In Situ Al3BC/Al Composite Fabricated via Solid-Solid Reaction: An Investigation on Microstructure and Mechanical Behavior

Abstract

1. Introduction

2. Experimental Details

2.1. Materials

2.2. Processing

2.3. Characterization

3. Results

3.1. Physical and Structrual Characterization

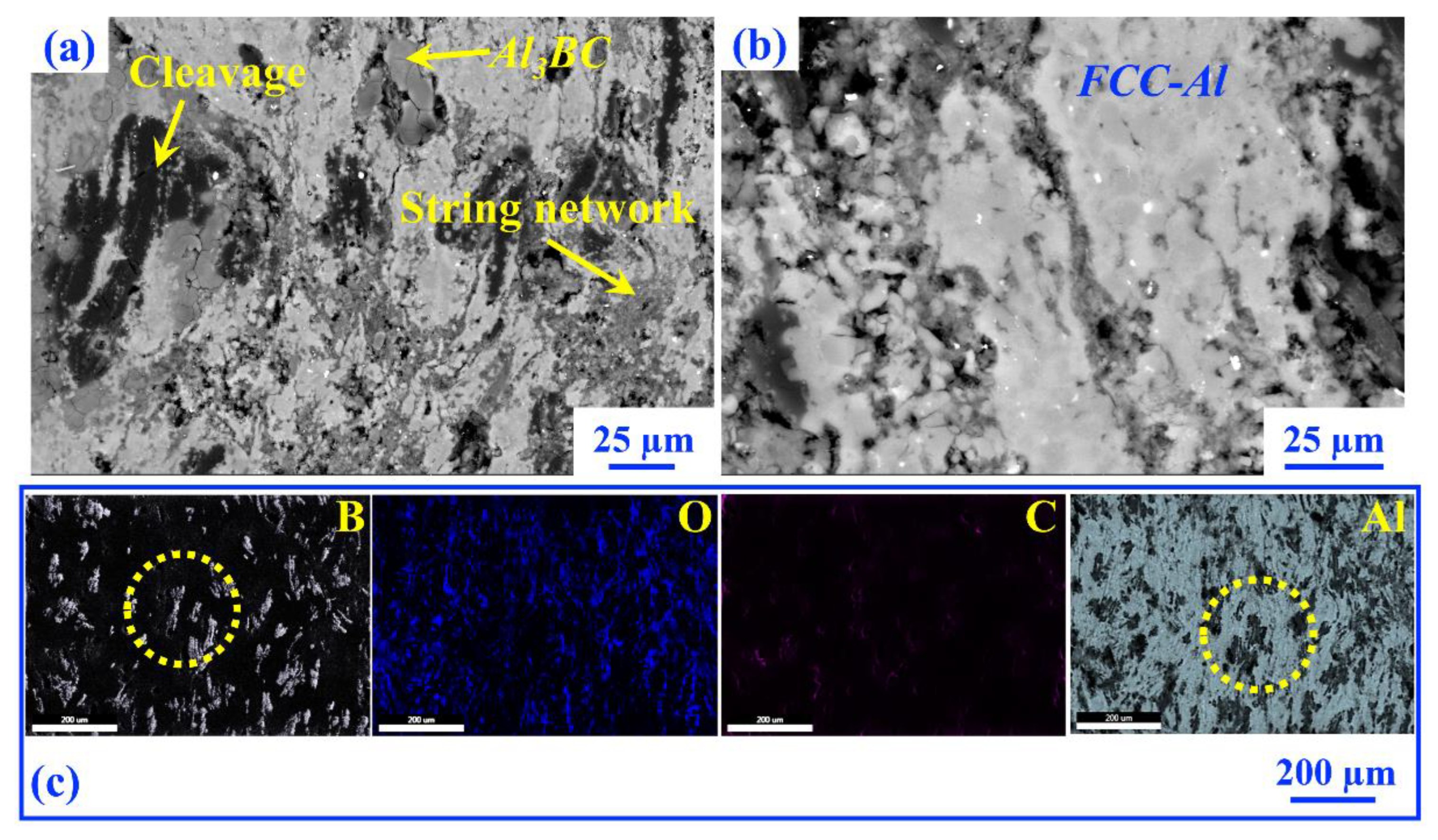

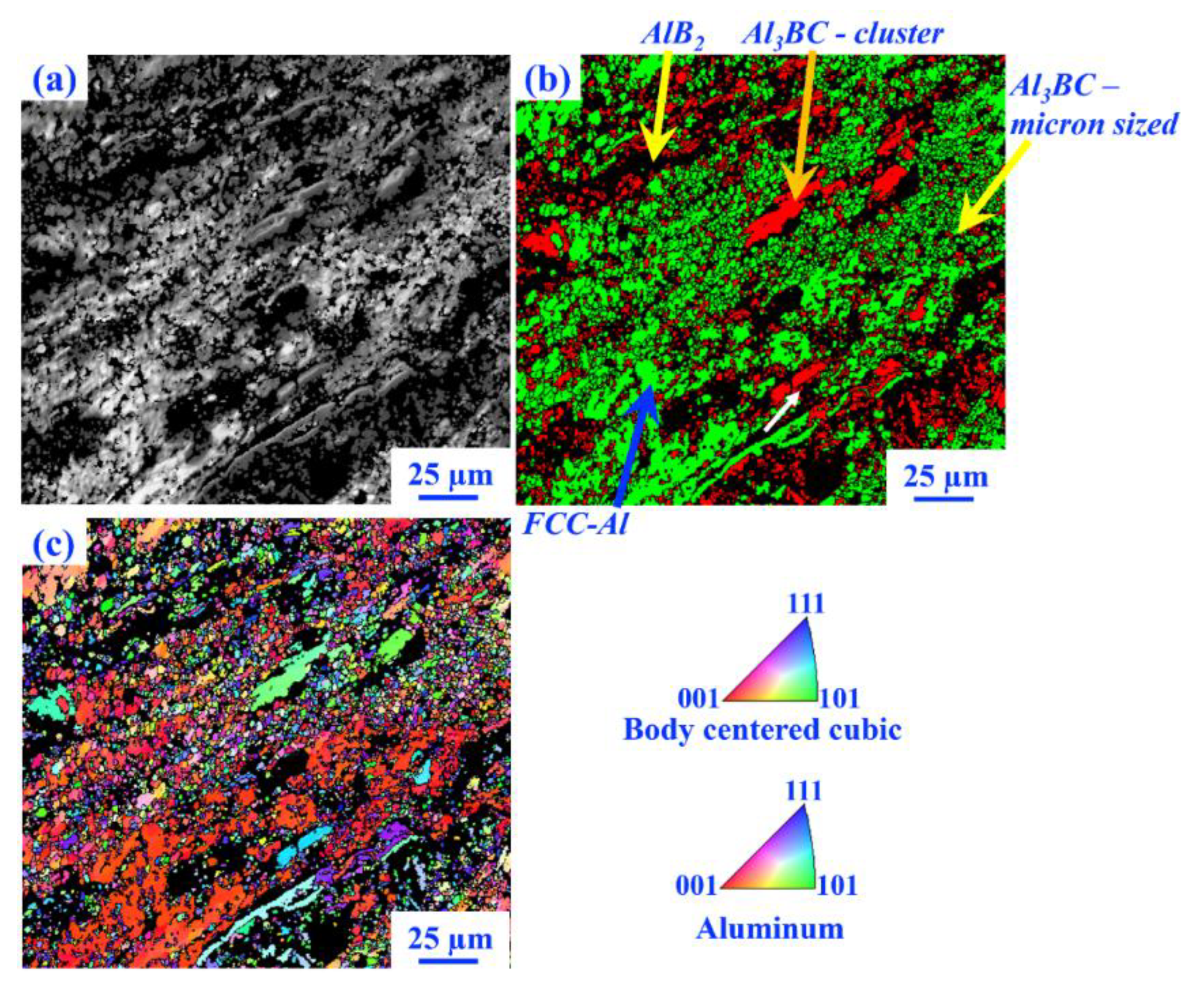

3.2. Microstructure Evolution and Reinforcement Distribution

3.3. Grain Structure Evolution

3.4. Evolution of Mechanical Properties

3.4.1. Compressive Response

3.4.2. Pronounced Strain Hardening Behavior

3.4.3. Strengthening Parameters Measurements

- Load-bearing contribution (ΔσLoad): The strength increment due to load-bearing capacity of Al3BC reinforcement was determined from the expression [59]:where υp denotes the volume fraction of Al3BC particles (υp = 0.65) and σm refers to the yield strength of the composite and the particle aspect ratio denoted by A (~1) [18,19]. Hence, the contribution ΔσLoad of Al3BC reinforcement was predicted to be ΔσLoad = 12 MPa, comparable to ΔσLoad = 16 MPa in the AlSi10Mg/SiC (10 wt.%) matrix composite, exhibiting UTS 350 MPa and elongation to failure up to ~3% [60].

- Strengthening capability contribution (R): The contribution of a specific volume fraction of Al3BC reinforcements to the strengthening of the Al matrix in Al3BC/Al composite, R, was evaluated from [61]:The strengthening capability of the Al3BC/Al composites, calculated as R = 5.6 is impressive. The value is close to FeSiB-reinforced Cu matrix composites (R = 5.9) [62] and even surpasses SiC-particle-reinforced (R = 2.5) [63] and Al2O3-particle-reinforced (R = 2.3) [48] Cu matrix composites by a factor of two. This finding highlights the remarkable strengthening efficiency achieved in Al3BC/Al composites.

- Furthermore, Pugh’s ratio, which is the ratio of the calculated bulk modulus (G = 80 GPa) to shear modulus (B = 196 GPa) (B/G), can be used to determine the ductility or brittleness of the material. A Pugh’s ratio greater than 1.75 indicates that the material is more ductile in nature [64]. Based on the calculated Pugh’s ratio, a B/G = 2.45 is observed for the as-developed Al3BC/Al composite. It can be concluded that the as-fabricated Al3BC/Al composite has superior ductility while considering the poison’s ratio of υ = 0.32. Furthermore, if the Vickers hardness of a material falls within the range of 10–20 GPa, it is typically referred to as hard [65]. According to this information, the composite (HTh = 15 ± 5 GPa) is categorized as a hard material.

4. Discussion

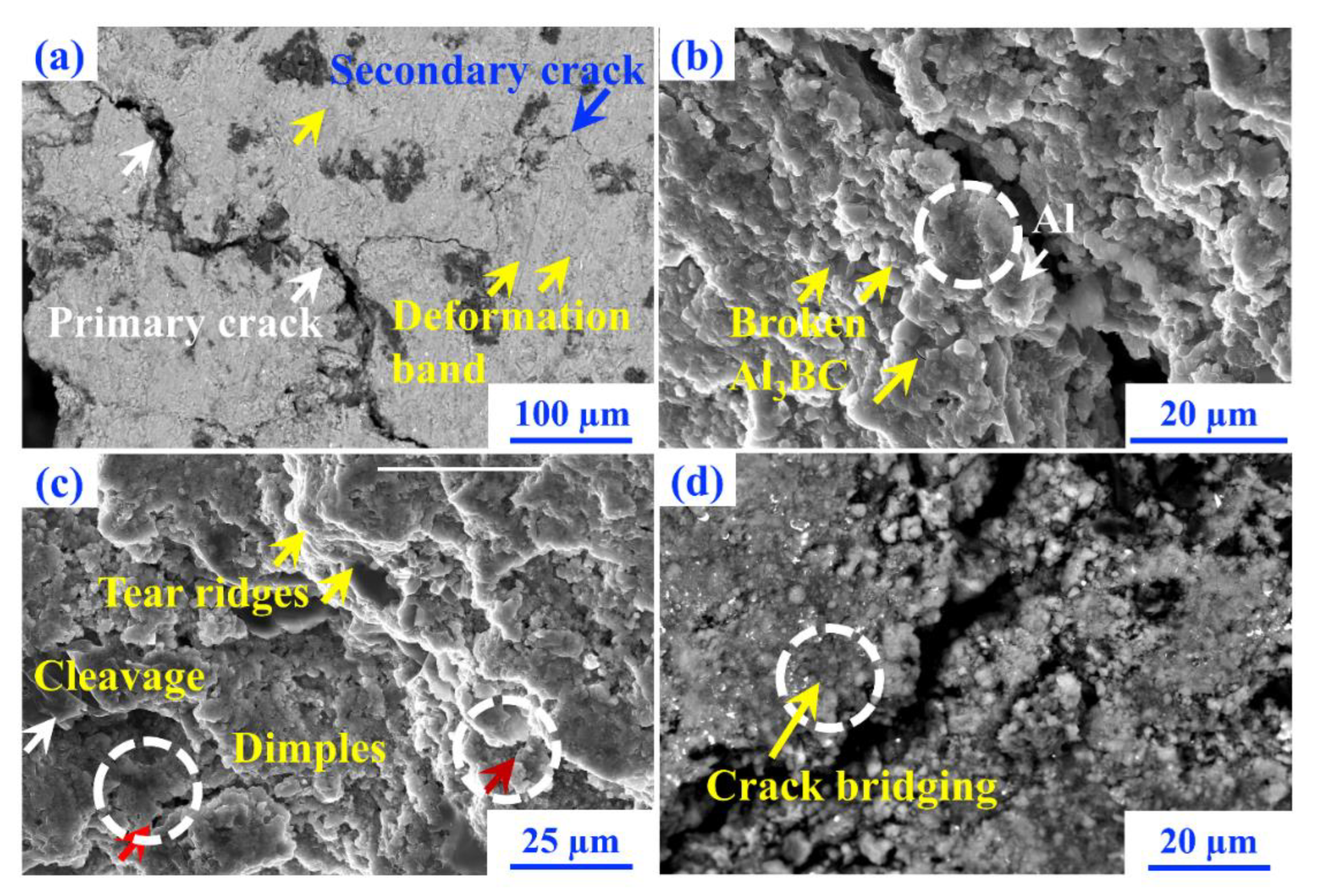

4.1. Fracture Surface Investigation

4.2. Understanding the Strength-Ductility Response in the Composite

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Das, D.K.; Mishra, P.C.; Singh, S.; Thakur, R.K. Properties of Ceramic-Reinforced Aluminium Matrix Composites—A Review. Int. J. Mech. Mater. Eng. 2014, 9, 12. [Google Scholar] [CrossRef]

- Tang, S.; Ummethala, R.; Suryanarayana, C.; Eckert, J.; Prashanth, K.G.; Wang, Z. Additive Manufacturing of Aluminum-Based Metal Matrix Composites—A Review. Adv. Eng. Mater. 2021, 23, 2100053. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Z.; Zhao, Q.; Prashanth, K.G. Metal-Metal Interpenetrating Phase Composites: A Review. J. Alloys Compd. 2024, 1009, 176951. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Scudino, S.; Eckert, J.; Prakash, O.; Ramamurty, U. Simultaneous Enhancements of Strength and Toughness in an Al-12Si Alloy Synthesized Using Selective Laser Melting. Acta Mater. 2016, 115, 285–294. [Google Scholar] [CrossRef]

- Milligan, W.W.; Milne, I.; Ritchie, R.O.; Karihaloo, B. Comprehensive Structural Integrity; Milligan, W.W., Milne, I., Ritchie, R.O., Karihaloo, B., Eds.; Elsevier Science: Pergamon, Türkiye, 2003; Volume 1, ISBN 978-0-08-043749-1. [Google Scholar]

- Chawla, N.; Shen, Y.-L. Mechanical Behavior of Particle Reinforced Metal Matrix Composites. Adv. Eng. Mater. 2001, 3, 357–370. [Google Scholar] [CrossRef]

- Liddicoat, P.V.; Liao, X.Z.; Zhao, Y.; Zhu, Y.; Murashkin, M.Y.; Lavernia, E.J.; Valiev, R.Z.; Ringer, S.P. Nanostructural Hierarchy Increases the Strength of Aluminium Alloys. Nat. Commun. 2010, 1, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, I.A.; Mohamed, F.A.; Lavernia, E.J. Particulate Reinforced Metal Matrix Composites—A Review. J. Mater. Sci. 1991, 26, 1137–1156. [Google Scholar] [CrossRef]

- Mayer, C.R.; Yang, L.W.; Singh, S.S.; Llorca, J.; Molina-Aldareguia, J.M.; Shen, Y.L.; Chawla, N. Anisotropy, Size, and Aspect Ratio Effects on Micropillar Compression of AlSiC Nanolaminate Composites. Acta Mater. 2016, 114, 25–32. [Google Scholar] [CrossRef]

- Slipenyuk, A.; Kuprin, V.; Milman, Y.; Goncharuk, V.; Eckert, J. Properties of P/M Processed Particle Reinforced Metal Matrix Composites Specified by Reinforcement Concentration and Matrix-to-Reinforcement Particle Size Ratio. Acta Mater. 2006, 54, 157–166. [Google Scholar] [CrossRef]

- Polat, S.; Sun, Y.; Çevik, E.; Colijn, H. Microstructure and Synergistic Reinforcing Activity of GNPs-B4C Dual-Micro and Nano Supplements in Al-Si Matrix Composites. J. Alloys Compd. 2019, 806, 1230–1241. [Google Scholar] [CrossRef]

- Xiao, P.; Gao, Y.; Yang, C.; Li, Y.; Huang, X.; Liu, Q.; Zhao, S.; Xu, F.; Gupta, M. Strengthening and Toughening Mechanisms of Mg Matrix Composites Reinforced with Specific Spatial Arrangement of In-Situ TiB2 Nanoparticles. Compos. B Eng. 2020, 198, 108174. [Google Scholar] [CrossRef]

- Sun, X.; Fan, Y.; Nie, J.; Chen, Y.; Xie, K.; Liu, S.; Zhao, Y.; Liu, X. Significant Improvement of the Room and Cryogenic Mechanical Properties of an AlN Particle Reinforced Al Matrix Composite by Alloying Element Magnesium. Compos. B Eng. 2024, 268, 111056. [Google Scholar] [CrossRef]

- Scudino, S.; Ali, F.; Surreddi, K.B.; Prashanth, K.G.; Sakaliyska, M.; Eckert, J. Al-Based Metal Matrix Composites Reinforced with Nanocrystalline Al-Ti-Ni Particles. J. Phys. Conf. Ser. 2010, 240, 012154. [Google Scholar] [CrossRef]

- Guan, C.; Chen, G.; Kai, X.; Cao, R.; Miao, C.; Xu, Z.; Zhao, Y. Evolution of Microstructure and Mechanical Properties of Graphene Nanoplates and ZrB2 Nanoparticles Reinforced AA6111 Composites during Hot Rolling Deformation. J. Alloys Compd. 2022, 920, 165910. [Google Scholar] [CrossRef]

- Geng, H.; Cui, C.; Liu, L.; Liang, Y. The Microstructures and Mechanical Properties of Hybrid In-Situ AlN-TiC-TiN-Al3Ti/Al Reinforced Al-Cu-Mn-Ti Alloy Matrix Composites. J. Alloys Compd. 2022, 903, 163902. [Google Scholar] [CrossRef]

- Yi, L.F.; Kunimoto, S.; Ishii, T.; He, L.; Onda, T.; Chen, Z.C. Improved Mechanical Properties of Mechanically Milled Mg2Si Particles Reinforced Aluminum-Matrix Composites Prepared by Hot Extrusion. Mater. Sci. Eng. A 2023, 871, 144904. [Google Scholar] [CrossRef]

- Zhao, Y.; Singaravelu, A.S.S.; Ma, X.; Zhang, Q.; Chang, S.L.Y.; Liu, X.; Chawla, N. Unveiling the Deformation Behavior and Strengthening Mechanisms of Al3BC/Al Composites via in-Situ Micropillar Compression. J. Alloys Compd. 2020, 823, 153842. [Google Scholar] [CrossRef]

- Zhao, Y.; Singaravelu, A.S.S.; Ma, X.; Zhang, Q.; Liu, X.; Chawla, N. Micromechanical Properties and Deformation Behavior of Al3BC/6061 Al Composites via Micropillar Compression. Mater. Sci. Eng. A 2020, 773, 138852. [Google Scholar] [CrossRef]

- Mei, Y.; Li, H.; Yang, W.; Wu, J.; Li, X.; Xiu, Z.; Fu, J.; Hussain, M.; Chen, G.; Wu, G. In-Situ Synthesis of Al3BC/Al Composites from Amorphous Boron and Graphene Nanoplates by Solid Reaction. J. Alloys Compd. 2020, 832, 154912. [Google Scholar] [CrossRef]

- Zhao, Y.; Singaravelu, A.S.S.; Ma, X.; Liu, X.; Chawla, N. Mechanical Properties of Al3BC by Nanoindentation and Micropillar Compression. Mater. Lett. 2020, 264, 127361. [Google Scholar] [CrossRef]

- Han, B.Q.; Huang, J.Y.; Zhu, Y.T.; Lavernia, E.J. Strain Rate Dependence of Properties of Cryomilled Bimodal 5083 Al Alloys. Acta Mater. 2006, 54, 3015–3024. [Google Scholar] [CrossRef]

- Tian, W.; Li, P.; Liu, X. Morphology Stability of Al3BC Phase in Aluminum Alloys. J. Alloys Compd. 2014, 583, 329–334. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, X.; Chen, H.; Zhao, X.; Liu, X. Preferred Orientation and Interfacial Structure in Extruded Nano-Al3BC/6061 Al. Mater. Des. 2017, 131, 23–31. [Google Scholar] [CrossRef]

- Lee, C. Do Effects of Microporosity on Tensile Properties of A356 Aluminum Alloy. Mater. Sci. Eng. A 2007, 464, 249–254. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Chaubey, A.K.; Löber, L.; Wang, P.; Attar, H.; Schimansky, F.P.; Pyczak, F.; Eckert, J. Processing of Al-12Si-TNM Composites by Selective Laser Melting and Evaluation of Compressive and Wear Properties. J. Mater. Res. 2016, 31, 55–65. [Google Scholar] [CrossRef]

- Roy, D.; Pal, T.; Ajay, S.; Prakash, A.; Dutta, S.; Maity, T. Improving Strain Hardening Behavior in Nano-Intermetallic Reinforced Aluminum in-Situ Composites through an Optimized Twostep Thermal Processing Method; Sintering and Uniaxial Forging. J. Alloys Compd. 2024, 982, 173688. [Google Scholar] [CrossRef]

- Wang, Z.; Qu, R.T.; Scudino, S.; Sun, B.A.; Prashanth, K.G.; Louzguine-Luzgin, D.V.; Chen, M.W.; Zhang, Z.F.; Eckert, J. Hybrid Nanostructured Aluminum Alloy with Super-High Strength. NPG Asia Mater. 2015, 7, 1–8. [Google Scholar] [CrossRef]

- Markó, D.; Prashanth, K.G.; Scudino, S.; Wang, Z.; Ellendt, N.; Uhlenwinkel, V.; Eckert, J. Al-Based Metal Matrix Composites Reinforced with Fe49.9Co35.1Nb7.7B4.5Si2.8 Glassy Powder: Mechanical Behavior under Tensile Loading. J. Alloys Compd. 2015, 615, S382–S385. [Google Scholar] [CrossRef]

- Surreddi, K.B.; Scudino, S.; Sakaliyska, M.; Prashanth, K.G.; Sordelet, D.J.; Eckert, J. Crystallization Behavior and Consolidation of Gas-Atomized Al84Gd6Ni7Co3 Glassy Powder. J. Alloys Compd. 2010, 491, 137–142. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S. Quasicrystalline Composites by Additive Manufacturing. Key Eng. Mater. 2019, 818, 72–76. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Kumar, S.; Scudino, S.; Murty, B.S.; Eckert, J. Fabrication and Response of Al70Y16Ni 10Co4 Glass Reinforced Metal Matrix Composites. Mater. Manuf. Process. 2011, 26, 1242–1247. [Google Scholar] [CrossRef]

- Xi, L.; Gu, D.; Guo, S.; Wang, R.; Ding, K.; Prashanth, K.G. Grain Refinement in Laser Manufactured Al-Based Composites with TiB2 Ceramic; Elsevier: Amsterdam, The Netherlands, 2020; Volume 9, pp. 2611–2622. [Google Scholar]

- Wang, Z.; Prashanth, K.G.; Scudino, S.; Chaubey, A.K.; Sordelet, D.J.; Zhang, W.W.; Li, Y.Y.; Eckert, J. Tensile Properties of Al Matrix Composites Reinforced with in Situ Devitrified Al84Gd6Ni7Co3 Glassy Particles. J. Alloys Compd. 2014, 586, 419–422. [Google Scholar] [CrossRef]

- Wang, Z.; Tan, J.; Scudino, S.; Sun, B.A.; Qu, R.T.; He, J.; Prashanth, K.G.; Zhang, W.W.; Li, Y.Y.; Eckert, J. Mechanical Behavior of Al-Based Matrix Composites Reinforced with Mg 58Cu28.5Gd11Ag2.5 Metallic Glasses. Adv. Powder Technol. 2014, 25, 635–639. [Google Scholar] [CrossRef]

- Wang, Z.; Prashanth, K.G.; Chaubey, A.K.; Löber, L.; Schimansky, F.P.; Pyczak, F.; Zhang, W.W.; Scudino, S.; Eckert, J. Tensile Properties of Al-12Si Matrix Composites Reinforced with Ti-Al-Based Particles. J. Alloys Compd. 2015, 630, 256–259. [Google Scholar] [CrossRef]

- Kubota, M.; Cizek, P. Synthesis of Al3BC from Mechanically Milled and Spark Plasma Sintered Al–MgB2 Composite Materials. J. Alloys Compd. 2008, 457, 209–215. [Google Scholar] [CrossRef]

- Li, D.; Hu, K.; Han, M.; Xie, K.; Liu, G.; Liu, X. Strength Adjust Mechanism of High Toughness Al4C3/Al-XMg Composites. Mater. Sci. Eng. A 2021, 824, 141842. [Google Scholar] [CrossRef]

- ASTM E10-15; Standard Test Method for Brinell Hardness of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM-E08; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Con-shohocken, PA, USA, 2022.

- Zhang, L.; Shi, G.; Xu, K.; Hao, W.; Li, Q.; Junyan, W.; Wang, Z. Phase Transformation and Mechanical Properties of B4C/Al Composites. J. Mater. Res. Technol. 2020, 9, 2116–2126. [Google Scholar] [CrossRef]

- Custodio, A.G.; Lindquist, K.J.; Tolentino, M.; Aranas, C.; Saha, G.C. Investigating the Nanoscale Hardness/Strength Properties of High-Entropy Alloy Particles Using the Nanoindentation Technique. J. Alloys Metall. Syst. 2023, 4, 100043. [Google Scholar] [CrossRef]

- Ma, X.; Cheng, B.; Zhao, K.; Yin, F.; Liu, X.; Chawla, N.; Zhao, Y. Microstructure Evolution and Mechanical Properties of High Fraction Al3BC/Al Composites Fabricated by a Reactive Hot Pressing Sintering Process. J. Alloys Compd. 2024, 1003, 175573. [Google Scholar] [CrossRef]

- Fjellstedt, J.; Jarfors, A.E.W. On the Precipitation of TiB2 in Aluminum Melts from the Reaction with KBF4 and K2TiF6. Mater. Sci. Eng. A 2005, 413–414, 527–532. [Google Scholar] [CrossRef]

- Bernacki, M. Kinetic Equations and Level-Set Approach for Simulating Solid-State Microstructure Evolutions at the Mesoscopic Scale: State of the Art, Limitations, and Prospects. Prog. Mater. Sci. 2024, 142, 101224. [Google Scholar] [CrossRef]

- Huang, K.; Marthinsen, K.; Zhao, Q.; Logé, R.E. The Double-Edge Effect of Second-Phase Particles on the Recrystallization Behaviour and Associated Mechanical Properties of Metallic Materials. Prog. Mater. Sci. 2018, 92, 284–359. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and Post-Dynamic Recrystallization under Hot, Cold and Severe Plastic Deformation Conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Gnjidić, Ž.; Božić, D.; Mitkov, M. The Influence of SiC Particles on the Compressive Properties of Metal Matrix Composites. Mater. Charact. 2001, 47, 129–138. [Google Scholar] [CrossRef]

- Sathish, S.; Venkatesh, J.; Johnson, P.; Annar, S.; Saranya, J.; Sai Chandra, J.; Subbiah, R.; Tharmalingam, S. Strain Hardening Behaviour of Friction Stir Welded Magnesium Alloy. Mater. Today Proc. 2023, 74, 34–39. [Google Scholar] [CrossRef]

- Luo, J.; Mei, Z.; Tian, W.; Wang, Z. Diminishing of Work Hardening in Electroformed Polycrystalline Copper with Nano-Sized and Uf-Sized Twins. Mater. Sci. Eng. A 2006, 441, 282–290. [Google Scholar] [CrossRef]

- SONG, M. Effects of Volume Fraction of SiC Particles on Mechanical Properties of SiC/Al Composites. Trans. Nonferrous Met. Soc. China 2009, 19, 1400–1404. [Google Scholar] [CrossRef]

- Shabani, A.; Toroghinejad, M.R.; Shafyei, A.; Logé, R.E. Evaluation of the Mechanical Properties of the Heat Treated FeCrCuMnNi High Entropy Alloy. Mater. Chem. Phys. 2019, 221, 68–77. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, J.P.; Chen, S.Y.; Xie, X.; Liaw, P.K.; Dahmen, K.A.; Qiao, J.W.; Wang, Y.L. Serration and Noise Behaviors in Materials. Prog. Mater. Sci. 2017, 90, 358–460. [Google Scholar] [CrossRef]

- Wei, S.; Moriarty, D.P.; Xu, M.; LeBeau, J.M.; Tasan, C.C. On the Plastic Deformation of a CoCrFeNiW-C Alloy at Elevated Temperatures: Part I. Serrated Plastic Flow and Its Latent Dynamics. Acta Mater. 2023, 242, 118430. [Google Scholar] [CrossRef]

- Hu, Q.; Guo, W.; Xiao, P.; Yao, J. First-Principles Investigation of Mechanical, Electronic, Dynamical, and Thermodynamic Properties of Al3BC. Phys. B Condens. Matter 2021, 616, 413127. [Google Scholar] [CrossRef]

- Yuan, Z.; Ma, Z.; Zhang, H.; Wang, K.; Yu, Y.; Li, S.; Zhang, X.; Wang, J.; Zhang, D. Macro-Micro Analysis of Mechanical Properties of Al0.6CoCrFeNi High-Entropy Alloy Particle-Reinforced Al-Based Composites. Mater. Sci. Eng. A 2023, 885, 145625. [Google Scholar] [CrossRef]

- Maity, T.; Prashanth, K.G.; Balci; Kim, J.T.; Schöberl, T.; Wang, Z.; Eckert, J. Influence of Severe Straining and Strain Rate on the Evolution of Dislocation Structures during Micro-/Nanoindentation in High Entropy Lamellar Eutectics. Int. J. Plast. 2018, 109, 121–136. [Google Scholar] [CrossRef]

- Kim, H.S. On the Rule of Mixtures for the Hardness of Particle Reinforced Composites. Mater. Sci. Eng. A 2000, 289, 30–33. [Google Scholar] [CrossRef]

- Tjong, S.C.; Ma, Z.Y. Microstructural and Mechanical Characteristics of in Situ Metal Matrix Composites. Mater. Sci. Eng. R Rep. 2000, 29, 49–113. [Google Scholar] [CrossRef]

- Chen, Y.; Ren, Y.; Li, K.; Dang, B.; Jian, Z. Laser Powder Bed Fusion of Oxidized Microscale SiC-Particle-Reinforced AlSi10Mg Matrix Composites: Microstructure, Porosity, and Mechanical Properties. Mater. Sci. Eng. A 2023, 870, 144860. [Google Scholar] [CrossRef]

- Cha, S.I.; Kim, K.T.; Arshad, S.N.; Mo, C.B.; Hong, S.H. Extraordinary Strengthening Effect of Carbon Nanotubes in Metal-Matrix Nanocomposites Processed by Molecular-Level Mixing. Adv. Mater. 2005, 17, 1377–1381. [Google Scholar] [CrossRef]

- Zhu, J.; Cai, Y.; Zhang, Y.; Liu, X.; Tian, J.; Ma, J.; Shen, J. Particle-Reinforced Cu Matrix Composites Fabricated by Sintering Core–Shell-Type Amorphous/Crystalline Composite Powders. Mater. Sci. Eng. A 2022, 854, 143823. [Google Scholar] [CrossRef]

- Martínez-Flores, E.; Negrete, J.; Villasenor, G.T. Structure and Properties of Zn–Al–Cu Alloy Reinforced with Alumina Particles. Mater. Des. 2003, 24, 281–286. [Google Scholar] [CrossRef]

- Pugh, S.F., XCII. Relations between the Elastic Moduli and the Plastic Properties of Polycrystalline Pure Metals. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1954, 45, 823–843. [Google Scholar] [CrossRef]

- Surucu, G.; Yildiz, B.; Erkisi, A.; Wang, X.; Surucu, O. The Investigation of Electronic, Anisotropic Elastic and Lattice Dynamical Properties of MAB Phase Nanolaminated Ternary Borides: M2AlB2 (M=Mn, Fe and Co) under Spin Effects. J. Alloys Compd. 2020, 838, 155436. [Google Scholar] [CrossRef]

| Phase | Vf (wt.%) | Lattice Parameter (Å) | Hardness (GPa) | Modulus (GPa) | Af (%) |

|---|---|---|---|---|---|

| Al3BC | 65 ± 2 | (a) 3.488 ± 0.003 (c) 11.535 ± 0.003 | 22 ± 7 | 326 [20] | 52 ± 4 |

| fcc-Al | 25 ± 2 | (a) 4.098 ± 0.001 | 3 ± 1 | 52 | 31 ± 2 |

| AlB2 | 10 ± 1 | (a) 2.978 ± 0.001 (c) 3.259 ± 0.001 | 2 ± 0.5 | 250 | 17 ± 3 |

| Alloy | σy (MPa) | σs (MPa) | εs (%) | H (GPa) | E (GPa) | σc | R | Ref. |

|---|---|---|---|---|---|---|---|---|

| Al3BC/Al Sintering + Hot pressing | 108 | 284 | 17 | 15 ± 5 | 212 | 1.63 | 5.6 | Present study |

| Ti/1TiB2 | 750 | 856 | 10 | - | 128 | 0.14 | - | [12] |

| Ti/4TiB2 | 576 | 689 | 27 | - | 103 | 0.20 | - | [12] |

| Al/15Mg2Si Sintering + Hot extrusion | 114 | 200 | 7 | - | 75 | 0.75 | - | [17] |

| Al/20SiC Sintering + Hot extrusion | 64.6 | 127 | 7 | - | - | 1.00 | - | [51] |

| Al/20Al2O3 SPS | - | 96 | - | - | - | - | - | [10] |

| Al/AlNp RT | 179 | 251 | - | 14 | - | 0.40 | - | [13] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maity, T.; Prakash, A.; Roy, D.; Prashanth, K.G. In Situ Al3BC/Al Composite Fabricated via Solid-Solid Reaction: An Investigation on Microstructure and Mechanical Behavior. Appl. Sci. 2025, 15, 5189. https://doi.org/10.3390/app15095189

Maity T, Prakash A, Roy D, Prashanth KG. In Situ Al3BC/Al Composite Fabricated via Solid-Solid Reaction: An Investigation on Microstructure and Mechanical Behavior. Applied Sciences. 2025; 15(9):5189. https://doi.org/10.3390/app15095189

Chicago/Turabian StyleMaity, Tapabrata, Aditya Prakash, Debdas Roy, and Konda Gokuldoss Prashanth. 2025. "In Situ Al3BC/Al Composite Fabricated via Solid-Solid Reaction: An Investigation on Microstructure and Mechanical Behavior" Applied Sciences 15, no. 9: 5189. https://doi.org/10.3390/app15095189

APA StyleMaity, T., Prakash, A., Roy, D., & Prashanth, K. G. (2025). In Situ Al3BC/Al Composite Fabricated via Solid-Solid Reaction: An Investigation on Microstructure and Mechanical Behavior. Applied Sciences, 15(9), 5189. https://doi.org/10.3390/app15095189