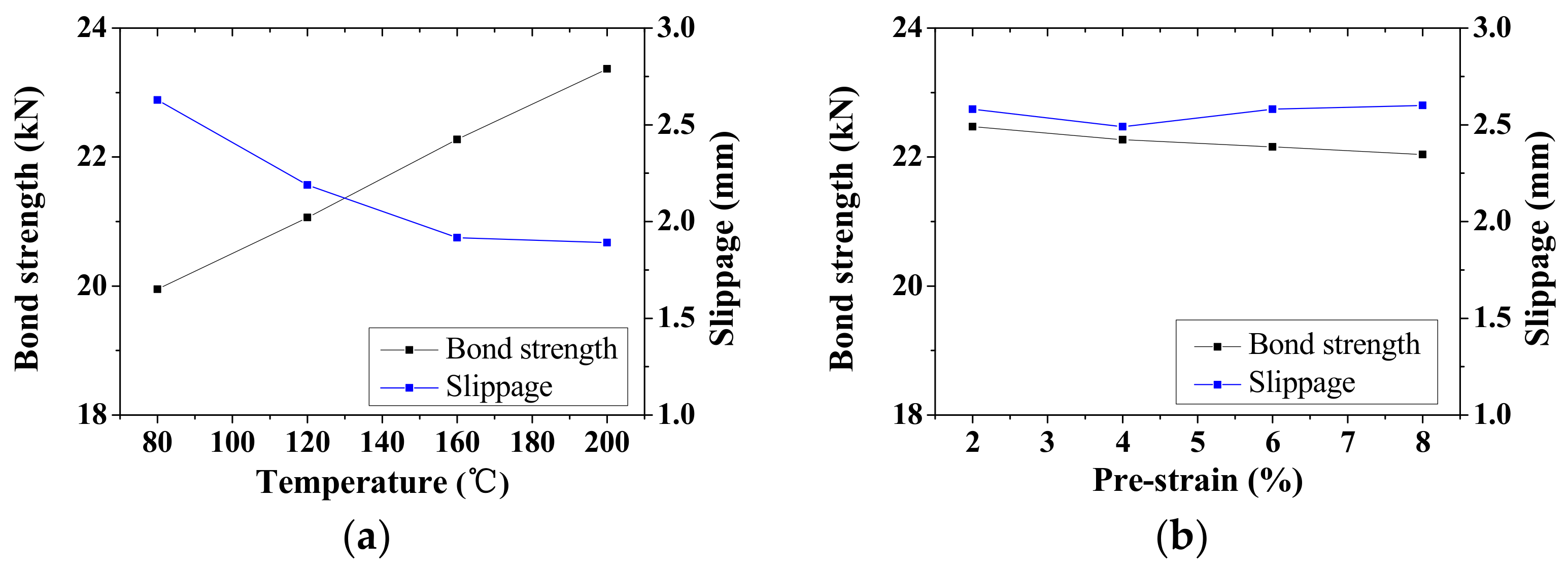

3.3. Bonding Test of Fe-SMA

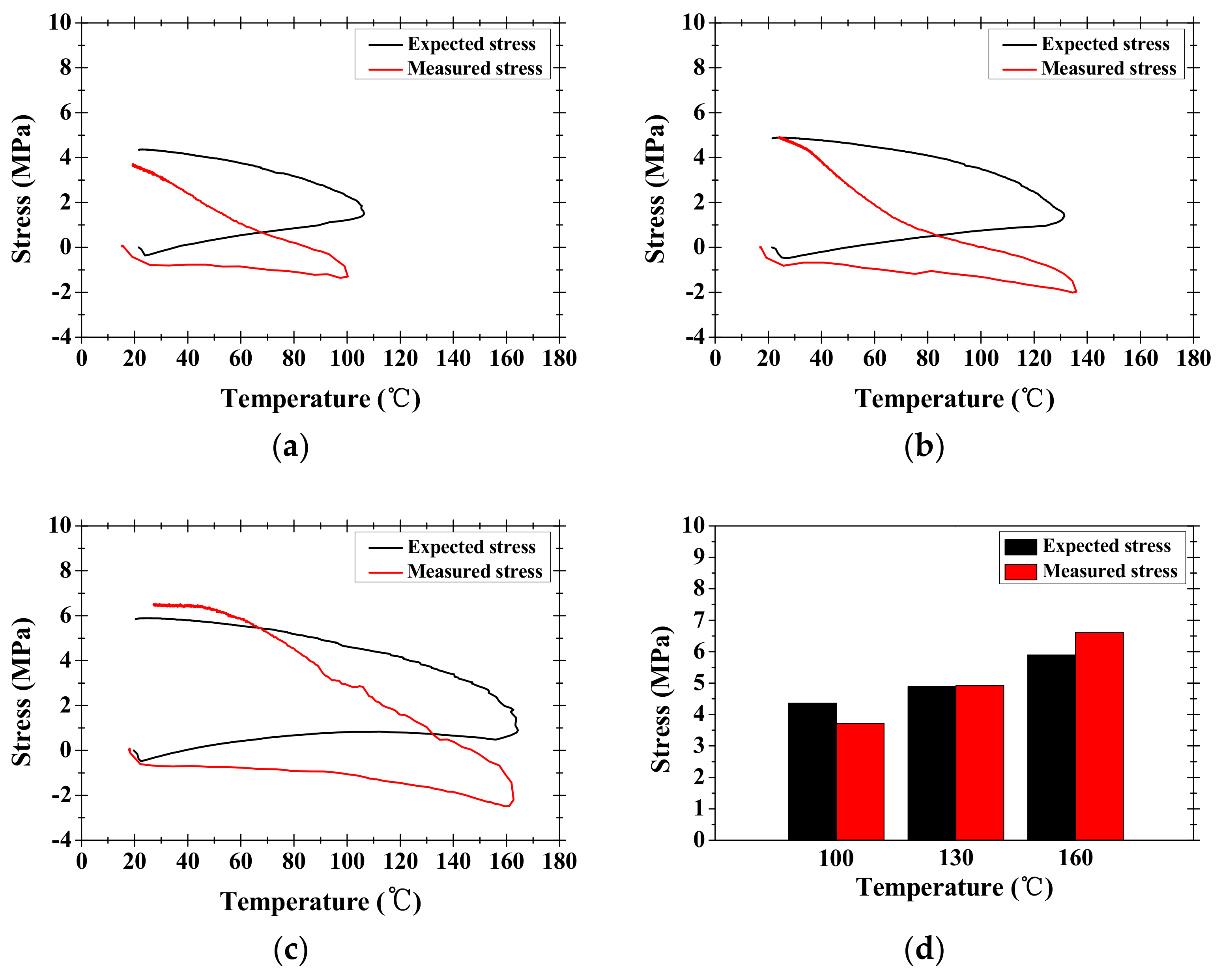

3.4. Result of Recovery Stress Transfer Test for Cement-Based Mortar Bar

4. Conclusions

- (1)

- The Fe-SMA shows sufficient potential to be applied as strengthening material when retrofitting damaged structures or strengthening civil structures. By applying a electric resistive heating temperature of 160 , the 4% pre-strained Fe-SMA embedded inside the concrete would show the shape memory effect (SME), which induces a compressive force on concrete. This compressive force plays an important role as the pre-stressing force on concrete structures.

- (2)

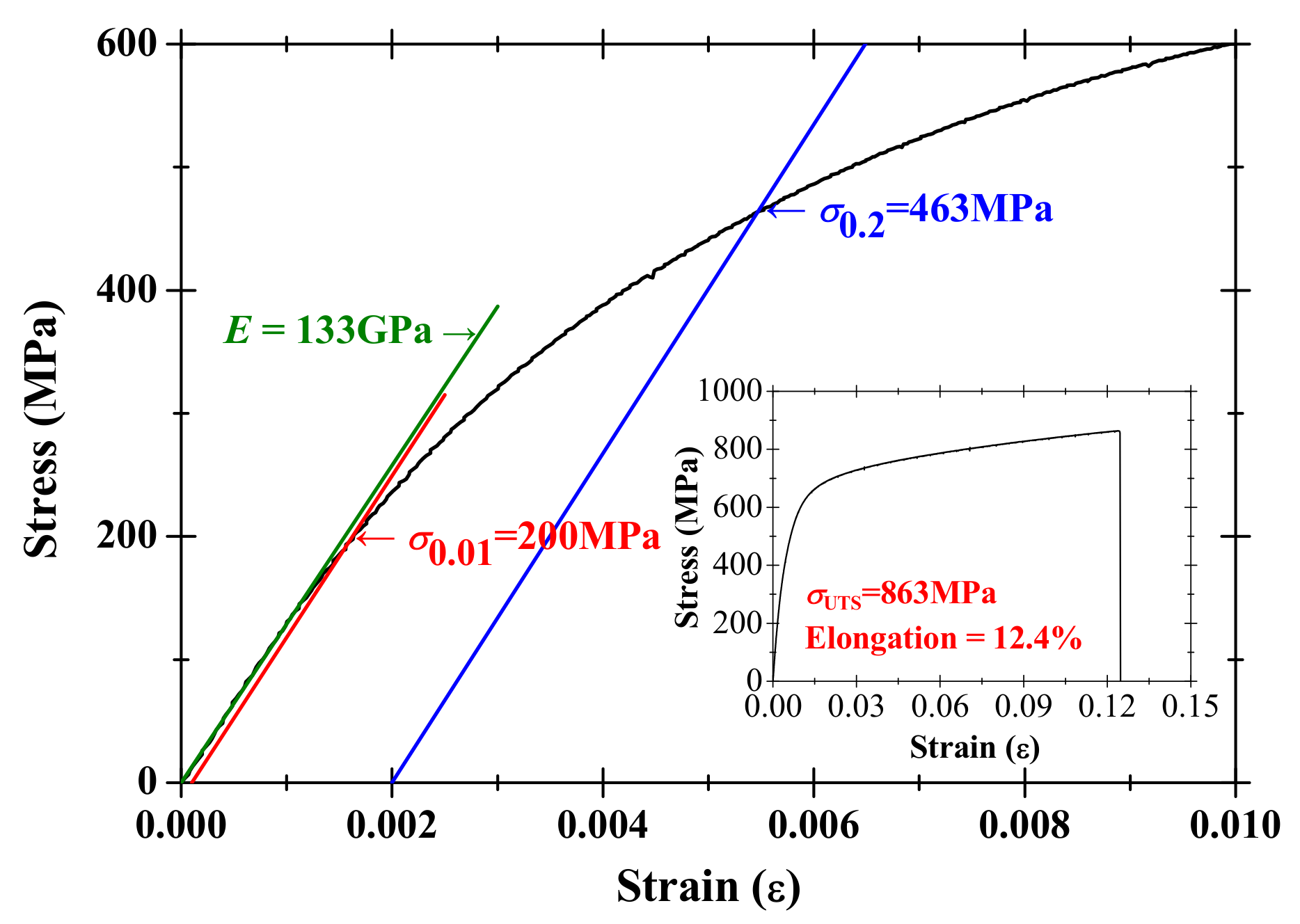

- From the direct tensile tests of the Fe-SMA, the limit of proportionality stress, the 0.2% offset stress, and the modulus of elasticity were 463 MPa, 863 MPa, and 133 GPa, respectively. Based on these mechanical properties, the recovery stresses of the Fe-SMA by the SME activation at recovery temperature from 100 to 220 range linearly from 207.59 MPa to 438.61 MPa, which is transferred to the surrounding concrete as the pre-stressing force.

- (3)

- The bonding strength and feasibility index of the Fe-SMAs were improved by an average of 8.8% with an increased embedding length from 250 mm to 450 mm. The regression analysis based on the feasibility index and bonding length of the Fe-SMA indicates that the pre-stressing force can be fully developed when the embedded length is over 600 mm.

- (4)

- Based on the recovery stress transfer tests, the amount of pre-stressing force applied on strengthened concrete structures could be estimated by the recovery stress of the Fe-SMA.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chang, L.C.; Read, T.A. Plastic deformation and diffusionless phase changes in metals—The gold-cadmium beta phase. JOM 1951, 3, 47–52. [Google Scholar] [CrossRef]

- Buehler, W.J.; Gilfrich, J.V.; Wiley, R.C. Effect of low-temperature phase changes on the mechanical properties of alloys near composition TiNi. J. Appl. Phys. 1963, 34, 1475–1477. [Google Scholar] [CrossRef]

- Hodgson, D.E.; Ming, W.H.; Biermann, R.J. Shape memory alloys. In ASM International, Metals Handbook, 10th ed.; ASM International: Almere, The Netherlands, 1990; Volume 2. [Google Scholar]

- Cederström, J.; Humbeeck, J.V. Relationship between shape memory material properties and applications. J. Phys. 1995, 5, C2-335. [Google Scholar] [CrossRef][Green Version]

- Wilkes, K.E.; Liaw, P.K. The fatigue behavior of shape-memory alloys. JOM 2000, 52, 45–51. [Google Scholar] [CrossRef]

- Cladera, A.; Weber, B.; Leinenbach, C.; Czaderski, C.; Shahverdi, M.; Motavalli, M. Iron-based shape memory alloys for civil engineering structures: An overview. Constr. Build. Mater. 2014, 63, 281–293. [Google Scholar] [CrossRef]

- Melton, K.N.; Mercier, O. The mechanical properties of NiTi-based shape memory alloys. Acta Metall. 1981, 29, 393–398. [Google Scholar] [CrossRef]

- Sato, A.; Chishima, E.; Soma, K.; Mori, T. Shape memory effect in γ⇄ϵ transformation in Fe-30Mn-1Si alloy single crystals. Acta Metall. 1982, 30, 1177–1183. [Google Scholar] [CrossRef]

- Lee, W.J.; Weber, B.; Feltrin, G.; Czaderski, C.; Motavalli, M.; Leinenbach, C. Phase transformation behavior under uniaxial deformation of an Fe-Mn-Si-Cr-Ni-VC shape memory alloy. Mater. Sci. Eng. A 2013, 581, 1–7. [Google Scholar] [CrossRef]

- Czaderski, C.; Shahverdi, M.; Brönnimann, R.; Leinenbach, C.; Motavalli, M. Feasibility of iron-based shape memory alloy strips for prestressed strengthening of concrete structures. Constr. Build. Mater. 2014, 56, 94–105. [Google Scholar] [CrossRef]

- Janke, L.; Czaderski, C.; Motavalli, M.; Ruth, J. Applications of shape memory alloys in civil engineering structures—Overview, limits and new ideas. Mater. Struct. 2005, 38, 578–592. [Google Scholar]

- Sawaguchi, T.; Sahu, P.; Kikuchi, T.; Ogawa, K.; Kajiwara, S.; Kushibe, A.; Higashino, M.; Ogawa, T. Vibration mitigation by the reversible fcc/hcp martensitic transformation during cyclic tension–compression loading of an Fe-Mn-Si-based shape memory alloy. Scr. Mater. 2006, 54, 1885–1890. [Google Scholar] [CrossRef]

- Yang, J.H.; Wayman, C.M. Development of Fe-based shape memory alloys associated with face-centered cubic-hexagonal close-packed martensitic transformations: Part III. microstructures. Metall. Trans. A 1992, 23, 1445–1454. [Google Scholar] [CrossRef]

- Otsuka, H.; Yamada, H.; Maruyama, T.; Tanahashi, H.; Matsuda, S.; Murakami, M. Effects of alloying additions on Fe-Mn-Si shape memory alloys. ISIJ Int. 1990, 30, 674–679. [Google Scholar] [CrossRef]

- Rong, L.J.; Ping, D.H.; Li, Y.Y.; Shi, C.X. Improvement of shape memory effect in Fe-Mn-Si alloy by Cr and Ni addition. Scr. Metal. Mater. 1995, 32. [Google Scholar] [CrossRef]

- Wang, Z.; Zu, X.; Feng, X.; Dai, J. Effect of thermomechanical treatment on the two-way shape memory effect of NiTi alloy spring. Mater. Lett. 2002, 54, 55–61. [Google Scholar] [CrossRef]

- Gu, Q.; Humbeeck, J.V.; Delaey, L.; Federzoni, L.; Guénin, G.; Gex, D. Effect of amount of deformation on the martensitic transformation and shape memory effect in Fe-Mn-Si based shape memory steel. J. Phys. 1995, 5, C2-311. [Google Scholar] [CrossRef][Green Version]

- Rojob, H.; El-Hacha, R. Self-Prestressing Using Iron-Based Shape Memory Alloy for Flexural Strengthening of Reinforced Concrete Beams. ACI Struct. J. 2017, 114, 523. [Google Scholar] [CrossRef]

- Kajiwara, S.; Liu, D.; Kikuchi, T.; Shinya, N. Remarkable improvement of shape memory effect in Fe-Mn-Si based shape memory alloys by producing NbC precipitates. Scr. Mater. 2001, 44, 2809–2814. [Google Scholar] [CrossRef]

- Farjami, S.; Hiraga, K.; Kubo, H. Shape memory effect and crystallographic investigation in VN containing Fe-Mn-Si-Cr alloys. Mater. Trans. 2004, 45, 930–935. [Google Scholar] [CrossRef]

- Dong, Z.; Klotz, U.E.; Leinenbach, C.; Bergamini, A.; Czaderski, C.; Motavalli, M. A Novel Fe-Mn-Si Shape Memory Alloy with Improved Shape Recovery Properties by VC Precipitation. Adv. Eng. Mater. 2009, 11, 40–44. [Google Scholar] [CrossRef]

- Leinenbach, C.; Kramer, H.; Bernhard, C.; Eifler, D. Thermo-Mechanical Properties of an Fe-Mn-Si-Cr-Ni-VC Shape Memory Alloy with Low Transformation Temperature. Adv. Eng. Mater. 2012, 14, 62–67. [Google Scholar] [CrossRef]

- Hsu, T.Y.; Zuyao, X. Martensitic transformation in Fe-Mn-Si based alloys. Mater. Sci. Eng. A 1999, 273, 494–497. [Google Scholar] [CrossRef]

- Lagoudas, D.C. (Ed.) Shape Memory Alloys: Modeling and Engineering Applications; Springer Science & Business Media: Berlin, Germany, 2008. [Google Scholar]

- Watanabe, Y.; Mori, Y.; Sato, A. Training effect in Fe-Mn-Si shape-memory alloys. J. Mater. Sci. 1993, 28, 1509–1514. [Google Scholar] [CrossRef]

- Maji, A.K.; Negret, I. Smart prestressing with shape-memory alloy. J. Eng. Mech. 1998, 124, 1121–1128. [Google Scholar] [CrossRef]

- Krstulovic-Opara, N.; Naaman, A.E. Self-stressing fiber composites. Struct. J. 2000, 97, 335–344. [Google Scholar]

- Soroushian, P.; Ostowari, K.; Nossoni, A.; Chowdhury, H. Repair and strengthening of concrete structures through application of corrective posttensioning forces with shape memory alloys. Transp. Res. Rec. J. Transp. Res. Board 2001, 1770, 20–26. [Google Scholar] [CrossRef]

- Deng, Z.; Li, Q.; Sun, H. Behavior of concrete beam with embedded shape memory alloy wires. Eng. Struct. 2006, 28, 1691–1697. [Google Scholar] [CrossRef]

- Moser, K.; Bergamini, A.; Christen, R.; Czaderski, C. Feasibility of concrete prestressed by shape memory alloy short fibers. Mater. Struct. 2005, 38, 593–600. [Google Scholar] [CrossRef]

- Hosseini, E.; Ghafoori, E.; Leinenbach, C.; Motavalli, M.; Holdsworth, S.R. Stress recovery and cyclic behaviour of an Fe-Mn-Si shape memory alloy after multiple thermal activation. Smart Mater. Struct. 2018, 27, 025009. [Google Scholar] [CrossRef]

- Ghafoori, E.; Hosseini, E.; Leinenbach, C.; Michels, J.; Motavalli, M. Fatigue behavior of a Fe-Mn-Si shape memory alloy used for prestressed strengthening. Mater. Des. 2017, 133, 349–362. [Google Scholar] [CrossRef]

- Park, S.; Yim, H.J.; Kwak, H.K. Evaluation of microcracks in thermal damaged concrete using nonlinear ultrasonic modulation technique. J. Korea Concr. Inst. 2012, 24, 651–658. [Google Scholar] [CrossRef]

| Specimen | Pre-Strain (%) | Recovery Temperature () |

|---|---|---|

| PS2-T100 | 2 | 100 |

| PS2-T130 | 2 | 130 |

| PS2-T160 | 2 | 160 |

| PS2-T190 | 2 | 190 |

| PS2-T220 | 2 | 220 |

| PS4-T100 | 4 | 100 |

| PS4-T130 | 4 | 130 |

| PS4-T160 | 4 | 160 |

| PS4-T190 | 4 | 190 |

| PS4-T220 | 4 | 220 |

| PS6-T100 | 6 | 100 |

| PS6-T130 | 6 | 130 |

| PS6-T160 | 6 | 160 |

| PS6-T190 | 6 | 190 |

| PS6-T220 | 6 | 220 |

| PS8-T100 | 8 | 100 |

| PS8-T130 | 8 | 130 |

| PS8-T160 | 8 | 160 |

| PS8-T190 | 8 | 190 |

| PS8-T220 | 8 | 220 |

| Specimen | Bond Length (mm) | Pre-Strained Value (%) | Recovery Temperature () |

|---|---|---|---|

| L250-PS0-T020 | 250 | 0 | 20 |

| L300-PS0-T020 | 300 | 0 | 20 |

| L350-PS0-T020 | 350 | 0 | 20 |

| L400-PS0-T020 | 400 | 0 | 20 |

| L450-PS0-T020 | 450 | 0 | 20 |

| L300-PS4-T080 | 300 | 4 | 80 |

| L300-PS4-T120 | 300 | 4 | 120 |

| L300-PS4-T160 | 300 | 4 | 160 |

| L300-PS4-T200 | 300 | 4 | 200 |

| L300-PS2-T160 | 300 | 2 | 160 |

| L300-PS4-T160 | 300 | 4 | 160 |

| L300-PS6-T160 | 300 | 6 | 160 |

| L300-PS8-T160 | 300 | 8 | 160 |

| Specimen | Pre-Strain (%) | Recovery Temperature () |

|---|---|---|

| Com-PS4-T100 | 4 | 100 |

| Com-PS4-T130 | 4 | 130 |

| Com-PS4-T160 | 4 | 160 |

| Com-PS4-T190 | 4 | 190 |

| Specimen | Pre-Strain | Recovered Strain | Maximum Stress | Recovery Temperature | Recovery Stress |

|---|---|---|---|---|---|

| (%) | (%) | (MPa) | () | (MPa) | |

| PS2-T100 | 1.94 | 1.02 | 644.80 | 114.6 | 287.06 |

| PS2-T130 | 1.91 | 1.05 | 641.85 | 130.7 | 322.37 |

| PS2-T160 | 1.96 | 1.03 | 636.11 | 163.4 | 358.08 |

| PS2-T190 | 2.00 | 1.12 | 631.00 | 191.9 | 398.73 |

| PS2-T220 | 1.99 | 1.12 | 644.38 | 228.2 | 404.73 |

| PS4-T100 | 3.94 | 2.83 | 691.30 | 106.4 | 323.06 |

| PS4-T130 | 4.00 | 2.90 | 695.73 | 131.4 | 337.80 |

| PS4-T160 | 4.00 | 2.96 | 676.39 | 164.3 | 397.50 |

| PS4-T190 | 4.00 | 2.91 | 698.18 | 191.3 | 426.89 |

| PS4-T220 | 4.00 | 2.89 | 694.79 | 209.6 | 438.61 |

| PS6-T100 | 6.00 | 4.75 | 712.45 | 110.0 | 306.31 |

| PS6-T130 | 6.00 | 4.80 | 692.42 | 138.4 | 332.34 |

| PS6-T160 | 6.00 | 4.49 | 675.29 | 173.0 | 374.47 |

| PS6-T190 | 6.00 | 4.79 | 699.70 | 194.0 | 416.65 |

| PS6-T220 | 6.00 | 4.76 | 704.71 | 219.9 | 422.51 |

| PS8-T100 | 8.00 | 6.69 | 734.97 | 96.4 | 207.59 |

| PS8-T130 | 8.00 | 6.66 | 742.24 | 130.0 | 271.14 |

| PS8-T160 | 8.00 | 6.60 | 753.66 | 163.4 | 351.58 |

| PS8-T190 | 8.00 | 6.70 | 726.49 | 188.6 | 386.08 |

| PS8-T220 | 8.02 | 6.66 | 752.47 | 220.0 | 407.26 |

| Specimen | Bond Strength (kN) | Slippage (mm) | F.I. (%) |

|---|---|---|---|

| L250-PS0-T020 | 14.87 | 1.46 | 57.39 |

| L300-PS0-T020 | 18.14 | 2.03 | 62.29 |

| L350-PS0-T020 | 18.32 | 2.64 | 70.71 |

| L400-PS0-T020 | 19.82 | 3.87 | 76.48 |

| L450-PS0-T020 | 20.77 | 5.04 | 80.17 |

| L300-PS4-T080 | 19.95 | 2.57 | 76.99 |

| L300-PS4-T120 | 21.06 | 3.45 | 81.82 |

| L300-PS4-T160 | 22.27 | 5.03 | 85.95 |

| L300-PS4-T200 | 23.38 | 6.64 | 90.19 |

| L300-PS2-T160 | 22.47 | 6.56 | 86.73 |

| L300-PS4-T160 | 22.27 | 5.03 | 85.95 |

| L300-PS6-T160 | 22.16 | 3.43 | 85.51 |

| L300-PS8-T160 | 22.04 | 3.05 | 85.05 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, K.; Lee, S.; Han, S.; Yeon, Y. Evaluation of Fe-Based Shape Memory Alloy (Fe-SMA) as Strengthening Material for Reinforced Concrete Structures. Appl. Sci. 2018, 8, 730. https://doi.org/10.3390/app8050730

Hong K, Lee S, Han S, Yeon Y. Evaluation of Fe-Based Shape Memory Alloy (Fe-SMA) as Strengthening Material for Reinforced Concrete Structures. Applied Sciences. 2018; 8(5):730. https://doi.org/10.3390/app8050730

Chicago/Turabian StyleHong, Kinam, Sugyu Lee, Sanghoon Han, and Yeongmo Yeon. 2018. "Evaluation of Fe-Based Shape Memory Alloy (Fe-SMA) as Strengthening Material for Reinforced Concrete Structures" Applied Sciences 8, no. 5: 730. https://doi.org/10.3390/app8050730

APA StyleHong, K., Lee, S., Han, S., & Yeon, Y. (2018). Evaluation of Fe-Based Shape Memory Alloy (Fe-SMA) as Strengthening Material for Reinforced Concrete Structures. Applied Sciences, 8(5), 730. https://doi.org/10.3390/app8050730