Microstructure and Mechanical Properties of Ti-6Al-4V Fabricated by Vertical Wire Feeding with Axisymmetric Multi-Laser Source

Abstract

:1. Introduction

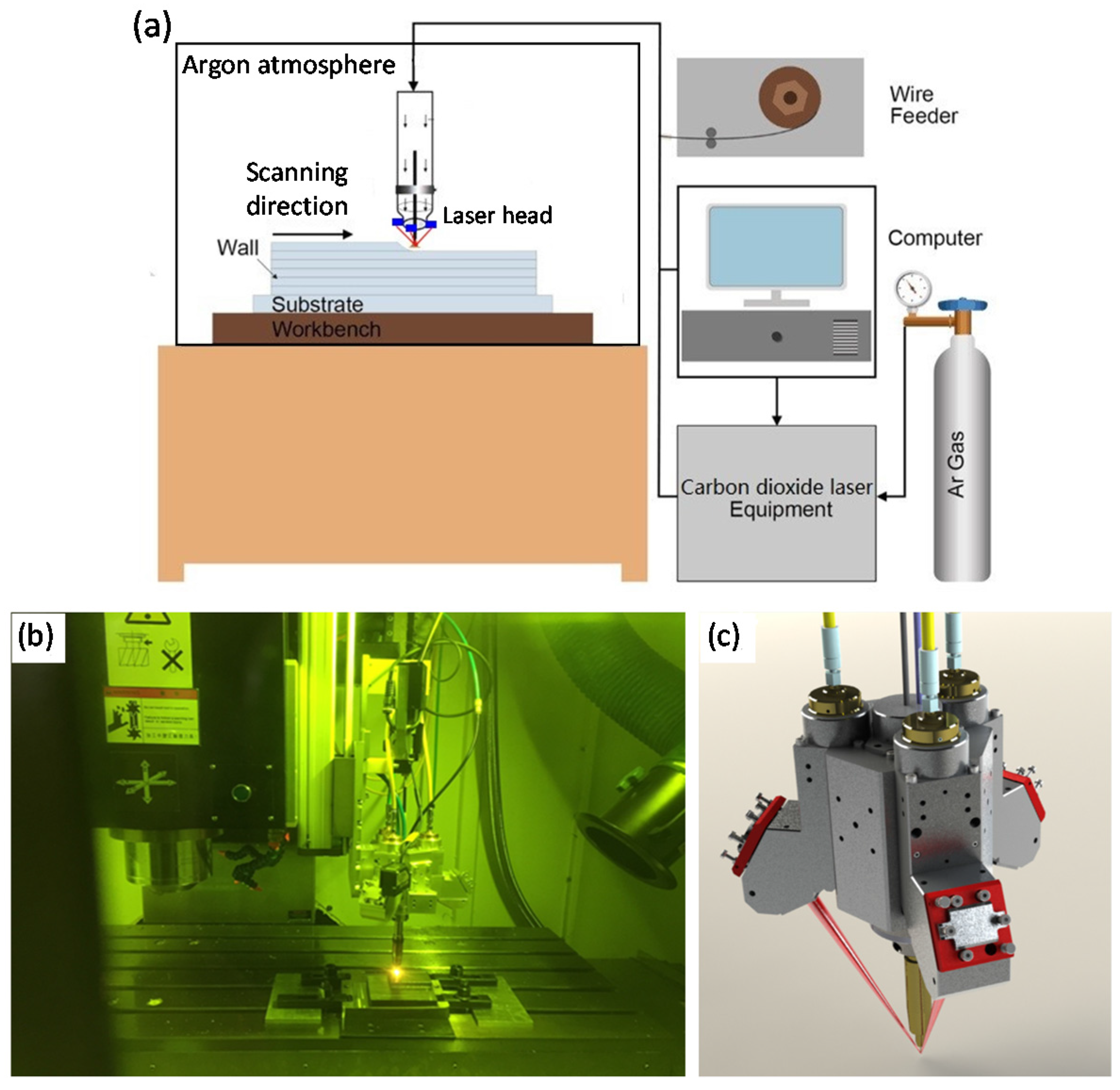

2. Experiment

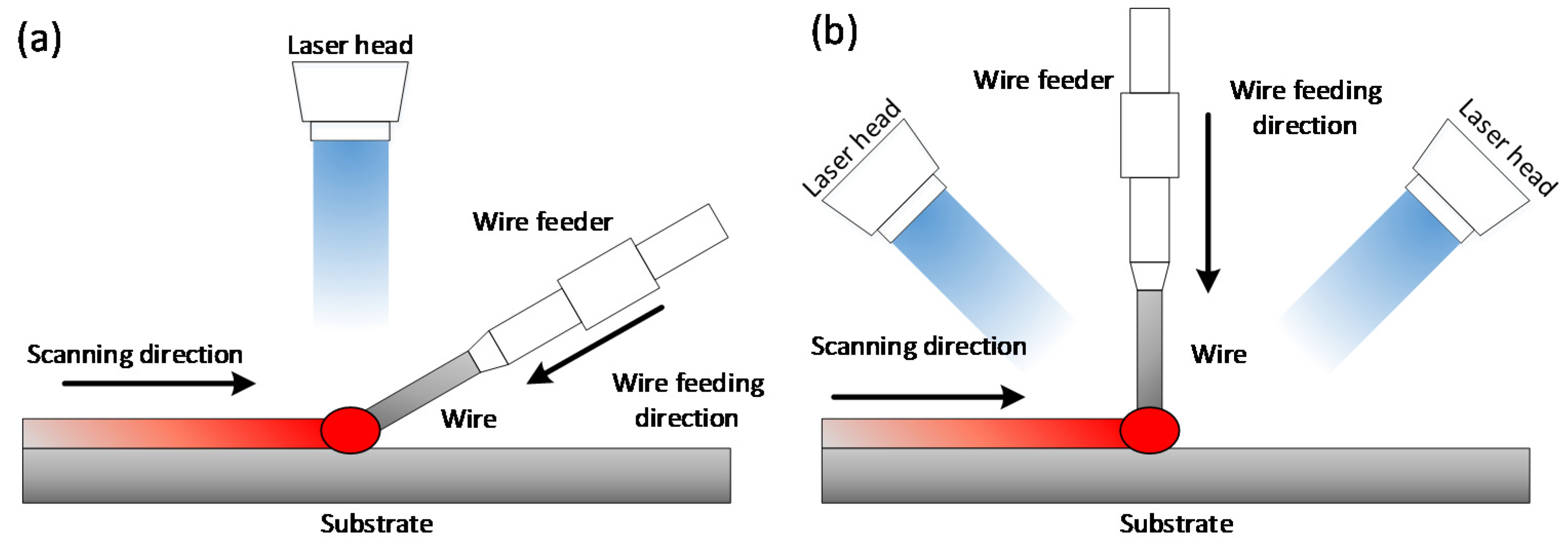

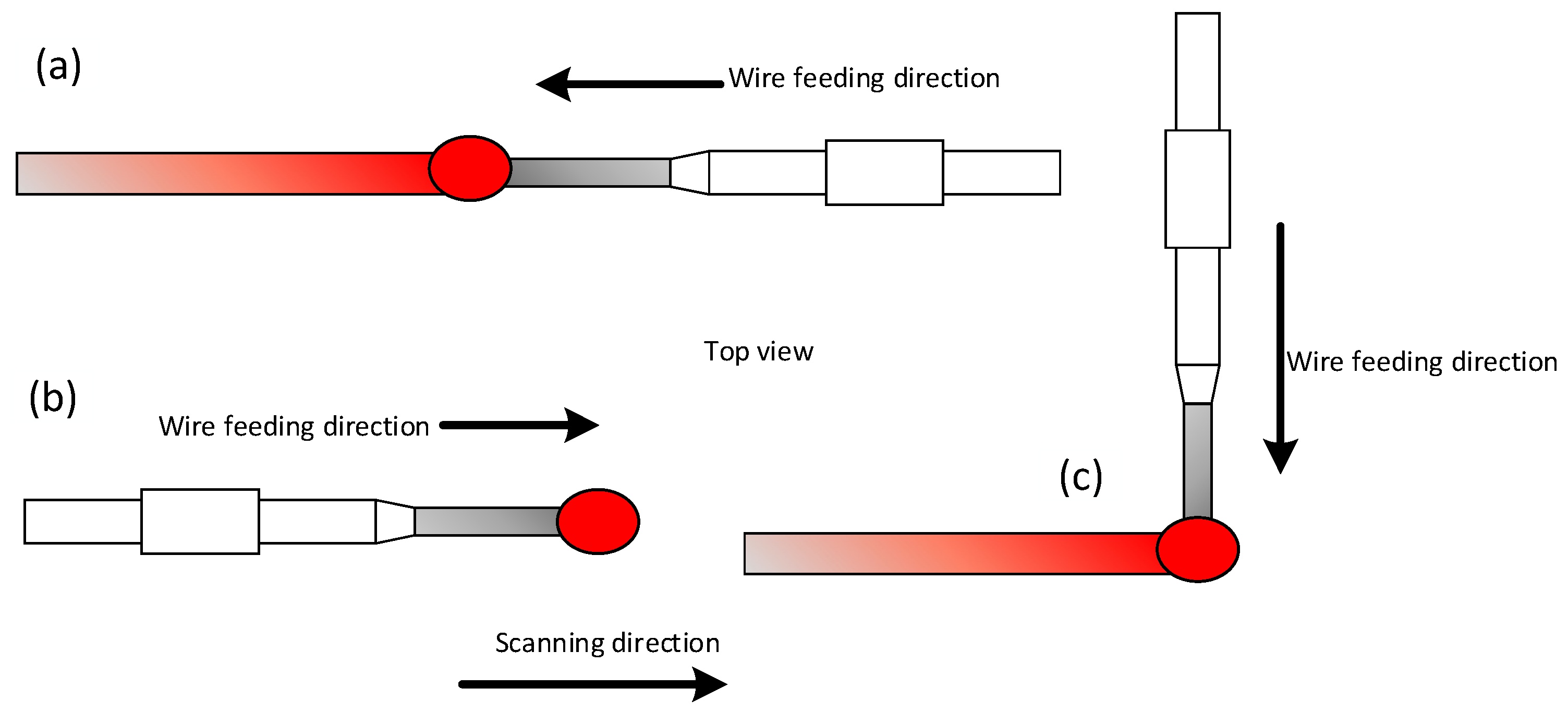

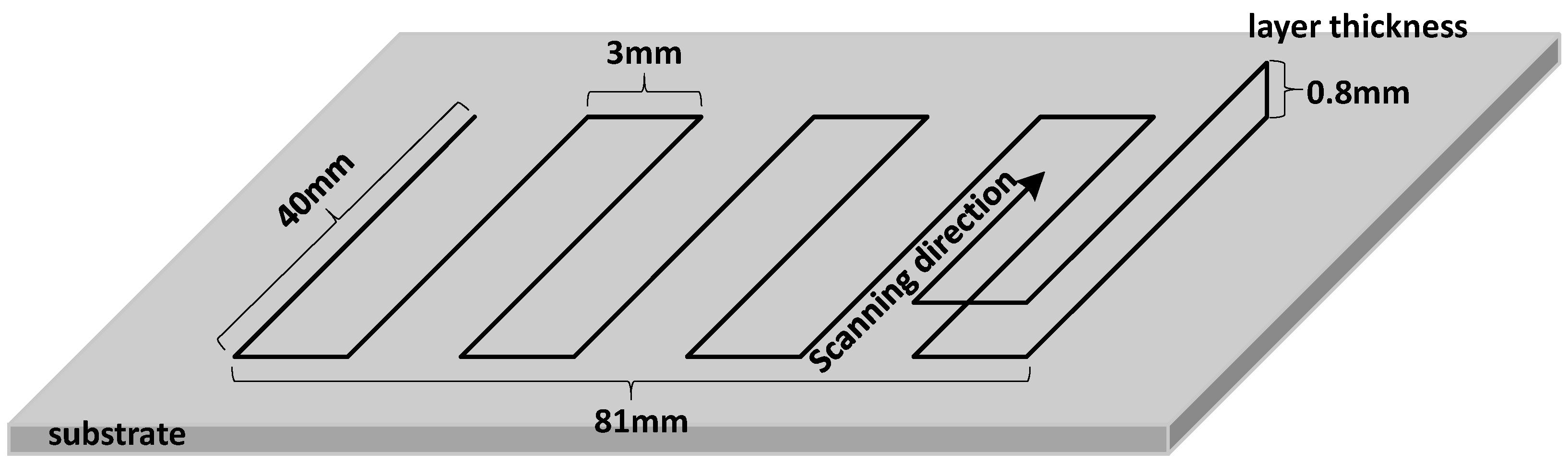

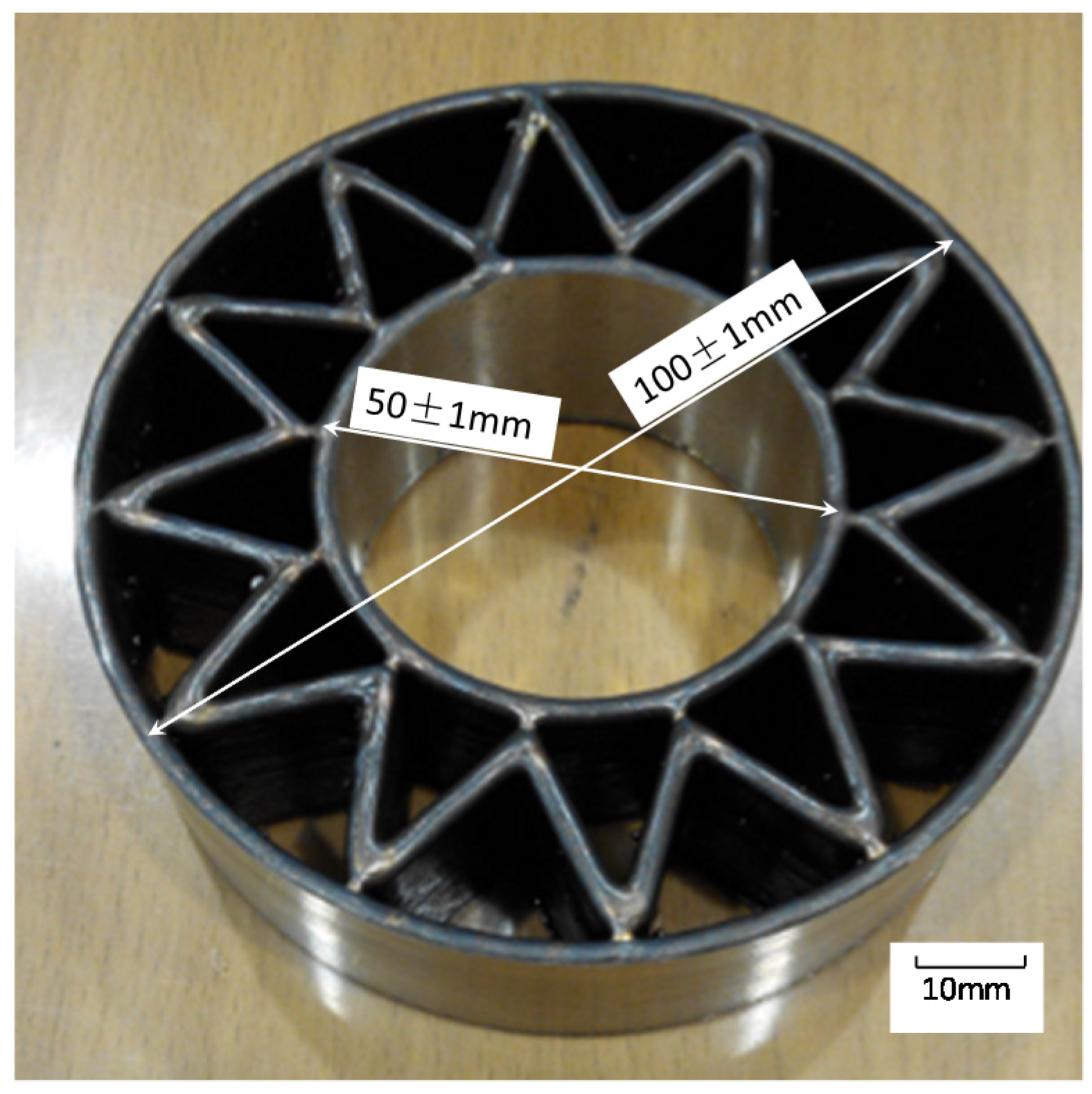

2.1. Deposition Process

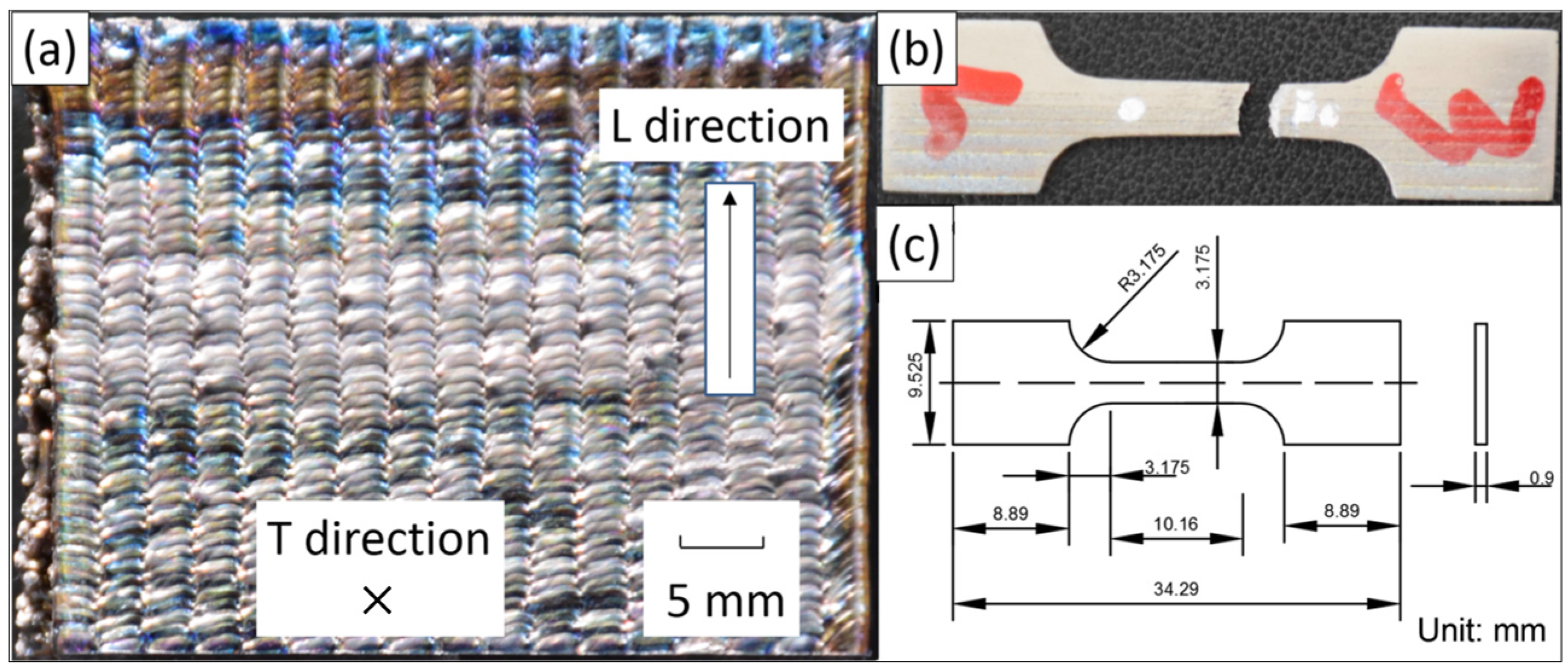

2.2. Mechanical Characterization

2.3. Microstructure and Morphology

3. Results

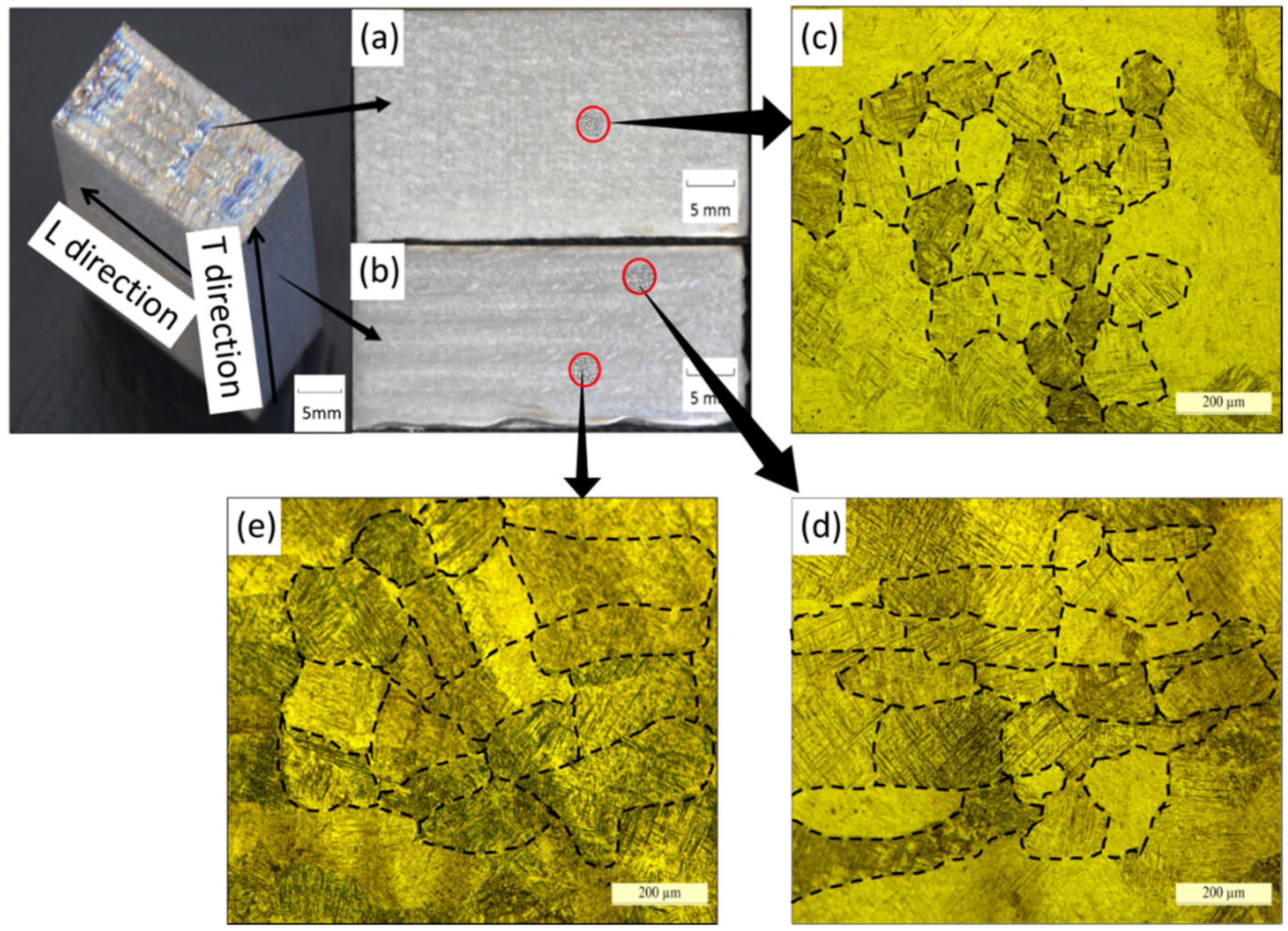

3.1. Macrostructure

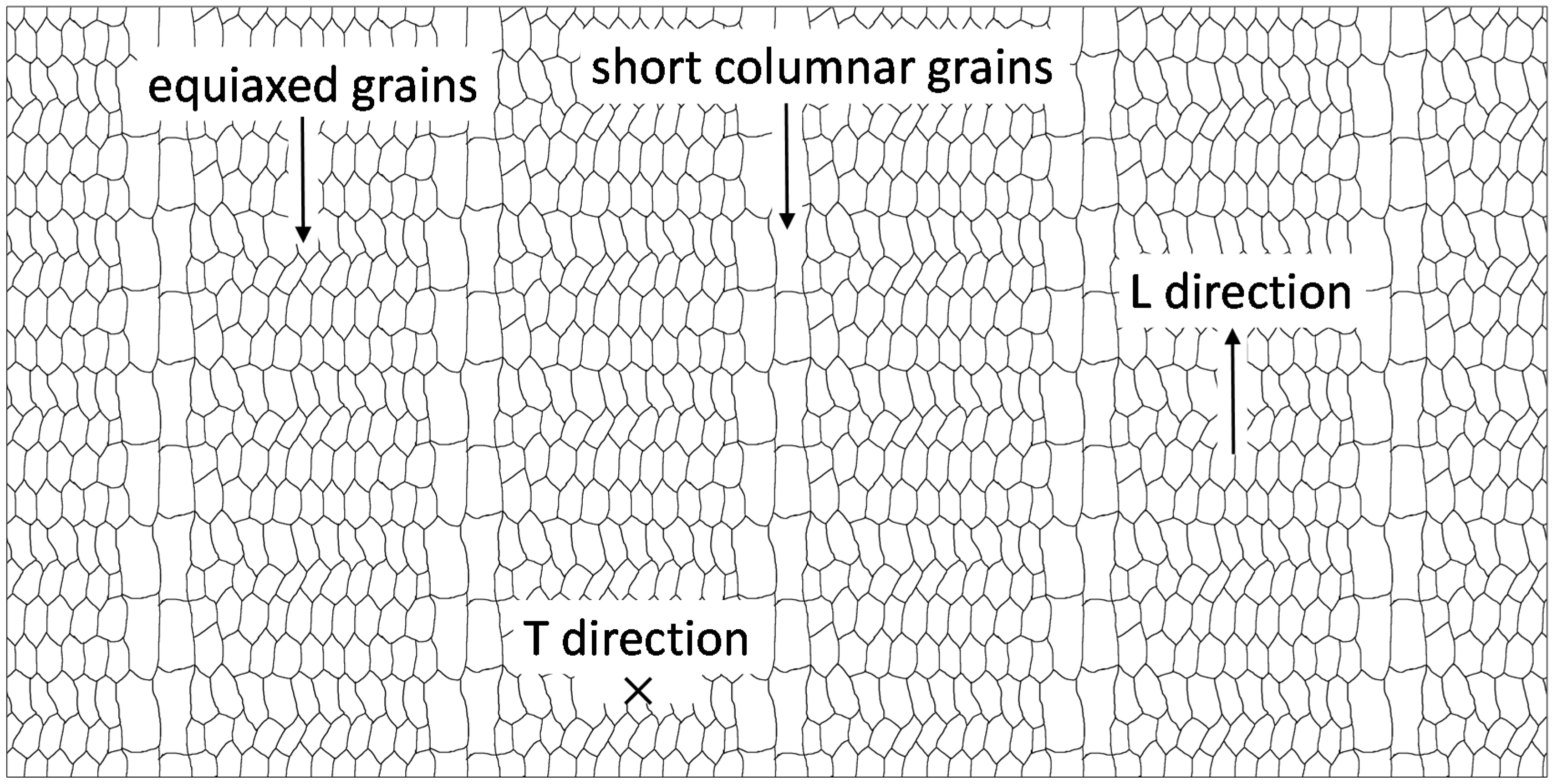

3.2. Grains

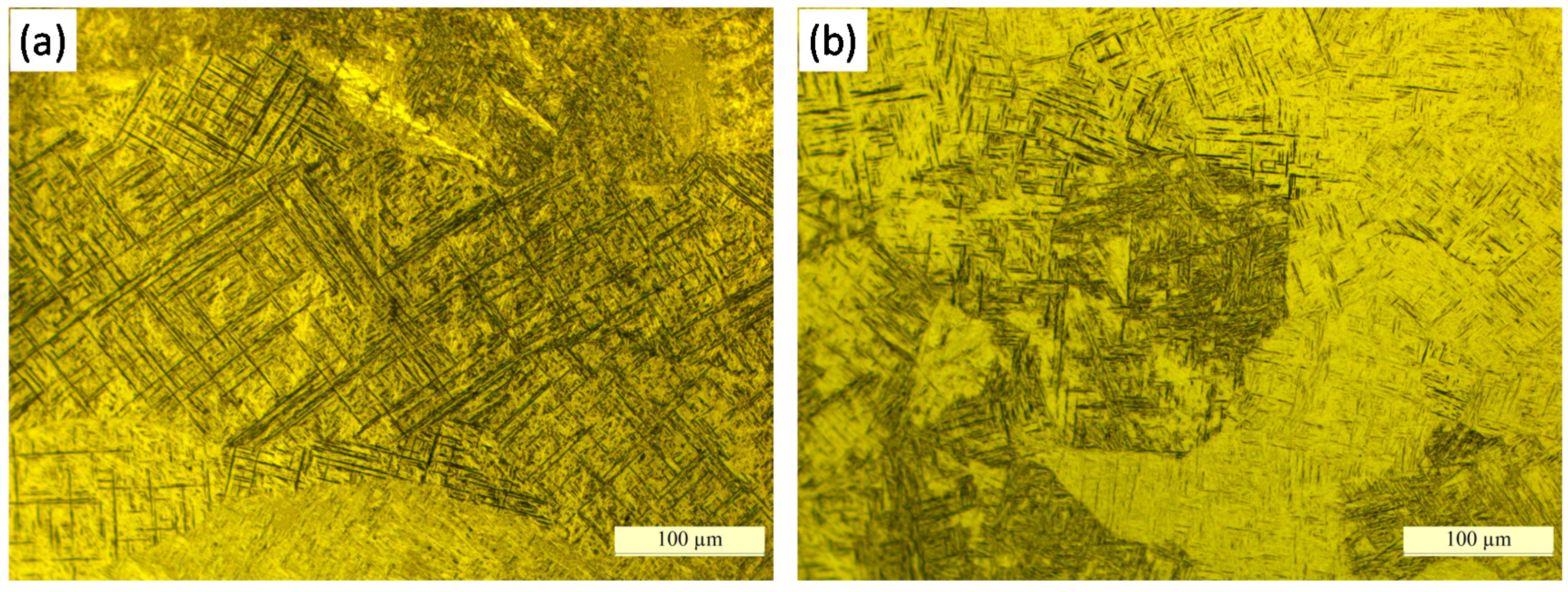

3.3. Microstructure

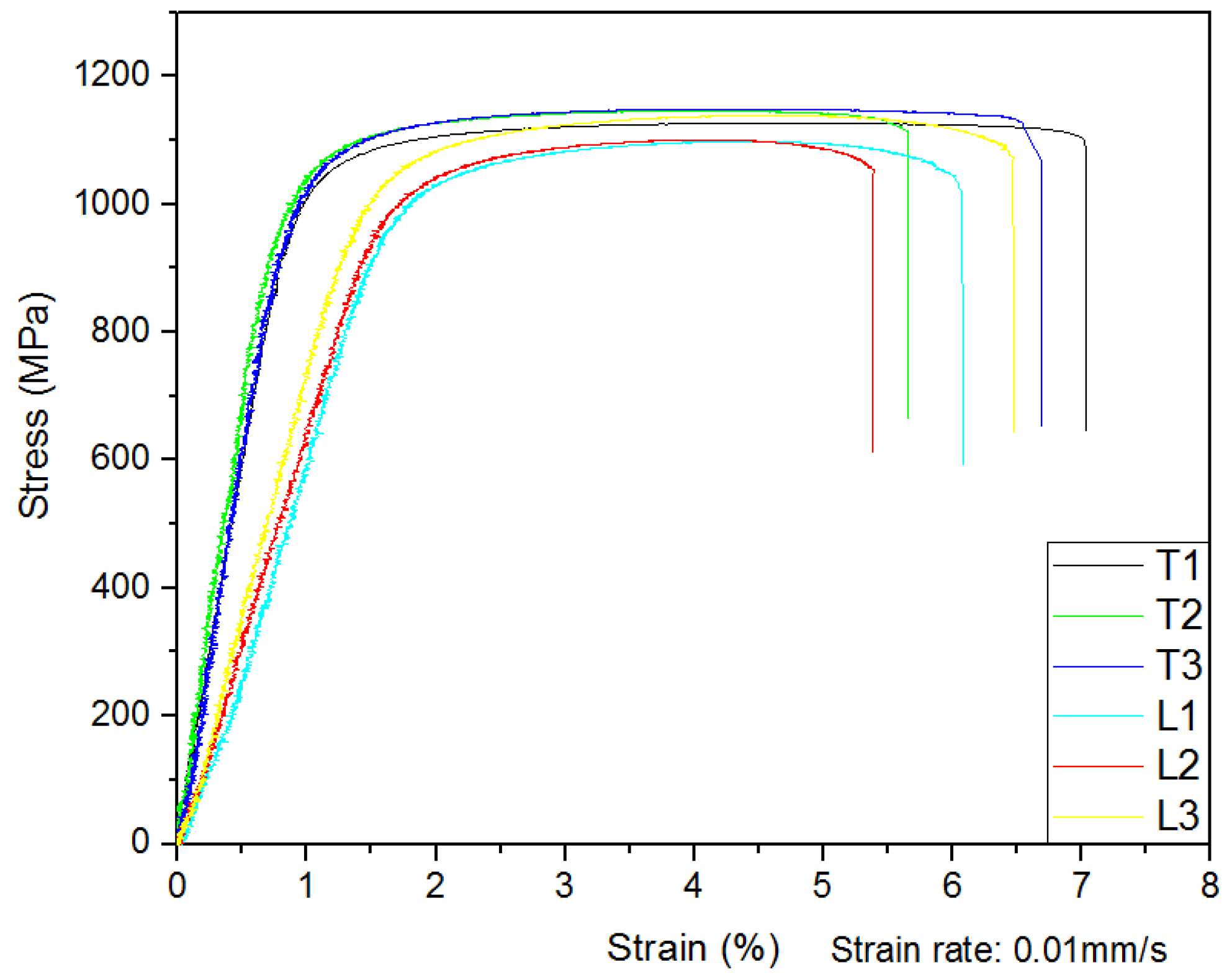

3.4. Mechanical Properties

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Peters, M.; Kumpfert, J.; Ward, C.H.; Leyens, C. Titanium alloys for aerospace applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Rawal, S.; Brantley, J.; Karabudak, N. Additive manufacturing of Ti-6Al-4V alloy components for spacecraft applications. In Proceedings of the International Conference on Recent Advances in Space Technologies, Istanbul, Turkey, 12–14 June 2013; pp. 5–11.

- Peters, M.; Hemptenmacher, J.; Kumpfert, J.; Leyens, C. Titan und titanlegierungen: Struktur, gefüge, eigenschaften. In Titan und Titanlegierungen; Wiley-VCH: Weinheim, Germany, 2002; pp. 1–37. [Google Scholar]

- Zhang, M.; Liu, C.; Shi, X.; Chen, X.; Chen, C.; Zuo, J.; Lu, J.; Ma, S. Residual stress, defects and grain morphology of Ti-6AL-4V alloy produced by ultrasonic impact treatment assisted selective laser melting. Appl. Sci. 2016, 6, 304. [Google Scholar] [CrossRef]

- Shi, X.; Ma, S.; Liu, C.; Chen, C.; Wu, Q.; Chen, X.; Lu, J. Performance of high layer thickness in selective laser melting of Ti-6Al-4V. Materials 2016, 9, 975. [Google Scholar] [CrossRef]

- Ravi, G.A.; Qiu, C.; Attallah, M.M. Microstructural control in a Ti-based alloy by changing laser processing mode and power during direct laser deposition. Mater. Lett. 2016, 179, 104–108. [Google Scholar] [CrossRef]

- Hong, M.-H.; Min, B.K.; Kwon, T.-Y. The influence of process parameters on the surface roughness of a 3D-printed Co–Cr dental alloy produced via selective laser melting. Appl. Sci. 2016, 6, 401. [Google Scholar] [CrossRef]

- Liu, C.M.; Tian, X.J.; Tang, H.B.; Wang, H.M. Microstructural characterization of laser melting deposited Ti–5AL-5Mo–5V–1Cr–1Fe near β titanium alloy. J. Alloys Compd. 2013, 572, 17–24. [Google Scholar] [CrossRef]

- Brandl, E.; Palm, F.; Michailov, V.; Viehweger, B.; Leyens, C. Mechanical properties of additive manufactured titanium (Ti-6Al-4V) blocks deposited by a solid-state laser and wire. Mater. Des. 2011, 32, 4665–4675. [Google Scholar] [CrossRef]

- Ader, C.; Brosemer, M.; Freyer, C.; Fricke, H.; Hennigs, D.; Klocke, F.; Kühne, V.; Meiners, W.; Over, C.; Pleteit, H. Research on layer manufacturing techniques at fraunhofer. In Proceedings of the Solid Freeform Fabrication Symposium 2004, Austin, TX, USA, 2–4 August 2004; pp. 26–37.

- Santos, E.C.; Shiomi, M.; Osakada, K.; Laoui, T. Rapid manufacturing of metal components by laser forming. Int. J. Mac. Tools Manuf. 2006, 46, 1459–1468. [Google Scholar] [CrossRef]

- Martina, F.; Colegrove, P.A.; Williams, S.W.; Meyer, J. Microstructure of interpass rolled wire + arc additive manufacturing Ti-6Al-4V components. Metall. Mater. Trans. A 2015, 46, 6103–6118. [Google Scholar] [CrossRef]

- Brandl, E.; Schoberth, A.; Leyens, C. Morphology, microstructure, and hardness of titanium (Ti-6Al-4V) blocks deposited by wire-feed additive layer manufacturing (ALM). Mater. Sci. Eng. A 2012, 532, 295–307. [Google Scholar] [CrossRef]

- Baufeld, B.; Biest, O.V.D.; Gault, R. Additive manufacturing of Ti–6AL–4V components by shaped metal deposition: Microstructure and mechanical properties. Mater. Des. 2010, 31, S106–S111. [Google Scholar] [CrossRef]

- Lopes, G.; Miranda, R.; Quintino, L.; Rodrigues, J. Additive manufacturing of Ti-6Al-4V based components with high power fiber lasers. In Virtual and Rapid Manufacturing; Tailor & Francis Group: London, UK, 2008; pp. 369–374. [Google Scholar]

- Shi, X.; Ma, S.; Liu, C.; Wu, Q.; Lu, J.; Liu, Y.; Shi, W. Selective laser melting-wire arc additive manufacturing hybrid fabrication of Ti-6Al-4V alloy: Microstructure and mechanical properties. Mater. Sci. Eng. A 2017, 684, 196–204. [Google Scholar] [CrossRef]

- Wang, Y.K.; Shi, S.H.; Fu, G.Y.; Li, C.S. Research on the key process parameters in direct laser deposition using coaxial inside-beam wire feeding. Appl. Mech. Mater. 2010, 43, 401–404. [Google Scholar] [CrossRef]

- Kim, J.D.; Peng, Y. Plunging method for ND: YAG laser cladding with wire feeding. Opt. Lasers Eng. 2000, 33, 299–309. [Google Scholar] [CrossRef]

- Sui, H.M.; Bi, G.; Folkes, J.; Pashby, I. Deposition of Ti–6AL–4V using a high power diode laser and wire, part I: Investigation on the process characteristics. Surf. Coat. Technol. 2008, 202, 3933–3939. [Google Scholar]

- Syed, W.U.H.; Li, L. Effects of wire feeding direction and location in multiple layer diode laser direct metal deposition. Appl. Surf. Sci. 2005, 248, 518–524. [Google Scholar] [CrossRef]

- Lu, Y.; Tang, H.B.; Fang, Y.L.; Liu, D.; Wang, H.M. Microstructure evolution of sub-critical annealed laser deposited Ti–6AL–4V alloy. Mater. Des. 2012, 37, 56–63. [Google Scholar] [CrossRef]

- Kelly, S.M.; Kampe, S.L. Microstructural evolution in laser-deposited multilayer Ti-6Al-4V builds: Part I. Microstructural characterization. Metall. Mater. Trans. A 2004, 35, 1861–1867. [Google Scholar] [CrossRef]

- Qiu, C.; Adkins, N.J.E.; Attallah, M.M. Selective laser melting of invar 36: Microstructure and properties. Acta Mater. 2015, 103, 382–395. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. Effect of the build orientation on the mechanical properties and fracture modes of slm Ti–6AL–4V. Mater. Sci. Eng. A 2014, 616, 1–11. [Google Scholar] [CrossRef]

- Wang, T.; Zhu, Y.Y.; Zhang, S.Q.; Tang, H.B.; Wang, H.M. Grain morphology evolution behavior of titanium alloy components during laser melting deposition additive manufacturing. J. Alloys Compd. 2015, 632, 505–513. [Google Scholar] [CrossRef]

- Fu, H.; Guo, J.; Liu, L.; Li, J. Directional Solidification and Processing of Advanced Materials; The Science Press: Beijing, China, 2008; p. 498. [Google Scholar]

| Unit | Parameter Set | |

|---|---|---|

| Laser wavelength | μm | 976 |

| Laser power (total) | kW | 1.65 |

| Diameter of laser beam | mm | 3 |

| Deposition speed | mm/min | 500 |

| Wire-feed speed | mm/min | 2200 |

| Wire feed angle | ° | 55 |

| Layer thickness | mm | 0.8 |

| Diameter of wire | mm | 1.2 |

| Deposit spacing | mm | 3 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, J.; Gong, L.; Zhang, Y.; Wu, Q.; Shi, X.; Chang, J.; Lu, J. Microstructure and Mechanical Properties of Ti-6Al-4V Fabricated by Vertical Wire Feeding with Axisymmetric Multi-Laser Source. Appl. Sci. 2017, 7, 227. https://doi.org/10.3390/app7030227

Fu J, Gong L, Zhang Y, Wu Q, Shi X, Chang J, Lu J. Microstructure and Mechanical Properties of Ti-6Al-4V Fabricated by Vertical Wire Feeding with Axisymmetric Multi-Laser Source. Applied Sciences. 2017; 7(3):227. https://doi.org/10.3390/app7030227

Chicago/Turabian StyleFu, Jie, Lin Gong, Yifei Zhang, Qianru Wu, Xuezhi Shi, Junchao Chang, and Jiping Lu. 2017. "Microstructure and Mechanical Properties of Ti-6Al-4V Fabricated by Vertical Wire Feeding with Axisymmetric Multi-Laser Source" Applied Sciences 7, no. 3: 227. https://doi.org/10.3390/app7030227

APA StyleFu, J., Gong, L., Zhang, Y., Wu, Q., Shi, X., Chang, J., & Lu, J. (2017). Microstructure and Mechanical Properties of Ti-6Al-4V Fabricated by Vertical Wire Feeding with Axisymmetric Multi-Laser Source. Applied Sciences, 7(3), 227. https://doi.org/10.3390/app7030227