Inter-Laboratory Correlation Exercise with Portable Emissions Measurement Systems (PEMS) on Chassis Dynamometers

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Protocol

2.2. Golden Vehicle and Laboratories

- FCA Powertrain Engineering, Pomigliano d’Arco (NA)

- FCA Powertrain Engineering, Cento (FE)

- FCA Product Engineering, Sangone, Torino (TO)

- Ferrari SpA, Maranello (MO)

- Innovhub SSI-SSC, San Donato Milanese (MI)

- Joint Research Centre, Ispra (VA)

- Lamborghini SpA, S. Agata Bolognese (BO)

- Landi Renzo, Cavriago (RE).

2.3. Instrumentation

2.4. Calculations

3. Results

3.1. Absolute Emission Levels

3.2. PEMS Differences

4. Discussion

- The installation of the flowmeters is critical. Sudden curves, sharp bends or diameter changes can result in high errors. Additionally, uncertainties at idle and low flow rates can result in over-or underestimation of the CO2 (e.g., Reference [14]).

- The exhaust flow measurement uncertainty at idle can influence the CO2 results (for the other pollutants the effect is small because cars typically have low emissions at idle and low loads/speeds) [25,26]. The zero calibration should be conducted with the dilution tunnel operating in order to minimize any influence of the under-pressure created by the constant volume sampler (CVS). Investigations with “open” CVS (i.e., the flowmeter is connected to the tubing via a cone that permits ambient air also to enter) would minimize pressure and pulsations from the CVS and should be further investigated in order to evaluate the true performance of the flowmeter on the road.

- The difference of the PN results can be high: partly due to PEMS uncertainties, but mainly due to lower PN concentrations reaching the dilution tunnel (diffusion losses, thermophoretic losses, coagulation etc.) [22].

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Disclaimer

Appendix A

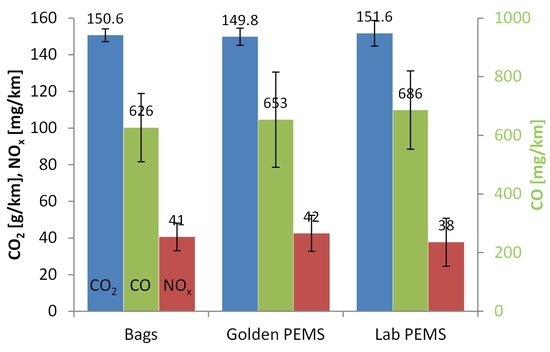

| CO2 | Bags | Golden PEMS | Lab PEMS |

|---|---|---|---|

| p | 8 | 7 | 5 |

| [g/km] | 150.6 | 149.8 | 151.6 |

| SR | 2.9% | 3.9% | 5.5% |

| SL | 2.4% | 3.2% | 5.5% |

| Sr | 1.6% | 2.2% | 0.6% |

| CO | Bags | Golden PEMS | Lab PEMS |

|---|---|---|---|

| p | 7 | 7 | 5 |

| [mg/km] | 626.3 | 653.3 | 686.0 |

| SR | 22% | 25% | 20% |

| SL | 18% | 21% | 17% |

| Sr | 13% | 14% | 11% |

| NOx | Bags | Golden PEMS | Lab PEMS |

|---|---|---|---|

| p | 8 | 7 | 4 |

| 40.5 | 42.5 | 41.7 | |

| SR | 23% | 25% | 31% |

| SL | 20% | 23% | 29% |

| Sr | 11% | 9% | 9% |

| PN | Tunnel | Golden PEMS | Lab PEMS |

|---|---|---|---|

| p | 4 | 6 | 4 |

| [particles/km] | 2.5 × 1011 | 3.2 × 1011 | 3.2 × 1011 |

| SR | 29% | 24% | 39% |

| SL | 15% | 13% | 30% |

| Sr | 25% | 21% | 25% |

References

- Berg, W. Legislation for the reduction of exhaust gas emissions. In The Handbook of Environmental Chemistry; 3(Part T); Springer: Berlin/Heidelberg, 2003; pp. 175–253. [Google Scholar]

- He, H.; Jin, L. A Historical Review of the U.S. Vehicle Emission Compliance Program and Emission Recall Cases; White paper; International Council on Clean Transportation: Washington, DC, USA, April 2017. [Google Scholar]

- Feist, M.; Sharp, C.; Spears, M. Determination of PEMS measurement allowances for gaseous emissions regulated under the heavy-duty diesel engine in-use testing program. Part 1—Project overview and PEMS evaluation procedures. SAE Int. J. Fuels Lubr. 2009, 2, 435–454. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Clairotte, M.; Valverde-Morales, V.; Bonnel, P.; Kregar, Z.; Franco, V.; Dilara, P. Framework for the assessment of PEMS (portable emissions measurement systems) uncertainty. Environ. Res. 2018, 166, 251–260. [Google Scholar] [CrossRef] [PubMed]

- RDE4 2018. Commission Regulation (EU) (Voted 3rd of May 2018) Amending Directive 2007/46/EC, Commission Regulation (EC) No 692/2008 and Commission Regulation (EU) 2017/1151 for the Purpose of Improving the Emission Type Approval Tests and Procedures for Light Passenger and Commercial Vehicles, Including Those for In-Service Conformity and Real-Driving Emissions and Introducing Devices for Monitoring the Consumption of Fuel and Electric Energy; Ares (2018)1297632; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- CEN/TC 301:2018. Road Vehicles. Portable Emission Measuring Systems (PEMS) Performance Assessment; Proposal for European Standard; European Committee for Standardization: Brussels, Belgium, 2018. [Google Scholar]

- ISO/IEC 17025:2017. General Requirements for the Competence of Testing and Calibration Laboratories; International Organization for Standardization: Geneva, Switzerland, 2017; Available online: https://www.iso.org/standard/66912.html (accessed on 16 November 2018).

- ISO/IEC 17020:2012. Conformity Assessment—Requirements for the Operation of Various Types of Bodies Performing Inspection; International Organization for Standardization: Geneva, Switzerland, 2012; Available online: https://www.iso.org/standard/52994.html (accessed on 16 November 2018).

- ISO/IEC 17043:2010. Conformity Assessment—General Requirements for Proficiency Testing; International Organization for Standardization: Geneva, Switzerland, 2010; Available online: https://www.iso.org/standard/29366.html (accessed on 16 November 2018).

- Mamakos, A.; Ntziachristos, L.; Samaras, Z. Comparability of particle emission measurements between vehicle testing laboratories: A long way to go. Meas. Sci. Technol. 2004, 15, 1855–1866. [Google Scholar] [CrossRef]

- Zervas, E.; Dorlhene, P.; Forti, L.; Perrin, C.; Momique, J.; Monier, R.; Ing, H.; Lopez, B. Inter-laboratory test of exhaust PM using ELPI. Aerosol Sci. Technol. 2005, 39, 333–346. [Google Scholar] [CrossRef]

- Zervas, E.; Dorlhene, P.; Forti, L.; Perrin, C.; Momique, J.; Monier, R.; Ing, H.; Lopez, B. Inter-laboratory study of the exhaust gas particle number measurements using the condensation particle counter (CPC). Energy Fuels 2006, 20, 2426–2431. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Dilara, P.; Andersson, J. Particle measurement programme (PMP) light-duty inter-laboratory exercise: Repeatability and reproducibility of the particle number method. Aerosol Sci. Technol. 2008, 42, 528–543. [Google Scholar] [CrossRef]

- Riccobono, F.; Giechaskiel, B.; Mendoza, P. Particle Number PEMS Inter-Laboratory Comparison Exercise: Performance of PN-PEMS for the Extension of the RDE Test Procedure to PN; JRC report EUR 28136 EN; Publication Office for the European Union: Luxembourg, 2016. [Google Scholar]

- Haniu, T.; Vallaude, C. Asian and European WLTP RRT. In Proceedings of the WLTP 19th Meeting, Geneva, Switzerland, 6 June 2017. [Google Scholar]

- Commission Regulation (EU). Commission Regulation (EU) 2017/1151 of 1 June 2017 supplementing Regulation (EC) No 715/2007 of the European Parliament and of the Council on type approval of motor vehicles with respect to emissions from light passenger and commercial vehicles (Euro 5 and Euro 6) and on access to vehicle repair and maintenance information, amending Directive 2007/46/EC of the European Parliament and of the Council, Commission Regulation (EC) No 692/2008 and Commission Regulation (EU) No 1230/2012 and repealing Commission Regulation (EC) No 692/2008. Off. J. Eur. Un. 2017, L175/1, 639. [Google Scholar]

- Commission Regulation (EU). Commission Regulation (EU) 2017/1154 of 7 June 2017 amending Regulation (EU) 2017/1151 supplementing Regulation (EC) No 715/2007 of the European Parliament and of the Council on type-approval of motor vehicles with respect to emissions from light passenger and commercial vehicles (Euro 5 and Euro 6) and on access to vehicle repair and maintenance information, amending Directive 2007/46/EC of the European Parliament and of the Council, Commission Regulation (EC) No 692/2008 and Commission Regulation (EU) No 1230/2012 and repealing Regulation (EC) No 692/2008 and Directive 2007/46/EC of the European Parliament and of the Council as regards real-driving emissions from light passenger and commercial vehicles (Euro 6). Off. J. Eur. Un. 2017, L175, 708–732. [Google Scholar]

- Nakamura, H.; Kihara, N.; Adachi, M.; Ishida, K. Development of a Wet-Based NDIR and Its Application to On-Board Emission Measurement System; SAE technical paper, Paper 2002-01-0612; Society of Automotive Engineers, Inc.: Detroit, MI, USA, 2002. [Google Scholar]

- Nakamura, H.; Akard, M.; Porter, S.; Kihara, N.; Adachi, M.; Khalek, I. Performance Test Results of a New On-Board Emission Measurement System Conformed with CFR Part 1065; SAE Technical Paper, 2007-01-1326; Society of Automotive Engineers, Inc.: Detroit, MI, USA, 2007. [Google Scholar]

- Kim, S.; Kondo, K.; Otsuki, Y.; Haruta, K. A New On-Board PN Analyzer for Monitoring the Real-Driving Condition; SAE Technical Paper, 2017-01-1001; Society of Automotive Engineers, Inc.: Detroit, MI, USA, 2007. [Google Scholar]

- Cao, T.; Durbin, T.; Cocker, D., III; Wanker, R.; Schimpl, T.; Pointner, V.; Oberguggenberger, K.; Johnson, K. A comprehensive evaluation of a gaseous portable emissions measurement system with a mobile laboratory. Emiss. Control Sci. Technol. 2016, 2, 173–180. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Riccobono, F.; Bonnel, P. Feasibility Study on the Extension of the Real Driving Emissions (RDE) Procedure to Particle Number (PN): Experimental Evaluation of Portable Emission Measurement Systems (PEMS) with Diffusion Chargers (DCs) to Measure Particle Number (PN) Concentration Chassis Dynamometer Evaluation of Portable Emission Measurement Systems (PEMS) to Measure Particle Number (PN) Concentration: Phase II; JRC report EUR 27451 EN; Publication Office for the European Union: Luxembourg, 2015. [Google Scholar]

- ISO 5725–2:1994. Accuracy (Trueness and Precision) of Measurement Methods and Results—Part 2: Basic Method for the Determination of Repeatability and Reproducibility of a Standard Measurement Method; International Organization for Standardization: Geneva, Switzerland, 1994. [Google Scholar]

- Joumard, R.; Laurikko, J.; Han, T.; Geivanidis, S.; Samaras, Z.; Merétei, T.; Devaux, P.; André, J.; Cornelis, E.; Lacour, S.; et al. Accuracy of exhaust emission factor measurements on chassis dynamometer. J. Air Waste Manag. Assoc. 2009, 59, 695–703. [Google Scholar] [CrossRef] [PubMed]

- Cappiello, A.; Chabini, I.; Nam, E.; Luè, A.; Abou Zeid, M. A statistical model of vehicle emissions and fuel consumption. In Proceedings of the IEEE 5th International Conference on Intelligent Transportation Systems, Singapore, 3–6 September 2002; pp. 801–809. [Google Scholar] [CrossRef]

- Varella, R.; Giechaskiel, B.; Sousa, L.; Duarte, G. Comparison of portable emissions measurement systems (PEMS) with laboratory grade equipment. Appl. Sci. 2018, 8, 1633. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Schwelberger, M.; Delacroix, C.; Marchetti, M.; Feijen, M.; Prieger, K.; Andersson, S.; Karlsson, H. Experimental assessment of solid particle number portable emissions measurement systems (PEMS) for heavy-duty vehicles applications. J. Aerosol Sci. 2018, 123, 161–170. [Google Scholar] [CrossRef]

| Laboratory | Golden PEMS | Laboratory PEMS | Comment |

|---|---|---|---|

| A | Yes | AVL MOVE (2 inches) | RDE |

| B | No | AVL MOVE (2 inches) | |

| C | Yes | Horiba OBS-ONE (2 inches) | RDE |

| D | Yes | No | |

| E | Yes | AVL MOVE (2.5 inches) | |

| F | Yes | No | |

| G | Yes | No | |

| H | Yes | AVL MOVE (2.5 inches) | |

| 8 Labs | 7 Labs | 5 Labs | 2 Labs |

| 13 Labs (No PEMS) | 8 Labs (No PEMS) | 8 Labs (with PEMS) | 5 Labs (No PEMS) | |

|---|---|---|---|---|

| Laboratories | 13 | 8 | 8 | 5 |

| Mean value [g/km] | 149.2 | 149.6 | 150.6 | 149.1 |

| Reproducibility | 2.3% | 2.1% | 2.9% | 2.1% |

| Repeatability | 1.7% | 0.8% | 1.6% | 1.1% |

| Emission Level | CO2 | CO | NOx | PN | Comments |

|---|---|---|---|---|---|

| Euro 3 1 | 1.8 | 7 | 24 | 30 | 4 labs, NEDC [11] |

| Euro 4 1,2 | 2.0 | 5 | 18 | 44 | 4 labs, NEDC [12] |

| Euro 3 | 5.0 | 40 | 40 | - | 9 labs, many cycles [24] |

| Euro 6 | 1.6 | 15 | 29 | 9 | 11 EU labs, WLTC [15] |

| Euro 6 eq. | 1.3 | 12 | 24 | - | 16 Asian labs, WLTC [15] |

| Euro 5 3 | 2.1 | - | 37 | 22 | 7 labs, WLTC [14] |

| 2.4 | - | 36 | 20 | 7 labs, 1 Golden PEMS | |

| Euro 6 | 2.9 | 22 | 23 | 29 | 8 labs, WLTC, this study |

| 3.9 | 25 | 25 | 24 | 7 labs, 1 Golden PEMS | |

| 5.5 | 20 | 31 | 39 | 5 labs, 5 Lab PEMS |

| Emission Level | CO2 | CO | NOx | PN | Comments |

|---|---|---|---|---|---|

| Euro 5 | +7.1% (3.6%) | - | +1.5% (15%) | +6% (20%) | 1 Golden PEMS [14] |

| Euro 6 | −1.0% (4.0%) | −0.7 (14%) | +2.0% (9%) | +36% (32%) | 1 Golden PEMS |

| +0.9% (3.4%) | +1.5% (13%) | +11.3% (18%) | +41% (33%) | 5 Lab PEMS |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giechaskiel, B.; Casadei, S.; Mazzini, M.; Sammarco, M.; Montabone, G.; Tonelli, R.; Deana, M.; Costi, G.; Di Tanno, F.; Prati, M.V.; et al. Inter-Laboratory Correlation Exercise with Portable Emissions Measurement Systems (PEMS) on Chassis Dynamometers. Appl. Sci. 2018, 8, 2275. https://doi.org/10.3390/app8112275

Giechaskiel B, Casadei S, Mazzini M, Sammarco M, Montabone G, Tonelli R, Deana M, Costi G, Di Tanno F, Prati MV, et al. Inter-Laboratory Correlation Exercise with Portable Emissions Measurement Systems (PEMS) on Chassis Dynamometers. Applied Sciences. 2018; 8(11):2275. https://doi.org/10.3390/app8112275

Chicago/Turabian StyleGiechaskiel, Barouch, Simone Casadei, Michele Mazzini, Mario Sammarco, Gisella Montabone, Roberto Tonelli, Mauro Deana, Giovanni Costi, Francesco Di Tanno, Maria Vittoria Prati, and et al. 2018. "Inter-Laboratory Correlation Exercise with Portable Emissions Measurement Systems (PEMS) on Chassis Dynamometers" Applied Sciences 8, no. 11: 2275. https://doi.org/10.3390/app8112275

APA StyleGiechaskiel, B., Casadei, S., Mazzini, M., Sammarco, M., Montabone, G., Tonelli, R., Deana, M., Costi, G., Di Tanno, F., Prati, M. V., Clairotte, M., & Di Domenico, A. (2018). Inter-Laboratory Correlation Exercise with Portable Emissions Measurement Systems (PEMS) on Chassis Dynamometers. Applied Sciences, 8(11), 2275. https://doi.org/10.3390/app8112275