Lithium Titanate Battery Management System Based on MPPT and Four-Stage Charging Control for Photovoltaic Energy Storage

Abstract

1. Introduction

2. Materials and Methods

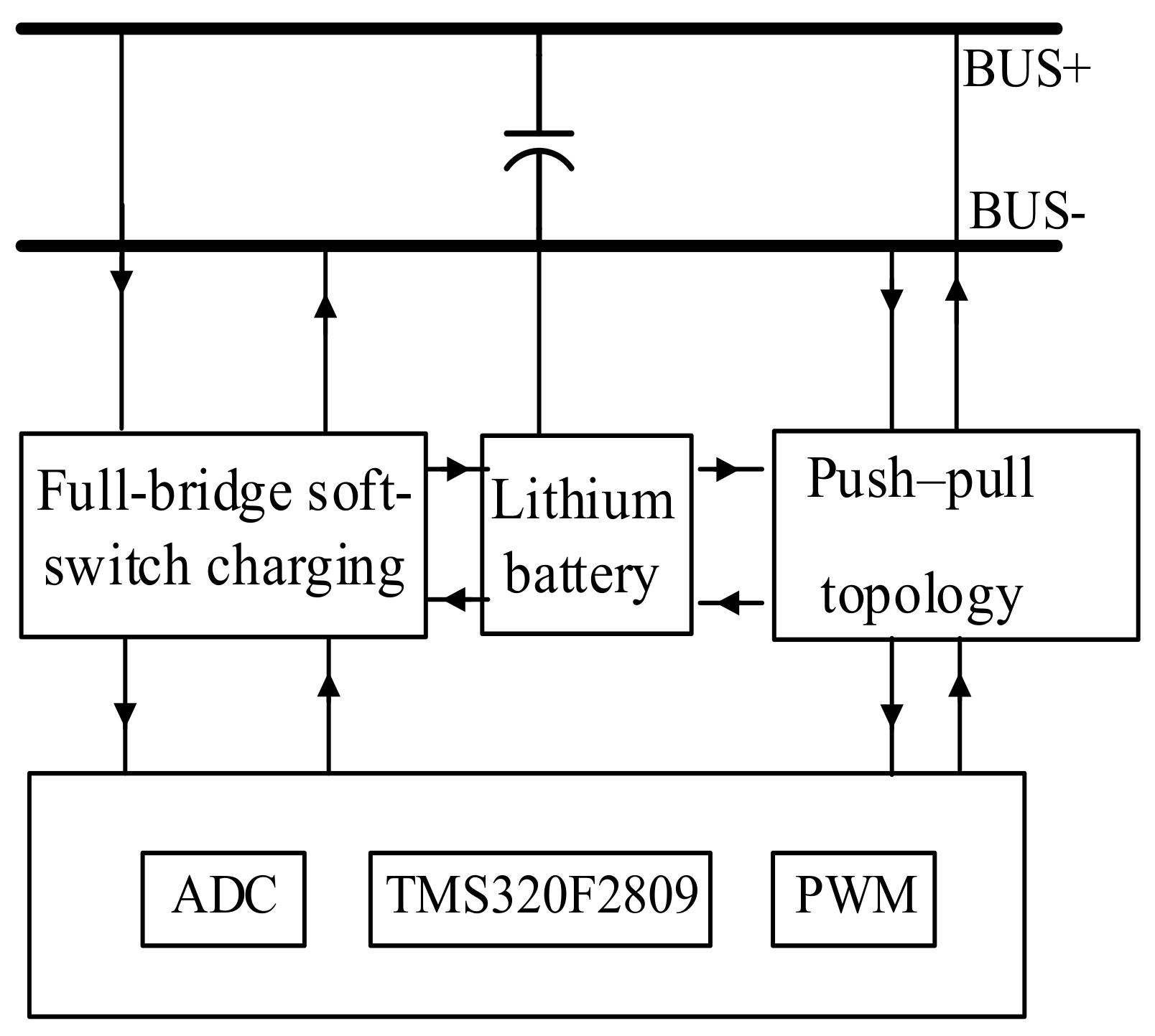

2.1. Hardware System

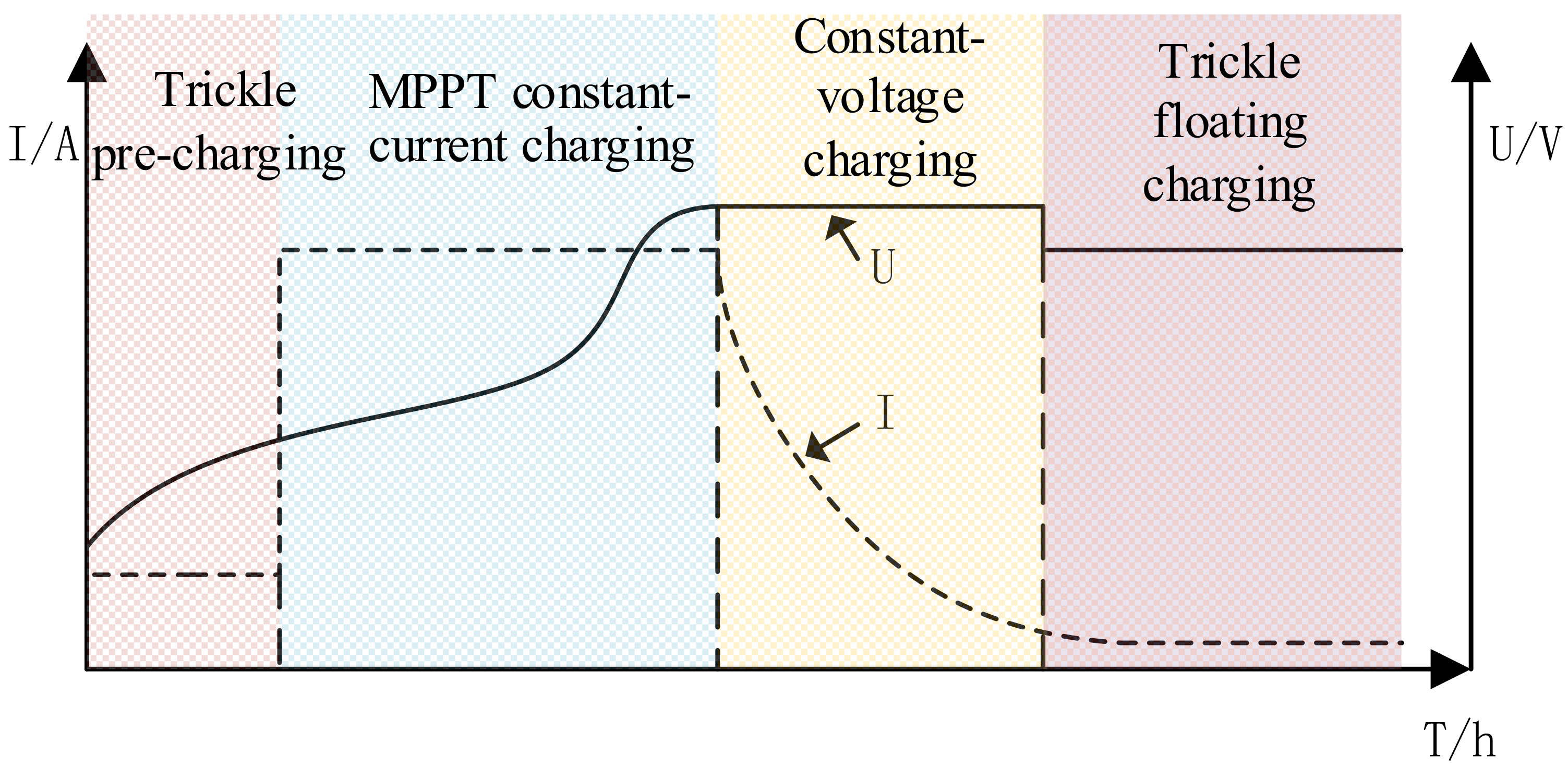

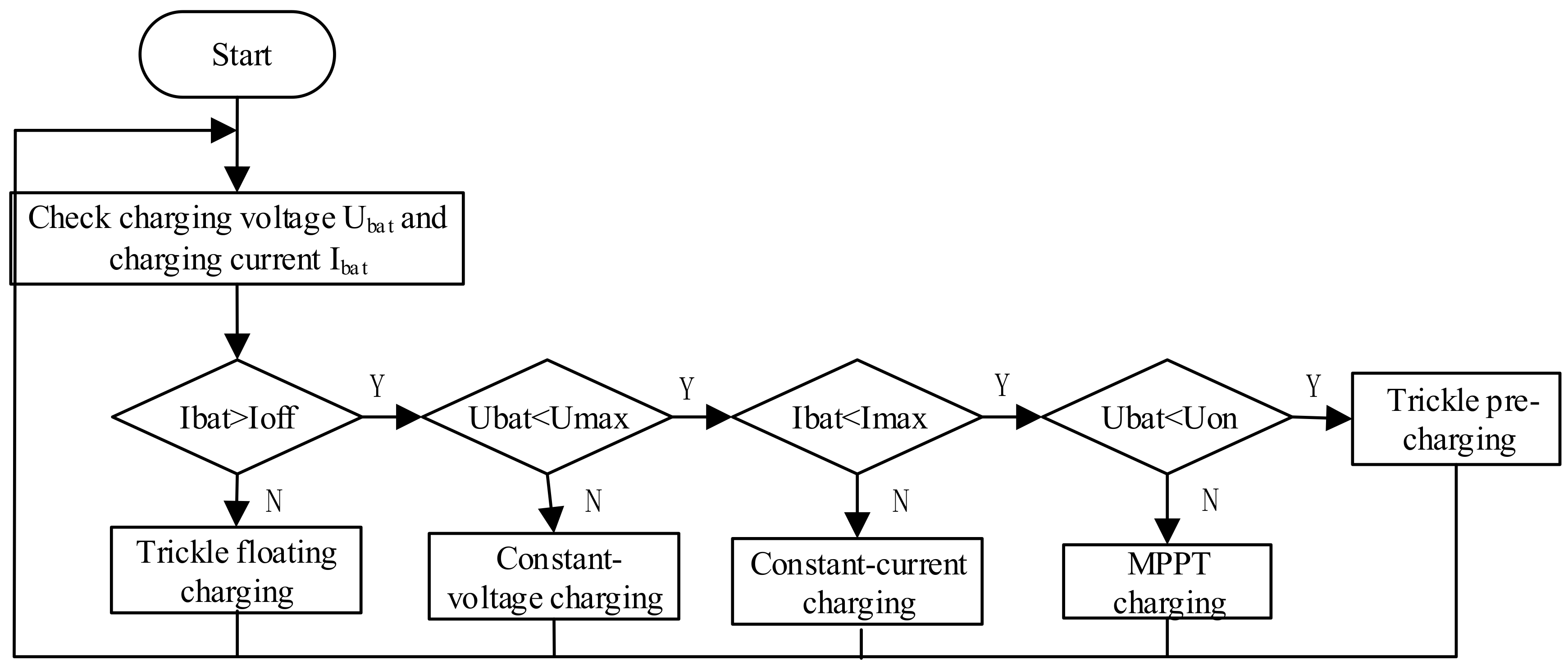

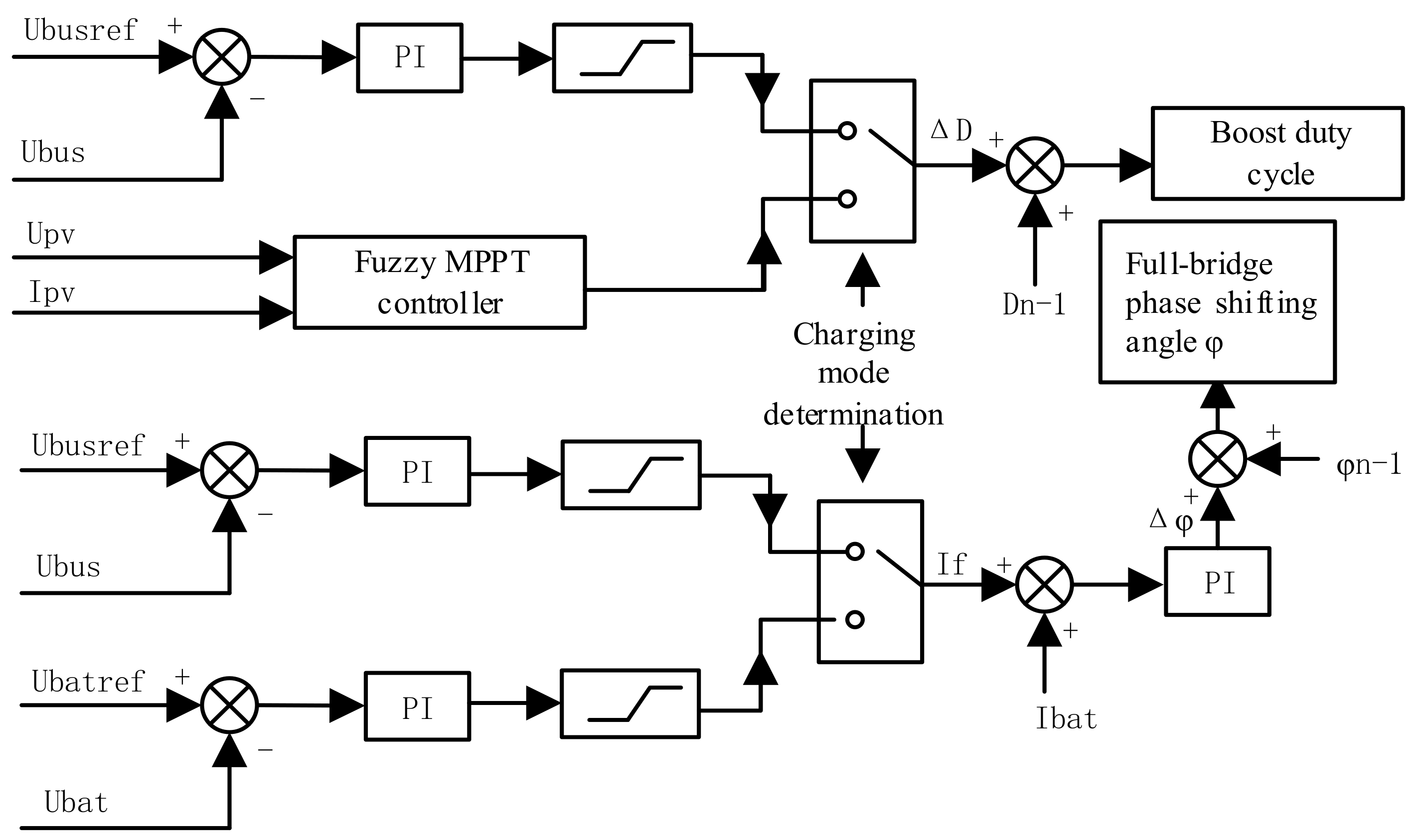

2.2. Charge and Discharge Control Strategy

- (1)

- First, determine whether the battery is over-discharged; if this is the case, the battery should be trickle pre-charged with a current of 0.05 C for activation.

- (2)

- After activation, the battery enters the constant-current charging stage. However, the maximum charging current that the battery can receive is limited; therefore, the charging current should be limited to the maximum charging current Imax (0.2 C) when the photovoltaic output power is greater than the battery receiving power. At this moment, the photovoltaic system does not work in the MPPT state. When the photovoltaic output power is lower than the battery receiving power, the photovoltaic system is maintained in the MPPT state. Although the battery is still in the constant-current charging stage, the charging current is lower than the maximum charging current.

- (3)

- During the MPPT constant-current charging stage, the battery voltage gradually increases with respect to the charging time. When the battery voltage increases to the maximum charging voltage, Umax, the constant-current charging stage is terminated, and the battery enters the constant-voltage charging stage, in which the charging current slowly decreases.

- (4)

- When the current decreases to a certain value in the constant-voltage charging stage, that is, Ioff, the battery charging voltage is reduced to perform trickle floating charging.

- (1)

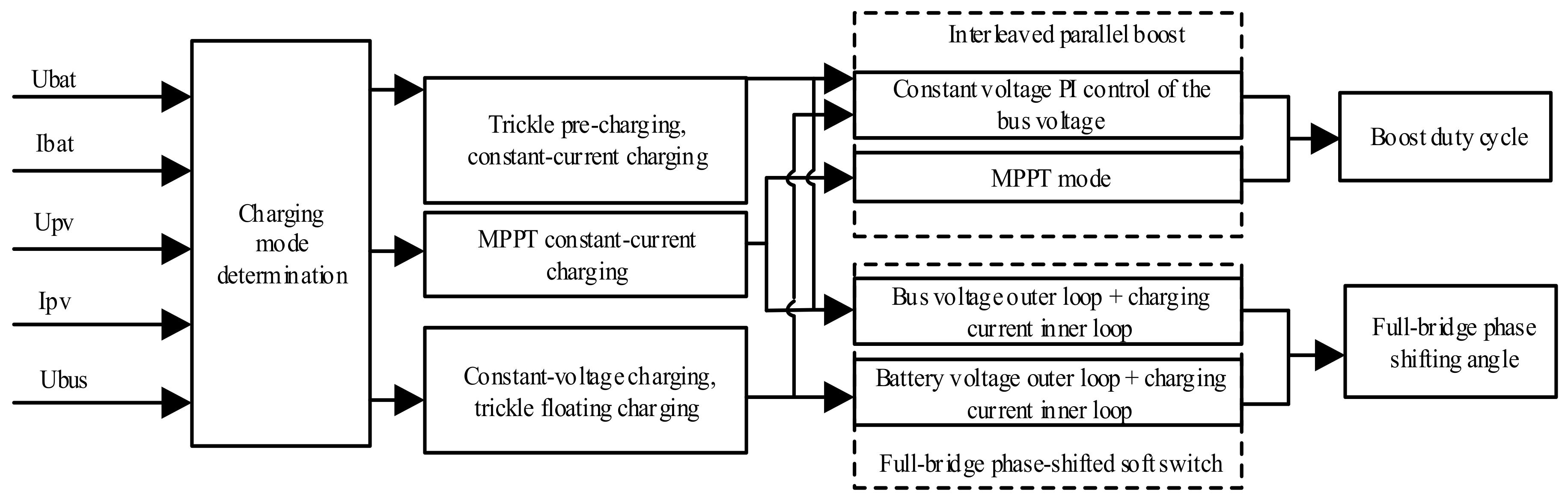

- When the system is in the trickle pre-charging or the constant-current charging stage, the photovoltaic battery does not work in the MPPT state. Therefore, the interleaved parallel boost is controlled by the bus voltage loop, and the bus voltage is controlled by the boost. The charging current is controlled by the post-stage full-bridge circuit, which uses a double loop control comprising a current inner loop and a bus outer loop to achieve a constant current.

- (2)

- When the system is in the MPPT constant-current charging stage, the photovoltaic battery works in the MPPT state, which controls the output power of the photovoltaic battery to the maximum. Therefore, at this stage, the bus voltage cannot be controlled by the boost, instead, it should be controlled by the post-stage full-bridge circuit. Thus, the post-stage full-bridge circuit uses the bus voltage outer ring and the current inter ring to achieve a constant current and stable bus voltage, respectively.

- (3)

- When the system is in the constant-voltage charging or the trickle floating charging stage, the photovoltaic battery does not work in the MPPT state. Therefore, the busbar should be controlled by the post-stage full-bridge circuit. Moreover, the charging voltage of the battery needs to be controlled at this stage. Thus, at this stage, the battery voltage outer ring is used as the voltage outer ring, and the charging voltage is stabilized at a set value. The busbar can also be clamped to a certain stable value, and the role of the charging inner loop is to limit the current.

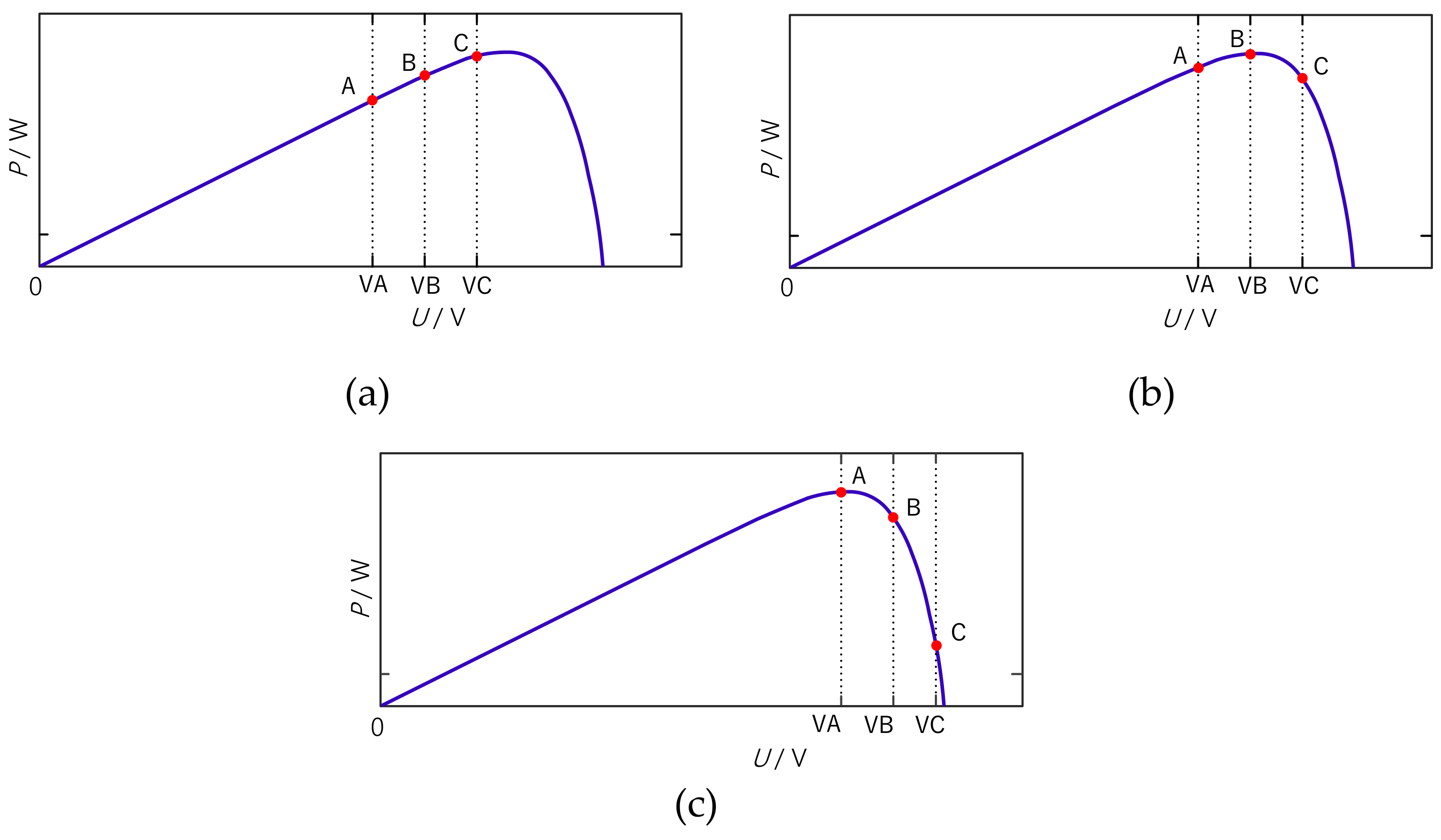

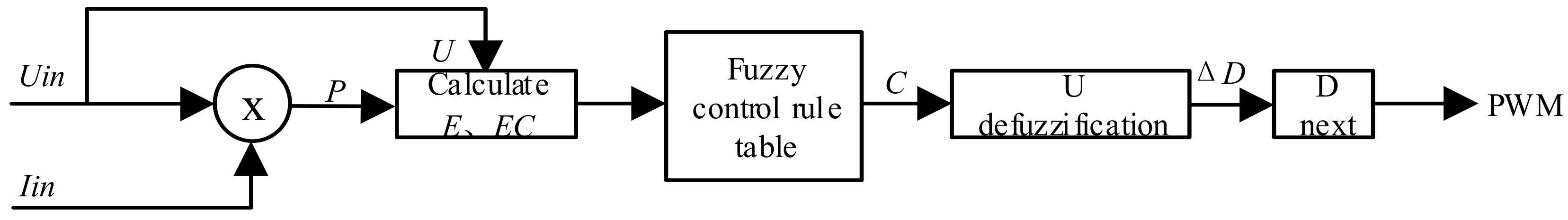

2.3. Three-Point Fuzzy MPPT Algorithm of Variable Step Size

- (1)

- The fixed voltage method needs fewer detection parameters and less hardware, but yields a poor control performance, thus, it is usually used in low power cases;

- (2)

- The disturbance observation method is simple to implement and yields a very good control performance. The disadvantage is that it easily produces oscillation near the maximum power point, and may lose its tracking ability when the light intensity changes abruptly.

- (3)

- The incremental conductance method yields the best control performance, but the hardware requirement of a photovoltaic power generation system is also higher, which increases the cost of the equipment.

- (1)

- The constant pressure method was used in the start-up phase of the disturbance observation method.

- (2)

- Three-point method of perturbation and observation method control.

3. Results and Discussion

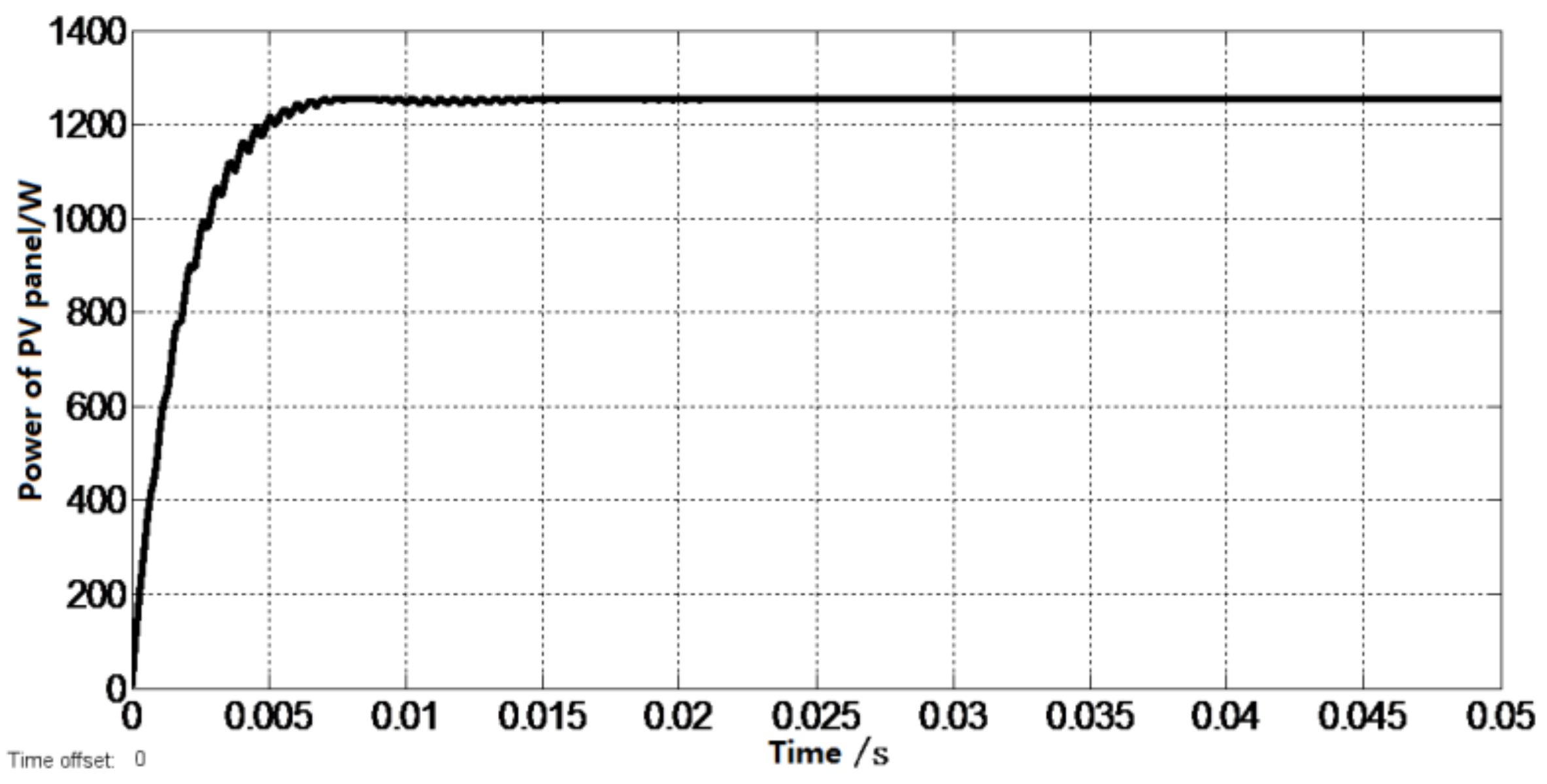

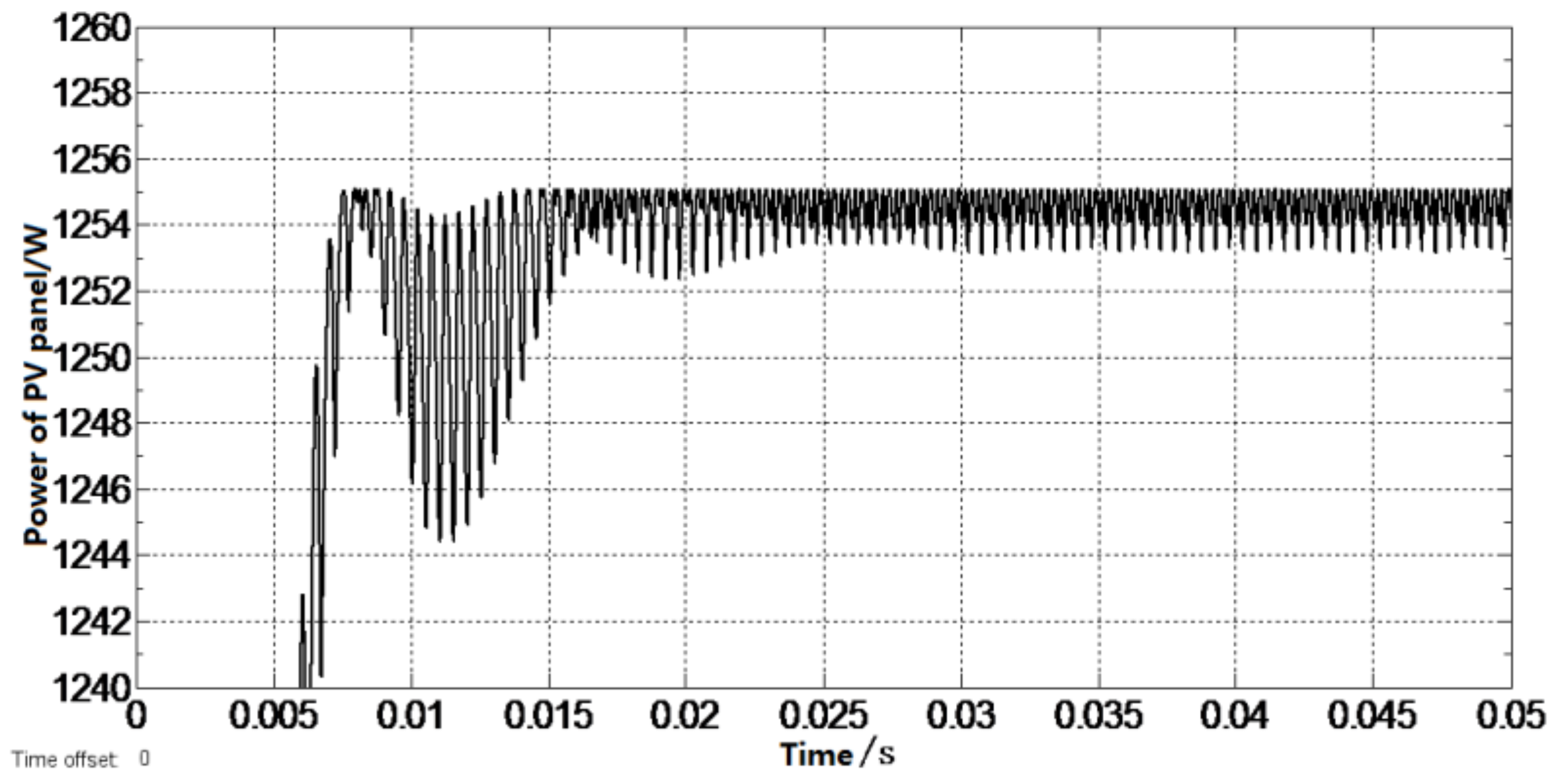

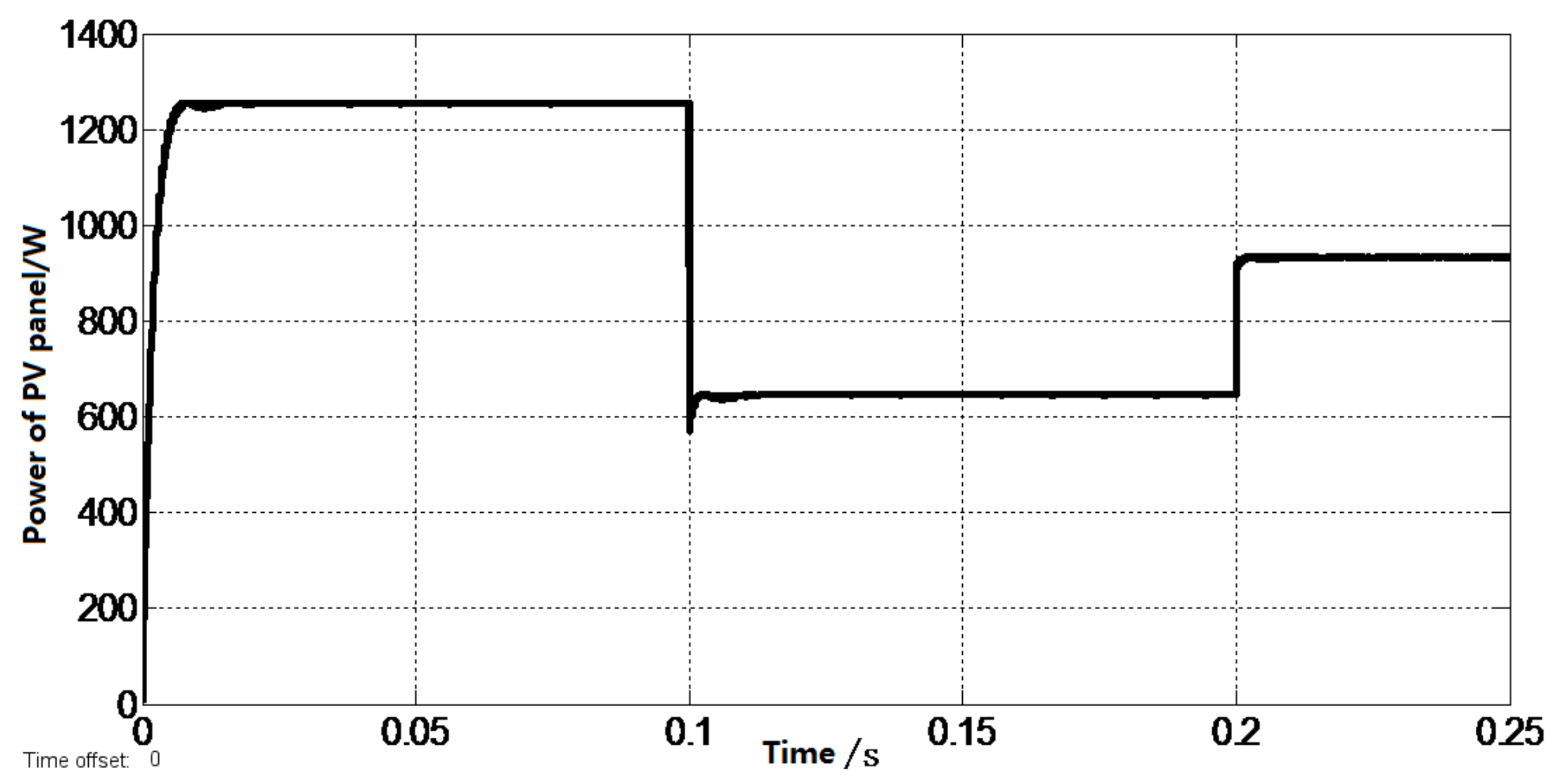

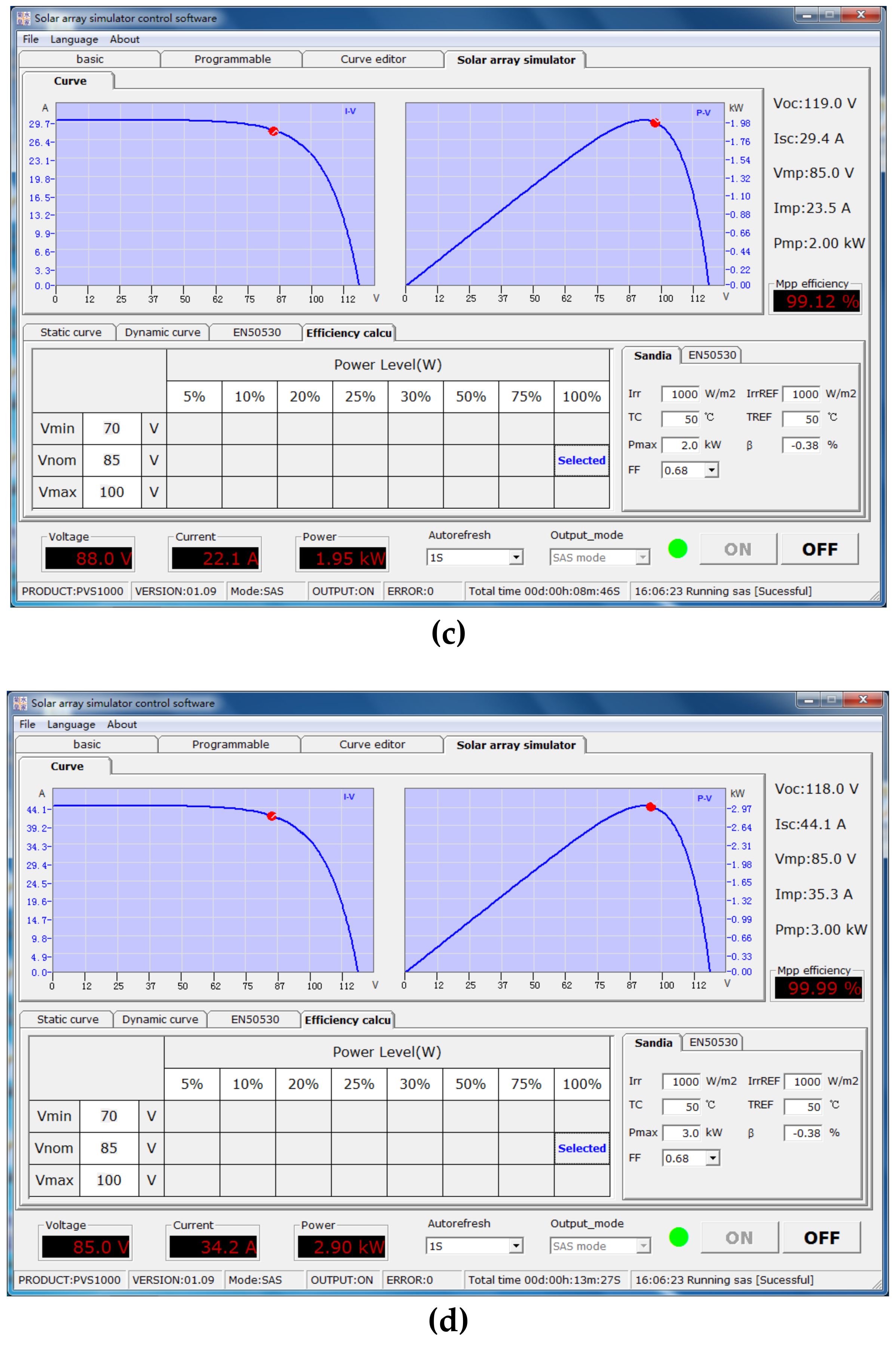

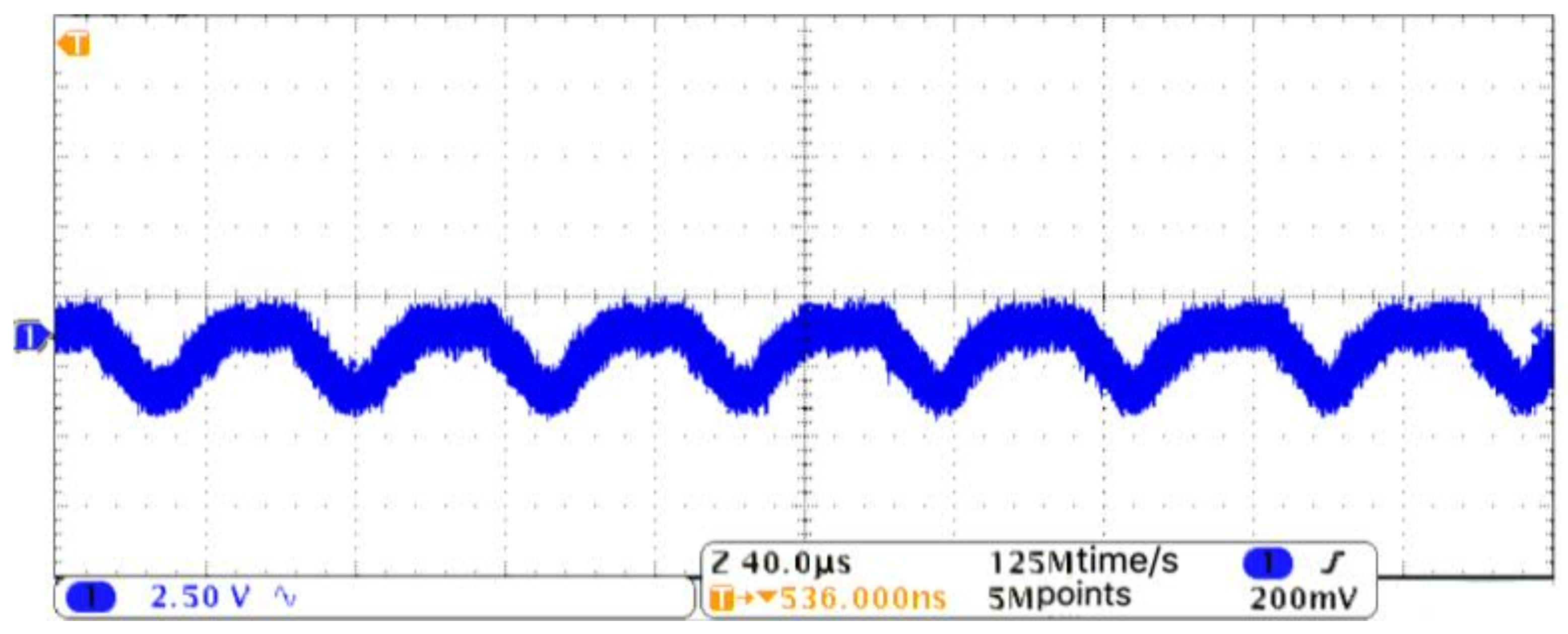

3.1. MPPT Test

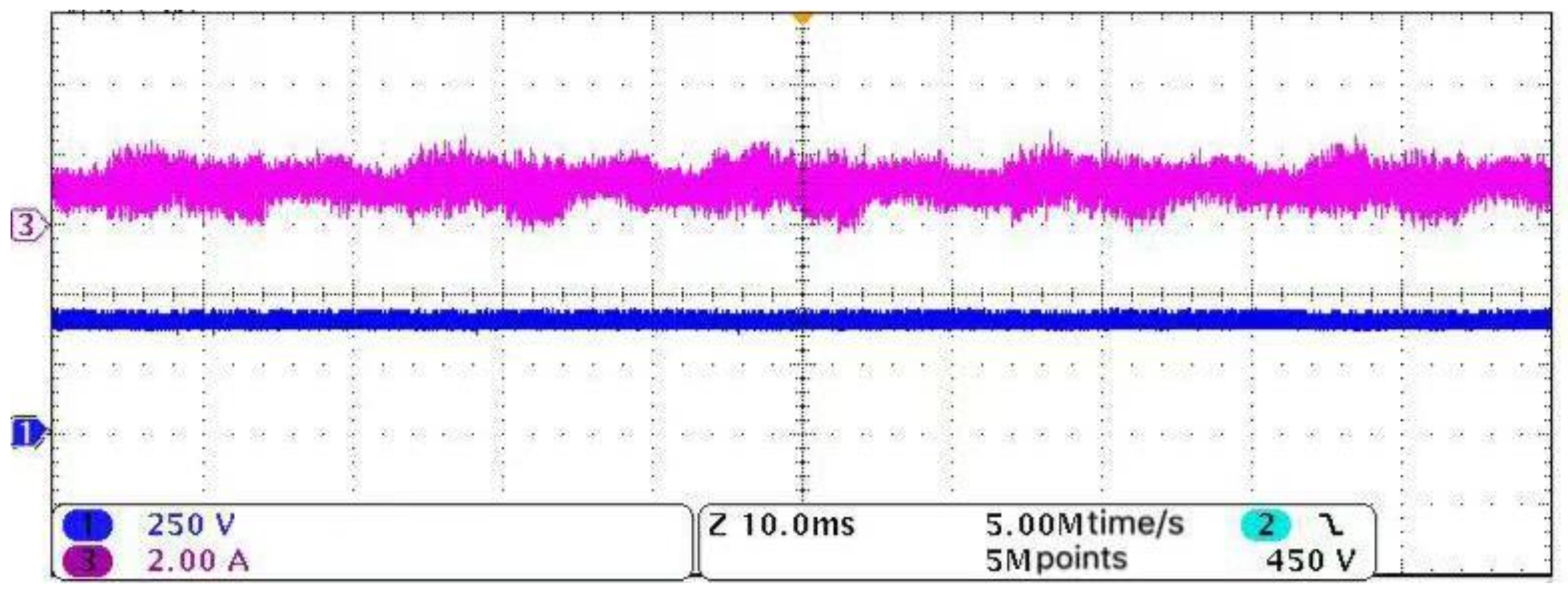

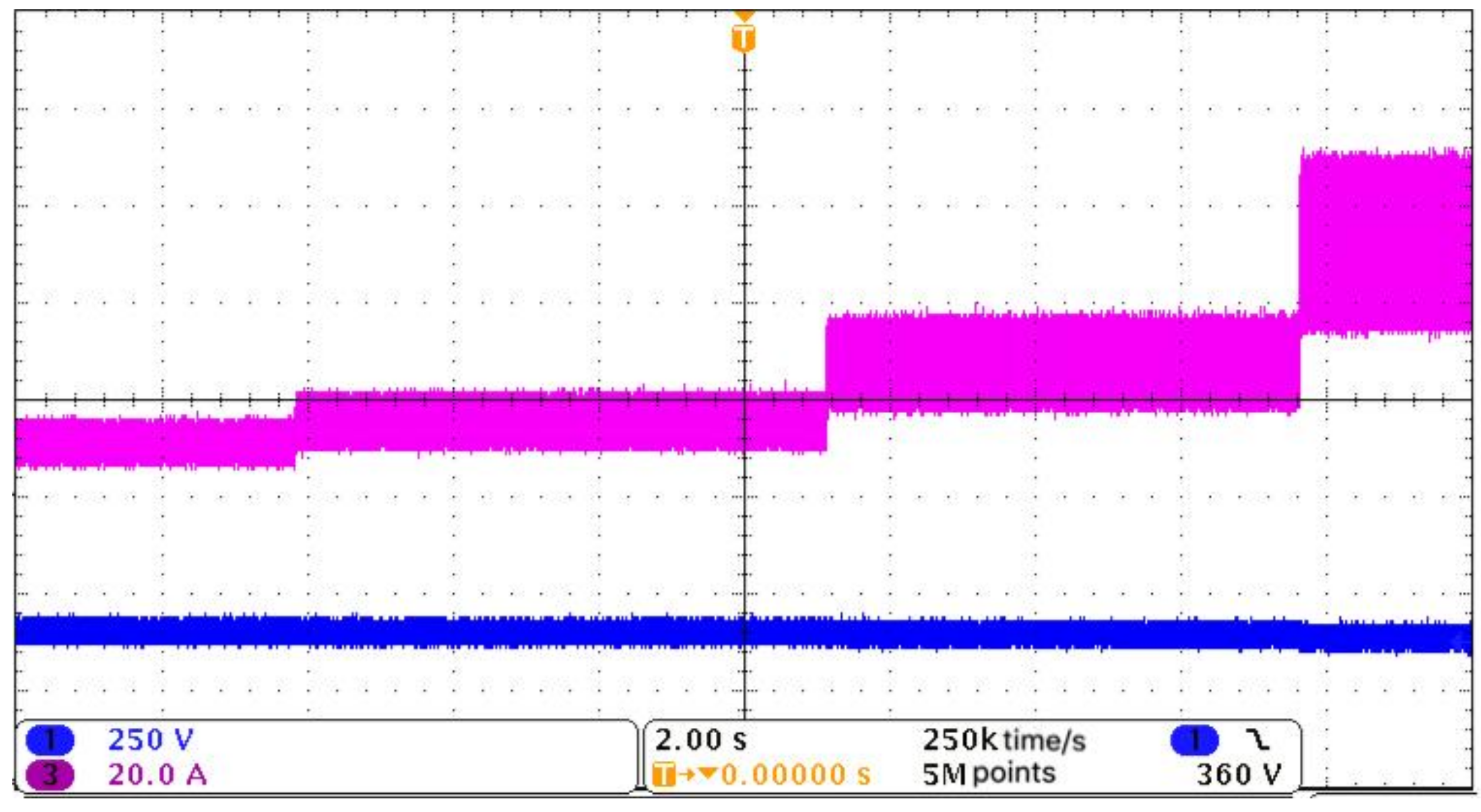

3.2. Discharge Bus Waveform Test

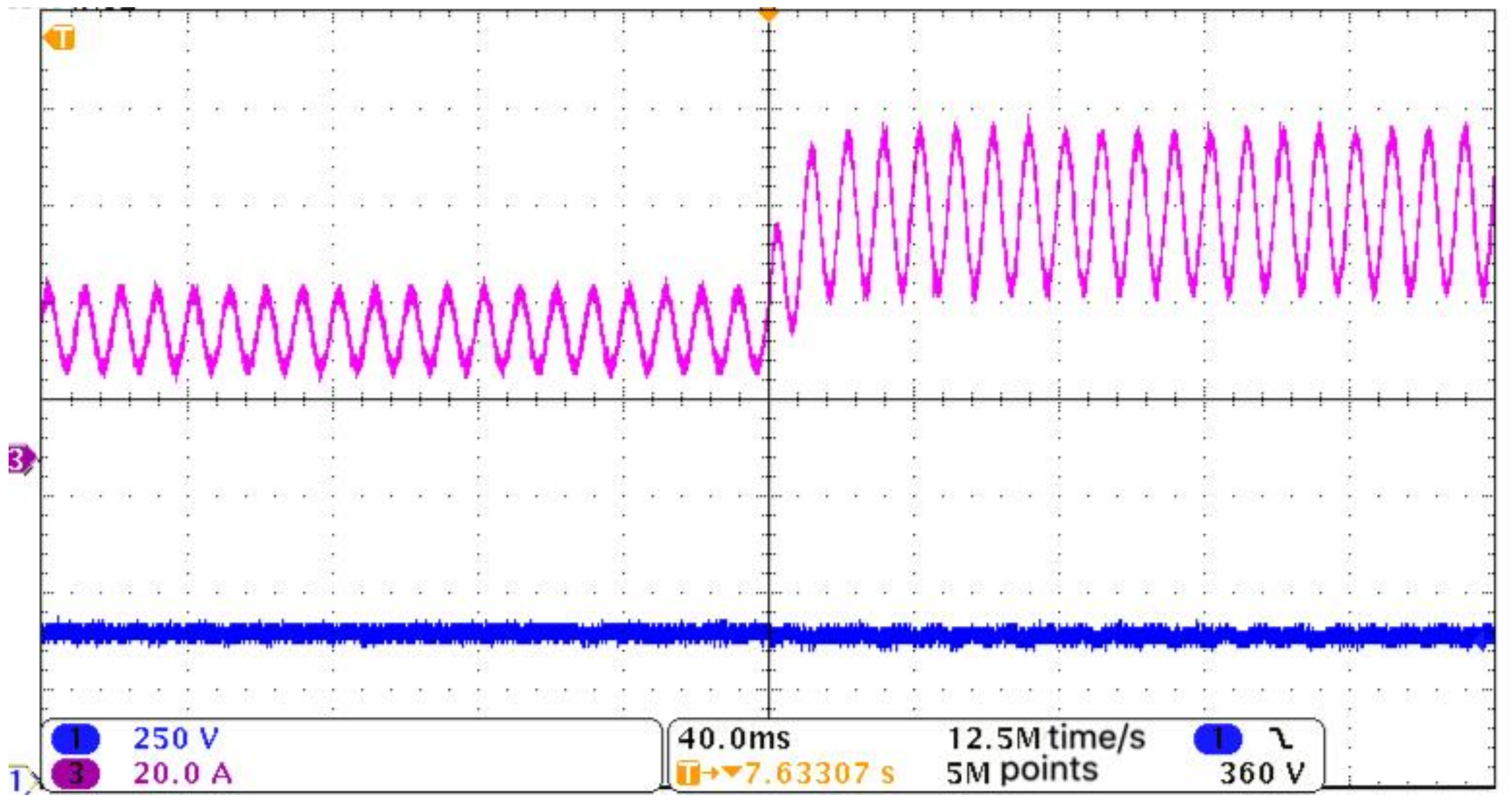

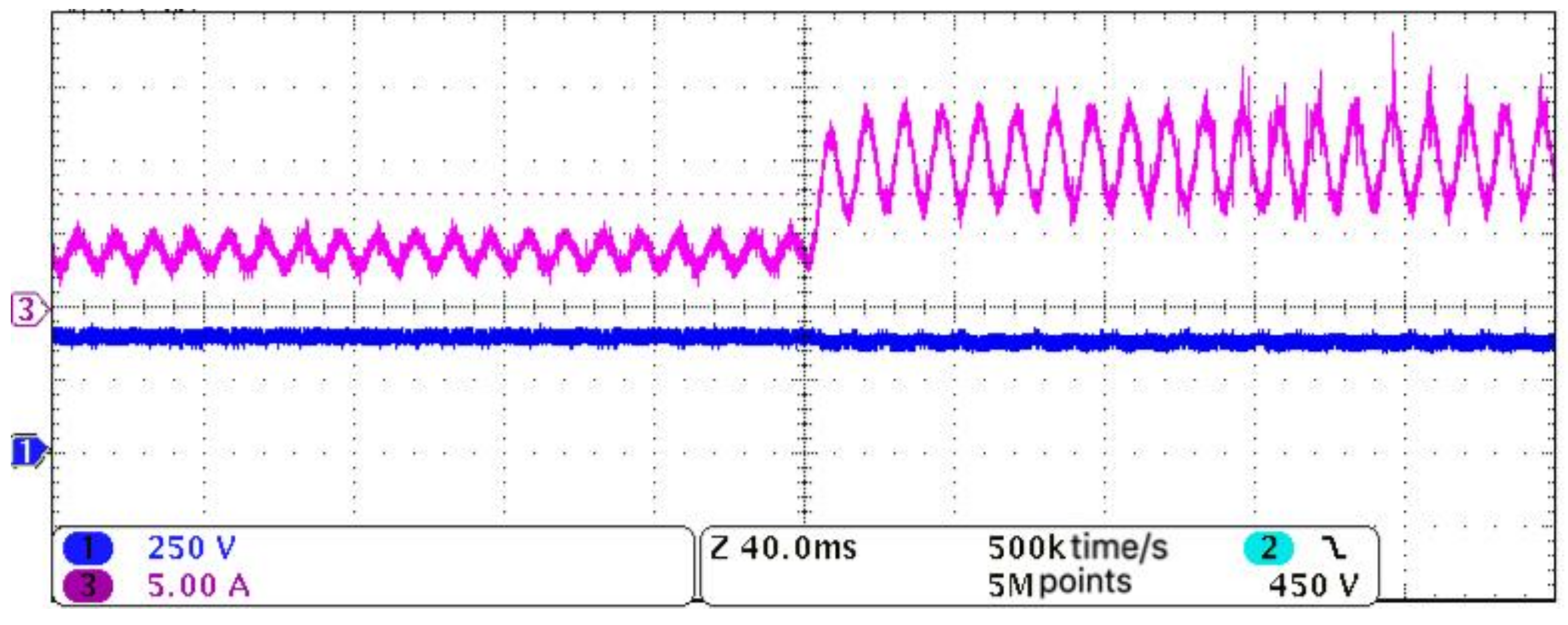

3.3. Push–Pull Discharge Load Switching Test

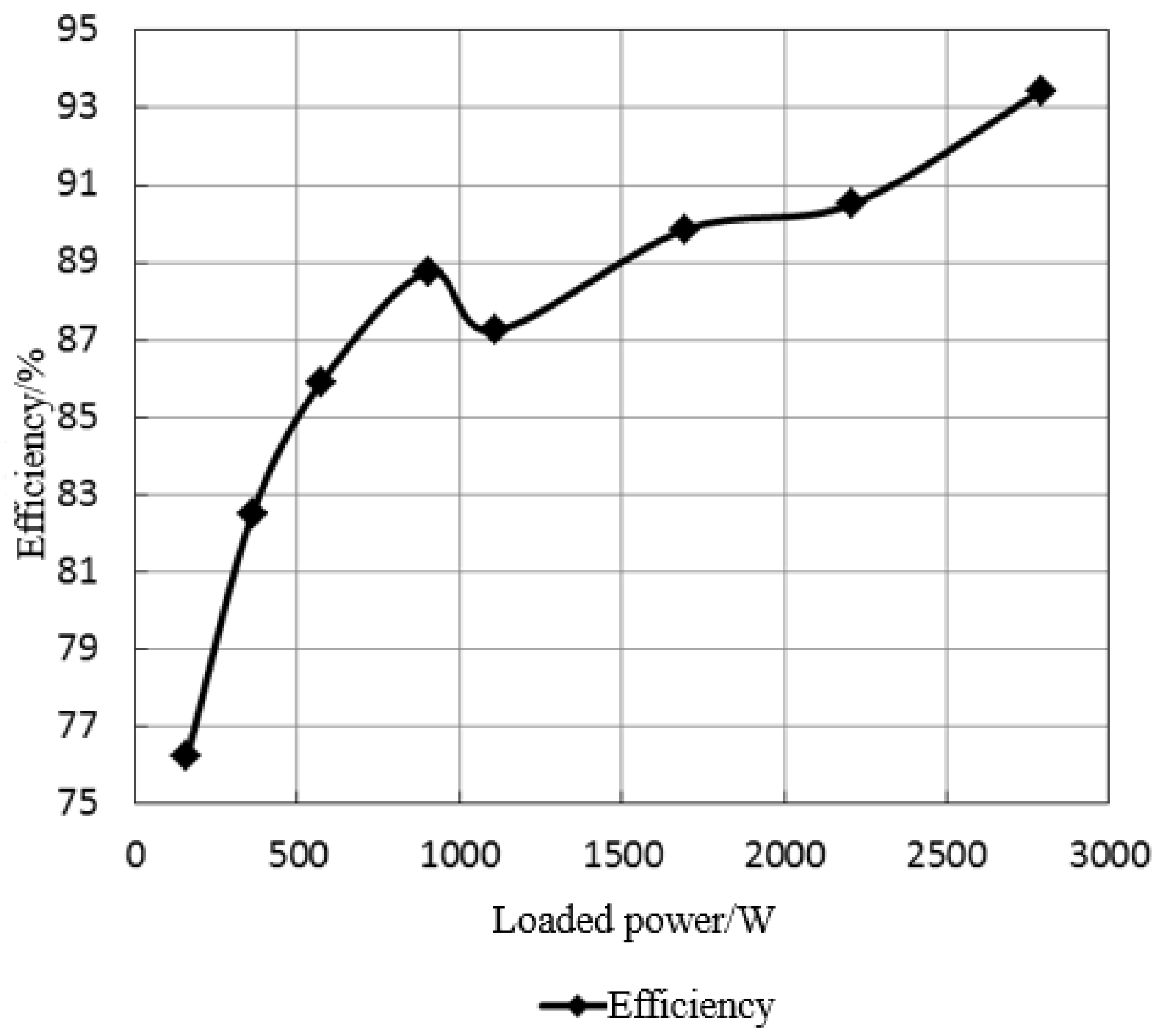

3.4. Push–Pull Circuit Efficiency Test

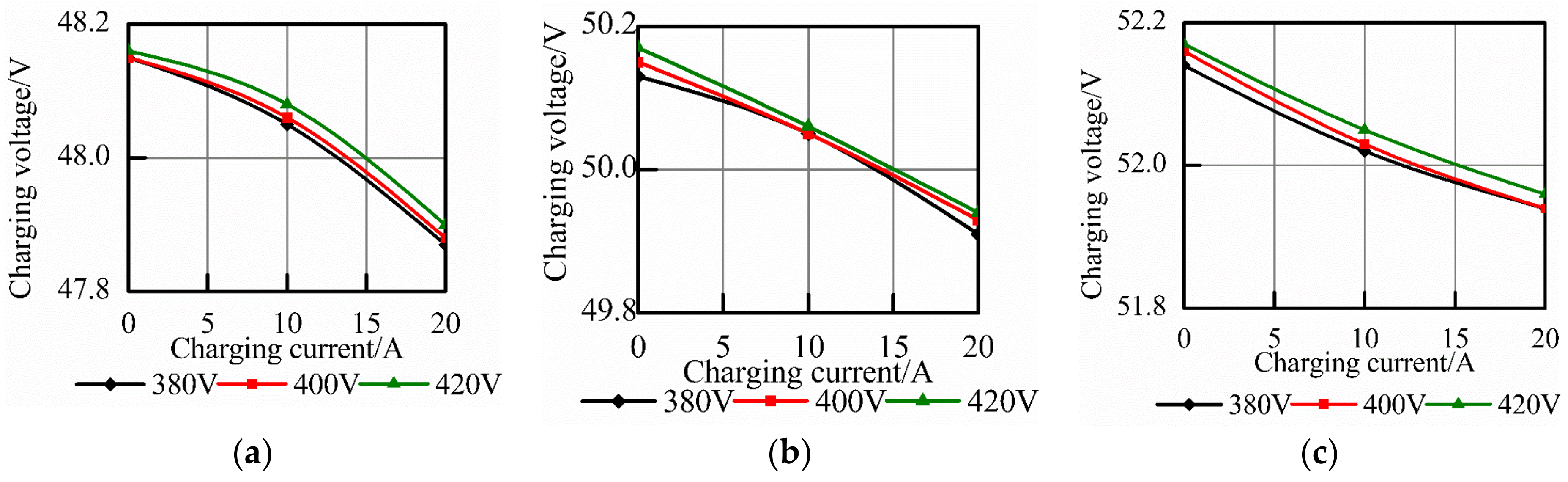

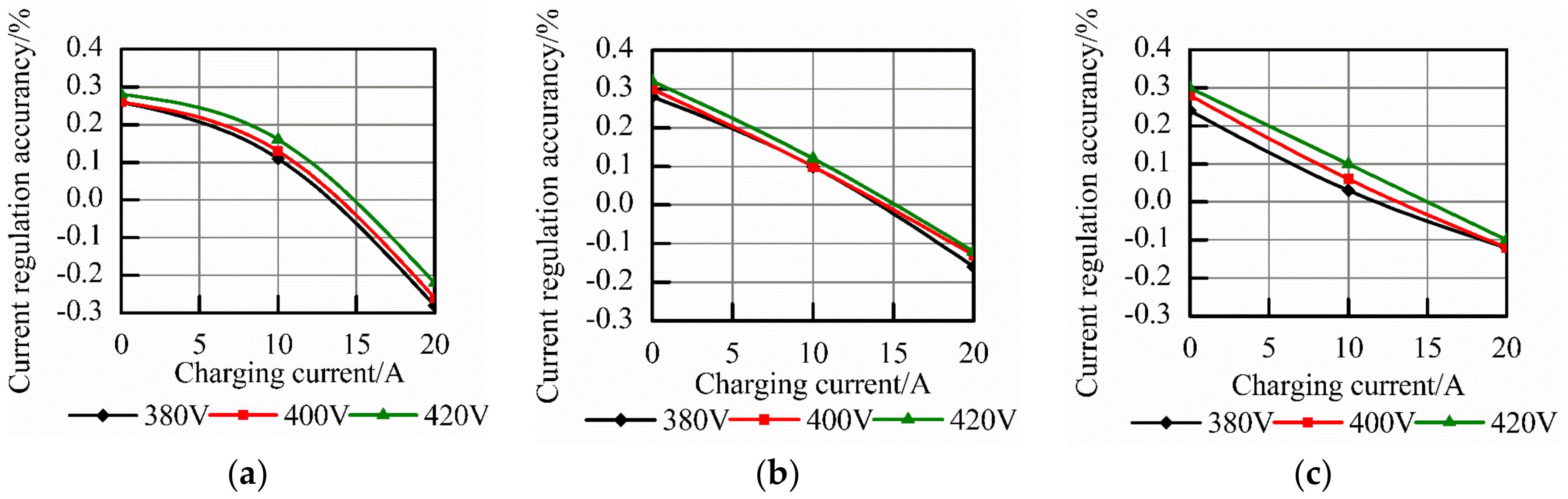

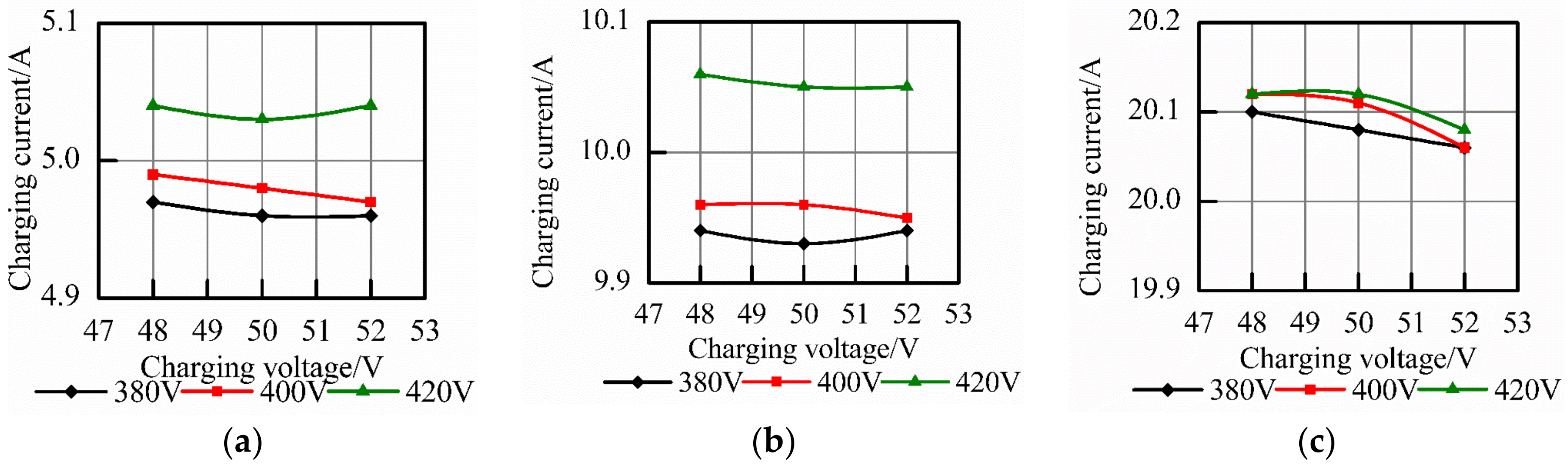

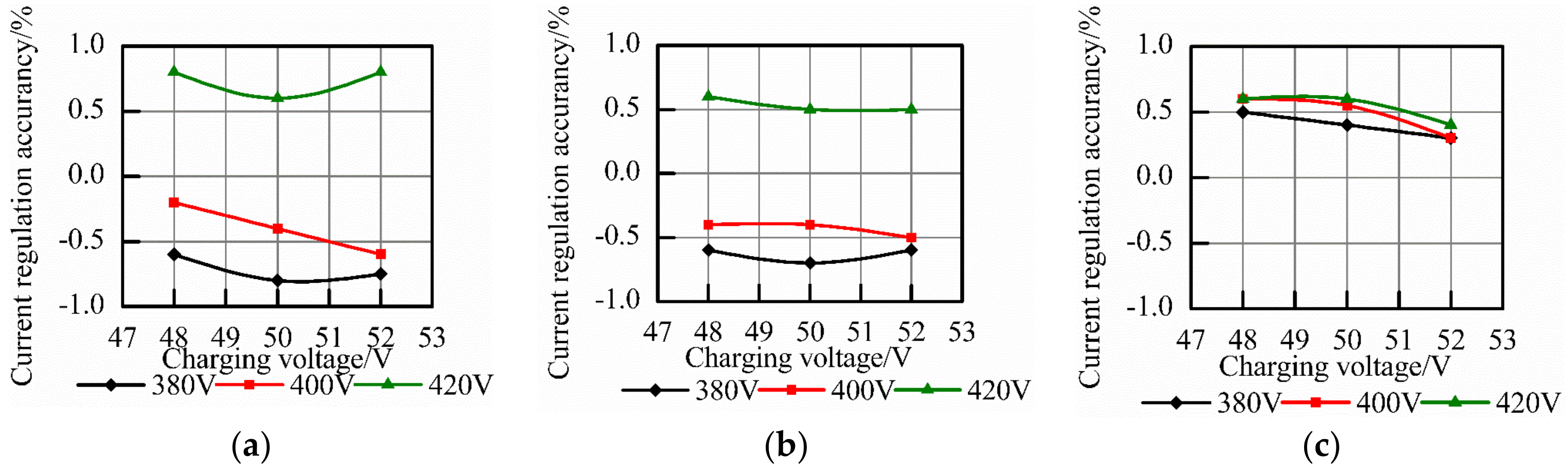

3.5. Voltage Regulation and Current Regulation Accuracy Tests

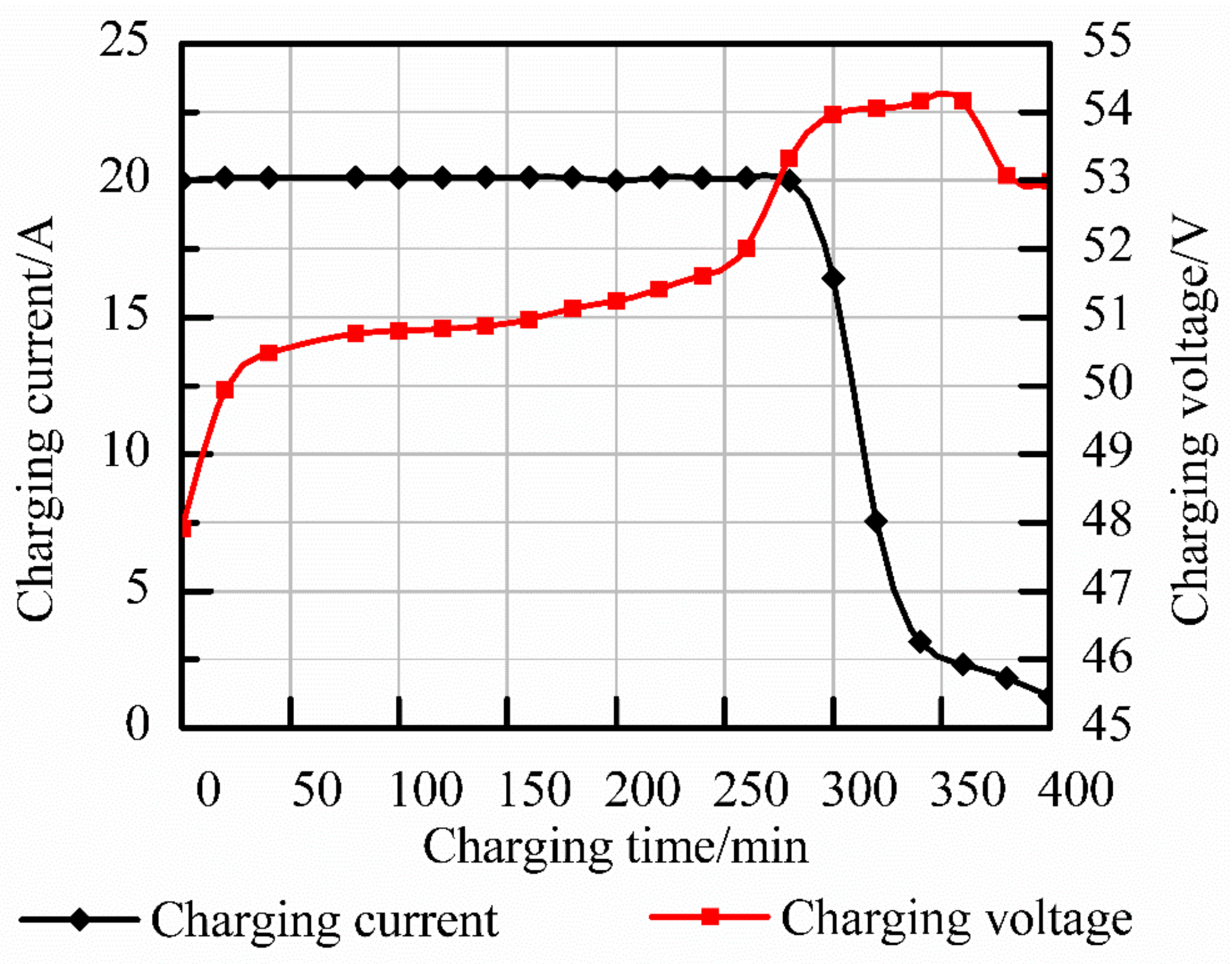

3.6. Charging Experiment Data Collection

4. Conclusions

- (1)

- An improved disturbance observation method with a three-point variable step size is proposed based on the traditional perturbation and observation method. Maximum power point tracking was carried out, combined with a fuzzy control. In this study, we systematically analyzed the design process of an improved three-point variable step-size perturbation and observation method, and the principle of a fuzzy control MPPT algorithm. Simulink simulation and experiments were conducted. We also analyzed the hardware and software implementation of the algorithm. The simulation and experimental results show that the proposed fuzzy MPPT algorithm can improve the tracking speed and accuracy.

- (2)

- Battery charge and discharge tests were then conducted using an experimental platform. The charging voltage and current waveforms, voltage and current regulation accuracies, discharge busbar waveforms when switching load, and a discharge efficiency of 93.43% were obtained. The results satisfy the design requirements. The battery charging data recorded by the system is consistent with the constant-voltage and constant-current charging algorithm designed for the charging process. The experimental results verified the feasibility of the hardware system and software algorithm developed for the charging and discharging system of lithium titanate batteries.

Author Contributions

Funding

Conflicts of Interest

References

- Dan, C.; Yan, C. A sociological survey of the survival and development of the global photovoltaic industry. J. Law Econ. 2012, 4, 87–88. [Google Scholar]

- Mundo-Hernández, J.; de Celis Alonso, B.; Hernández-Álvarez, J.; de Celis-Carrillo, B. An overview of solar photovoltaic energy in Mexico and Germany. Renew. Sustain. Energy Rev. 2014, 31, 639–649. [Google Scholar] [CrossRef]

- Aamir, M.; Ahmed Kalwar, K.; Mekhilef, S. Review: Uninterruptible Power Supply (UPS) system. Renew. Sustain. Energy Rev. 2016, 58, 1395–1410. [Google Scholar] [CrossRef]

- Song, D.; Jiao, H.; Fan, C.T. Overview of the photovoltaic technology status and perspective in China. Renew. Sustain. Energy Rev. 2015, 48, 848–856. [Google Scholar] [CrossRef]

- Bukhari, S.S.H.; Atiq, S.; Lipo, T.A.; Kwon, B.-I. A Cost-Effective, Single-Phase Line-Interactive UPS System that Eliminates Inrush Current Phenomenon for Transformer-Coupled Loads. J. Electr. Eng. Technol. 2016, 11, 675–682. [Google Scholar] [CrossRef]

- Fuente, D.V.D.L.; Rodrguez, C.L.T.; Garcer, G.; Figueres, E.; Gonzalez, R.O. Photovoltaic Power System With Battery Backup With Grid-Connection and Islanded Operation Capabilities. IEEE Trans. Ind. Electron. 2012, 60, 1571–1581. [Google Scholar] [CrossRef]

- Tolani, S.; Sensarma, P. Extended Bandwidth Instantaneous Current Sharing Scheme for Parallel UPS Systems. IEEE Trans. Power Electron. 2017, 32, 4960–4969. [Google Scholar] [CrossRef]

- Wu, T.; Liu, Z.; Liu, J.; Wang, S.; You, Z. A Unified Virtual Power Decoupling Method for Droop-Controlled Parallel Inverters in Microgrids. IEEE Trans. Power Electron. 2016, 31, 5587–5603. [Google Scholar] [CrossRef]

- Laurischkat, K.; Jandt, D. Techno-economic analysis of sustainable mobility and energy solutions consisting of electric vehicles, photovoltaic systems and battery storages. J. Clean. Prod. 2018, 179, 642–661. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I.; Gastaldi, M.; Stornelli, V.; Rosen, M.A. Solar photovoltaic panels combined with energy storage in a residential building: An economic analysis. Sustainability 2018, 10, 3117. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, H. Analysis of Networked Control Schemes and Data-Processing Method for Parallel Inverters. IEEE Trans. Ind. Electron. 2014, 61, 1834–1844. [Google Scholar] [CrossRef]

- Yan, X.W.; Wang, Y.R.; Wang, X.H. Study on power decoupling and robust droop control method of parallel inverter. J. Electr. Power Sci. Technol. 2016, 1, 003. [Google Scholar]

- Zhang, Q.; An, L.; Chen, Y.; Peng, C.; Peng, Z. Analysis of Output Impedance for Parallel Inverters and Voltage Control Strategy. Trans. China Electrotech. Soc. 2014, 29, 98–105. [Google Scholar]

- Dolara, A.; Grimaccia, F.; Mussetta, M.; Ogliari, E.; Leva, S. An Evolutionary-Based MPPT Algorithm for Photovoltaic Systems under Dynamic Partial Shading. Appl. Sci. 2018, 8, 558. [Google Scholar] [CrossRef]

- Atawi, I.; Kassem, A. Optimal Control Based on Maximum Power Point Tracking (MPPT) of an Autonomous Hybrid Photovoltaic/Storage System in Micro Grid Applications. Energies 2017, 10, 643. [Google Scholar] [CrossRef]

- Lu, X.; Guerrero, J.M.; Sun, K.; Vasquez, J.C. An Improved Droop Control Method for DC Microgrids Based on Low Bandwidth Communication with DC Bus Voltage Restoration and Enhanced Current Sharing Accuracy. IEEE Trans. Power Electron. 2013, 29, 1800–1812. [Google Scholar] [CrossRef]

- Zhong, Q.-C.; Zeng, Y. Universal Droop Control of Inverters with Different Types of Output Impedance. IEEE Access 2016, 4, 702–712. [Google Scholar] [CrossRef]

- Jia-Xin, L.; Zhang, Y.C.; Qian, X.S.; Cheng, S.; Zhao, Z.M. Analysis of Virtual Output-impedance for Parallel-connected Inverters with Wireless Load-sharing Control. J. Power Supply 2014, 12, 54–60. [Google Scholar]

- Zhao, J.; Liu, H.; Keqing, Q.U.; Fen, L.I. An Improved Droop Control Strategy Based on Virtual Impedance in Inverter Parallel System. J. Shanghai Univ. Electr. Power 2015, 2, 001. [Google Scholar]

- Haoran, L.I.; Yang, X.; Feng, C. Control strategy research of output impedance analysis and improved droop control based on multiple-inverters parallel. Power Syst. Prot. Control 2015, 43, 29–35. [Google Scholar]

| Type | Fixed Voltage Method | Perturbation and Observation Method | Incremental Conductance Method |

|---|---|---|---|

| 92.8% | 97.1% | 98.4% | |

| 88.2% | 96.6% | 98.3% | |

| Advantages | Less parameters Simple realization | Better control | Better control |

| Disadvantages | Poor control | Power oscillation exists | Accuracy of sampling is high and amount of computation is large |

| Charging Time (min) | Charging Current (A) | Charging Voltage (V) | Charging Time (min) | Charging Current (A) | Charging Voltage (V) |

|---|---|---|---|---|---|

| 0 | 19.99 | 47.91 | 220 | 20.12 | 51.41 |

| 20 | 20.12 | 49.94 | 240 | 20.09 | 51.61 |

| 40 | 20.12 | 50.48 | 260 | 20.08 | 52.01 |

| 80 | 20.11 | 50.76 | 280 | 19.98 | 53.32 |

| 100 | 20.11 | 50.8 | 300 | 16.41 | 53.96 |

| 120 | 20.11 | 50.83 | 320 | 7.55 | 54.05 |

| 140 | 20.12 | 50.87 | 340 | 3.15 | 54.15 |

| 160 | 20.12 | 50.97 | 360 | 2.32 | 54.16 |

| 180 | 20.11 | 51.13 | 380 | 1.82 | 53.07 |

| 200 | 19.99 | 51.23 | 400 | 1.15 | 52.98 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, Z.; Fan, Y.; Cai, X.; Zheng, Z.; Xue, J.; Zhang, K. Lithium Titanate Battery Management System Based on MPPT and Four-Stage Charging Control for Photovoltaic Energy Storage. Appl. Sci. 2018, 8, 2520. https://doi.org/10.3390/app8122520

Fu Z, Fan Y, Cai X, Zheng Z, Xue J, Zhang K. Lithium Titanate Battery Management System Based on MPPT and Four-Stage Charging Control for Photovoltaic Energy Storage. Applied Sciences. 2018; 8(12):2520. https://doi.org/10.3390/app8122520

Chicago/Turabian StyleFu, Zhihe, Yibiao Fan, Xiaowei Cai, Zhaohong Zheng, Jiaxiang Xue, and Kun Zhang. 2018. "Lithium Titanate Battery Management System Based on MPPT and Four-Stage Charging Control for Photovoltaic Energy Storage" Applied Sciences 8, no. 12: 2520. https://doi.org/10.3390/app8122520

APA StyleFu, Z., Fan, Y., Cai, X., Zheng, Z., Xue, J., & Zhang, K. (2018). Lithium Titanate Battery Management System Based on MPPT and Four-Stage Charging Control for Photovoltaic Energy Storage. Applied Sciences, 8(12), 2520. https://doi.org/10.3390/app8122520