Experimental Study of Ground Subsidence Mechanism Caused by Sewer Pipe Cracks

Abstract

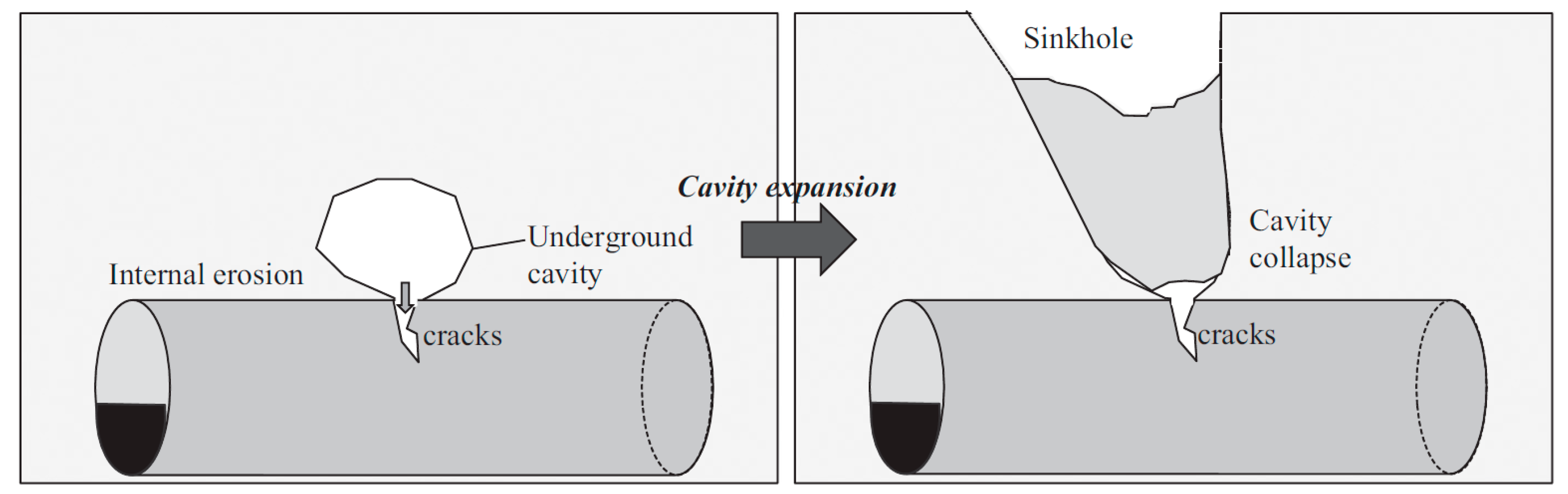

:1. Introduction

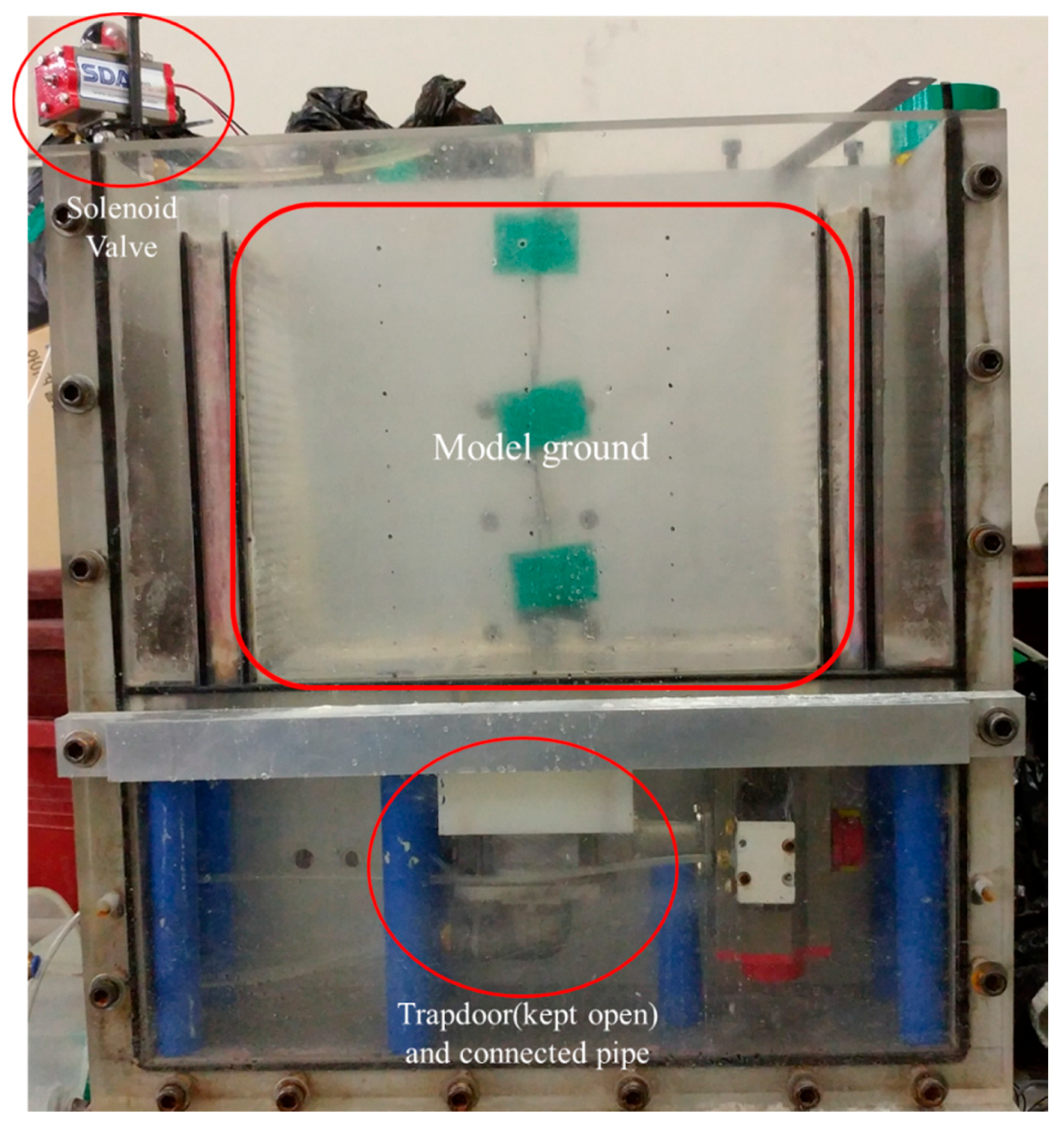

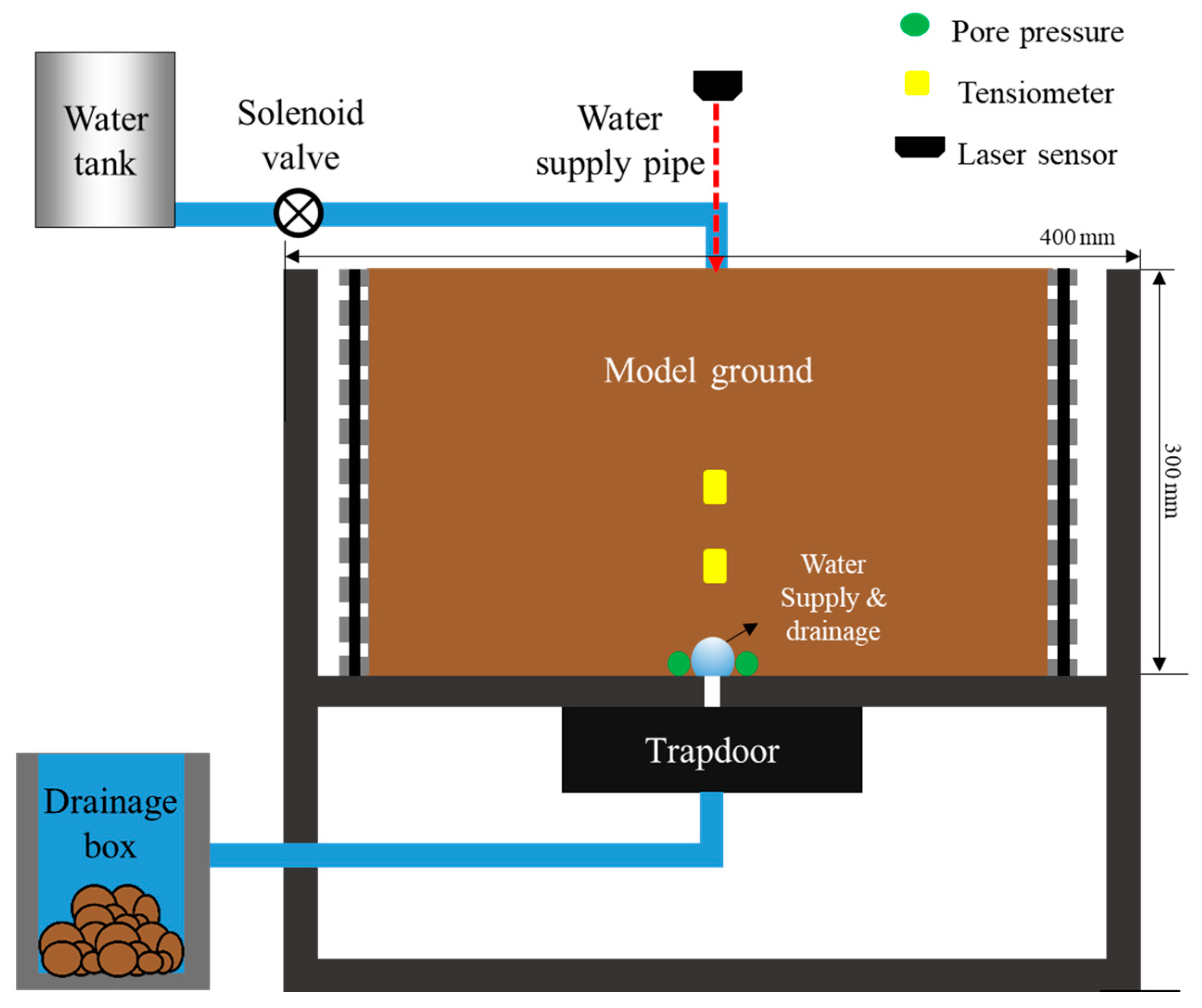

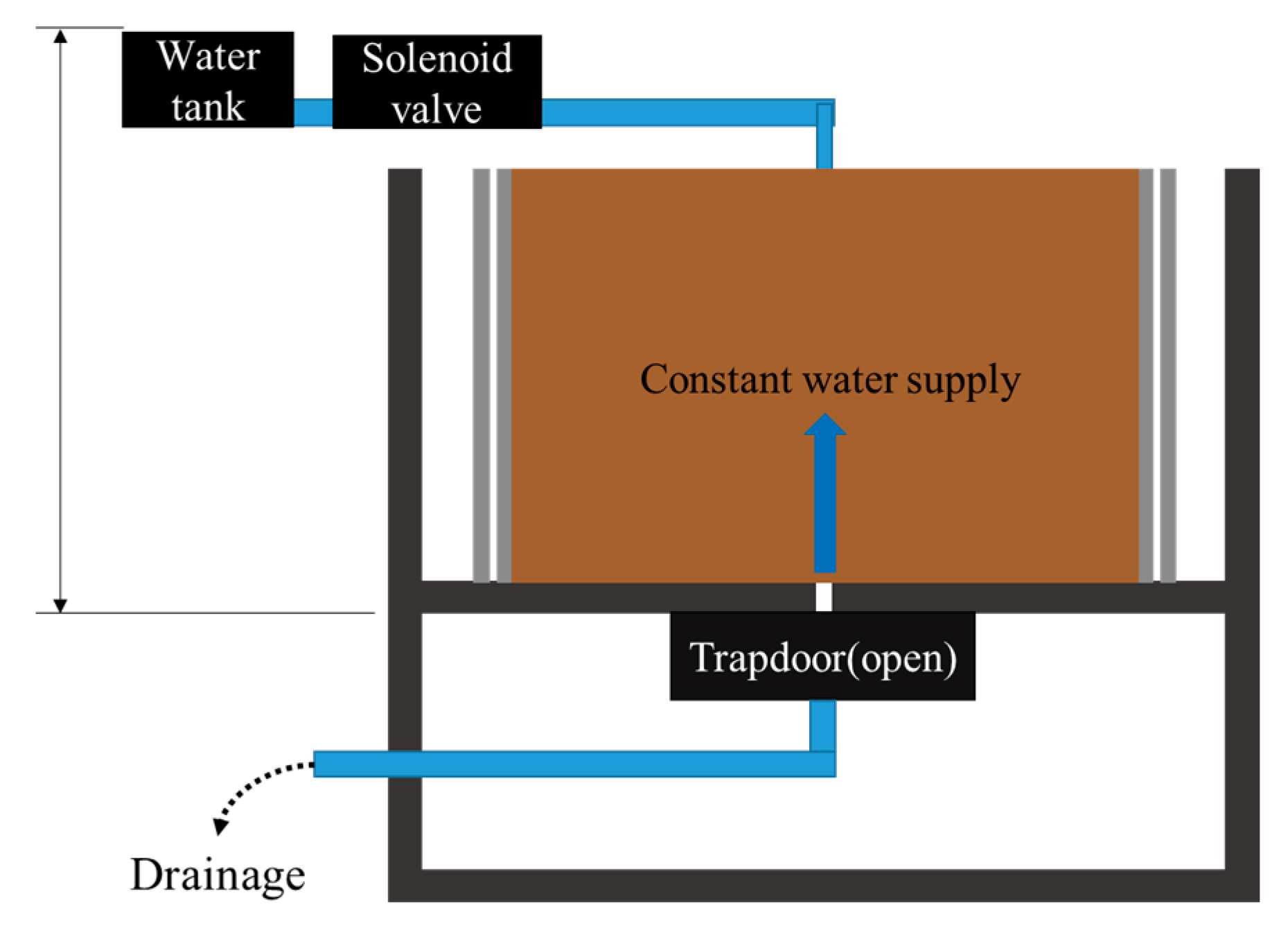

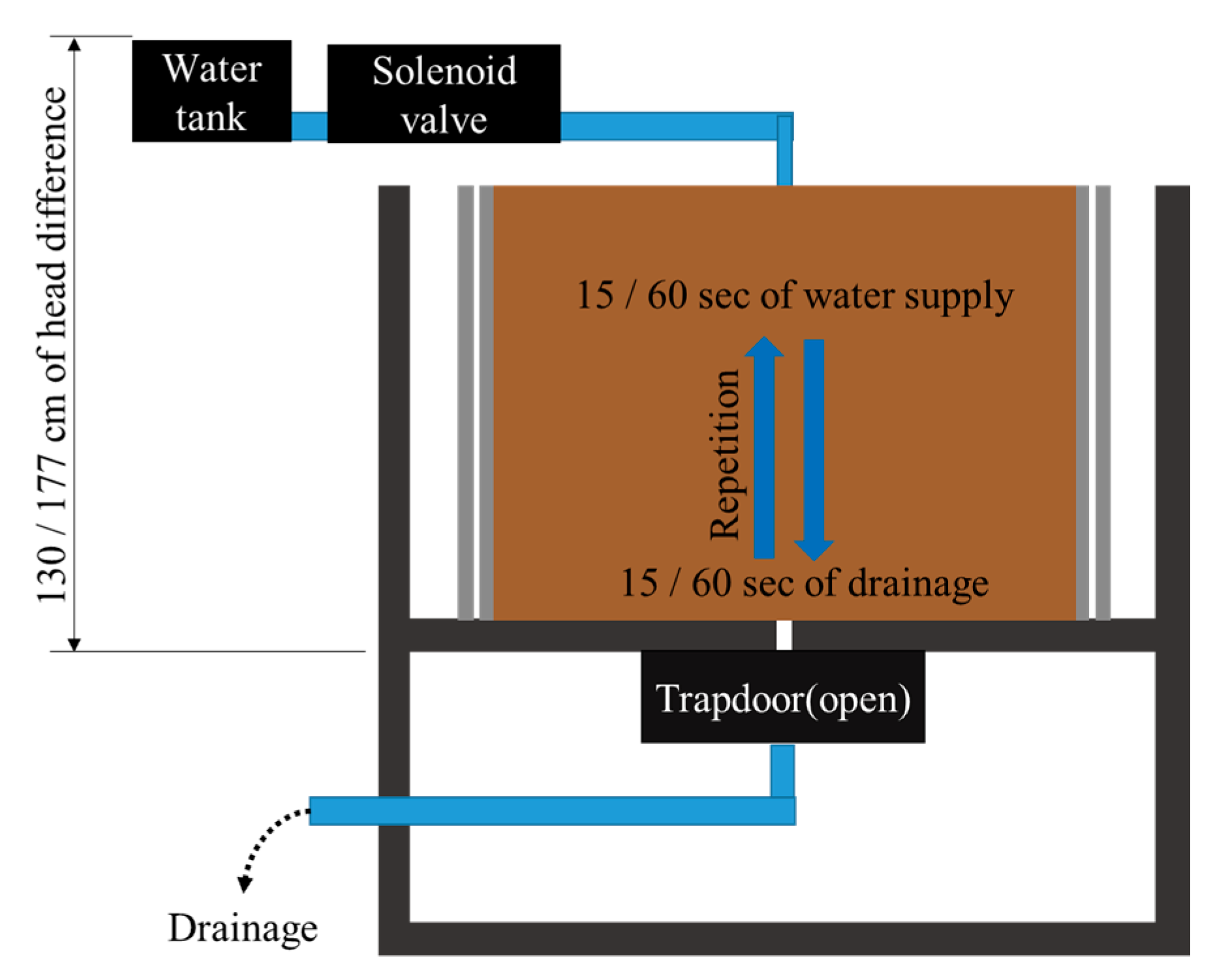

2. Materials and Methods

3. Test Results and Discussion

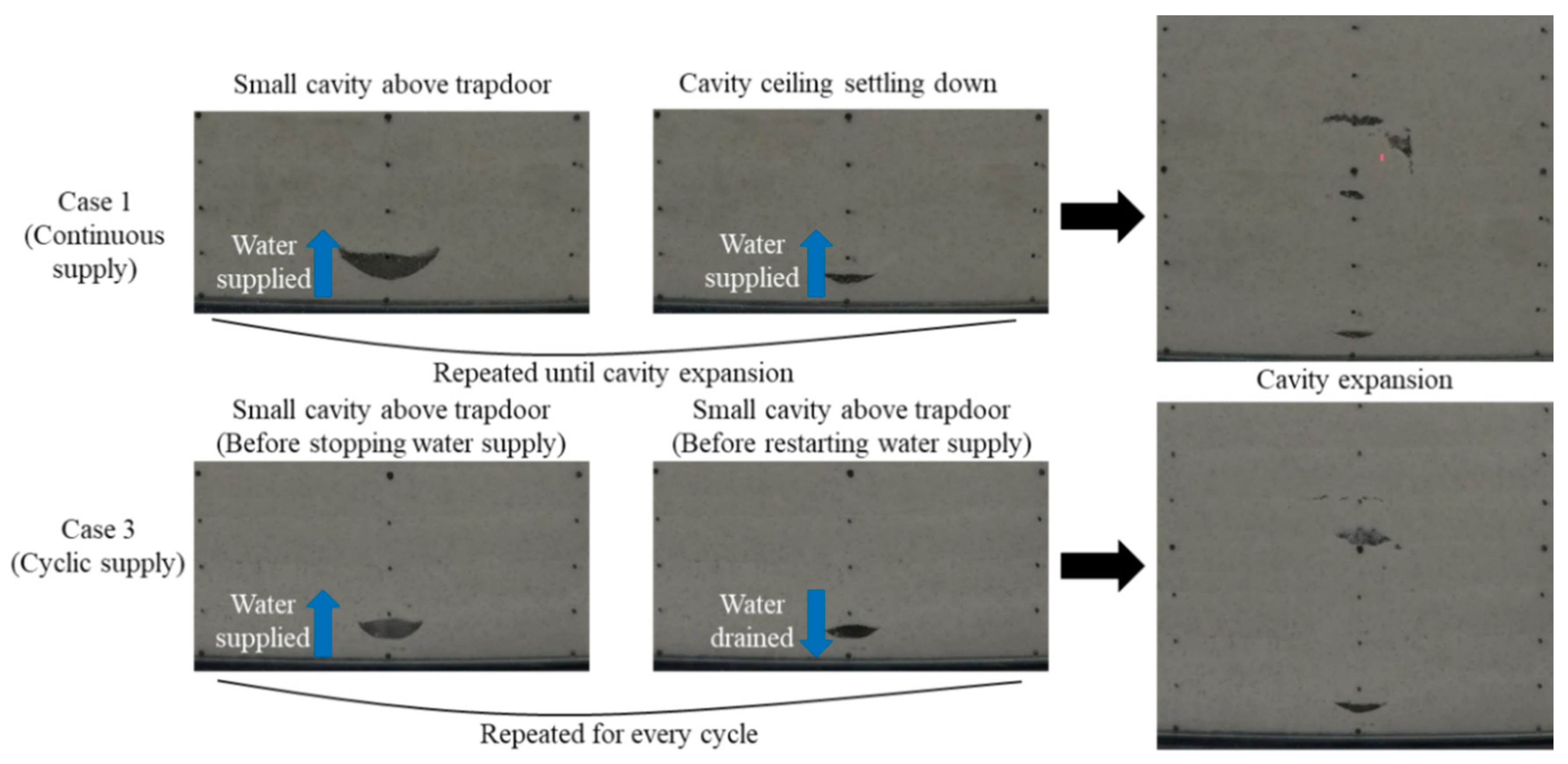

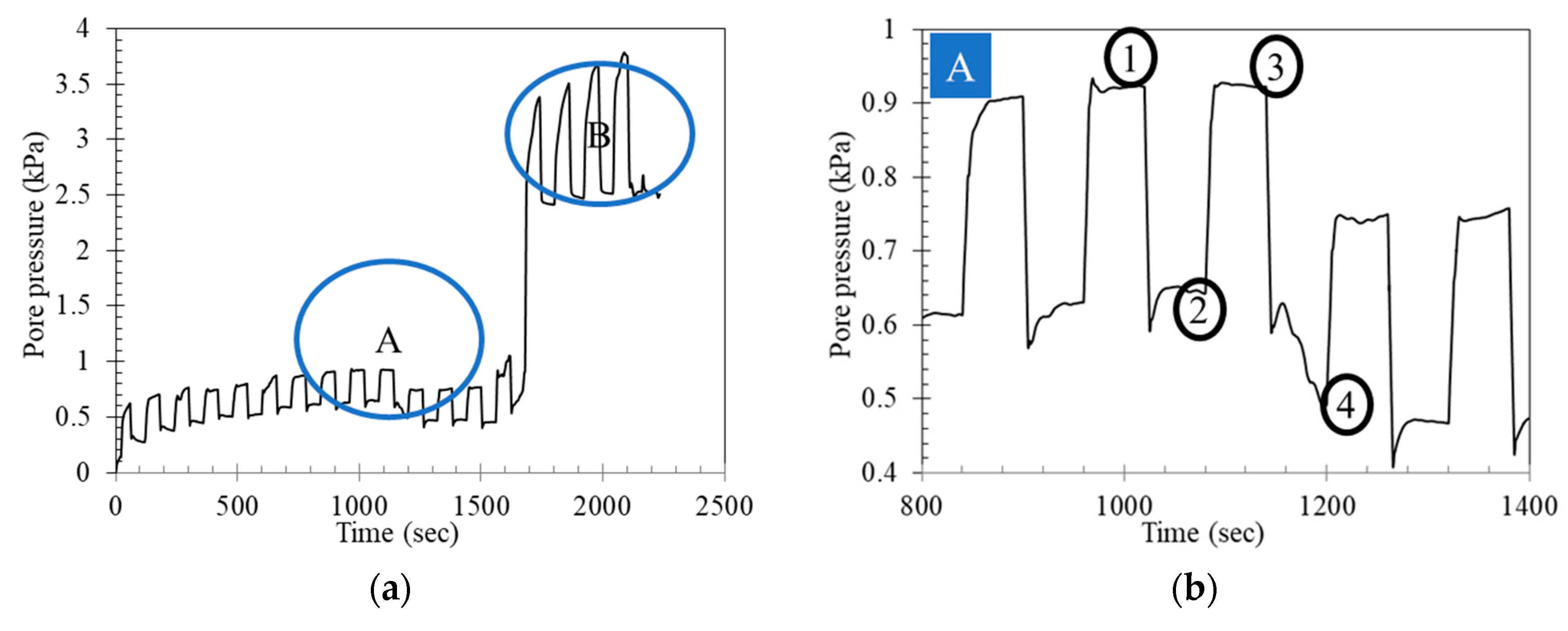

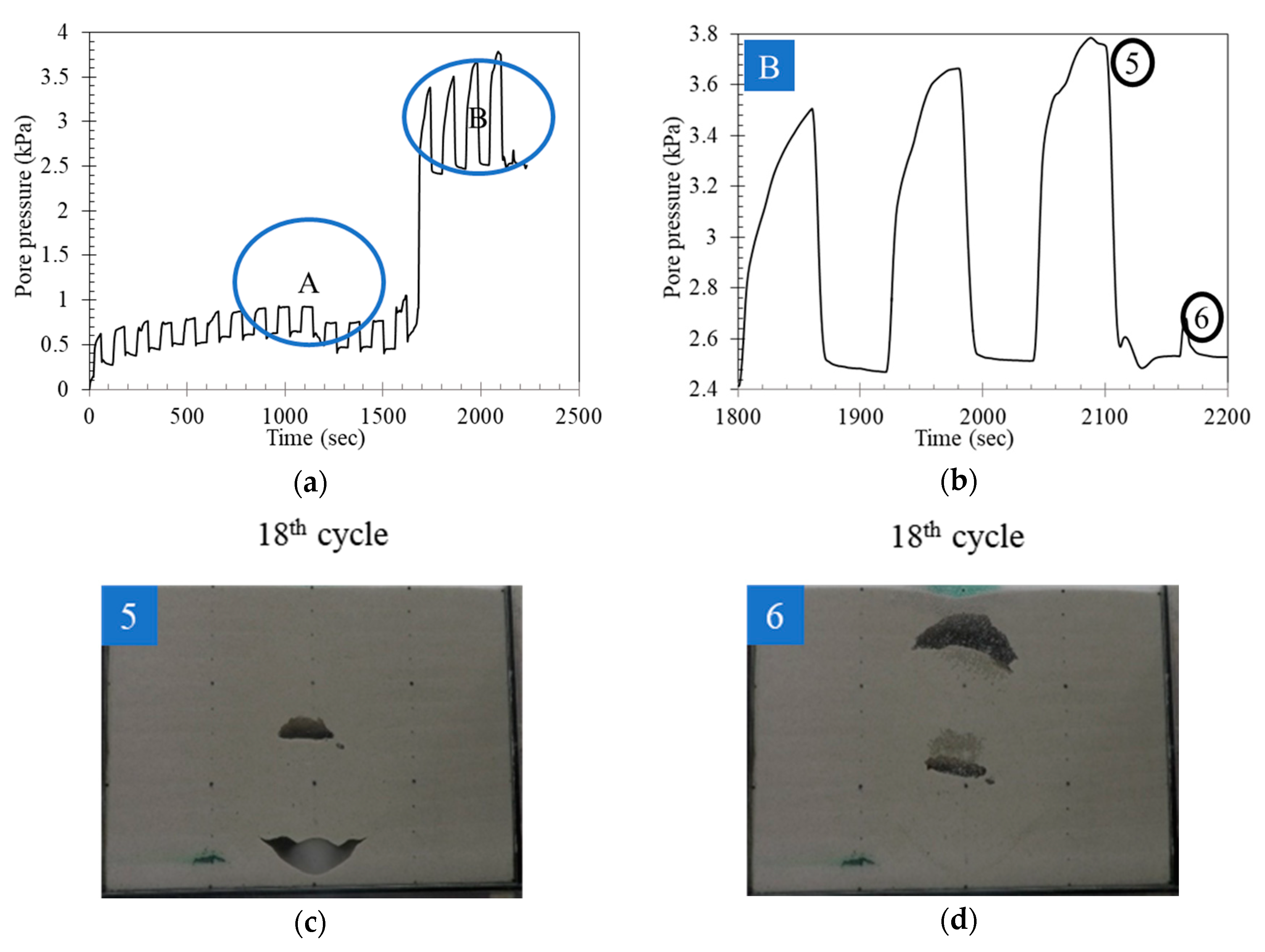

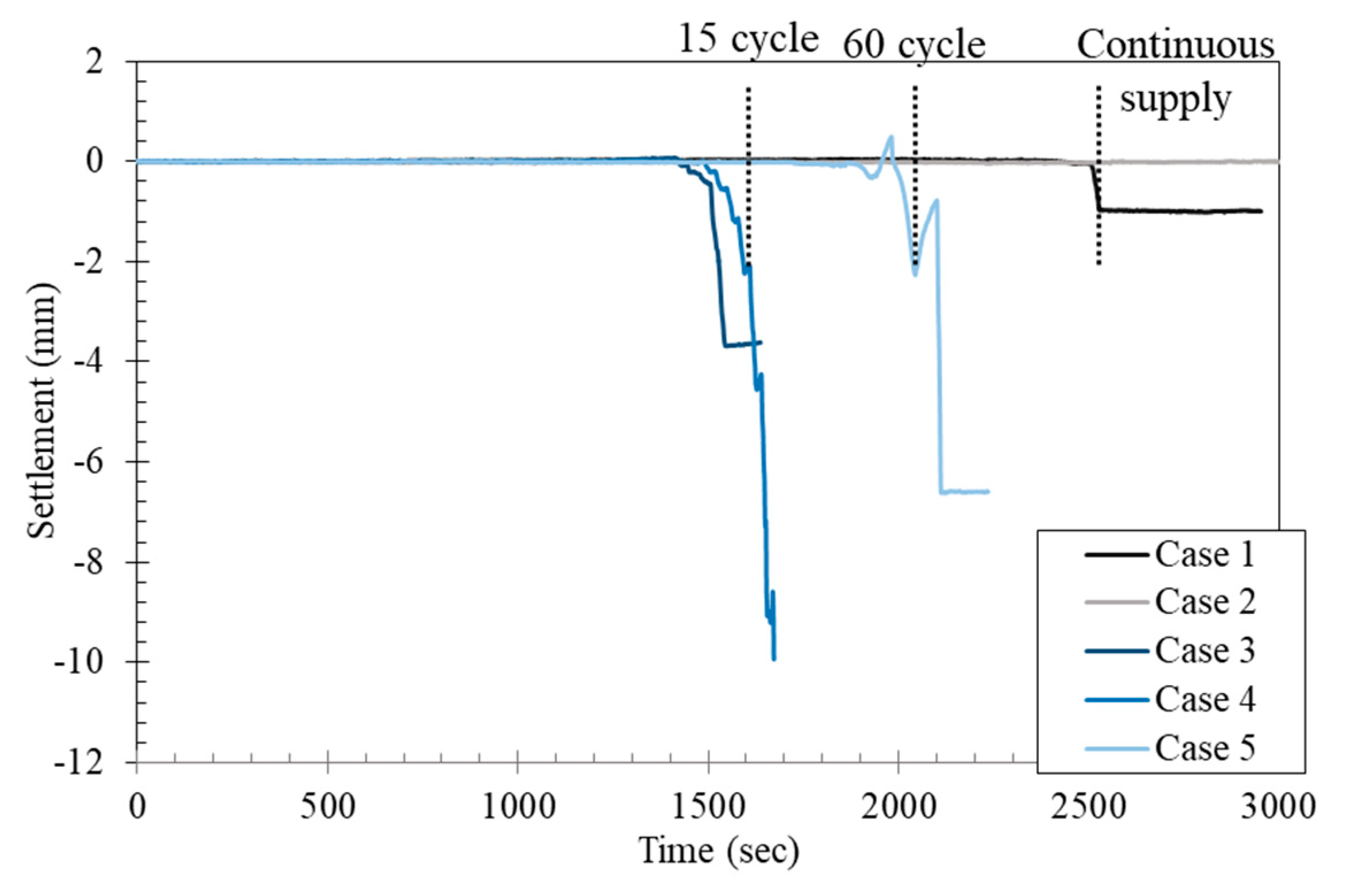

3.1. Continuous Water Supply vs. Cyclic Water Supply

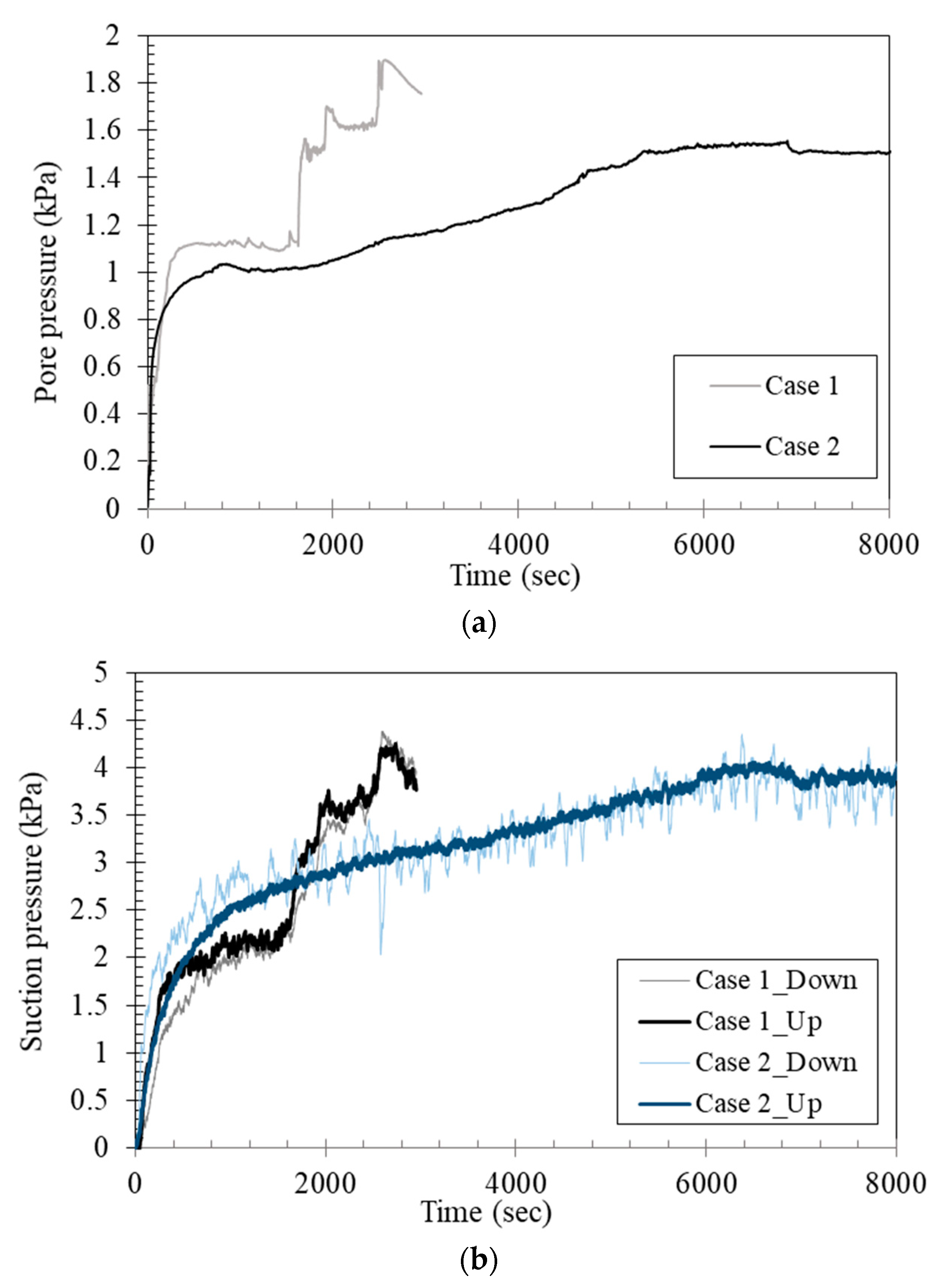

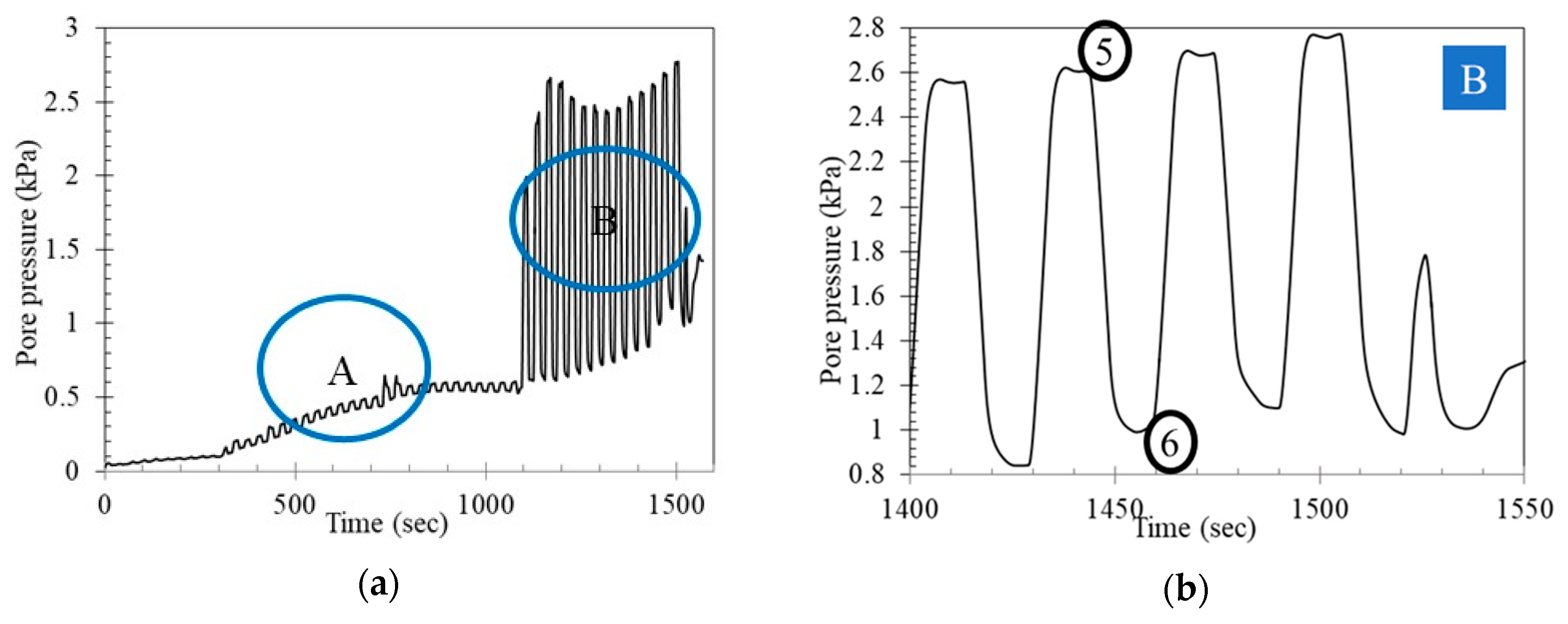

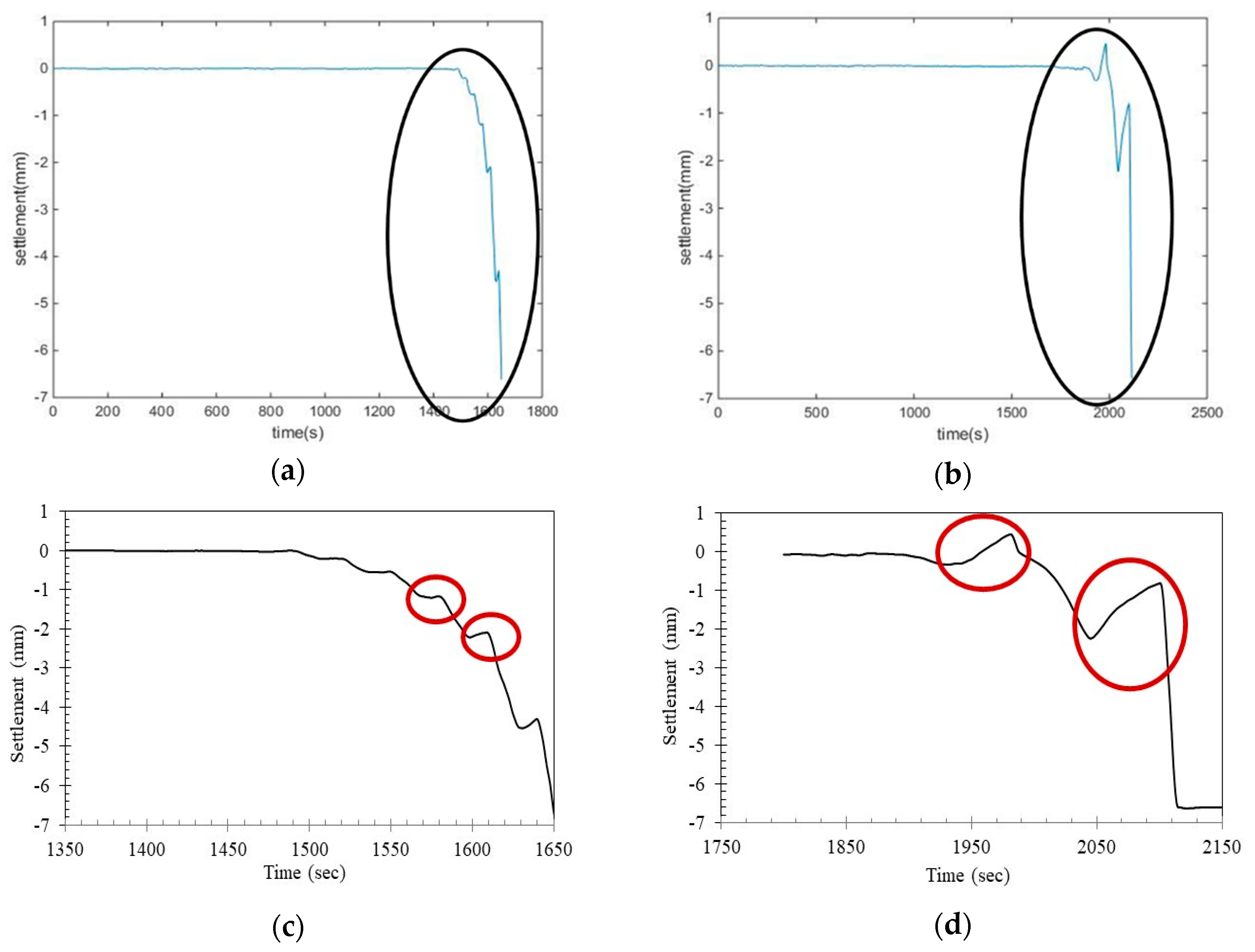

3.2. Ground Subsidence Process Speed According to the Water Supply Mode

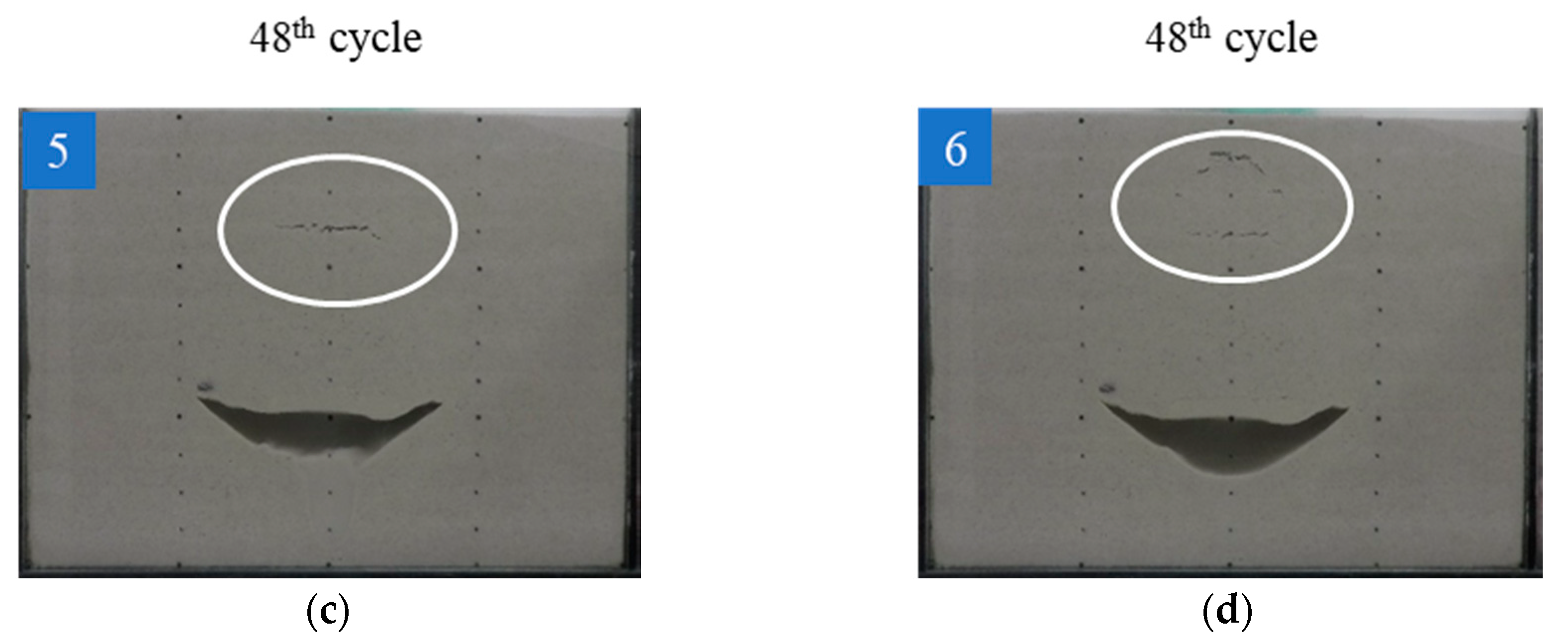

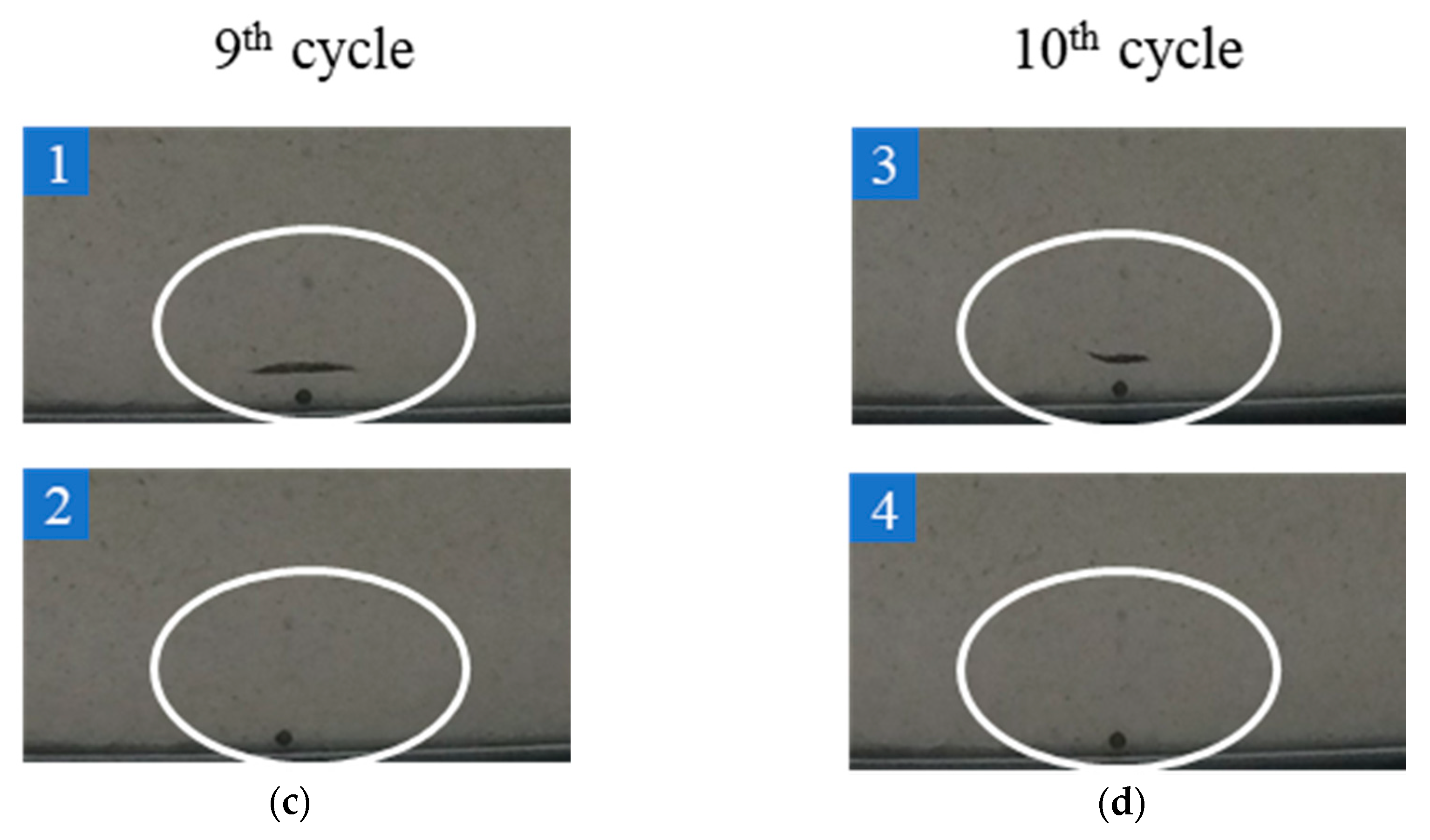

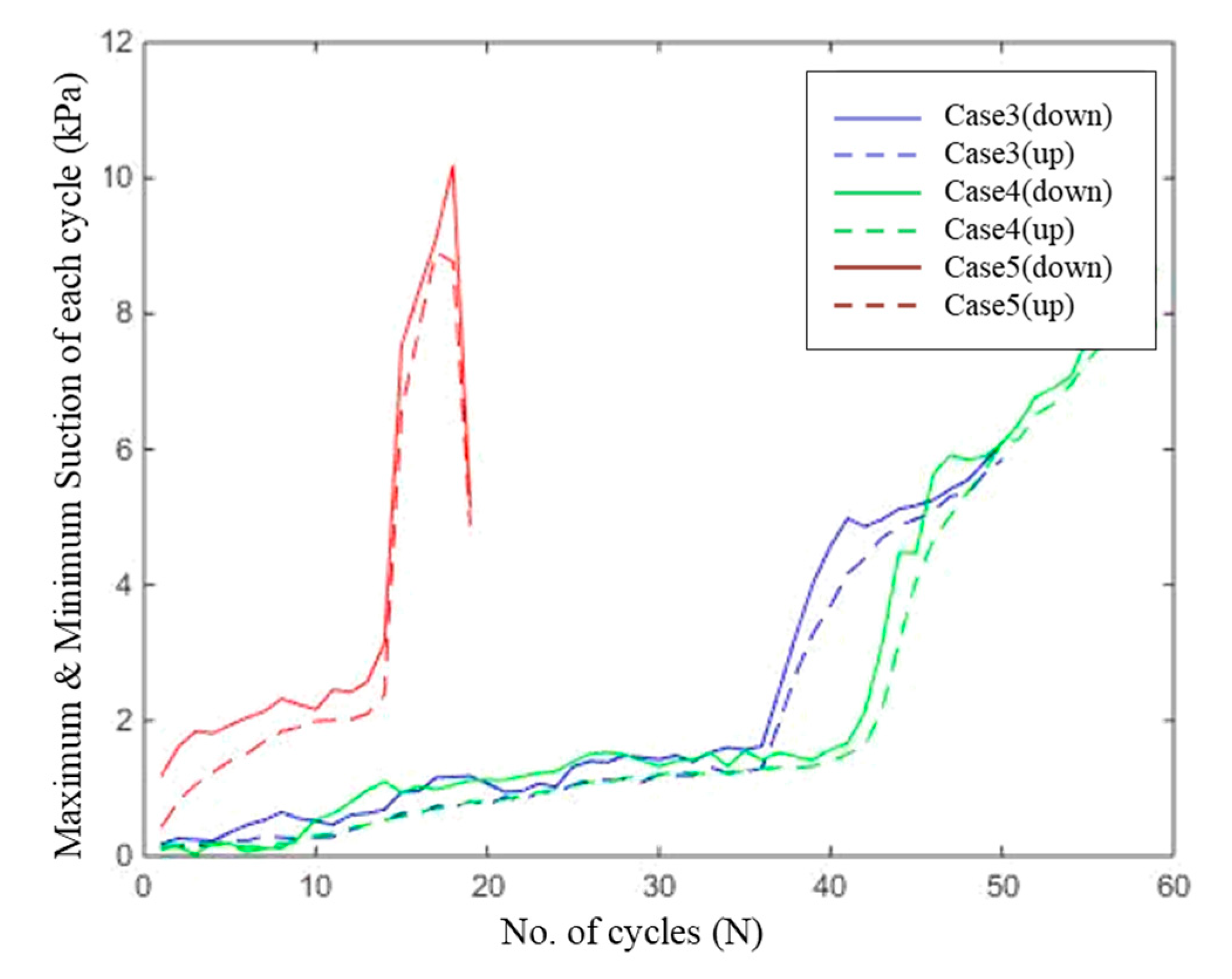

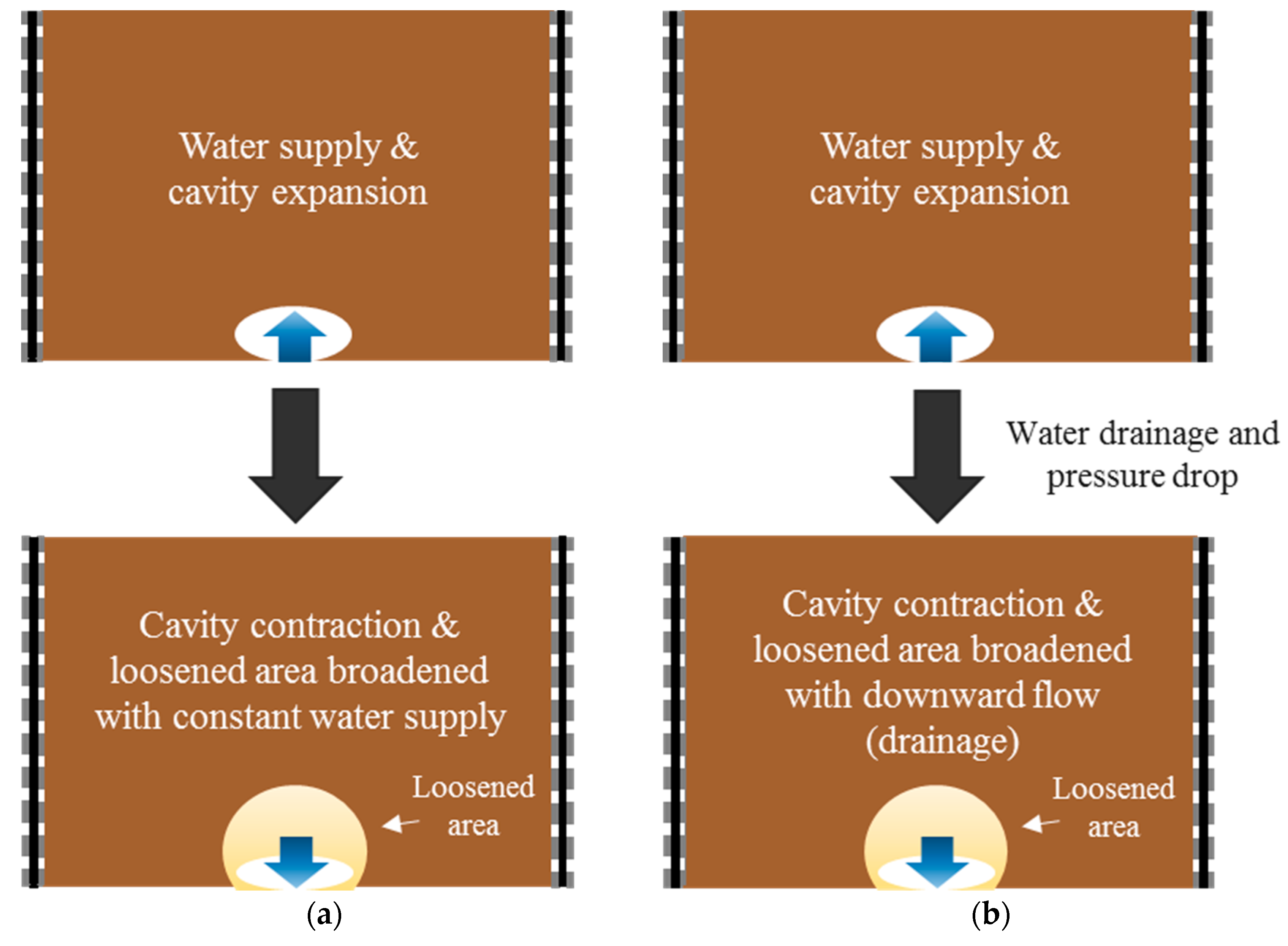

3.3. Effect of Buoyancy on the Cavity Expansion and Contraction

3.4. Summarized Ground Subsidence Mechanism and Influence Factors

4. Conclusions

- The process of ground subsidence occurrence is cavity formation around the groundwater leakage point, either by ground loosening or by external soil erosion, cavity expansion, and ceiling collapse due to insufficient support within the cavity. These mechanisms are repeated until the collapse of the soil specimen.

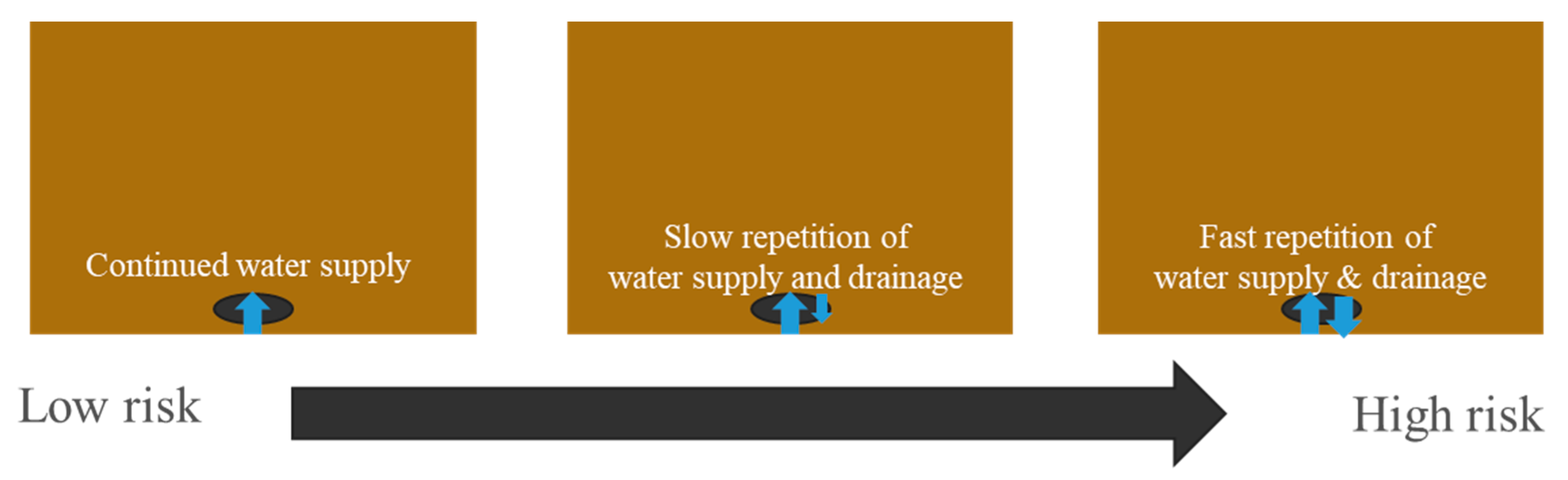

- The way ground water is supplied and leaked shows the difference in the ground subsidence mechanism. The ground loosening caused by a succession of water supply and drainage cycles leads to a faster collapse than a continuous leakage system.

- A succession of fast water supply and drainage cycles leads to a faster collapse than slow water supply and drainage cycles.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Kuwano, R.; Horii, T.; Kohashi, H.; Yamauchi, K. Defects of sewer pipes causing cave-in’s in the road. In Proceedings of the 5th International Symposium on New Technologies for Urban Safety of Mega Cities in Asia, Phuket, Thailand, 16–17 November 2006. [Google Scholar]

- Hachiya, M.; Tohda, J.; Tokumasu, K.; Takatsuka, Y.; Sano, Y. A new design method for buried pipelines subjected to differential ground settlement. In Proceedings of the 15th International Conference on Soil Mechanics and Geotechnical Engineering, Istanbul, Turkey, 31 August 2001; pp. 1319–1322. [Google Scholar]

- Tohda, J.; Hachiya, M. Response and design of buried pipelines subjected to differential ground settlement. In Proceedings of the 16th International Conference on Soil Mechanics and Geotechnical Engineering, Osaka, Japan, 12–16 September 2005; pp. 1659–1662. [Google Scholar]

- Mukunoki, T.; Kumano, N.; Otani, J.; Kuwano, R. Visualization of three dimensional failure in sand due to water inflow and soil drainage from defective underground pipe using X-ray CT. Soils Found. 2009, 49, 959–968. [Google Scholar] [CrossRef]

- Mukunoki, T.; Otani, J.; Nonaka, S.; Horii, T.; Kuwano, R. Evaluation of cavity generation in soils subjected to sewerage defects using X-ray CT. In Advances in X-ray Tomography for Geomaterials; John Wiley & Sons: Hoboken, NJ, USA, 2006; pp. 365–371. [Google Scholar]

- Indiketiya, S.; Jegatheesan, P.; Rajeev, P. Evaluation of defective sewer pipe–induced internal erosion and associated ground deformation using laboratory model test. Can. Geotech. J. 2017, 54, 1184–1195. [Google Scholar] [CrossRef]

- Seoul Metropolitan Government. Seoul Metropolitan Government to Issue the Result of Investigation on ‘Road Cave-In’, and Special Countermeasure; Seoul Metropolitan Government: Seoul, Korea, 2014.

- Jo, Y.S.; Cho, S.H.; Jang, Y.S. Field investigation and analysis of ground sinking development in a metropolitan city. Environ. Earth Sci. 2016, 75, 1353. [Google Scholar] [CrossRef]

- Asahi. (2016/11/08). Available online: www.asahi.com/topics/word/%E5%8D%9A%E5%A4%9A%E9%A7%85%E5%89%8D%E9%99%A5%E6%B2%A1.html (accesed on 25 April 2018). (In Japanese).

- Nishi Nippon. (2016/11/08). Available online: www.nishinippon.co.jp/feature/attention/article/301843/ (accesed on 25 April 2018). (In Japanese).

- Youtube. (2016/11/07). Available online: https://www.youtube.com/watch?v=LJB1NKe0r2o (accesed on 25 April 2018). (In Japanese).

| Index | Value | |

|---|---|---|

| Specific gravity (Gs) | 2.63 | |

| #200 sieve passing ratio (%) | 0.9 | |

| Maximum dry density () | 15.5 | |

| Minimum dry density () | 12.3 | |

| Particle size (mm) | D10 | 0.194 |

| D50 | 0.322 | |

| D60 | 0.344 | |

| Unified soil classification system (USCS) | SP | |

| Uniformity constant (Cu) | 1.77 | |

| Plasticity index (PI) | Non-plastic (NP) | |

| Water Head (cm) | Continuous Water Supply | 15 s Supply & Drainage Cycles | 60 s Supply & Drainage Cycles |

|---|---|---|---|

| 177 | Case 1 | Case 3 | Case 5 |

| 130 | Case 2 | Case 4 | - |

| Time (s) | Continuous | Cyclic | |||

|---|---|---|---|---|---|

| 15 s | 60 s | ||||

| Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | |

| Collapse time | 2521 | No settlement | 1507 | 1532 | 2011 |

| Total water supply time | 2521 | - | 750 | 765 | 1020 |

| Total cycles | - | - | 50 | 51 | 17 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karoui, T.; Jeong, S.-Y.; Jeong, Y.-H.; Kim, D.-S. Experimental Study of Ground Subsidence Mechanism Caused by Sewer Pipe Cracks. Appl. Sci. 2018, 8, 679. https://doi.org/10.3390/app8050679

Karoui T, Jeong S-Y, Jeong Y-H, Kim D-S. Experimental Study of Ground Subsidence Mechanism Caused by Sewer Pipe Cracks. Applied Sciences. 2018; 8(5):679. https://doi.org/10.3390/app8050679

Chicago/Turabian StyleKaroui, Tarek, Seong-Yun Jeong, Yeong-Hoon Jeong, and Dong-Soo Kim. 2018. "Experimental Study of Ground Subsidence Mechanism Caused by Sewer Pipe Cracks" Applied Sciences 8, no. 5: 679. https://doi.org/10.3390/app8050679

APA StyleKaroui, T., Jeong, S.-Y., Jeong, Y.-H., & Kim, D.-S. (2018). Experimental Study of Ground Subsidence Mechanism Caused by Sewer Pipe Cracks. Applied Sciences, 8(5), 679. https://doi.org/10.3390/app8050679