High Performance Shape Memory Polyurethane Synthesized with High Molecular Weight Polyol as the Soft Segment

Abstract

:1. Introduction

2. Experiments

2.1. Synthesis of SMPUs

| Sample | MDI | IPDI | γ |

|---|---|---|---|

| PEG-H1, PCL-S1 | 19.95 | 0 | 1.0 |

| PEG-H2, PCL-S2 | 16.5 | 3.37 | 0.83 |

| PEG-H3, PCL-S3 | 13.36 | 6.65 | 0.668 |

| PEG-H4, PCL-S4 | 10.0 | 10.0 | 0.50 |

| PEG-H5, PCL-S5 | 6.6 | 13.7 | 0.325 |

2.2. Characterization of Crystal Structure and Thermal Properties

2.3. Characterization of Shape Memory Properties

3. Results and Discussions

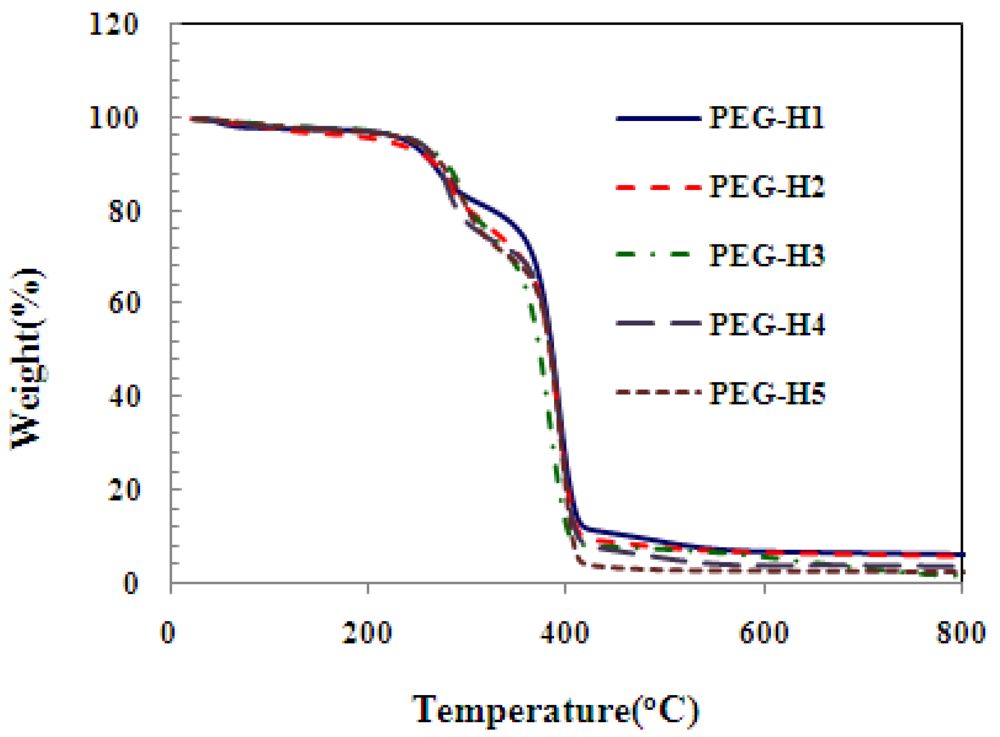

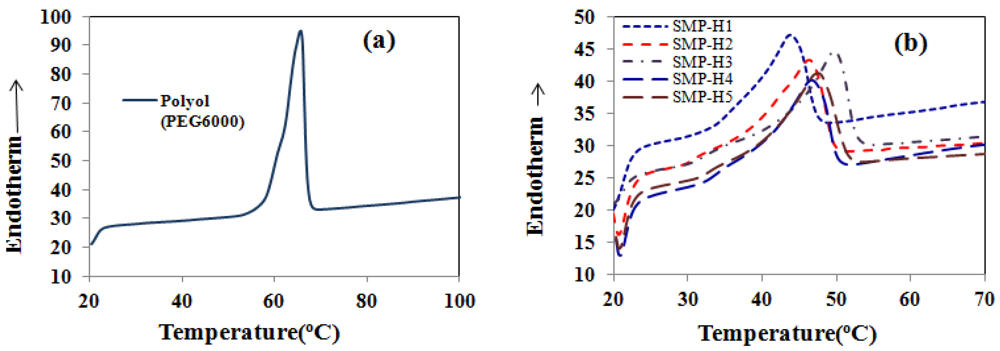

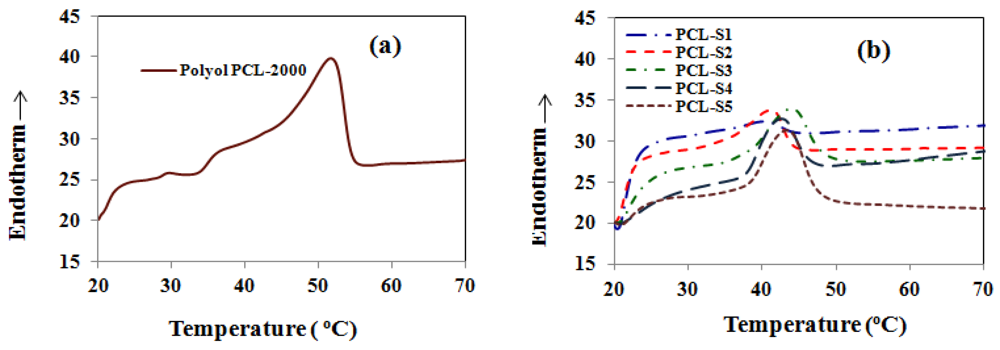

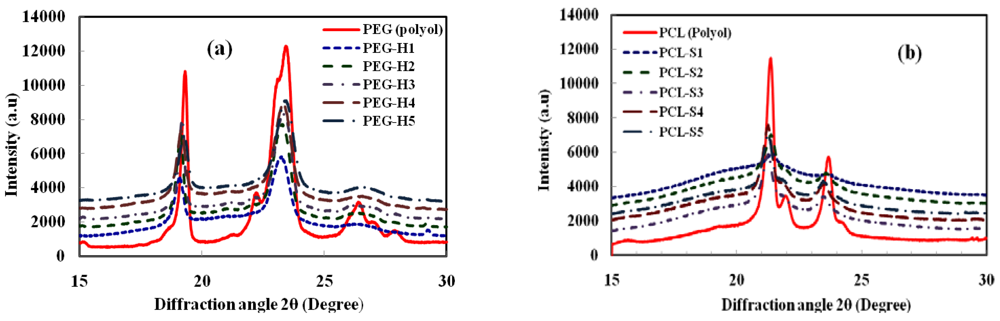

3.1. Thermal Property and Crystallinity

| Sample | Weight Loss at (410 °C) | Tm | ΔHf | Stress at Break | Strain at Break |

| % | °C | Jg−1 | MPa | % | |

| Peg-6000 | N/A | 65.0 | 822.0 | N/A | N/A |

| PEG-H1 | 86 | 43.6 | 59.5 | 4.49 | 425 |

| PEG-H2 | 88 | 46.3 | 75.6 | 5.15 | 170 |

| PEG-H3 | 92 | 50.0 | 79.4 | 5.40 | 110 |

| PEG-H4 | 90 | 46.0 | 71.6 | 6.37 | 50 |

| PEG-H5 | 94 | 47.0 | 83.4 | 8.20 | 12 |

| PCL-2000 | N/A | 51.6 | 76.6 | N/A | N/A |

| PCL-S1 | 94 | 40.3 | 8.6 | 6.99 | 930 |

| PCL-S2 | 94 | 41.3 | 18.8 | 6.24 | 869 |

| PCL-S3 | 94 | 44.3 | 23.4 | 5.64 | 790 |

| PCL-S4 | 98 | 42.6 | 20.5 | 4.39 | 334 |

| PCL-S5 | 98 | 43.3 | 27.2 | 3.06 | 192 |

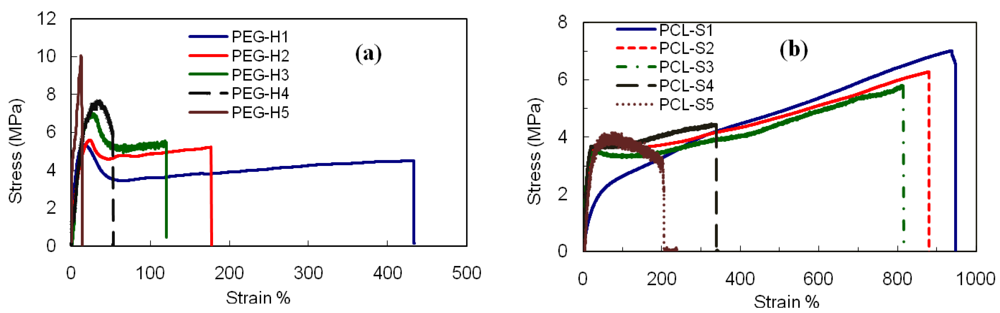

3.2. Thermal Mechanical Properties

3.3. Shape Memory Properties

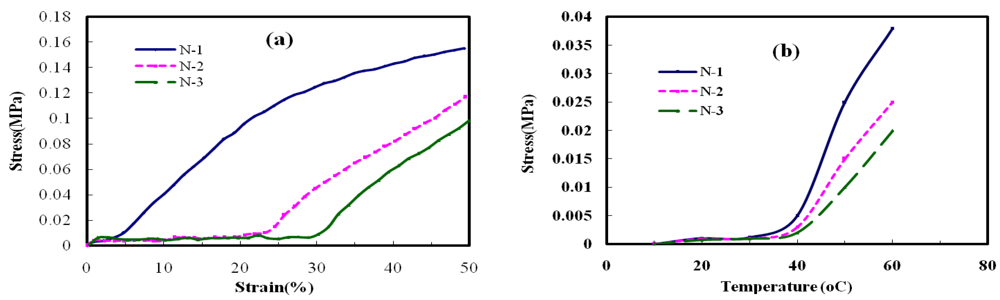

3.3.1. Recovery Stress

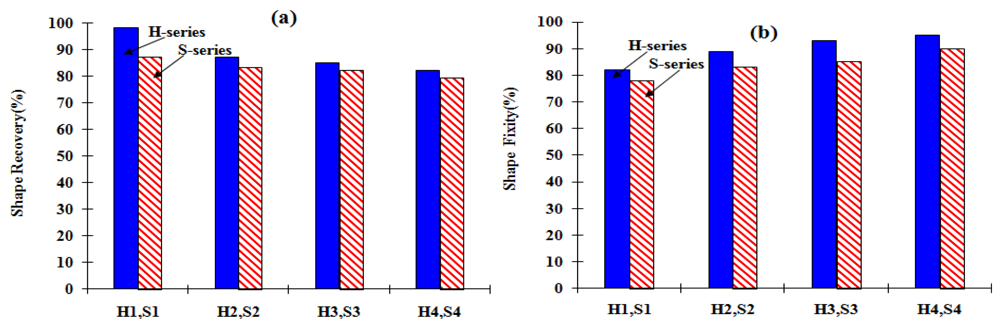

3.3.2. Shape Recovery Ratio and Shape Fixity

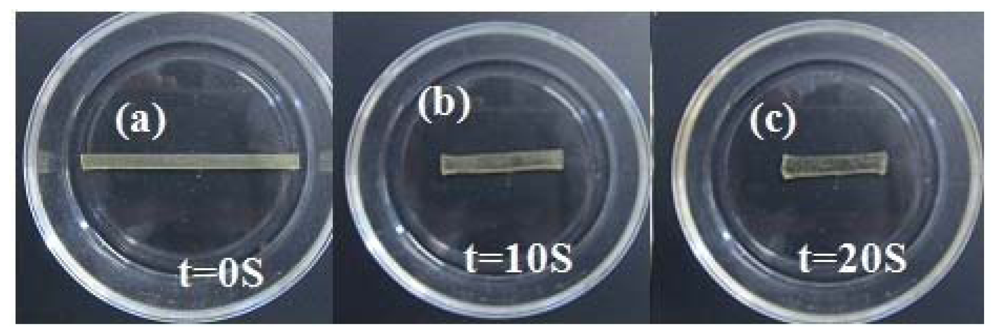

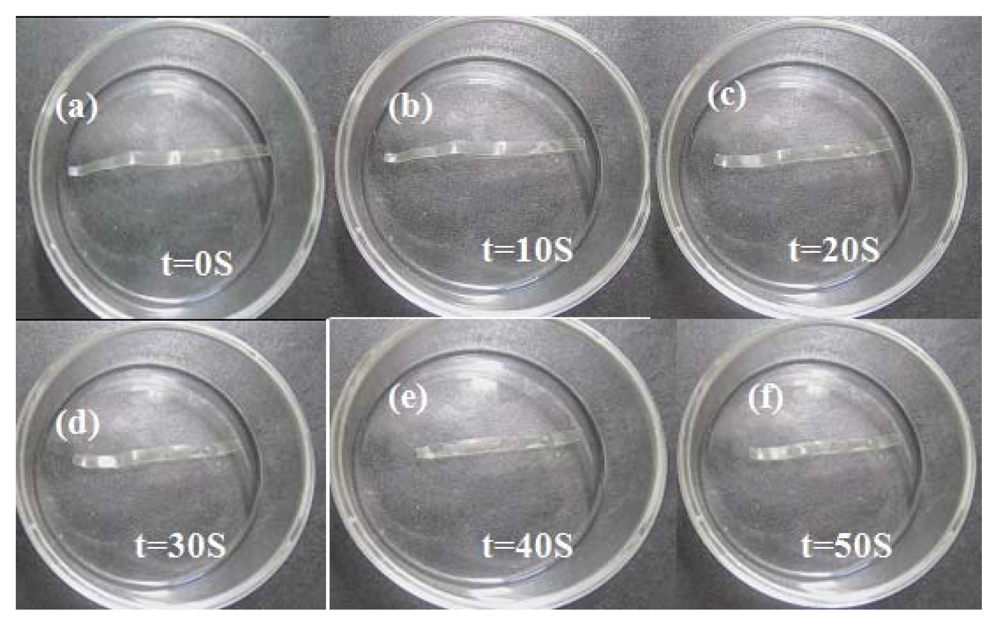

3.4. Physical Shape Recovery Test

4. Conclusions

- The PEG-SMPUs show a slightly better thermal stability than PCL-SMPUs. Both sample series have transition temperatures between 40~50 °C, suitable for medical device applications.

- The PEG-SMPUs have a higher crystallinity and lower phase compatibility than those of PCL-SMPU samples. With the increase of IPDI concentration, the crystallinity increases, leading to deteriorated phase compatibility and shape memory effect for both the sample series.

- The PCL-SMPUs have larger elongations at break and recovery stresses than those of the PEG-SMPUs, i.e., high mechanical strength at room temperature. Longer molecular chains, lower cross-link density and higher crystallinity are believed to be responsible for the weaker thermal mechanical properties of the PEG-SMPUs.

- The PEG-SMPUs have a higher recovery ratio, a higher fixity and a much shorter shape recovery time, and demonstrate superior SME effect as compared to the PCL-SMPUs. SMPUs with high molecular weight polyol can be excellent candidates for applications in engineering and as microactuators, in particular when fast actuation is required.

Acknowledgements

References

- Tobushi, H.; Hashimoto, T.; Ito, N.; Hayashi, S.; Yamada, E. Shape fixity and shape recovery in a film of shape memory polymer of polyurethane series. J. Intell. Mater. Syst. Struct. 1998, 9, 127–136. [Google Scholar] [CrossRef]

- Lendlein, A.; Langer, R. Biodegradable, Elastic shape-memory polymers for potential biomedical applications. Science 2002, 296, 1673–1677. [Google Scholar] [CrossRef]

- Tobushi, H.; Haray, H.; Yamaday, E.; Hayashiz, S. Thermomechanical properties in a thin film of shape memory polymer of polyurethane series. Smart Mater. Str. 1996, 5, 483–491. [Google Scholar] [CrossRef]

- Liang, C.; Rogers, C.A.; Malafeew, E. Preliminary investigation of shape memory polymers and their hybrid composites. Smart Struct. Mater. 1991, 24, 97–103. [Google Scholar]

- Hayashi, S.; Ishikawa, N.; Jiordano, C. High moisture per-meability polyurethane for textile application. J. Coated Fabrics 1993, 23, 74–83. [Google Scholar]

- Huang, W.M.; Yang, B.; Zhao, Y.; Ding, Z. Thermo-moisture responsive polyurethane shape-memory polymer and composites: A review. J. Mater. Chem. 2010, 20, 3367–3381. [Google Scholar] [CrossRef]

- Wei, Z.G.; Sandstrom, R.; Miyazaki, S. Review shape-memory materials and hybrid composites for smart systems. J. Mater. Sci. 1998, 33, 3745–3762. [Google Scholar]

- Chun, B.C.; Cha, S.H.; Chung, Y.C.; Cho, J.W. Enhanced dynamic mechanical and shape-memory properties of a poly(ethylene terephthalate)poly(ethylene glycol) copolymer crosslinked by maleic anhydride. J. Appl. Polym. Sci. 2002, 83, 27–37. [Google Scholar] [CrossRef]

- Lee, H.S.; Wang, Y.K.; Macknight, W.J.; Hsu, S.L. Spectroscopic analysis of phase-separation kinetics in model polyurethanes. Macromolecules 1988, 21, 270–273. [Google Scholar] [CrossRef]

- Xia, H.S.; Song, M.; Zhang, Z.Y.; Richardson, M. Microphase separation, stress relaxation, and creep behavior of polyurethane nanocomposites. J. Appl. Polym. Sci. 2007, 103, 2992–3002. [Google Scholar] [CrossRef]

- Coleman, M.M.; Lee, K.H.; Skrovanek, D.J.; Painter, P.C. Hydrogen-bonding in polymers. 4. Infrared temperature studies of a simple polyurethane. Macromolecules 1986, 19, 2149–2157. [Google Scholar] [CrossRef]

- Seymour, R.W.; Allegrezza, A.E.; Cooper, S.L. Segmental orientation studies of block polymers. i. hydrogen-bonded polyurethanes. Macromolecules 1973, 6, 896–908. [Google Scholar] [CrossRef]

- Lee, B.S.; Chun, B.C.; Chung, Y.C.; Sul, K.I.; Cho, J.W. Structure and thermomechanical properties of polyurethane block copolymers with shape memory effect. Macromolecules 2001, 34, 6431–6437. [Google Scholar] [CrossRef]

- Lee, H.S.; Kim, J.W.; Kim, K.B. Shape memory polyurethanes having crosslinks in soft and hard segments. Smart. Mater. Struct. 2004, 13, 1345–1350. [Google Scholar] [CrossRef]

- Kim, B.K.; Lee, S.Y. Polyurethanes having shape memory effects. Polymer 1996, 37, 5781–5793. [Google Scholar] [CrossRef]

- Li, F.; Zhang, X.; Hou, J.; Xu, M.; Luo, X.; Ma, D.; Kim, B.K. Studies on thermally stimulated shape memory effect of segmented polyurethanes. J. Appl. Polym. Sci. 1997, 64, 1511–1516. [Google Scholar] [CrossRef]

- Mondal, S.; Hu, J.L. Studies of shape memory property on thermoplastic segmented polyurethanes: Influence of PEG 3400. J. Elastomer & Plastic. 2007, 39, 81–91. [Google Scholar]

- Chen, S.; Hu, J.; Liu, Y.; Liem, H.; Zhu, Y.; Meng, Q. Effect of molecular weight on shape memory behavior in polyurethane films. Polym. Int. 2007, 56, 1128–1134. [Google Scholar] [CrossRef]

- Hu, J.; Yang, Z.; Yeung, L.; Ji, F.; Liu, Y. Crosslinked polyurethanes with shape memory properties. Polym. Int. 2005, 54, 854–859. [Google Scholar] [CrossRef]

- Ahmad, M.; Luo, J.K.; Xu, B.; Purnawali, H.; King, P.J.; Chalker, P.; Fu, Y.Q.; Huang, W.M.; Miraftab, M. Synthesis and characterization of polyurethane based shape memory polymers. Macromol. Chem. Phys. 2011, 202, 592–602. [Google Scholar]

- Lendlein, A.; Kelch, S. Shape memory polymers. Angew Chem. Int. Edit. 2002, 41, 2034–2057. [Google Scholar] [CrossRef]

- Tobushi, H.; Hara, H.; Yamada, E.; Hayashi, S. Thermomechanical properties in a thin film of shape memory polymer of polyurethane series. Smart Mater. & Struct. 1996, 5, 483–496. [Google Scholar]

- Tien, Y.I.; Wei, K.H. The effect of nano-sized silicate layers from montmorillonite on glass transition, dynamic mechanical, and thermal degradation properties of segmented polyurethane. Appl. Polym. Sci. 2002, 86, 1741–1748. [Google Scholar] [CrossRef]

- Hayashi, S.; Kondo, S.; Kapadia, P.; Ushioda, E. Room-temperature-functional shape-memory polymers. Plast. Eng. 1995, 51, 29–31. [Google Scholar]

- Huang, W.M. Thermo-moisture responsive polyurethane shape memory polymer for biomedical devices. J. Open Med. Device 2010, 2, 11–19. [Google Scholar] [CrossRef]

- Ahmad, M.; Luo, J.K.; Miraftab, M. Feasibility study of polyurethane shape-memory polymer actuators for pressure bandage application. Sci. Technol. Adv. Mater. 2012, 13, 015006–015013. [Google Scholar] [CrossRef]

- Cho, J.W.; Jung, Y.C.; Chung, Y.C.; Chun, B.C. Improved mechanical properties of shape-memory polyurethane block copolymers through the control of the soft-segment arrangement. J. Appl. Polym. Sci. 2004, 93, 2410–2015. [Google Scholar] [CrossRef]

- Wilkes, G.L.; Wildnauer, R. Kinetic behavior of the thermal and mechanical properties of segmented urethanes. J. Appl. Phys. 1975, 46, 4148–4152. [Google Scholar] [CrossRef]

- Bassi, M.; Tonelli, C.; Di, A.M. Glass transition behavior of a microphase segregated polyurethane based on PFPE and IPDI: A calorimetric study. Macromolecules 2003, 36, 8015–8023. [Google Scholar] [CrossRef]

- Lendlein, A.; Jiang, H.; Junger, O.; Langer, R. Light-induced shape memory polymer. Nature 2005, 434, 879. [Google Scholar] [CrossRef]

- Small, W.; Wilson, T.S.; Benett, W.J.; Loge, J.M.; Maitland, D.J. Laser-activated shape memory polymer intravascular thrombectomy device. Opt. Express 2005, 13, 8204–8213. [Google Scholar] [CrossRef]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Ahmad, M.; Xu, B.; Purnawali, H.; Fu, Y.; Huang, W.; Miraftab, M.; Luo, J. High Performance Shape Memory Polyurethane Synthesized with High Molecular Weight Polyol as the Soft Segment. Appl. Sci. 2012, 2, 535-548. https://doi.org/10.3390/app2020535

Ahmad M, Xu B, Purnawali H, Fu Y, Huang W, Miraftab M, Luo J. High Performance Shape Memory Polyurethane Synthesized with High Molecular Weight Polyol as the Soft Segment. Applied Sciences. 2012; 2(2):535-548. https://doi.org/10.3390/app2020535

Chicago/Turabian StyleAhmad, Manzoor, Bin Xu, Hendra Purnawali, Yongqing Fu, Weimin Huang, Mohsen Miraftab, and Jikui Luo. 2012. "High Performance Shape Memory Polyurethane Synthesized with High Molecular Weight Polyol as the Soft Segment" Applied Sciences 2, no. 2: 535-548. https://doi.org/10.3390/app2020535

APA StyleAhmad, M., Xu, B., Purnawali, H., Fu, Y., Huang, W., Miraftab, M., & Luo, J. (2012). High Performance Shape Memory Polyurethane Synthesized with High Molecular Weight Polyol as the Soft Segment. Applied Sciences, 2(2), 535-548. https://doi.org/10.3390/app2020535