Modeling and Solving the Three Seaside Operational Problems Using an Object-Oriented and Timed Predicate/Transition Net

Abstract

:1. Introduction

2. Literature Review

2.1. Studies Focusing on BAP or QCAP

2.2. Studies Focusing on QCSP

2.3. Studies Focusing on Simultaneous Problems

3. Problem Definitions and Formulation

3.1. The Definitions of BAP, QCAP, and QCSP

| i | a ship number |

| j | a berth number |

| m | the total number of ships |

| n | the total number of berths |

| t | a time period () |

| S | a set of ships; S = {1,…,m} |

| B | a set of berths; B = {1,…,n} |

| the draft of ship i | |

| the length of ship i | |

| the length of berth j | |

| the depth of berth j | |

| a set of constraints | |

| T | the planning horizon in units of hours T = {1,…,H}; H = 168 h for 1 week |

| a decision variable; if ship i is assigned to berth j at time period t then = 1; Otherwise, = 0. | |

| a collection of sets of solutions with ship-to-berth assignments; | |

| . | |

| f1 | an objective function maps to a time/cost value |

| I | a ship number () |

| K | a task number () |

| Q | a quay crane number () |

| m | the total number of ships |

| n | the total number of berths |

| t | a time period () |

| Ki | the total number of tasks of ship i |

| l | the total number of QCs |

| S | a set of ships; S = {1,…,m} |

| B | a set of berths; B = {1,…,n} |

| a set of constraints | |

| Q | a set of quay crane; Q = {1,…,l} |

| T | the planning horizon in units of hours T = {1,…,H}; H = 168 h (10,080 min) for 1 week. |

| a decision variable; if quay crane q is assigned to process the task k of ship i at time t then ; otherwise . | |

| a collection of sets of QC-to-task assignments for ships i = 1,…,m; | |

| f2 | an objective function that maps to a time/cost value |

| i | a ship number (i ) |

| k | a task number (k ) |

| q | a quay crane number (q ) |

| m | the number of ships |

| l | the total number of quay cranes |

| li | the total number of quay cranes assigned to the ship i () |

| Ki | the total number of tasks of ship i |

| S | a set of ships; S = {1,…,m} |

| B | a set of berths; B = {1,…,n} |

| a set of constraints | |

| Q | a set of quay cranes Q = {1,…,l} |

| a decision variable; the beginning time of QC q to process the task k of ship i | |

| a decision variable; the end time of the QC q to process the task k of ship i | |

| T | the planning horizon in units of hours T = {1,…,H}; H = 168 h (10,080 min) for 1 week. |

| a collection of sets of QC schedules for all ships; | |

| f3 | a function that maps to a time/cost value |

3.2. The Mathematical Formulation of the Integrated Problem

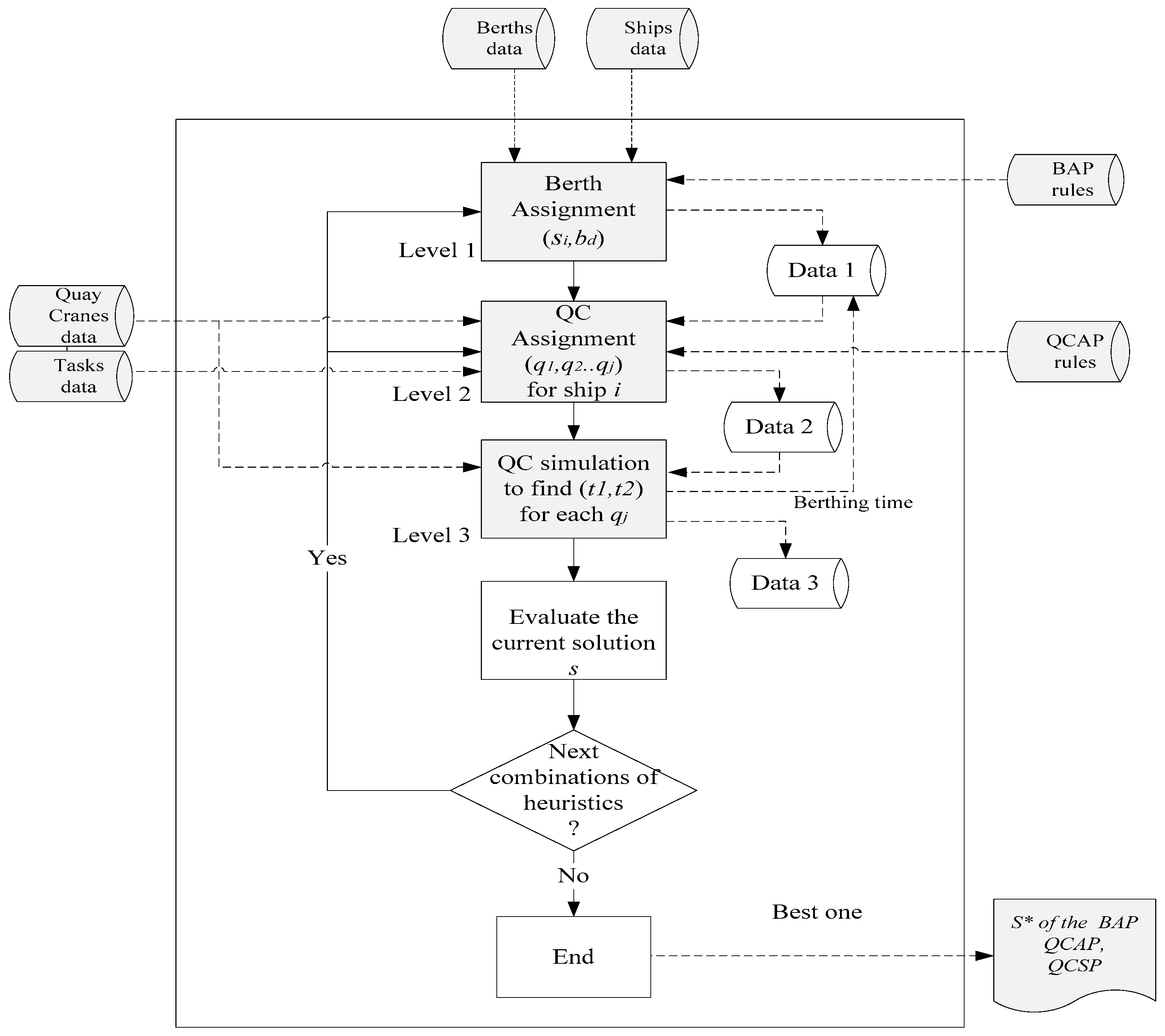

3.3. A Three-Level Framework of Planning

- Level 1:

- this level deals with the BAP. In this stage, heuristic rules can be used to allocate ships to berths. For example, the least workload (LWL) rule always assigns a ship to a berth that currently has the least workload. As a result, the workload among berths are balanced. The algorithm of the LWL is detailed below.

- Step 1.

- Set the current workload of each berth to zero.

- Step 2.

- Sort the calling ships by their Estimated Time of Arrivals (ETAs) to an ascending list S.

- Step 3.

- Sort the berths by their workloads to an ascending set B.

- Step 4.

- If S ≠ ∅ then

- Assign the first ship in S to the first berth in B

- Remove the first ship from S

- Go to Step 5

Else- Go to Step 6

End if. - Step 5.

- Update the current workload of the selected berth, and then go to Step 3.

- Step 6.

- End

- Level 2:

- this level deals with QCAP and QCSP. In this level, heuristics rules are used to assign QCs to ships. For example, the Load Balance (LB) rule assigns QCs to berths according to the workloads of ships assigned to berths. After determining the number of QCs assigned to each berth, the QCs are sequentially assigned to berths according to the QC number (Assume that QC along the quayside are assigned with an increasing QC number). Then, each task of a ship can be assigned to an assigned QC to that ship by using a LB rule, subjecting to the non-crossing characteristic of QCs. The LB rule is detailed below.

- Step 1.

- Calculate the numbers of QCs (, ) to be assigned to each berth j using Equation (13), in which the round operator rounds each off to the nearest whole digit; is the total number of containers to be handled for the task k of ship i; is the number of ships assigned to berth j at Level 1.

- Step 2.

- Set the workload of each QC q to zero (i.e., , q ). And, set u = 1 and i = 1.

- Step 3.

- Sort all QCs into an ascending set Q = {} according to their QC numbers.

- Step 4.

- Allocate QCs one by one to each berth according to the QC numbers until the amount is reached. Then the QCs assigned to a same berth are a group and denoted as , where .

- Step 5.

- Sort the tasks of each ship i into an ascending task set according to the task numbers.

- Step 6.

- Calculate the current workload of ship i () by totaling the numbers of containers to load ( and unload ( for each task k in the task set using Equation (14).

- Step 7.

- Calculate the average number of containers () as a benchmark using Equation (15).

- Step 8.

- Calculate the respective workload of the first task k (denoted as ) and the second task k + 1 (denoted as ) in the task set Ti by totaling the number of containers to load and unload.

- Step 9.

- Estimate the expected workload ( of the first QC in if the task k of ship i is added using Equation (16).

- Step 10.

- If then

- assign the task k of ship i to the QC q

- pop the task k out of the

- pop the QC q out of the

- q = q + 1 (change to the next QC)

Else if and )- assign the task k of ship i to the QC q

- pop the task k out of the task set

- pop the QC q out of the

- q = q + 1 (change to the next QC)

Else- assign the task k of ship i to the QC q

- pop the task k out of the task set

End if - Step 11.

- If then

- k = k + 1 (change to the next task)

- u = u + 1

- Go to Step 6

Else- i = i + 1 (change to the next ship)

- Go to Step 12

End if - Step 12.

- If then

- Go to Step 13

Else- u = 1

- Go to Step 5

End if - Step 13.

- End

- Level 3:

- this level deals with the QCSP. After determining which task is handled by which QC in level 2, this level uses a discrete simulation approach to simulate container loading and unloading for each task of a ship. As a result, the beginning and ending times of each task can be determined. Finally, the starting and ending working time of a ship are fed back to level 1 as the berthing time of each ship. The following steps are used in this level.

- Step 1.

- Find the task token with least available time.

- Step 2.

- Find the QC assigned to the task token.

- Step 3.

- Determine the beginning time and the end time of the task based on the available time of the assigned QC.

- Step 4.

- Update the available time of the QC after serving this task token.

- Step 5.

- Return the assigned QC.

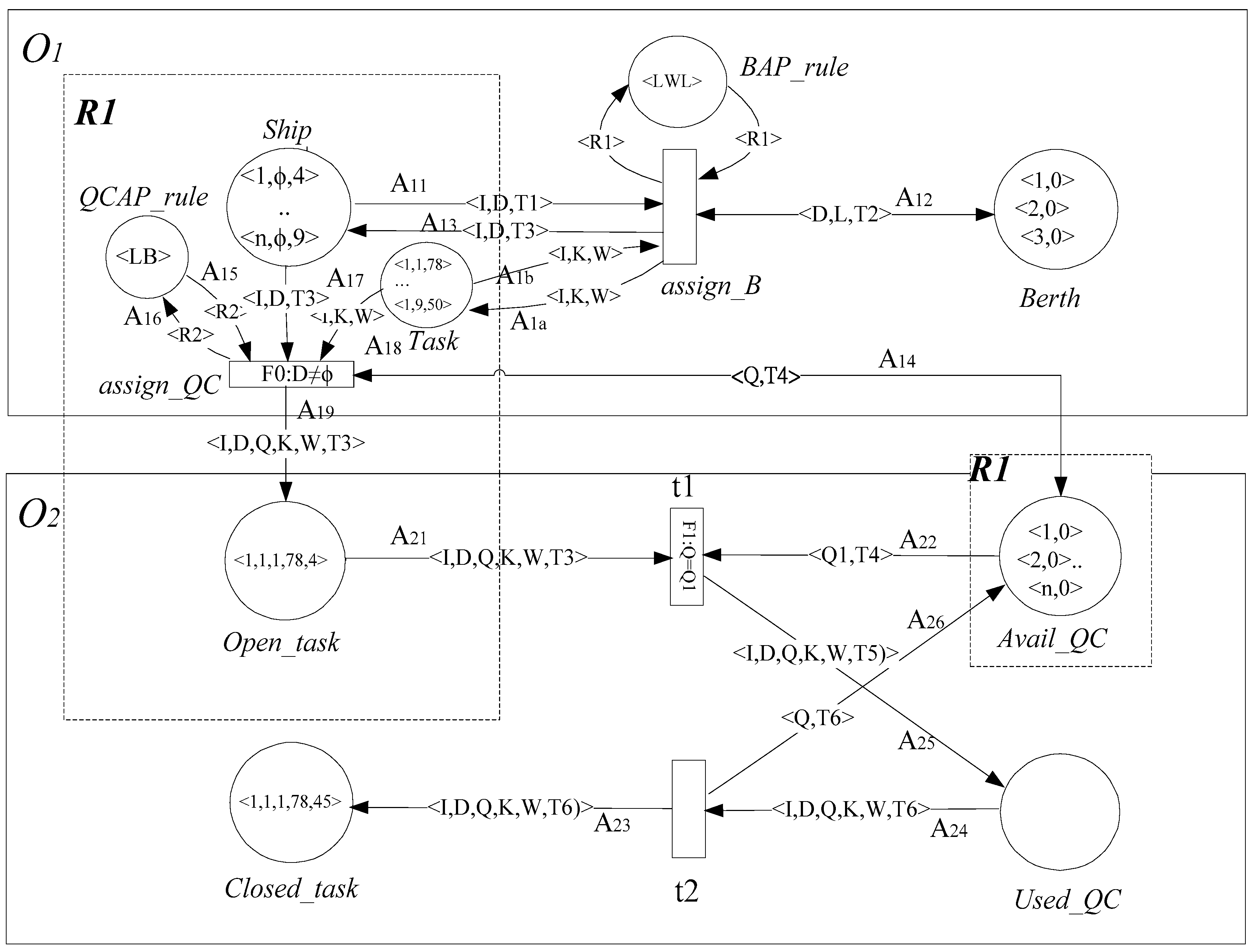

4. Modeling and Implementing the Three-Level Framework of Heuristics and Simulation

4.1. The Definition of Object-Oriented and Timed Predicate/Transition Net

| a set of predicates. , or . , is the set of timed predicates while is the set of predicates with zero time | |

| T | a set of transitions (with logical formulas) |

| A | a set of arcs |

| Σ | a structure Σ consisting of some sort of individual tokens together with some operations (OPj) and relations (Rk), i.e., Σ = (T1,...,Ti; OP1,...,OPj; R1,...,Rk) |

| L | a labeling of all arcs with a formal sum of n attributes of the token’s variables (attributes), including zero-attributes that indicate a no-argument token |

| LF | a set of inscriptions on some transitions being logical formulas built from the operations and relations of the structure Σ; Variables occurring free in a formula have to occur at an adjacent arc |

| M | a marking M of the predicates of P with formal sums of n-topples of individual tokens. |

| F | firing rule of each element of T representing a class of possible changes of markings. Such a change, also called transition firing, consists of removing tokens from a subset of predicates and adding them to other subsets of predicates according to the expressions labeling the arcs. A transition is enabled whenever a set of tokens associated with that transition are satisfied. |

| ; is a function mapping to a handling time ; . |

- O: is a set of finite subnet objects.

- R: is a set of communication relations between Oi.

4.2. The OOTPr/Tr Net Model for the Three-Level Framework

4.3. The Algorithm for Implementing the OOTPr/Tr Net Model

| Step 1 | Place the Ship_token <I,D,T1>, Berth_token <D,L,T2>, BAP_rule_token <R1>, QCAP_rule_token <R2>, Task_token <I,D,W>, Avail_QC_token <Q1,T4> at the predicates Ship, Berth, BAR_rule, QCAP_rule, Task, and Avail_QC, respectively. |

| Step 2 | (In O1) trigger the transition assign_B, it will assign a berth_token <D,L,T2> to the Ship_token <I,D,T1> using a BAP_rule_token <R1>. |

| Step 3 | Trigger the transition assign_QC, it will assign a number of QCs to each berth (D) using the QCAP_rule_token <R2>. In addition, a QC (Q) will be subsequently assigned to handle a specific Open_Task_token <I,D,Q,K,W,T3> of the specific ship I. |

| Step 4 | (In O2) trigger the transition t1, it will simulate loading and unloading Open_Task_tokens <I,D,Q,K,W,T3> based on assigned QCs. Repeat this until all Open_Task_tokens <I,D,Q,K,W,T3> have been completed and transited to the predicate Close_task as Close_task_tokens <I,D,Q,K,W,T6>. During the simulation, generate the beginning time ( and the end time ( for each task of a ship. This results in a solution s. |

| Step 5 | Evaluate the solution s using the objective function defined in Equation (1). |

| Step 6 | Compare the solution s to the current best solution s*. If s > s* then s* = s. |

| Step 7 | Check whether there are other BAP_rule_token <R1> and/or QCAP_rule_token <R2>. If “yes” then go to Step 1; Otherwise, go to Step 8. |

| Step 8 | Determine the berthing time (BTi) of each ship i using Equation (10). |

| Step 9 | End |

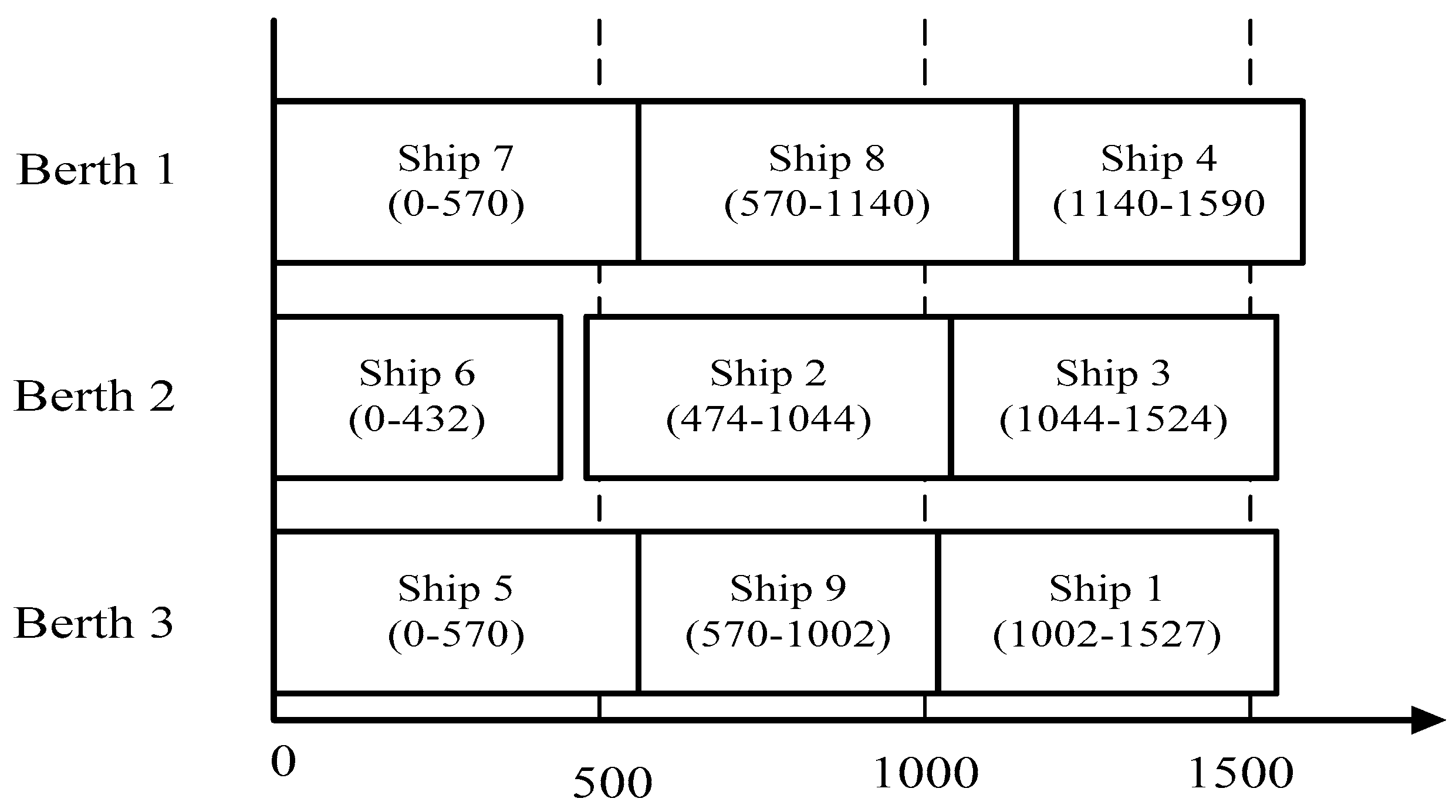

5. Numerical Example

5.1. Inputs

5.2. Outputs

6. Conclusions and Future Research Direction

- (1)

- We have initiated a novel graphical tool, termed OOTPr/Tr net, which can be used for modeling and problem solving.

- (2)

- Using this novel graphical tool, we have successfully modeling the three seaside operational problems. This model was found to be quite flexible since resources such as ships, berths, and QCs are represented as tokens that can easily added into the model. In addition, we have implemented the derived OOTPr/Tr net as an evaluation tool.

- (3)

- The approach proposed in this study can be regarded as a simulation approach based on a reduced search space formed by the combinations of BAP and QCAP heuristic rules.

Author Contributions

Conflicts of Interest

Appendix A

- Ship_tokens (<I,D,T1>)

- ship_token (“ship 1”,0,40).

- ship_token (“ship 2”,0,10).

- ship_token (“ship 3”,0,30).

- ship_token (“ship 4”,0,20).

- ship_token (“ship 5”,0,0).

- ship_token (“ship 6”,0,0).

- ship_token (“ship 7”,0,0).

- ship_token (“ship 8”,0,5).

- ship_token (“ship 9”,0,10).

- Berth_tokens (<D,T2>)

- berth_token (1,0).

- berth_token (2,0).

- berth_token (3,0).

- Avail_QC_tokens (<J,T4>)

- avail_qc_token (1,0).

- avail_qc_token (2,0).

- avail_qc_token (3,0).

- avail_qc_token (4,0).

- avail_qc_token (5,0).

- avail_qc_token (6,0).

- avail_qc_token (7,0).

- avail_qc_token (8,0).

- avail_qc_token (9,0).

- avail_qc_token (10,0).

- BAP_rule_tokens (<R1>)

- bap_rule_token (“LWL”).

- bap_rule_token (“SPT”).

- QCAP_rule_tokens (<R2>)

- qcap_rule_token (“LB”).

- Task_tokens (<I,D,container(K,)>)

- task_token (“ship 1”,0,container(1,40,30)).

- task_token (“ship 1”,0,container(3,50,45)).

- task_token (“ship 1”,0,container(5,30,25)).

- task_token (“ship 1”,0,container(7,30,45)).

- task_token (“ship 1”,0,container(9,55,43)).

- task_token (“ship 1”,0,container(11,50,45)).

- task_token (“ship 1”,0,container(13,38,42)).

- task_token (“ship 1”,0,container(15,50,45)).

- task_token (“ship 2”,0,container(3,30,45)).

- task_token (“ship 2”,0,container(5,50,35)).

- task_token (“ship 2”,0,container(7,30,45)).

- task_token (“ship 2”,0,container(9,50,49)).

- task_token (“ship 2”,0,container(11,50,45)).

- task_token (“ship 2”,0,container(15,50,45)).

- task_token (“ship 3”,0,container(1,22,35)).

- task_token (“ship 3”,0,container(3,50,25)).

- task_token (“ship 3”,0,container(5,25,45)).

- task_token (“ship 3”,0,container(7,50,40)).

- task_token (“ship 3”,0,container(9,45,45)).

- task_token (“ship 3”,0,container(11,50,45)).

- task_token (“ship 3”,0,container(13,50,15)).

- task_token (“ship 4”,0,container(1,50,50)).

- task_token (“ship 4”,0,container(3,33,45)).

- task_token (“ship 4”,0,container(5,20,35)).

- task_token (“ship 4”,0,container(7,10,45)).

- task_token (“ship 4”,0,container(9,50,45)).

- task_token (“ship 5”,0,container(1,50,35)).

- task_token (“ship 5”,0,container(5,50,45)).

- task_token (“ship 5”,0,container(7,50,44)).

- task_token (“ship 5”,0,container(9,50,45)).

- task_token (“ship 5”,0,container(11,50,33)).

- task_token (“ship 5”,0,container(13,60,47)).

- task_token (“ship 5”,0,container(15,50,45)).

- task_token (“ship 6”,0,container(5,20,24)).

- task_token (“ship 6”,0,container(7,50,45)).

- task_token (“ship 6”,0,container(9,28,35)).

- task_token (“ship 6”,0,container(11,50,45)).

- task_token (“ship 6”,0,container(13,27,22)).

- task_token (“ship 6”,0,container(15,50,45)).

- task_token (“ship 7”,0,container(1,23,35)).

- task_token (“ship 7”,0,container(5,30,25)).

- task_token (“ship 7”,0,container(7,50,44)).

- task_token (“ship 7”,0,container(9,40,40)).

- task_token (“ship 7”,0,container(11,20,30)).

- task_token (“ship 7”,0,container(13,20,40)).

- task_token (“ship 8”,0,container(1,23,35)).

- task_token (“ship 8”,0,container(5,30,25)).

- task_token (“ship 8”,0,container(7,50,44)).

- task_token (“ship 8”,0,container(9,40,40)).

- task_token (“ship 8”,0,container(11,20,30)).

- task_token (“ship 8”,0,container(13,20,40)).

- task_token (“ship 9”,0,container(5,20,24)).

- task_token (“ship 9”,0,container(7,50,45)).

- task_token (“ship 9”,0,container(9,28,35)).

- task_token (“ship 9”,0,container(11,50,45)).

- task_token (“ship 9”,0,container(13,27,22)).

- task_token (“ship 9”,0,container(15,50,45)).

References

- Chung, S.H.; Choy, K.L. A modified genetic algorithm for quay crane scheduling operations. Expert Syst. Appl. 2012, 39, 4213–4221. [Google Scholar] [CrossRef]

- Salido, M.A.; Mario, R.M.; Barber, E. A decision support system for managing combinatorial problems in a container terminal. Knowl. Based Syst. 2012, 29, 63–74. [Google Scholar] [CrossRef]

- Liu, Y.B.; Zhou, C.G.; Guo, D.G.; Wang, K.P.; Pang, W.P.; Zhai, Y.K. A decision support system using soft computing for modern international container transportation services. Appl. Soft Comput. 2012, 10, 1087–1095. [Google Scholar] [CrossRef]

- Vis, I.F.A.; de Koster, R. Transshipment of container at a container terminal: An overview. Eur. J. Oper. Res. 2003, 147, 1–16. [Google Scholar] [CrossRef]

- Bierwirth, C.; Meisel, F. A survey of berth allocation and quay crane scheduling problems in container terminals. Eur. J. Oper. Res. 2010, 202, 615–627. [Google Scholar] [CrossRef]

- Lee, Y.; Chen, C.Y. An optimization heuristic for the berth scheduling problem. Eur. J. Oper. Res. 2009, 196, 500–508. [Google Scholar] [CrossRef]

- Liang, C.J.; Huang, Y.F.; Yang, Y. A quay crane dynamic scheduling problem by hybrid evolutionary algorithm for berth allocation planning. Comput. Ind. Eng. 2009, 56, 1021–1028. [Google Scholar] [CrossRef]

- Raa, B.; Dullaert, W.; Schaeren, R.V. An enriched model for the integrated berth allocation and quay crane assignment problem. Expert Syst. Appl. 2011, 38, 14136–14147. [Google Scholar] [CrossRef]

- Zhang, C.R.; Zheng, L.; Zhang, Z.H.; Shi, L.Y.; Armstrong, A.J. The allocation of berths and quay cranes by using a sub-gradient optimization technique. Comput. Ind. Eng. 2010, 58, 40–50. [Google Scholar] [CrossRef]

- Lee, D.H.; Wang, H.Q.; Miao, L. Quay crane scheduling with handling priority in port container terminals. Eng. Optim. 2008, 40, 179–189. [Google Scholar] [CrossRef]

- Canonaco, P.; Legato, P.; Mazza, R.M.; Musmanno, R. A queuing network model for the management of berth crane operations. Comput. Oper. Res. 2008, 35, 2432–2446. [Google Scholar] [CrossRef]

- Kim, K.H.; Park, Y.M. A crane scheduling method for port container terminals. Eur. J. Oper. Res. 2004, 156, 752–768. [Google Scholar] [CrossRef]

- Zhang, H.; Kim, K.H. Maximizing the number of dual-cycle operations of quay cranes in container terminals. Comput. Ind. Eng. 2009, 56, 979–992. [Google Scholar] [CrossRef]

- Legato, P.; Mazza, R.M. Berth planning and resource optimization at container terminal via discrete event simulation. Eur. J. Oper. Res. 2001, 133, 537–547. [Google Scholar] [CrossRef]

- Peterkofsky, R.I.; Daganzo, C.R. A branch and bound solution method for the crane scheduling problem. Transp. Res. B 1990, 24, 159–172. [Google Scholar] [CrossRef]

- Sun, Z.; Lee, L.H.; Chew, E.P.; Tan, K. MicroPort: A general simulation platform for seaport container terminals. Adv. Eng. Inform. 2012, 26, 80–89. [Google Scholar] [CrossRef]

- Liang, C.J.; Guo, J.Q.; Yang, Y. Multi-objective hybrid genetic algorithm for quay crane dynamic assignment in birth allocation planning. J. Intell. Manuf. 2011, 22, 471–479. [Google Scholar] [CrossRef]

- Jin, Z.H.; Li, N. Optimization of quay crane dynamic scheduling based on berth schedules in container terminal. J. Transp. Syst. Eng. Inf. Technol. 2011, 1, 58–64. [Google Scholar] [CrossRef]

- Imai, A.; Chen, H.C.; Nishimura, E.; Papadimitriou, S. The simultaneous berth and quay crane allocation problem. Transp. Res. E 2008, 44, 900–920. [Google Scholar] [CrossRef]

- Zhou, P.R.; Kang, H.G. Study on berth and quay-crane allocation under stochastic environments in container terminal. Syst. Eng. Theory Pract. 2008, 28, 161–169. [Google Scholar] [CrossRef]

- Chang, D.F.; Jiang, Z.H.; Yan, W.; He, J.L. Integrating berth allocation and quay crane assignments. Transp. Res. E 2010, 46, 975–990. [Google Scholar] [CrossRef]

- Lee, D.H.; Wang, H.Q. Integrated discrete berth allocation and quay crane scheduling in port container terminals. Eng. Optim. 2010, 42, 747–761. [Google Scholar] [CrossRef]

- Han, X.L.; Lu, Z.Q.; Xi, L.R. A proactive approach for simultaneous berth and quay crane scheduling problem with stochastic arrival and handling time. Eur. J. Oper. Res. 2010, 207, 1327–1340. [Google Scholar] [CrossRef]

- Xu, D.S.; Li, C.L.; Leung, J.Y.T. Berth allocation with time-dependent physical limitations on vessels. Eur. J. Oper. Res. 2012, 216, 47–56. [Google Scholar] [CrossRef]

- Ng, W.C.; Mak, K.L. Quay crane scheduling in container terminals. Eng. Optim. 2006, 38, 723–737. [Google Scholar] [CrossRef]

- Legato, P.; Trunfio, R.; Meisel, F. Modeling and solving rich quay crane scheduling problems. Comput. Oper. Res. 2012, 39, 2063–2078. [Google Scholar] [CrossRef]

- Maione, G.; Mangini, A.M.; Ottomanelli, M. A Generalized Stochastic Petri Net Approach for Modeling Activities of Human Operators in Intermodal Container Terminals. IEEE Trans. Autom. Sci. Eng. 2016, 13, 1504–1516. [Google Scholar] [CrossRef]

- Zhang, F.A.H.; Jiang, S.B.Z. Modeling and Analysis of Container Terminal Logistics System by Extended Generalized Stochastic Petri Nets. In Proceedings of the 2006 IEEE International Conference on Service Operations and Logistics, and Informatics, Shanghai, China, 21–23 June 2006; pp. 310–315.

- Murty, K.G.; Liu, J.Y.; Wan, Y.W.; Linn, R. A decision support system for operations in a container terminal. Decis. Support Syst. 2005, 59, 309–332. [Google Scholar] [CrossRef]

- Song, L.I.; Cherrett, T.; Guan, W. Study on berth planning problem in a container seaport: Using an integrated programming approach. Comput. Ind. Eng. 2012, 62, 119–128. [Google Scholar] [CrossRef]

- Wu, N.Q.; Zhou, M.C.; Li, Z.W. Short-Term Scheduling of Crude-Oil Operations: Enhancement of Crude-Oil Operations Scheduling Using a Petri Net-Based Control-Theoretic Approach. IEEE Robot. Autom. Mag. 2015, 22, 64–76. [Google Scholar] [CrossRef]

- Yang, R.; Wu, N.; Qiao, Y.; Zhou, M.C. Petri Net-Based Polynomially Complex Approach to Optimal One-Wafer Cyclic Scheduling of Hybrid Multi-Cluster Tools in Semiconductor Manufacturing. IEEE Trans. Syst. Man Cybern. Syst. 2014, 44, 1598–1610. [Google Scholar] [CrossRef]

- Wu, N.; Zhou, M.C. Schedulability Analysis and Optimal Scheduling of Dual-Arm Cluster Tools with Residency Time Constraint and Activity Time Variation. IEEE Trans. Autom. Sci. Eng. 2012, 9, 203–209. [Google Scholar]

- Petering, M.E.H. Decision support for yard capacity, fleet composition, truck substitutability, and scalability issues at seaport container terminals. Transp. Res. E 2011, 47, 85–103. [Google Scholar] [CrossRef]

- Kim, K.H.; Moon, K.C. Berth scheduling by simulated annealing. Transp. Res. B 2003, 37, 541–560. [Google Scholar] [CrossRef]

- Wang, F.; Lim, A. A stochastic beam search for the berth allocation problem. Decis. Support Syst. 2007, 42, 2186–2196. [Google Scholar] [CrossRef]

- Zhen, L.; Hay, L.H.; Chew, E.P. A decision model for berth allocation under uncertainty. Eur. J. Oper. Res. 2011, 212, 54–68. [Google Scholar] [CrossRef]

- Buhrkal, K.; Zuglian, S.; Ropke, S.; Larsen, J.; Lusby, R. Models for the discrete berth allocation problem: A computational comparison. Transp. Res. E 2011, 47, 461–473. [Google Scholar] [CrossRef]

- Yin, X.R.; Khoo, L.P.; Chen, C.H. A distributed agent system for port planning and scheduling. Adv. Eng. Inform. 2011, 25, 403–412. [Google Scholar] [CrossRef]

- Zeng, Q.C.; Yang, Z.Z.; Lai, L.Y. Models and algorithms for multi-crane oriented scheduling method in container terminals. Transp. Policy 2009, 16, 271–278. [Google Scholar] [CrossRef]

- Pratap, S.; Daultani, Y.; Tiwari, M.K.; Mahanty, B. Rule based optimization for a bulk handling port operations. J. Intell. Manuf. 2015, 1–25. [Google Scholar] [CrossRef]

- Hsu, H.P.; Su, S.T. The implementation of an Activity-Based Costing collaborative production planning system for semiconductor backend production. Int. J. Prod. Res. 2005, 43, 2473–2492. [Google Scholar] [CrossRef]

- Hsu, H.P.; Hsu, H.M. Systematic modeling and implementation of a resource planning system for virtual enterprise by Predicate/Transition net. Expert Syst. Appl. 2008, 35, 1841–1857. [Google Scholar] [CrossRef]

| j | = 1 | Duration | ||||

|---|---|---|---|---|---|---|

| q | i | k | ||||

| 1 | 1 | ship 7 | 1 | 0 | 174 | 174 |

| 1 | 1 | ship 7 | 5 | 174 | 339 | 165 |

| 1 | 2 | ship 7 | 7 | 0 | 282 | 282 |

| 1 | 3 | ship 7 | 9 | 0 | 240 | 240 |

| 1 | 3 | ship 7 | 11 | 240 | 390 | 150 |

| 1 | 3 | ship 7 | 13 | 390 | 570 | 180 |

| 1 | 1 | ship 8 | 1 | 570 | 744 | 174 |

| 1 | 1 | ship 8 | 5 | 744 | 909 | 165 |

| 1 | 2 | ship 8 | 7 | 570 | 852 | 282 |

| 1 | 3 | ship 8 | 9 | 570 | 810 | 240 |

| 1 | 3 | ship 8 | 11 | 810 | 960 | 150 |

| 1 | 3 | ship 8 | 13 | 960 | 1140 | 180 |

| 1 | 1 | ship 4 | 1 | 1140 | 1440 | 300 |

| 1 | 2 | ship 4 | 3 | 1140 | 1374 | 234 |

| 1 | 2 | ship 4 | 5 | 1374 | 1539 | 165 |

| 1 | 3 | ship 4 | 7 | 1140 | 1305 | 165 |

| 1 | 3 | ship 4 | 9 | 1305 | 1590 | 285 |

| 2 | 4 | ship 6 | 5 | 0 | 132 | 132 |

| 2 | 4 | ship 6 | 7 | 132 | 417 | 285 |

| 2 | 5 | ship 6 | 9 | 0 | 189 | 189 |

| 2 | 5 | ship 6 | 11 | 189 | 474 | 285 |

| 2 | 6 | ship 6 | 13 | 0 | 147 | 147 |

| 2 | 6 | ship 6 | 15 | 147 | 432 | 285 |

| 2 | 4 | ship 2 | 3 | 474 | 699 | 225 |

| 2 | 4 | ship 2 | 5 | 699 | 954 | 255 |

| 2 | 5 | ship 2 | 7 | 474 | 699 | 225 |

| 2 | 5 | ship 2 | 9 | 699 | 996 | 297 |

| 2 | 6 | ship 2 | 11 | 474 | 759 | 285 |

| 2 | 6 | ship 2 | 15 | 759 | 1044 | 285 |

| 2 | 4 | ship 3 | 1 | 1044 | 1215 | 171 |

| 2 | 4 | ship 3 | 3 | 1215 | 1440 | 225 |

| 2 | 4 | ship 3 | 5 | 1440 | 1650 | 210 |

| 2 | 5 | ship 3 | 7 | 1044 | 1314 | 270 |

| 2 | 5 | ship 3 | 9 | 1314 | 1584 | 270 |

| 2 | 6 | ship 3 | 11 | 1044 | 1329 | 285 |

| 2 | 6 | ship 3 | 13 | 1329 | 1524 | 195 |

| 3 | 7 | ship 5 | 1 | 0 | 255 | 255 |

| 3 | 7 | ship 5 | 5 | 255 | 540 | 285 |

| 3 | 8 | ship 5 | 7 | 0 | 282 | 282 |

| 3 | 8 | ship 5 | 9 | 282 | 567 | 285 |

| 3 | 9 | ship 5 | 11 | 0 | 249 | 249 |

| 3 | 9 | ship 5 | 13 | 249 | 570 | 321 |

| 3 | 10 | ship 5 | 15 | 0 | 285 | 285 |

| 3 | 7 | ship 9 | 5 | 570 | 702 | 132 |

| 3 | 7 | ship 9 | 7 | 702 | 987 | 285 |

| 3 | 8 | ship 9 | 9 | 570 | 759 | 189 |

| 3 | 9 | ship 9 | 11 | 570 | 855 | 285 |

| 3 | 10 | ship 9 | 13 | 570 | 717 | 147 |

| 3 | 10 | ship 9 | 15 | 717 | 1002 | 285 |

| 3 | 7 | ship 1 | 1 | 1002 | 1212 | 210 |

| 3 | 7 | ship 1 | 3 | 1212 | 1497 | 285 |

| 3 | 8 | ship 1 | 5 | 1002 | 1167 | 165 |

| 3 | 8 | ship 1 | 7 | 1167 | 1392 | 225 |

| 3 | 9 | ship 1 | 9 | 1002 | 1296 | 294 |

| 3 | 9 | ship 1 | 11 | 1296 | 1581 | 285 |

| 3 | 10 | ship 1 | 13 | 1002 | 1242 | 240 |

| 3 | 10 | ship 1 | 15 | 1242 | 1527 | 285 |

| j | Duration | |||||

|---|---|---|---|---|---|---|

| q | i | k | ||||

| 1 | 1 | ship 7 | 1 | 0 | 174 | 174 |

| 1 | 1 | ship 7 | 5 | 174 | 339 | 165 |

| 1 | 1 | ship 8 | 1 | 570 | 744 | 174 |

| 1 | 1 | ship 8 | 5 | 744 | 909 | 165 |

| 1 | 1 | ship 4 | 1 | 1140 | 1440 | 300 |

| 1 | 2 | ship 7 | 7 | 0 | 282 | 282 |

| 1 | 2 | ship 8 | 7 | 570 | 852 | 282 |

| 1 | 2 | ship 4 | 3 | 1140 | 1374 | 234 |

| 1 | 2 | ship 4 | 5 | 1374 | 1539 | 165 |

| 1 | 3 | ship 7 | 9 | 0 | 240 | 240 |

| 1 | 3 | ship 7 | 11 | 240 | 390 | 150 |

| 1 | 3 | ship 7 | 13 | 390 | 570 | 180 |

| 1 | 3 | ship 8 | 9 | 570 | 810 | 240 |

| 1 | 3 | ship 8 | 11 | 810 | 960 | 150 |

| 1 | 3 | ship 8 | 13 | 960 | 1140 | 180 |

| 1 | 3 | ship 4 | 7 | 1140 | 1305 | 165 |

| 1 | 3 | ship 4 | 9 | 1305 | 1590 | 285 |

| 2 | 4 | ship 6 | 5 | 0 | 132 | 132 |

| 2 | 4 | ship 6 | 7 | 132 | 417 | 285 |

| 2 | 4 | ship 2 | 3 | 474 | 699 | 225 |

| 2 | 4 | ship 2 | 5 | 699 | 954 | 255 |

| 2 | 4 | ship 3 | 1 | 1044 | 1215 | 171 |

| 2 | 4 | ship 3 | 3 | 1215 | 1440 | 225 |

| 2 | 4 | ship 3 | 5 | 1440 | 1650 | 210 |

| 2 | 5 | ship 6 | 9 | 0 | 189 | 189 |

| 2 | 5 | ship 6 | 11 | 189 | 474 | 285 |

| 2 | 5 | ship 2 | 7 | 474 | 699 | 225 |

| 2 | 5 | ship 2 | 9 | 699 | 996 | 297 |

| 2 | 5 | ship 3 | 7 | 1044 | 1314 | 270 |

| 2 | 5 | ship 3 | 9 | 1314 | 1584 | 270 |

| 2 | 6 | ship 6 | 13 | 0 | 147 | 147 |

| 2 | 6 | ship 6 | 15 | 147 | 432 | 285 |

| 2 | 6 | ship 2 | 11 | 474 | 759 | 285 |

| 2 | 6 | ship 2 | 15 | 759 | 1044 | 285 |

| 2 | 6 | ship 3 | 11 | 1044 | 1329 | 285 |

| 2 | 6 | ship 3 | 13 | 1329 | 1524 | 195 |

| 3 | 7 | ship 5 | 1 | 0 | 255 | 255 |

| 3 | 7 | ship 5 | 5 | 255 | 540 | 285 |

| 3 | 7 | ship 9 | 5 | 570 | 702 | 132 |

| 3 | 7 | ship 9 | 7 | 702 | 987 | 285 |

| 3 | 7 | ship 1 | 1 | 1002 | 1212 | 210 |

| 3 | 7 | ship 1 | 3 | 1212 | 1497 | 285 |

| 3 | 8 | ship 5 | 7 | 0 | 282 | 282 |

| 3 | 8 | ship 5 | 9 | 282 | 567 | 285 |

| 3 | 8 | ship 9 | 9 | 570 | 759 | 189 |

| 3 | 8 | ship 1 | 5 | 1002 | 1167 | 165 |

| 3 | 8 | ship 1 | 7 | 1167 | 1392 | 225 |

| 3 | 9 | ship 5 | 11 | 0 | 249 | 249 |

| 3 | 9 | ship 5 | 13 | 249 | 570 | 321 |

| 3 | 9 | ship 9 | 11 | 570 | 855 | 285 |

| 3 | 9 | ship 1 | 9 | 1002 | 1296 | 294 |

| 3 | 9 | ship 1 | 11 | 1296 | 1581 | 285 |

| 3 | 10 | ship 5 | 15 | 0 | 285 | 285 |

| 3 | 10 | ship 9 | 13 | 570 | 717 | 147 |

| 3 | 10 | ship 9 | 15 | 717 | 1002 | 285 |

| 3 | 10 | ship 1 | 13 | 1002 | 1242 | 240 |

| 3 | 10 | ship 1 | 15 | 1242 | 1527 | 285 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsu, H.-P.; Wang, C.-N.; Chou, C.-C.; Lee, Y.; Wen, Y.-F. Modeling and Solving the Three Seaside Operational Problems Using an Object-Oriented and Timed Predicate/Transition Net. Appl. Sci. 2017, 7, 218. https://doi.org/10.3390/app7030218

Hsu H-P, Wang C-N, Chou C-C, Lee Y, Wen Y-F. Modeling and Solving the Three Seaside Operational Problems Using an Object-Oriented and Timed Predicate/Transition Net. Applied Sciences. 2017; 7(3):218. https://doi.org/10.3390/app7030218

Chicago/Turabian StyleHsu, Hsien-Pin, Chia-Nan Wang, Chien-Chang Chou, Ying Lee, and Yuan-Feng Wen. 2017. "Modeling and Solving the Three Seaside Operational Problems Using an Object-Oriented and Timed Predicate/Transition Net" Applied Sciences 7, no. 3: 218. https://doi.org/10.3390/app7030218

APA StyleHsu, H.-P., Wang, C.-N., Chou, C.-C., Lee, Y., & Wen, Y.-F. (2017). Modeling and Solving the Three Seaside Operational Problems Using an Object-Oriented and Timed Predicate/Transition Net. Applied Sciences, 7(3), 218. https://doi.org/10.3390/app7030218