Development of an Energy-Efficient Smart Socket Based on STM32F103

Abstract

:Featured Application

Abstract

1. Introduction

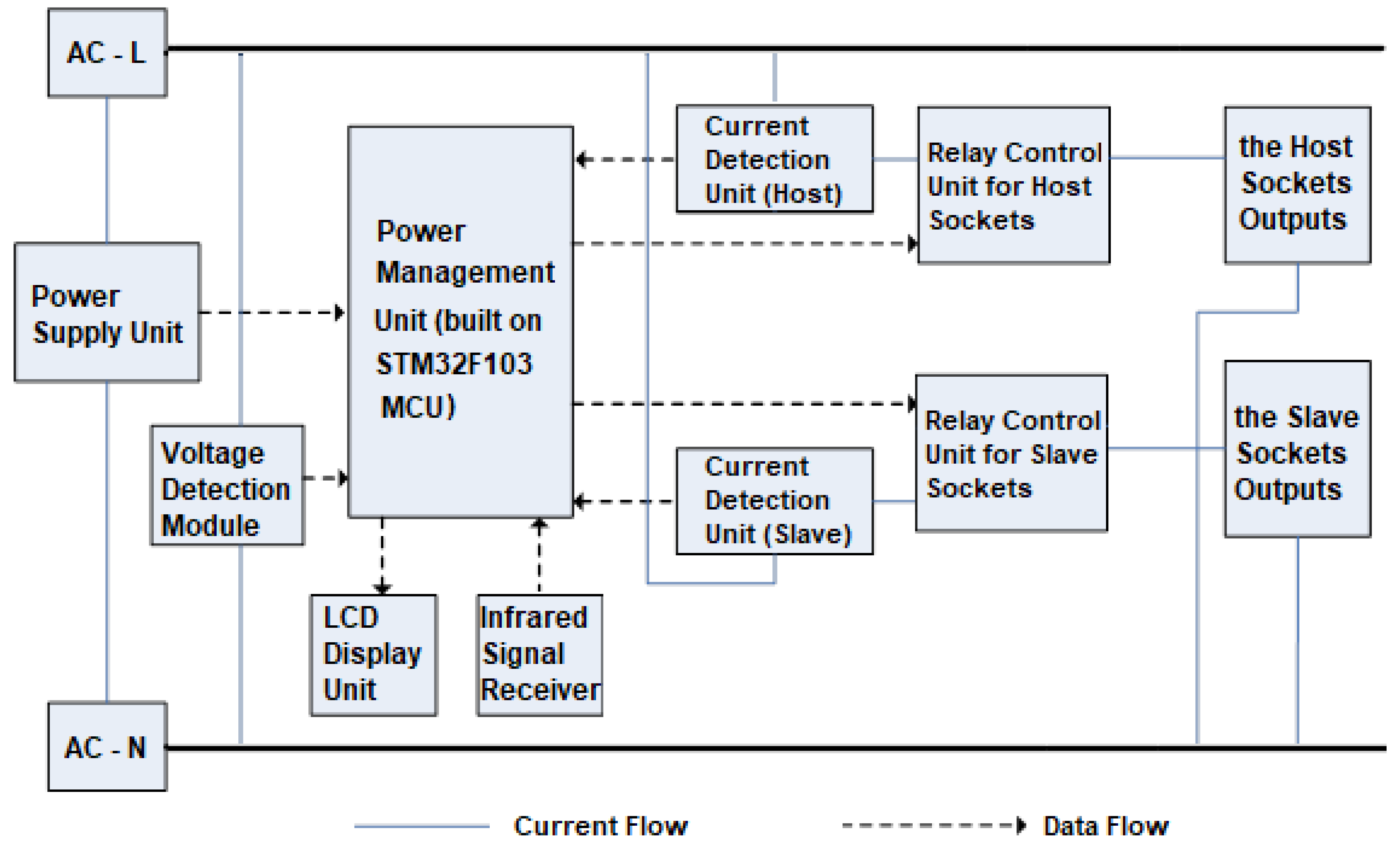

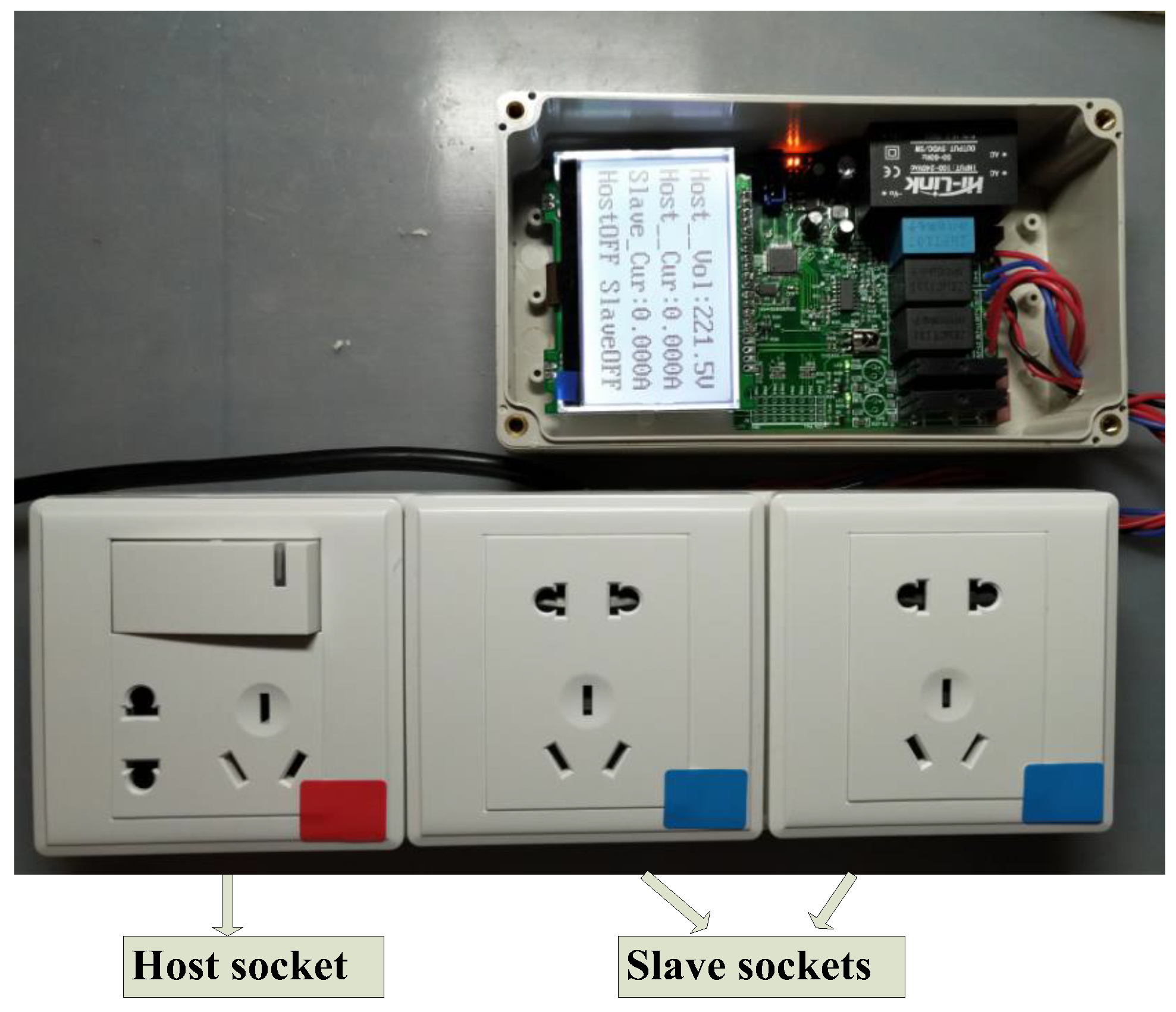

- A host-slave mechanism was applied to the control strategy for standby energy saving. The working status (switching on or off) of auxiliary/slave devices are controlled by that of the main/host equipment. Once the embodied power management unit built on microchip STM32F103 detected sharp current dropping in host plugs, which is supposed to be a switch-off operation conducted by the occupants, it will then respond quickly to power off the smart socket for the reduction of standby energy waste.

- The smart socket is compatible with normal remote controllers of electrical appliances, which expanded its application and allows the occupants to switch off or power on the developed smart socket conveniently with normal remote controllers.

- The safety protection measures have been employed to avoid overvoltage, which is normally recognized to be hazardous in electricity consumption.

- The developed smart socket system can be easily integrated into the existing household power network. Neither extra wiring nor network connection is required, which promotes the economic attractiveness of the proposed system.

- An energy-efficient switching power module was designed to power the proposed system, which can further reduce the energy consumption of the smart socket. This allows a reduction in the standby consumption of appliance to zero secondly at a cost of only 0.8 W operational energy use.

2. Literature Review

3. System Development

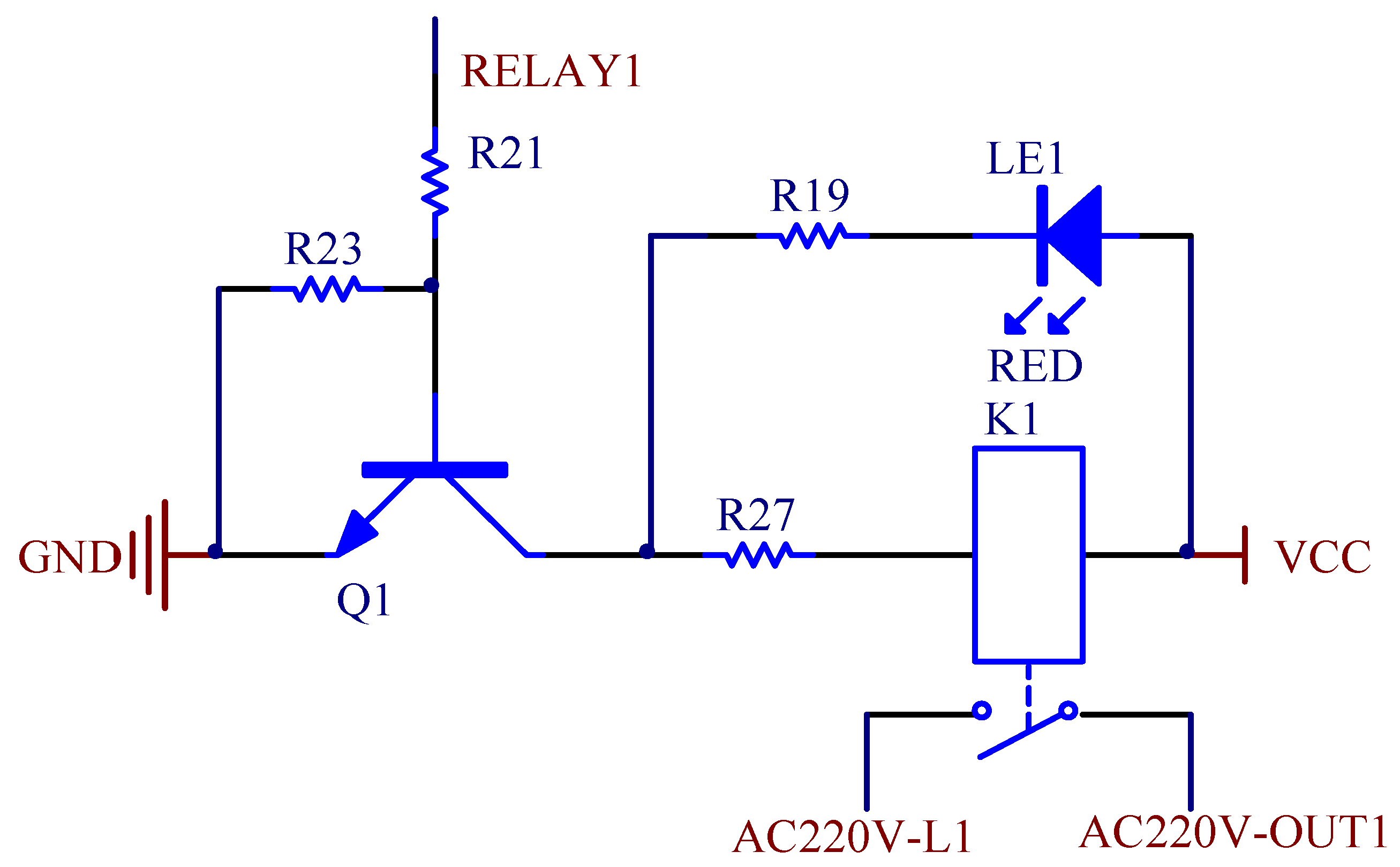

3.1. Framework of the Hardware System

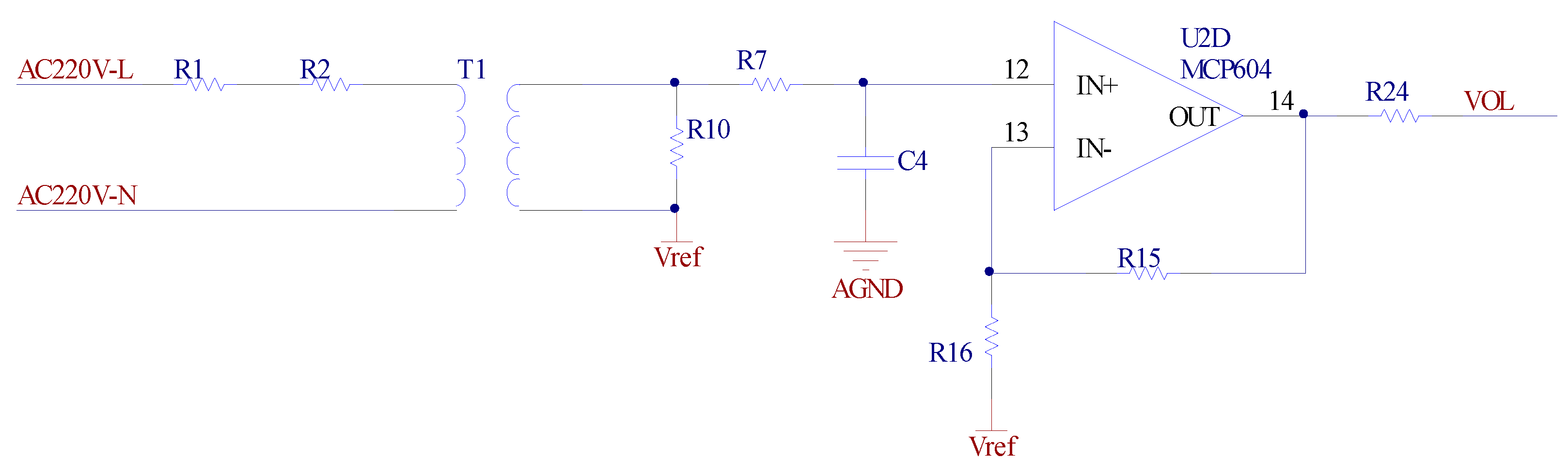

3.2. Voltage Monitoring Unit

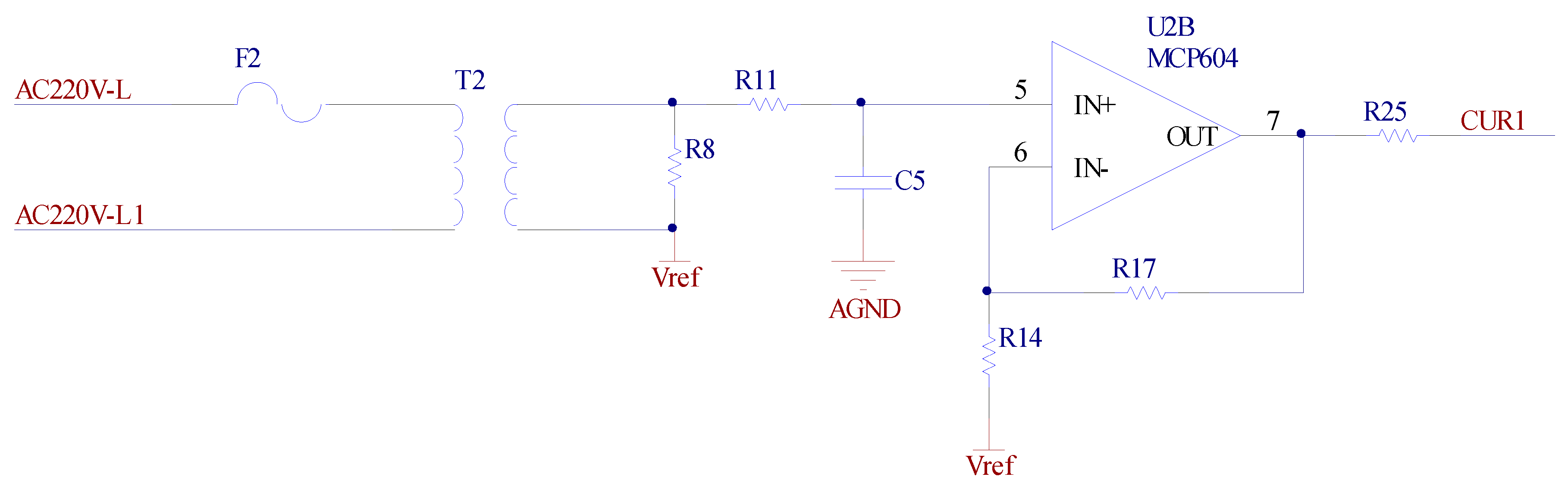

3.3. Current Monitoring Unit

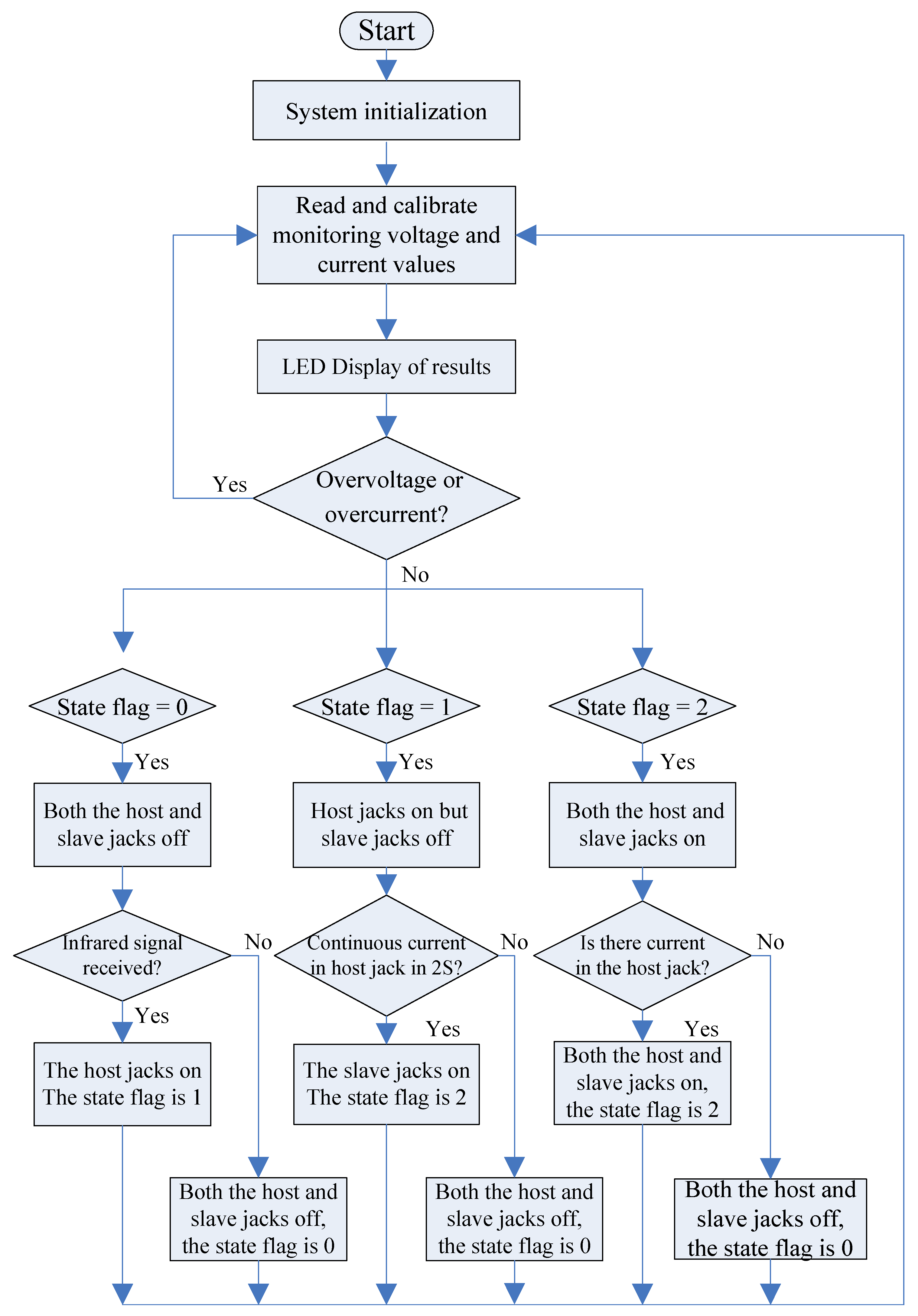

3.4. Flowchart and System Control Operations

- System initialization, the value of the flag is set as 0.

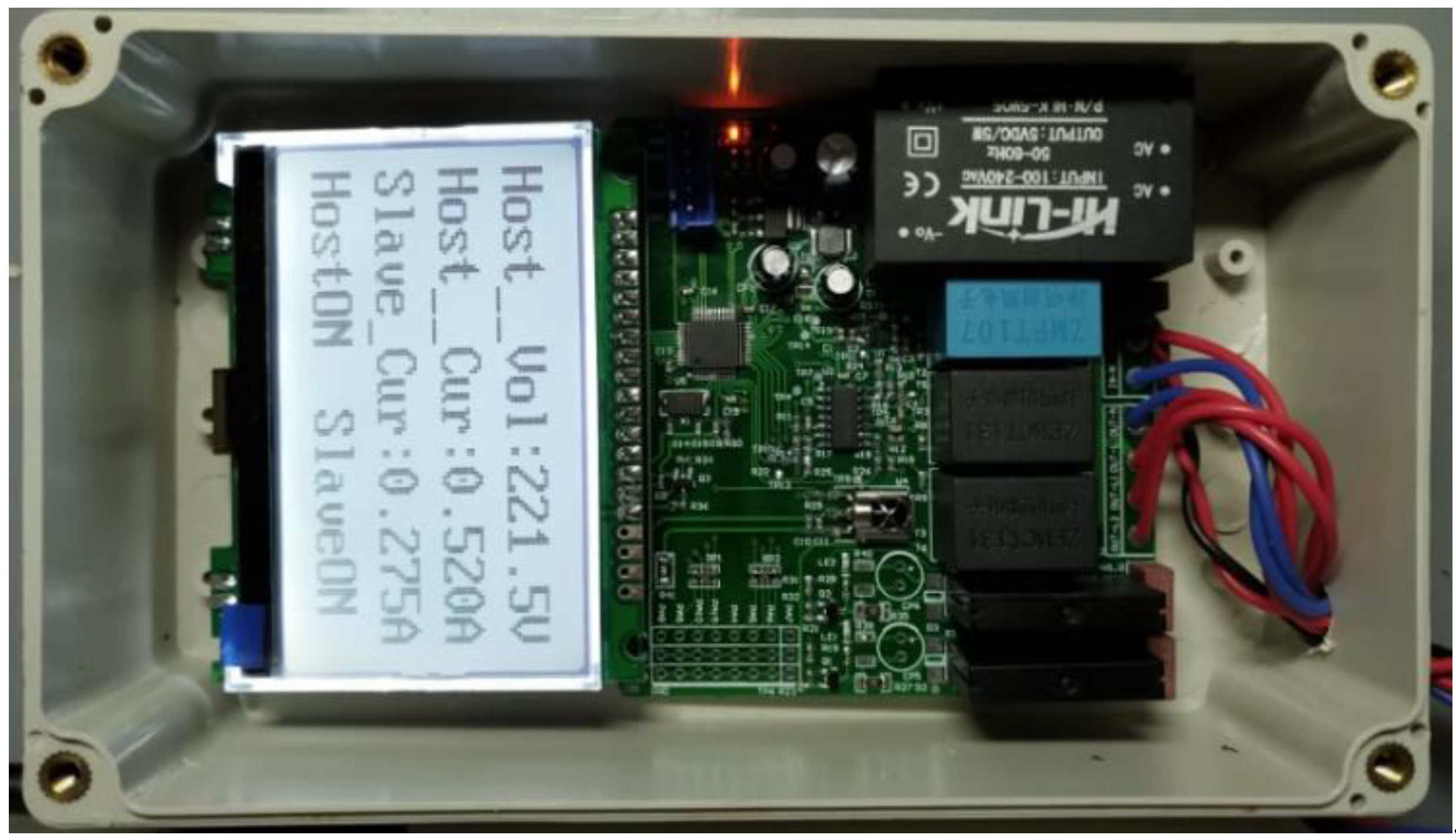

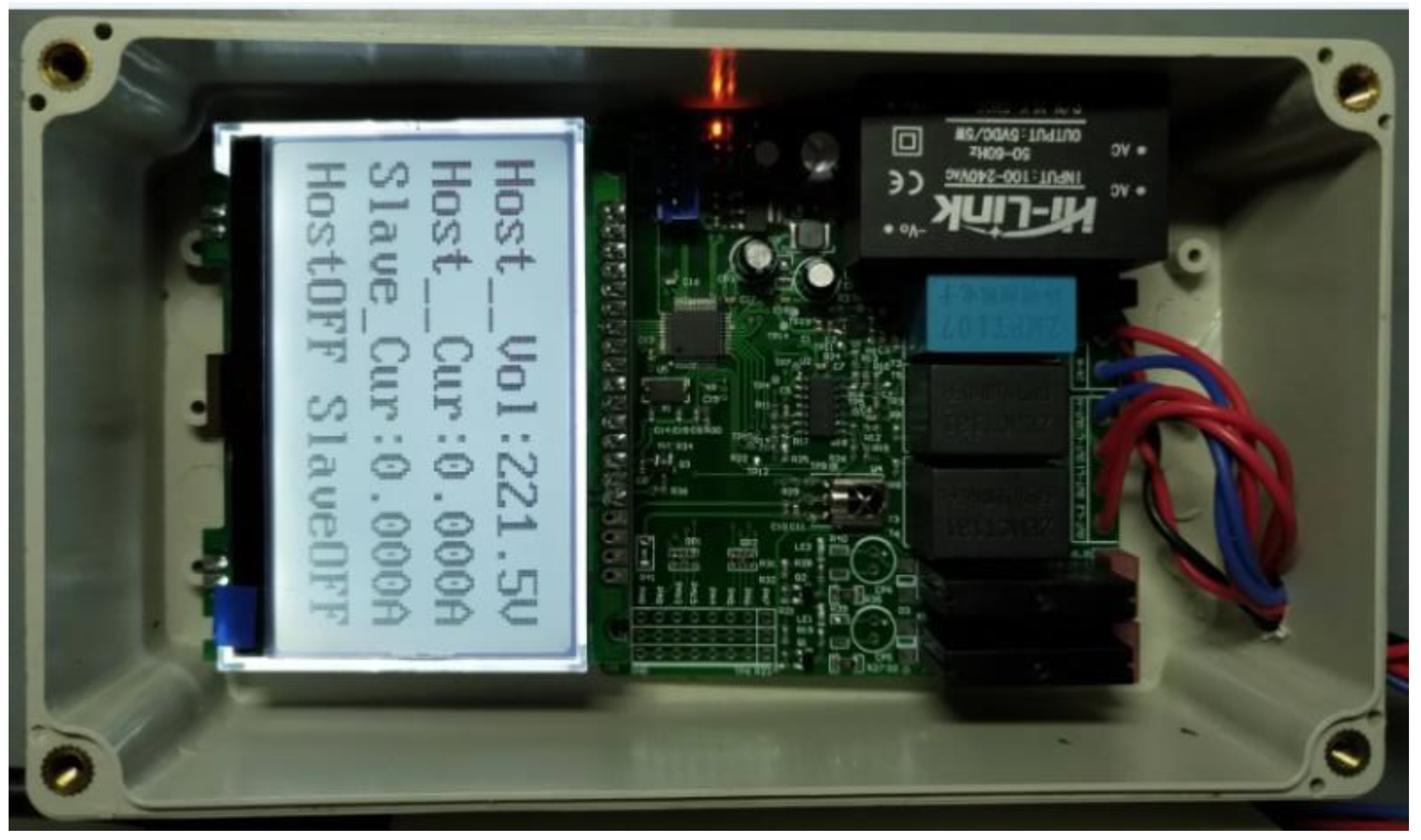

- Read current and voltage values for the host and slave jacks, with the data then transmitted to the power management unit for processing.

- After processing and calibration, the values of voltage and current then can be loop displayed on the LCD module.

- Overvoltage and overcurrent checking. Both the host and slave jacks would be powered off if either overvoltage or overcurrent was detected.

- Logical decision making considering the flowing three scenarios: Scenario 1, the value of the status flag is 0. If infrared control instruction has been received, the host jacks then would be powered on with the flag set as 1, otherwise, both the host and slave jacks would be powered off with the flag set as 0. Scenario 2, the value of the status flag is read as 1. If the current in host jack continues within 2 s, the slave jacks would be powered on with the flag set as 2, otherwise, both the host and slave jacks would be switched off with the flag set as 0. Scenario 3, the value of the status flag equals to 2. If the host jacks are powered on, no response required, otherwise both the host and slave jacks would be switched off with the flag set as 0. The procedure for smarter control operations can then be described as:

If (Status flag == 0)Both the host and slave jacks are offIf (Infrared signal received)The host jacks are on and the status flag is set as 1elseBoth the host and slave jacks are off; the state flag is set as 0endelse if (Status flag == 1)Host jacks are on but slave jacks are offIf (continuous current was detected in host jacks within 2 seconds)The slave jacks are on and the status flag is set as 2elseBoth the host and slave jacks are off; the status flag is set as 0endelse if (Status flag == 2)Both the host and slave jacks are onIf (current was detected in the host jacks)Both the host and slave jacks are on; the status flag is set as 2elseBoth the host and slave jacks are off; the status flag is set as 0endend

4. Experimental Validation and Discussion

Functional Validation and Lifecycle Assessment

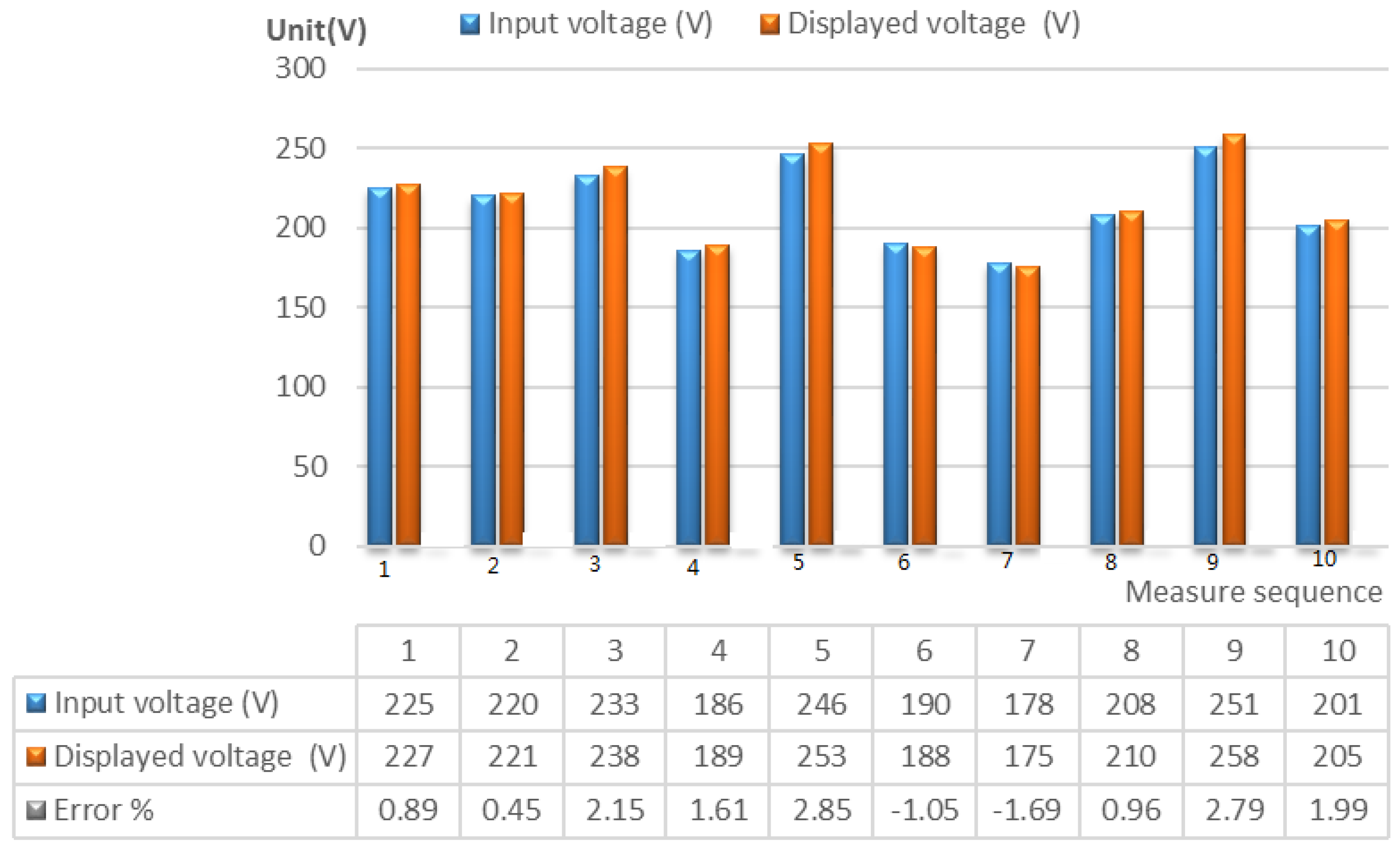

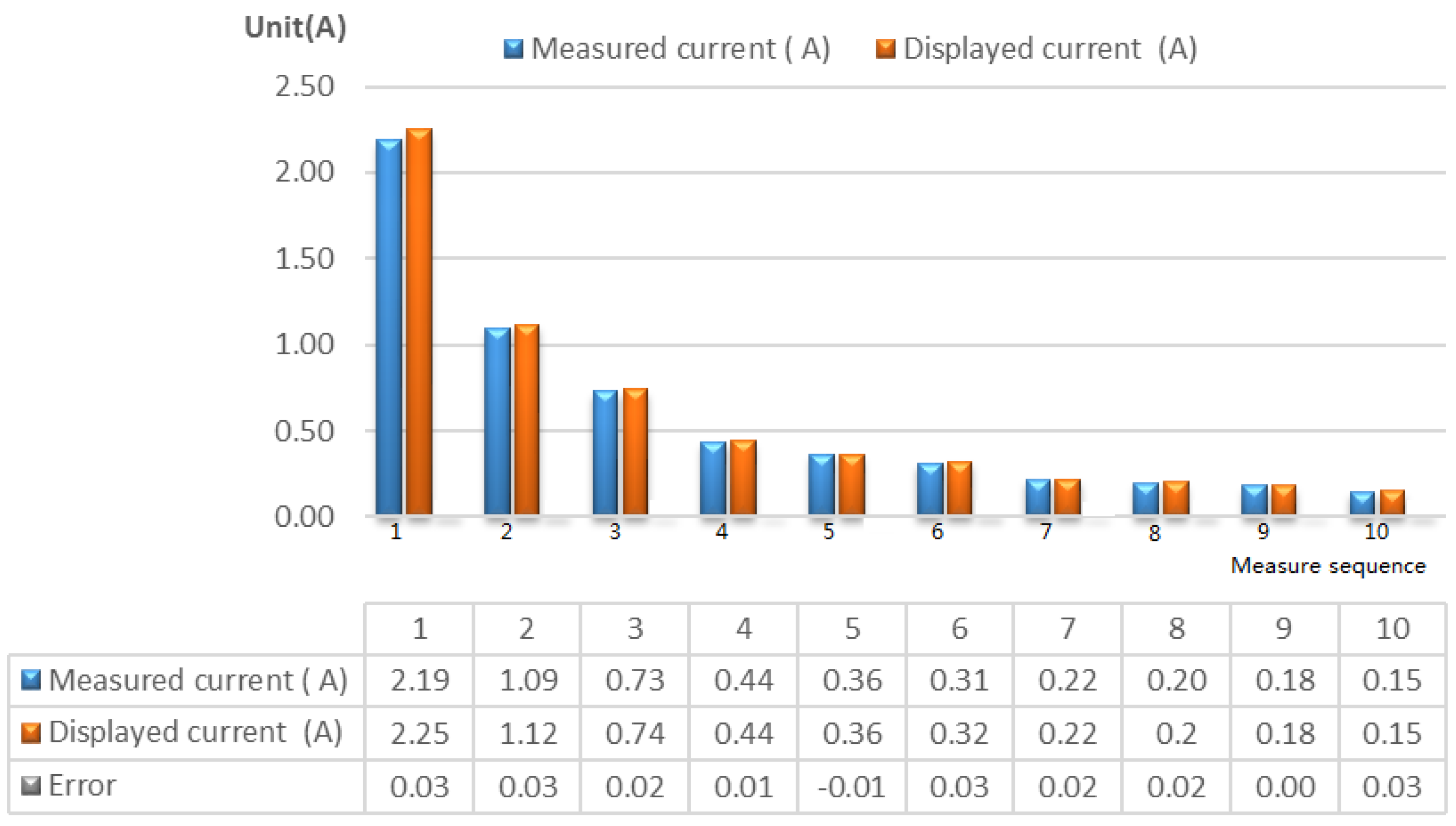

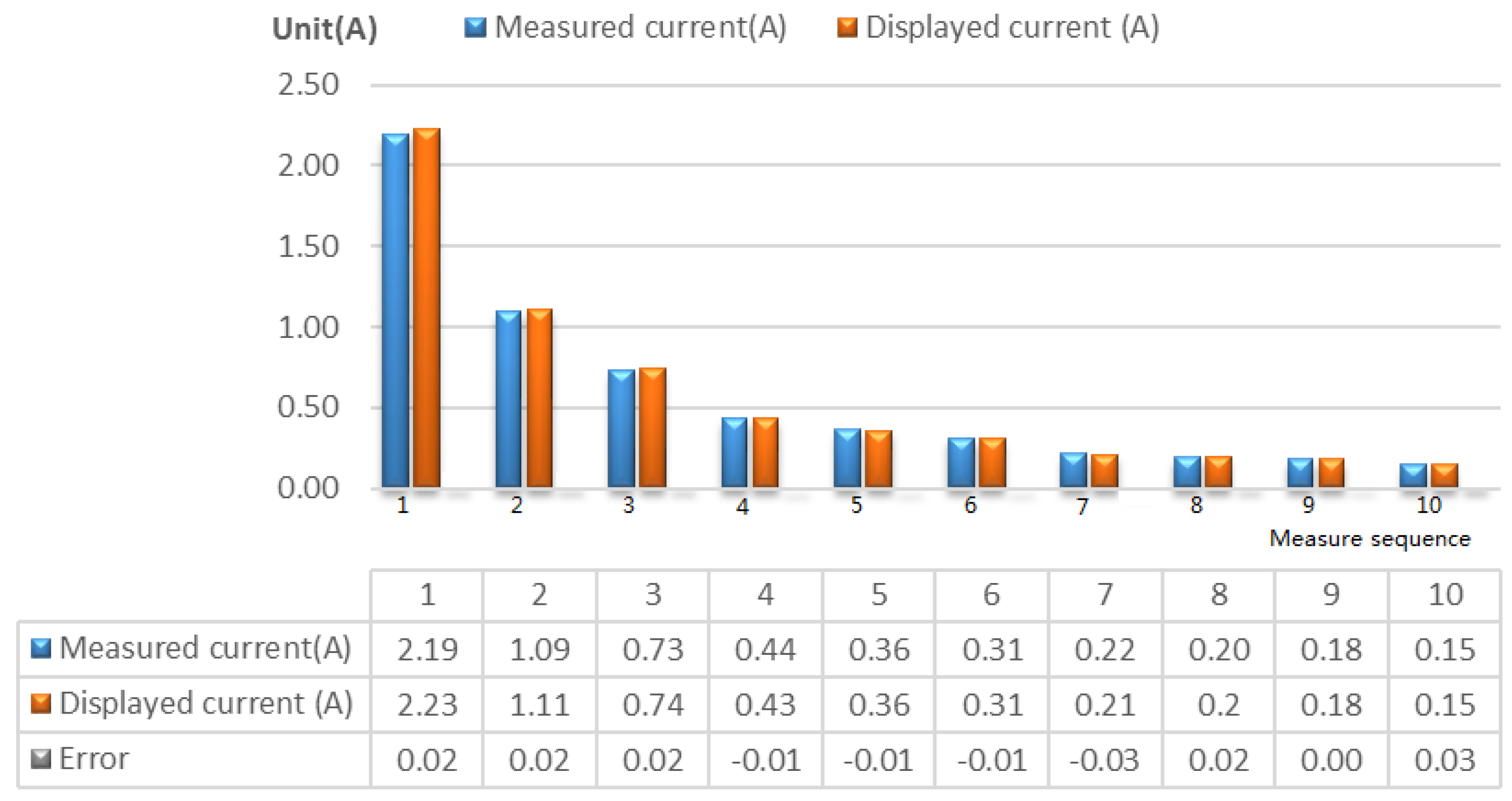

5. Precision Testing and Error Analysis

6. Concluding Remarks

- Experimental testing and scenario analysis indicate that the developed system can fully satisfy the functional requirements and realize the proposed host-slave control mechanism. The response delay is less than 2 s.

- Lifecycle analysis illustrated that the integration of the developed smart socket can contribute to 6.40%, 77.76%, and 38.76% of energy saving for TV, TV receiver box and stereo system respectively. Regarding the economic concern, the assessment results indicated that an investment of 125.60 Chinese yuan on the smart socket resulting in a standby cost saving up to 1725.60 Chinese yuan over 20 years. The investment payback period is within 159 days.

- Precision testing and error analysis were conducted in this research to validate the reliability and stability of the designed system. Results showed that an acceptable error ratio of less than 3.00% appeared in the measurements of voltage and current values. For the monitoring voltage value, there is a random error which might result from the characteristics of electronic elements. In contrast, the errors in measured current values are proportional to the input current values.

Author Contributions

Funding

Conflicts of Interest

References

- Tsai, K.L.; Leu, F.Y.; You, I. Residence energy control system based on wireless smart socket and IoT. IEEE Access 2016, 4, 2885–2894. [Google Scholar] [CrossRef]

- Tompros, S.; Mouratidis, N.; Draaijer, M.; Foglar, A.; Hrasnica, H. Enabling applicability of energy saving applications on the appliances of the home environment. IEEE Netw. 2009, 23, 8–16. [Google Scholar] [CrossRef]

- Executive Order–Energy Efficient Standby Power Device. Available online: https://georgewbush-whitehouse.archives.gov/news/releases/2001/07/20010731-10.html (accessed on 19 October 2018).

- Archived Copy. Available online: https://web.archive.org/web/20110209212259/http://www.fypower.org/news/?p=1386 (accessed on 19 October 2018).

- Standby and Off Leaflet. Available online: https://web.archive.org/web/20111109020207/http://www.bis.gov.uk/assets/bispartners/nmo/docs/eup/leaflets/standby-and-off-leaflet.pdf (accessed on 19 October 2018).

- Lien, C.H.; Bai, Y.W.; Lin, M.B. Remote-controllable power outlet system for home power management. IEEE Trans. Consum. Electron. 2007, 53, 1634–1641. [Google Scholar] [CrossRef]

- Lien, C.H.; Chen, H.C.; Bai, Y.W.; Lin, M.B. Power monitoring and control for electric home appliances based on power line communication. In Proceedings of the 2008 IEEE Instrumentation and Measurement Technology Conference, Victoria, BC, Canada, 12–15 May 2008; IEEE: Piscataway, NJ, USA, 2008. [Google Scholar]

- Horvat, I.; Lukac, N.; Pavlovic, R.; Starcevic, D. Smart plug solution based on Bluetooth low energy. In Proceedings of the 2015 IEEE 5th International Conference on Consumer Electronics, Berlin, Germany, 6–9 September 2015; IEEE: Piscataway, NJ, USA, 2015. [Google Scholar]

- Morsali, H.; Shekarabi, S.M.; Ardekani, K.; Khayami, H.; Fereidunian, A.; Ghassemian, M.; Lesani, H. Smart plugs for building energy management systems. In Proceedings of the Iranian Conference on Smart Grids, Tehran, Iran, 24–25 May 2012; IEEE: Piscataway, NJ, USA, 2012. [Google Scholar]

- Hu, Q.R.; Li, F.X. Hardware design of smart home energy management system with dynamic price response. IEEE Trans. Smart Grid 2013, 4, 1878–1887. [Google Scholar] [CrossRef]

- Son, Y.S.; Pulkkinen, T.; Moon, K.; Kim, C. Home energy management system based on power line communication. IEEE Trans. Consum. Electron. 2010, 56, 1380–1386. [Google Scholar] [CrossRef]

- Apostolopoulos, P.A.; Tsiropoulou, E.E.; Papavassiliou, S. Demand response management in smart grid networks: A two-stage game-theoretic learning-based approach. Mob. Netw. Appl. 2018, 10. [Google Scholar] [CrossRef]

- Palensky, P.; Dietrich, D. Demand side management: Demand response, intelligent energy systems, and smart loads. IEEE Trans. Ind. Inf. 2011, 7, 381–388. [Google Scholar] [CrossRef]

- Lee, M.; Uhm, Y.; Kim, Y.; Kim, G.; Park, S. Intelligent power management device with middleware based living pattern learning for power reduction. IEEE Trans. Consum. Electron. 2009, 55, 2081–2089. [Google Scholar] [CrossRef]

- Han, J.; Lee, H.; Park, K.R. Remote-controllable and energy-saving room architecture based on ZigBee communication. IEEE Trans. Consum. Electron. 2009, 55, 264–268. [Google Scholar] [CrossRef]

- Yaowaluk, T.; Wanchalerm, P. A low-cost Wi-Fi smart plug with on-off and Energy Metering functions. In Proceedings of the 2016 13th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Chiang Mai, Thailand, 28 June–1 July 2016; IEEE: Piscataway, NJ, USA, 2016. [Google Scholar]

- Xu, A.A.; He, S.P. The wireless smart socket control system design. In Proceedings of the 2nd International Conference on Advanced Robotics and Mechatronics (ICARM), Hefei, China, 27–31 August 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Arduinoall Smart Plug Wi-Fi Kankunit Smart Plug 2015. Available online: http://www.arduinoall.com (accessed on 19 October 2018).

- Lazada OMG Smart Plug On/Off by 3G Wi-Fi Support an-droid&ios 2015. Available online: http://www.lazada.co.th (accessed on 19 October 2018).

- Choi, M.; Park, W.K.; Lee, I. Smart office energy-saving service using bluetooth low energy beacons and smart plugs. In Proceedings of the IEEE International Conference on Data Science and Data Intensive Systems, Sydney, Australia, 11–13 December 2015; IEEE: Piscataway, NJ, USA, 2015. [Google Scholar]

- Han, J.; Choi, C.S.; Park, W.K.; Lee, I.; Kim, S.H. Smart home energy management system including renewable energy based on ZigBee and PLC. IEEE Trans. Consum. Electron. 2014, 60, 198–202. [Google Scholar] [CrossRef]

- Bai, Y.W.; Hung, C.H. Remote power On/Off control and current measurement for home electric outlets based on a low-power embedded board and ZigBee communication. In Proceedings of the IEEE International Symposium on Consumer Electronics, Vilamoura, Portugal, 14–16 April 2008; IEEE: Piscataway, NJ, USA, 2008. [Google Scholar]

- Ahmed, M.S.; Mohamed, A.; Homod, R.Z.; Shareef, H.; Sabry, A.H.; bin Khalid, K. Smart plug prototype for monitoring electrical appliances in Home Energy Management System. In Proceedings of the IEEE Student Conference on Research and Development (SCOReD), Kuala Lumpur, Malaysia, 13–14 December 2015; IEEE: Piscataway, NJ, USA, 2015. [Google Scholar]

- Caramés, T.M.F. An intelligent power outlet system for the smart home of the internet of things. Int. J. Distrib. Sens. Netw. 2015, 11. [Google Scholar] [CrossRef]

- Blanco-Novoa, O.; Fernandez-Carames, TM.; Fraga-Lamas, P.; Castedo, L. An electricity price-aware open-source smart socket for the internet of energy. Sensors 2017, 17, 643. [Google Scholar] [CrossRef] [PubMed]

| Description | Voltage Transformer Specifications | Primary Resistors (Ω) | Secondary Resistor (Ω) | Amplification Coefficient (Av) | Reference Voltage (V) |

|---|---|---|---|---|---|

| Parameters | 2 mA:2 mA | 100 k×2 | 100 | 4.9 | 1.25 |

| Description | Current Transformer | Primary Resistor (Ω) | Secondary Resistor (Ω) | Amplification Coefficient (Av) | Reference Voltage (V) |

|---|---|---|---|---|---|

| Parameters | 5 A:2.5 mA | -- | 100 | 3.9 | 1.25 |

| Scenario | Input Voltage (V) | Load of the Host Jack (Ω) | Load of the Slave Jack (Ω) | Current in the Host Jack (A) | Current in the Slave Jack (A) |

|---|---|---|---|---|---|

| 1 | 220.00 | 100.00 | 100.00 | 2.23 | 2.25 |

| 2 | 220.00 | 100.00 | 200.00 | 2.23 | 1.11 |

| 3 | 220.00 | 100.00 | 0.00 | 2.22 | 0.00 |

| 4 | 220.00 | 200.00 | 100.00 | 1.11 | 2.23 |

| 5 | 220.00 | 200.00 | 200.00 | 1.11 | 1.11 |

| 6 | 220.00 | 200.00 | 0.00 | 1.10 | 0.00 |

| 7 | 220.00 | 0.00 | 100.00 | 0.00 | 0.00 |

| 8 | 220.00 | 0.00 | 200.00 | 0.00 | 0.00 |

| 9 | 220.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| 10 | 220.00 | 500.00 | 500.00 | 0.43 | 0.44 |

| Description | Operational Power (W) | Standby Power (W) | Daily Operating Hours (h) | Lifecycle Operational Cost (¥) | Lifecycle Standby Cost (¥) | |

|---|---|---|---|---|---|---|

| TV | 100.00 | 1.80 | 5.00 | 2190.00 | 149.80 | |

| TV receiver box | 10.00 | 9.20 | 5.00 | 219.00 | 765.60 | |

| Stereo system | 60.00 | 10.00 | 5.00 | 1314.00 | 832.20 | |

| Smart socket operational | 1.00 | 0.80 | 5.00 | 22.00 | 66.60 | |

| Total operational | 171.00 | 21.80 | 5.00 | 3745.00 | 1814.20 | |

| Smart socket embodied | 37.00 | |||||

| PCB (Printed Circuit Board) | 6.00 | |||||

| Components | 14.00 | |||||

| Shell and Packing | 5.00 | |||||

| Patch board | 12.00 | |||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, M.; Huang, B.; Wang, B.; Chen, J.; Liao, L. Development of an Energy-Efficient Smart Socket Based on STM32F103. Appl. Sci. 2018, 8, 2276. https://doi.org/10.3390/app8112276

Ma M, Huang B, Wang B, Chen J, Liao L. Development of an Energy-Efficient Smart Socket Based on STM32F103. Applied Sciences. 2018; 8(11):2276. https://doi.org/10.3390/app8112276

Chicago/Turabian StyleMa, Mei, Bin Huang, Bin Wang, Jian Chen, and Lida Liao. 2018. "Development of an Energy-Efficient Smart Socket Based on STM32F103" Applied Sciences 8, no. 11: 2276. https://doi.org/10.3390/app8112276

APA StyleMa, M., Huang, B., Wang, B., Chen, J., & Liao, L. (2018). Development of an Energy-Efficient Smart Socket Based on STM32F103. Applied Sciences, 8(11), 2276. https://doi.org/10.3390/app8112276