Scheduling of Crude Oil Operations in Refinery without Sufficient Charging Tanks Using Petri Nets

Abstract

:1. Introduction

2. Refinery Process and Short-Term Scheduling

2.1. Crude Oil Operations in Refinery

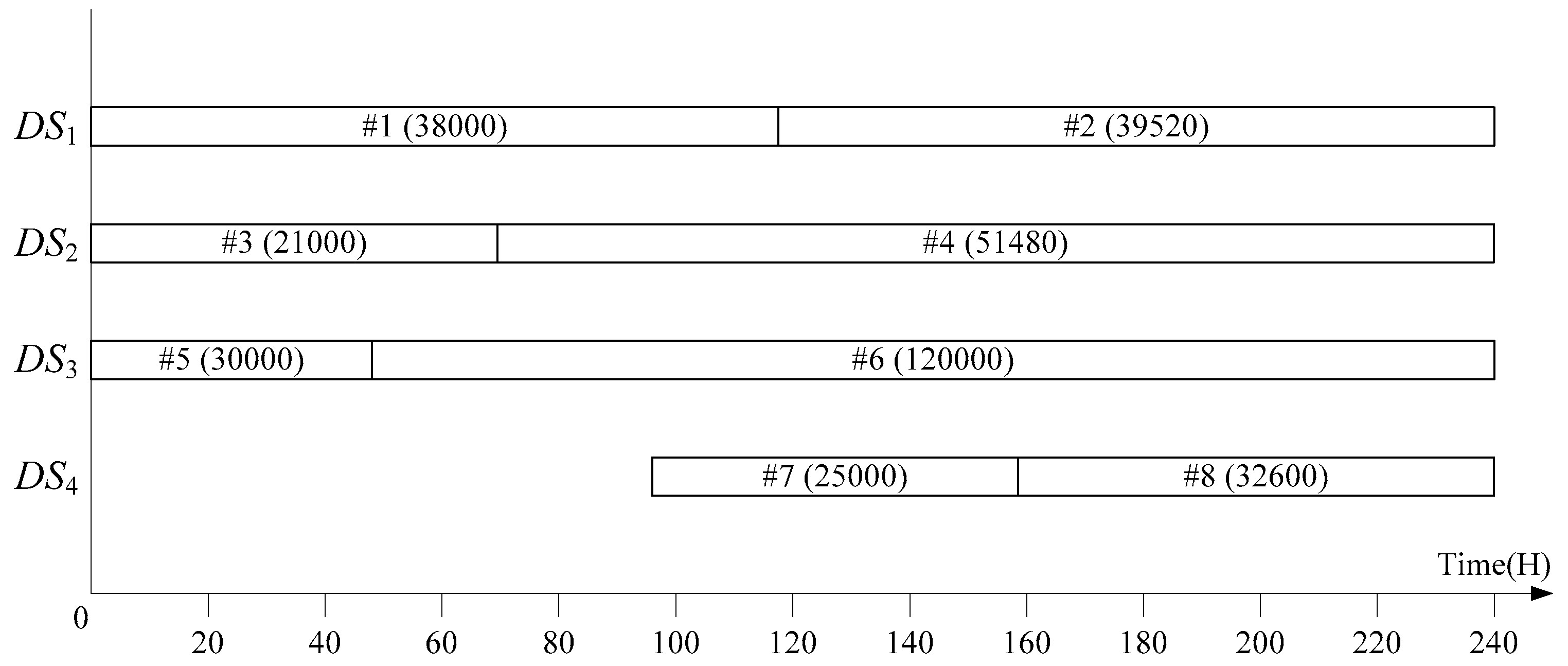

2.2. The Scheduling Problem

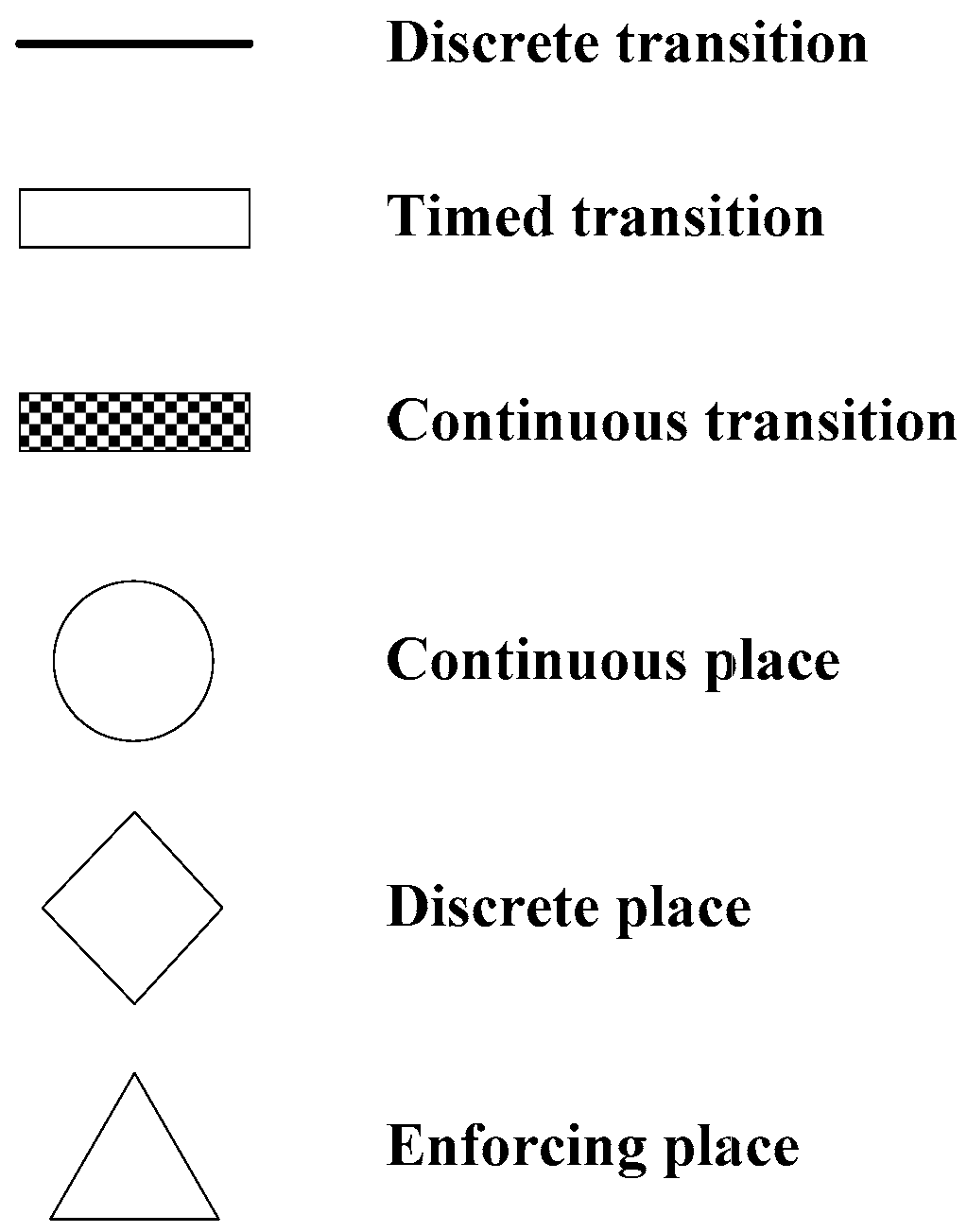

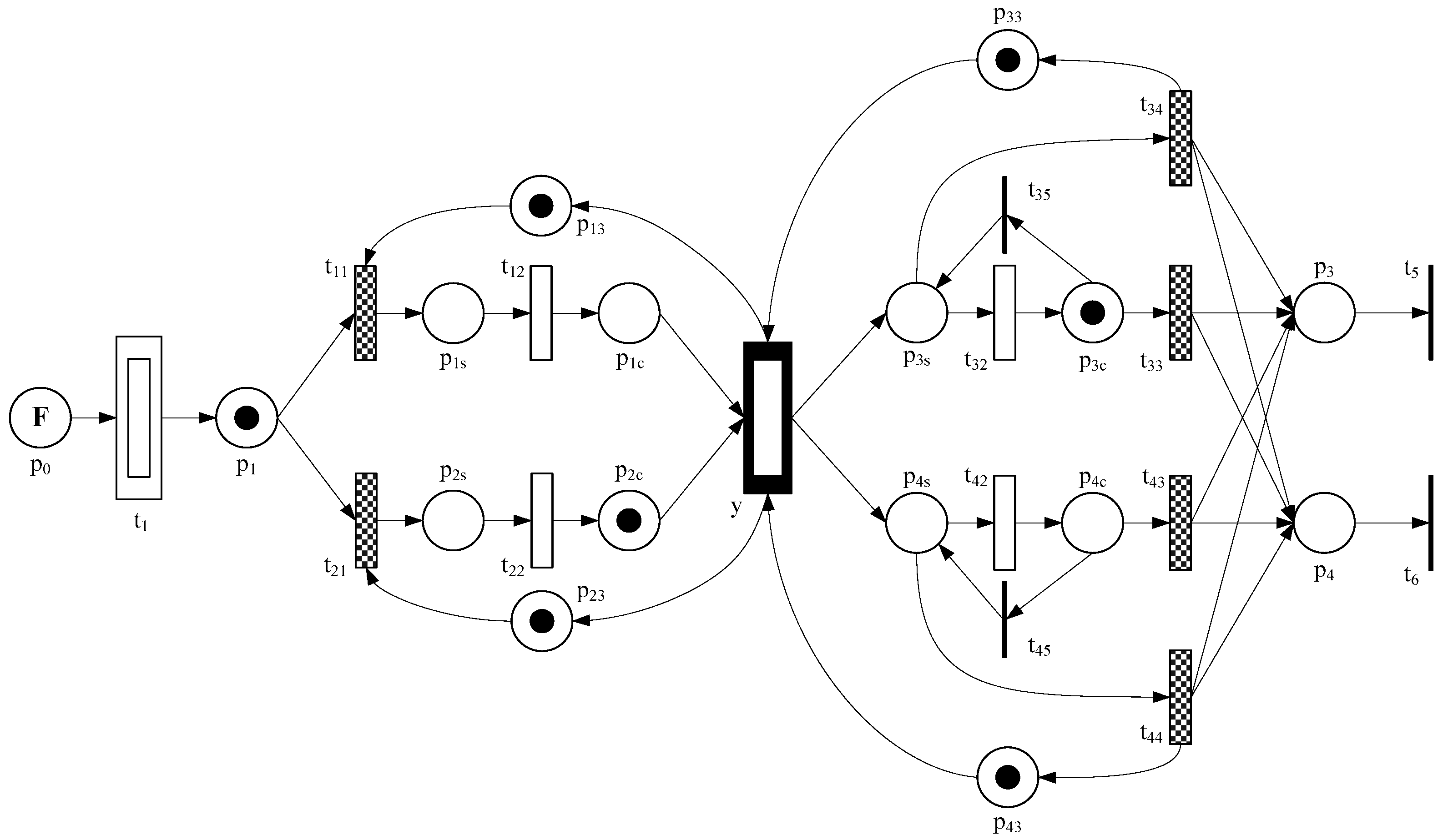

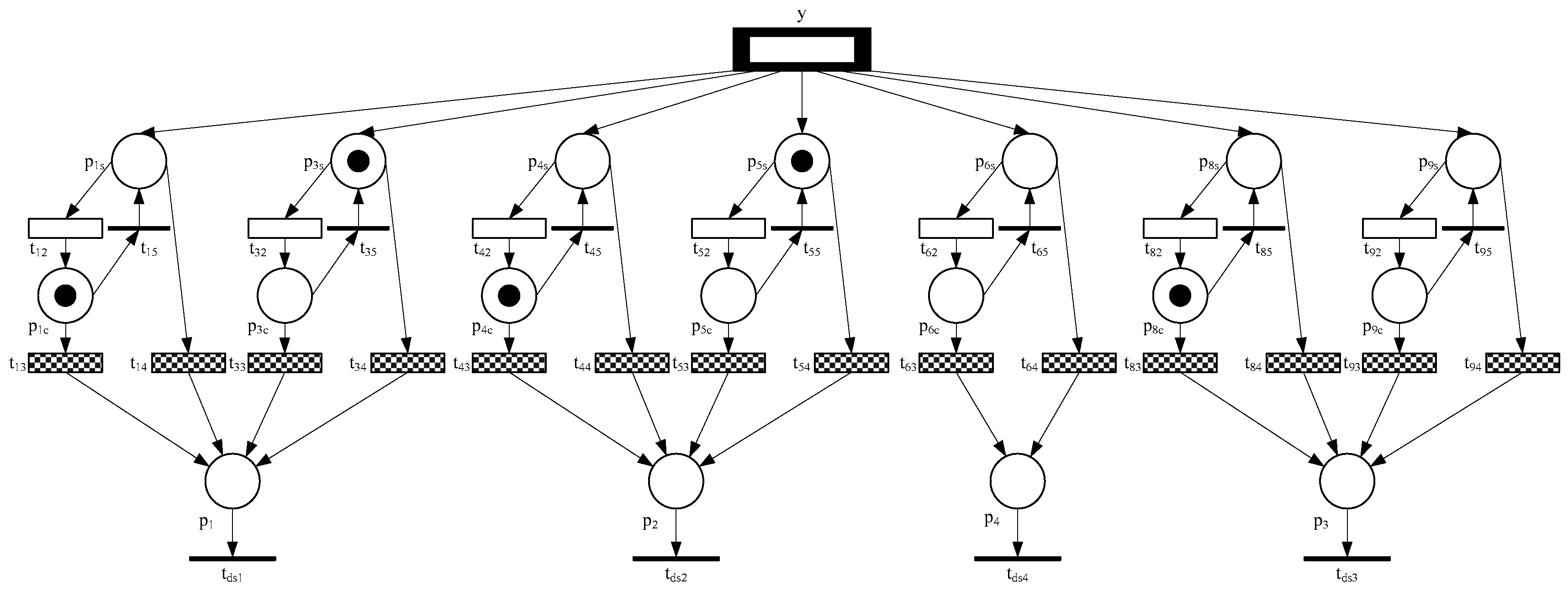

3. System Modeling with Petri Nets

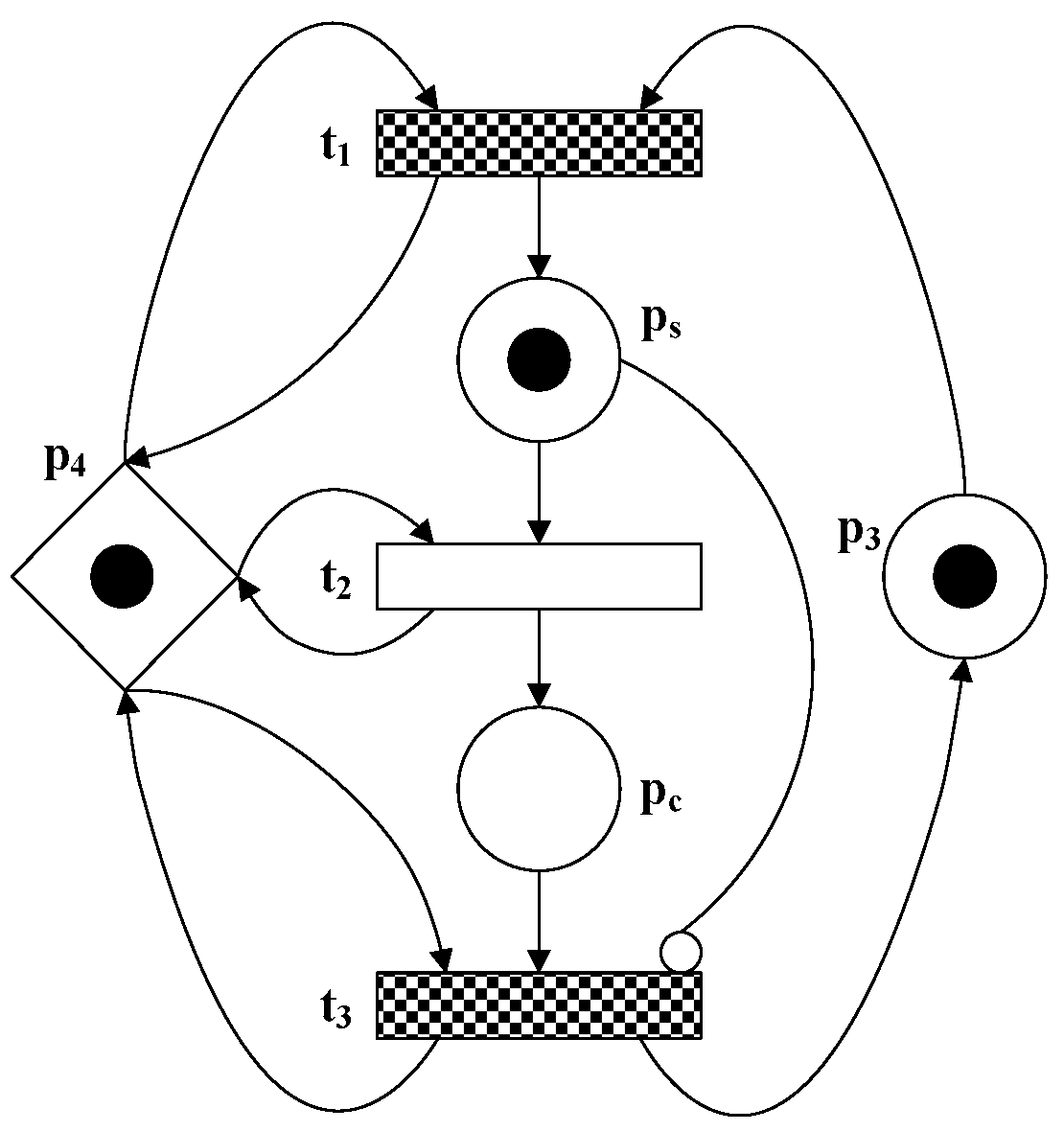

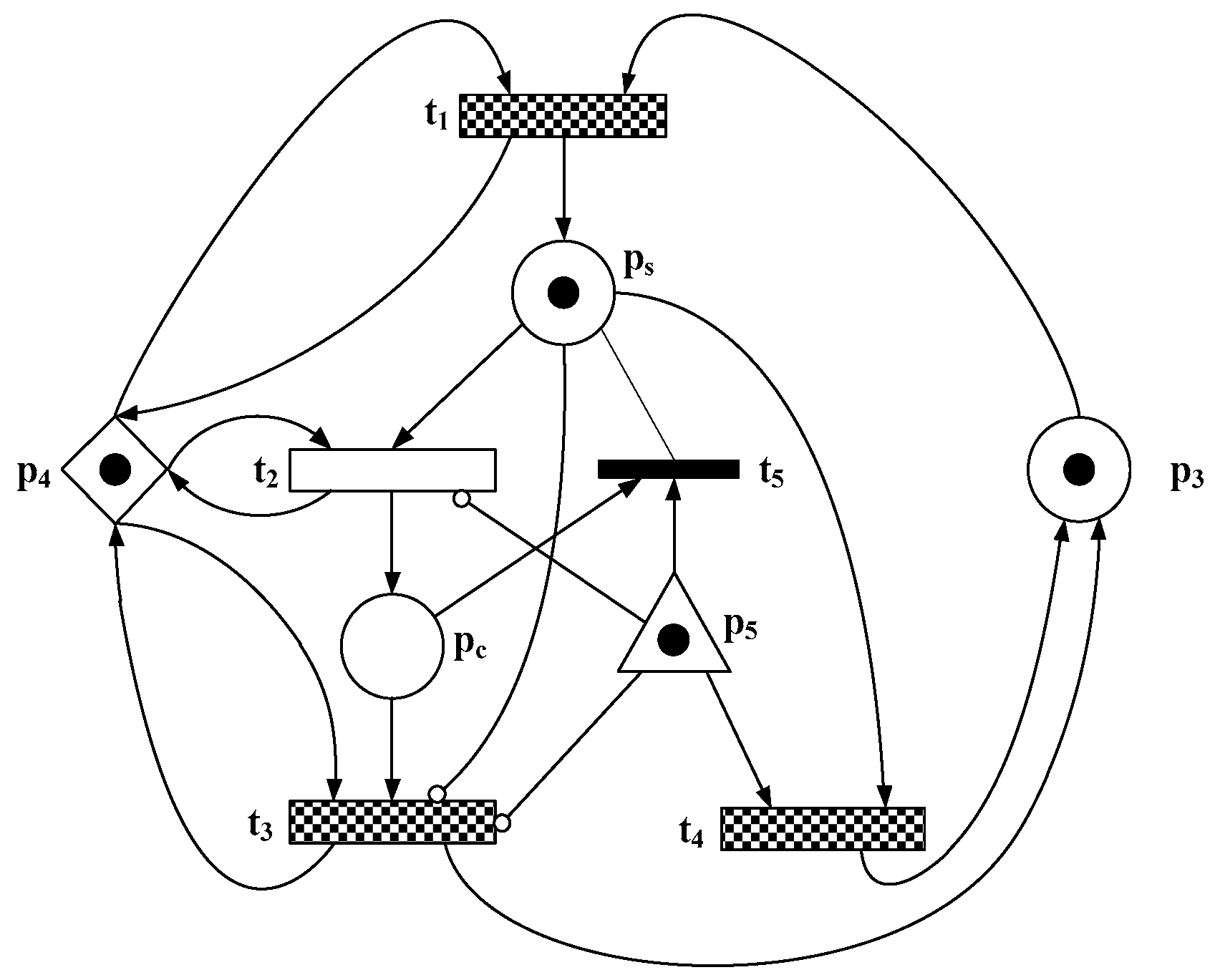

3.1. Device Modeling

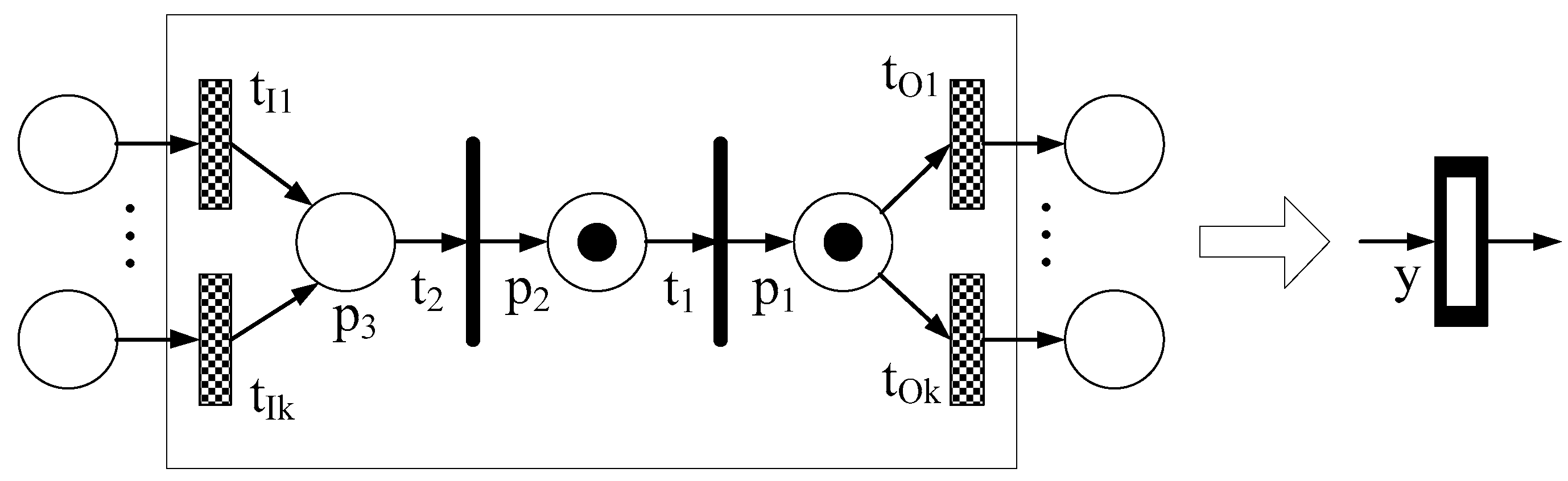

3.2. PN Model for the Whole System

4. Scheduling Method

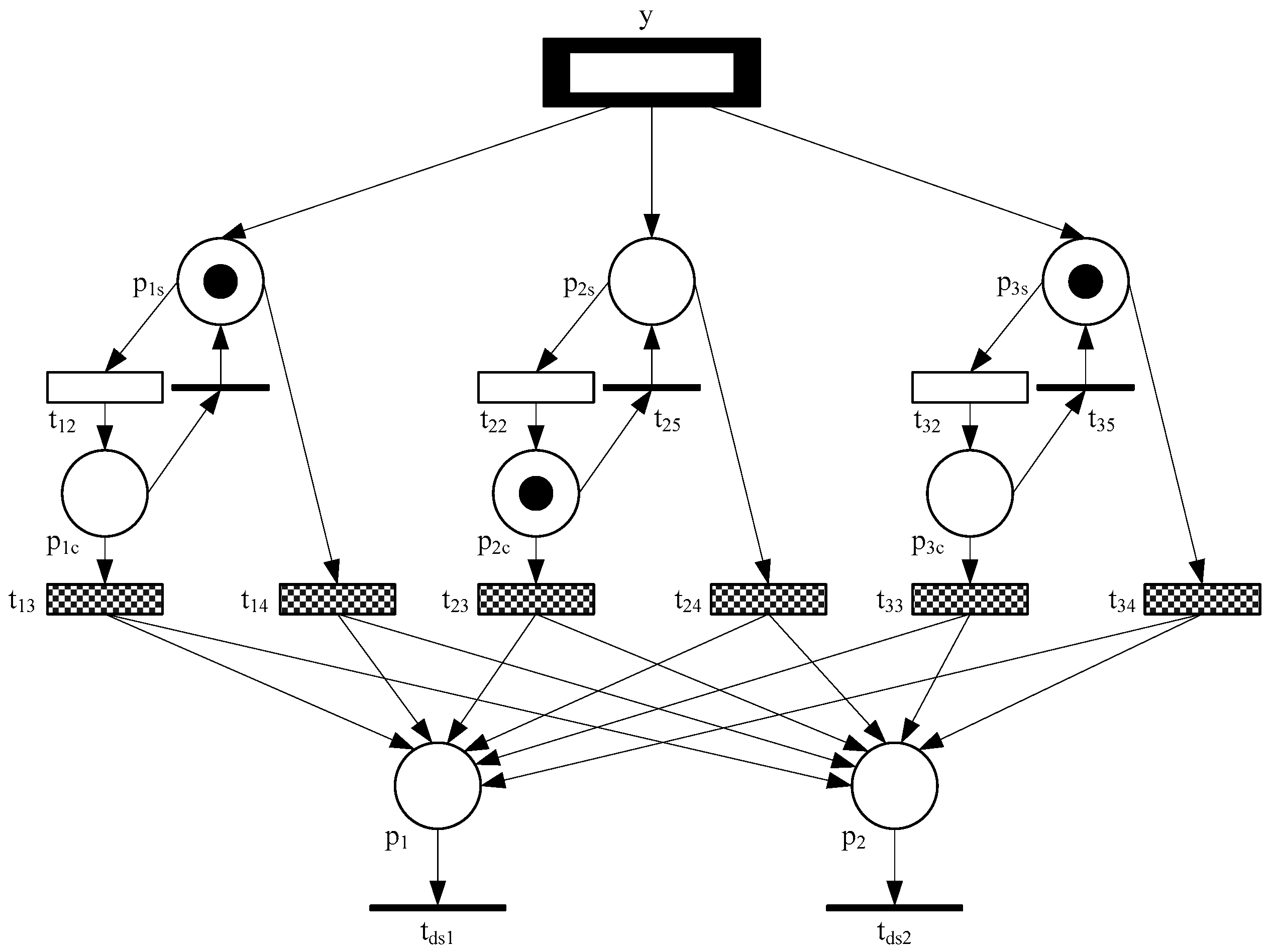

4.1. Systems with Two Distillers

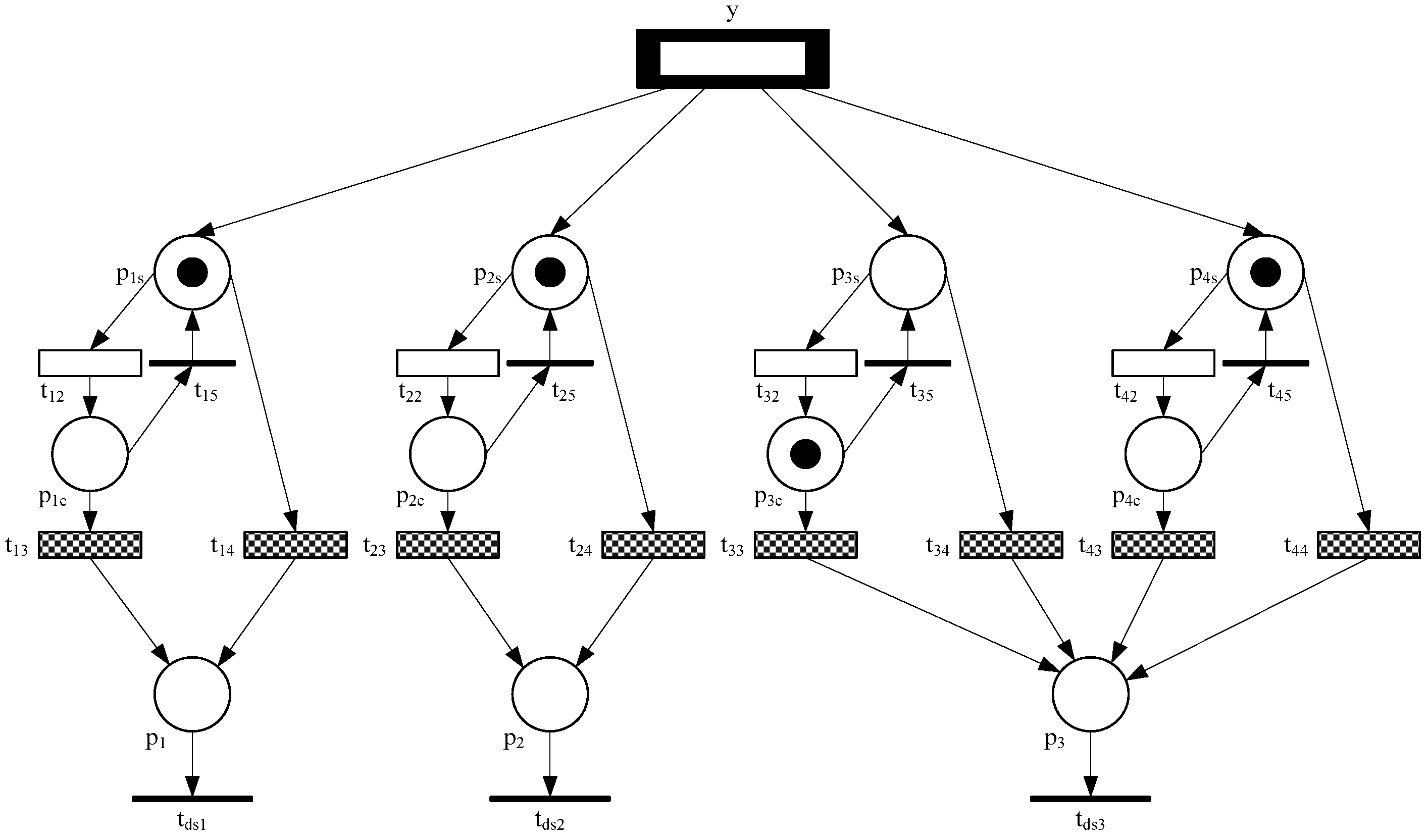

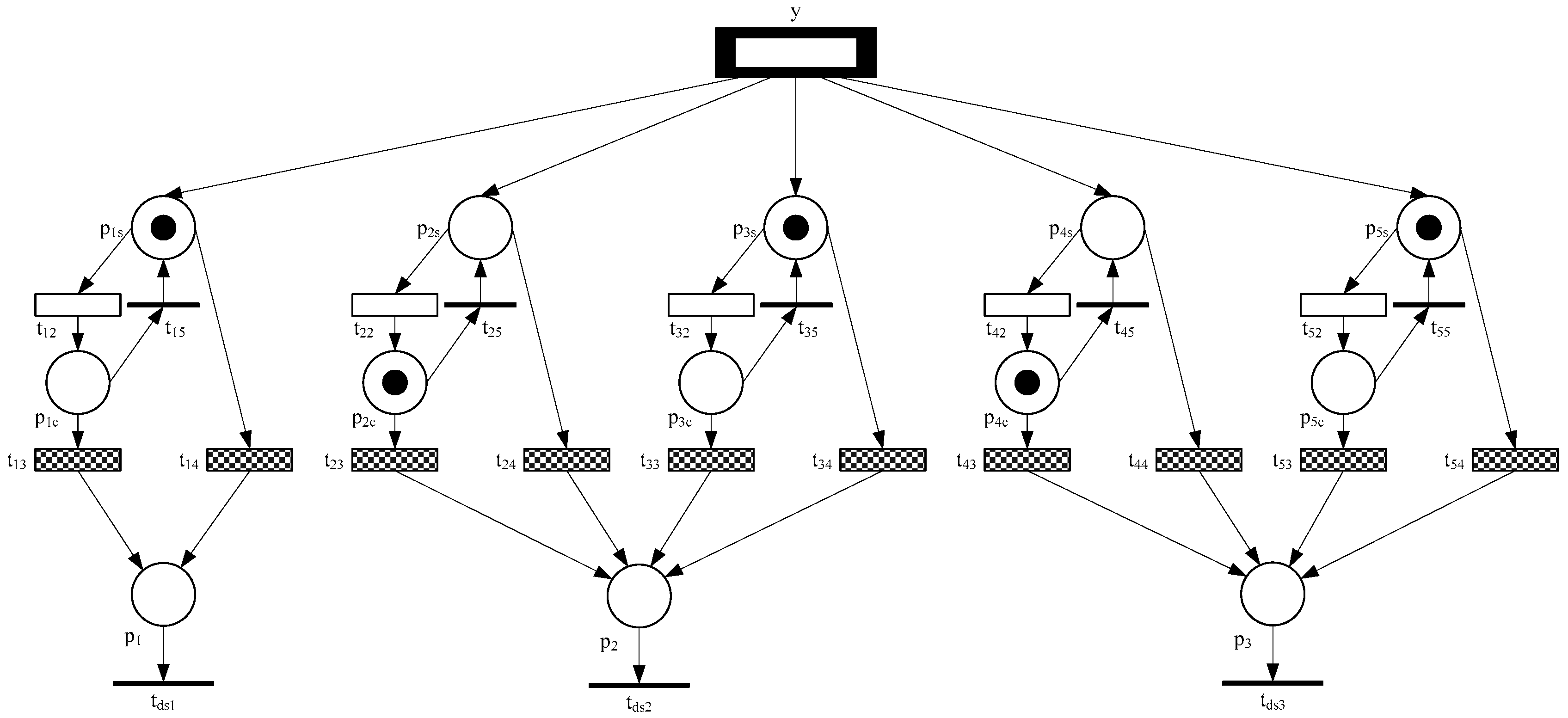

4.2. Scheduling a System with Three Distillers

4.2.1. Case 1: Four Charging Tanks

4.2.2. Case 2: Five Charging Tanks

5. Scheduling for General Systems

Case 1: 2K − N Charging Tanks

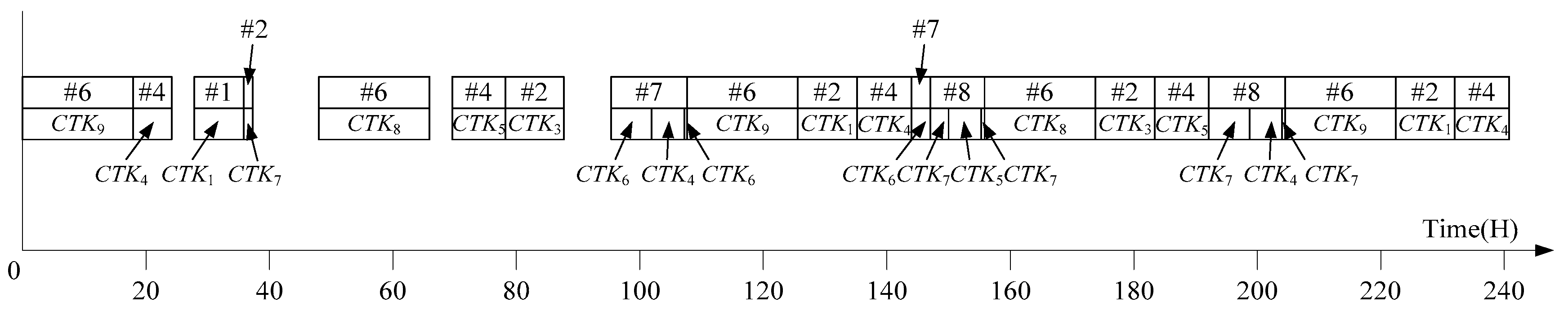

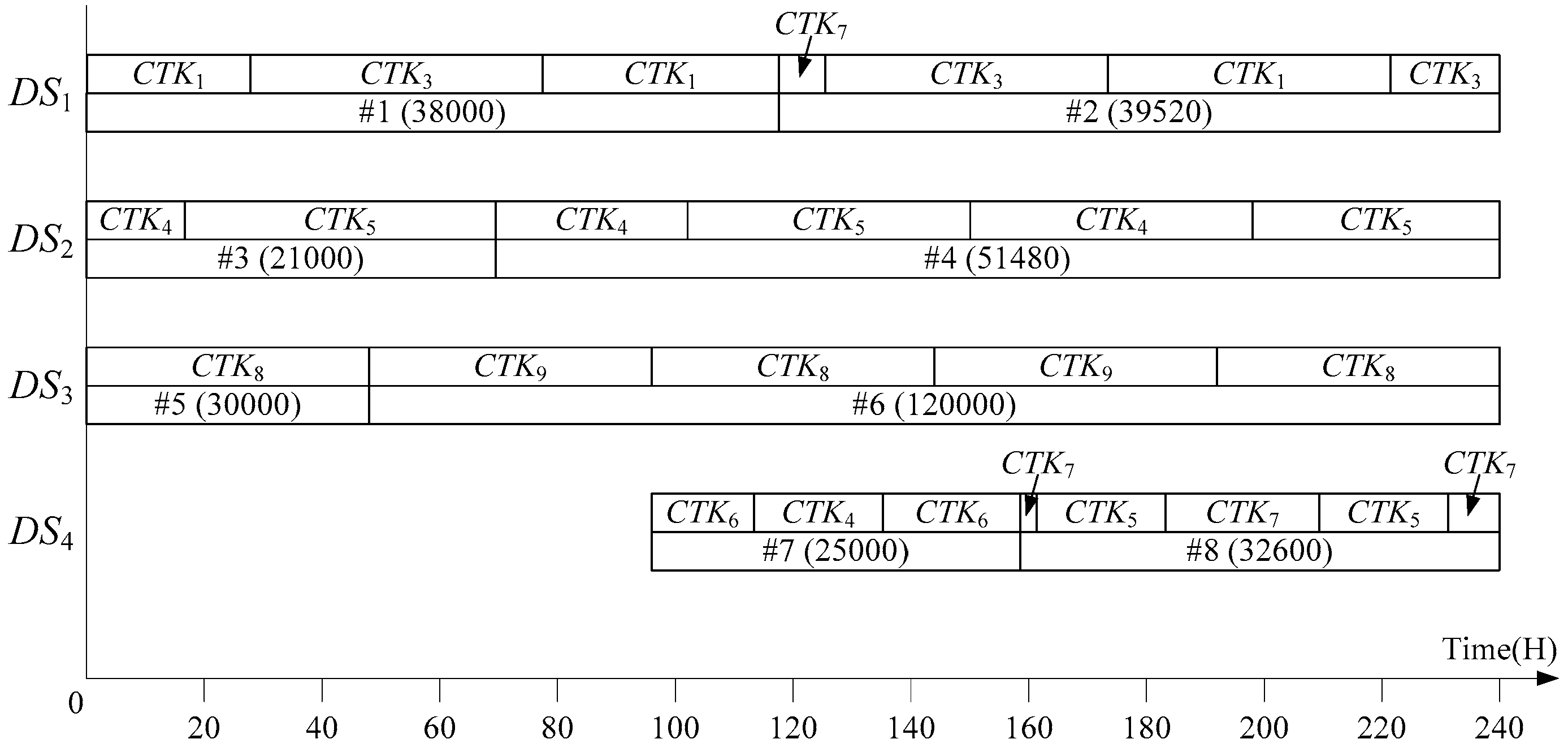

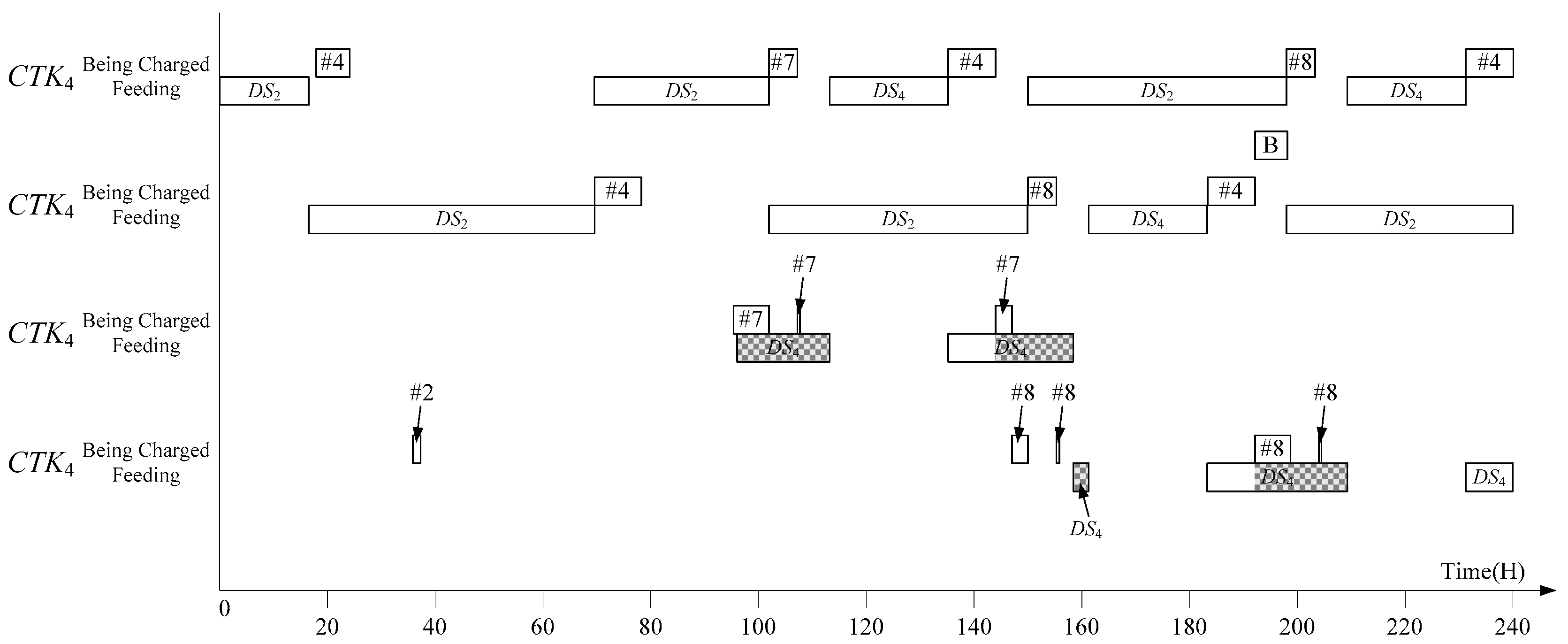

6. Industrial Case Study

7. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

Appendix A.1. Proof of Proposition 1

Appendix A.2. Proof of Proposition 2

Appendix A.3. Proof of Proposition 3

Appendix A.4. Proof of Proposition 4

Appendix A.5. Proof of Proposition 5

Appendix A.6. Proof of Proposition 6

Appendix A.7. Proof of Proposition 7

Appendix A.8. Proof of Proposition 8

References

- Shah, N. Planning and Scheduling-Single-and Multisite Planning and Scheduling: Current Status and Future Challenges. AIChE Symp. Ser. 1998, 34, 75–90. [Google Scholar]

- Moro, L.F.L. Process technology in the petroleum refining industry—Current situation and future trends. Comput. Chem. Eng. 2003, 27, 1303–1305. [Google Scholar] [CrossRef]

- Kallestrup, K.B.; Lynge, L.H.; Akkerman, R.; Oddsdottir, T.A. Decision support in hierarchical planning systems: The case of procurement planning in oil refining industries. Decis. Support Syst. 2014, 68, 49–63. [Google Scholar] [CrossRef]

- Pinto, J.M.; Moro, L.F.L. A planning model for petroleum refineries. Braz. J. Chem. Eng. 2000, 17, 575–585. [Google Scholar] [CrossRef]

- Pelham, R.; Pharris, C. Refinery Operations and Control: A Future Vision; National Petroleum Refiners Association: Washington, DC, USA, 1996. [Google Scholar]

- Shobrys, D.E.; White, D.C. Planning, scheduling and control systems: Why cannot they work together. Comput. Chem. Eng. 2002, 26, 149–160. [Google Scholar] [CrossRef]

- Honkomp, S.J.; Lombardo, S.; Rosen, O.; Pekny, J.F. The curse of reality—Why process scheduling optimization problems are difficult in practice. Comput. Chem. Eng. 2000, 24, 323–328. [Google Scholar] [CrossRef]

- Lee, H.; Pinto, J.M.; Grossmann, I.E.; Park, S. Mixed-Integer Linear Programming Model for Refinery Short-Term Scheduling of Crude Oil Unloading with Inventory Management. Ind. Eng. Chem. Res. 1996, 35, 1630–1641. [Google Scholar] [CrossRef]

- Pinto, J.M.; Joly, M.; Moro, L.F.L. Planning and scheduling models for refinery operations. Comput. Chem. Eng. 2000, 24, 2259–2276. [Google Scholar] [CrossRef]

- Saharidis, G.K.D.; Minoux, M.; Dallery, Y. Scheduling of loading and unloading of crude oil in a refinery using event-based discrete time formulation. Comput. Chem. Eng. 2009, 33, 1413–1426. [Google Scholar] [CrossRef]

- Shah, N. Mathematical programming techniques for crude oil scheduling. Comput. Chem. Eng. 1996, 20, S1227–S1232. [Google Scholar] [CrossRef]

- Jia, Z.Y.; Ierapetritou, M. Efficient short-term scheduling of refinery operations based on a continuous time formulation. Comput. Chem. Eng. 2004, 28, 1001–1019. [Google Scholar] [CrossRef]

- Jia, Z.Y.; Ierapetritou, M.; Kelly, J.D. Refinery short-term scheduling using continuous time formulation: Crude-oil operations. Ind. Eng. Chem. Res. 2003, 42, 3085–3097. [Google Scholar] [CrossRef]

- Mouret, S.; Grossmann, I.E.; Pestiaux, P. A Novel Priority-Slot Based Continuous-Time Formulation for Crude-Oil Scheduling Problems. Ind. Eng. Chem. Res. 2009, 48, 8515–8528. [Google Scholar] [CrossRef]

- Mendez, C.A.; Grossmann, I.E.; Harjunkoski, I.; Kabore, P. A simultaneous optimization approach for off-line blending and scheduling of oil-refinery operations. Comput. Chem. Eng. 2006, 30, 614–634. [Google Scholar] [CrossRef]

- Bai, L.P.; Wu, N.Q.; Li, Z.W.; Zhou, M.C. Optimal one-wafer cyclic scheduling and buffer space configuration for single-arm multicluster tools with linear topology. IEEE Trans. Syst. Man Cybern. Syst. 2016, 46, 1456–1467. [Google Scholar] [CrossRef]

- Wu, N.Q.; Chu, F.; Chu, C.B.; Zhou, M.C. Petri net modeling and cycle time analysis of dual-arm cluster tools with wafer revisiting. IEEE Trans. Syst. Man Cybern. Syst. 2013, 43, 196–207. [Google Scholar] [CrossRef]

- Wu, N.Q.; Zhou, M.C. Modeling, analysis and control of dual-arm cluster tools with residency time constraint and activity time variation based on Petri nets. IEEE Trans. Autom. Sci. Eng. 2012, 9, 446–454. [Google Scholar]

- Wu, N.Q.; Zhou, M.C. Schedulability analysis and optimal scheduling of dual-arm cluster tools with residency time constraint and activity time variation. IEEE Trans. Autom. Sci. Eng. 2012, 9, 203–209. [Google Scholar]

- Yang, F.J.; Wu, N.Q.; Qao, Y.; Zhou, M.C.; Li, Z.W. Scheduling of single-arm cluster tools for an atomic layer deposition process with residency time constraints. IEEE Trans. Syst. Man Cybern. Syst. 2017, 47, 502–516. [Google Scholar] [CrossRef]

- Wu, N.Q.; Chu, F.; Chu, C.; Zhou, M.C. Short-term schedulability analysis of crude oil operations in refinery with oil residency time constraint using Petri nets. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 2008, 38, 765–778. [Google Scholar] [CrossRef]

- Wu, N.Q.; Chu, F.; Chu, C.; Zhou, M.C. Short-term schedulability analysis of multiple distiller crude oil operations in refinery with oil residency time constraint. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 2009, 39, 1–16. [Google Scholar]

- Wu, N.Q.; Zhou, M.C.; Chu, F. A Petri net-based heuristic algorithm for realizability of target refining schedule for oil refinery. IEEE Trans. Autom. Sci. Eng. 2008, 5, 661–676. [Google Scholar]

- Wu, N.Q.; Zhou, M.C.; Li, Z.W. Short-term scheduling of crude-oil operations: Petri net-based control-theoretic approach. IEEE Robot. Autom. Mag. 2015, 22, 64–76. [Google Scholar] [CrossRef]

- Wu, N.Q.; Chu, F.; Chu, C.B.; Zhou, M.C. Hybrid Petri net modeling and schedulability analysis of high fusion point oil transportation under tank grouping strategy for crude oil operations in refinery. IEEE Trans. Syst. Man Cybern. Part C 2010, 40, 159–175. [Google Scholar]

- Wu, N.Q.; Chu, F.; Chu, C.B.; Zhou, M.C. Tank cycling and scheduling analysis of high fusion point oil transportation for crude oil operations in refinery. Comput. Chem. Eng. 2010, 34, 529–543. [Google Scholar] [CrossRef]

- Wu, N.Q.; Chu, C.; Chu, F.; Zhou, M.C. Schedulability Analysis of Short-Term Scheduling for Crude Oil Operations in Refinery with Oil Residency Time and Charging-Tank-Switch-Overlap Constraints. IEEE Trans. Autom. Sci. Eng. 2011, 8, 190–204. [Google Scholar] [CrossRef]

- Wu, N.Q.; Zhou, M.C.; Bai, L.P.; Li, Z.W. Short-term scheduling of crude oil operations in refinery with high fusion point oil and two transportation pipelines. Enterp. Inform. Syst. 2016, 10, 581–610. [Google Scholar] [CrossRef]

- Wu, N.Q.; Bai, L.P.; Zhou, M.C. An efficient scheduling method for crude oil operations in refinery with crude oil type mixing requirements. IEEE Trans. Syst. Man Cybern. Syst. 2016, 46, 413–426. [Google Scholar] [CrossRef]

- Wu, N.Q.; Bai, L.P.; Zhou, M.C.; Chu, F.; Mammar, S. A novel approach to optimization of refining schedules for crude oil operations in refinery. IEEE Trans. Syst. Man Cybern. Part C 2012, 42, 1042–1053. [Google Scholar]

- Gribaudo, M.; Sereno, M.; Horv, A.; Bobbio, A. Fluid stochastic petri nets augmented with flush-out arcs: Modelling and analysis. Discret. Event Dyn. Syst. 2001, 11, 97–117. [Google Scholar] [CrossRef]

- Horton, G.; Kulkarni, V.G.; Nicol, D.M.; Trivedi, K.S. Fluid stochastic petri nets: Theory, applications, and solution techniques. Eur. J. Oper. Res. 1998, 105, 184–201. [Google Scholar] [CrossRef]

- Sanders, W.H.; Meyer, J.F. Stochastic Activity Networks: Formal Definitions and Concepts⋆. In Lectures on Formal Methods and Performance Analysis; Springer: Berlin, Germany, 2001; pp. 315–343. [Google Scholar]

- Wang, J. Timed Petri Nets: Theory and Application; Springer: New York, NY, USA, 1998. [Google Scholar]

- Zhou, M.C.; Venkatesh, K. Modeling, Simulation, and Control of Flexible Manufacturing Systems: A Petri Net Approach; World Scientific: Singapore, 1999. [Google Scholar]

| Tank | Capacity (Ton) | Type of Oil Filled | Volume (Ton) |

|---|---|---|---|

| CTK1 | 16,000 | Oil #1 | 9000 |

| CTK2 | 16,000 | ||

| CTK3 | 16,000 | Oil #1 | 16,000 |

| CTK4 | 16,000 | Oil #3 | 5000 |

| CTK5 | 16,000 | Oil #3 | 16,000 |

| CTK6 | 20,000 | ||

| CTK7 | 20,000 | ||

| CTK8 | 30,000 | Oil #5 | 30,000 |

| CTK9 | 30,000 | ||

| CTK10 | 30,000 | Oil #9 | 30,000 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, Y.; Wu, N.; Hon, C.T.; Li, Z. Scheduling of Crude Oil Operations in Refinery without Sufficient Charging Tanks Using Petri Nets. Appl. Sci. 2017, 7, 564. https://doi.org/10.3390/app7060564

An Y, Wu N, Hon CT, Li Z. Scheduling of Crude Oil Operations in Refinery without Sufficient Charging Tanks Using Petri Nets. Applied Sciences. 2017; 7(6):564. https://doi.org/10.3390/app7060564

Chicago/Turabian StyleAn, Yan, NaiQi Wu, Chi Tin Hon, and ZhiWu Li. 2017. "Scheduling of Crude Oil Operations in Refinery without Sufficient Charging Tanks Using Petri Nets" Applied Sciences 7, no. 6: 564. https://doi.org/10.3390/app7060564

APA StyleAn, Y., Wu, N., Hon, C. T., & Li, Z. (2017). Scheduling of Crude Oil Operations in Refinery without Sufficient Charging Tanks Using Petri Nets. Applied Sciences, 7(6), 564. https://doi.org/10.3390/app7060564