1. Introduction

High-speed, pressure-compensated piston pumps are widely used in aircraft hydraulic systems for their high power density. As a key component in the variable displacement mechanism, the swash plate is adjusted through the action of a pressure-compensated control valve, which uses pressure feedback so that the instantaneous output flow of the pump is exactly enough to maintain a presetting pressure. Reduction of the pressure pulsation and vibration of the piston pump, caused by the fluid–solid interaction, is a constant subject of research. The vibration of the high-speed piston pump can shorten its service life and negatively influence flight safety. The oscillating swash plate is one of the major excitation sources in a high-speed piston pump, which is caused by the actuator piston and the piston-slipper units. Currently, research into the swash plate mainly focuses on the torque from the pumping pistons, the toque from both the pumping pistons and the actuator piston, and the control characteristics of the piston pump systems.

Many studies have considered the torques on the swash plate from the pumping pistons in their models. Zeiger et al. [

1] have conducted a dynamic analysis of the swash plate control of an axial piston pump and found that the pump shaft rotational speed and the discharge volume affect the dynamic behavior. Moreover, the averaged torque on the swash plate at zero angular velocity was calculated and compared to experimental results, indicating a good correlation. Manring et al. calculated the torques through the given approximate distribution of the pressure in the pumping pistons [

2,

3]. To improve accuracy, some studies deduced the differential equation of the pumping piston pressure from the kinematical equations and the continuity equations of flow, which consider the pressure overshoot and pressure undershoot in the transition regions [

3,

4]. Ericson [

5] investigated the oscillations of swash plates caused by pumping piston forces acting on the swash plate and surmised that the flow pulsations have minor variations between fixed and oscillating swash plates. Miller [

6] designed a simplified pump structure, consisting of the swash plate and the housing, and measured the interfacial properties of the bearing interface between the swash plate and the pump housing under static, modal, and transient conditions. Fornarelli et al. [

7] analyzed the forces acting on the swash plate in stationary and non-stationary conditions using the software LMS-AMESim

®. Liu et al. [

8] simulated the single pumping piston torque on the swash plate based on a hydraulic–mechanical co-simulation model and reduced the flow ripple rates through integration and optimization. Pan et al. [

9] established a flexible multi-body dynamic model of an axial piston pump and found that the main noise source is the excitation force of the swash plate on the housing.

The actuator piston in the variable displacement mechanism constitutes another main part of the torque on the swash plate. Kim et al. [

10] conducted a study on the sensitivity of the outlet pressure control to certain parameters within the pump system, and the total torque on yoke due to the force of pumping pistons and bias pistons was given. However, the high-frequency swash plate oscillation was not discussed. Norhirni et al. [

11] derived the equations for the actuator forces applied on the swash plate, which could be used to obtain the control and containment requirements for any steady-state operating condition of any pump with similar swash plate design. The control valve and actuator were modeled by Ericson to investigate the oscillations on the swash plate [

12]. He found out that the oscillations of the swash plate become bigger at small speeds, small setting angles, and larger pressures. Achten [

13] built a simulation model to investigate swash plate oscillation in a variable displacement floating cup pump and came to similar conclusions to Ericson. Maiti et al. [

14] measured the low-frequency variation in the swash plate control torque when the swash plate starts moving at the vicinity of the set pressure zone, and the simulated torque shows similarities with the experimental result, except for at the low flow zone. Milind et al. [

15,

16] developed a multi-body dynamic model without the consideration of fluid to study the bearing forces, control piston force, swash plate motion, and torque ripple. Milind summarized the variation of the angular oscillations of the swash plate about the axis perpendicular to the driveshaft.

Other scholars have also studied the control characteristics of the piston pump system. They analyzed the stability of the load-sensing (LS) controlled variable displacement pump system and found that the LS systems are prone to oscillation or even unstable behavior, because the load dynamics and the pump dynamics become inherently heavily coupled through an LS mechanism [

17,

18,

19]. Kim et al. [

20] used an electronic angle sensor and an acceleration sensor to measure the dynamic state of the swash plate of a modified high-bandwidth pump control system. They achieved adjustable swash plate vibration reduction at the desired frequency by the active vibration control. In the studies on the electro-hydraulically controlled variable displacement pumps [

21,

22,

23,

24], the swash plate angle of the piston pump was measured and controlled, but no obvious oscillatory behavior of the swash plate angle was noticed. The displacement angle was also measured with a Hall-effect sensor in a hardware-in-the-loop simulation test rig by Larsson et al.; he used a pole placement approach combined with a lead-compensator controller architecture to control the swash plate angle [

25,

26]. Ma et al. [

27] designed a fault diagnosis method for an intelligent hydraulic pump system using a nonlinear unknown input observer based on the output pressure and swash plate angle signals.

In previous studies, although some researches modeled both the variable displacement mechanism and the piston-slipper units, they did not analyze the influence of the structure parameters on the swash plate dynamics in the piston pump. In the high-speed piston pump, the vibration of the swash plate could lead to serious damage of the pump. Therefore, this paper presents an improved model for investigating the dynamic performance of the swash plate at a high frequency, analyzing and optimizing its structure parameters.

2. Theoretical Model

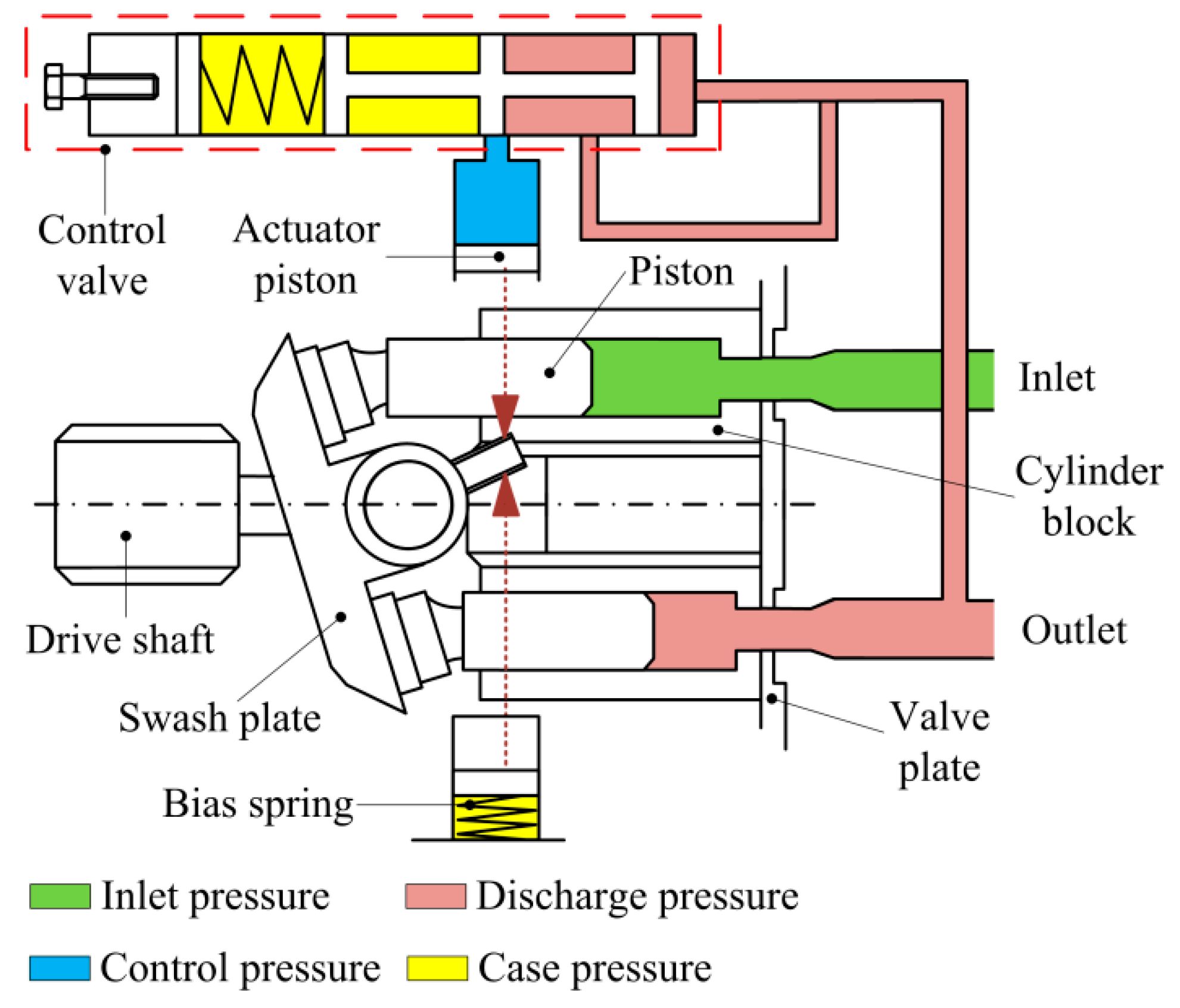

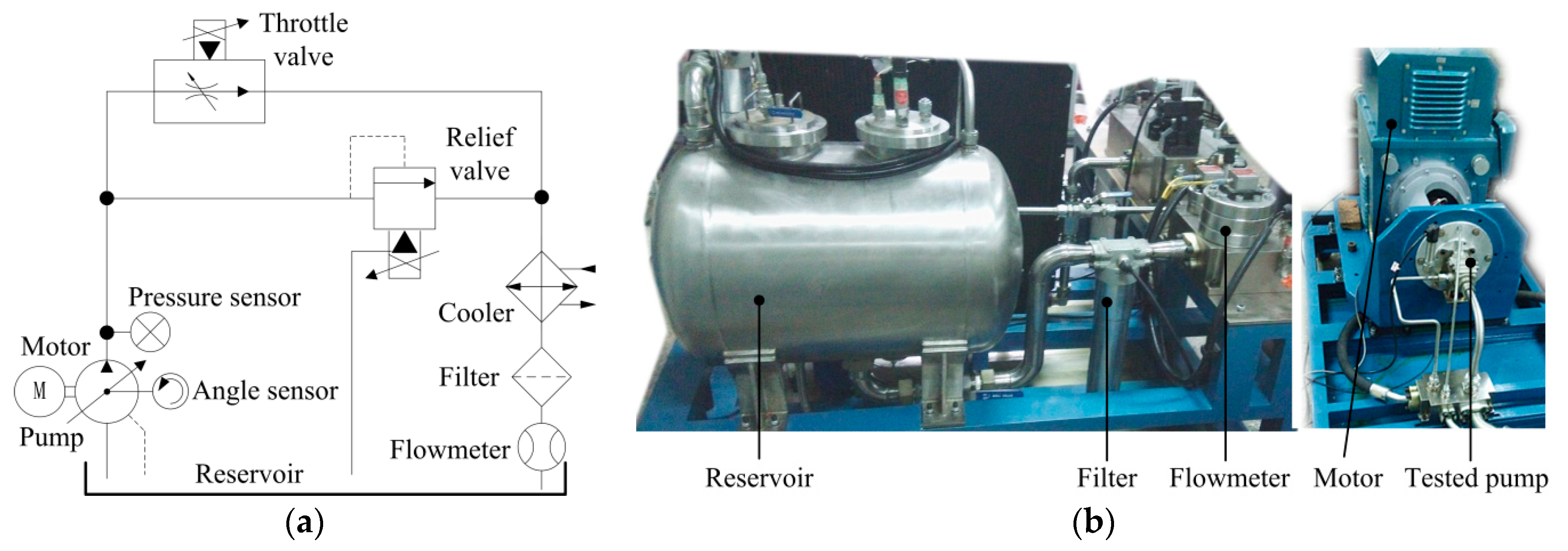

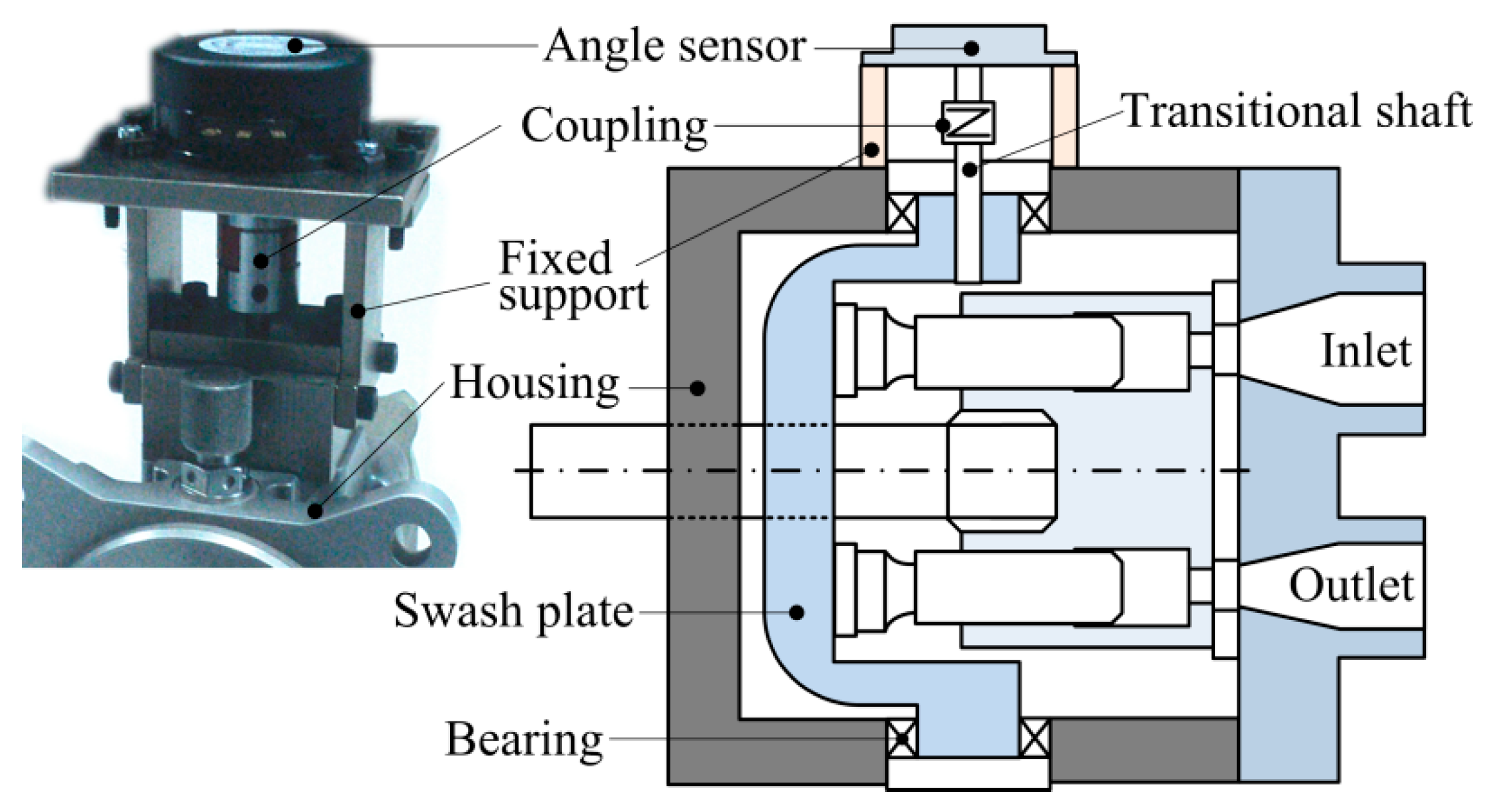

Figure 1 presents the basic principle of the high-speed, pressure-compensated piston pump. The oscillation of the swash plate is defined by the bias spring, the actuator piston, and the piston-slipper units. The swash plate with the bias spring can be treated as a second-order system (with inertia

Js, damping coefficient

bs, and spring stiffness

Ks). Two driving torques act on the swash plate system, namely the torque

Tp from the nine piston-slipper units and the torque

Ta from the variable displacement mechanism.

The control mechanism of the swash plate consists of the actuator part, the control valve part, the outlet chamber, the load, and the pipes (shown in

Figure 2). The ripple flow input

Q0 from the pumping pistons causes a pulsation pressure

P0 in the outlet chamber

V0. Most of the pressured oil flows to the load valve through a long pipe (with diameter

d4, length

l4), and the rest goes to the chamber

V1 in front of the valve spool through a long, slim pipe (with diameter

d1, length

l1). The pressure

P1 force acting on the valve spool against the spring force drives the valve spool to change the flow rate through the control valve. The oil flowing into or out of the actuator piston chamber

V3 through a long slim pipe (with diameter

d2, length

l2) directly changes the chamber pressure

P3, and hence the torque

Ta on the swash plate.

2.1. Piston-Slipper Assembly

The torque from the pumping pistons to the swash plate can be given as follows:

In Equation (1), li is identified as the moment arm of the ith slipper shoe relative to the rotation axis of the swash plate, Pi is pressure of the ith pumping piston chamber, and Ap is the action area of the pumping piston.

When the piston completely connects to the pump discharge region, the pumping piston pressure is equal to the discharge pressure (Pd). Similarly, the pumping piston pressure is the intake pressure (Pi) when the pumping piston is in the suction region.

2.2. Outlet Chamber

The flow in the outlet chamber can be divided into three parts: the input flow rate Q0, the flow rate Q01 to the control valve, and the flow rate Q04 to the load valve.

The total flow rate comes from the downward moving pumping pistons in the discharge region. According to the kinematic relationship, the ideal flow of each pumping piston is given as follows:

where

ω is the angular velocity of the cylinder block,

rp is the pitch radius of pumping piston and

θi is the angular displacement of the

ith pumping piston.

The kinematic flow fluctuation is the superposition of the flow ripples from different pumping pistons connected to the discharge port. Through Laplace transform, the flow rate to the load system can be expressed as follows:

where

Z04 is the equivalent impedance of the load valve and the pipe between the outlet chamber and load valve.

Finally, the continuity equation of flow in the outlet chamber is given by the following:

Equation (4) is also can be written as a four-pole pattern as follows:

2.3. Pipes

There are two long, slim pipes in the variable displacement mechanism and one pipe before the load valve. The series impedance

Z(

s) and parallel admittance

Y(

s) of a pipe (with diameter

d, sectional area

A, length

l) can be given as follows:

where

v0 is the kinematic viscosity of the hydraulic oil,

ρ0 is the density of the hydraulic oil, and

a0 is the velocity of the pressure wave.

The characteristic impedance

Zc(

s) and propagator

Γ(

s) of a pipe can be expressed as follows:

Hence, the transfer function of the pipe behind the control valve can be expressed as a four-pole pattern as below:

where the transfer matrix

Ap2 is given by the following:

Similarly, the transfer function of the pipe before the control valve in the variable displacement mechanism and the pipe before the load valve can be expressed as follows:

where

Ap1 and

Ap4 are the transfer matrices of the two pipes.

2.4. Pressure Control Valve

The three-way control valve is the key component that regulates the pressure of the outlet chamber near the preset pressure. For small perturbations at the initial working point, the flow of the control valve can be linearized by means of an incremental method as below:

where

Kq is the flow gain of the valve and

Kc is the flow pressure coefficient.

Hence, the transfer function of the valve flow can be given by the following:

For the moving spool of the control valve, the transfer function can be derived as follows:

The continuity equation of flow in the chamber between the spool and the pipe:

To summarize the dynamics of the control valve, Equations (15)–(17) are solved simultaneously to give the following result as a four-pole form:

where

G1(

s),

G2(

s), and

G3(

s) can be given as follows:

The flow of the chamber behind the valve spool

V2 consists of the flow from the valve and the flow to the pipe and actuator piston chamber. The continuity equation of flow in this chamber is given as follows:

2.5. Actuator Piston

The pressure of the fluid in the actuator piston chamber is affected by the flow from the pipe

Q3, the position of the actuator piston

xa, and the leakage flow

Ql3. Hence, the continuity equation of flow can be expressed as follows:

where

C3 is the leakage flow coefficient.

Equation (23) can also be written as a four-pole form as below:

The torque

Ta from the actuator piston can be expressed as below:

where the equivalent impedance

Zs can be expressed as follows:

In Equation (27), ls is the moment arm length of the bias spring force and φ is the swash plate oscillation angle.

2.6. Load System

The load consists of a long pipe and a load valve. The transfer function of the load pipe is already given in Equation (13). The load valve is considered as a constant orifice (with the flow coefficient

K4). Hence, the linear flow equation can be expressed as follows:

where

Z4 is the equivalent impedance, and can be expressed as below:

Substituting Equation (28) into Equation (13), the equivalent impedance of the load system can be obtained as follows:

where

Ap4(

i,

j) is the element of the

ith row and the

jth column of the transfer matrix

Ap4.

2.7. Whole Model

In summary, the improved model of the swash plate vibration containing the whole part of the variable displacement mechanism is given below.

Similarly, the common model for the displacement controller design and evaluation of the piston pump system [

15,

16,

17,

18,

19] can be modeled as follows:

where

A00 is a simplified form of

A0, which does not consider the influence of the load pipe (without

Z04).

It can be seen from Equation (33) that the effects of the pipes before and after the control valve, the load pipe, and the chambers before and after the control valve are not included in the common model.

4. Discussion

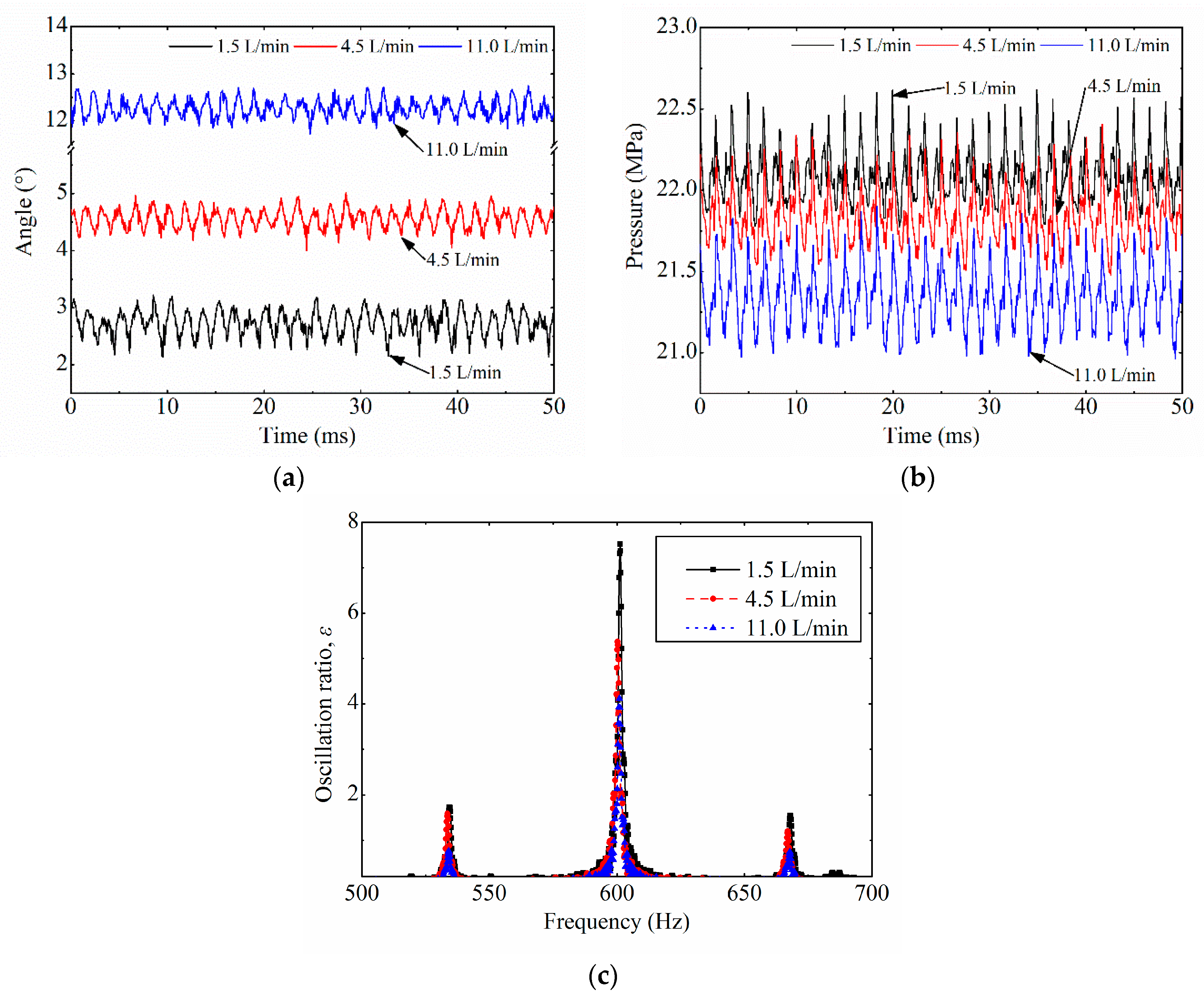

In order to demonstrate the influences of the variable displacement mechanism on the swash plate oscillation, the major parameters of the variable displacement mechanism are analyzed here. As the effects of the parameters inside the pump are difficult to measure directly, simulation analysis is a reasonably good method for this purpose. The simulation results of the amplitude and phase of the swash plate oscillation at the rotation speed 4000 r/min (600 Hz) are provided and discussed below.

4.1. The Volume of the Chambers

There are two oil chambers, as shown in

Figure 2: the outlet chamber (

V0) and the actuator piston chamber (

V3). In

Figure 7a,b, the amplitude and phase of the swash plate oscillation change dramatically with the volume of the outlet chamber and the actuator piston chamber. Conversely, the chambers before or behind the valve spool (

V1 and

V2) have little influence on oscillation, because of the narrow intervals of the changing volumes. When

V0 is near 6 × 10

−6 m

3 or

V3 is near 5 × 10

−7 m

3, the amplitude of the oscillation reaches the maximum, and the phase drops remarkably; approximately 170 degrees and 130 degrees, respectively.

Hence, a reasonable interval of the volume of the outlet chamber V0 and the actuator piston chamber V3 will minimize the oscillation amplitude of the swash plate. For the outlet chamber, it should be larger than 3 × 10−5 m3. It should not be too large, otherwise it can involve large bulk and heavy weight of the pump assembly. When the volume exceeds 6 × 10−5 m3, the effect of a larger volume on the reduction of vibration is not obvious. The volume V3 of the actuator piston chamber should be set between 3 × 10−7 m3 and 7 × 10−7 m3. However, a large volume may slow down the response speed of the swash plate, which also needs to be taken into consideration.

4.2. The Length and Diameter of the Pipes

In addition to the load pipe, there are two long, slim pipes in the variable displacement mechanism affecting the oscillation of the swash plate. There are severe resonance points when the pipe’s length increases in

Figure 8a, which coincide with the pressure response of a typical pipe. Hence, resonance points of the swash plate oscillation are due to the length of the pipe when it equals the integral multiples of the pressure wavelength in the pipe. Increasing the load pipe diameter can significantly increase the amplitude of the oscillation, as shown in

Figure 8b. The oscillation reaches its maximum at a diameter of 16 mm. Once the diameter of the load pipe exceeds 16 mm, the larger the diameter, the lower the oscillation amplitude. This is because the large diameter of the pipe can be considered as additional volume of the outlet chamber. The amplitude increases as the length of the pipe increases before the control valve in

Figure 8c, and similar trends can be observed in

Figure 8e. The changing amplitude range of the pipe behind the control valve is about 0.04, which is almost twice as large as the pipe before the control valve. The diameters of the two pipes have an almost converse influence on each other. The large diameter of the pipe before the control valve shows stronger capacitive characteristics than an additional volume of the outlet chamber. Meanwhile, the influence of the pipe diameter behind the control valve and the volume

V3 of the actuator piston chamber show similar performance.

A short length and large diameter pipe before the control valve, and a short length and small diameter pipe behind the control valve, are a reasonable design choice to reduce the amplitude of the swash plate oscillation.

4.3. The Stiffness of the Springs

The influence of the spring stiffness on the swash plate oscillation is shown in

Figure 9. The amplitude decreases by approximately 80% in the stiffness range of the control valve spring. Hence, choosing a stiff spring for the control valve can be a method to reduce the amplitude of the swash plate oscillation. It is also known from the simulation results that the stiffness of the swash plate spring has less influence on the swash plate oscillation than the control valve spring.

4.4. The Action Diameters

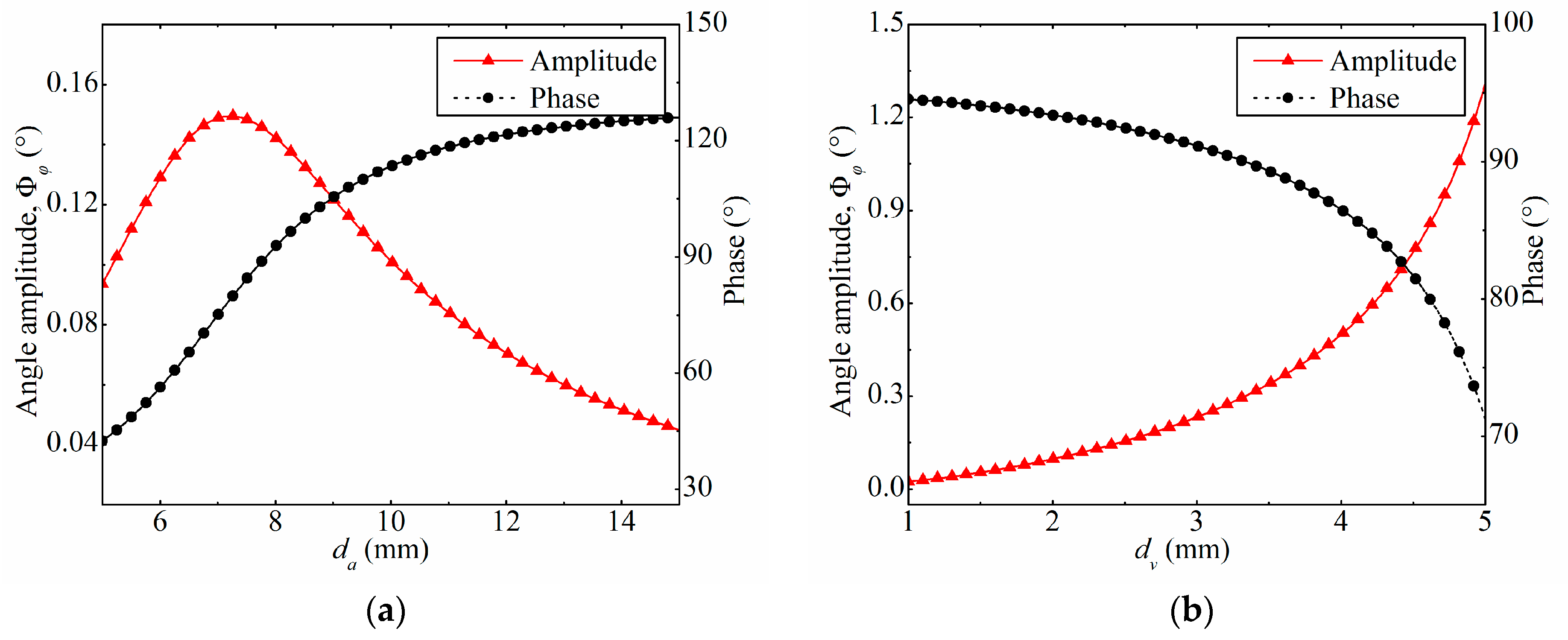

The action area of the actuator piston can dramatically affect the oscillation. There is a resonance point when the diameter of the actuator piston is near 7 mm in

Figure 10a. Unlike the chambers in

Figure 7, the phase of the swash plate oscillation increases rapidly near the resonance point. As shown in

Figure 10b, the amplitude increases to about 1.3 in the changing range 1–5 mm.

In order to reduce the oscillation amplitude, the diameter of the actuator piston should keep away from the peak range. A reasonably large diameter should be considered in the design process, because a small action area may lead to slow response of the swash plate and a much larger action area may introduce additional weight on the pump. A reasonably small control valve spool may also be a good design, because a much smaller diameter may cause a much slower response speed of the swash plate.

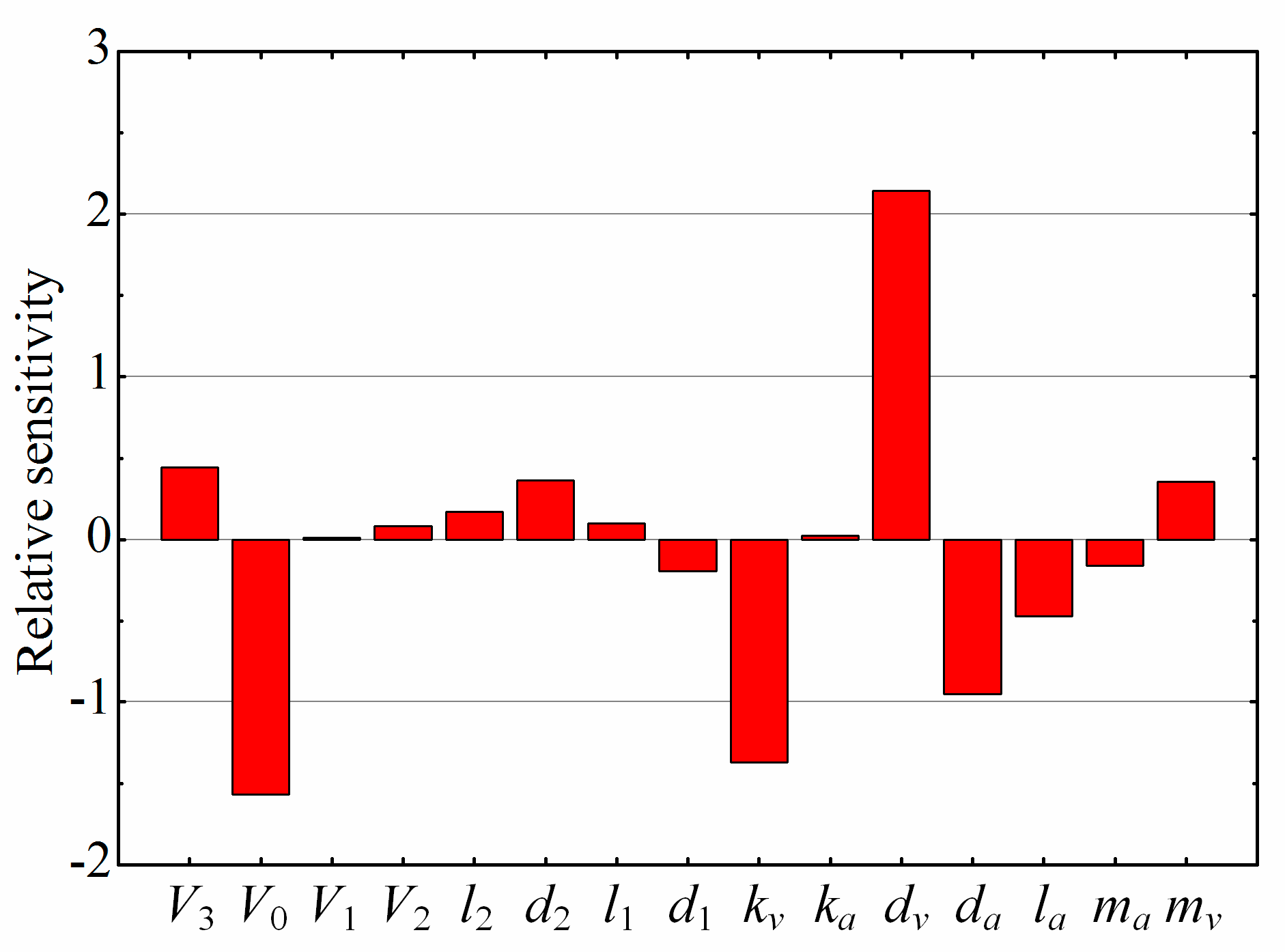

4.5. The Sensitivity of the Parameters

In order to characterize the influence of every structural parameter on the oscillation of the swash plate, the local relative sensitivity, based on the differential method, is given in

Figure 11. We can see that the volume

V0 of the outlet chamber, the stiffness

kv of the control valve spring, the action area of the actuator piston, and offset distance

la of the actuator piston are the four key parameters that have a large effect on the swash plate dynamic response. Reducing the values of the four parameters results in a significant increase in the amplitude of the swash plate oscillation and may even cause resonance. Hence, these four values need to be further increased to the appropriate sizes. On the other hand, the diameter

dv of the control valve spool and the dead volume

V3 of the actuator piston chamber also have a large effect on the swash plate dynamic response. A reasonable decrease in the values of the two parameters can further reduce the oscillation amplitude of the swash plate.