A Fruit Fly-Optimized Kalman Filter Algorithm for Pushing Distance Estimation of a Hydraulic Powered Roof Support through Tuning Covariance

Abstract

:1. Introduction

2. Preliminaries

2.1. Kalman Filter

(1) Prediction

(2) Correction

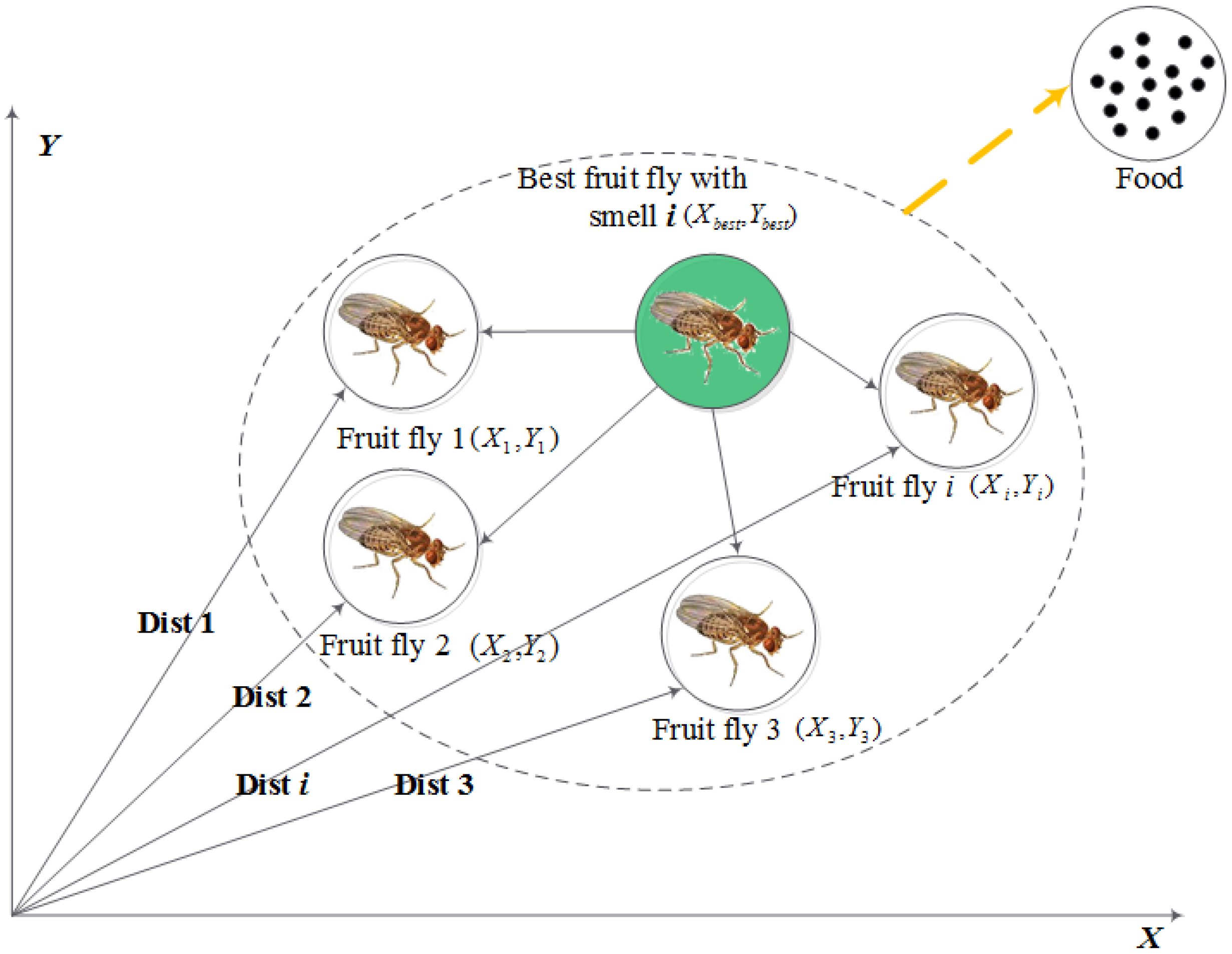

2.2. Fruit Fly Optimization Algorithm

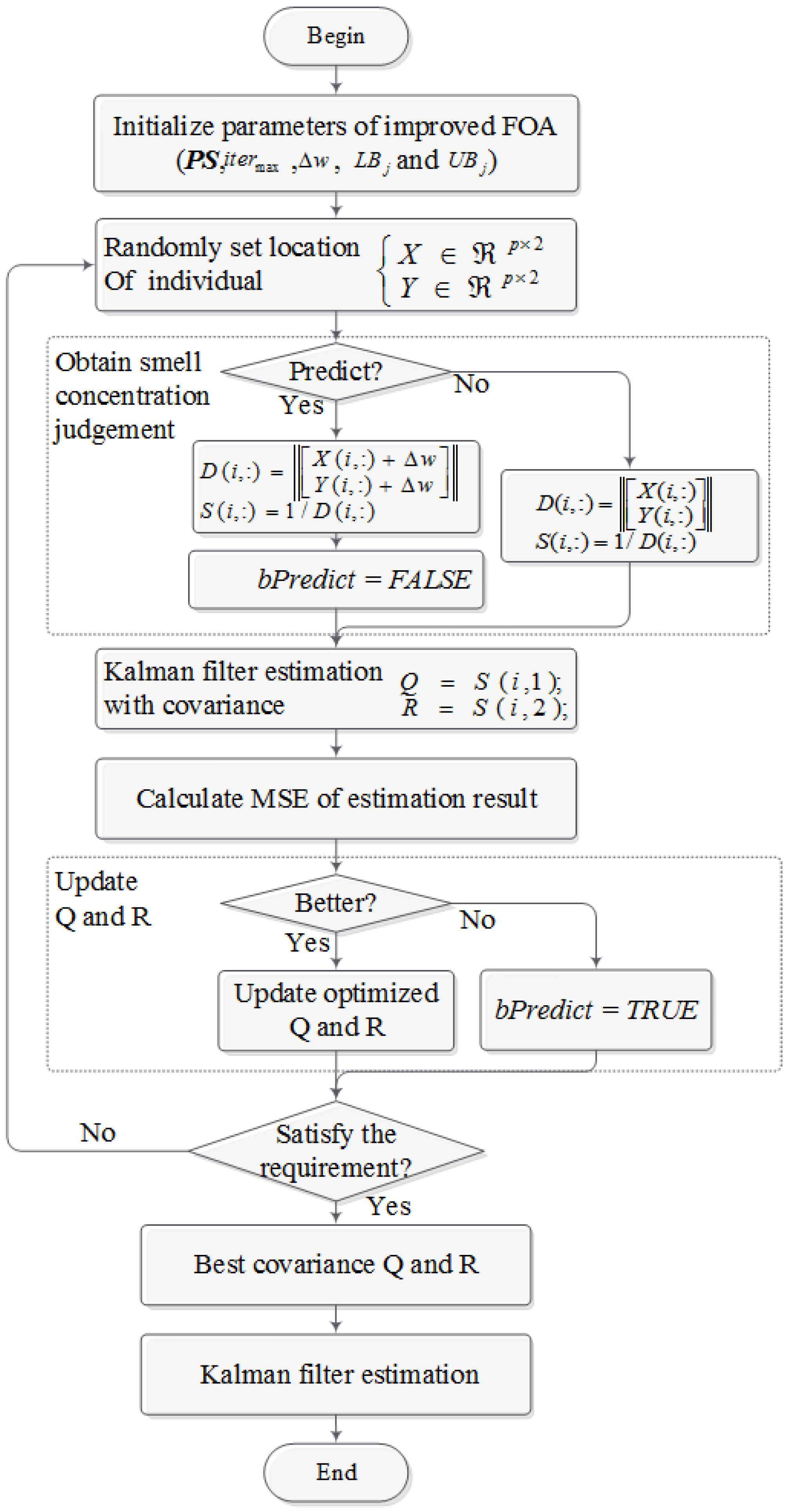

3. Proposed Method

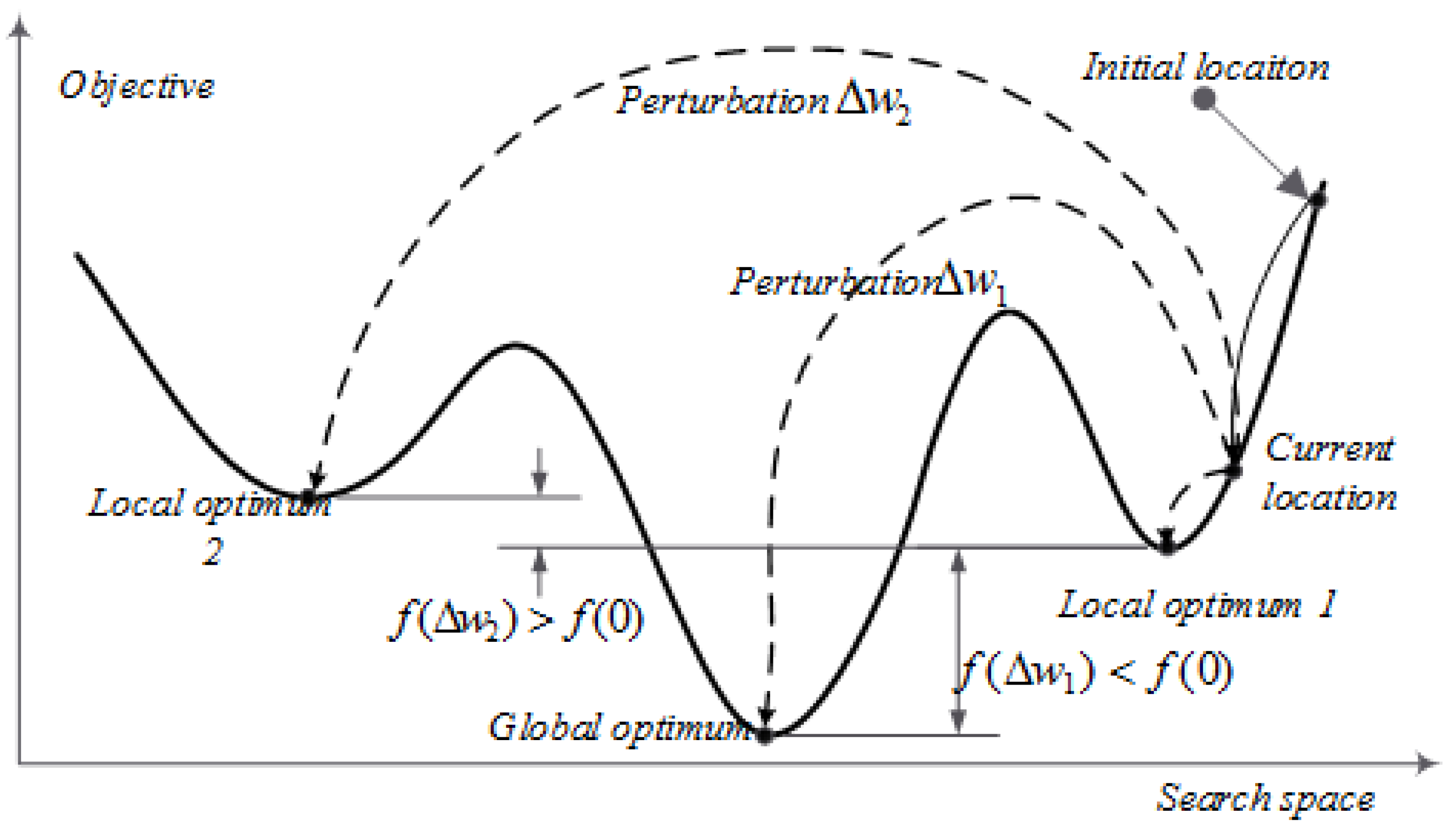

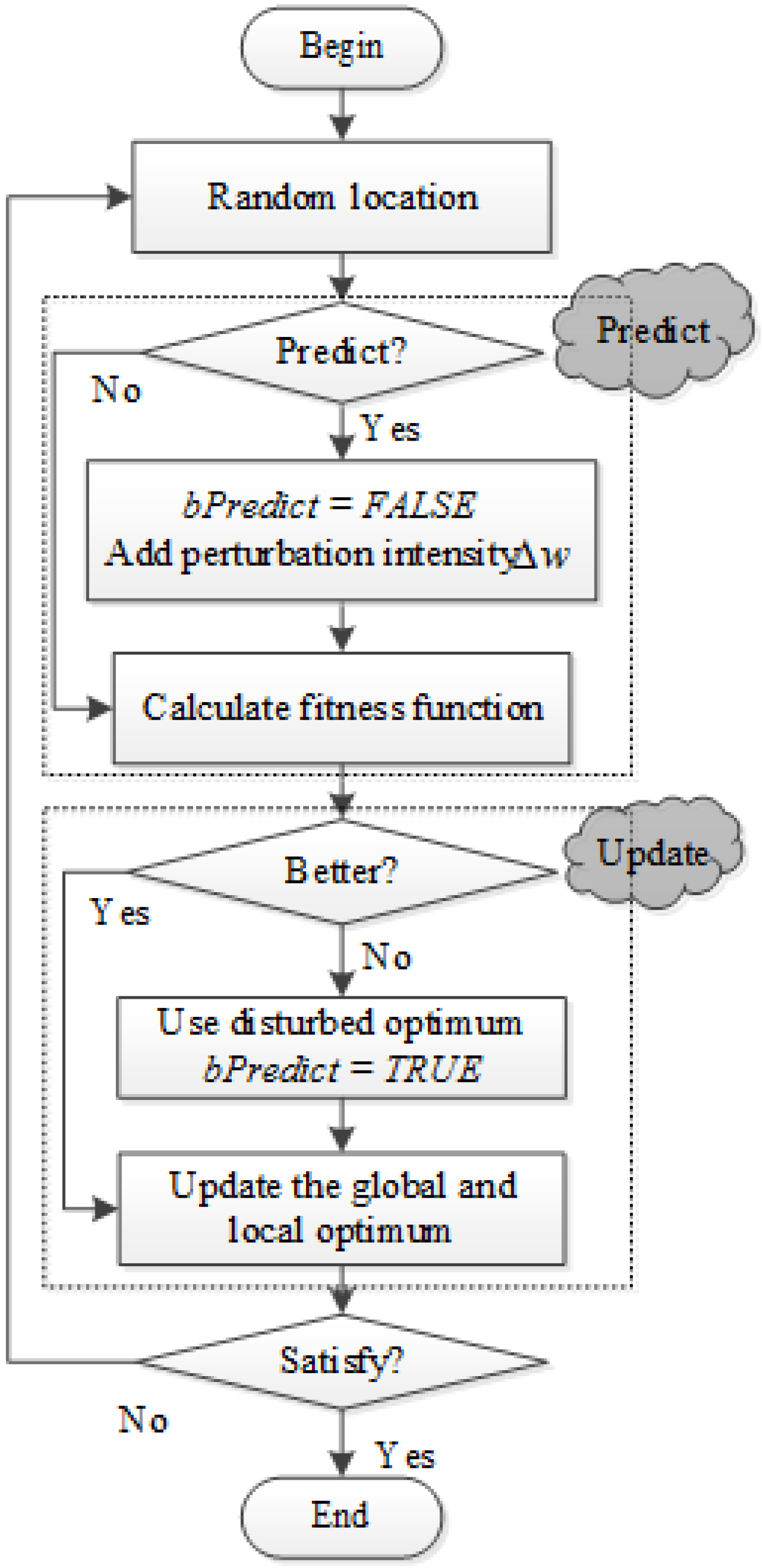

3.1. The Proposed IFOA

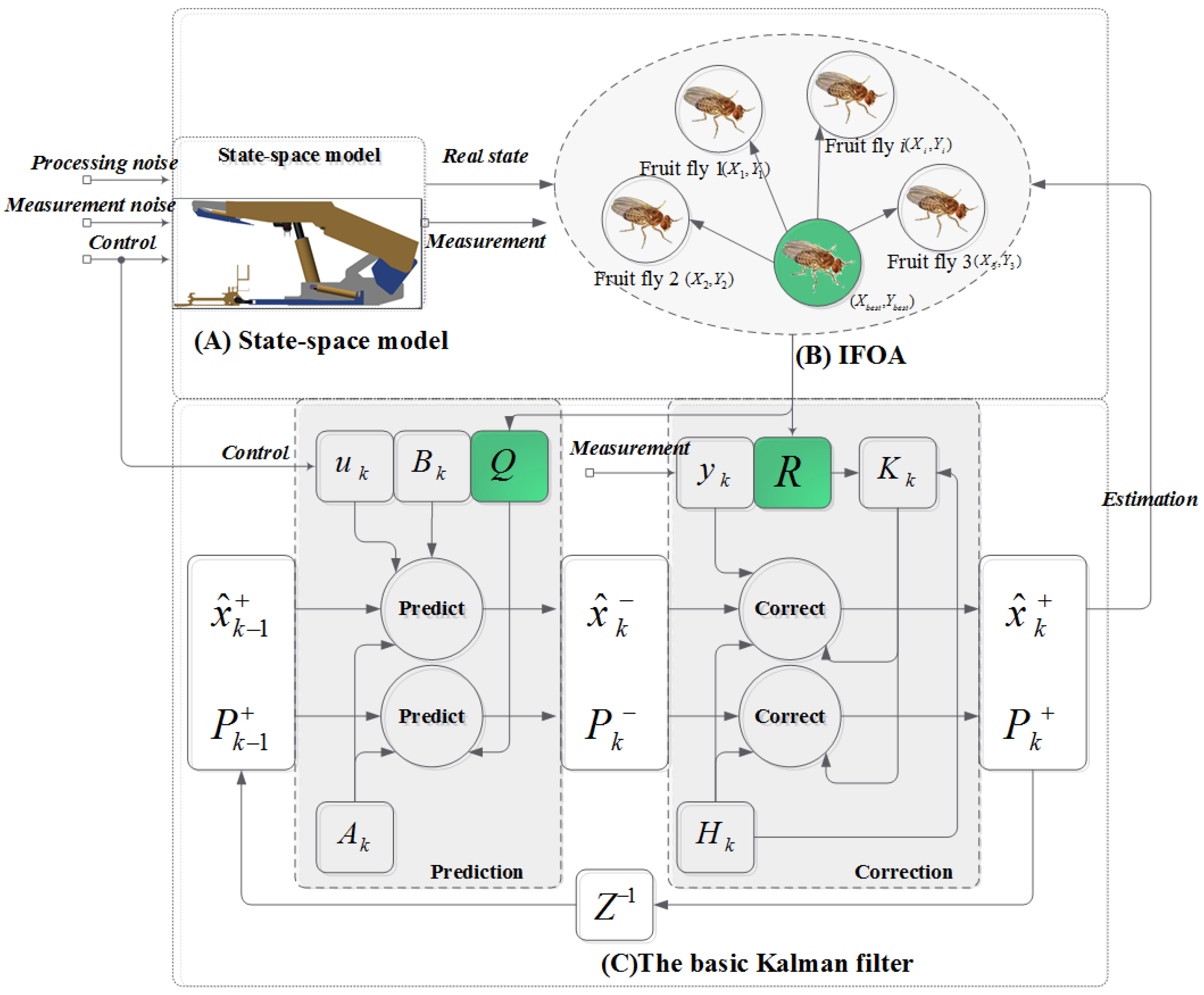

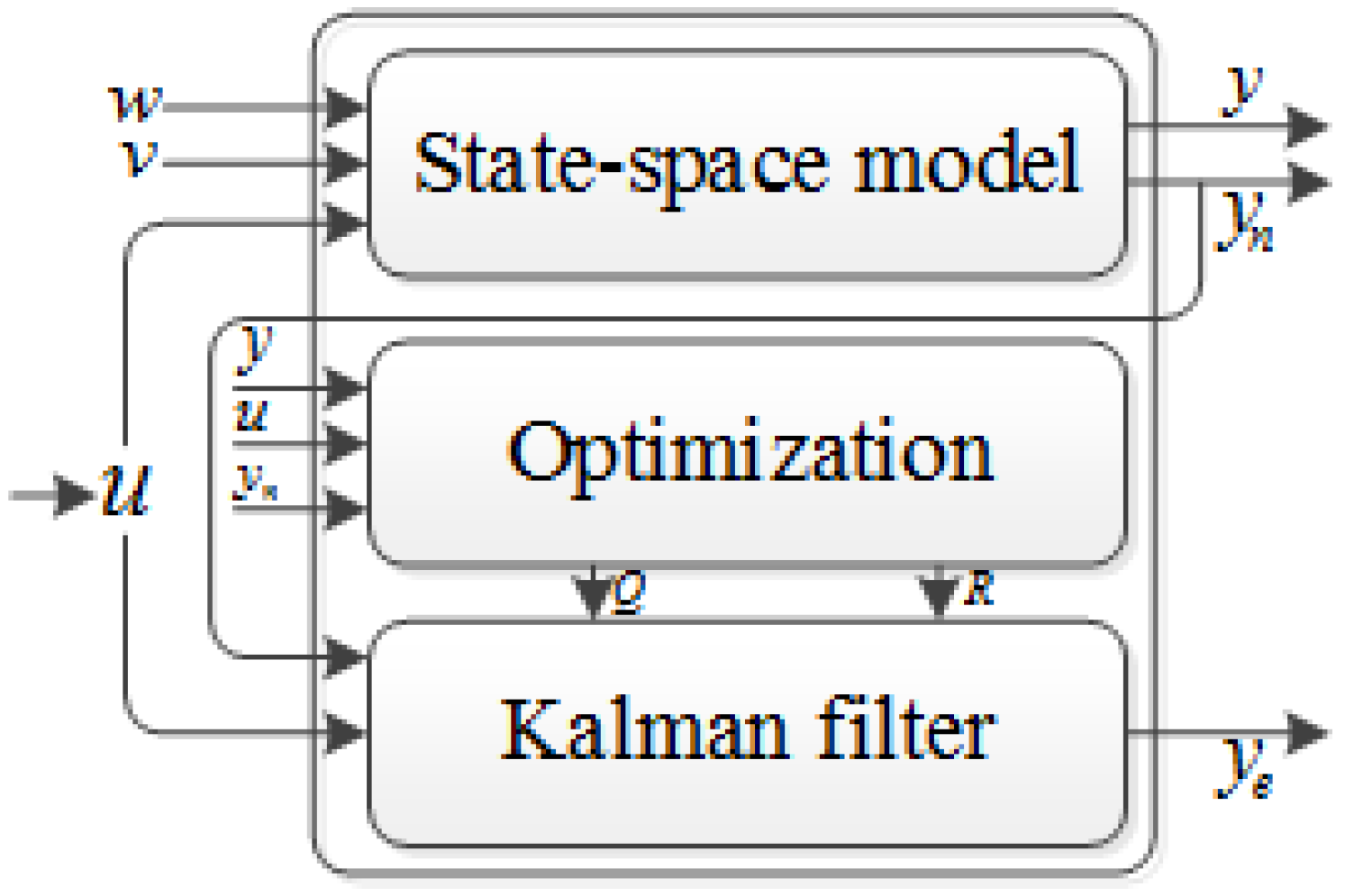

3.2. The Optimized Kalman Filter Based on IFOA(IFOA-KF)

(1) State-Space Model

(2) Fitness Function

(3) Kalman Filter

| Procedure: IFOA-KF |

| Parameters: PS, , , , |

| Outputs: Q,R |

| % Initialization |

| Set population size PS, maximum generation , and perturbation intensity and , |

| %Set random initial position of fruit fly swarm |

| For i = 1, 2,…, PS |

| End |

| %Set individual with best smell concentration |

| For j = 1: |

| % if prediction is enabled |

| If bPredicte == TRUE then bPredicte = FALSE |

| End |

| For i = 1, 2,…, PS |

| % Random direction and distance |

| If then |

| If then |

| % obtain smell concentration |

| % MSE of Kalman filter estimation result |

| End |

| If then |

| If then bPredicte = TRUE |

| % Kalman filter estimation using best covariance |

| END |

4. Simulation and Application

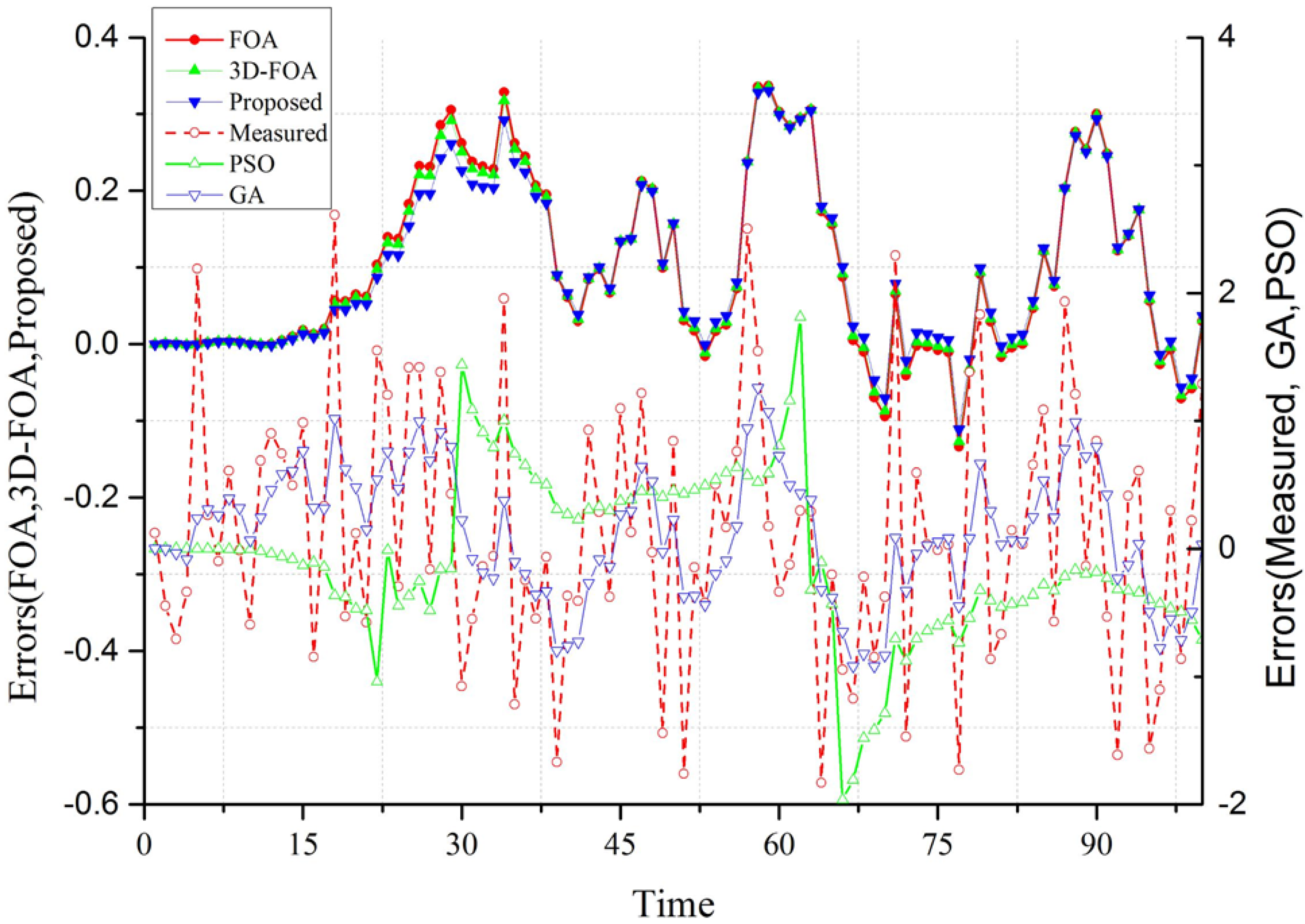

4.1. Simulation with an Artificial Signal

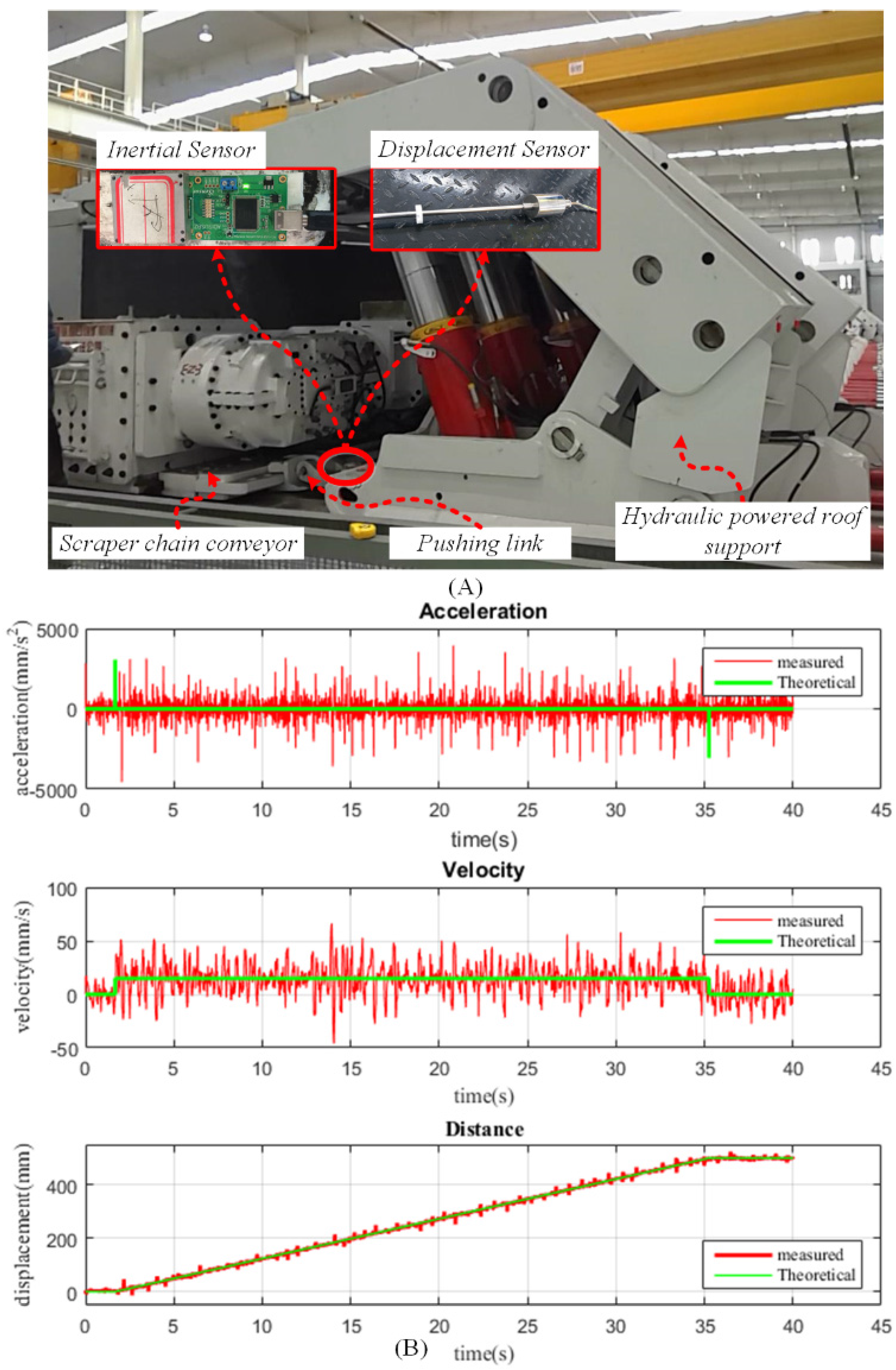

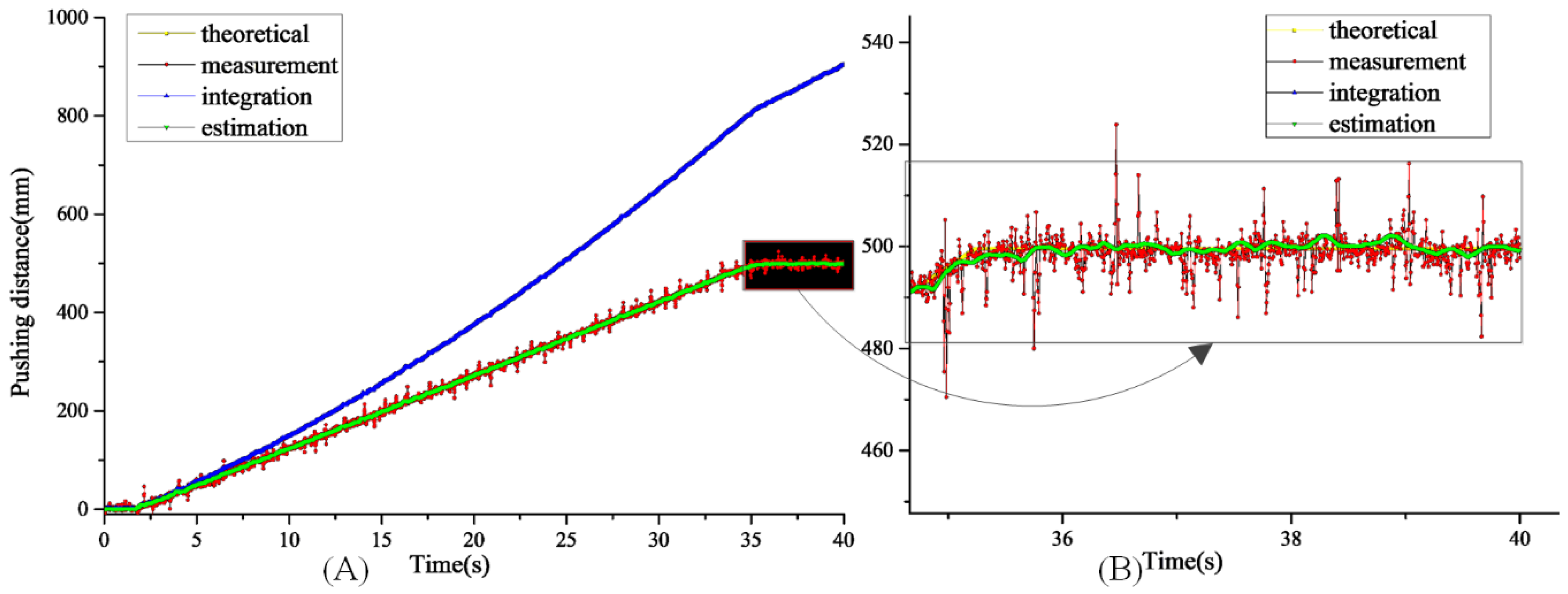

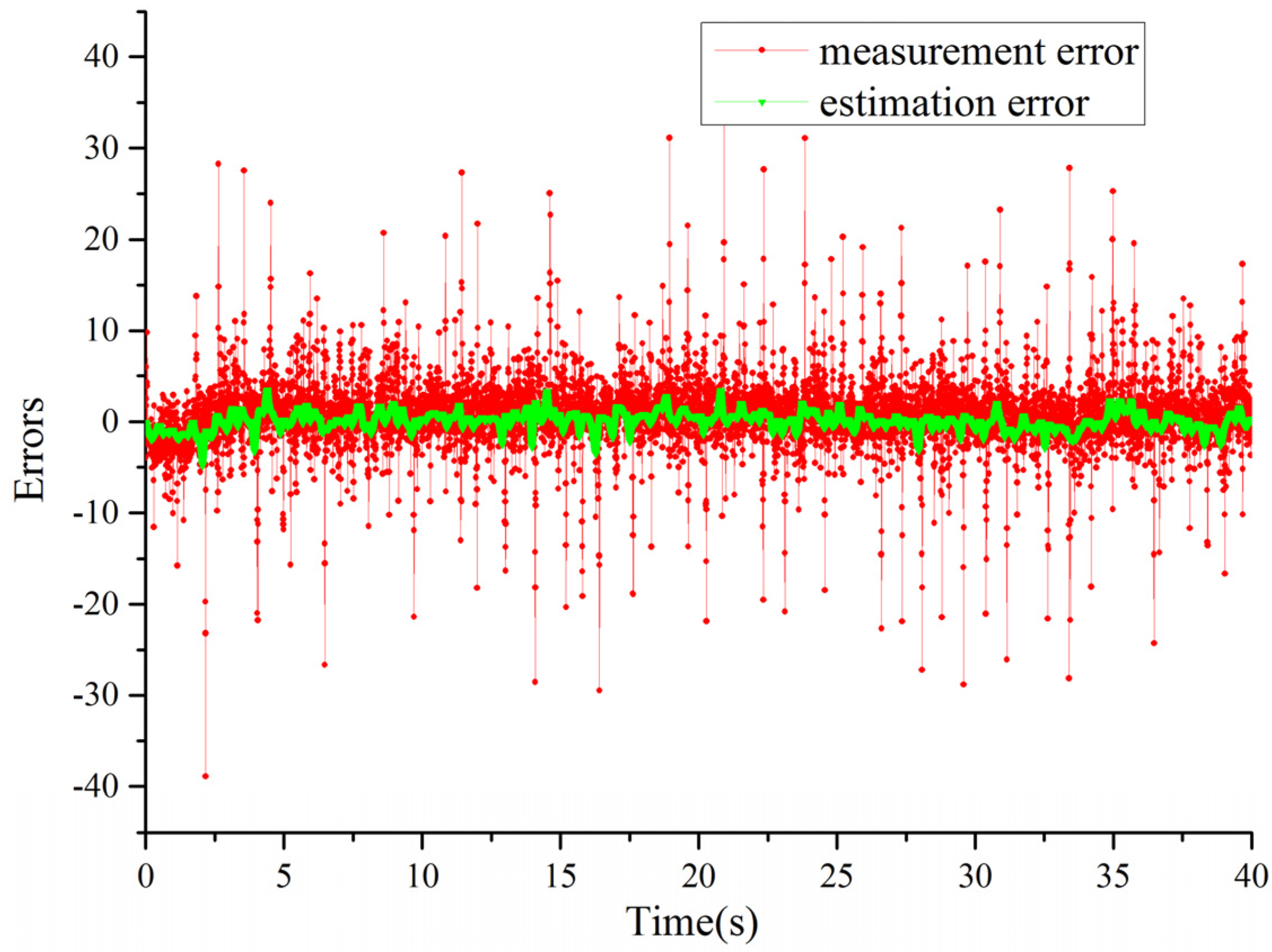

4.2. Application in Pushing Distance Estimation

5. Conclusions and Future Work

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, J. Present status and development tendency of fully mechanized coal mining technology and equipment with high cutting height in China. Coal Sci. Technol. 2006, 34, 4–7. [Google Scholar]

- Gong, X.; Ma, X.; Zhang, Y.; Yang, J. Application of fuzzy neural network in fault diagnosis for scraper conveyor vibration. In Proceedings of the 2013 IEEE International Conference on Information and Automation (ICIA), Yinchuan, China, 26–28 August 2013; pp. 1135–1140.

- Brown, A.K. GPS/INS uses low-cost MEMS IMU. IEEE Aerosp. Electron. Syst. Mag. 2005, 20, 3–10. [Google Scholar] [CrossRef]

- Lee, T.; Shin, J.; Cho, D. Position estimation for mobile robot using in-plane 3-axis IMU and active beacon. In Proceedings of the 2009 IEEE International Symposium on Industrial Electronics, Seoul, Korea, 5–8 July 2009; pp. 1956–1961.

- Steinbis, J.; Hoff, W.; Vincent, T.L. 3D Fiducials for Scalable AR Visual Tracking. In Proceedings of the International Symposium on Mixed and Augmented Reality, Cambridge, UK, 15–18 September 2008; pp. 183–184.

- Sprager, S.; Juric, M. Inertial Sensor-Based Gait Recognition: A Review. Sensors 2015, 15, 22089–22127. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, N.; Ghazilla, R.A.R.; Khairi, N.M.; Kasi, V. Reviews on Various Inertial Measurement Unit (IMU) Sensor Applications. Int. J. Signal Proc. Syst. 2013, 256–262. [Google Scholar] [CrossRef]

- Chen, Z.H.; Zhu, Q.C.; Soh, Y.C. Smartphone Inertial Sensor-Based Indoor Localization and Tracking With iBeacon Corrections. IEEE Trans. Ind. Inform. 2016, 12, 1540–1549. [Google Scholar] [CrossRef]

- Zhong, M.Y.; Guo, J.; Yang, Z.H. On Real Time Performance Evaluation of the Inertial Sensors for INS/GPS Integrated Systems. IEEE Sens. J. 2016, 16, 6652–6661. [Google Scholar] [CrossRef]

- Wu, Y.X.; Luo, S.T. On Misalignment between Magnetometer and Inertial Sensors. IEEE Sens. J. 2016, 16, 6288–6297. [Google Scholar] [CrossRef]

- Abruzzo, B.A.; Recchia, T.G. Online Calibration of Inertial Sensors for Range Correction of Spinning Projectiles. J. Guid. Control Dyn. 2016, 39, 1918–1924. [Google Scholar] [CrossRef]

- Rettig, M.J.; Leelamankong, P.; Rungsri, P.; Lischer, C.J. Effect of sedation on fore- and hindlimb lameness evaluation using body-mounted inertial sensors. Equine Vet. J. 2016, 48, 603–607. [Google Scholar] [CrossRef] [PubMed]

- Atrsaei, A.; Salarieh, H.; Alasty, A. Human Arm Motion Tracking by Orientation-Based Fusion of Inertial Sensors and Kinect Using Unscented Kalman Filter. J. Biomech. Eng.-Trans. ASME 2016, 138. [Google Scholar] [CrossRef] [PubMed]

- Davidson, S.P.; Cain, S.M.; McGinnis, R.S.; Vitali, R.R.; Perkins, N.C.; McLean, S.G. Quantifying warfighter performance in a target acquisition and aiming task using wireless inertial sensors. Appl. Ergon. 2016, 56, 27–33. [Google Scholar] [CrossRef] [PubMed]

- Coyte, J.L.; Stirling, D.; Ros, M.; Du, H.; Gray, A. Displacement profile estimation using low cost inertial motion sensors with applications to sporting and rehabilitation exercises. In Proceedings of the 2013 IEEE/ASME International Conference on Advanced Intelligent Mechatronics: Mechatronics for Human Wellbeing, Wollongong, Australia, 9–12 July 2013; pp. 1290–1295.

- Kalman, R.E. A New Approach to Linear Filtering and Prediction Problems. ASME Trans. J. Basic Eng. 1960, 82, 35–45. [Google Scholar] [CrossRef]

- Ljung, L. Asymptotic-behavior of the extended Kalman filter as a parameter estimator for linear-systems. IEEE Trans. Autom. Control 1979, 24, 36–50. [Google Scholar] [CrossRef]

- Deng, Z.A.; Hu, Y.; Yu, J.G.; Na, Z.Y. Extended Kalman Filter for Real Time Indoor Localization by Fusing WIFI and Smartphone Inertial Sensors. Micromachines 2015, 6, 523–543. [Google Scholar] [CrossRef]

- Urrea, C.; Munoz, R. Joints Position Estimation of a Redundant Scara Robot by Means of the Unscented Kalman Filter and Inertial Sensors. Asian J. Control 2016, 18, 481–493. [Google Scholar] [CrossRef]

- Liu, L.J.; Qi, B.; Cheng, S.M.; Xi, Z.R. High precision estimation of inertial rotation via the extended Kalman filter. Eur. Phys. J. D 2015, 69. [Google Scholar] [CrossRef]

- Plett, G.L. Extended Kalman filtering for battery management systems of LiPB-based HEV battery packs—Part 3. State and parameter estimation. J. Power Sources 2004, 134, 277–292. [Google Scholar] [CrossRef]

- Julier, S.J.; Uhlmann, J.K. Unscented filtering and nonlinear estimation. Proc. IEEE 2004, 92, 401–422. [Google Scholar] [CrossRef]

- Sum, J.; Leung, C.S.; Young, G.H.; Kan, W.K. On the Kalman filtering method in neural-network training and pruning. IEEE Trans. Neural Netw. 1999, 10, 161–166. [Google Scholar] [CrossRef] [PubMed]

- Song, E.; Xu, J.; Zhu, Y. Optimal Distributed Kalman Filtering Fusion with Singular Covariance of Filtering Errors and Measurement Noises. IEEE Trans. Autom. Control 2014, 59, 1271–1282. [Google Scholar] [CrossRef]

- Zhang, P.; Qi, W.; Deng, Z. Parallel Covariance Intersection Fusion Optimal Kalman Filter. Appl. Mech. Mater. 2014, 475, 436–441. [Google Scholar] [CrossRef]

- Beravs, T.; Begus, S.; Podobnik, J.; Munih, M. Magnetometer Calibration Using Kalman Filter Covariance Matrix for Online Estimation of Magnetic Field Orientation. IEEE Trans. Instrum. Meas. 2014, 63, 2013–2020. [Google Scholar] [CrossRef]

- Lee, G.B. A Fast Moving Object Tracking Method by the Combination of Covariance Matrix and Kalman Filter Algorithm. J. Korea Inst. Inform. Commun. Eng. 2015, 19, 1477–1484. [Google Scholar] [CrossRef]

- Wang, X.; You, Z.; Zhao, K. Inertial/celestial-based fuzzy adaptive unscented Kalman filter with Covariance Intersection algorithm for satellite attitude determination. Aerosp. Sci. Technol. 2016, 48, 214–222. [Google Scholar] [CrossRef]

- Hashlamon, I.; Erbatur, K. An improved real-time adaptive Kalman filter with recursive noise covariance updating rules. Turk. J. Electr. Eng. Comput. Sci. 2016, 24, 524–540. [Google Scholar] [CrossRef]

- Wei, C.; Ye, S.; Li, X.; Xie, M.; Yi, F. The Selection of Process Noise Covariance Q and Measurement Noise Covariance R on Kalman Filter. Appl. Mech. Mater. 2014, 513, 4342–4345. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Alavi, A.H. Krill herd: A new bio-inspired optimization algorithm. Commun. Nonlinear Sci. Numer. Simul. 2012, 17, 4831–4845. [Google Scholar] [CrossRef]

- Wang, G.; Guo, L.; Gandomi, A.H.; Hao, G.; Wang, H. Chaotic Krill Herd algorithm. Inform. Sci. 2014, 274, 17–34. [Google Scholar] [CrossRef]

- Wang, G.; Gandomi, A.H.; Alavi, A.H. Stud krill herd algorithm. Neurocomputing 2014, 128, 363–370. [Google Scholar] [CrossRef]

- Wang, G.; Gandomi, A.H.; Alavi, A.H.; Hao, G. Hybrid krill herd algorithm with differential evolution for global numerical optimization. Neural Comput. Appl. 2014, 25, 297–308. [Google Scholar] [CrossRef]

- Wang, G.; Gandomi, A.H.; Alavi, A.H. A chaotic particle-swarm krill herd algorithm for global numerical optimization. Kybernetes 2013, 42, 962–978. [Google Scholar] [CrossRef]

- Wang, G.; Gandomi, A.H.; Alavi, A.H.; Deb, S. A multi-stage krill herd algorithm for global numerical optimization. Int. J. Artif. Intell. Tools 2016, 25. [Google Scholar] [CrossRef]

- Wang, G.; Deb, S.; Gandomi, A.H.; Alavi, A.H. Opposition-based krill herd algorithm with cauchy mutation and position clamping. Neurocomputing 2016, 177, 147–157. [Google Scholar] [CrossRef]

- Wang, G.; Gandomi, A.H.; Alavi, A.H. An effective krill herd algorithm with migration operator in biogeography-based optimization. Appl. Math. Model. 2014, 38, 2454–2462. [Google Scholar] [CrossRef]

- Guo, L.; Wang, G.; Gandomi, A.H.; Alavi, A.H.; Duan, H. A new improved krill herd algorithm for global numerical optimization. Neurocomputing 2014, 138, 392–402. [Google Scholar] [CrossRef]

- Wang, G.; Gandomi, A.H.; Alavi, A.H.; Deb, S. A hybrid method based on krill herd and quantum-behaved particle swarm optimization. Neural Comput. Appl. 2016, 27, 989–1006. [Google Scholar] [CrossRef]

- Wang, G.; Gandomi, A.H.; Yang, X.; Alavi, A.H. A new hybrid method based on krill herd and cuckoo search for global optimization tasks. Int. J. Bio-Inspir. Comput. 2016, 8, 286–298. [Google Scholar] [CrossRef]

- Wang, G.; Deb, S.; Cui, Z. Monarch butterfly optimization. Neural Comput. Appl. 2015. [Google Scholar] [CrossRef]

- Wang, G.; Deb, S.; Zhao, X.; Cui, Z. A new monarch butterfly optimization with an improved crossover operator. Oper. Res. 2016. [Google Scholar] [CrossRef]

- Feng, Y.; Wang, G.; Deb, S.; Lu, M.; Zhao, X. Solving 0–1 knapsack problem by a novel binary monarch butterfly optimization. Neural Comput. Appl. 2015. [Google Scholar] [CrossRef]

- Wang, G. Moth search algorithm: A bio-inspired metaheuristic algorithm for global optimization problems. Memet. Comput. 2016. [Google Scholar] [CrossRef]

- Wang, G.G.; Deb, S.; Coelho, L.D.S. Earthworm Optimization Algorithm: A Bio-Inspired Metaheuristic Algorithm for Global Optimization Problems. Int. J. Bio-Inspir. Comput. 2015. Available online: https://www.researchgate.net/publication/224309395_Biogeography-Based_Optimization (accessed on 17 October 2016). [Google Scholar]

- Wang, G.; Deb, S.; Gandomi, A.H.; Zhang, Z.; Alavi, A.H. Chaotic cuckoo search. Soft Comput. 2016, 20, 3349–3362. [Google Scholar] [CrossRef]

- Wang, G.; Gandomi, A.H.; Zhao, X.; Chu, H.C.E. Hybridizing harmony search algorithm with cuckoo search for global numerical optimization. Soft Comput. 2016, 20, 273–285. [Google Scholar] [CrossRef]

- Wang, G.; Chu, H.E.; Mirjalili, S. Three-dimensional path planning for UCAV using an improved bat algorithm. Aerosp. Sci. Technol. 2016, 49, 231–238. [Google Scholar] [CrossRef]

- Yang, X. A New Metaheuristic Bat-Inspired Algorithm. Comput. Knowl. Technol. 2010, 284, 65–74. [Google Scholar]

- Yang, X. Nature-Inspired Metaheuristic Algorithms; Luniver Press: Frome, UK, 2010; pp. 79–89. [Google Scholar]

- Wang, G.; Guo, L.; Duan, H.; Wang, H. A New Improved Firefly Algorithm for Global Numerical Optimization. J. Comput. Theor. Nanosci. 2014, 11, 477–485. [Google Scholar] [CrossRef]

- Pan, W.T. A new Fruit Fly Optimization Algorithm: Taking the financial distress model as an example. Knowl.-Based Syst. 2012, 26, 69–74. [Google Scholar] [CrossRef]

- Li, H.; Guo, S.; Li, C.; Sun, J. A hybrid annual power load forecasting model based on generalized regression neural network with fruit fly optimization algorithm. Knowl.-Based Syst. 2013, 37, 378–387. [Google Scholar] [CrossRef]

- Niu, J.; Zhong, W.; Liang, Y.; Luo, N.; Qian, F. Fruit fly optimization algorithm based on differential evolution and its application on gasification process operation optimization. Knowl.-Based Syst. 2015, 88, 253–263. [Google Scholar] [CrossRef]

- Lin, W.Y. A novel 3D fruit fly optimization algorithm and its applications in economics. Neural Comput. Appl. 2016, 27, 1391–1413. [Google Scholar] [CrossRef]

- Shi, Z.B.; Miao, Y. Prediction Research on the Failure of Steam Turbine Based on Fruit Fly Optimization Algorithm Support Vector Regression. Adv. Mater. Res. 2013, 614–615. [Google Scholar]

- Zheng, X.L.; Wang, L.; Wang, S.Y. A novel fruit fly optimization algorithm for the semiconductor final testing scheduling problem. Knowl.-Based Syst. 2014, 57, 95–103. [Google Scholar] [CrossRef]

- Wang, L.; Shi, Y.; Liu, S. An improved fruit fly optimization algorithm and its application to joint replenishment problems. Expert Syst. Appl. 2015, 42, 4310–4323. [Google Scholar] [CrossRef]

- Shyam Mohan, M.; Naik, N.; Gemson, R.M.O.; Ananthasayanam, M.R. Introduction to the Kalman Filter and Tuning Its Statistics for Near Optimal Estimates and Cramer Rao Bound; TR/EE2015/401; Cornell University Library: Ithaca, NY, USA, 2015. [Google Scholar]

is the output port of the state-space model;

is the output port of the state-space model;  is the input port of the Kalman filter observation model, and the input port and output port are connected to each other.

is the input port of the Kalman filter observation model, and the input port and output port are connected to each other.

is the output port of the state-space model;

is the output port of the state-space model;  is the input port of the Kalman filter observation model, and the input port and output port are connected to each other.

is the input port of the Kalman filter observation model, and the input port and output port are connected to each other.

| Index | Configuration |

|---|---|

| Processor | Intel Core i7, 2.5 GHz |

| RAM | 8 G |

| System | Win 10, x64 |

| Software | MATLAB |

| Algorithms | MSE | Time (s) |

|---|---|---|

| PSO | 0.39747 | 7.7298 |

| GA | 0.26777 | 13.002 |

| FOA | 0.022869 | 7.0885 |

| 3D-FOA | 0.022089 | 7.3534 |

| Proposed IFOA | 0.020527 | 7.2502 |

| GA | PSO | ||

|---|---|---|---|

| Parameter | Value | Parameter | Value |

| Generations | 100 | Generations | 100 |

| Population size | 20 | Population size | 20 |

| Initial Population | [2, 2] | Particle length | 2 |

| Crossover Fraction | 0.8 | Population range | [−5, 5] |

| Migration Fraction | 0.2 | Velocity range | [−1, 1] |

| Function to corssover | crossoverarithmetic | Acceleration coefficients | [1.49445, 1.49445] |

| Function for mutation | mutationadaptfeasible | Inertia weight factor | 0.729 |

| Index | Equipment | Information |

|---|---|---|

| 1 | Hydraulic powered roof Support | ZY9000/15/28D |

| 2 | Displacement sensor | PR-500 mm |

| 3 | Data acquisition card | Smacq USB-4432 |

| 4 | Inertial Sensor | ADIS 16448 |

| Covariances | Values |

|---|---|

| Q | 0.1758 |

| R | 0.4935 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Wang, Z.; Tan, C.; Si, L.; Liu, X.; Feng, S. A Fruit Fly-Optimized Kalman Filter Algorithm for Pushing Distance Estimation of a Hydraulic Powered Roof Support through Tuning Covariance. Appl. Sci. 2016, 6, 299. https://doi.org/10.3390/app6100299

Zhang L, Wang Z, Tan C, Si L, Liu X, Feng S. A Fruit Fly-Optimized Kalman Filter Algorithm for Pushing Distance Estimation of a Hydraulic Powered Roof Support through Tuning Covariance. Applied Sciences. 2016; 6(10):299. https://doi.org/10.3390/app6100299

Chicago/Turabian StyleZhang, Lin, Zhongbin Wang, Chao Tan, Lei Si, Xinhua Liu, and Shang Feng. 2016. "A Fruit Fly-Optimized Kalman Filter Algorithm for Pushing Distance Estimation of a Hydraulic Powered Roof Support through Tuning Covariance" Applied Sciences 6, no. 10: 299. https://doi.org/10.3390/app6100299

APA StyleZhang, L., Wang, Z., Tan, C., Si, L., Liu, X., & Feng, S. (2016). A Fruit Fly-Optimized Kalman Filter Algorithm for Pushing Distance Estimation of a Hydraulic Powered Roof Support through Tuning Covariance. Applied Sciences, 6(10), 299. https://doi.org/10.3390/app6100299