Abstract

The production of agricultural residues causes environmental pollution, especially in regions with intensive horticultural production. The solution is to maximise the use of residues, applying the ‘zero waste’ model and using them to develop construction materials. Natural fibres used to reinforce materials have environmental and economic benefits due to their low cost. This research presents an innovative characterisation using an inverted-plate optical microscope, a high-resolution scanning electron microscope (HRSEM) and a 3D X-ray microscope. A physico-mechanical and chemical characterisation of horticultural fibres was also conducted. The fibres analysed were those produced in the highest quantities, including those from tomatoes, peppers, zucchinis, cucumbers and aubergines. The viability of these natural fibres for use as reinforcements in biocomposites was investigated. The analysis centred on studying the microstructure, porosity, chemical composition, tensile strength, water absorption and environmental degradation of the natural fibres. The results showed a porosity ranging from 47.44% to 61.18%, which contributes to the lightness of the materials. Cucumber stems have a higher tensile strength than the other stems, with an average value of 19.83 MPa. The SEM analysis showed a similar chemical composition of the scanned fibres. Finally, the life cycle of the materials made from horticultural residue was analysed, and negative GWP (global warming potential) CO2eq values were obtained for two of the proposed materials, such as stabilised soil reinforced with agricultural fibres and insulation panels made of agricultural fibres.

1. Introduction

In recent decades, the construction of plastic and polycarbonate greenhouses has expanded. The total global area occupied by greenhouses has grown to 1.3 million hectares [1].

According to this analysis, the country with the largest area of intensive greenhouse agriculture in the world is China. In Europe, the countries with the largest areas are Spain, Italy, the Netherlands and France.

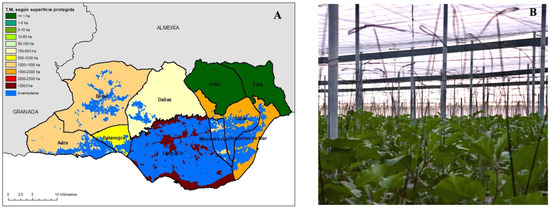

Spain is the second country in the world with the largest extension of greenhouses, and Almeria, in the Autonomous Community of Andalusia, is the region with the highest concentration of greenhouses [2]. According to the comparative study carried out by the Regional Ministry of Agriculture, Livestock, Fisheries and Sustainable Development on the cartography of greenhouses in Almeria, Granada and Malaga in 2020, Almeria concentrates most of the area with greenhouses. This province has a total of 32,554 hectares, mainly located in the regions of Campo de Dalías, Campo de Níjar and Bajo Andarax. In Granada, an estimated greenhouse area of 3381 hectares is located mainly in the region of La Costa. In Malaga, it has been estimated that a total of 777 hectares have greenhouses, concentrated mainly in the Vélez-Málaga region [2].

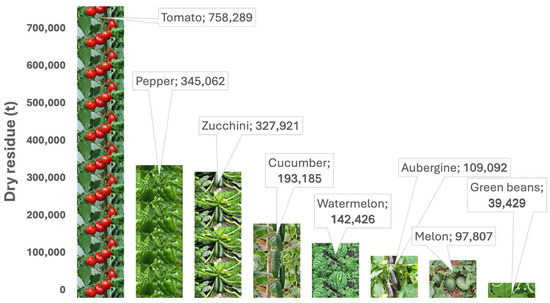

Because of this great extension of greenhouses and considering the annual crop rotation to supply consumer demand, the production of vegetable residue per year in the Almeria region is 2,013,210 tons of fresh residue that corresponds to 269,770 tons of dry residue [3]. The largest amount of vegetable residue generated are tomato, pepper, zucchini, cucumber, watermelon and aubergine plants (Figure 1). It should be noted that watermelon plant residue was discarded for this study, as it is a seasonal crop and was only available at the recycling plant in spring [4]. Furthermore, the annual production of the polypropylene residue that appears intertwined with the crop stems, in order to maintain the verticality of the plant and improve plant exposure to sunlight, is 4.813 tons [5].

Figure 1.

Tons of plant residues per crop in Almeria, Spain. Modified from López et al., 2016 [2].

Regarding the agricultural residue production, the European Directive EU 2018/851 [6] aims to move towards a circular economy, as well as to improve the traceability of the residue, preventing it from ending up in landfills or being illegally burned [7]. To comply with this regulation, several residue management companies and recycling plants have emerged in recent years in Andalusia, especially in Almeria, the region with the highest concentration of intensive agriculture in Europe [2,5,8]. Currently, agricultural residue is often burned to produce energy, used as animal feed or as a natural fertiliser [9,10]. It is worth noting that agricultural residues can also be promising feedstocks for materials development, as they come from renewable sources and are widely available [11,12].

In line with this situation and in order to make use of these residues in the field of construction, this research proposes the use of agricultural residues as reinforcement in construction materials. Thus, these residues can be by-products for the development of these materials. In this context, construction materials reinforced with plant fibres are currently of great interest due to their lower dependence on non-renewable energy resources, biodegradable behaviour and very interesting specific mechanical characteristics [13,14,15].

In addition to the advantages of the use of fibres from a sustainable development point of view, fibres bring additional benefits such as reduction in linear shrinkage and cracking. This is shown in other studies on both compacted earth walls and earth concrete materials [16,17,18,19]. However, the effectiveness of fibre reinforcement varies with soil type and the quantity of reinforcement fibres [20]. In addition, clay reinforced with natural fibres shows higher water absorption at low humidities [21]; this may be due to the high water absorption capacity of the fibres. Therefore, it is important to consider the hygrothermal properties of earth-based materials, as these are influenced by temperature, relative humidity and wind speed [22]. Furthermore, it should be noted that consolidation treatments designed to enhance the weathering resistance of earth-based building materials have been evaluated by Elert et al. (2022) [23].

In contrast, the performance of polypropylene fibre-reinforced materials has been the subject of numerous studies. These studies have analysed the improvement of the bonding between polypropylene fibres and the matrix in compromised concrete composites, primarily due to the hydrophobic nature of polypropylene. In this regard, methodologies such as surface modification of fibres with calcium nanocarbonate [24] or copolymerisation of polypropylene with non-ionic surfactants [25] have been investigated. These treatments have been shown to enhance interfacial adhesion, consequently leading to improved mechanical properties of composites [26]. Consequently, there is a necessity for innovation of polypropylene-reinforced construction materials to achieve greater strength, ductility and crack resistance.

Another potential alternative is the utilisation of fibres in the fabrication of insulation panels as building material. The consumption of virgin wood for insulation panels compromises biodiversity; the quality and quantity of forests and their protection are part of global and regional policies, for example, in the EU Biodiversity Strategy 2030 or the Sustainable Development Goals (SDGs) [11,27]. Consequently, the wood-based panel industry has shifted its focus towards exploring alternative raw material sources, including the utilisation of recycled materials and by-products. It is important to emphasise the extant research in the direction of biopolymer-based materials and to draw parallels with the present research. The research of Kuang et al. (2024) and Pei et al. (2025) [28,29], as well as other research in this field, is centred on the development of biodegradable, sustainable and high-performance materials.

Numerous studies have been conducted on the potential of agricultural residue for panel development [30,31], and no studies have been found specifically using tomato, pepper, zucchini, cucumber and aubergine fibres for the development of this building material. All of this justifies this research through the study of the physical, mechanical and chemical properties to characterise these by-products as raw materials and analyse the partial or total replacement of wood in insulating panels.

2. Materials and Methods

2.1. Materials

2.1.1. Organic Residues from Intensive Agriculture

The residue from intensive agriculture was collected in a recycling plant located in El Ejido, Almería (Spain). The province of Almería is the region in Spain with the highest concentration of greenhouses, and this economic activity is primarily concentrated in the regions of Campo de Dalías, Campo de Níjar and Bajo Andarax (Figure 2A). The residue present in large-scale recycling plants can be classified as either organic or inorganic.

Figure 2.

(A) Distribution of greenhouses (in blue) and classification of municipalities according to surface area in the region of Campo de Dalías in Almería [2]. (B) Details of greenhouse crop with polypropylene raffia placed vertically.

The organic residues selected for this study were those that generate the greatest amount of vegetable residue, such as tomato, pepper, zucchini, cucumber and aubergine [3]. Seasonal crops were discarded, such as watermelon, due to the unavailability of this residue throughout the year [4].

The average length of a horticultural fibre ranged from 916 ± 173 mm for zucchini stems to 2705 ± 432 mm for cucumber stems, both belonging to the Cucurbitaceae plant family. Conversely, the average length of the solanaceae plant family, comprising tomato, pepper and aubergine, ranged from 1804 ± 158 mm for pepper stems to 2577 ± 383 mm for tomato stems, according to samples collected at the recycling plant (Table 1). It should be noted that, in the current research, at least three samples of each type were analysed.

Table 1.

Average length of stems, lignin and polypropylene content of horticultural fibres collected from the recycling plant.

2.1.2. Inorganic Residues from the Intensive Agriculture

In this case, organic residue, due to the cultivation process, was found together with inorganic residue consisting of polypropylene fibres. This residue was stored in the recycling plants in this region due to the difficulty of recycling it [33]. It is also usually found intertwined with the stems of tomato, pepper, zucchini, cucumber and aubergine plants, making it very difficult to separate (Figure 2B). This residue appeared mixed with the stems in the proportion shown in Table 1. According to Sayadi-Gmada et al. (2019) [5], the estimated annual production of this residue in 35,000 hectares of intensive agriculture is 4813 tons.

In relation to the characteristics of polypropylene raffia, the most prevalent type used in intensive agricultural contexts is in the range of 700 to 1200 m/kg, with availability in diverse colour options. The base material is subjected to a fibrillation process which provides the raffia with high flexibility. In addition, to achieve the durability and strength required to maintain the verticality of the crops, state-of-the-art stabilisers are incorporated into the polypropylene, which guarantees its effectiveness for use in greenhouses. The best-known suppliers are Ejidofil S.L. and Reyenvas S.A., among others.

In the case of this residue, no characterisation studies were carried out. However, in the present study, it must be highlighted as inorganic material, as it appears mixed and intertwined with the stems of the plants (Figure 2B).

2.2. Methods

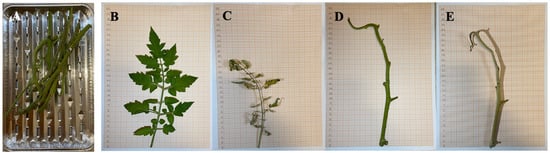

2.2.1. Moisture Content of the Agricultural Residue

The moisture content of the agricultural residues was determined by drying the samples to constant weight in a drying oven, of the forced-draught type. In the first step, leaf and stem samples were distributed on metal trays and weighed. In addition, stem diameters were measured. Afterwards, the samples were placed in the drying oven, at a temperature of 70 ± 5 °C, until constant weighing (Figure 3A). The temperature was maintained within this range to avoid any potential damage to the plant structure arising from excessive heat. Figure 3B–E show the samples after oven-drying.

Figure 3.

(A) Distribution of agricultural residue in trays, (B) tomato leaf in fresh state, (C) leaf after drying process, (D) tomato stem in fresh state, (E) stem after drying process.

The moisture content of the samples was calculated as the percentage loss in weight relative to the final weight after drying in the oven. For this purpose, Equation (1) was employed:

2.2.2. Analysis of the Water Absorption of the Fibres

In order to study the water absorption capacity of the plant fibres under study, a range of procedures were analysed from the existing literature [34,35] and the methodology described below was implemented. Initially, three samples of each fibre type consisting of 100 g of chopped fibres (with lengths of about 10 mm) were dried for 24 h at 70 °C ± 5 °C. Thereafter, the samples were immersed in water for a total duration of 60 min (Figure 4A). During this period, the samples were periodically removed from the water and several weight measurements were taken every 10 min (Figure 4B).

Figure 4.

(A) Immersion of the fibres in water, (B) extraction of the fibres, (C) removal of surface water from the fibres.

To ensure the effective removal of surface water, the fibres were extracted from the water, placed on a wet wallet and subjected to a pressure of 600 g for a duration of 30 s (Figure 4C), according to the procedure described by Cottrell et al. (2023) [35].

The percentage of water absorption (W%) of the fibres was calculated using Equation (2).

2.2.3. Analysis of Weight Loss of Agricultural By-Product Due to Environmental Degradation Effects

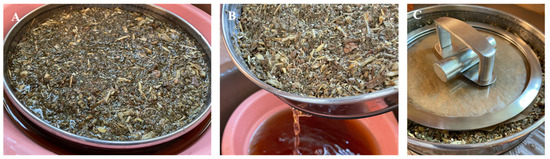

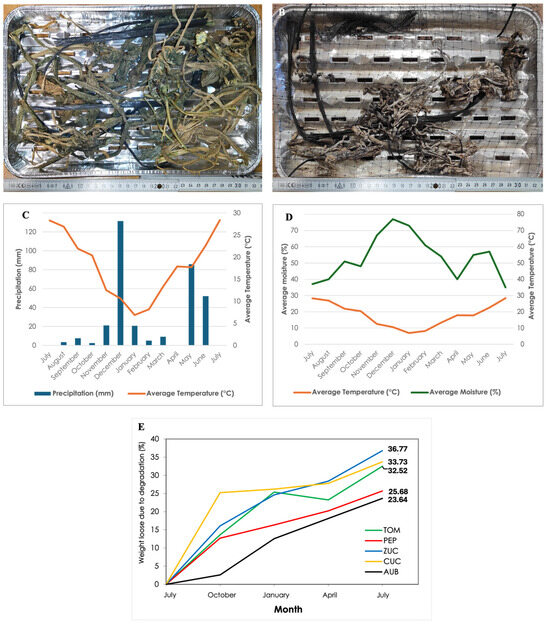

The by-products were placed in perforated metal trays (Figure 5A), and these were placed on the exterior roof, in an area free of shading elements, of the Laboratory of Architectural Constructions of the University of Granada, Spain. Consequently, dimensional changes (see Figure 5A,B), as well as weight loss due to the effects of inclement weather conditions typical of a Mediterranean climate (Csa) and a cold semi-arid climate (BsK), according to Köppen’s classification, were analysed.

Figure 5.

(A) Preparation of the samples on the perforated metal tray before testing, (B) samples after 12 months on the exterior roof, (C) average temperature (°C) and precipitations (mm) (data from the meteorological station of Granada from July 2022 to July 2023 [36]), (D) average temperature (°C) and moisture (%) (data from the meteorological station of Granada from July 2022 to July 2023 [36]), and (E) results graph showing weight loss (%) due to environmental degradation effects as a function of time.

The aforementioned factors resulted in the stems and leaves undergoing processes of expansion due to moisture absorption during the wetter seasons and shrinkage due to drying during the less rainy months. The trial spanned a period of 12 months, commencing in July 2022 and concluding in July 2023, with precipitations, average temperature and moisture data for this period obtained from the meteorological station of Granada [36], as shown in Figure 5C,D. Regarding environmental conditions, as illustrated in Figure 5C, it is noteworthy that the months with the highest rainfall were concentrated in winter and spring, and the lowest average temperature was recorded in January. The graph comparing average temperature and moisture (Figure 5D) demonstrates that, in general, the months with the highest average humidity correspond to the months with the lowest temperatures. During the trial period, weight control measurements of the samples were taken every 3 months (Figure 5E).

2.2.4. Tensile Strength of the Fibres

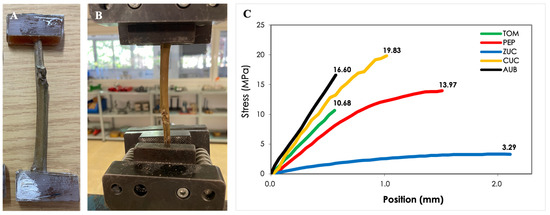

In order to execute the test, the following materials were prepared: tomato, pepper, zucchini, cucumber and aubergine stems measuring approximately 8 cm in length. Then, the ends of the stems were drilled with a 1 mm diameter drill to insert a metal reinforcement. The selected stems were then embedded in resin with the metal reinforcement to achieve a better grip of the sample with the resin (Figure 6A).

Figure 6.

(A) Sample preparation for tensile strength test. (B) Aubergine stem tensile test. (C) Representative tensile strength–strain diagram.

The tensile strength of each stem type was evaluated by performing the tensile strength test, according to the standard ASTM D 3822 [37]. Tests were carried out on a machine form company CONTROLS S.A., S-110 model with one electrical actuator having a maximum load capacity of 100 kN. The specimens were held in place with two mechanically tightened vices (Figure 6B). The loading was applied with a controlled displacement rate of 3 mm/min, and the values of the applied force were recorded by a personal computer. This computerised system also monitored the progress of the machine and displayed the recorded values in real time (Figure 6B).

2.2.5. Microstructure Analysis with the Inverted-Plate Optical Microscope

A detailed analysis of the microstructure of tomato, pepper, zucchini, cucumber and aubergine stems was conducted using a Nikon Epiphot 200 microscope (Japan) with an inverted plate and polarised light. The optical microscope was equipped with a 7 Mp digital camera connected to a computer, and the software used was Clear Vision’s Perfect Image (NIS BR 4.60x version), which enabled the transformation of the digitised image from pixels to micrometres. The lens used in this study offered a magnification of 5×.

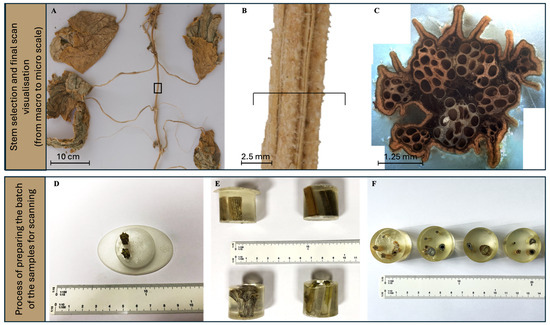

The following methodology was employed for the sample preparation: firstly, sections of the best-preserved stems were selected (see Figure 7A,B) and dried at 70 ± 5 °C for 24 h. Subsequently, the stems were affixed to the support (Figure 7D) and embedded in low-viscosity resin (Epofix Resin, Struers) utilising the epoxy vacuum machine (Struers CitoVac, 4.5 bar). As the resin hardened and the fibres were fixed and stable (Figure 7E), the samples were cut without causing any damage to the cell walls or the structure of the elementary fibres.

Figure 7.

(A) Best-preserved cucumber stem selection, (B) cutting of the selected stem sample, (C) visualisation after scanning with the inverted-plate optical microscope, (D) fixation of stems on resin embedding holder, (E) sample batch after resin embedding and resin curing, (F) sample batch after cutting/polishing process and ready for scanning with the inverted-plate optical microscope.

After the cutting process, the specimens were subjected to a series of polishing procedures. These procedures commenced with the highest grit and concluded with the lowest grit, utilising diamond discs (MD-Piano, DiaPro Allegro and MD-Dac) and an automatic polishing machine (Struers TegraPol-11). The final polishing stage was undertaken utilising a 1-micron grit of diamond of alumina (Metkon). The duration of polishing was meticulously determined for each specimen, according to the scratch marks caused by the cutting disc and to ensure a correct visualisation of the specimen under the microscope. Figure 7F shows one of the batches of specimens after polishing.

In order to complete the study of each sample, the images were joined using Adobe Photoshop 2023 software, thus obtaining a complete view of the section of the stems (Figure 7C). In addition, this software was also used to facilitate the quantification of the pores of the samples of the Solanaceae plant family, as it allows the selection of irregular areas with greater precision.

2.2.6. High-Resolution Scanning Electron Microscope (HRSEM) Analysis

A second batch of samples was prepared in accordance with the methodology outlined in the preceding section (see Figure 7D–F). Moreover, in this instance, an ultrasonic cleaning of the samples was performed. To reduce charging, the samples were subjected to a carbon coating process in the Emitech K975X carbon evaporator, as recommended by reference studies for the preparation of biological samples [38].

The observation and chemical analysis of the samples was conducted using the Zeiss Auriga Cross Beam workstation (FIB-FESEM), manufactured by ZEISS in Oberkochen, Germany, and equipped with an Oxford Instruments EDX detector.

2.2.7. Three-Dimensional X-Ray Microscope Analysis

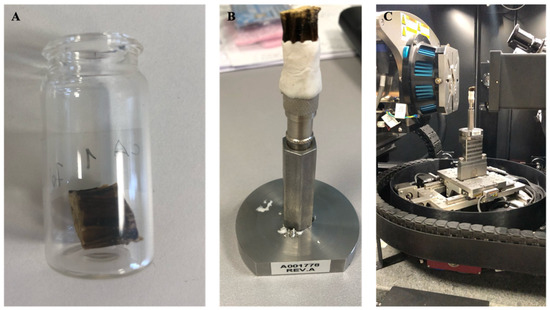

The sample preparation protocol was conducted in the designated biological sample preparation laboratory, with the objective of dehydrating the samples through a gradual increase in ethanol concentrations. The solutions employed in this process included 70% ethanol (70 mL of 100% ethanol + 30 mL of distilled water), 90% ethanol (90 mL of 100% ethanol + 10 mL of distilled water) and 100% ethanol (100 mL of 100% ethanol). The 100% ethanol solution was prepared with the addition of 1% iodine to ensure correct visualisation of the stems, in accordance with Donaldson and Frankland (2004) and Yaklich et al. (1999) [39,40]. Then, the samples were left to dry in the oven at 35 °C for 3 days, after which they were prepared for X-ray microscopy analysis (Figure 8A).

Figure 8.

(A) Stem sample after dehydration, staining and drying, (B) fixing process of the sample to the scanning stand, (C) detail of sample placement inside the 3D X-ray microscope (Xradia 510 Versa Zeiss).

The sample was then affixed in the scanning holder (Figure 8B). For the analysis, a high-resolution 3D X-ray microscope (Xradia 510 VERSA ZEISS, manufactured by ZEISS in Oberkochen, Germany) and computed tomography scanner were employed to obtain advanced non-destructive three-dimensional imaging solutions formed with high-contrast and submicron-resolution images (700 nm). This method is applicable to samples such as stems that are relatively large (Figure 8C).

This analysis enabled the detection of the chemical elements present in the complete sample by studying the different densities of each of them. This analysis was complementary to the analysis with the high-resolution scanning electron microscope (HRSEM), as in this case, the entire sample was analysed in three dimensions. Additionally, a study of the porosity of the stems was conducted to ascertain the reduction in weight of the construction materials when incorporating these additions of plant fibres.

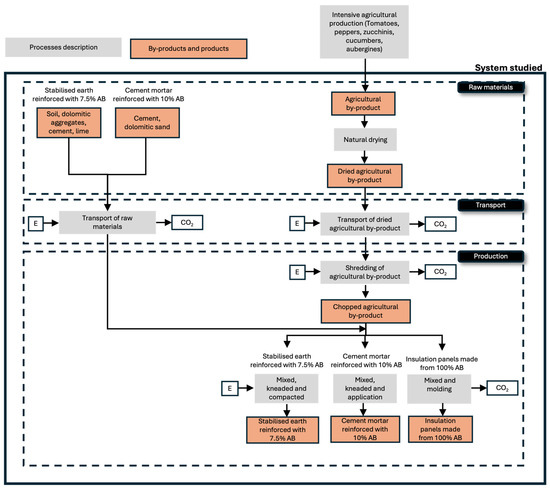

2.2.8. Life Cycle Analysis (LCA)

The objective of this LCA study was to determine and compare the environmental impact associated with the production of materials from industrial agricultural residue, according to UNE-EN ISO 14040:2006 [41] and UNE-EN ISO 14044:2006/A2:2021 [42], as specified in Figure 9. In relation to the processes encompassed in this study, the life cycle of the plant and the use cycle of polypropylene in intensive agriculture were excluded, i.e., the intensive agricultural production of crops was excluded (Figure 9). The present study focused on the following materials:

Figure 9.

Description of the production process of the materials and system applied for the calculation of the LCA.

- Stabilised earth reinforced with 7.5% agricultural by-product.

- Cement mortar reinforced with 10.0% agricultural by-product.

- 100% agricultural by-product semi-rigid insulating panel.

The dosages of the materials are described in Table 2.

In accordance with the Environmental Product Declaration (EPD) for construction materials (CEN 2021) and the LCA of the ISO 2021 standard, the following impact category were considered: climate change-PCA, including biogenic carbon (kg CO2 eq.). In accordance with the classification included in the UNE-EN ISO 14040:2006 and UNE-EN ISO 14044:2006/A2:202 standards, the present study focuses on the product manufacturing process, which includes the stages of extraction of raw materials (A1), transport to the factory (A2) and manufacturing (A3). The calculation of the carbon footprint was conducted by employing the calculation method of the GHG Protocol to determine fossil CO2, biogenic CO2 and CO2 absorption. Embodied energy, EE (MJ), was defined as the sum of all the energy required to produce any good or service, considered as if that energy were incorporated in the product itself. To conduct this analysis, Cype 2024 software (Version 2024.e) was employed in conjunction with other studies [43,44,45,46,47,48,49,50] that calculated the LCA of similar materials reinforced with natural fibres or materials developed from fibres, according to the references specified in Table 2. The ‘Life Cycle Analysis’ module is a Cype 2024 tool that calculates the environmental impact caused by the construction of a building project, in which the impact of specific materials can also be calculated. This software can assess the variation in environmental impact resulting from any modification to the project’s construction units and, therefore, objectively decide on the changes that can be made to minimise this impact. The programme offers nine environmental indicators to carry out this assessment; the one selected in this study is the GWP. Therefore, the software offers stages between A1 and C4, which are included in the UNE-EN ISO 14040-14044 standard.

Table 2.

Dosage table of the analysed construction materials and reference studies.

Table 2.

Dosage table of the analysed construction materials and reference studies.

| Material | Agricultural Residue Proportion (%) | Mass Soil or Cement (kg) | References |

|---|---|---|---|

| Stabilised earth reinforced with 7.5% agricultural by-product (AB) | 7.5% 1 | 2500 | [43,44,47,48,49,50] |

| Cement mortar reinforced with 10.0% AB | 10.0% 2 | 0.45 | [43,45,49] |

| 100% AB semi-rigid insulating panel | 100% | - | [43,46,49] |

1 by the weight of the soil. 2 by the weight of the cement.

3. Results

3.1. Moisture Content of the Agricultural Residue

Following the collection of fresh samples of organic residues from intensive agriculture, the moisture content of the stems and leaves of the selected crops was calculated: tomato, pepper, zucchini, cucumber and aubergine. The highest moisture content was observed in the plant family Cucurbitaceae, with an average moisture content of stems and leaves of 90.43 ± 3.05% for zucchini and 89.02 ± 2.00% for cucumber. Conversely, the Solanaceae plant family, comprising tomato, pepper and aubergine, exhibited a reduced mean stem and leaf moisture content, as detailed in Table 3. Similar values can be found in other studies such as Crawford Jr et al. (2018) and Ramirez et al. (1988) [51,52].

Table 3.

Average moisture content of fresh leaves/stems from horticultural residue and drying time to constant weight.

The highest average moisture content was found in the leaves of all the organic residues studied, with the exception of pepper. Pepper stems were the only ones with a higher percentage of moisture than the leaves. This is attributable to the internal microstructure of the stem, which is more closed with minimal porosity, thereby restricting the entry of drying air. It is also noteworthy that these stems exhibited minimal deformation or curling during the drying process, despite water loss.

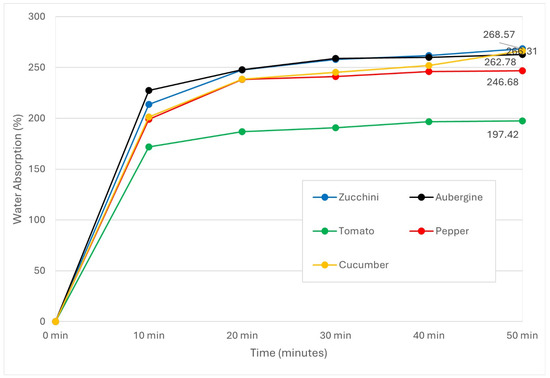

3.2. Analysis of the Water Absorption of the Fibres

As illustrated in Figure 10, the samples exhibited a rapid absorption phase during the initial 20–30 min of soaking. This behaviour is comparable and consistent with other research on natural fibres [53]. The saturation point was generally reached between 40 and 50 min of soaking, except for cucumber fibres, which demonstrated an ongoing increase in absorption. The average water absorption values after 50 min of soaking demonstrated that the fibres belonging to the Cucurbitaceae plant family exhibited the highest absorption capacity, with zucchini and cucumber reaching mean values of 268.57 ± 2.03% and 266.31 ± 1.88%, respectively (Figure 10 and Table 4). Conversely, the fibres with the lowest mean absorption values were tomato and pepper. The percentage of water absorbed is similar to that of other natural fibres, such as banana, sisal, bagasse and jute fibres [35,54,55].

Figure 10.

Water absorption (%) of fibres by immersion.

Table 4.

Details of stem diameters after drying process.

The findings of this study are consistent with those reported in Section 3.1, as the fibres with the highest water content demonstrated the greatest absorption capacity after undergoing the drying process. This behaviour is a critical factor in determining the most suitable fibre type, given the moisture conditions to which the building materials intended for development are exposed. The absorption capacity of each type of fibre defined its expansion and contraction behaviour in the presence of moisture.

3.3. Analysis of Weight Loss of Agricultural By-Product Due to Environmental Degradation Effects

The weight loss due to environmental degradation effects demonstrated the potential for utilisation of fibre-reinforced materials in outdoor applications. The weight loss percentage over a 12-month period is illustrated in Figure 5E. The results indicated that the fibres can be categorised into the group of Cucurbitaceae plants, which included zucchini and cucumber, and demonstrated higher degradation levels, reaching values of 36.77 ± 0.04% and 33.73 ± 0.05%, respectively. Conversely, the group of Solanaceae plants exhibited degradation levels below 32.52 ± 0.04%. Within this group, the highest degradation was observed in the tomato plant, reaching 32.52 ± 0.04%. Pepper and aubergine plants showed the least degradation, with values of 25.68 ± 0.03% and 23.64 ± 0.02%, respectively (Figure 5E).

In the visual analysis, the Cucurbitaceae plants exhibited significant stem shrinkage and leaf crinkling, particularly evident in the zucchini plants (Figure 5A,B). In contrast, the aubergine and pepper plants demonstrated minimal stem shortening or shrinkage. In general, all the plants exhibited a gradual loss of the most superficial layer of the epidermis of the stems over the months, which was especially due to the shrinkage effects of fibres undergoing moisture absorption and loss periods [56].

Furthermore, a comparison of Figure 5E with Figure 5C,D reveals that during the initial months of the test, there was significant degradation in practically all fibres, with the exception of the aubergine fibres. It is also noteworthy that, during months with minimal rainfall and reduced ambient moisture, degradation by weight experiences a period of stagnation. This phenomenon is especially evident during the period spanning from February to April.

3.4. Tensile Behaviour of Fibres

This section presents the results of the behaviour and tensile strength of the stems (Figure 6C). Through analysis of these results, it was possible to divide the stems into two distinct groups: medium yielding fibres and low yielding fibres. Tomato, pepper, cucumber and aubergine stems demonstrated an average tensile strength above 10 MPa, while zucchini stems exhibited an average tensile strength of 3.29 MPa. Conversely, cucumber stems exhibited the highest tensile strength, reaching 19.83 MPa. These values could be compared with other reference studies (Table 5) in which oil palm, tomato and Alfa fibres reached values in this range [57,58,59,60]. It is also noteworthy that the tensile strength achieved in this study, as shown in Table 5, was significantly lower than that of high-performance fibres produced for specific industrial applications, such as jute and flax [58,61,62]. It is also important to note that these high-performance fibres do not support the circular economy, in contrast to fibres derived from by-products of intensive agriculture. A range of variables that may impact the mechanical properties of fibres was analysed by other researchers. These include chemical composition, structural characteristics, growing conditions, extraction methods, harvesting timing and storage procedures [63]. In this regard, the studies from Bos et al. (2002) [64] demonstrated a decline in strength within five days post-optimal harvest.

Table 5.

Details of tensile strength results compared with high-performance fibres.

It is important to highlight the linear tendency exhibited in the tensile strength–displacement graph (Figure 6C). As illustrated in Figure 6C, in the case of aubergine and tomato stems, the maximum resistance was reached quickly and with minimal displacement, which is less than 0.60 mm. In contrast, the behaviour exhibited by pepper and zucchini stems was more ductile, with maximum resistance being attained at displacements ranging from 1.41 mm to 2.11 mm, respectively. The displacement of cucumber was situated at an intermediate value of 1.02 mm when reaching its maximum value of tensile strength. A notable observation was the less linear behaviour exhibited by the cucumber stem graph, characterised by less continuous increases in tension and minor fluctuations.

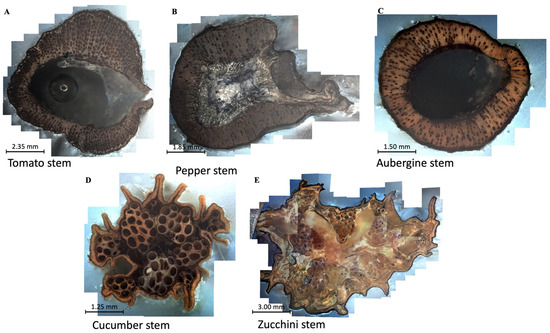

3.5. Microstructure Analysis with the Inverted-Plate Optical Microscope

In the analysis undertaken with the inverted-plate optical microscope, the diameter of tomato, pepper, zucchini, cucumber and aubergine stems was accurately determined (see Table 6). In addition, the depth of the folds formed in the collenchyma/cortex (the exterior layer of the stems) due to moisture loss was also determined. Furthermore, the porosity of the stems belonging to the Solanaceae plant family, which were characterised by a differentiated pith and porosity that was discernible under microscopic examination, was the subject of study in order to establish a range of the lightening of the building material that has been added with these fibres.

Table 6.

Details of stem diameters after drying process.

As shown in Figure 11A–E and Table 6, a comparison of the cross-sections of the tomato, pepper, zucchini, cucumber and aubergine provides insights into the geometry and size of the stems under investigation. The mean diameter of the stems of Solanaceae plants following the drying process ranged from 3273 ± 1114 μm to 6155 ± 1255 μm. The zucchini stem demonstrated the greatest mean diameter, measuring 17,287 ± 7403 μm. The substantial variation in stem thickness between the root zone, characterised by the largest diameter, and the upper zones, exhibiting the smallest diameter, was evident. The average diameter of the cucumber stem was the smallest, with a value of 2065 ± 387 μm. The deviations in this stem typology were smaller than the deviations in the other stems analysed due to the presence of similar thicknesses in the stems of the upper and lower zones of the plant (see Table 4).

Figure 11.

(A) Image of tomato stem, (B) pepper stem, (C) aubergine stem, (D) cucumber stem, (E) zucchini stem obtained by scanning with the inverted-plate optical microscope.

As demonstrated in Table 6, it is noteworthy that the cucumber stem experienced the most significant shrinkage or variation in diameter due to moisture loss, reaching a value of 63.71%. In contrast, the tomato exhibited the least pronounced change in diameter due to moisture loss, with a value of 16.66%. It is important to consider this aspect when utilising these fibres as additives in materials that are exposed to moisture, as it can affect the bond between the matrix and the fibre.

A comparison of Table 3 and Table 6 reveals a correlation between the fresh/dry stem diameter and the percentage moisture content for each stem type within the Solanaceae plant family. However, this correlation was not observed in the Cucurbitaceae plant family. This discrepancy may be attributed to the fact that, while the zucchini stem exhibited a higher percentage of moisture, its stem shrinkage when losing water was less significant than that of the cucumber. This enabled the zucchini stem to maintain its internal structure to a greater extent.

On the other hand, the stem morphology of members of the Solanaceae plant family, including those of pepper, aubergine and tomato, exhibited analogous structures accompanied by a discernible central medullary cavity (see Figure 11A–C). In these instances, there was an absence of notable folds in the cortex, attributable to the stem’s contraction resulting from water loss. Conversely, the analysis of the Cucurbitaceae plant family revealed that the zucchini stem image displayed slight folds in the cortex due to water loss, though less pronounced than those observed in the cucumber stem (Figure 11D,E).

Figure 11A–C illustrate that the microstructure of the Solanaceae plant family stems consists primarily of epidermis, cortex, vascular bundle and medullary cavity or pith.

As demonstrated in the relevant literature [60], the fracture resistance capacity of a stem is contingent on the thickness of its cortex and the extent and development of its vascular bundle. It can thus be concluded that, in determining the fracture resistance of a stem, the primary factors are the epidermis, cortex and vascular bundle, with the function of the pith being to connect and transfer the load.

The microstructure of tomato, pepper and aubergine stems belonging to the Solanaceae plant family was similar, but the thickness of the cortex, as well as the surface and distribution of the vascular bundle varied in each stem typology (see Figure 11A–C). Of particular note was the regular distribution of the vascular bundle across the entire diameter of the aubergine stem, with a cortex thickness ranging from 64.7 μm to 112.3 μm (Figure 11C). This characteristic contributed to the aubergine stem’s distinction as the Solanaceae plant family member with the highest tensile strength (Figure 6C). In contrast, the vascular bundle distribution in pepper was characterised by irregularity (Figure 11B), while in tomato, the cortex exhibited localised discontinuities and an irregular distribution of the vascular bundle. The observed discontinuities in the cortex were attributed to the shrinkage of the stem during the drying process in the oven (Figure 11B).

Regarding the microstructure of cucumber and zucchini stems, which belong to the Cucurbitaceae plant family, there were more differences than those present in the previous plant family. In this case, the structures that appear were similar, but the distribution of these structures, the morphology and the diameter of the stem varied significantly between cucumber and zucchini (Figure 11D,E). It is noteworthy that the distribution of the vascular bundle of the cucumber stem occupied practically the entire stem section, and that the cortex thickness ranged from 60.6 μm to 140.6 μm (Figure 11D). By contrast, the zucchini stem had a central zone with an irregular pith and a discontinuous distribution of the vascular bundle. This resulted in weaker punctate areas near the cortex or stem edge, as they were not reinforced by a nearby vascular bundle, affecting the tensile strength (Figure 11E).

It is also important to note the correlation between stem diameter and tensile strength, whereby an increase in stem diameter is associated with a decrease in tensile strength. The correlation is also consistent with the research of Mohd Zuhri et al. (2009) [59]. This phenomenon occurs because, upon the application of force, the initial concentration of force is localised to a specific area of the stem, thereby weakening that particular area and consequently affecting the overall tensile strength. Consequently, the stem structure functions not as a unit but rather as a series of distinct components, with the area receiving first tensile force being the primary site of impact. Additionally, it is important to acknowledge that oven-dried stems exhibited increased fragility and reduced flexibility compared to wet stems. This means that they were less able to undergo a wide range of adjustments or adaptive movements when tensile force was applied.

Finally, the porosity of the stem of the Solanaceae plant family was analysed. This analysis was made possible by the technique employed, given the highly differentiated medullary cavity or pith of the stems, as well as their regular, concentric structure with a certain symmetry. Following the analysis of the three typologies, it was determined that the range of porosity of the stems of this family of plants is between 47.44% and 60.36%. Specifically, the stems of pepper and aubergine exhibited the lowest percentages, with values of 47.44% and 48.85%, respectively, while the tomato stem demonstrated an average porosity of 60.36%. This finding aligns with the observations shown in Figure 11A, which show that the porosity present in the woody part of the tomato stem is higher compared to that observed in the other typologies within the same plant family.

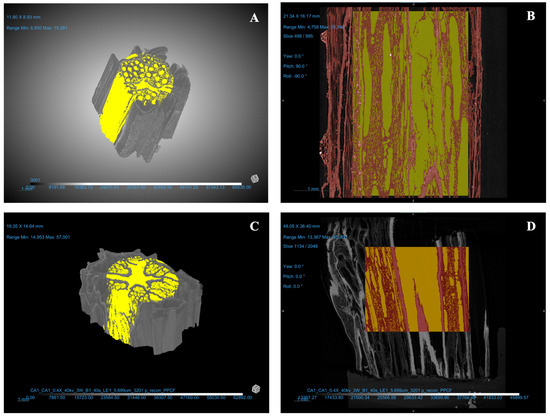

3.6. Analysis of Stems of the Plant Family Cucurbitacea with the 3D X-Ray Microscope

In order to study the porosity of the fibres and to analyse the lightening of the construction material to which the reinforcing fibres will be added, the stems of the Cucurbitaceae plant family, i.e., cucumber and zucchini stems, were scanned using a 3D X-ray microscope, manufactured by ZEISS in Oberkochen, Germany. It should be noted that this family had a poorly differentiated pith and a more complex internal structure than the Solanacea plant family. Consequently, the employment of this technique was imperative to ensure the attainment of consistent results, thereby facilitating the accurate measurement of the real porosity of the stems.

As illustrated in Figure 12A,C, the area of cucumber and zucchini stems was examined with Dragonfly Software version 2022. In this instance, the pore volume was analysed within a cylindrical volume, as the cylinder is the fundamental shape that most closely resembles the shape of a plant stem and is compatible with the analysis of the software used. In both cases, Figure 12B,D, the sample was scanned along its entire length. It should be noted that in the case of the zucchini stem, Figure 12D, this stem was inclined and less regular in shape than the cucumber stem, resulting in a shorter length that could be reliably studied.

Figure 12.

(A) Three-dimensional visualisation of cucumber stem with pore analysis area, (B) lateral visualisation of cucumber stem, (C) three-dimensional visualisation of zucchini stem with pore analysis area, and (D) lateral visualisation of zucchini stem.

Following a thorough analysis of both stems, it was ascertained that the proportion of connected and non-connected pores was equivalent. Consequently, the pores present in the samples were interconnected and exhibited a porosity of 61.18% in the cucumber sample and 55.89% in the zucchini sample.

3.7. Comparison Between High-Resolution Scanning Electron Microscope (HRSEM) and 3D X-Ray Microscope Analysis

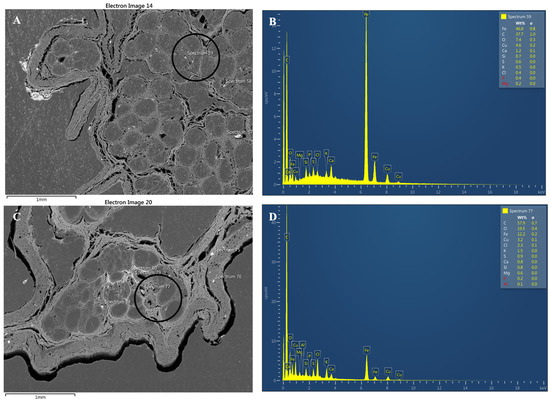

The HRSEM images (Figure 13A–D) provided a clear understanding of the chemical elements present in the study samples through the point analysis of the sample crystallisations. The crystallisations of the sample had a higher density than the plant structures and the epoxy resin and were therefore clearly differentiated from the other structures. These crystallisations had a whitish colour. In the samples of Figure 13A,C, the chemical elements present in the selected crystallisation were clearly observable (indicated by the circle).

Figure 13.

(A) Analysis from specific cucumber stem region with the HSEM. (B) Chemical elements found in the sample. (C) Analysis from a second specific cucumber stem region with the HSEM. (D) Chemical elements found in the sample.

In the scanning procedure, firstly, the sample was scanned to detect the distribution and location of the whitish crystallisations. Then, these were analysed in different locations, always avoiding those presented in the outer part of the cortex. The reason for this was that impurities external to the sample (such as dust or dirt) could be located in this area and were not relevant for this study.

The ensuing images present the analysis of Spectrum 59 (Figure 13A) and Spectrum 77 (Figure 13C). The chemical elements detected in the analysis area were Fe, Cu and Ca for Spectrum 59 (Figure 13B); the elements detected for Spectrum 77 were Fe, Cu and Cl (Figure 13D). These chemical elements are prevalent in fertilisers employed in intensive agriculture to enhance crop yield and fruit and vegetable production. Conversely, chemical elements such as carbon (C) and oxygen (O) were often disregarded, as these elements are the most abundant in the chemical composition of plant structure.

3.8. Life Cycle Analysis (LCA) and Production Potential of the Construction Materials Reinforced with Agricultural By-Product

Annually, 2,013,210 tons of organic residue and 4813 tons of polypropylene are produced from intensive agriculture [3,5]. Fibres from these residues can be used for the production of construction materials, specifically as reinforcement fibres in stabilised earth walls and masonry mortars, as well as for the development of thermal insulation.

The utilisation of these by-products on a localised scale, particularly within regions characterised by a high density of greenhouses, has the potential to mitigate the environmental impact of the supply chain and transportation processes. From an ecological and economic perspective, the reduction in transport distances can lead to significant cost savings in production. Additionally, the environmental benefits encompass a reduction in pollution and CO2 emissions. It is important to consider the design of the materials taking into account all the aspects needed to reach the development of more sustainable products [69].

In terms of the processes considered in this study for obtaining agricultural by-products and calculating their global warming potential (GWP), the life cycle of the plant or the use cycle of polypropylene in intensive agriculture was discarded, as shown in Figure 9. This means that this study focuses on the stage from which plant residues and polypropylene are considered as residue and become by-products for the development of building materials.

Therefore, drying (ideally with sunlight), storage, transport and chopping phases were considered, with a low impact on energy consumption and greenhouse gas (GHG) emissions. Regarding the use of organic and inorganic fibres from intensive agriculture for construction applications, the aim was to minimise the processing of the by-product as much as possible, as well as the energy input in the necessary processes.

Moreover, from an economic perspective, the results and applications presented in this study have the potential to provide valuable insights that could lead to an increased direct utilisation of these by-products, which have been regarded as residue until now. This development is particularly beneficial for farmers, institutions and regions where intensive agriculture is prevalent.

As demonstrated in Table 7, the production of materials from intensive agricultural residue was evaluated on the basis of analysed data. Based on the utilisation of these materials, i.e., the already specified amount of 2,013,210 t/year of organic residue and 4813 t/year of polypropylene residue [3,5], it is estimated that 1,067,737,037 m2 of 40 mm-thick semi-rigid insulation panel could be produced. In terms of earth materials reinforced with agricultural by-product, 17,725,279 m3 of stabilised earth wall could be produced, equivalent to approximately 50,643,654 m2 of 35 cm-thick wall. Finally, 1,148,030,862 m2 of cement mortar reinforced with agricultural by-product could be produced with a thickness of 10 mm.

Table 7.

Details of the production of building materials from agricultural by-product.

With regard to the calculation of the global warming potential (GWP), the lowest value was observed in the stabilised soil reinforced with agricultural by-product, which reached a value of −67.036 kg/m3. In contrast, the highest value was recorded for cement mortar reinforced with agricultural by-product, with a value of 3.826 kg/m2 (see Table 7). Although these values are not directly comparable, as these are materials with different uses and specifications, it can be stated that the higher the use of cement, the higher the value of GWP due to the impact of cement in the manufacturing phase of the product. These values are consistent with reference studies [43,44,45,46,49].

The present research was concerned with the characterisation of fibres employed for the purpose of reinforcing biocomposites. However, a direct relationship has been observed between the results of fibre characterisation and the physico-mechanical properties obtained from earth biocomposites reinforced with fibres from intensive agriculture [16]. Consequently, in order to facilitate the effective development and research of these materials, it is imperative to consider the conditioning factors presented in this study. These include the absorption capacity of the fibres, tensile strength, the behaviour of the fibres exposed to environmental conditions and the porosity of the fibres.

With regard to the biocomposite of compacted earth reinforced with agricultural by-product (AB), the test specimens were prepared in accordance with standard UNE 103500: 1994 [70] as described in previous research [16]. After performing the unconfined compression test, in accordance with standard UNE-EN ISO 17892–7:2019 [71], it was found that the reinforcement of cucumber and polypropylene fibres at a ratio of 7.5% of the weight of the earth achieved a compressive strength of 1.82 MPa. This value was only 4% lower than the value of the samples without fibre reinforcement. In addition, this research examined the degradation of earth biocomposites due to environmental effects, observing contraction and expansion movements of the fibres due to humidity fluctuations and periods of rain. A very high increase in porosity was also observed compared to the sample without fibre reinforcement [16].

In relation to cement mortar reinforced with 10.0% agricultural by-product, it is proposed that this material be tested in the laboratory by preparing mortar test tubes reinforced with agricultural by-product (AB), in accordance with standard UNE-EN 1015-2:1999 [72]. Following the hardening of the mortar, the samples can be subjected to testing to calculate their flexural and compressive strengths. This testing should be conducted in accordance with the specifications outlined in the standard UNE-EN 1015-11:2020 [73].

Regarding the 100% semi-rigid insulating panel composed of agricultural by-products, it is recommended that this material undergo testing in a laboratory setting. This testing should involve the formation of plates containing AB fibres, followed by the application of pressure and temperature. Subsequent to the formation of the plates, they will undergo testing to calculate their resistance to bending and compression, in accordance with the specifications of standard UNE-EN 310, 1994 [74].

In the process of planning the methodology for laboratory testing of each proposed material, it is necessary to analyse all variables and take into account the current characterisation of the fibres. It is imperative to consider the varying degrees of humidity, in addition to meticulously planning the percentages of fibre addition, as this has a significant impact on the lightening of the material.

In this context and given the significant residue generation associated with intensive agriculture, this research proposes the utilisation of high doses of by-products from intensive agriculture as a reinforcement for the proposed construction materials, provided that the necessary physical and technical specifications are achieved. The use of high doses of by-products from intensive agriculture is important for the revalorisation of the residue, thereby promoting the circular economy.

4. Conclusions

In this research, the analysis and discussion were carried out with real reference data relating to the hypothetical production of a semi-rigid insulation building panel based on agricultural by-products, stabilised soil reinforced with fibres from agricultural by-product, as well as cement mortar reinforced also with agricultural fibres from intensive agriculture.

To this end, the present study constitutes an innovative examination of the physical–mechanical properties of the agricultural by-product under consideration, with a particular emphasis on a detailed analysis of the microstructure of the fibres utilised. This analysis was conducted employing the inverted-plate optical microscope, and the porosity of the fibres was also studied for the purpose of calculating the lightening of the fibre-added construction materials. This was achieved by means of the 3D X-ray microscope. In addition, the use of the high-resolution scanning electron microscope (HRSEM) allowed the detection of crystallisations in the samples and the study of the chemical elements present in the agricultural by-product.

The results of this experimental study led to the following conclusions:

- The agricultural by-product studied exhibited a high water absorption range, between 197.42 ± 1.57% and 268.57 ± 2.03%. On average, residues from the Cucurbitaceae plant family, such as cucumber and zucchini, had a 13.5% higher absorption capacity than the Solanaceae plant family.

- Cucumber fibres were found to demonstrate a maximum tensile strength of 19.83 MPa. This by-product had smaller diameter stems than the other typologies, which facilitated a better distribution of the applied tensile force across the section (i.e., its microstructure) and length of the stem. This resulted in the stem functioning as a whole and not weakening in specific areas, which would otherwise have affected its mechanical performance.

- The porosity of the fibres under consideration ranged from 47.44% to 60.36% within the Solanaceae plant family and from 55.89% to 61.18% within the Cucurbitaceae plant family. Porosity is a determining factor in the calculation of the lightening of the construction materials developed with the use of these fibres.

- The analysis of crystallisations in the plant structures of the agricultural by-products studied by HRSEM scanning revealed the presence of chemical elements. These elements were attributed to the fertilisers employed in intensive agriculture, as well as to the nutrients presented in the soil in which the plants were cultivated. It is important to consider their presence in order to specify the optimal use of the building materials to be developed.

- The use of agricultural by-products as a reinforcement material for stabilised soil and for use as a semi-rigid panel offered significant ecological benefits, attaining negative GWP values of −67.036 kg/m3 CO2 equivalent and −1.104 kg/m2 CO2 equivalent, respectively. Cement mortar reinforced with the agriculture by-product achieved a GWP value of 3.862 kg/m2 CO2 equivalent.

- The comprehensive characterisation of agricultural fibres presented in the current manuscript has a direct impact on the development of materials from these by-products. In consideration of this aforementioned characterisation, a specific plan for the development of materials from agricultural fibres can be formulated. A consistent planning includes the following aspects:

- The implementation of various pre-soaking techniques on fibres must be considered, given their high water absorption capacity. This can potentially impact the workability of the mixture and the mechanical properties of the developed material.

- An analysis of fibre-reinforced material cracking and its ductile behaviour is also necessary.

- A microstructure analysis of fibre-reinforced materials exposed to weathering or high moisture and temperature oscillations is required. This phenomenon has the capacity to compromise the fibre-matrix bond, a consequence of the contraction and expansion movements of the fibres.

- The study of the lightening and porosity of the materials as a consequence of the addition of fibres is also required.

Ultimately, the valorisation of agricultural by-products from intensive agriculture has the potential to meet the demand of the Spanish construction sector. These by-products can be used as an additive to building materials (e.g., soils or mortars) or as a main component of insulation. In view of the fact that the fibres utilised for natural insulation products can currently be sourced predominantly from the wood industry in Sweden, Finland, France, Germany, among other countries [75,76], this analysis underscores the significance of leveraging national, and even local, materials to assist in reducing the environmental impact through the optimisation of the logistics and supply phases. However, it is important to note that non-recycled and inorganic materials, such as glass fibres and polypropylene [77,78,79], which are manufactured specifically for this purpose, are currently being used to reinforce mortars and soils. This results in a higher environmental impact at the product manufacturing stage.

The present study provides a foundation for future research in the field of analysing the physical–mechanical properties of materials reinforced with fibres from intensive agriculture or developed from these agricultural by-products.

Author Contributions

A.C.-M.: Conceptualisation, methodology, validation, formal analysis, investigation, writing—original draft; I.V.-P.: Methodology, formal analysis, investigation, writing—review and editing, supervision; A.P.-R.: Methodology, formal analysis. R.F.-G.: Methodology, formal analysis. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available on request.

Acknowledgments

The authors would like to thank the Department of Building Construction of the University of Granada (Spain), the TEP942 Research Group of the Andalusian Research Plan, funded by the Andalusian Government in Spain and the company Ejido Medio Ambiente S.A. for providing the samples used for this research.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the research reported in this paper.

Abbreviations

GWP: global warming potential; TOM: tomato; PEP: pepper; ZUC: zucchini; CUC: cucumber; AUB: aubergine; AB: agricultural by-product.

References

- Tong, X.; Zhang, X.; Fensholt, R.; Jensen, P.; Li, S.; Larsen, M.; Reiner, F.; Tian, F.; Brandt, M. Global Area Boom for Greenhouse Cultivation Revealed by Satellite Mapping. Nat. Food 2024, 5, 513–523. [Google Scholar] [CrossRef] [PubMed]

- López, J.C.; Pérez, C.; Acien, F.G. Vegetable Waste from the Greenhouses of Almeria (Original Article in Spanish: Residuos Vegetales Procedentes de Los Invernaderos de Almería). 2016. Available online: https://www.cajamar.es/storage/documents/017-restos-vegetales-1466406472-2d5fa.pdf (accessed on 29 April 2025).

- Junta de Andalucía Mapping of Greenhouses in Almería, Granada and Málaga (Original Document in Spanish: Cartografía de Invernaderos En Almería, Granada y Málaga). Consejería de Agricultura, Ganadería, Pesca y Desarrollo Sostenible, Junta de Andalucía. 2020. Available online: https://www.juntadeandalucia.es/export/drupaljda/producto_estadistica/19/06/Cartografia%20_inv_AL_GR_MA_v201127.pdf (accessed on 29 April 2025).

- Céspedes, A.J.; García, M.C.; Pérez, J.J.; Cuadrado, I.M. Characterisation of the Protected Horticultural Exploitation of Almeria (Article Original in Spanish: Caracterización de La Explotación Hortícola Protegida de Almería). 2009. Available online: https://www.juntadeandalucia.es/export/drupaljda/noticias/16/07/160708_El%20Sistema%20de%20Producci%C3%B3n%20Hort%C3%ADcola%20de%20la%20Provincia%20de%20Almer%C3%ADa.pdf (accessed on 29 April 2025).

- Sayadi-Gmada, S.; Rodríguez-Pleguezuelo, C.R.; Rojas-Serrano, F.; Parra-López, C.; Parra-Gómez, S.; García-García, M.d.C.; García-Collado, R.; Lorbach-Kelle, M.B.; Manrique-Gordillo, T. Inorganic Waste Management in Greenhouse Agriculture in Almeria (SE Spain): Towards a Circular System in Intensive Horticultural Production. Sustainability 2019, 11, 3782. [Google Scholar] [CrossRef]

- Directive EU 2018/851 European Parliament Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Residue (Text with EEA Relevance). 2018, Volume 150. Available online: http://data.europa.eu/eli/dir/2018/851/oj/eng (accessed on 29 April 2025).

- Cassou, E. Field Burning. Agricultural Pollution. World Bank: Washington, DC, USA, 2018. Available online: https://documents1.worldbank.org/curated/en/989351521207797690/pdf/124342-repl-WB-Knowledge-Burning.pdf (accessed on 29 April 2025).

- Chang, J.; Wu, X.; Wang, Y.; Meyerson, L.A.; Gu, B.; Min, Y.; Xue, H.; Peng, C.; Ge, Y. Does Growing Vegetables in Plastic Greenhouses Enhance Regional Ecosystem Services beyond the Food Supply? Front. Ecol. Environ. 2013, 11, 43–49. [Google Scholar] [CrossRef]

- Sadh, P.K.; Duhan, S.; Duhan, J.S. Agro-Industrial Wastes and Their Utilization Using Solid State Fermentation: A Review. Bioresour. Bioprocess. 2018, 5, 1. [Google Scholar] [CrossRef]

- Sapwarobol, S.; Saphyakhajorn, W.; Astina, J. Biological Functions and Activities of Rice Bran as a Functional Ingredient: A Review. Nutr. Metab. Insights 2021, 14, 11786388211058559. [Google Scholar] [CrossRef]

- Neitzel, N.; Hosseinpourpia, R.; Walther, T.; Adamopoulos, S. Alternative Materials from Agro-Industry for Wood Panel Manufacturing—A Review. Materials 2022, 15, 4542. [Google Scholar] [CrossRef]

- Pędzik, M.; Janiszewska, D.; Rogoziński, T. Alternative Lignocellulosic Raw Materials in Particleboard Production: A Review. Ind. Crops Prod. 2021, 174, 114162. [Google Scholar] [CrossRef]

- Guimaraes, J.L.; Frollini, E.; Da Silva, C.G.; Wypych, F.; Satyanarayana, K.G. Characterization of Banana, Sugarcane Bagasse and Sponge Gourd Fibers of Brazil. Ind. Crops Prod. 2009, 30, 407–415. [Google Scholar] [CrossRef]

- Hamza, S.; Saad, H.; Charrier, B.; Ayed, N.; Charrier-El Bouhtoury, F. Physico-Chemical Characterization of Tunisian Plant Fibers and Its Utilization as Reinforcement for Plaster Based Composites. Ind. Crops Prod. 2013, 49, 357–365. [Google Scholar] [CrossRef]

- Turco, C.; Paula Junior, A.C.; Teixeira, E.R.; Mateus, R. Optimisation of Compressed Earth Blocks (CEBs) Using Natural Origin Materials: A Systematic Literature Review. Constr. Build. Mater. 2021, 309, 125140. [Google Scholar] [CrossRef]

- Cervilla-Maldonado, A.; Valverde-Palacios, I.; Fuentes-García, R.; Martín-Villegas, F. Earth Composites as Construction Material Reinforced with Intensive Agricultural Fibres: Tomato, Pepper, Zucchini, Cucumber, Aubergine and Polypropylene Fibres. Constr. Build. Mater. 2025, 470, 140538. [Google Scholar] [CrossRef]

- Imanzadeh, S.; Jarno, A.; Hibouche, A.; Bouarar, A.; Taibi, S. Ductility Analysis of Vegetal-Fiber Reinforced Raw Earth Concrete by Mixture Design. Constr. Build. Mater. 2020, 239, 117829. [Google Scholar] [CrossRef]

- Kouta, N.; Saliba, J.; Saiyouri, N. Effect of Flax Fibers on Early Age Shrinkage and Cracking of Earth Concrete. Constr. Build. Mater. 2020, 254, 119315. [Google Scholar] [CrossRef]

- Sangma, S.; Tripura, D.D. Experimental Study on Shrinkage Behaviour of Earth Walling Materials with Fibers and Stabilizer for Cob Building. Constr. Build. Mater. 2020, 256, 119449. [Google Scholar] [CrossRef]

- Galán-Marín, C.; Rivera-Gómez, C.; Bradley, F. The Mechanical Properties and Molecular Bonding Characteristics of Cla Y-Based Natural Composites Reinforced with Animal Fibres. J. Biobased Mater. Bioenergy 2013, 7, 143–151. [Google Scholar] [CrossRef]

- Bahammou, Y.; Kouhila, M.; Tagnamas, Z.; Lamsyehe, H.; Lamharrar, A.; Idlimam, A. Hygroscopic Behavior of Water Absorbed by Capillarity and Stabilization of a Bio-Composite Building Material: Clay Reinforced with Chamarrops humilis Fibers. Int. Commun. Heat Mass Transf. 2022, 135, 106077. [Google Scholar] [CrossRef]

- Azil, A.; Touati, K.; Sebaibi, N.; Le Guern, M.; Streiff, F.; Goodhew, S.; Gomina, M.; Boutouil, M. Monitoring of Drying Kinetics Evolution and Hygrothermal Properties of New Earth-Based Materials Using Climatic Chamber Simulation. Case Stud. Constr. Mater. 2023, 18, e01798. [Google Scholar] [CrossRef]

- Elert, K.; Jroundi, F.; Benavides-Reyes, C.; Correa Gómez, E.; Gulotta, D.; Rodriguez-Navarro, C. Consolidation of Clay-Rich Earthen Building Materials: A Comparative Study at the Alhambra Fortress (Spain). J. Build. Eng. 2022, 50, 104081. [Google Scholar] [CrossRef]

- Feng, J.; Yang, F.; Qian, S. Improving the Bond between Polypropylene Fiber and Cement Matrix by Na No Calcium Carbonate Modification. Constr. Build. Mater. 2021, 269, 121249. [Google Scholar] [CrossRef]

- Ali, S.M.; Lepech, C.; D. Lemos, C.; Soto-Oviedo, M.A. Tailoring of Polypropylene Fibers for the Design of Sustainable Fiber-Reinforced Cement-Based Composites. In Proceedings of the IIBCC, International Inorganic-Bonded Fiber Composites Conference, Colombo, Sri Lanka, 17–20 November 2020; Available online: hhttps://www.iibcc.biz/wp-content/uploads/2019/05/IIBCC2014-Proceedings-Tailoring-polypropylene-fibers-design-sustainable-fiber-reinforced-cement-based-composites.pdf (accessed on 29 April 2025).

- Del Prete, C.; Buratti, N.; Manzi, S.; Mazzotti, C. Macro Synthetic Fibre Reinforced Concrete: Influence of the Matrix Mix Design on Interfacial Bond Behavior. IOP Conf. Ser. Mater. Sci. Eng. 2019, 596, 012025. [Google Scholar] [CrossRef]

- Moor, H.; Eggers, J.; Fabritius, H.; Forsell, N.; Henckel, L.; Bradter, U.; Mazziotta, A.; Nordén, J.; Snäll, T. Rebuilding Green Infrastructure in Boreal Production Forest given Future Global Wood Demand. J. Appl. Ecol. 2022, 59, 1659–1669. [Google Scholar] [CrossRef]

- Kuang, T.; Guo, H.; Guo, W.; Liu, W.; Li, W.; Saeb, M.R.; Vatankhah-Varnosfaderani, M.; Sheiko, S.S. Boosting the Strength and Toughness of Polymer Blends via Ligand-Modulated MOFs. Adv. Sci. 2024, 11, 2407593. [Google Scholar] [CrossRef] [PubMed]

- Pei, C.; Zhang, H.; Li, Y.; Gu, Z.; Chen, X.; Kuang, T. Robust and Durable Biodegradable Polymer-Based Triboelectric Nanogenerators Enabled by Trace Amounts of Melanin-like Nanoparticles. Nano Energy 2025, 135, 110643. [Google Scholar] [CrossRef]

- Shakir, M.A.; Ahmad, M.I.; Ramli, N.K.; Yusup, Y.; Alosaimi, A.M.; Alorfi, H.S.; Hussein, M.A.; Rafatullah, M. Review on the Influencing Factors towards Improving Properties of Composite Insulation Panel Made of Natural Waste Fibers for Building Application. J. Ind. Text. 2023, 53, 1–33. [Google Scholar] [CrossRef]

- Zhao, J.R.; Zheng, R.; Tang, J.; Sun, H.J.; Wang, J. A Mini-Review on Building Insulation Materials from Perspective of Plastic Pollution: Current Issues and Natural Fibres as a Possible Solution. J. Hazard. Mater. 2022, 438, 129449. [Google Scholar] [CrossRef]

- Gallego Fernández, L.M.; Portillo Estévez, E.; Navarrete, B.; González Falcón, R. Estimation of Methane Production through the Anaerobic Digestion of Greenhouse Horticultural Waste: A Real Case Study for the Almeria Region. Sci. Total Environ. 2022, 807, 151012. [Google Scholar] [CrossRef]

- Sayadi-Gmada, S.; Torres-Nieto, J.M.; Parra Gómez, S.; García-García, M.C.; Parra-López, C. Critical Point Analysis in Solid Inorganic Waste Production in the Protected Cultivation Systems in Almeria—Approaches to Reduce the Impact. In Proceedings of the XI International Symposium on Protected Cultivation in Mild Winter Climates and I International Symposium on Nettings and Screens in Horticulture, Tenerife, Spain, 27–31 January 2019; ISHS: Korbeek-Lo, Belgium, 2020; pp. 205–212. [Google Scholar] [CrossRef]

- Begum, H.A.; Tanni, T.R.; Shahid, M.A. Analysis of Water Absorption of Different Natural Fibers. J. Text. Sci. Technol. 2021, 7, 152–160. [Google Scholar] [CrossRef]

- Cottrell, J.A.; Ali, M.; Tatari, A.; Martinson, D.B. Effects of Fibre Moisture Content on the Mechanical Properties of Jute Reinforced Compressed Earth Composites. Constr. Build. Mater. 2023, 373, 130848. [Google Scholar] [CrossRef]

- Meteorological station Granada Summary of Meteorogical Data of Granada-Albayzín (Original in Spanish: Resumen de Datos Meteo de Granada-Albayzín). Available online: https://www.ugr.es/~velilla/meteo-albayzin/resumen.htm (accessed on 24 March 2025).

- ASTM D3822 Standard Test Method for Tensile Properties of Single Textile Fibers. Available online: https://store.astm.org/d3822_d3822m-14r20.html (accessed on 29 April 2025).

- Becker, R.P. Proceedings of Scanning. Scanning 2005, 27, 59–111. [Google Scholar] [CrossRef]

- Donaldson, L.; Frankland, A. Ultrastructure of Iodine Treated Wood. Holzforschung 2004, 58, 219–225. [Google Scholar] [CrossRef]

- Yaklich, R.W.; Wergin, E.F.; Erbe, E.F.; Murphy, C. Scanning and Transmission Electron Microscopy of the Soybean Carpel Pericarp. Seed Sci. Technol. 1999, 27, 579–590. [Google Scholar]

- UNE-EN ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0038060 (accessed on 29 April 2025).

- UNE-EN ISO 14044:2006/A2:2021; Environmental Management—Life Cycle Assessment—Requirements and Guidelines—Amendment 2. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0066259 (accessed on 29 April 2025).

- Alsabri, A.; Tahir, F.; Al-Ghamdi, S.G. Life-Cycle Assessment of Polypropylene Production in the Gulf Cooperation Council (GCC) Region. Polymers 2021, 13, 3793. [Google Scholar] [CrossRef] [PubMed]

- Cype 2024 FNA010 Stabilised Earth Retaining Wall (Original Document in Spanish: Muro de Carga de Fábrica de Tapia de Tierra Estabilizada). 2024.

- Cype 2024 RBE050 Base Layer of Cement Mortar on Interior Face (Original Document in Spanish: Capa Base de Mortero de Cemento Sobre Paramento Interior). 2024.

- Cype 2024 NVF020 Thermal Insulation with Wood Fibre Panels. (Original Document in Spanish: Aislamiento Térmico Con Paneles de Fibras de Madera). 2024.

- Fuentes-Garcia, R.; Valverde-Espinosa, I.; Valverde-Palacios, I. Procedure of preparing soil for use in construction by spraying (original in Spanish: Procedimiento para la adecuacion de tierra para ser puesta en obra mediante proyeccion). 2009. [Google Scholar]

- Fuentes-García, R.; Valverde-Palacios, I.; Valverde-Espinosa, I. A New Procedure to Adapt Any Type of Soil for the Consolidation and Construction of Earthen Structures: Projected Earth System|Materiales de Construcción. Available online: https://materconstrucc.revistas.csic.es/index.php/materconstrucc/article/view/1856 (accessed on 3 October 2023).

- Llorach-Massana, P.; Cirrincione, L.; Sierra-Perez, J.; Scaccianoce, G.; La Gennusa, M.; Peña, J.; Rieradevall, J. Environmental Assessment of a New Building Envelope Material Derived from Urban Agriculture Wastes: The Case of the Tomato Plants Stems. Int. J. Life Cycle Assess. 2023, 28, 813–827. [Google Scholar] [CrossRef]

- Valverde-Palacios, I.; Fuentes-García, R.; Cervilla-Maldonado, A.; Valverde-Espinosa, I. Earth as a Sustainable Construction Material. Characterization of Different Mixtures and Implementation Using the Projected Earth System. In New Technologies in Building and Construction: Towards Sustainable Development; Springer: Berlin/Heidelberg, Germany, 2022; pp. 299–320. [Google Scholar]

- Crawford, T., Jr.; Stroehlein, J.; Kuehl, R. Manganese Stresses and Mineral Nutrition of Cucumber Plants; Vegetable Report; College of Agriculture, University of Arizona: Tucson, AZ, USA, 2018. [Google Scholar]

- Ramirez, D.; Wehner, T.; Miller, C. Source Limitation by Defoliation and Its Effect on Dry Matter Production and Yield of Cucumber. HortScience 1988, 23, 704–706. [Google Scholar] [CrossRef]

- Majumder, A.; Stochino, F.; Farina, I.; Valdes, M.; Fraternali, F.; Martinelli, E. Physical and Mechanical Characteristics of Raw Jute Fibers, Threads and Diatons. Constr. Build. Mater. 2022, 326, 126903. [Google Scholar] [CrossRef]

- Bui, H.; Hussain, M.; Levacher, D.; Bui, H.; Hussain, M.; Levacher, D. Recycling of Tropical Natural Fibers in Building Materials. In Natural Fiber; IntechOpen: London, UK, 2022; ISBN 978-1-80355-214-9. [Google Scholar]

- Danso, H.; Martinson, D.B.; Ali, M.; Williams, J.B. Physical, Mechanical and Durability Properties of Soil Building Blocks Reinforced with Natural Fibres. Constr. Build. Mater. 2015, 101, 797–809. [Google Scholar] [CrossRef]

- Danso, H.; Martinson, D.B.; Ali, M.; Williams, J.B. Mechanisms by Which the Inclusion of Natural Fibres Enhance the Proper Ties of Soil Blocks for Construction. J. Compos. Mater. 2017, 51, 3835–3845. [Google Scholar] [CrossRef]

- Garrouri, S.; Lakhal, W.; Benazzouk, A.; Sediki, E. Potential Use of Alfa Fibers in Construction Material: Physico-Mechanical and Thermal Characterisation of Reinforced Specimen. Constr. Build. Mater. 2022, 342, 127787. [Google Scholar] [CrossRef]

- Hiremath, V.S.; Reddy, D.M.; Reddy Mutra, R.; Sanjeev, A.; Dhilipkumar, T. Thermal Degradation and Fire Retardant Behaviour of Natural Fibre Reinforced Polymeric Composites- A Comprehensive Review. J. Mater. Res. Technol. 2024, 30, 4053–4063. [Google Scholar] [CrossRef]

- Yusoff, M.Z.M.; Sapuan, S.M.; Ismail, N. Tensile Properties of Single Oil Palm Empty Fruit Bunch (OPEFB) Fibre. Sains Malays. 2009, 38, 525–529. [Google Scholar]

- Zhang, X.; Guo, Q.; Xu, Y.; Li, P.; Chen, C.; Wu, S. Mechanical Testing of Tomato Plant Stem in Relation to Structural Composition. Agric. Res. 2016, 5, 236–245. [Google Scholar] [CrossRef]

- Alves Fidelis, M.E.; Pereira, T.V.C.; Gomes, O.d.F.M.; de Andrade Silva, F.; Toledo Filho, R.D. The Effect of Fiber Morphology on the Tensile Strength of Natural Fibers. J. Mater. Res. Technol. 2013, 2, 149–157. [Google Scholar] [CrossRef]

- Eichhorn, S.J.; Baillie, C.A.; Zafeiropoulos, N.; Mwaikambo, L.Y.; Ansell, M.P.; Dufresne, A.; Entwistle, K.M.; Herrera-Franco, P.J.; Escamilla, G.C.; Groom, L.; et al. Review: Current International Research into Cellulosic Fibres and Composites. J. Mater. Sci. 2001, 36, 2107–2131. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A Review of Recent Developments in Natural Fibre Composites and Their Mechanical Performance. Compos. Part Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Bos, H.L.; Van Den Oever, M.J.A.; Peters, O.C.J.J. Tensile and Compressive Properties of Flax Fibres for Natural Fibre Reinforced Composites. J. Mater. Sci. 2002, 37, 1683–1692. [Google Scholar] [CrossRef]

- Prakash, R.; Thenmozhi, R.; Raman, S.N.; Subramanian, C. Fibre Reinforced Concrete Containing Waste Coconut Shell Aggregate, Fl y Ash and Polypropylene Fibre. Rev. Fac. Ing. Univ. Antioq. 2020, 94, 33–42. [Google Scholar] [CrossRef]

- Lu, N.; Swan, R.H., Jr.; Ferguson, I. Composition, Structure, and Mechanical Properties of Hemp Fiber Reinforced Composite with Recycled High-Density Polyethylene Matrix. J. Compos. Mater. 2012, 46, 1915–1924. [Google Scholar] [CrossRef]

- Dallel, M. Evaluation Du Potentiel Textile Des Fibres d’Alfa (Stipa tenacissima L.): Caractérisation Physico-Chimique de La Fibre Au Fil. Ph.D. Thesis, Université de Haute Alsace-Mulhouse, Mulhouse, France, 2012. [Google Scholar]

- Mohod, M.V. Performance of Polypropylene Fibre Reinforced Concrete. IOSR J. Mech. Civ. Eng. 2015, 12, 28–36. [Google Scholar]

- Ljungberg, L.Y. Materials Selection and Design for Development of Sustainable Products. Mater. Des. 2007, 28, 466–479. [Google Scholar] [CrossRef]

- UNE 103500:1994; Geotechnic. Compactation Test. Standard Proctor. Available online: https://en.tienda.aenor.com/norma-une-103500-1994-n0007850 (accessed on 29 April 2023).

- UNE EN ISO 17892-7:2019; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 7: Unconfined Compression Test (ISO 17892-7:2017). Available online: https://www.en-standard.eu/une-en-iso-17892-7-2019-geotechnical-investigation-and-testing-laboratory-testing-of-soil-part-7-unconfined-compression-test-iso-17892-7-2017/ (accessed on 29 April 2023).

- UNE-EN 1015-2:1999; Methods of Test for Mortar for Masonry—Part 2: Bulk Sampling of Mortars and Preparation of Test Mortars. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0009378 (accessed on 21 April 2025).

- UNE-EN 1015-11:2020; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0063703 (accessed on 21 April 2025).

- UNE-EN 310:1994; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0008516 (accessed on 21 April 2025).

- Kauppinen, T.; Vincent, R.; Liukkonen, T.; Grzebyk, M.; Kauppinen, A.; Welling, I.; Arezes, P.; Black, N.; Bochmann, F.; Campelo, F.; et al. Occupational Exposure to Inhalable Wood Dust in the Member States of the European Union. Ann. Occup. Hyg. 2006, 50, 549–561. [Google Scholar] [CrossRef]

- Peña, S.V.; Plágaro, A.V.; Rojas, I.M.; Hernando, J.; Laína, R. The Wood Industry in Spain in the Context of the World and of Europe (Article Original in Spanish: La Industria Maderera en España en el Contexto del Mundo Y de Europa), Technical Report from Universidad Politécnica de Madrid, Identifying Number DC: 2014. Available online: https://oa.upm.es/23225/ (accessed on 29 April 2025).

- Araya-Letelier, G.; Maturana, P.; Carrasco, M.; Antico, F.C.; Gómez, M.S. Mechanical-Damage Behavior of Mortars Reinforced with Recycled Polypropylene Fibers. Sustainability 2019, 11, 2200. [Google Scholar] [CrossRef]

- Ruan, B.; Ding, H.; Teng, J.; Deng, W.; Zheng, S.; Ruan, C. Mechanical Properties and Microstructure of Polypropylene Fiber Reinforced Cement Mortar Soil. KSCE J. Civ. Eng. 2021, 25, 1985–1997. [Google Scholar] [CrossRef]

- Van Thillo, L.; Blom, J.; Moreels, A.; Craeye, B. Influence of Aggregates, Glass Fibre Reinforcement and Recycled Aggregates on Polyester Mortar. Constr. Build. Mater. 2021, 293, 123534. [Google Scholar] [CrossRef]