Contact Pressure Algorithm of Multi-Layer Interference Fit Considering Centrifugal Force and Temperature Gradient

Abstract

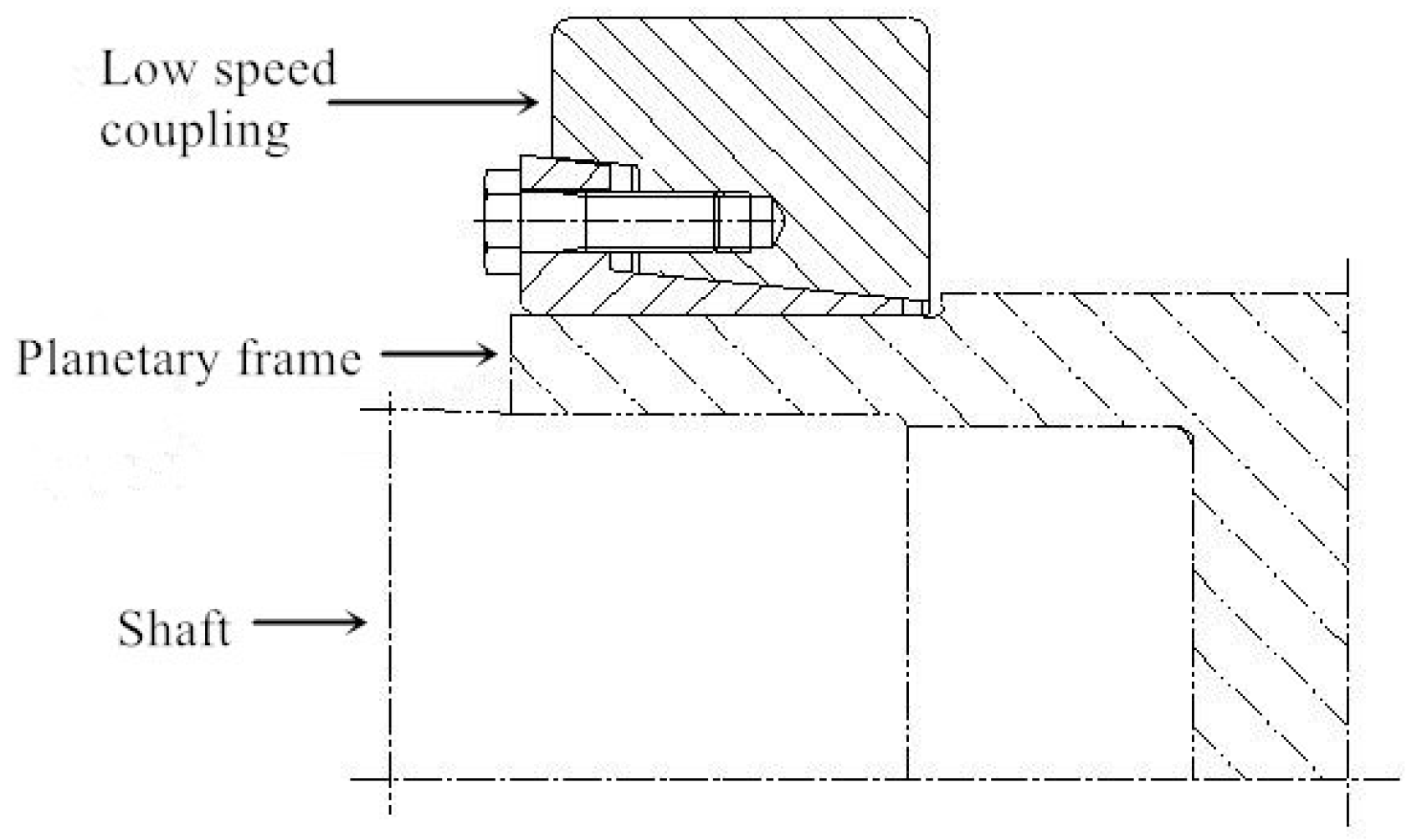

:1. Introduction

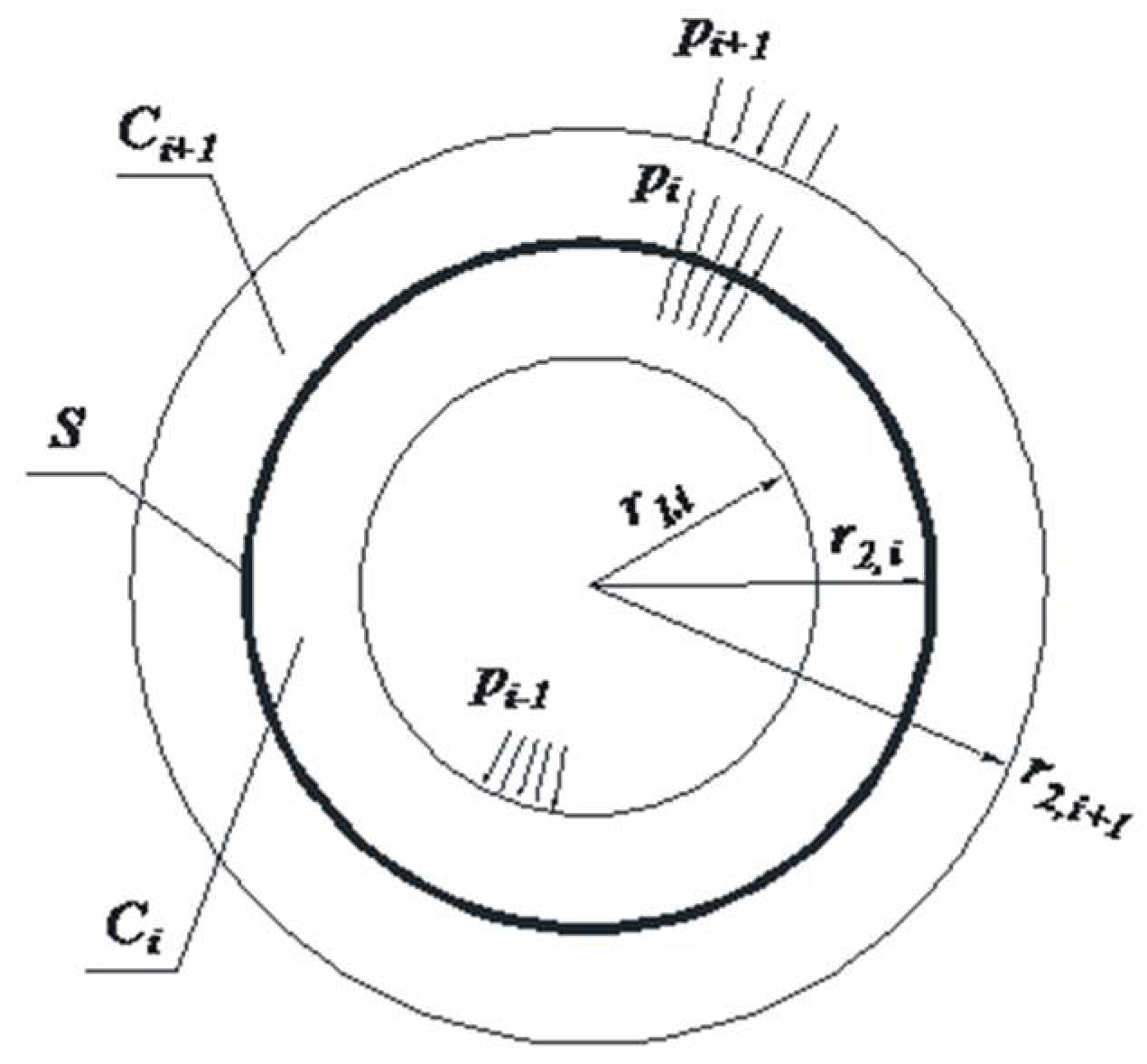

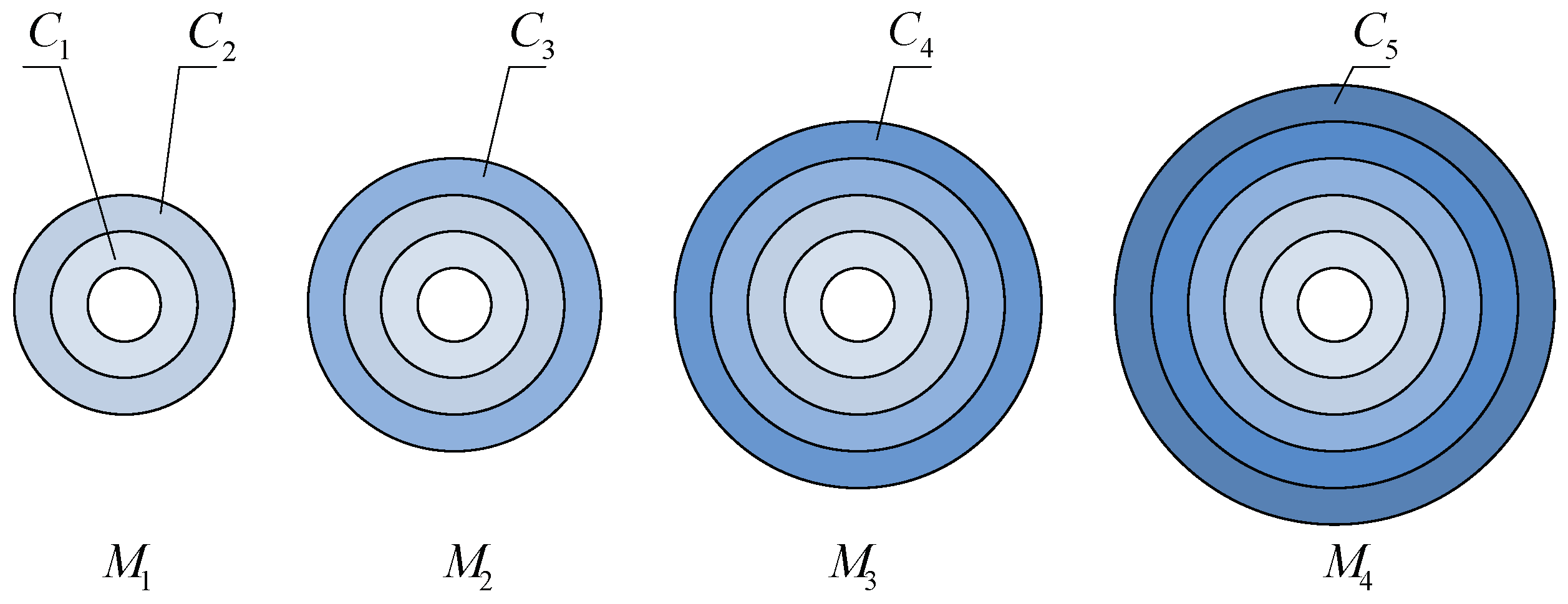

2. Algorithm for Multi-Layer Interference Cylinder

3. Algorithm Considering Centrifugal Force and Temperature Gradient

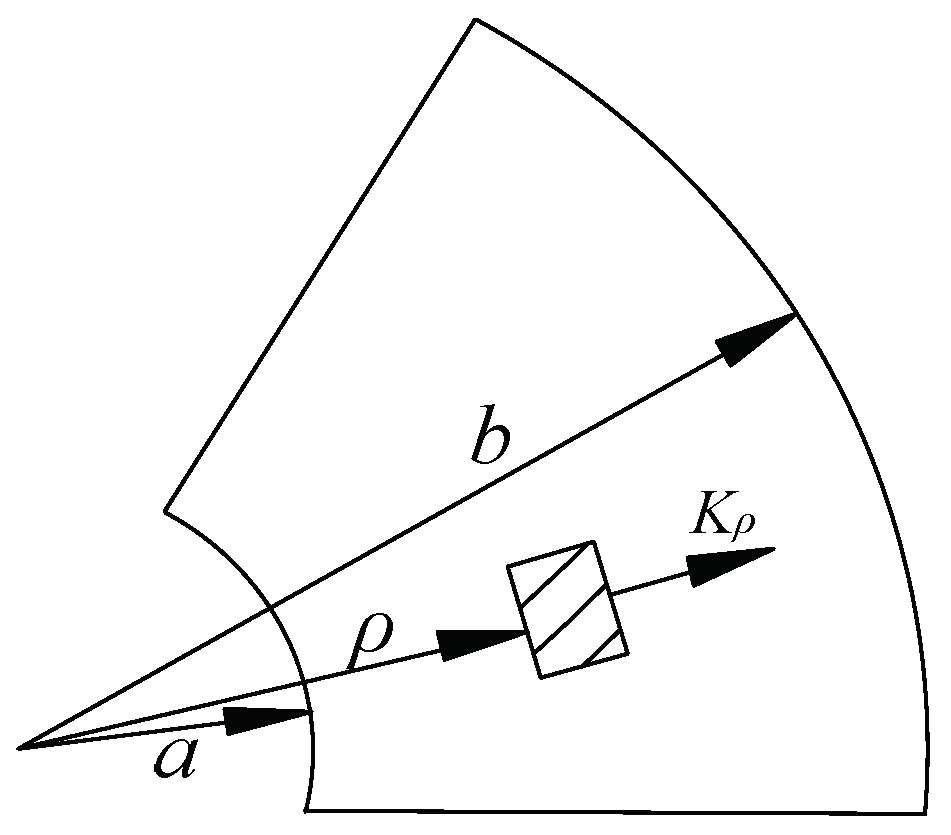

3.1. Centrifugal Force

3.2. Temperature Gradient

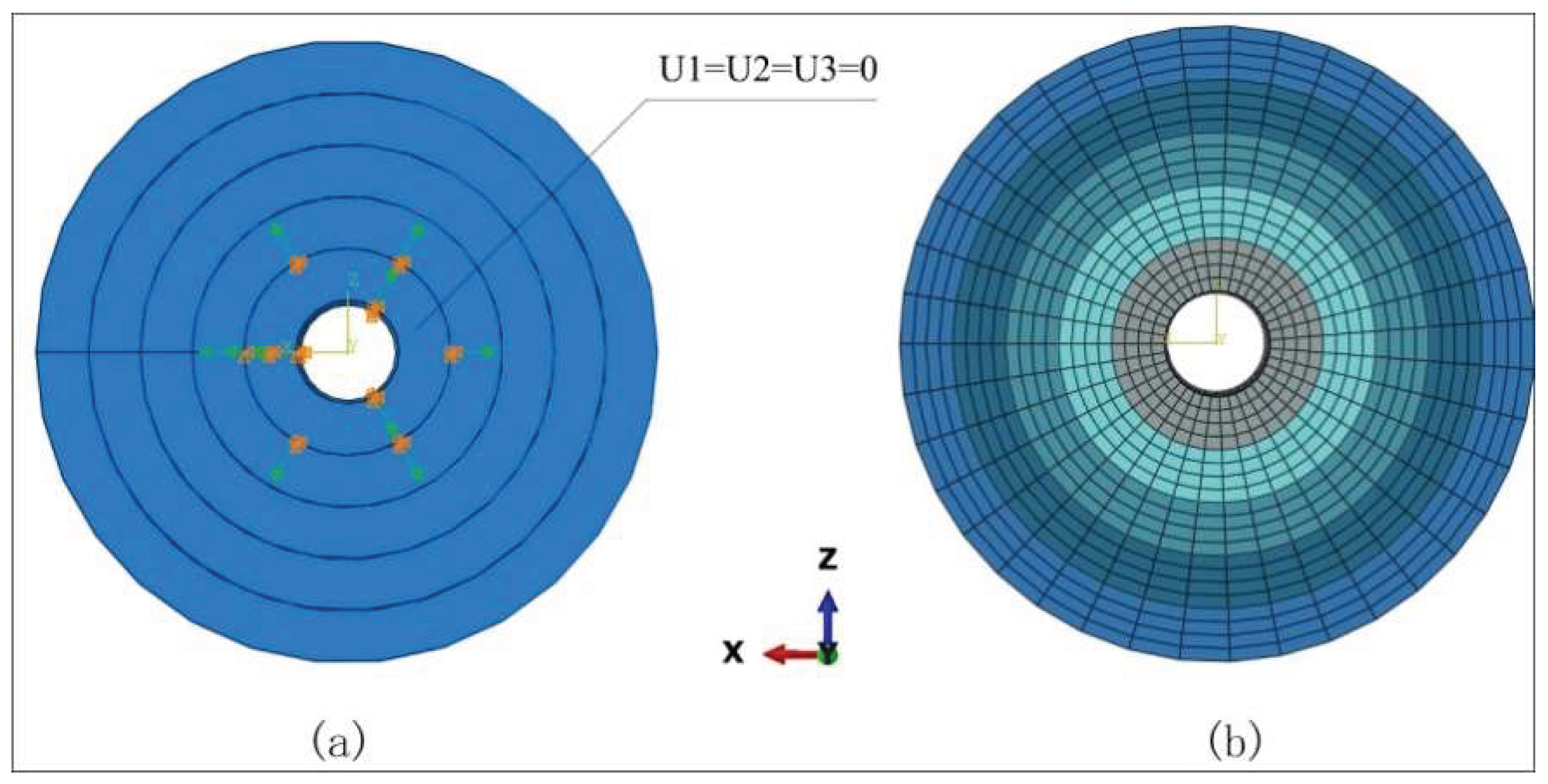

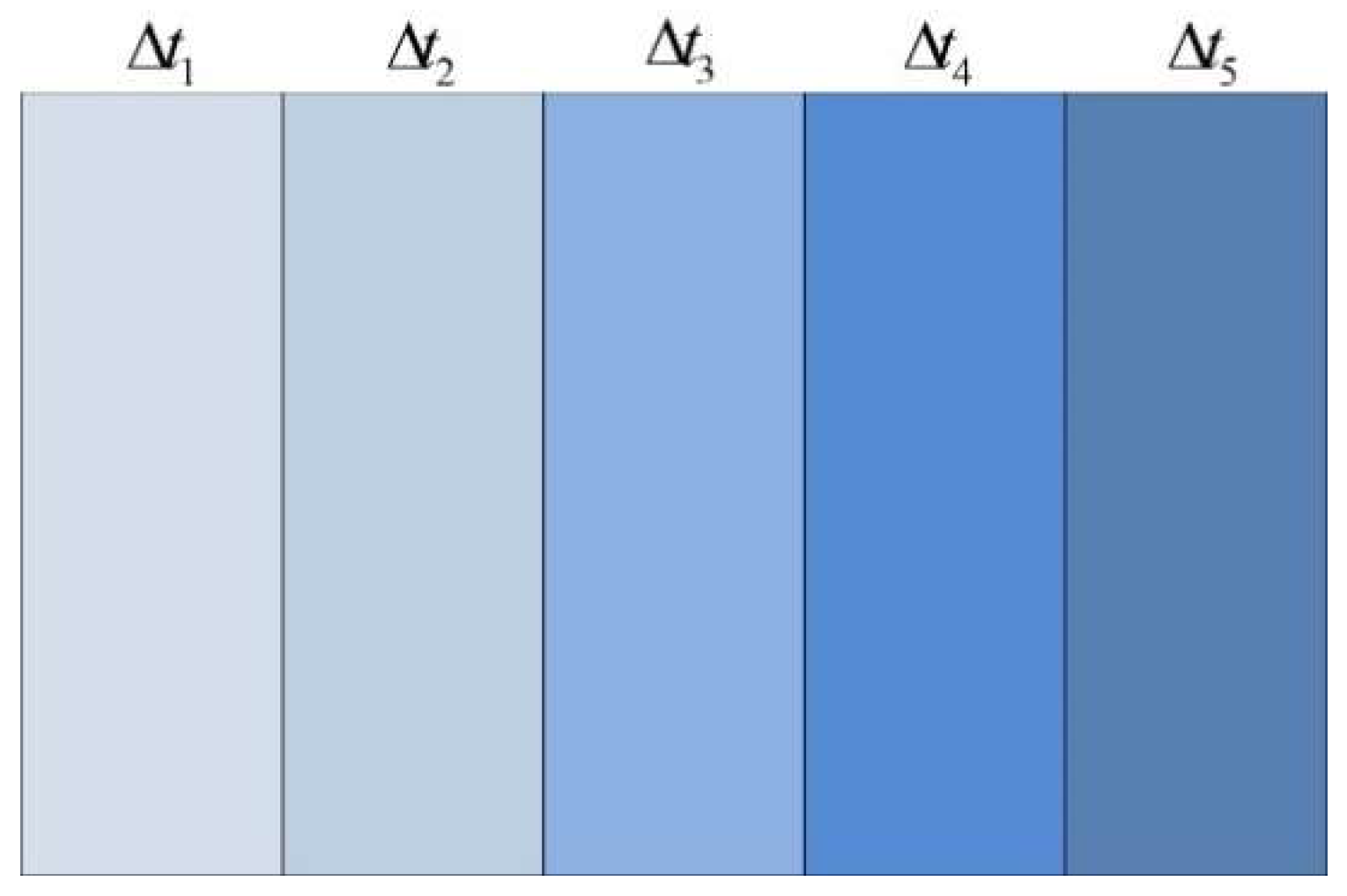

4. Finite Element Model

5. Results and Discussion

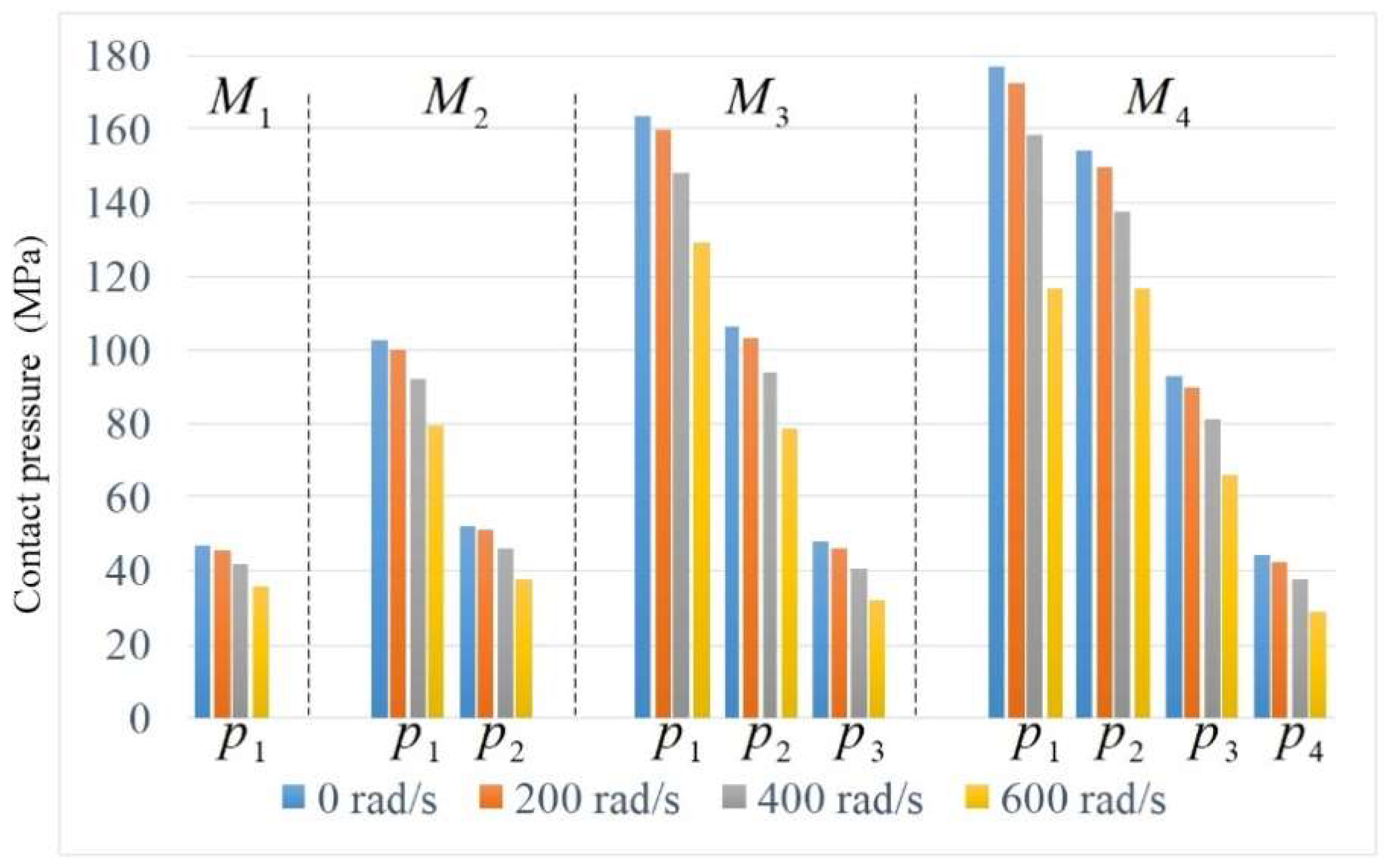

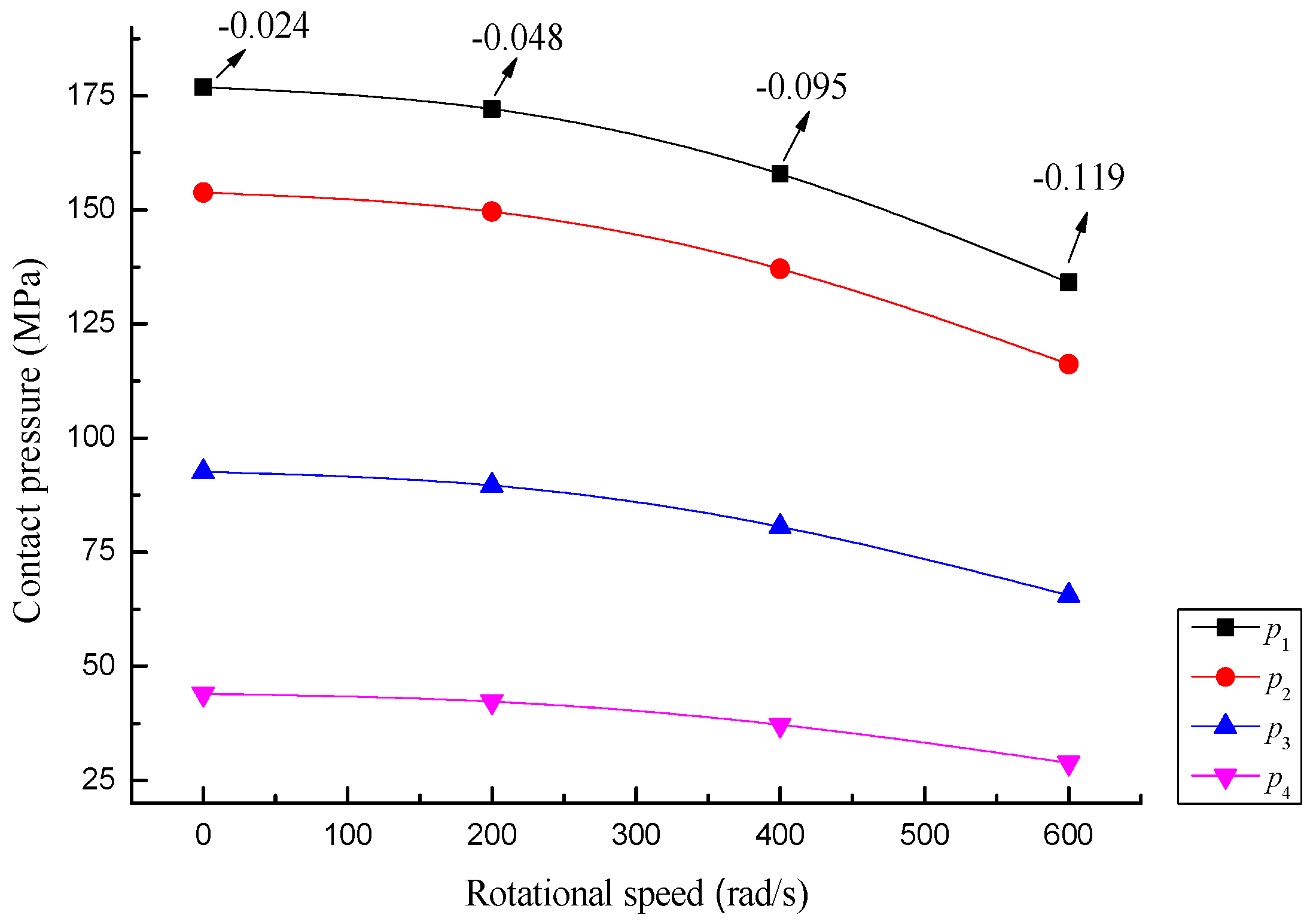

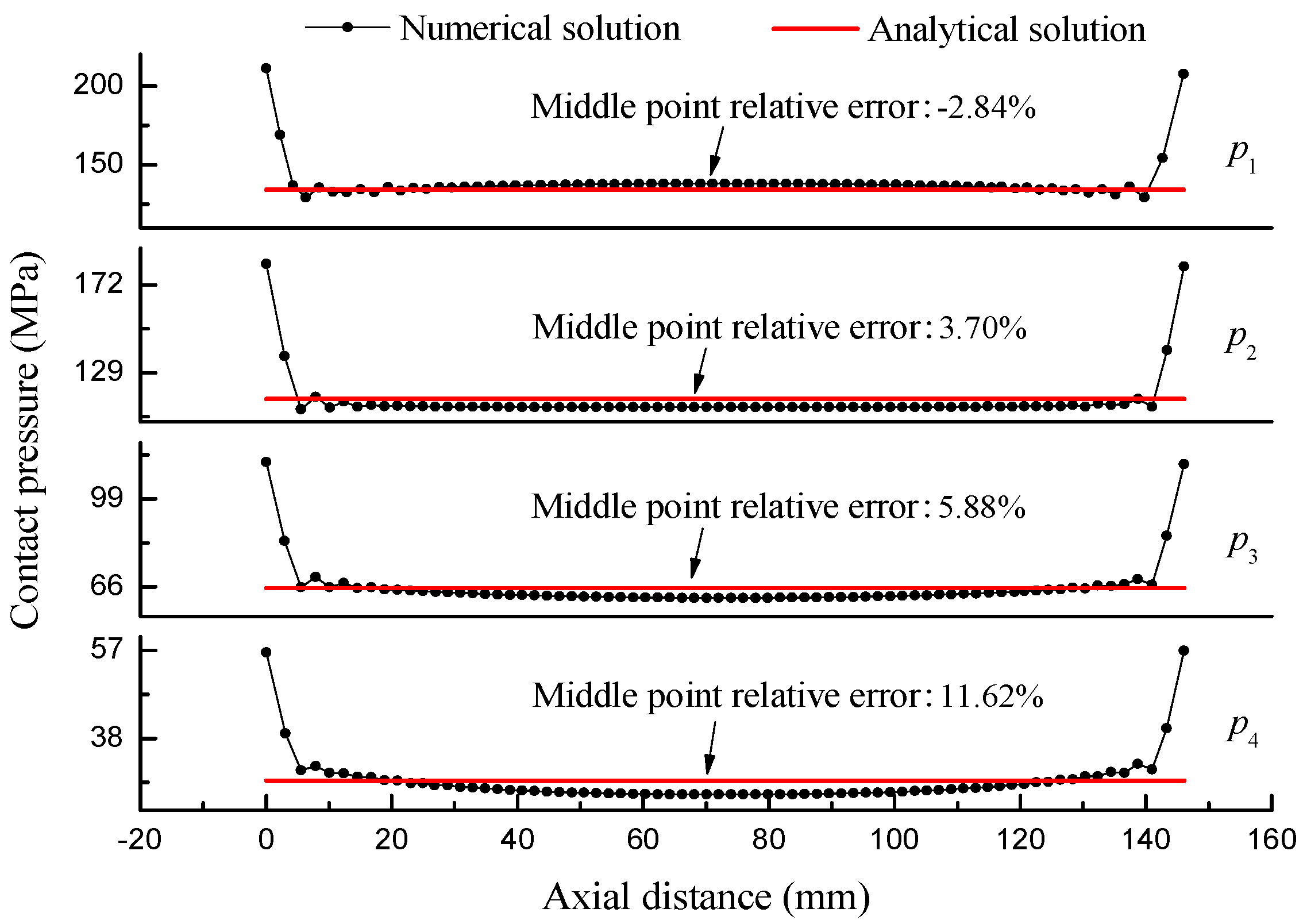

5.1. Influences of Centrifugal Force

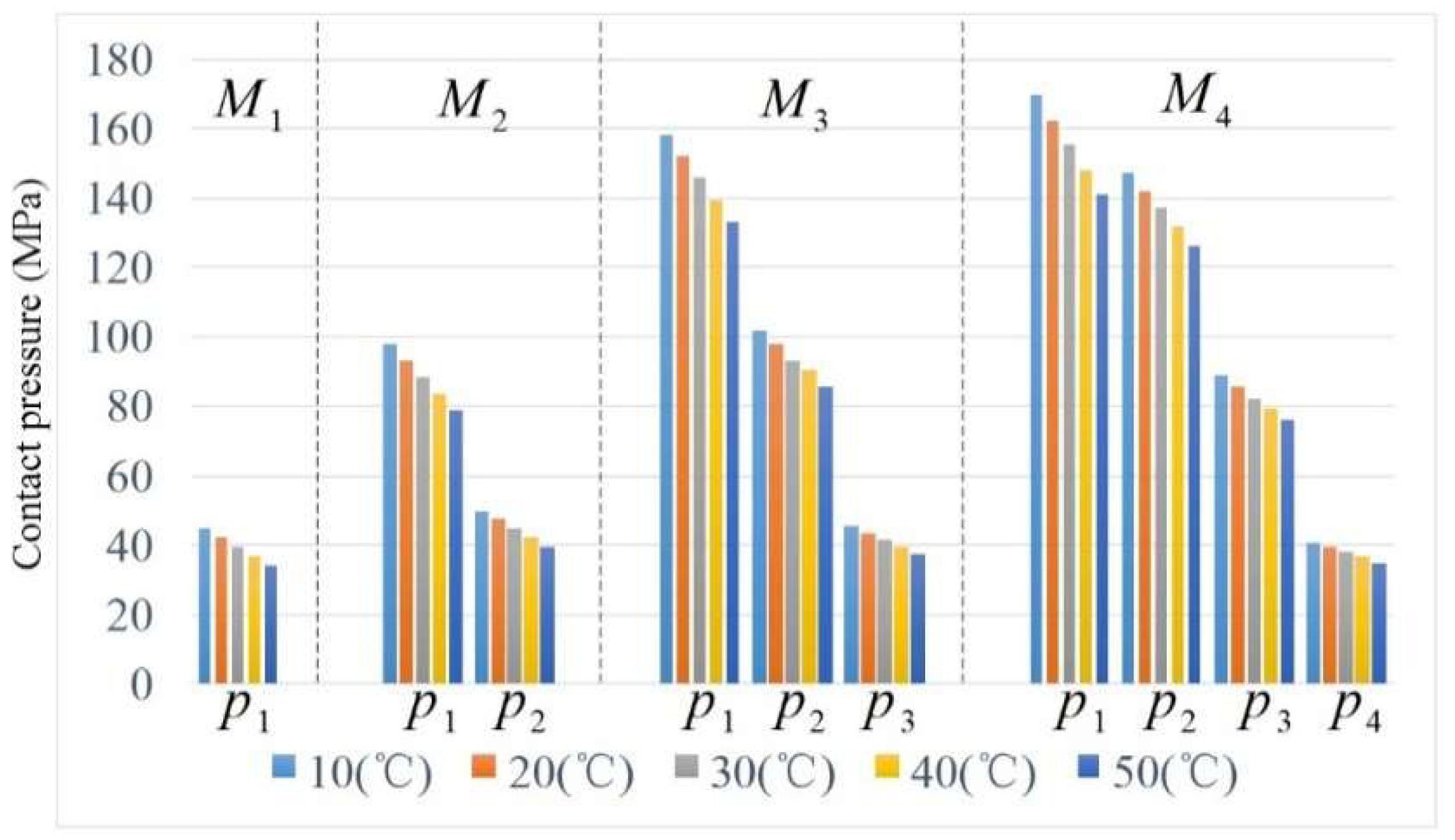

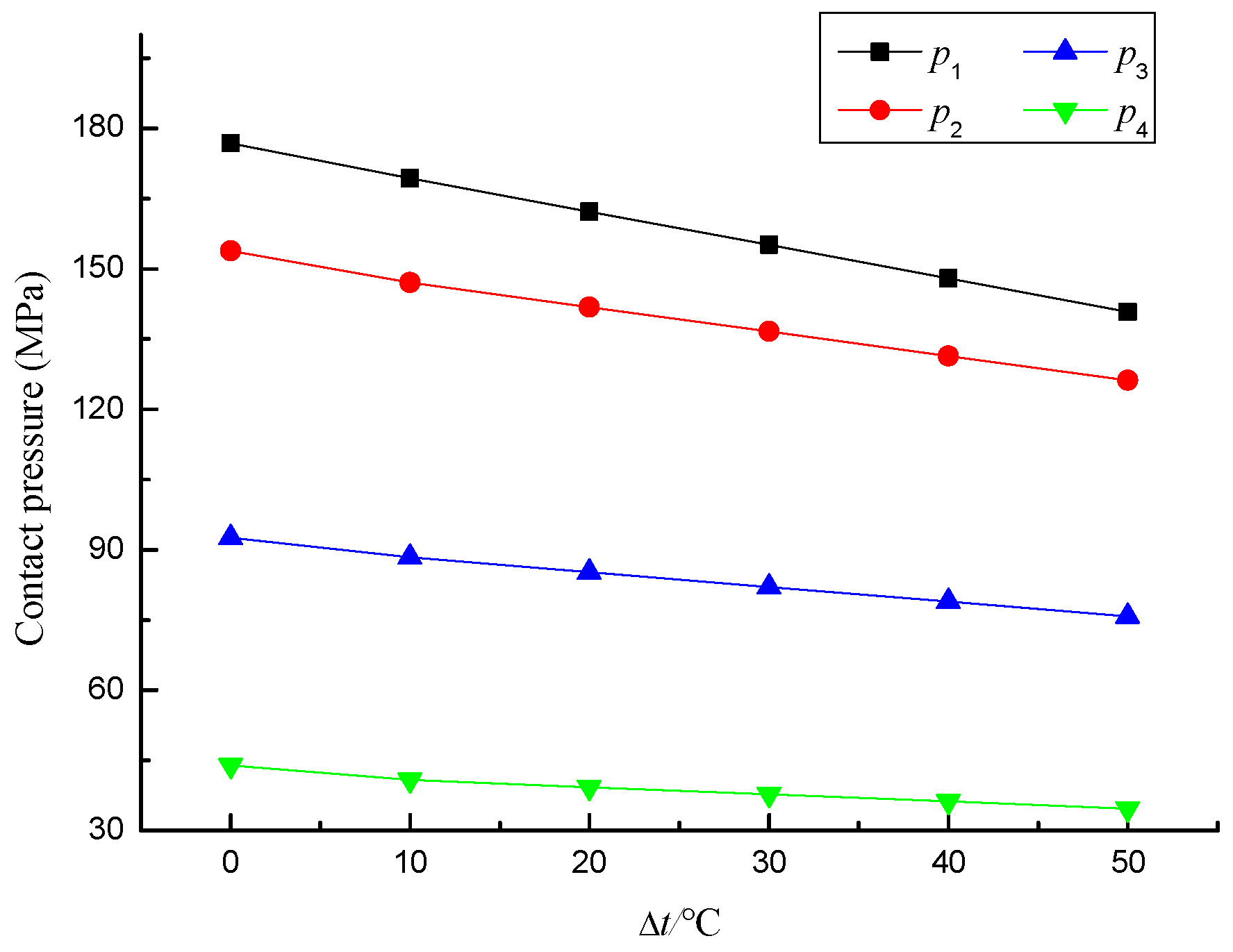

5.2. Influence of Temperature Gradient

6. Conclusions

- (1)

- The matrix models of the relationship between contact pressure and interference magnitude of a multi-layer interference cylinder under centrifugal force and temperature gradient are deduced based on elastic mechanics and thick-wall cylinder theory.

- (2)

- The contact pressure of multi-layer interference cylinder under centrifugal effect decreases with the increase of rotational speed, and the curve slope increases with the increase of rotational speed. The maximum radial displacement of contact surface is at the outmost layer of interference cylinder. In the same model, the radial displacement of contact surface is gradually increased from inside to outside. The interference magnitude should be compensated according to the centrifugal force during the design of multi-layer interference fit.

- (3)

- Without considering the stress concentration, the numerical solution is in good agreement with the analytical solution. Even if the maximum relative error of midpoint is 11.62%, it is kept within the allowable range of design, which shows that the matrix model of multi-layer interference fit under centrifugal force can be used for design reference.

- (4)

- The contact pressure of multi-layer interference cylinder decreases linearly with increase of temperature gradient. The maximum relative error of analytical solution and numerical solution under temperature gradient is −7.69%, which is in the allowable design range. It indicates that the matrix model of multi-layer interference fit under the same temperature gradient can be used for reference.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Wang, J.; Ning, K.; Xu, J.; Li, Z. Reliability-based robust design of wind turbine’s shrink disk. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017. [Google Scholar] [CrossRef]

- Sogalad, I.; Ashoka, H.N.; Udupa, N.G.S. Influence of cylindricity and surface modification on load bearing ability of interference fitted assemblies. Precis. Eng. 2012, 36, 629–640. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, S. Analysis of contact stress and dynamic performance of conical interference fit based fit based on FEA model. J. Donghua Univ. 2014, 40, 117–121. [Google Scholar]

- Wang, J.; Kang, J.; Tang, L. Theoretical and experimental studies for wind turbine’s shrink disk. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 229, 325–334. [Google Scholar]

- Wang, J.; Kang, J.; Tao, D. The design method of multi-layer interference fit. J. Sichuan Univ. 2013, 45, 84–89. [Google Scholar]

- McMillan, M.D.; Booker, J.D.; Smith, D.J. Analysis of increasing torque with recurrent slip in interference-fits. Eng. Fail. Anal. 2016, 62, 58–74. [Google Scholar] [CrossRef]

- Boutoutaou, H.; Bouaziz, M.; Fontaine, J.F. Modeling of interference fits taking form defects of the surfaces in contact into account. Mater. Des. 2011, 32, 3692–3701. [Google Scholar] [CrossRef]

- Boutoutaou, H.; Bouaziz, M.; Fontaine, J.F. Modelling of interference fits with taking into account surfaces roughness with homogenization technique. Int. J. Mech. Sci. 2013, 69, 21–31. [Google Scholar] [CrossRef]

- Li, J.; Zhang, K.; Li, Y.; Liu, P.; Xia, J. Influence of interference-fit size on bearing fatigue response of single-lap carbon fiber reinforced polymer/Ti alloy bolted joints. Tribol. Int. 2016, 93, 151–162. [Google Scholar] [CrossRef]

- Li, J.; Li, Y.; Zhang, K.; Liu, P.; Zhou, P. Interface damage behaviour during interference-fit bolt installation process for CFRP/Ti alloy joining structure. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 1359–1371. [Google Scholar] [CrossRef]

- Kurvinen, E.; Sopanen, J.; Mikkola, A. Ball bearing model performance on various sized rotors with and without centrifugal and gyroscopic forces. Mech. Mach. Theory 2015, 90, 240–260. [Google Scholar] [CrossRef]

- Guo, T.; Ma, X.; Gu, Y.; Chen, J. Effect of the Interference Fit Amount Impact on the Dynamic Characteristics of Spindle. J. Beijing Univ. Technol. 2016, 42, 51–59. [Google Scholar]

- Ding, H.; Xiao, L.; Zhang, H. Interference Fit Calculation and Stress Analysis for Rotor Sleeve of High-speed Permanent Magnet Electric Machine. Mech. Des. Res. 2011, 27, 95–98. [Google Scholar]

- Zhou, H.; Wang, Z.; Xie, Y. Precision Analysis of Interference Fits for Drive Shaft based on FEA. Mech. Drive 2010, 34, 60–62. [Google Scholar]

- Qiu, J.; Zhou, M. Analytical Solution for Interference Fit for Multi-Layer Thick-Walled Cylinders and the Application in Crankshaft Bearing Design. Appl. Sci. 2016, 6, 167. [Google Scholar] [CrossRef]

- Wang, J.; Ning, K.; Tang, L.; Malekian, R.; Liang, Y.; Li, Z. Modeling and Finite Element Analysis of Load-Carrying Performance of a Wind Turbine Considering the Influence of Assembly Factors. Appl. Sci. 2017, 7, 298. [Google Scholar] [CrossRef]

- Xu, J.; Wang, J.; Ning, K.; Li, P. Study on contact pressure algorithm of N layer interference fit. J. Eng. Des. 2017, 24, 83–88. [Google Scholar]

- Xu, Z. Elastic Mechanics; Higher Education Press: Beijing, China, 2006; pp. 54–57. [Google Scholar]

- Luo, Z.; Fei, Y. Research on deformation of hollowed parts based on heat and stress state. J. Harbin Inst. Technol. 2006, 38, 1586–1589. [Google Scholar]

- Croccolo, D.; Agostinis, M.D. Analytical solution of stress and strain distributions in press fitted orthotropic cylinders. Int. J. Mech. Sci. 2013, 71, 21–29. [Google Scholar] [CrossRef]

- Croccolo, D.; Vincenzi, N. A generalized theory for shaft–hub couplings. ARCHIVE Proceedings of the Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2009, 223, 2231–2239. [Google Scholar] [CrossRef]

- Urade, S.D.; Bhope, D.V.; Khamankar, S.D. Stress Analysis of Multilayer Pressure Vessel. Int. J. Eng. Tech. Res. 2014, 2. [Google Scholar] [CrossRef]

| Cylinder No | |||||

|---|---|---|---|---|---|

| Internal diameter (mm) | 100 | 200 | 300 | 400 | 500 |

| External diameter (mm) | 200 | 300 | 400 | 500 | 600 |

| Height (mm) | 150 | ||||

| Elastic modulus | 206 GPa | ||||

| Poisson ratio | 0.3 | ||||

| Density | 7800 kg/m3 | ||||

| Coefficient of linear expansion | 1.1 × 10−5 | ||||

| Comparison Parameters | Numerical Value | |||

|---|---|---|---|---|

| Rotational Speed (rad/s) | 0 | 200 | 400 | 600 |

| Contact pressure (MPa) | 176 | 172 | 158 | 134 |

| Slope | −0.024 | −0.048 | −0.095 | −0.119 |

| Inner Surface of /Outer Surface of | Temperature of Inner and Outer Surfaces | |||||

|---|---|---|---|---|---|---|

| (°C) | 0 | 10 | 20 | 30 | 40 | 50 |

| Contact Pressure (MPa) | ||||

|---|---|---|---|---|

| Analytical solution | 169.374 | 147.059 | 88.408 | 40.801 |

| Numerical solution | 172.561 | 146.768 | 95.783 | 41.929 |

| Relative error | −1.85% | 0.198% | −7.69% | −2.69% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, Z.; Wang, J.; Ning, K.; Hou, D. Contact Pressure Algorithm of Multi-Layer Interference Fit Considering Centrifugal Force and Temperature Gradient. Appl. Sci. 2018, 8, 726. https://doi.org/10.3390/app8050726

Bai Z, Wang J, Ning K, Hou D. Contact Pressure Algorithm of Multi-Layer Interference Fit Considering Centrifugal Force and Temperature Gradient. Applied Sciences. 2018; 8(5):726. https://doi.org/10.3390/app8050726

Chicago/Turabian StyleBai, Zebing, Jianmei Wang, Ke Ning, and Dingbang Hou. 2018. "Contact Pressure Algorithm of Multi-Layer Interference Fit Considering Centrifugal Force and Temperature Gradient" Applied Sciences 8, no. 5: 726. https://doi.org/10.3390/app8050726

APA StyleBai, Z., Wang, J., Ning, K., & Hou, D. (2018). Contact Pressure Algorithm of Multi-Layer Interference Fit Considering Centrifugal Force and Temperature Gradient. Applied Sciences, 8(5), 726. https://doi.org/10.3390/app8050726