Effect of Aggregate Mineralogy and Concrete Microstructure on Thermal Expansion and Strength Properties of Concrete

Abstract

:1. Introduction

2. Materials and Design Methods

2.1. Materials

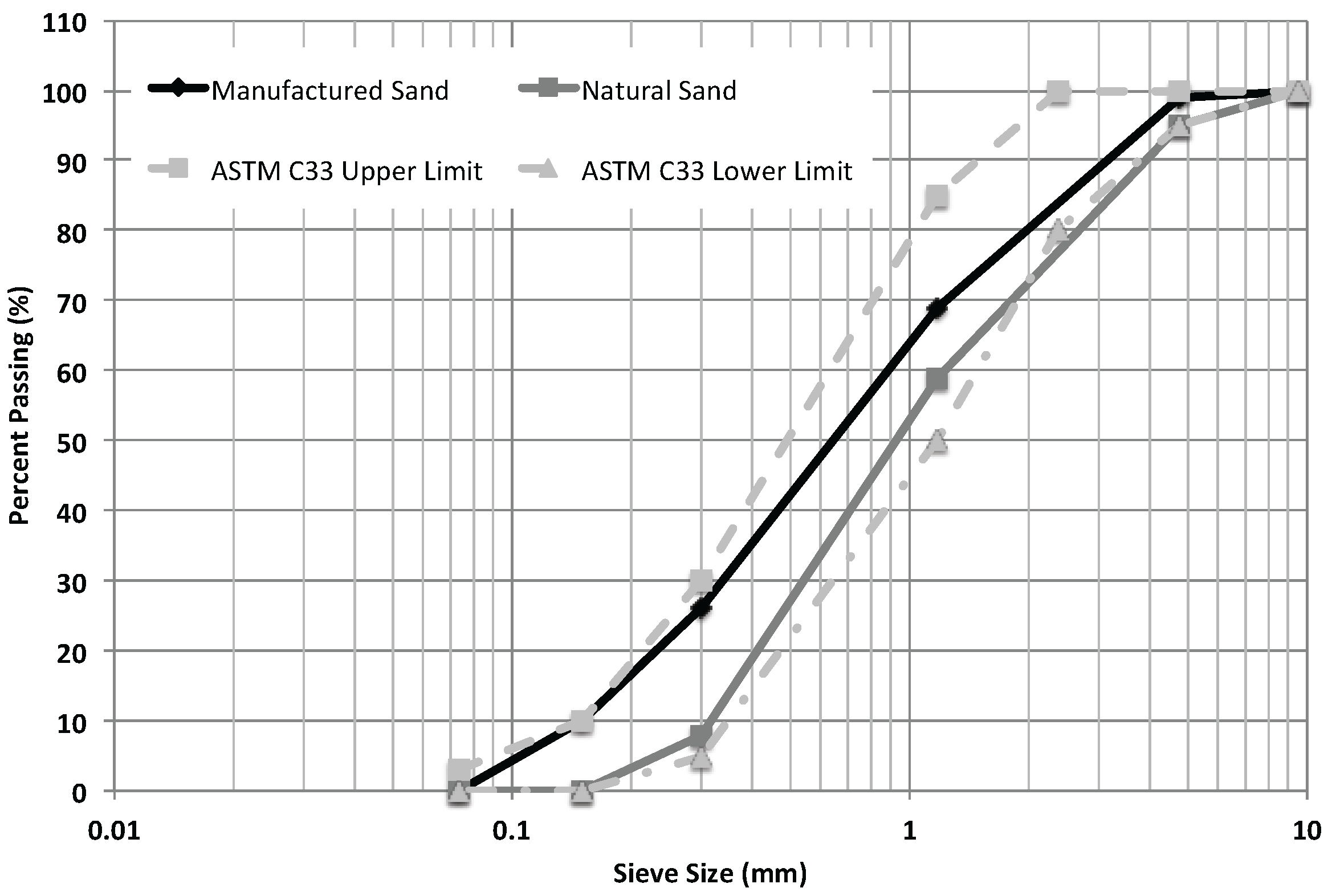

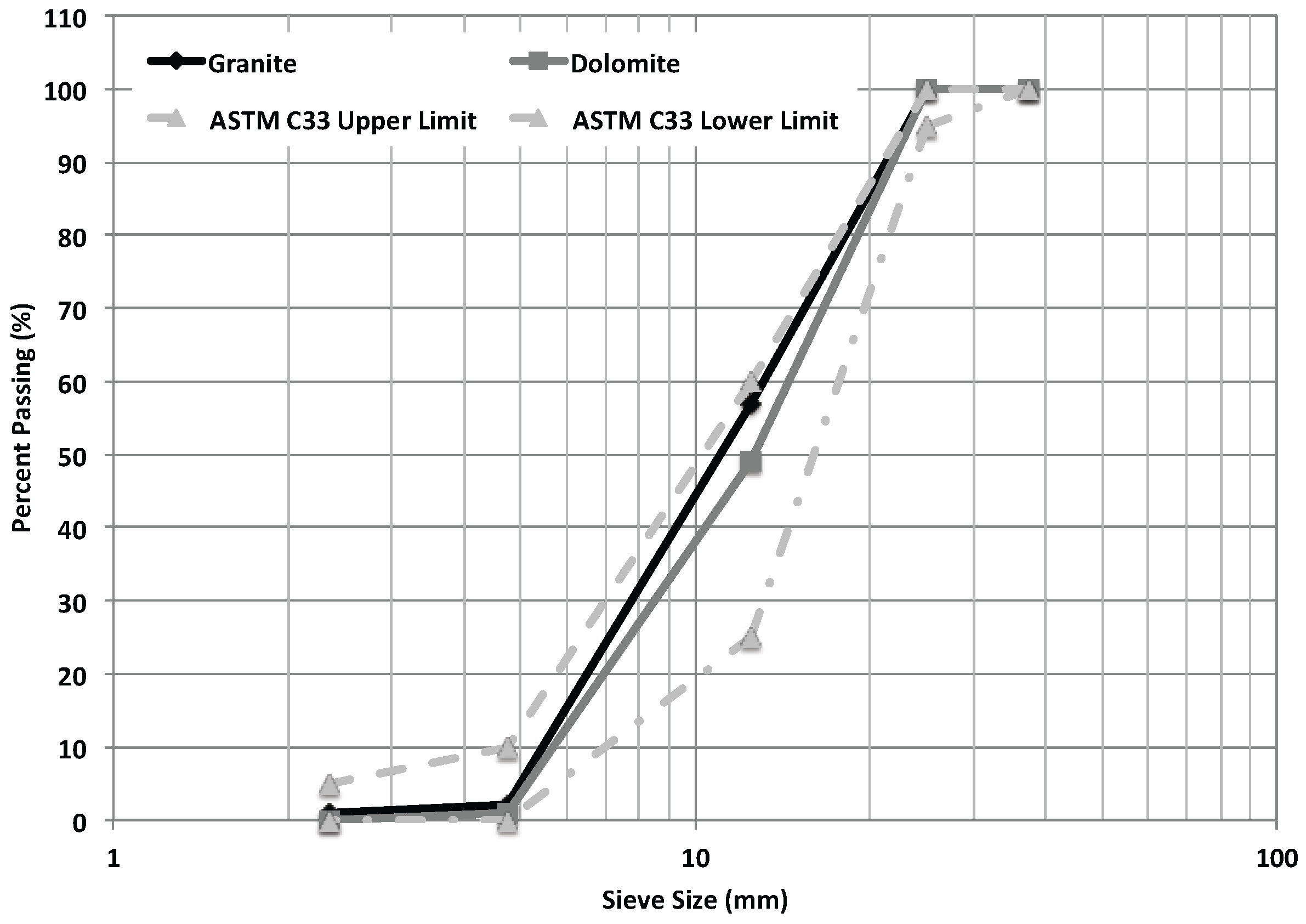

2.1.1. Aggregate Material Properties

2.1.2. Cementitious Materials

2.2. Mixture Design

2.3. Concrete Batching and Testing Methods

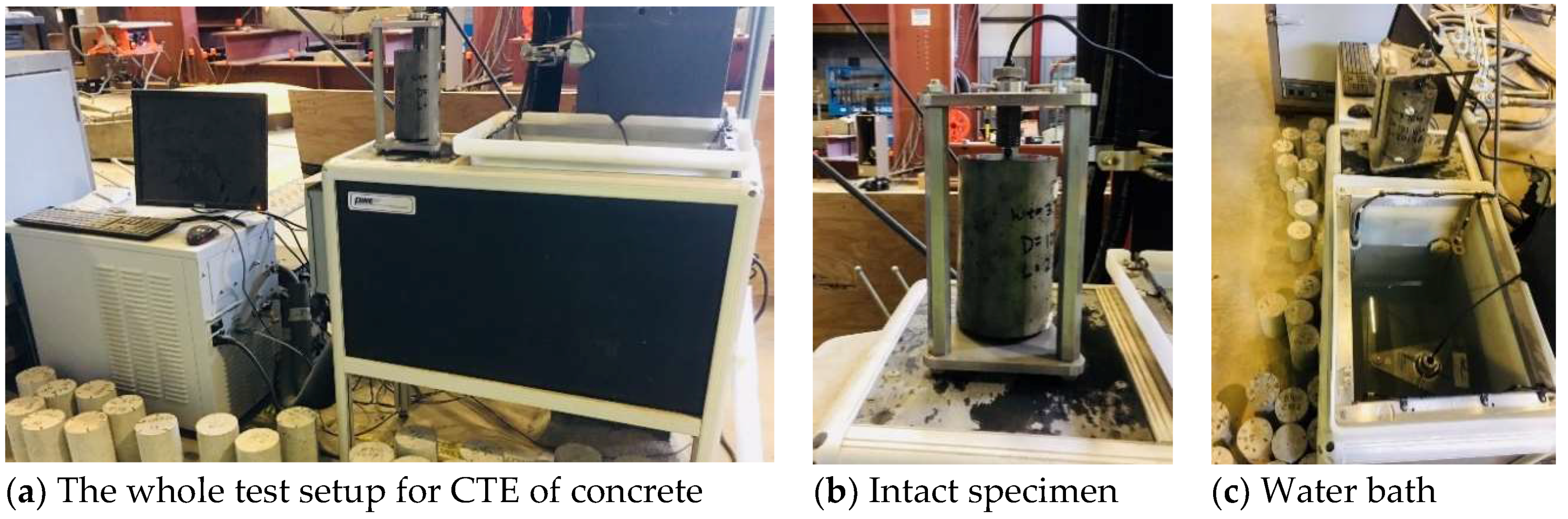

2.3.1. Coefficient of Thermal Expansion

2.3.2. Compressive Strength

2.3.3. Petrographic Examination

3. Experimental Results

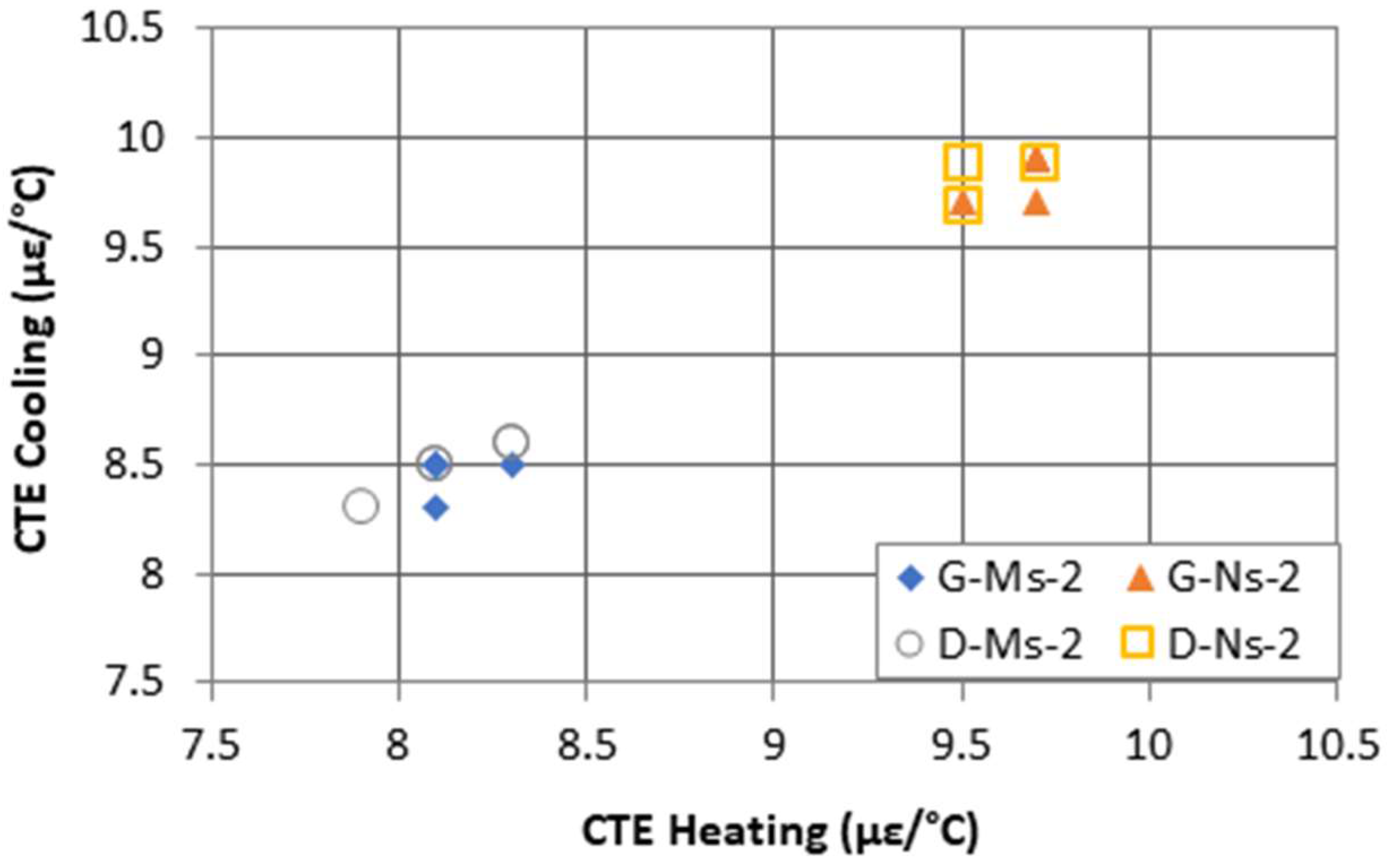

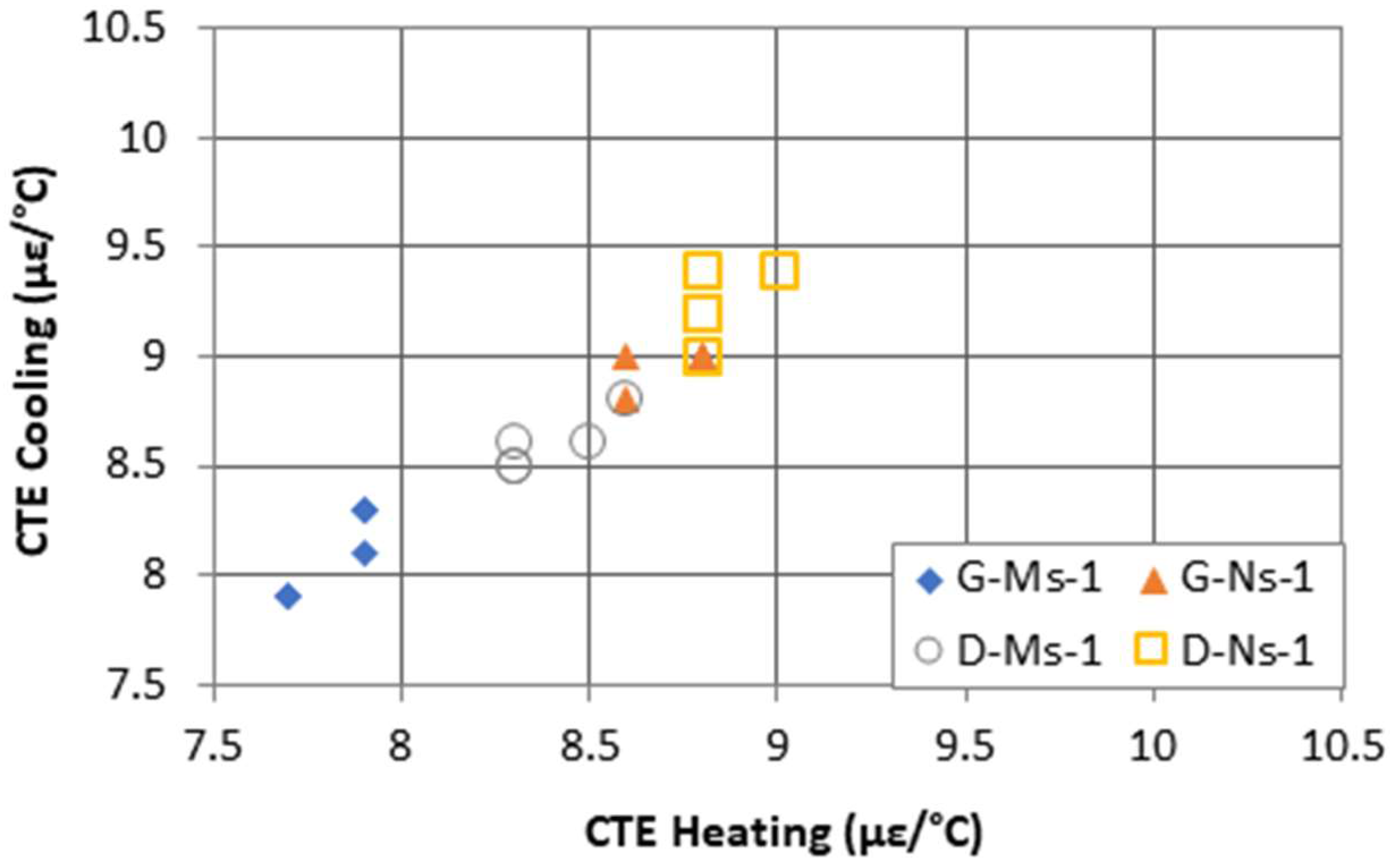

3.1. CTE Tests

3.2. Compressive Strength Tests

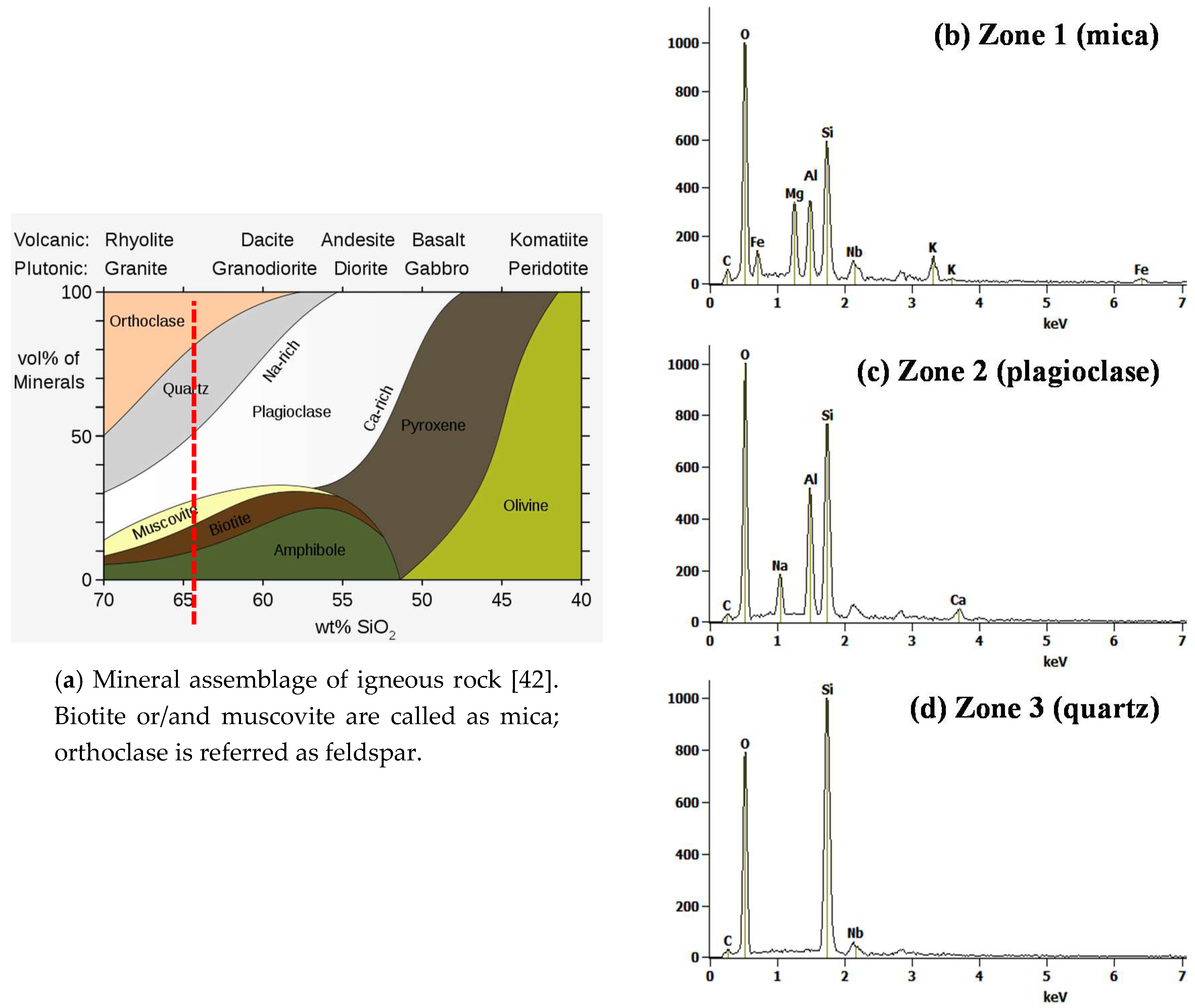

3.3. Mineral Characterization

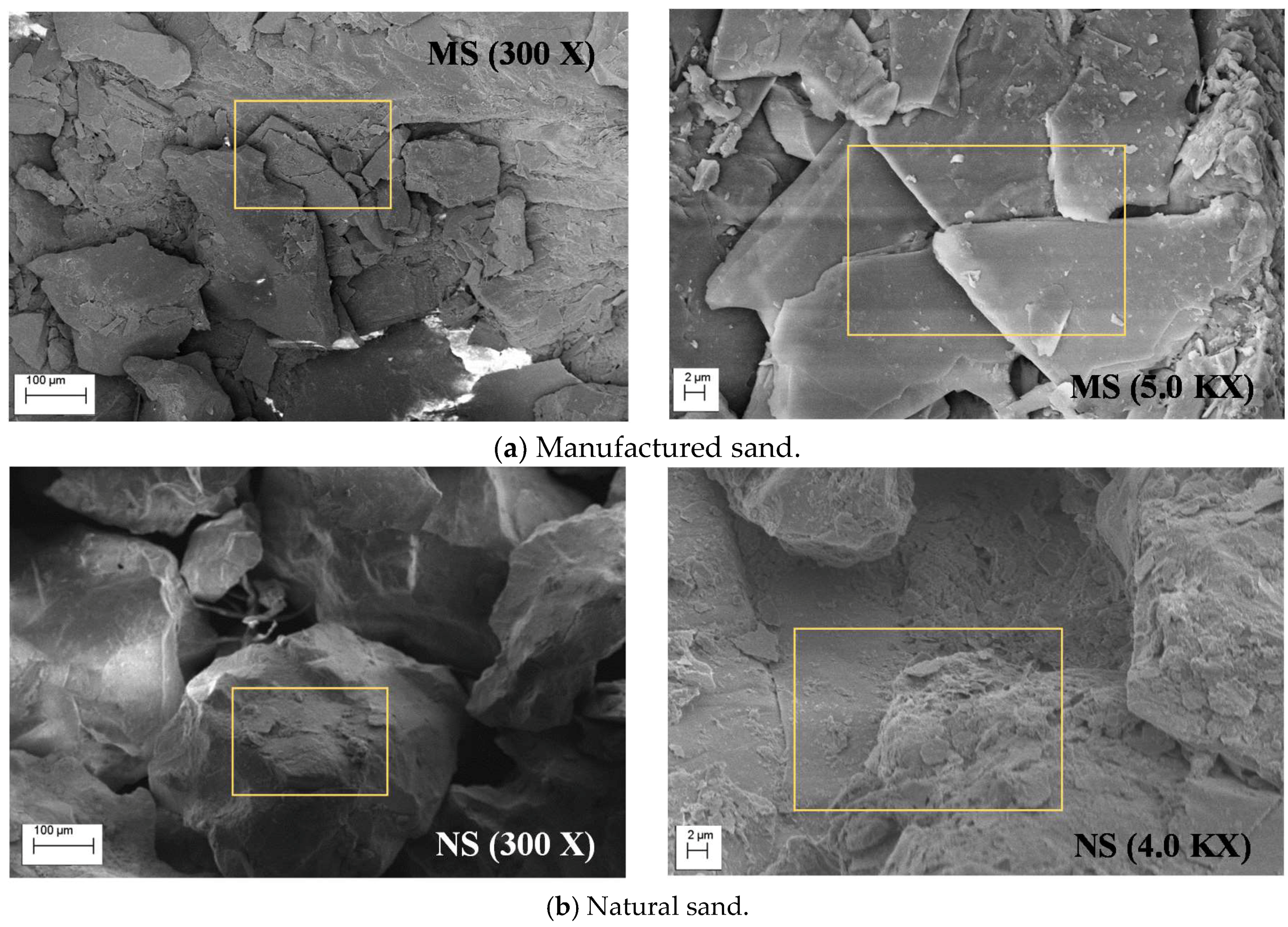

3.3.1. Fine Aggregate: Manufactured and Natural Sand

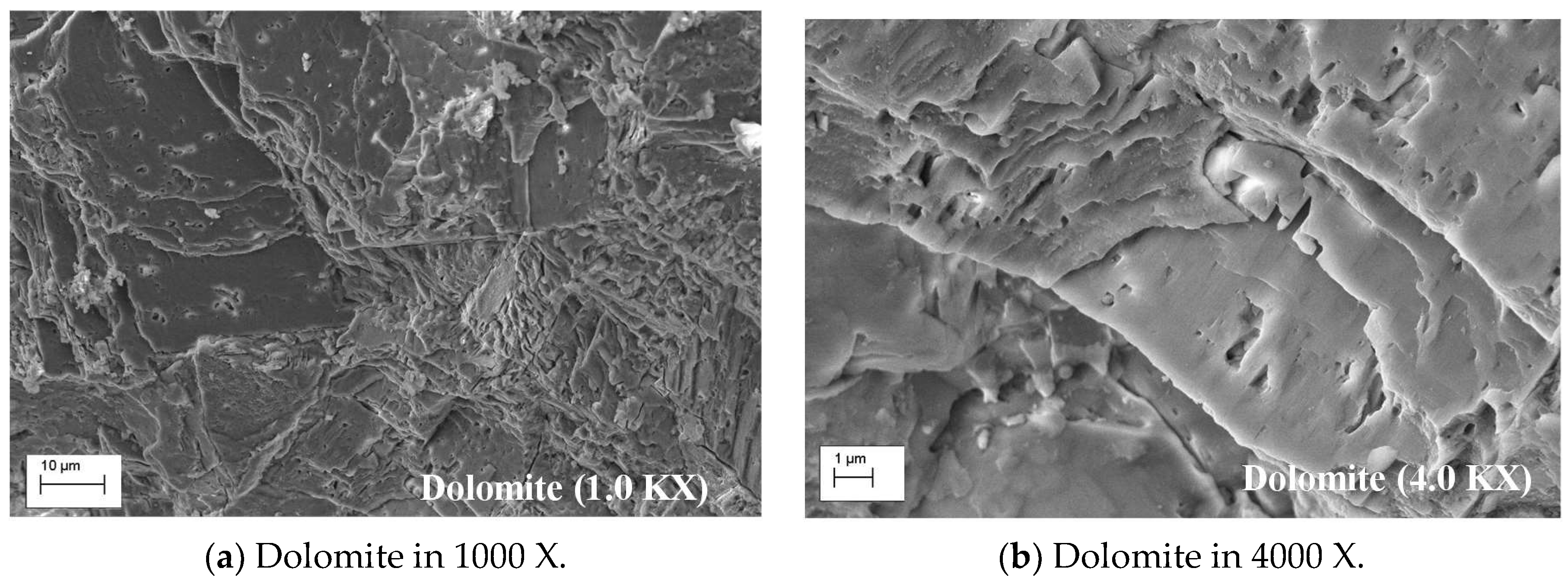

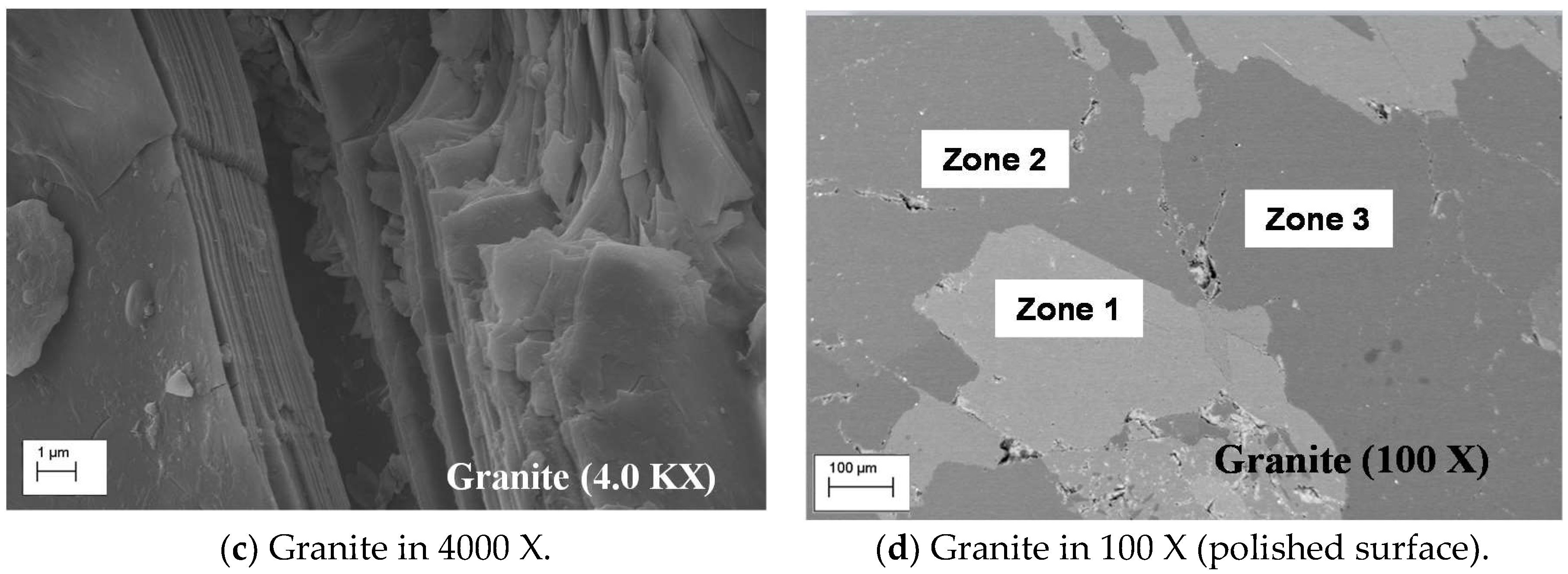

3.3.2. Coarse Aggregate: Dolomite and Granite

3.4. Microstructural Evaluation

3.4.1. Micro-Pores and Micro-Cracks

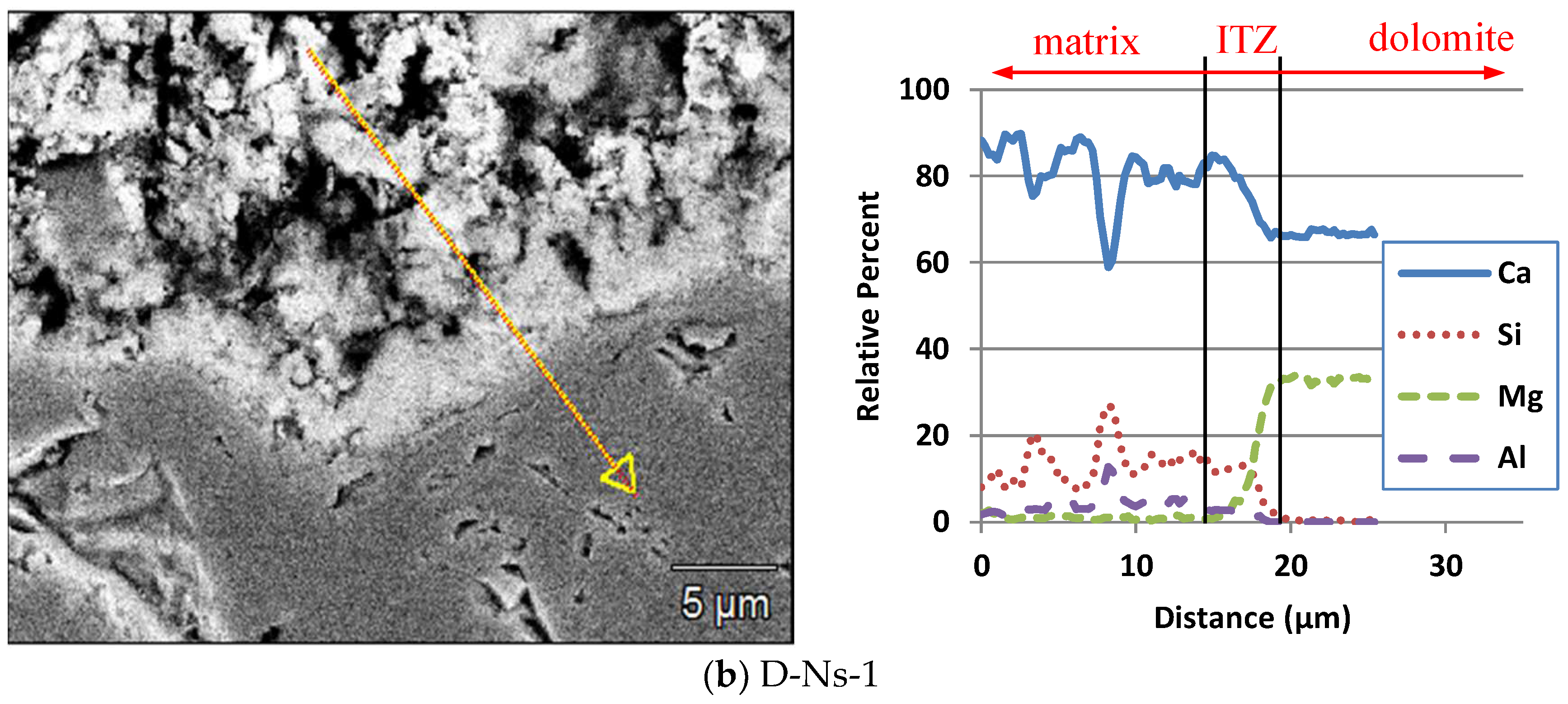

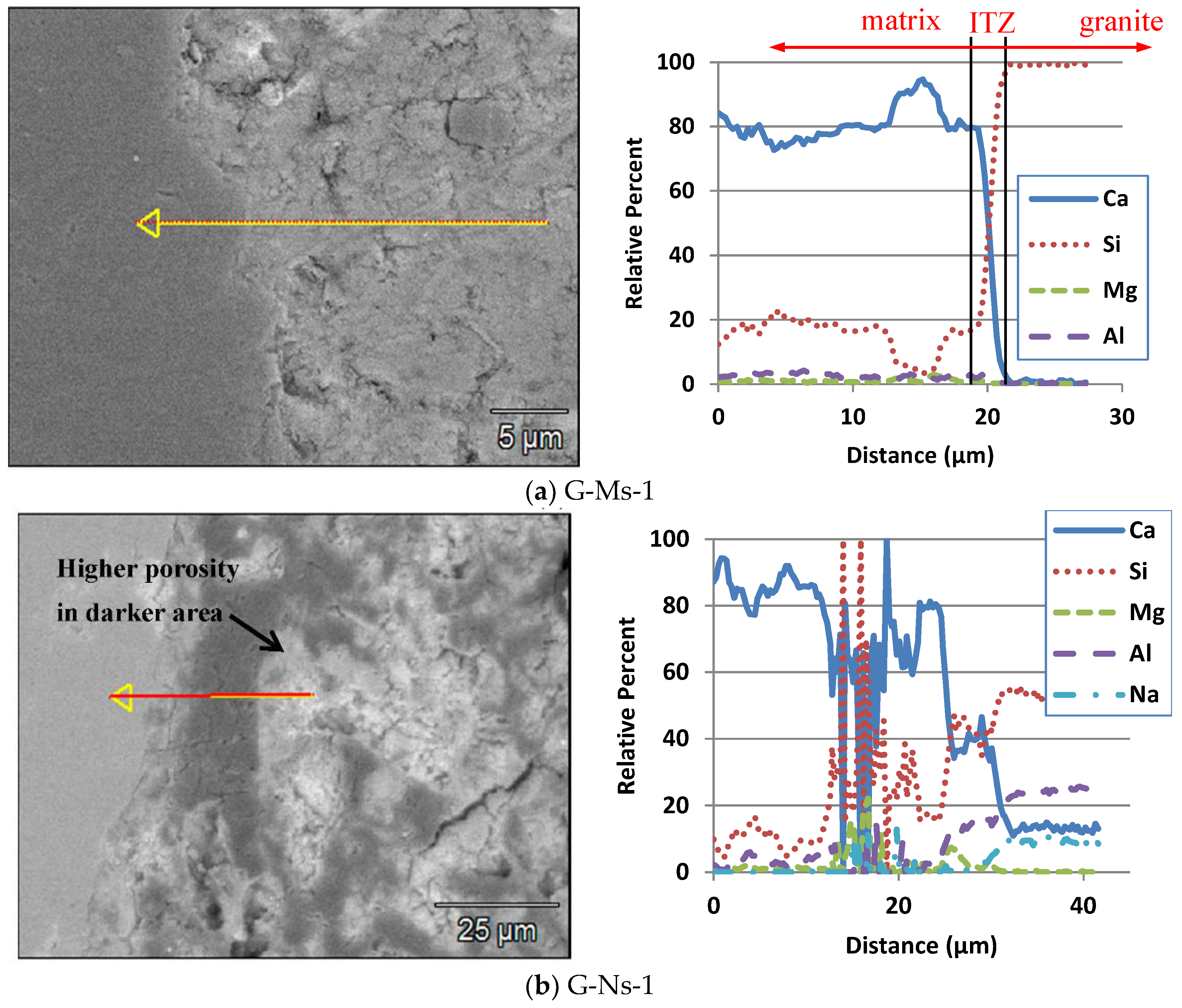

3.4.2. Characterization of Interfacial Transition Zone (ITZ)

4. Discussion of Findings

5. Conclusions

- Based on the proposed technology which the line scanning analyses (SEM and EDX) of ITZ regions, it is feasible to establish a ITZ database for the different types of aggregate used in concrete with sensitive analyses. The ITZ database which can be established by this proposed technology may help engineers to identify potential problem of micro-cracking due to the different types of aggregate.

- With the proposed technology, the ITZ and CTE database of a wide range of aggregates such as lightweight aggregate (porous limestone, expanded shale, clay and slate, etc.) and recycled concrete aggregate (RCA) can be established and characterized thus structural and field engineers can be aware of the probability of nano- and micro-cracks due to the aggregate types.

- The type of fine aggregate and its volume were found to have a significant effect on CTE, which increased with the Si volume content in the fine aggregate. Natural sand had approximately twice the Si content of manufactured sand in petrographic analyses, and the CTE of natural sand concrete specimens was thus always higher than that of manufactured sand specimens. Thus, it is recommendable to determine the volume content of Si in aggregates before engineer decides a concrete mix proportion.

- The concrete specimens with dolomite coarse aggregate had a higher CTE than specimens with granite, but the influence of the coarse aggregate type on the concrete CTE appears to be relatively small.

- For the concrete specimens with higher CTE, the micro-crack density in the ITZ tended to be higher. This is attributed to the early-age thermal cracking. Specimens with higher CTE are expected to be more susceptible to thermal stress.

- Higher CTE appears to result in lower compressive strength, suggesting that specimens with natural sand would have higher CTE values but lower compressive strength than manufactured sand specimens.

- From SEM images, the manufactured sand has a more angular shape and rougher surface than the natural sand. This angular shape provides better interlocking and the rough surface texture develops a greater mechanical bond with the cement paste so that higher compressive strength can be achieved.

6. Further Research

Acknowledgments

Author Contributions

Conflicts of Interest

References

- ARA, Inc. Guide for Mechanistic-Empirical Design of New and Rehabilitated Pavement Structures; National Cooperative Highway Research Program, Transportation Research Board, National Research Council: Washington, DC, USA, 2004. [Google Scholar]

- Cusson, D.; Hoogeveen, T. Measuring Early-Age Coefficient of Thermal Expansion in High-Performance Concrete. In Proceedings of the International RILEM Conference on Volume Changes of Hardening Concrete: Testing and Mitigation, Lyngby, Denmark, 20–23 August 2006; pp. 321–330. [Google Scholar]

- Jeong, J.H.; Zollinger, D.G. Finite-Element Modeling and Calibration of Temperature Prediction of Hydrating Portland Cement Concrete Pavements. J. Mater. Civ. Eng. 2006, 18, 317–324. [Google Scholar] [CrossRef]

- Kada, H.; Lachemi, M.; Petrov, N.; Bonneau, O.; Aïtcin, P.C. Determination of the Coefficient of Thermal Expansion of High Performance Concrete from Initial Setting. Mater. Struct. 2002, 35, 35–41. [Google Scholar] [CrossRef]

- Jeong, J.H.; Lee, J.H.; Suh, Y.C.; Zollinger, D.G. Effect of Slab Curling on Movement and Load Transfer Capacity of Saw-Cut Joints. Transp. Res. Rec. 2006, 1947, 69–78. [Google Scholar] [CrossRef]

- Mallela, J.; Abbas, A.; Harman, T.; Rao, C.; Liu, R.; Darter, M.I. Measurement and Significance of the Coefficient of Thermal Expansion of Concrete in Rigid Pavement Design. Transp. Res. Rec. 2005, 1919, 38–46. [Google Scholar] [CrossRef]

- Mindess, S.; Young, F.; Darwin, D. Concrete; Prentice Hall, Inc.: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- American Association of State Highway and Transportation Officials (AASHTO). Standard Method of Test for Coefficient of Thermal Expansion of Hydraulic Cement Concrete. In Standard Specifications for Transportation Materials and Methods of Sampling and Testing; AASHTO TP 60-00; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2005. [Google Scholar]

- American Association of State Highway and Transportation Officials (AASHTO). Mechanistic-Empirical Pavement Design Guide: A Manual of Practice; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2008. [Google Scholar]

- Federal Highway Administration (FHWA). Coefficient of Thermal Expansion in Concrete Pavement Design, TechBrief; Federal Highway Administration: Washington, DC, USA, 2011.

- Grattan-Bellew, P.E.; Beaudoin, J.J.; Vallée, V.G. Effect of Aggregate Particle Size and Composition on Expansion of Mortar Bars Due to Delayed Ettringite Formation. Cem. Concr. Res. 1998, 28, 1147–1156. [Google Scholar] [CrossRef]

- Hobbs, D.W. The Dependence of the Bulk Modulus, Young’s Modulus, Creep, Shrinkage and Thermal Expansion of Concrete upon Aggregate Volume Concentration. Mater. Struct. 1971, 4, 107–114. [Google Scholar] [CrossRef]

- Won, M. Improvements of Testing Procedures for Concrete Coefficient of Thermal Expansion. Transp. Res. Rec. 2005, 1919, 23–28. [Google Scholar] [CrossRef]

- Jeong, J.H.; Zollinger, D.G. Age and Moisture Effects on Thermal Expansion of Concrete Pavement Slabs. J. Mater. Civ. Eng. 2012, 24, 8–15. [Google Scholar] [CrossRef]

- Sellevold, E.J.; Bjøntegaard, Ø. Coefficient of Thermal Expansion of Cement Paste and Concrete: Mechanisms of Moisture Interaction. Mater. Struct. 2006, 39, 809–815. [Google Scholar] [CrossRef]

- Yeon, J.; Choi, S.; Won, M. Effect of Relative Humidity on Coefficient of Thermal Expansion of Hardened Cement Paste and Concrete. Transp. Res. Rec. 2009, 2113, 83–91. [Google Scholar] [CrossRef]

- Tanesi, J.; Kutay, M.; Abbas, A.; Meininger, R. Effect of Coefficient of Thermal Expansion Test Variability on Concrete Pavement Performance as Predicted by Mechanistic-Empirical Pavement Design Guide. Transp. Res. Rec. 2007, 2020, 40–44. [Google Scholar] [CrossRef]

- Alungbe, G.D.; Tia, M.; Bloomquist, D.G. Effects of Aggregate, Water/Cement Ratio, and Curing on the Coefficient of Linear Thermal Expansion of Concrete. Transp. Res. Rec. 1992, 1335, 41–51. [Google Scholar]

- Al-Oraimi, S.K.; Taha, R.; Hassan, H.F. The Effect of the Mineralogy of Coarse Aggregate on the Mechanical Properties of High-Strength Concrete. Constr. Build. Mater. 2006, 20, 499–503. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monterio, P.J.M. Concrete: Structure, Properties, and Materials; Prentice Hall, Inc.: Englewood Cliffs, NJ, USA, 1993. [Google Scholar]

- Aitcin, P.C.; Mehta, P.K. Effect of Coarse Aggregate Characteristics on Mechanical Properties of High Strength Concrete. ACI Mater. J. 1990, 87, 103–107. [Google Scholar]

- Strategic Highway Research Program (SHRP). High Performance Concrete: A State-of-The-Art Report; SHRP-C/FR-91-103; Strategic Highway Research Program, National Research Council: Washington, DC, USA, 1991. [Google Scholar]

- Aitcin, P.C.; Mindess, S. High-performance concrete: Science and applications. In Materials Science of Concrete V; Skalny, J., Mindess, S., Eds.; American Ceramic Society: Westerville, OH, USA, 1998; pp. 477–511. [Google Scholar]

- ACI Committee 363. State-of-The-Art Report on High Strength Concrete; American Concrete Institute: Farmington Hill, MI, USA, 1984. [Google Scholar]

- Goble, C.; Cohen, M. Influence of Aggregate Surface Area on Mechanical Properties of Mortar. ACI Mater. J. 1999, 96, 657–662. [Google Scholar]

- Bonavetti, V.; Irassar, E.F. The Effect of Stone Dust Content in Sand. Cem. Concr. Res. 1994, 24, 580–590. [Google Scholar] [CrossRef]

- Celik, T.; Marar, K. Effects of Crushed Stone Dust on Some Properties of Concrete. Cem. Concr. Res. 1996, 26, 1121–1130. [Google Scholar] [CrossRef]

- ASTM International. Standard Specification for Concrete Aggregates. In Annual Book of ASTM Standards; ASTM C33/C33M-13; American Society for Testing and Materials: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Kim, S.H.; Yang, J.; Nam, B.H.; Jeong, J.H. Effect of Materials and Age on the Coefficient of Thermal Expansion of Concrete Paving Mixtures. Road Mater. Pavement Des. 2015, 16, 445–458. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Resistance to Degradation of Large-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. In Annual Book of ASTM Standards; ASTM C535-12; American Society for Testing and Materials: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM International. Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. In Annual Book of ASTM Standards; ASTM C127-15; American Society for Testing and Materials: West Conshohocken, PA, USA, 2015. [Google Scholar]

- American Association of State Highway and Transportation Officials (AASHTO). Coefficient of Thermal Expansion of Hydraulic Cement Concrete. In Standard Specifications for Transportation Materials and Methods of Sampling and Testing; AASHTO T 336; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2011. [Google Scholar]

- ASTM International. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. In Annual Book of ASTM Standards; ASTM C39/C39M-15; American Society for Testing and Materials: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM International. Standard Practice for Petrographic Examination of Hardened Concrete. In Annual Book of ASTM Standards; ASTM C856-17; American Society for Testing and Materials: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Little, D.; Button, J.; Jayawickrama, P.; Solaimanian, M.; Hudson, B. Quantify Shape, Angularity and Surface Texture of Aggregates Using Image Analysis and Study Their Effect on Performance; FHWA/TX-06/0-1707-4; Texas Transportation Institute, The Texas A&M University System: College Station, TX, USA, 2003. [Google Scholar]

- Walther, J. Essentials of Geochemistry; Jones & Bartlett Learning: Sudbury, MA, USA, 2009. [Google Scholar]

- Blatt, H.; Middleton, G.V.; Murray, R.C. Origin of Sedimentary Rocks; Prentice Hall, Inc.: Englewood Cliffs, NJ, USA, 1972. [Google Scholar]

- Nam, B.H.; Yeon, J.H.; Behring, Z. Effect of Daily Temperature Variations on the Continuous Deflection Profiles of Airfield Jointed Concrete Pavements. Constr. Build. Mater. 2014, 73, 261–270. [Google Scholar] [CrossRef]

- Tasneem, K.M.; Nam, B.H.; Kim, J.Y.; Kim, S.H.; Park, Y.J. Effects of Aggregate on the Thermal Expansion Behavior of Concrete. In Proceedings of the Second Transportation & Development Congress, Orlando, FL, USA, 8–11 June 2014. [Google Scholar]

- Nam, B.H.; Stokoe, K.H.; Lee, J.S.; Scullion, T.; Leidy, J.; Oshinski, E. Characterization of Jointed Concrete Pavement Under Daily and Seasonal Temperature Variations Using RDD and FWD Measurements. In Proceedings of the Transportation Research Board 90th Annual Meeting, Washington, DC, USA, 24 January 2011. [Google Scholar]

- Tyrrell, G.W. The Principles of Petrology; John Wiley & Sons, Inc.: New York, NY, USA, 1973. [Google Scholar]

- Ehlers, G.E.; Blatt, H. Petrology, Igneous Sedimentary and Metamorphic; CBS Publishers and Distribution: Delhi, India, 1997. [Google Scholar]

- Parker, R.L.; Fleischer, L. Geochemistry of Niobium and Tantalum; Geological Survey Professional Paper 612; US Department of the Interior: Washington, DC, USA, 1968.

- Bisschop, J.; Van Mier, J.G.M. How to Study Drying Shrinkage Microcracking in Cement-Based Materials Using Optical and Scanning Electron Microscopy? Cem. Concr. Res. 2002, 32, 279–287. [Google Scholar] [CrossRef]

- Shah, S.P.; Swartz, S.E.; Ouyang, C. Fracture Mechanics of Concrete: Applications of Fracture Mechanics to Concrete, Rock and Other Quasi-Brittle Materials; John Wiley & Sons, Inc.: New York, NY, USA, 1995. [Google Scholar]

- Neville, A.M. Properties of Concrete; Pitman Pub.: London, UK, 1981. [Google Scholar]

- Scrivener, K.L.; Crumbie, A.K.; Laugesen, P. The Interfacial Transition Zone (ITZ) between Cement Paste and Aggregate in Concrete. Interface Sci. 2004, 12, 411–421. [Google Scholar] [CrossRef]

- Neville, A.M.; Brooks, J.J. Concrete Technology; Longman Scientific & Technical: London, UK, 1993. [Google Scholar]

- Triantafyllou, G.G.; Rousakis, T.C.; Karabinis, A.I. Analytical assessment of the bearing capacity of RC beams with corroded steel bars beyond concrete cover cracking. Compos. Part B Eng. 2017, 119, 132–140. [Google Scholar] [CrossRef]

| Properties | Test Values | Test Methods | ||

|---|---|---|---|---|

| Dolomite | Granite | |||

| Specific gravity | (SSD) | 2.82 | 2.69 | ASTM C127 |

| (Apparent) | 2.86 | 2.72 | ASTM C127 | |

| Absorption capacity, % | 0.6 | 0.6 | ASTM C127 | |

| L.A. abrasion mass loss, % | 21 | 33 | ASTM C535 | |

| Mixture ID | w/c | Water (kg/m3) | Cement (kg/m3) | Fly Ash (kg/m3) | Coarse Aggregate | Fine Aggregate | ||

|---|---|---|---|---|---|---|---|---|

| Dolomite (kg/m3) | Granite (kg/m3) | Manufactured Sand (kg/m3) | Natural Sand (kg/m3) | |||||

| D-Ms-1 | 0.5 | 184 | 273 | 95 | 1245 | - | 595 | - |

| D-Ms-2 | 0.5 | 184 | 273 | 95 | 682 | - | 1127 | - |

| D-Ns-1 | 0.5 | 184 | 273 | 95 | 1245 | - | - | 517 |

| D-Ns-2 | 0.5 | 184 | 273 | 95 | 682 | - | - | 979 |

| G-Ms-1 | 0.5 | 184 | 273 | 95 | - | 1245 | 595 | - |

| G-Ms-2 | 0.5 | 184 | 273 | 95 | - | 682 | 1127 | - |

| G-Ns-1 | 0.5 | 184 | 273 | 95 | - | 1245 | - | 517 |

| G-Ns-2 | 0.5 | 184 | 273 | 95 | - | 682 | - | 979 |

| Mixture ID | CTE (με/°C) | Mixture ID | CTE (με/°C) | ||||

|---|---|---|---|---|---|---|---|

| Heating | Cooling | Average | Heating | Cooling | Average | ||

| D-Ms-1 | 8.3 | 8.5 | 8.5 (0.07 *) | G-Ms-1 | 7.7 | 7.9 | 7.9 (0.19 *) |

| 8.6 | 8.8 | 7.9 | 8.3 | ||||

| 8.5 | 8.6 | 7.7 | 7.9 | ||||

| 8.3 | 8.6 | 7.9 | 8.3 | ||||

| 8.3 | 8.5 | 7.9 | 8.1 | ||||

| D-Ms-2 | 8.1 | 8.5 | 8.3 (0.05 *) | G-Ms-2 | 8.1 | 8.3 | 8.3 (0.18 *) |

| 8.3 | 8.6 | 8.1 | 8.5 | ||||

| 8.1 | 8.5 | 8.1 | 8.5 | ||||

| 8.3 | 8.6 | 8.1 | 8.5 | ||||

| 7.9 | 8.3 | 8.3 | 8.5 | ||||

| D-Ns-1 | 8.8 | 9.2 | 9.0 (0.15 *) | G-Ns-1 | 8.8 | 9.0 | 8.8 (0.10 *) |

| 9.0 | 9.4 | 8.8 | 9.0 | ||||

| 8.8 | 9.2 | 8.8 | 9.0 | ||||

| 8.8 | 9.4 | 8.6 | 9.0 | ||||

| 8.8 | 9.0 | 8.6 | 8.8 | ||||

| D-Ns-2 | 9.5 | 9.9 | 9.7 (0.18 *) | G-Ns-2 | 9.7 | 9.9 | 9.7 (0.13 *) |

| 9.7 | 9.9 | 9.7 | 9.9 | ||||

| 9.5 | 9.9 | 9.7 | 9.7 | ||||

| 9.5 | 9.7 | 9.7 | 9.9 | ||||

| 9.5 | 9.9 | 9.5 | 9.7 | ||||

| Element | Coarse Aggregate | Fine Aggregate | ||

|---|---|---|---|---|

| Dolomite | Granite | Manufactured Sand | Natural Sand | |

| C | 15.27 | 4.6 | 5.33 | 8.35 |

| O | 47.28 | 27.91 | 25.32 | 26.97 |

| Na | - | 2.65 | 2.15 | - |

| Mg | 12.18 | 1.53 | 1.11 | 0.38 |

| Al | 0.07 | 4.71 | 7.09 | 14.54 |

| Si | 0.12 | 18.59 | 11.49 | 20.6 |

| K | - | 0.79 | 1.14 | 8.71 |

| Ca | 25.08 | 2.82 | 2.99 | 0.35 |

| Ti | - | 0.36 | 0.29 | 0.76 |

| V | - | 0.38 | 0.09 | - |

| Cr | - | 0.2 | - | - |

| Mn | - | 0.21 | - | 1.14 |

| Fe | - | 12.7 | 15 | 13.76 |

| Co. | - | 3.43 | 3.52 | - |

| Ni | - | 3.9 | 5.49 | 2.84 |

| Cu | - | 1.91 | 1.31 | 0.29 |

| Zn | - | 0.86 | 2.89 | 1.29 |

| Nb | - | 3.62 | 4.58 | - |

| Ta | - | 8.82 | 10.23 | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, J.; Kim, S.S.; Nam, B.H.; Durham, S.A. Effect of Aggregate Mineralogy and Concrete Microstructure on Thermal Expansion and Strength Properties of Concrete. Appl. Sci. 2017, 7, 1307. https://doi.org/10.3390/app7121307

An J, Kim SS, Nam BH, Durham SA. Effect of Aggregate Mineralogy and Concrete Microstructure on Thermal Expansion and Strength Properties of Concrete. Applied Sciences. 2017; 7(12):1307. https://doi.org/10.3390/app7121307

Chicago/Turabian StyleAn, Jinwoo, S. Sonny Kim, Boo Hyun Nam, and Stephan A. Durham. 2017. "Effect of Aggregate Mineralogy and Concrete Microstructure on Thermal Expansion and Strength Properties of Concrete" Applied Sciences 7, no. 12: 1307. https://doi.org/10.3390/app7121307

APA StyleAn, J., Kim, S. S., Nam, B. H., & Durham, S. A. (2017). Effect of Aggregate Mineralogy and Concrete Microstructure on Thermal Expansion and Strength Properties of Concrete. Applied Sciences, 7(12), 1307. https://doi.org/10.3390/app7121307