Effect of Yttrium on Microstructure and Magnetocaloric Properties in La1−xYxFe11.5Si1.5 Compounds

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

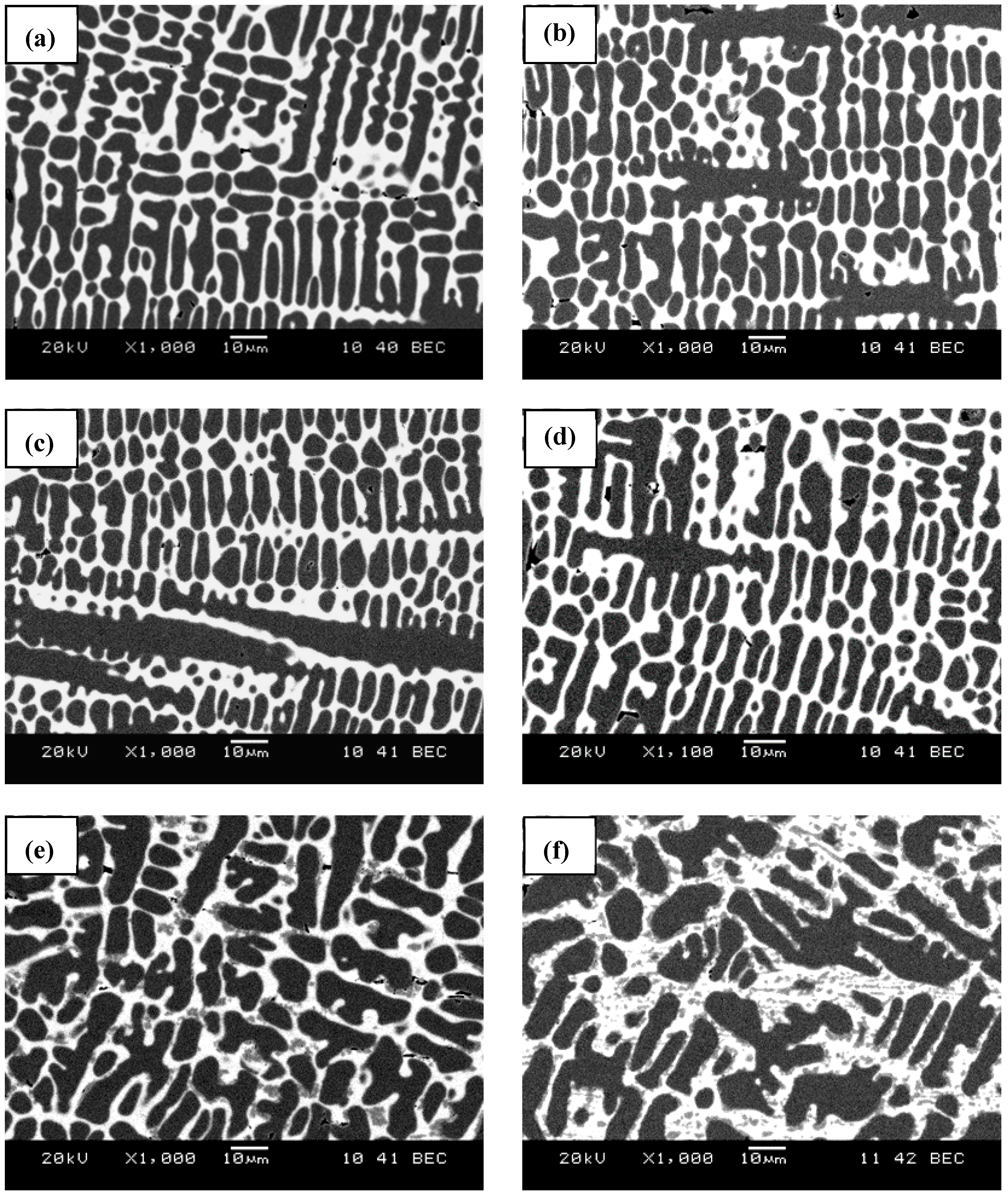

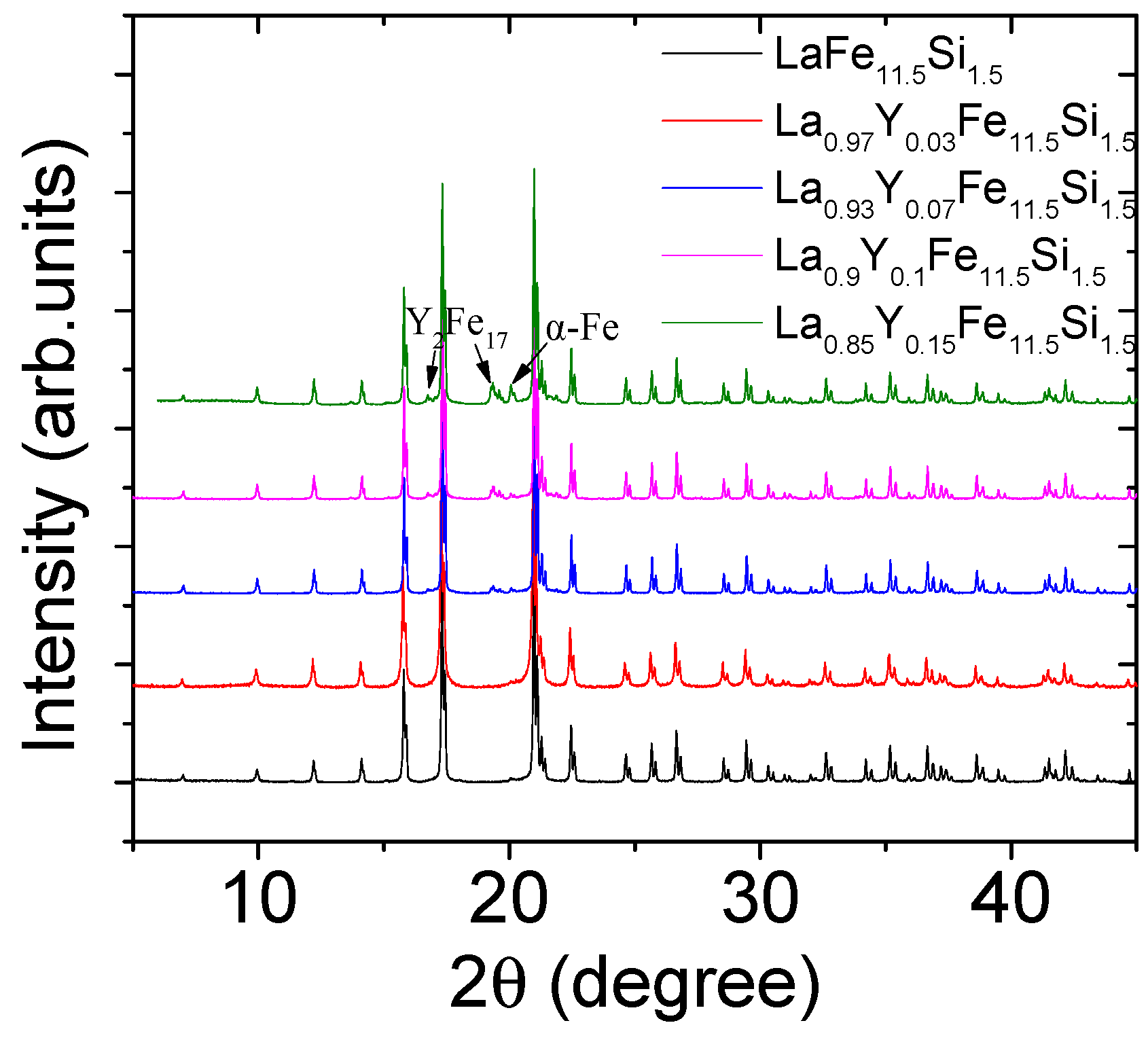

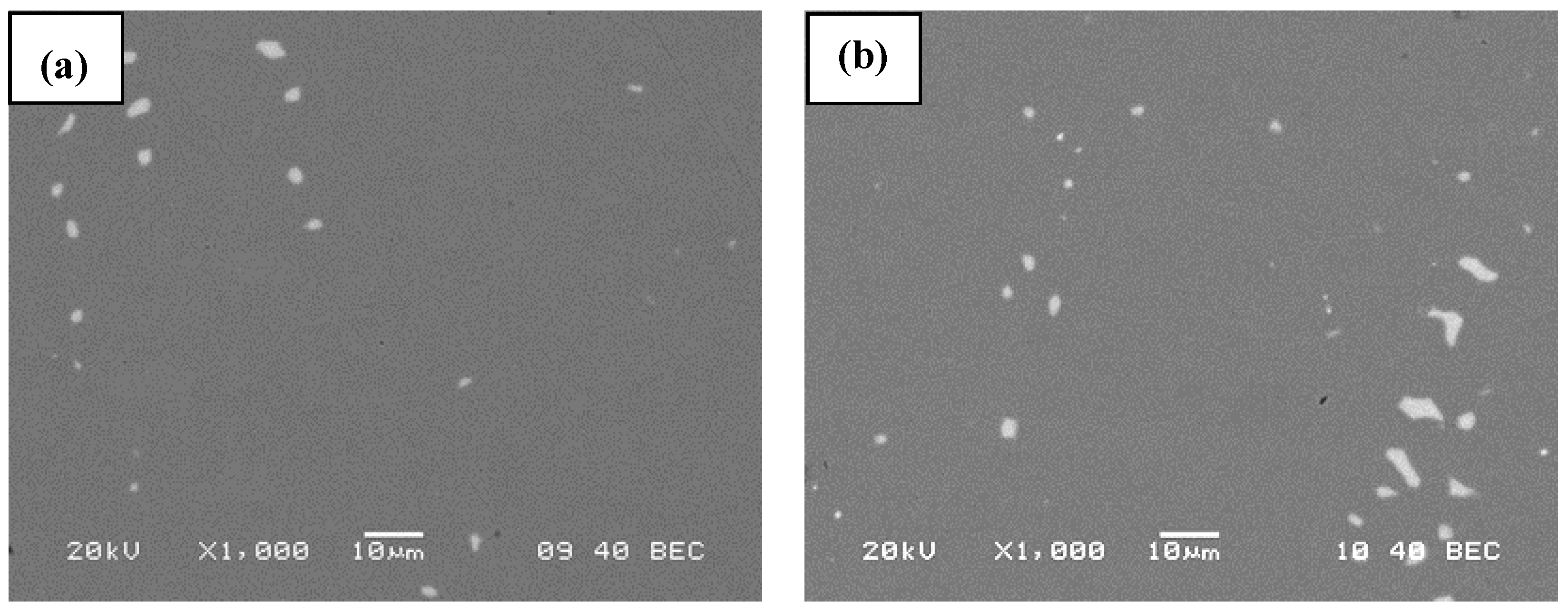

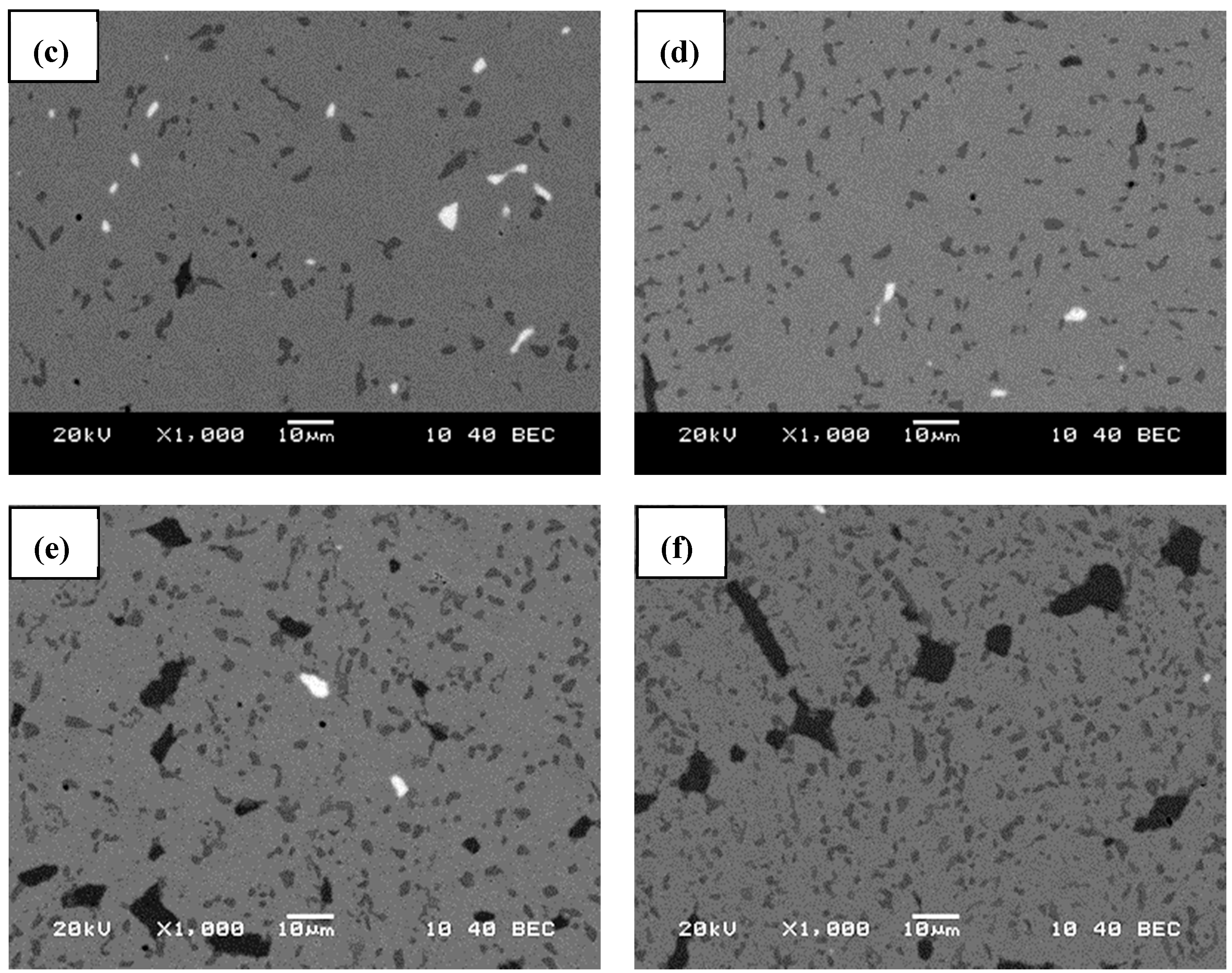

3.1. Crystal Structure and Morphologies

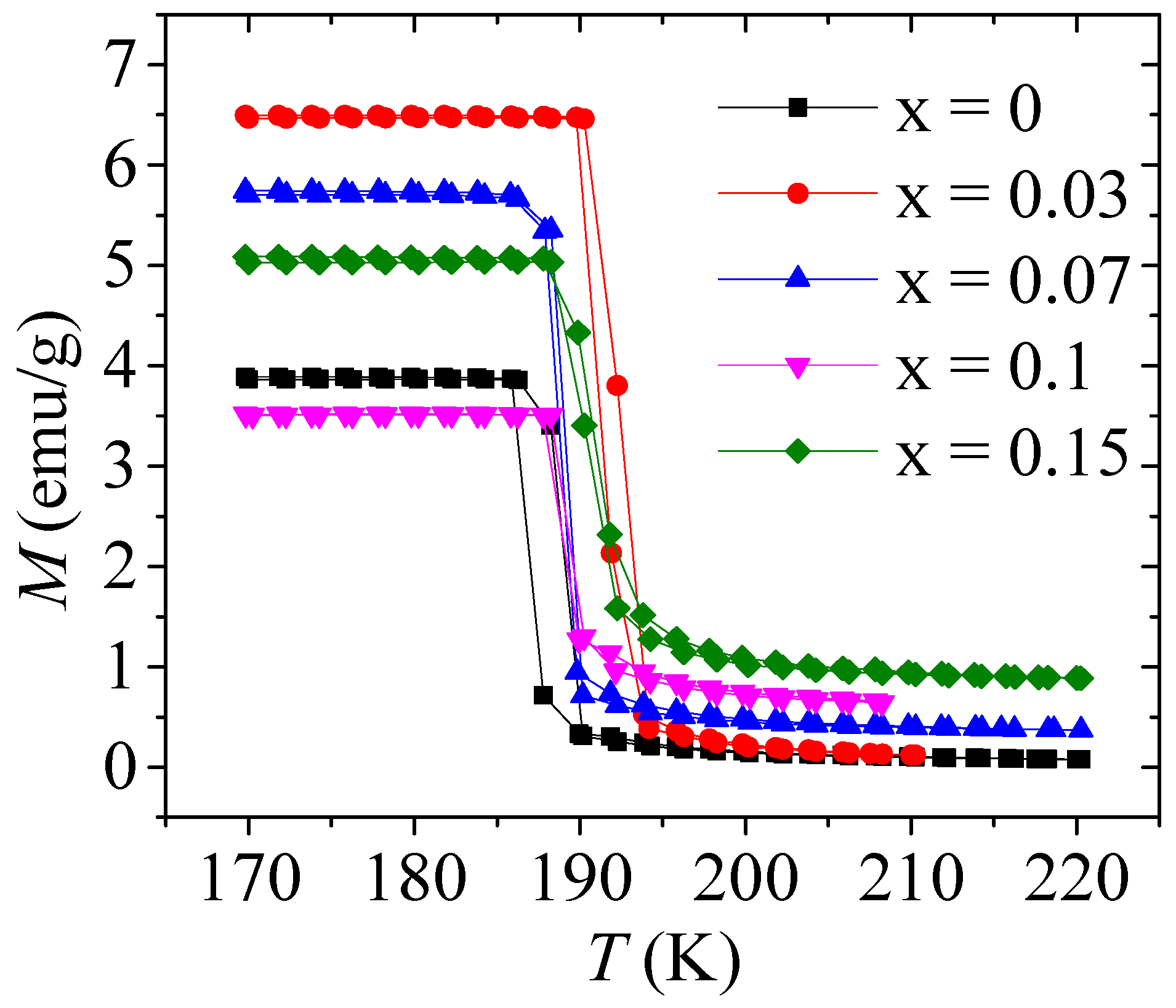

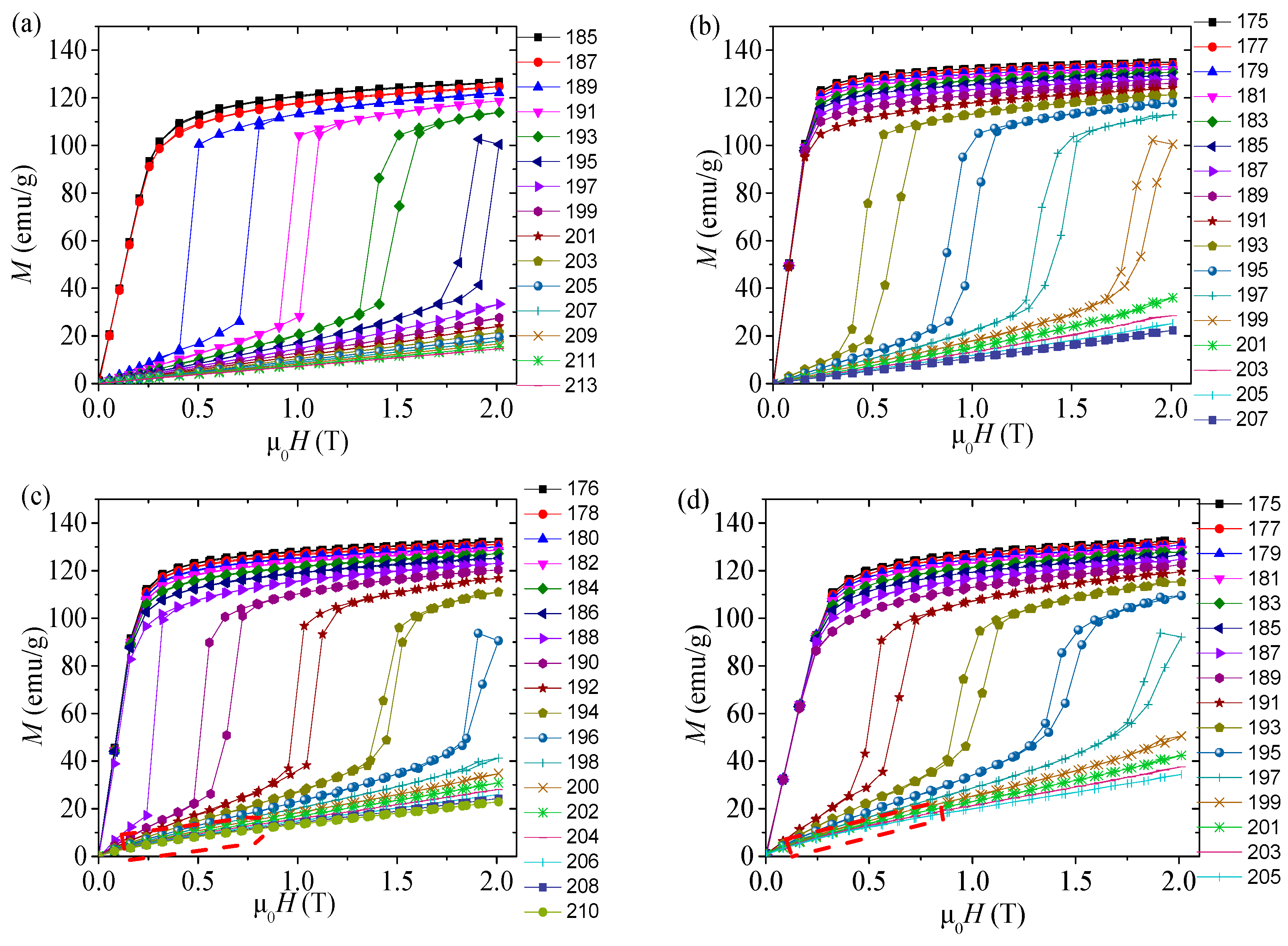

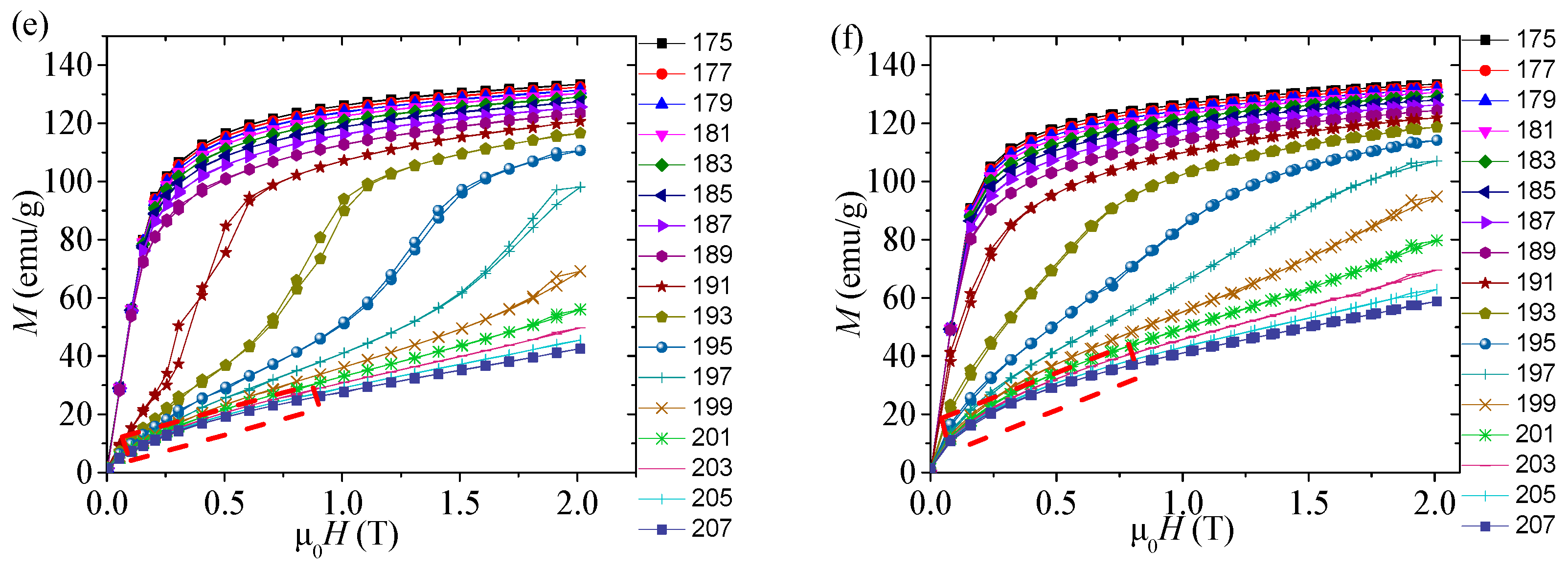

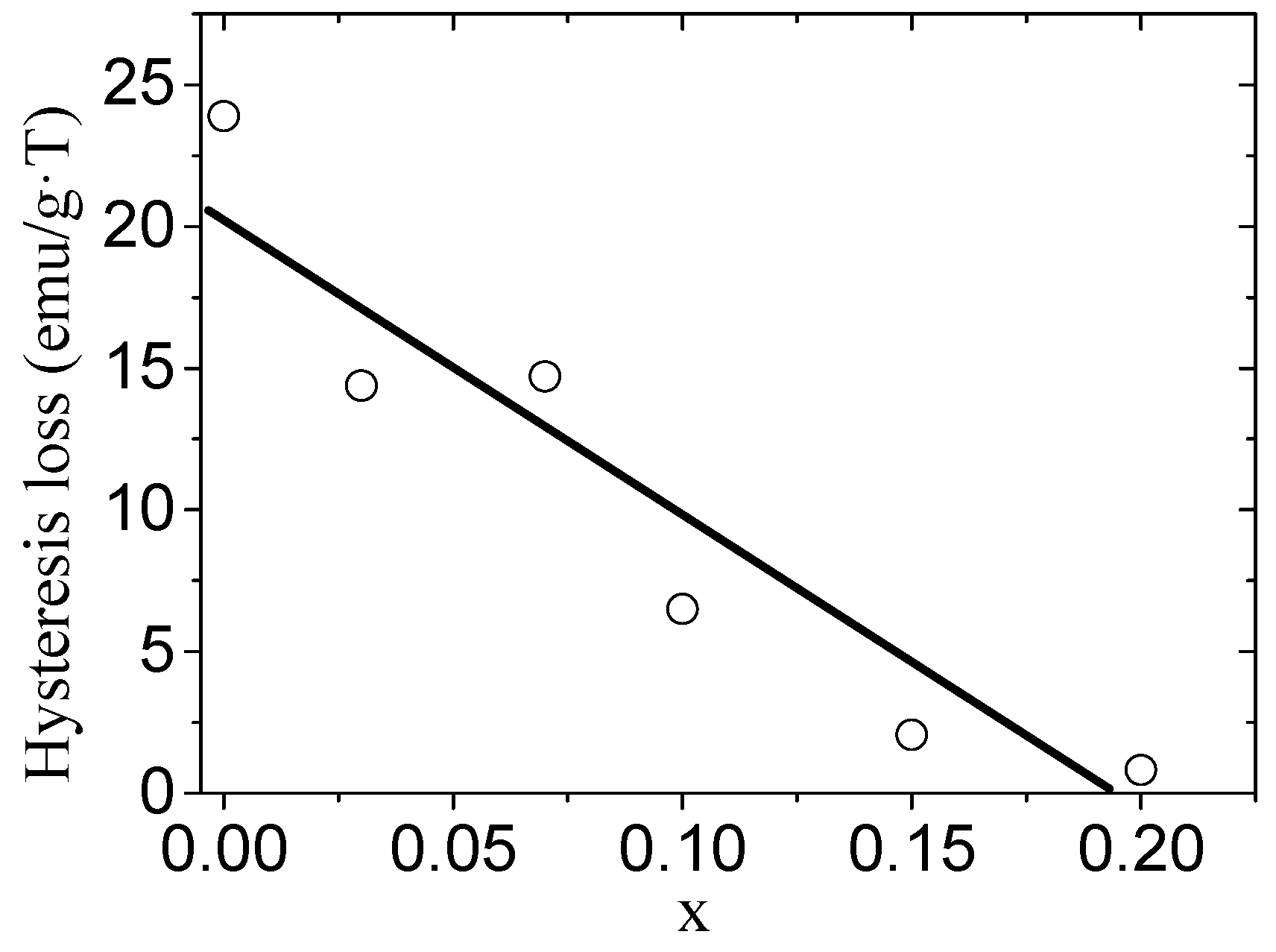

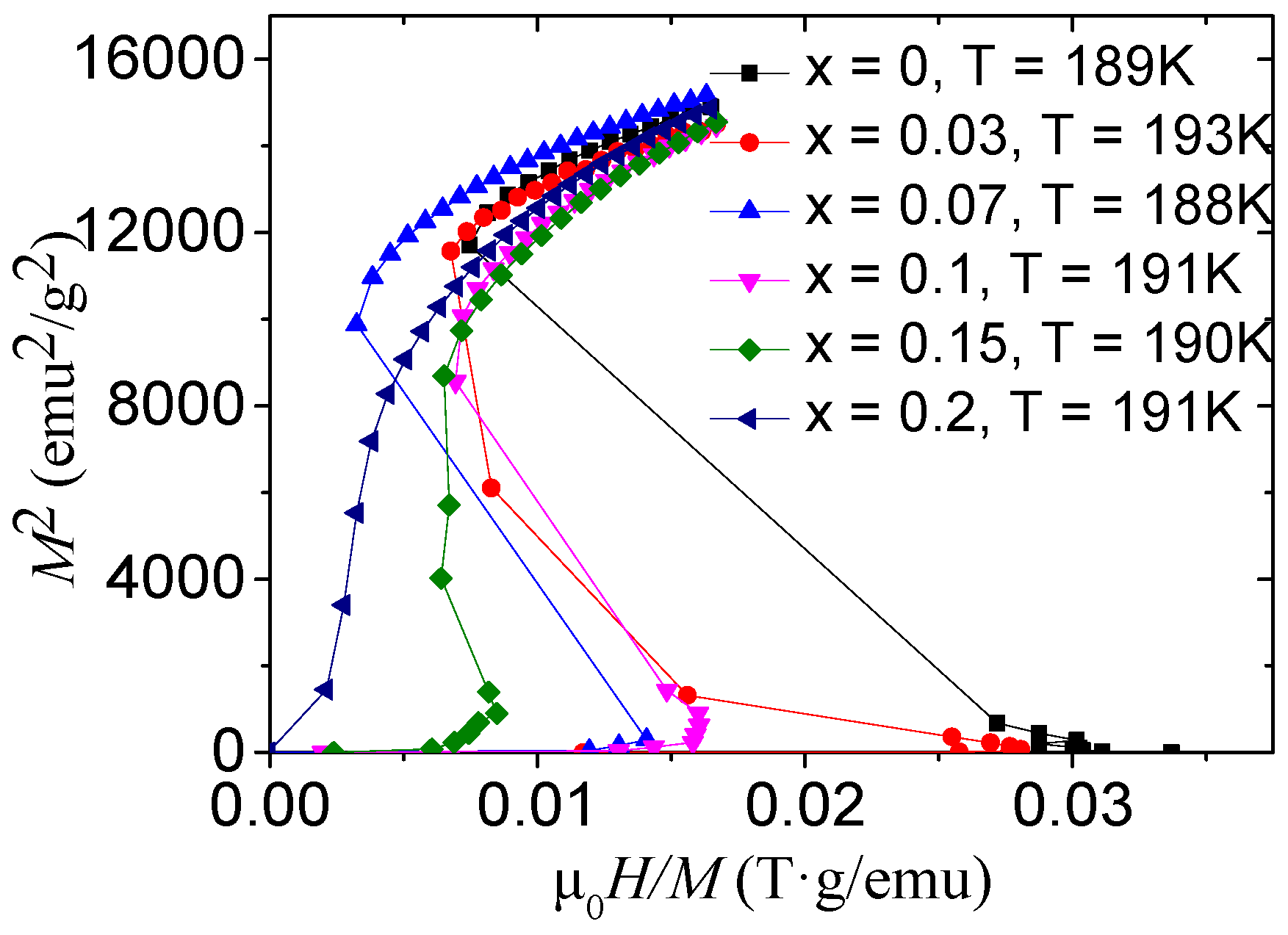

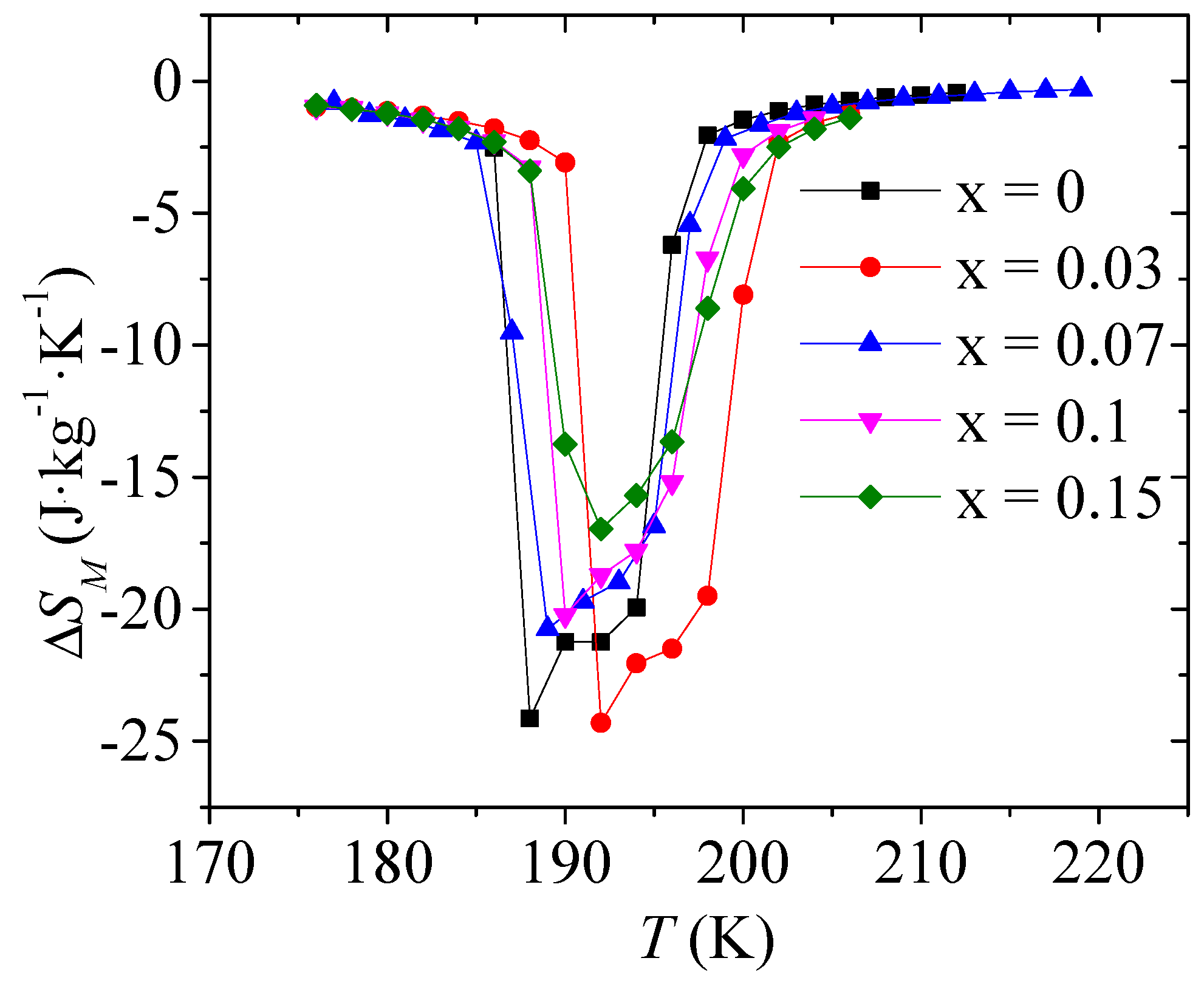

3.2. Magnetic Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| μ0 | Magnetic constant (T·m/A) |

| μ0H | Magnetic field (T) |

| M | Magnetization (emu/g) |

| ΔSM | Mass specific isothermal entropy change (J·kg−1·K−1) |

| T | Temperature (K) |

| TC | Curie temperature (K) |

| ΔTad | Adiabatic temperature change (K) |

References

- Hu, F.X.; Shen, B.G.; Sun, J.R.; Zhang, X.X. Great magnetic entropy change in La(Fe, M)13 (M = Si, Al) with Co doping. Chin. Phys. 2000, 9, 550–553. [Google Scholar]

- Fujita, A.; Yako, H. Kinetics of thermally induced first-order magnetic transition in La(Fe0.88Si0.12)13 itinerant electron meta-magnet. J. Alloys Compd. 2013, 577, 48–51. [Google Scholar] [CrossRef]

- Moya, X.; Kar-Narayan, S.; Mathur, D. Caloric materials near ferroic phase transitions. Nat. Mater. 2014, 13, 439–450. [Google Scholar] [CrossRef] [PubMed]

- Aprea, C.; Greco, A.; Maiorino, A.; Masselli, C. Solid-state refrigeration: A comparison of the energy performances of caloric materials operating in an active caloric regenerator. Energy 2018, 165, 439–455. [Google Scholar] [CrossRef]

- Brey, W.; Nellis, G.; Klein, S. Thermodynamic modeling of magnetic hysteresis in AMRR cycles. Int. J. Refrig. 2014, 47, 85–97. [Google Scholar] [CrossRef]

- Skokov, K.P.; Müller, K.H.; Moore, J.D.; Liu, J.; Karpenkov, A.Y.; Krautz, M.; Gutfleisch, O. Influence of thermal hysteresis and field cycling on the magnetocaloric effect in LaFe11.6Si1.4. J. Alloys Compd. 2013, 552, 310–317. [Google Scholar] [CrossRef]

- Moya, X.; Defay, E.; Heine, V.; Mathur, D. Too cool to work. Nat. Phys. 2015, 11, 202–205. [Google Scholar] [CrossRef]

- Franco, V.; Blázquez, J.S.; Ipus, J.J.; Law, J.Y.; Moreno-Ramírez, L.M.; Conde, A. Magnetocaloric effect: From materials research to refrigeration devices. Prog. Mater. Sci. 2017, 93, 112–232. [Google Scholar] [CrossRef]

- Gębara, P.; Pawlik, P. Broadening of temperature working range in magnetocaloric La(Fe, Co, Si)13-based multicomposite. J. Magn. Magn. Mater. 2017, 442, 145–151. [Google Scholar] [CrossRef]

- Zong, S.T.; Ni, Z.Y.; Long, Y.; Xue, J.N.; Wang, Y.X. The effect of segregation on the Curie temperature in large-sized La-Fe-Co-Si alloys. J. Magn. Magn. Mater. 2018, 461, 111–115. [Google Scholar] [CrossRef]

- Hu, F.X.; Chen, L.; Wang, J.; Bao, L.F.; Sun, J.R.; Shen, B.G. Particle size dependent hysteresis loss in La0.7Ce0.3Fe11.6Si1.4C0.2 first order systems. Appl. Phys. Lett. 2012, 100, 072403. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, F.; Shen, B.; Wang, G.J.; Sun, J.R. Magnetism and magnetic entropy change of LaFe11.6Si1.4Cx (x = 0–0.6) interstitial compounds. J. Appl. Phys. 2003, 93, 1323–1325. [Google Scholar] [CrossRef]

- Zong, S.T.; Wang, C.L.; Long, Y.; Fu, B.; Shi, J.M.; Han, J. Solid solubility in 1:13 phase of doping element for La(Fe, Si)13 alloys. AIP Adv. 2016, 6, 056223. [Google Scholar] [CrossRef]

- Luis, M.; Moreno-Ramírez, C.; Romero-Muniz, L.M.; Law, J.Y.; Franco, V.; Conde, A.; Radulov, I.A.; Maccari, F.; Skokov, K.P.; Gutfleisch, O. The role of Ni in modifying the order of the phase transition of La(Fe, Ni, Si)13. Acta Mater. 2018, 160, 137–146. [Google Scholar] [CrossRef]

- Kaeswurm, B.; Franco, V.; Skokov, K.P.; Gutfleisch, O. Assessment of the magnetocaloric effect in La, Pr(Fe, Si) under cycling. J. Magn. Magn. Mater. 2016, 406, 259–265. [Google Scholar] [CrossRef]

- Shen, J.; Li, Y.X.; Sun, J.R.; Shen, B.G. Effect of R substitution on magnetic properties and magnetocaloric effects of La1−xRxFe11.5Si1.5 compounds with R = Ce, Pr and Nd. Chin. Phys. B 2009, 18, 2058–2062. [Google Scholar]

- Pecharsky, V.K.; Gschneidner, K.A., Jr. Magnetocaloric effect from indirect measurements: Magnetization and heat capacity. J. Appl. Phys. 1999, 86, 565–575. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Xue, J.; Liu, C.; Zhou, H.; Long, Y. Effect of Yttrium on Microstructure and Magnetocaloric Properties in La1−xYxFe11.5Si1.5 Compounds. Appl. Sci. 2018, 8, 2198. https://doi.org/10.3390/app8112198

Wu Y, Xue J, Liu C, Zhou H, Long Y. Effect of Yttrium on Microstructure and Magnetocaloric Properties in La1−xYxFe11.5Si1.5 Compounds. Applied Sciences. 2018; 8(11):2198. https://doi.org/10.3390/app8112198

Chicago/Turabian StyleWu, Yuanyuan, Jianing Xue, Chang Liu, He Zhou, and Yi Long. 2018. "Effect of Yttrium on Microstructure and Magnetocaloric Properties in La1−xYxFe11.5Si1.5 Compounds" Applied Sciences 8, no. 11: 2198. https://doi.org/10.3390/app8112198

APA StyleWu, Y., Xue, J., Liu, C., Zhou, H., & Long, Y. (2018). Effect of Yttrium on Microstructure and Magnetocaloric Properties in La1−xYxFe11.5Si1.5 Compounds. Applied Sciences, 8(11), 2198. https://doi.org/10.3390/app8112198