1. Introduction

Shaft-hole fit is a common form of fitting in rotating mechanical products. Dimension error, geometric shape error, and fit error of shafts and holes are important sources of assembly error [

1,

2,

3]. They directly affect the assembly accuracy, kinematic accuracy and service life of products, for example, the rotation accuracy of a machine tool spindle, gear transmission error, and service life of the bearing [

4]. Therefore, it is necessary to discuss the relationship between assembly system performance and geometric and fit error of the shaft-hole.

Historically, scholars have conducted extensive research work on this issue. However, most studies have focused on the tolerance analysis of assembly systems, including the Direct Linearization Method [

5], Matrix method [

6], Unified Jacobian-Torsor method [

7], and the Small Displacement Torsor method [

8]. Assembly error with clearance fit is mainly studied by equivalent substitution. For example, Desrochers et al. [

9] proposed the Matrix method to view shaft-hole clearance fit into coaxiality tolerance. Chase et al. [

5] regarded different fit states in all kinds of kinematic pairs according to the Direct Linearization Method. Desrochers et al. [

7] expressed the contact and kinematic relationship between fitting parts by the Torsor method. They established error propagation models based on the dimension chain, which regard the tolerance value and clearance value as constrained boundaries for variation in the tolerance feature (TF) through an optimization method or conducting statistical analysis with the tolerance domain being the boundary, so as to realize error analysis of the assembly system [

10].

Tolerance analysis models like the Matrix method and the Small Displacement Torsor method give a range of 12 ultimate values for TF from the angle of six degrees of freedom (DOF). Influenced by the principle of the algorithm itself, the search for the limiting state of TF by the optimization method is probably formed by multiple uncertain combinations of deviations on multiple DOF, but it does not determined the limit deviation from the expected DOF. Therefore, when the limiting situation or statistical situation for all kinds of product performances with errors such as the kinematics and dynamical properties, is carried out in the product design phase, input parameters may not be accurate enough and will affect the accuracy of the analysis results. Therefore, before performance analysis of products with errors, pose (position and orientation [

11]) decoupling on six spatial DOF must be implemented for TF so that the actual deviations of TF on all DOF are obtained [

12,

13]. In this way, the error range of the target feature can be more accurately obtained and this range should be smaller than error ranges given by the Matrix method and the Small Displacement Torsor method, etc. Moreover, explicit analytic expression of target feature error can be obtained, especially when ultimate error is not solved through optimized mathematical iteration method. Thus, explicit solutions for six DOF at arbitrary positions, including the limiting position of TF, can be realized.

Currently, when prediction and analysis of the mechanical properties of assembly systems with errors is conducted in the product design phase, the error value is usually manually set [

14], and it is not derived from tolerance values given by designers. Therefore, in order to explore a method which establishes the relation between tolerance of part of the dimension chain and performance of the assembly system, TF of shaft-hole fit-axis TF [

15] was taken as an example in this paper, to examine a pose decoupling model. Inspiration for this method came from the Tolerance-Map (T-Map) model proposed by Davidson et al. [

16] and the Deviation-Domain model proposed by Giordano et al. [

15]. The two methods are still essentially tolerance analysis methods. The T-Map model is a widely used method which uses a hypothetical Euclidean point-space of a convex polyhedron and is completely compatible with ASME Y 14.5-1994 standards.

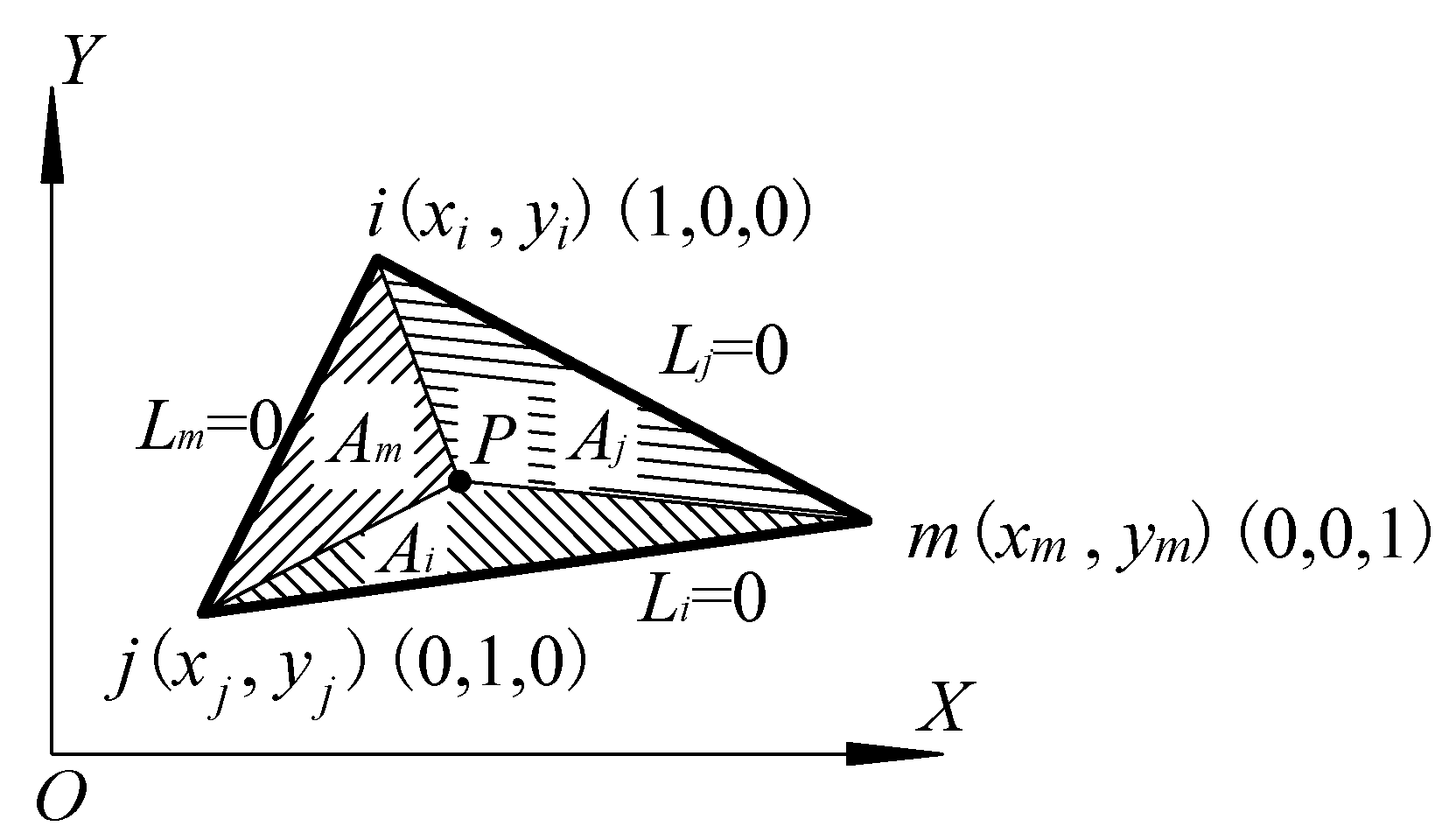

Its shape, dimension and internal subset reflect TF type, size, shape and all possible variations of pose [

17]. The variation range of each TF which is gained by the T-Map model through the area coordinate system is also called the convex hull. Points in the convex hull have a one-to-one mapping relation with all possible error variations of TFs in the tolerance zone. T-Map uses the Minkowski mum algorithm to calculate the ultimate variation of the target feature. This algorithm scans vertexes and boundaries of the convex hull along the dimension chain of TFs one by one in a recursive manner, finally getting the convex hull which describes variations of the target feature. This is a model that calculates the boundaries of target feature variation by geometric operation. The calculation load of Minkowski sum shows exponential growth with the increase in component links in the dimension chain. The calculation load for complicated dimension chains is extremely good. As the T-Map method does not suggest an analytical model between the convex hull vertex of the target feature and the convex hull vertex of each TF on the dimension chain, deviation data expressed by the convex hull vertex of each TF and any point within the convex hull cannot be used in product performance analysis.

Therefore, based on the T-Map, the area coordinate system was used in this paper to study a shaft-hole relative pose description method with the existence of tolerance and clearance fit. The mapping relationship between the area coordinate system and Cartesian coordinate system was further established for each TF on the dimension chain. A tolerance analysis model based on tracking local coordinate systems [

18], as proposed previously, was combined to obtain analytic expression of pose decoupling of the axis TF as expressed by the area coordinate system. This method not only accurately obtained the ultimate error of the target feature through permutation and combination of ultimate area coordinate values, with a greatly reduced calculated quantity when compared with the T-Map method, but also obtained the sole deviation value of TF on arbitrary DOF within the tolerance domain by changing the corresponding area coordinate value. Therefore, it provides the foundations for accurate analysis of product performance.

2. Error Transformation Matrix of Axis TF

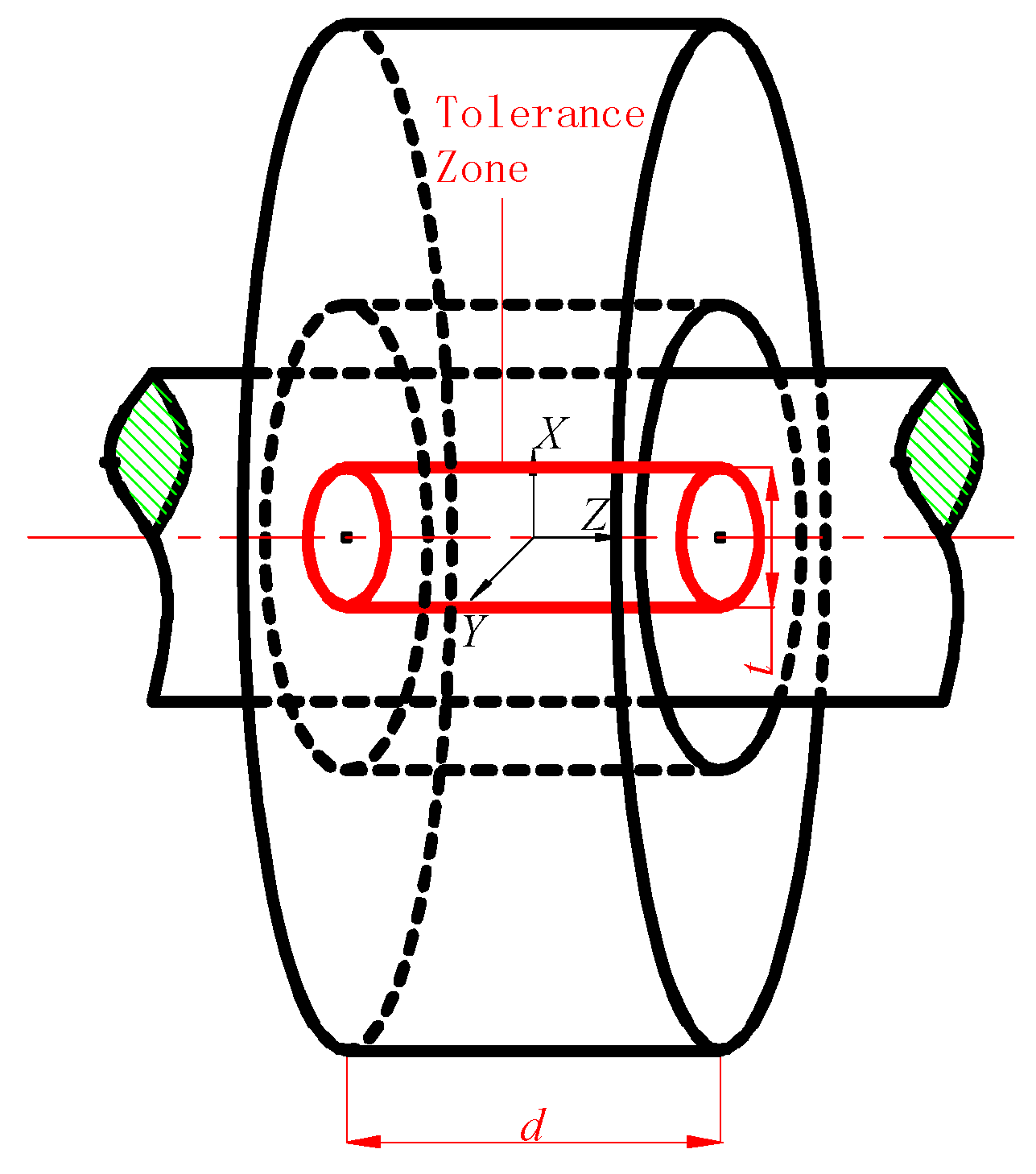

For shaft-hole fit (

Figure 1), the cylinder tolerance zone is acquired by expressing clearance value at the axis, so the variation of shaft in the hole is equivalent to the variation of the axis in the cylinder tolerance zone in

Figure 2. During tolerance analysis, the error transformation matrix

Di reflects variation of TF [

18].

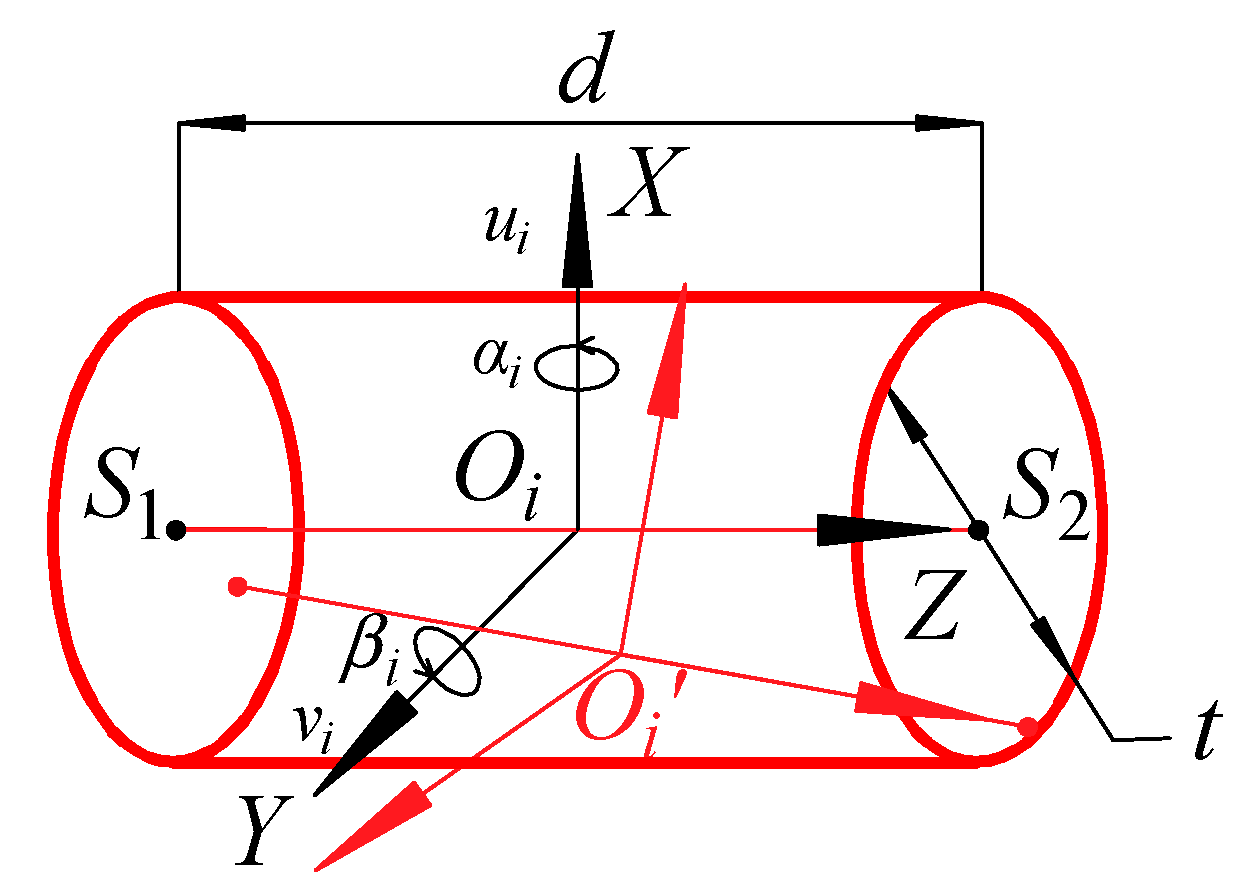

Di is gained from homogeneous transform matrix (HTM) based on DOF. According to TTRS(Technologically and Topologically Related Surfaces) theory [

9], the axis TF in

Figure 2 has four DOFs in the Cartesian coordinate system

O-

XYZ, including the horizontal displacement

ui,

vi along

X and

Y axes as well as rotation

αi,

βi around

X and

Y axes. Basic HTMs on these four DOFs are:

Due to small errors,

and

. These are similar to

. Therefore, the corresponding error transformation matrix

Di is:

In fact, pose decoupling of axis TF determines the relationships between ui, vi, αi, βi and the tolerance value and clearance value. Here, the analytic relationships of the tolerance value and clearance value of shaft-hole fit with error variables on each DOF were disclosed according to the T-Map followed by interpolation of area coordinate system in the Finite Element Theory. In this way, pose decoupling of axis TF in the tolerance domain is realized.

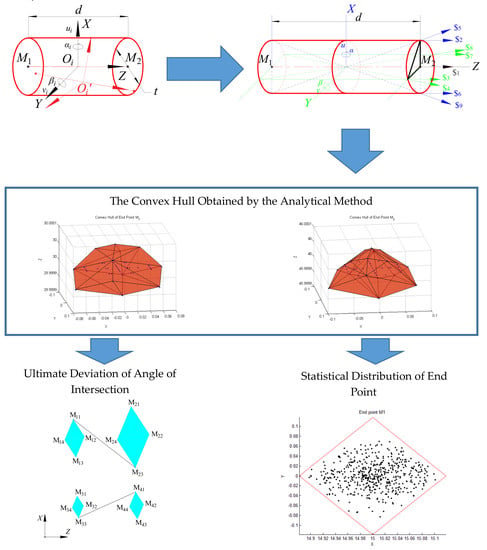

5. Case Study

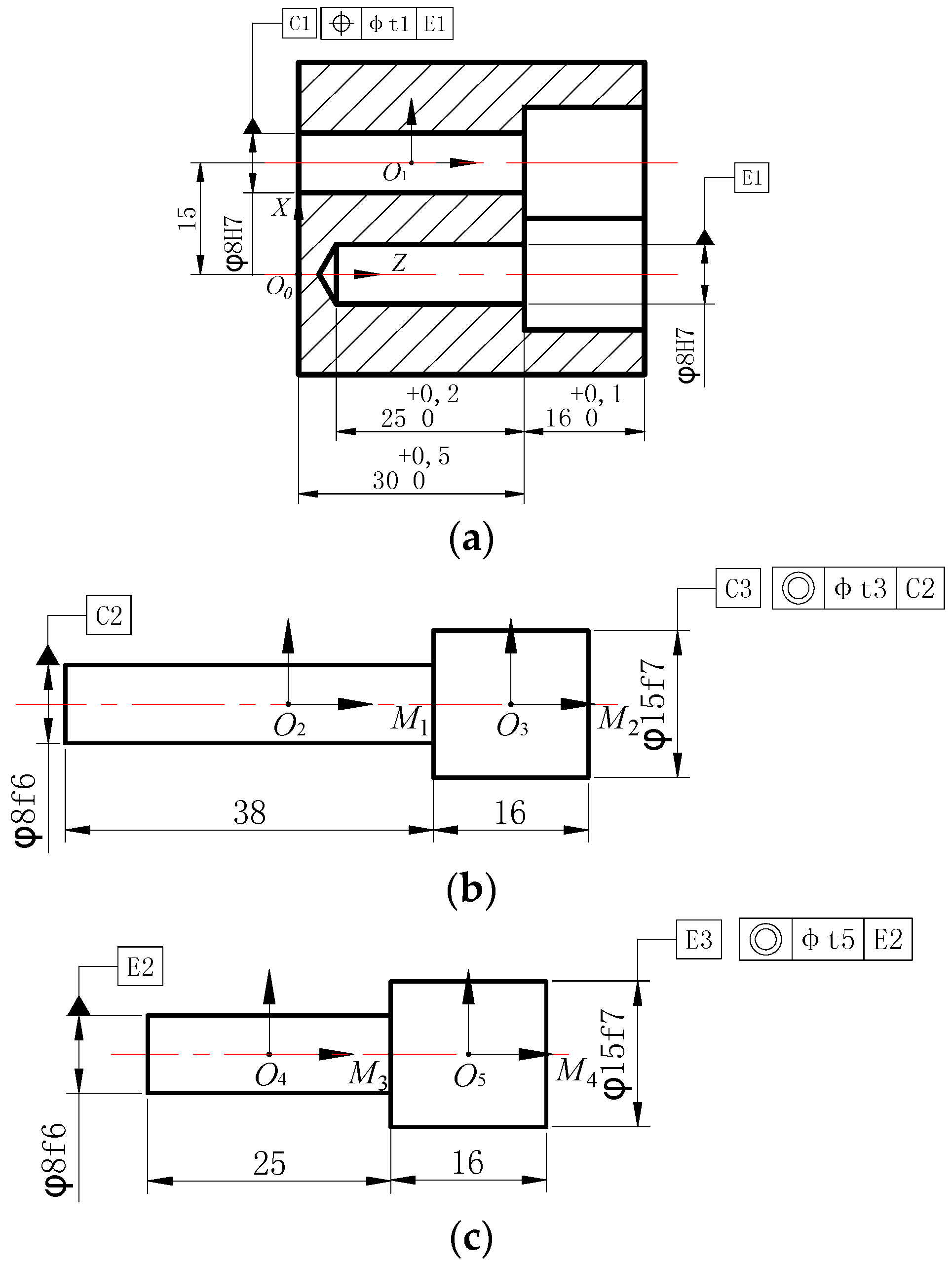

The gear pump [

9,

23] in

Figure 5 is composed of (a) pump body, (b) leading shaft and gear, and (c) shaft and gear. The gear is made of 45

# steel. The number of teeth is

z = 10 and the number of modules is

m = 1.5. Rated pressure is 25 Mpa and rated speed is 1450 r/min. The proportional factor of temperature deviation is 1. In the following text, the proposed model is used for pose decoupling analysis of the gear axis.

In

Figure 5, local coordinate systems are constructed at TF of each part. Since the nominal coordinate system is very close to the tracking local coordinate system and actual local coordinate system, only the nominal coordinate system is expressed [

19]. Through analysis, this gear pump can construct two open-looped dimension chains which have a consistent starting point. The starting point of two open-looped dimension chains is in the origin of the reference coordinate system,

O0 in

Figure 5.

Dimension chain 1 included three links: tolerance feature C1 (corresponding to position tolerance t1), tolerance features C1 & C2 (corresponding to clearance fit tolerance t2) and C3 (corresponding to coaxiality tolerance t2), while dimension chain 2 only included two links: tolerance features E1 & E2 (corresponding to gap fit tolerance t4) and E3 (corresponding to coaxiality tolerance t5). Tolerance and the type of TF of dimension chain 2 could be found in dimension chain 1 which was more complicated with greater representativeness. Therefore, only dimension chain 1 was selected for explanation.

Dimension chain 1 is formed by connecting nominal coordinate systems

O0,

O1,

O2 and

O3, whereas dimension chain 2 is formed by connecting nominal coordinate systems

O0,

O4 and

O5. Here, the dimension chain 1 was used as the example. Transformation among the nominal local coordinate systems (

T1) is:

The homogeneous coordinate value of end point, M

1 in the nominal local coordinate system,

O3 is

. Then, the coordinate value in the reference coordinate system

O0 is [

M1]

O0:

Combined with Equation (16), [

M1]

O0 which is expressed by the area coordinate value can be obtained:

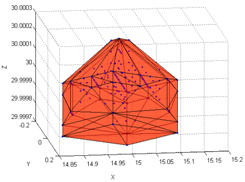

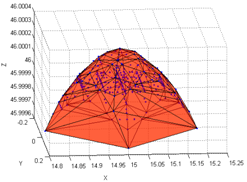

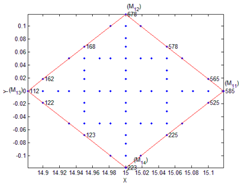

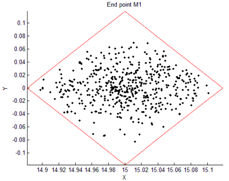

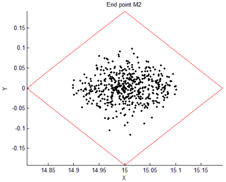

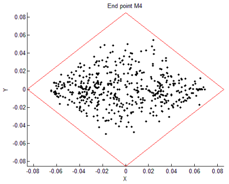

Equation (20) not only establishes relationships between any pose of point M

1 and the tolerance value and clearance value, but it can also find the limits of target feature variations when

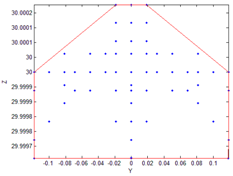

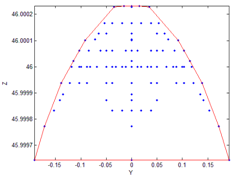

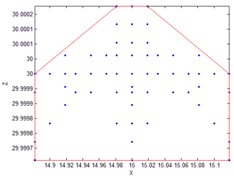

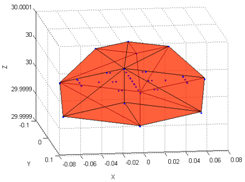

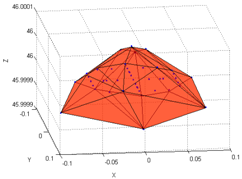

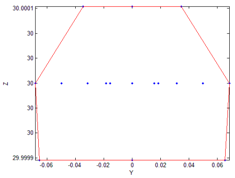

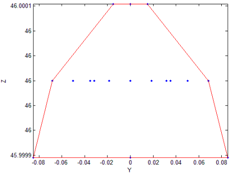

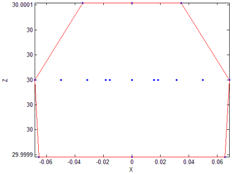

λi = ±1 (

i = 1~5), that is, the vertex of the convex hull. After calculation, permutation and combination of basic area coordinate values in Equation (17) are brought into Equation (20), then the three-dimensional scatter points in Euclidean space can be acquired. Each scatter point represents one possible limit value. Next, using MATLAB (R2012b, MathWorks, Natick, MA, USA), the smallest convex hull model which covers all scatter points is searched for Vertexes of the convex hull are the pose limits of point M

1. Convex hulls concerning variations of point M

1 and point M

2, as well as their projection on three coordinate planes of the reference coordinate system,

O0 are listed in

Table 1.

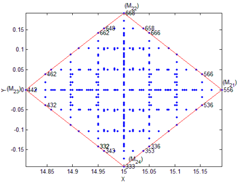

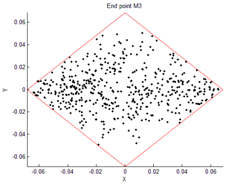

Similarly, convex hulls of end point M

3 and M

4 variations, as well as their projections on three coordinate planes of the reference coordinate system,

O0 are listed in

Table 2.

Accurate coordinate values for the variation range of end points of the gear axis with consideration to deviations can be gained from

Table 1 and

Table 2. They are listed in

Table 3. Therefore, accurate pose of the gear axis with different ultimate deviations could be acquired, thus enabling simulation analysis on the performance of the gear pump with consideration of deviation.

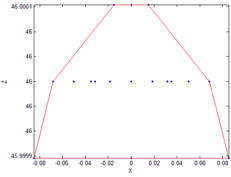

Table 3 reveals that the maximum magnitude of deviation along

Z direction is 10

−4 and the magnitude along

X and

Y directions ranges from 10

−1 to ~10

−2. Generally, deviation along the

Z direction can be neglected.

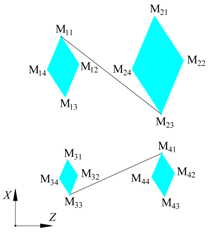

For gear pump (see

Figure 5), gear engagement performance can significantly influence the flow rate of the gear pump. The parallel misalignment, deviation of the angle of intersection and deviation of the angle of stagger between M

1M

2 and M

3M

4 will influence gear engagement, thus affecting the service ability of the gear pump. Therefore, all accumulated errors on dimension chain 1 and dimension chain 2 can be concentrated into the gear axis during performance simulation of the gear pump. This is demonstrated by taking the angle of intersection, for example.

According to the definition of an intersection angle, it can easily be seen from the second row of

Table 1 and

Table 2, that the extreme value of the error in the angle intersection is 1.6604°. As the deviation along the

Z axis is neglected, the error is a combined effect of deviations at two DOFs, namely, translation along the

X axis and rotation around the

Y axis. Ultimate pose combinations of two gear axes are M

11M

23 + M

33M

41 and M

13M

21 + M

31M

43, respectively. Since the tolerance zone is symmetric in this case, the ultimate angles of interaction which is gained from the combination of two groups of poses are equal in numerical value and opposite in direction. Therefore, calculating the angle of intersection of one combination is enough. In the following analysis, M

11M

23 + M

33M

41 is chosen. Accumulative errors of the two dimension chains are converted to local coordinate systems

O3 and

O5, so translation deviations of M

1M

2 and M

3M

4 in dimension chains 1 and 2 along the

X axis are

u3_C1 and

u5_C2, and the rotation deviations around the

Y axis are

β3_C1 and

β5_C2. Specific data are listed in

Table 4. It only remains to bring these data into gear engagement analysis with the ultimate deviation of angle of intersection. Similarly, the translation deviation and rotation deviation of M

13M

21 + M

31M

43 could be acquired.

Therefore, the accurate ultimate deviation of the angle of intersection can be obtained through pose decoupling of the gear axis. Similarly, the pose combinations of ultimate parallel misalignment between two gear axes are M11M21 + M33M43 and M13M23 + M31M41, and the pose combinations of ultimate angle deviation of stagger are M12M24 + M34M42 and M14M22 + M32M44, respectively. Accurate deviations on corresponding DOF can be gained in the same way as the angle of interaction.

This decoupling model is also applicable to statistical analysis. It is already known that area coordinate values of TF

i meet constraint relation as shown in Formula (9), based on which area coordinate values

,

,

,

;

,

,

,

;

,

,

in Formula (20) can be given through sampling method in statistics. Through multiple simulations in Formula (20), namely Monte Carlo simulation, the distribution diagram of four end points M

1, M

2, M

3 and M

4 of gear axis can be obtained in

Table 5.

The error value of each TF in the corresponding dimension chain can be found for each point in in

Table 5. The error value can be the input data in the analysis of product performance.