Effect of Oxygen Lance Copper Tip Position Management on Corrosion of MgO–C Refractory Lining in Basic Oxygen Furnace During Campaign

Abstract

1. Introduction

2. Materials and Methods

2.1. Details of the Analyzed Campaign and Evaluation Methodology

2.2. Refractory Lining Details in Analyzed Zone of Trunnions

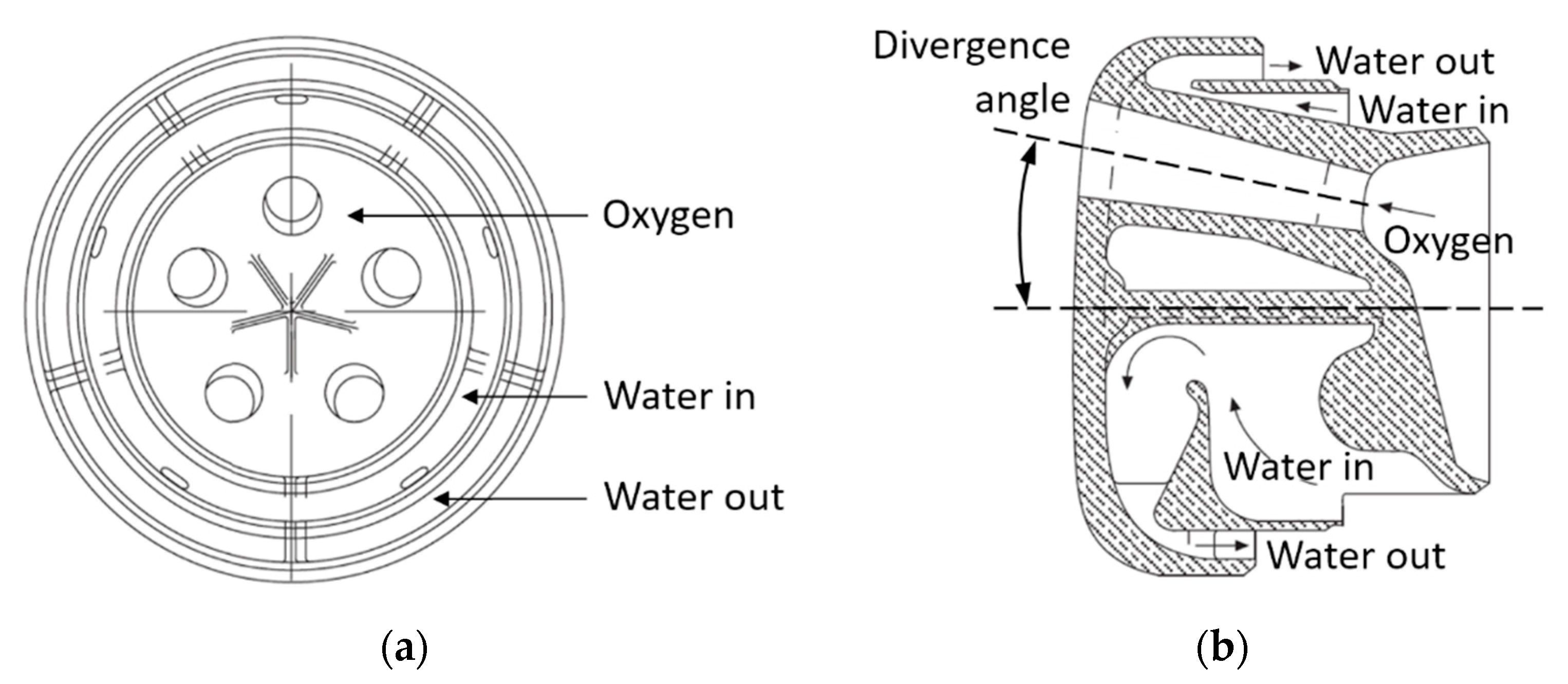

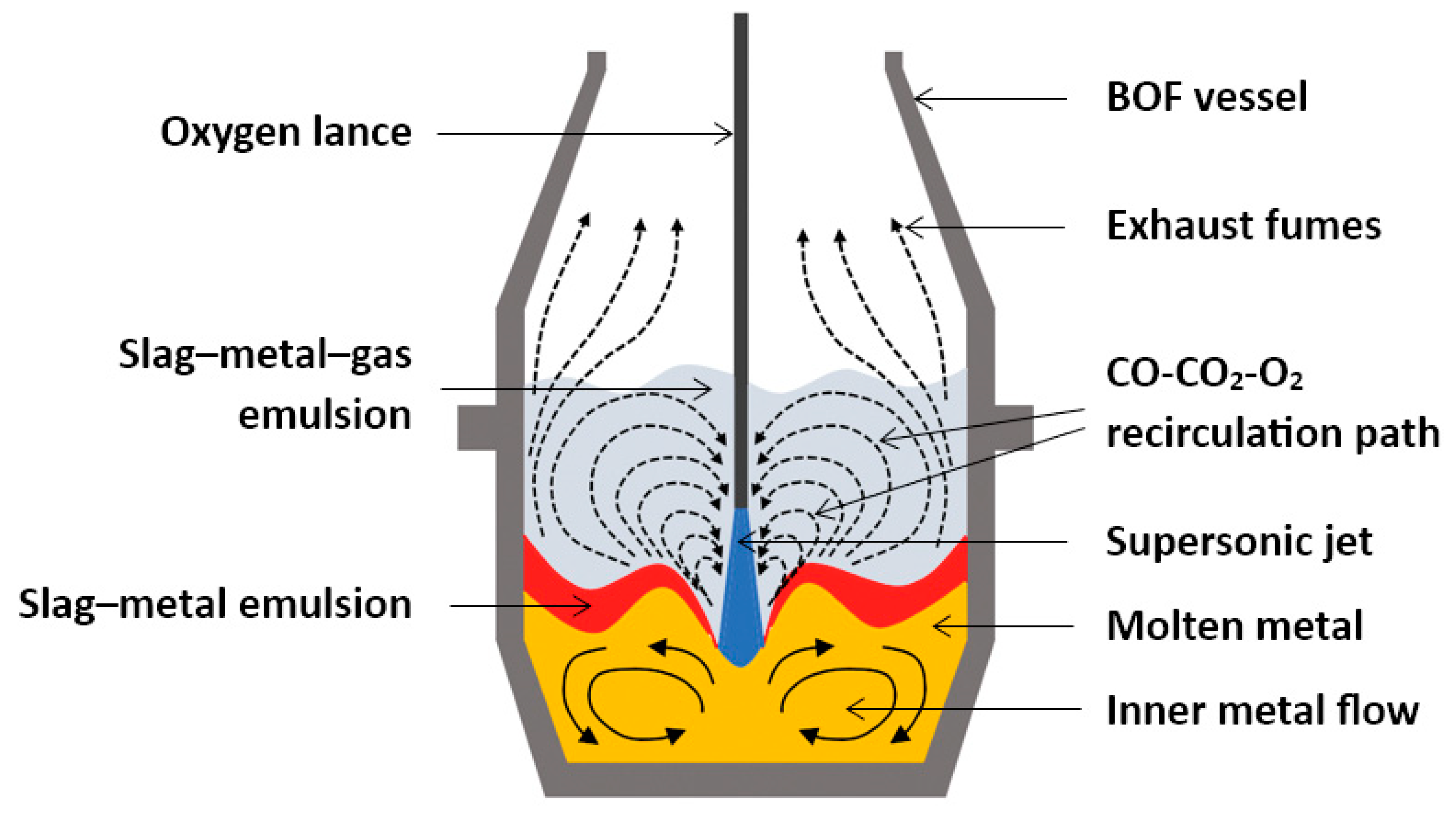

2.3. Influence of Oxygen Lance on Melt Splashing and Spitting

2.4. Wear of Refractory Lining by Erosion

2.5. Recirculation Flow of Gas Mixture over Melt in BOF

3. Results

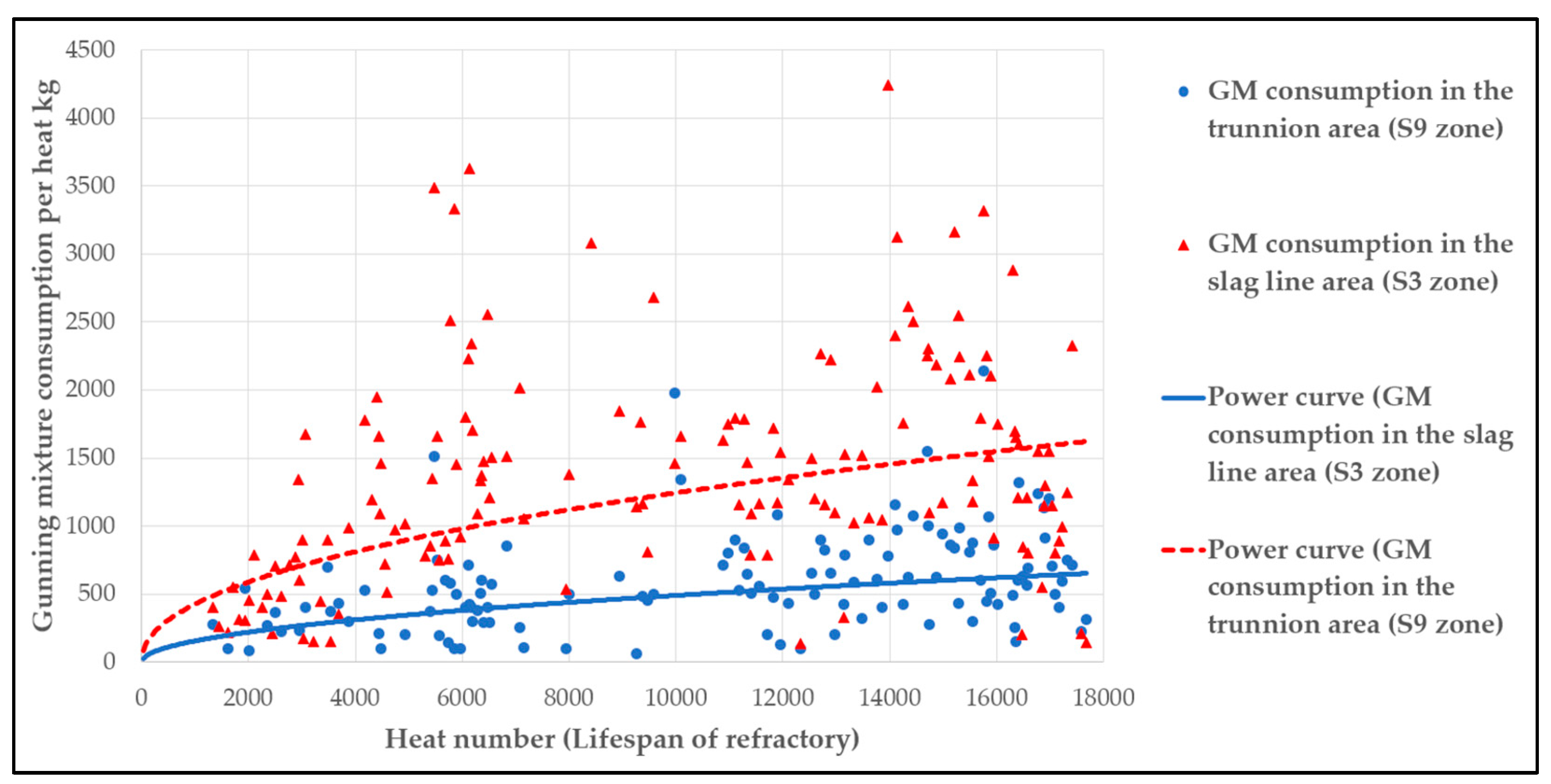

3.1. Gunning Refractory Mixture Consumption During Analyzed Campaign

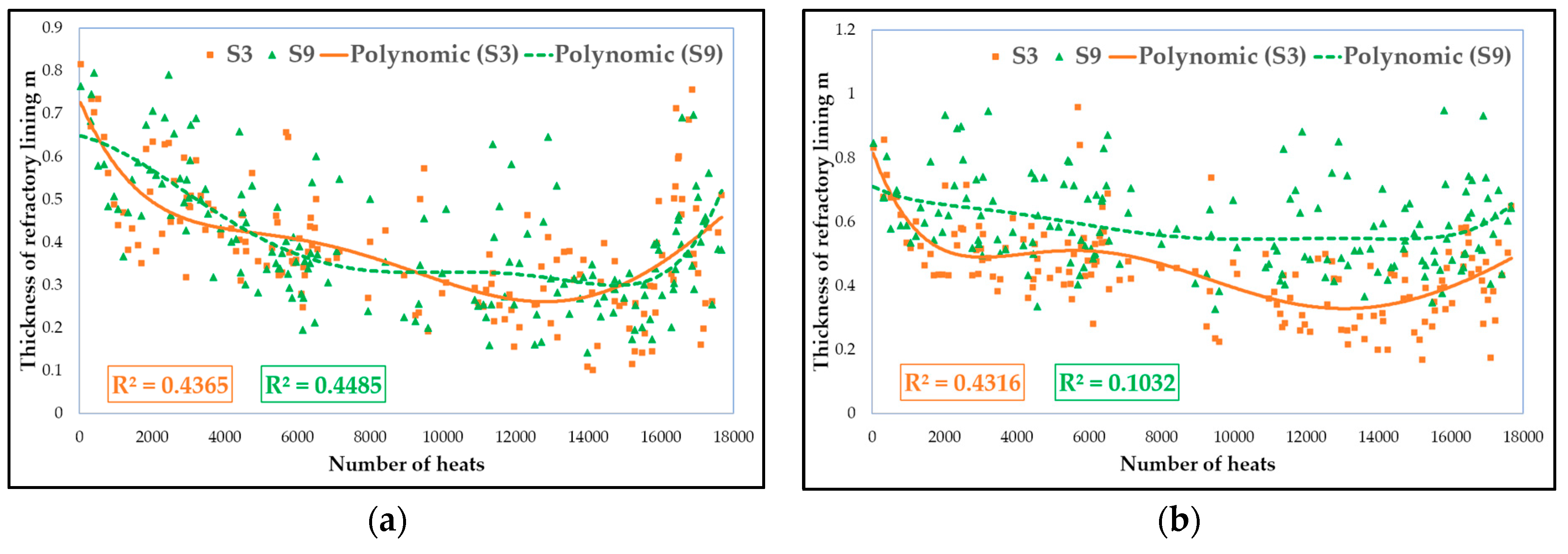

3.2. Inner Profile Evolution of MgO–C Lining Within Analyzed Zones

3.3. Reasons for MgO–C Refractory Wear from a Technological Perspective

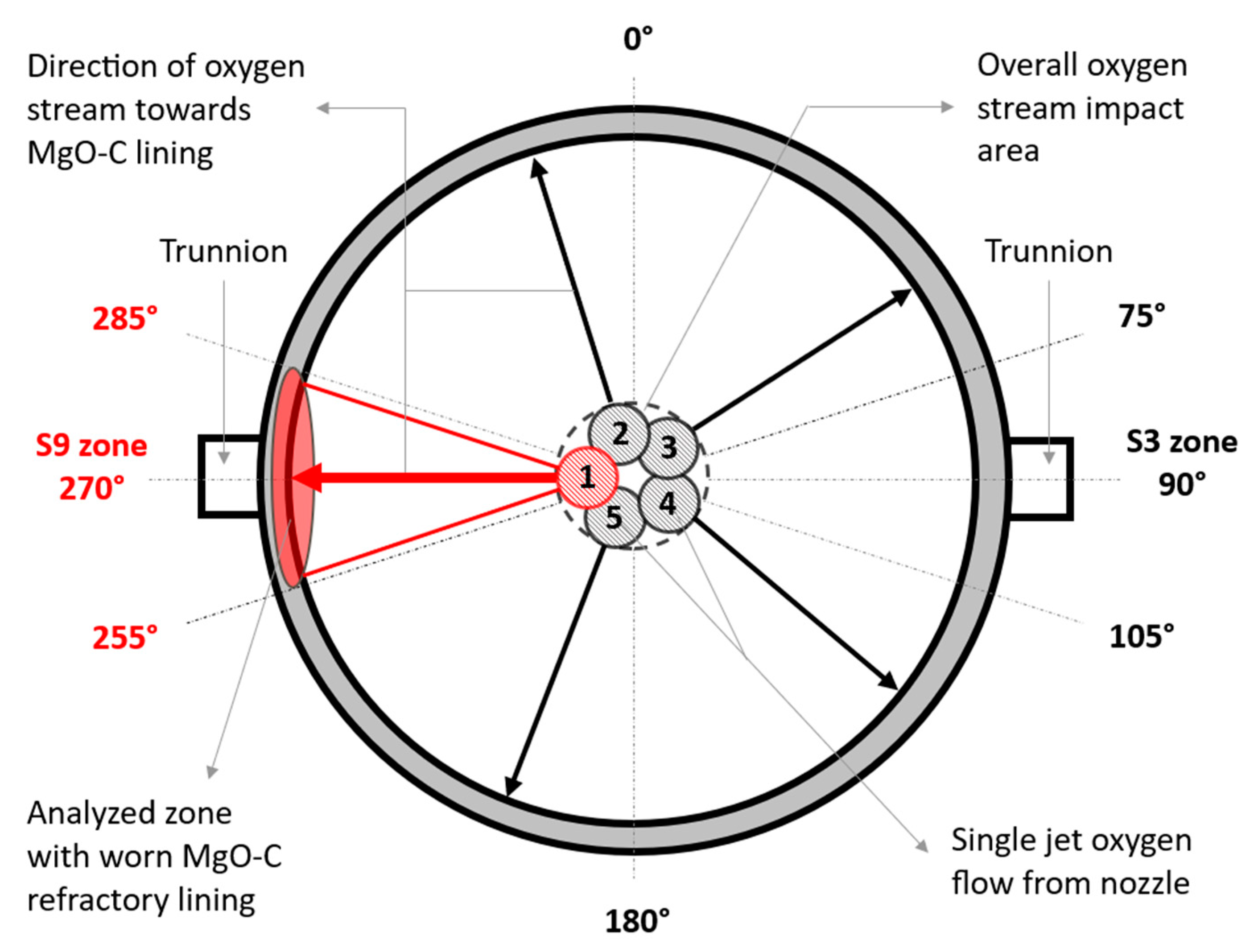

4. Discussion

5. Conclusions

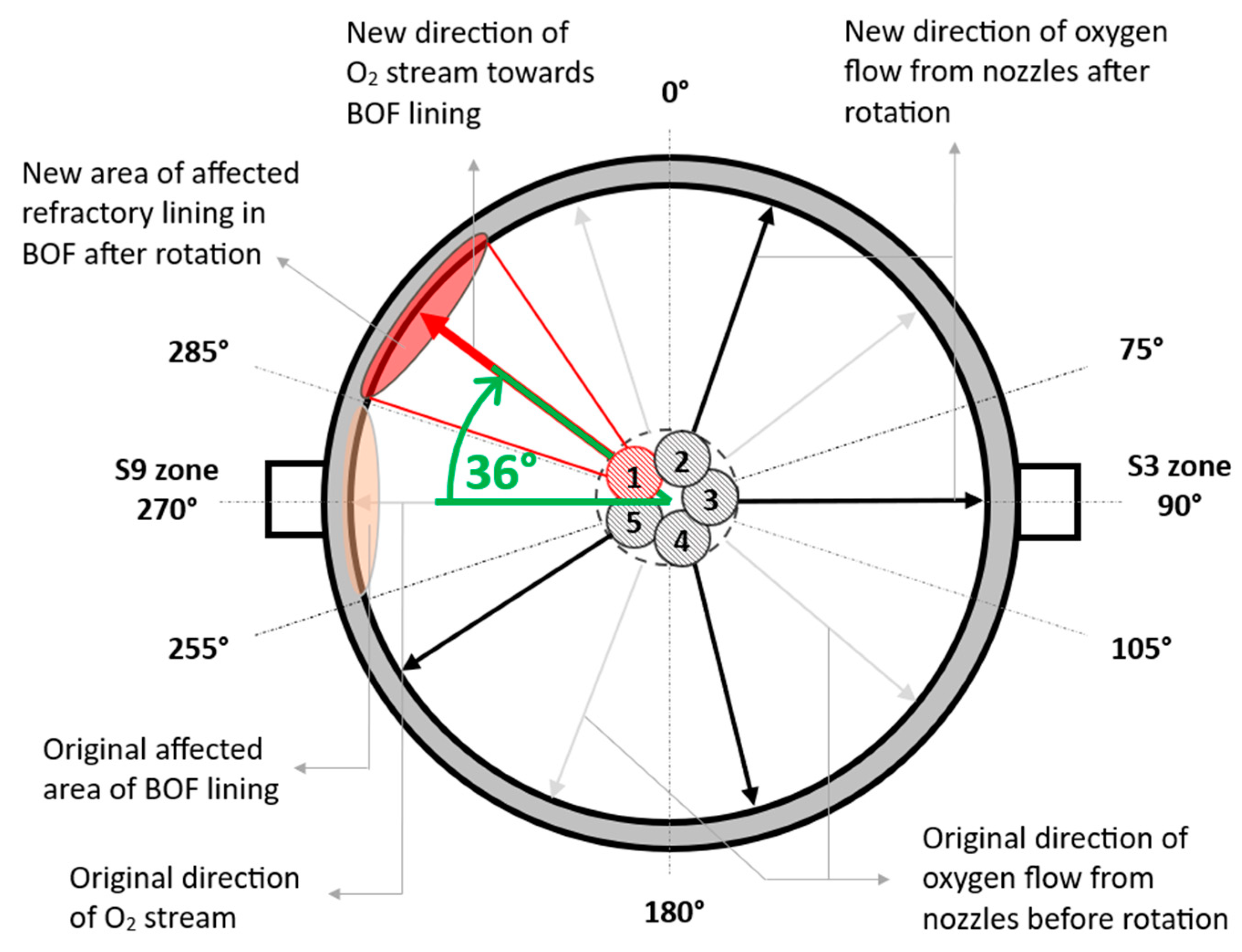

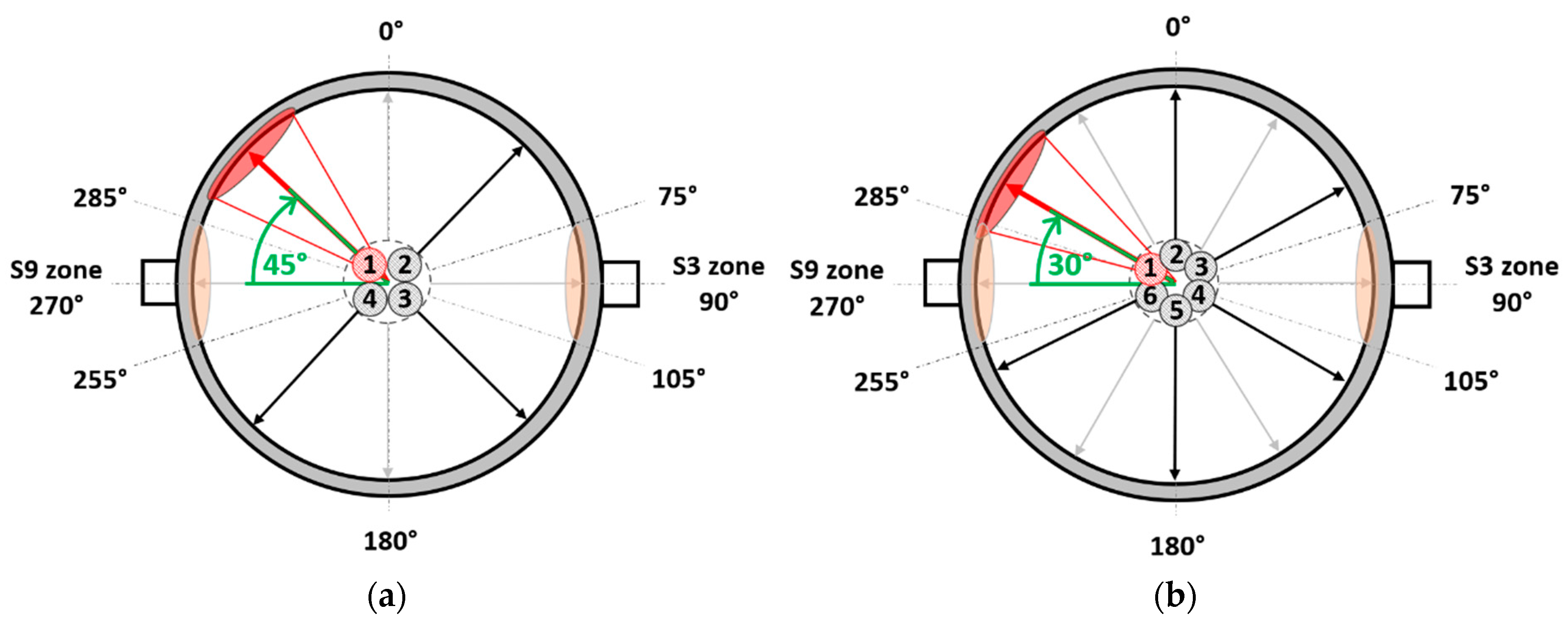

- Turn and weld the new 5-hole copper tip of the oxygen lance by 36° from its original position when replacing a worn tip (Figure 9). When replacing a 4-hole copper tip, rotate and weld the new tip 45° from its original position (Figure 10a). When replacing a 6-hole copper tip, turn and weld the new one by 30° from its initial position (Figure 10b).

- Using a 5-hole tip and alternating Periods 1 and 2, the copper tip rotates, exposing only one trunnion area of the MgO–C refractory lining to direct oxygen jets and molten metal and slag splashes at a time. In Period 1, the S3 zone is exposed while the opposite S9 zone is preserved. In Period 2, the roles reverse, saving the gunning mixture on the non-exposed side. Other MgO–C refractory zones in the BOF are repaired primarily through slag splashing and high-basic slag coating techniques.

- The following position management is used when using 4-hole or 6-hole copper tip. In Period 1, nozzles expose the S3 and S9 trunnion zones to oxygen jets and molten metal and slag splashes, causing refractory wear and consuming the gunning mixture. After turning the copper tip (30° for 6-hole, 45° for 4-hole) in Period 2, no oxygen jets directly hit the trunnion areas, reducing wear and conserving the gunning mixture. Laser measurements and consumption analysis confirm no excess gunning mixture usage in non-exposed areas. Slag splashing and high-basic slag coating techniques will prioritize repairing other refractory zones.

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Higuchi, Y.; Tago, Y. Effect of Lance Design on Jet Behavior and Spitting Rate in Top Blown Process. ISIJ Int. 2001, 41, 1454–1459. [Google Scholar] [CrossRef]

- Fabritius, T.M.J.; Luomala, M.J.; Virtanen, E.O.; Tenkku, H.; Fabritius, T.L.J.; Siivola, T.P.; Härkki, J.J. Effect of Bottom Nozzle Arrangement on Splashing and Spitting in Combined Blowing Converter. ISIJ Int. 2002, 42, 861–867. [Google Scholar] [CrossRef]

- Sabah, S.; Brooks, G. Splash Distribution in Oxygen Steelmaking. Metall. Mater. Trans. B 2015, 46, 863–872. [Google Scholar] [CrossRef]

- Schacht, C. Refractories Handbook, 1st ed.; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar] [CrossRef]

- Li, M.; Li, Q.; Zou, Z.; An, X. Computational Investigation of Swirling Supersonic Jets Generated Through a Nozzle-Twisted Lance. Metall. Mater. Trans. B 2017, 48, 713–725. [Google Scholar] [CrossRef]

- Lv, M.; Chen, S.; Yang, L.; Wei, G. Research Progress on Injection Technology in Converter Steelmaking Process. Metals 2022, 12, 1918. [Google Scholar] [CrossRef]

- Luomala, M.J.; Fabritius, T.M.J.; Virtanen, E.O.; Siivola, T.P.; Härkki, J.J. Splashing and Spitting Behaviour in the Combined Blown Steelmaking Converter. ISIJ Int. 2002, 42, 944–949. [Google Scholar] [CrossRef]

- Fruehan, R.J. The Making, Shaping, and Treating of Steel: Steelmaking and Refining Volume, 11th ed.; The AISE Steel Foundation: Pittsburgh, PA, USA, 1998; ISBN 978-0-930767-03-7. [Google Scholar]

- Lv, M.; Zhu, R. Research on Coherent Jet Oxygen Lance in BOF Steelmaking Process. Metall. Res. Technol. 2019, 116, 502. [Google Scholar] [CrossRef]

- Li, M.; Li, Q.; Kuang, S.B.; Zou, Z. Coalescence Characteristics of Supersonic Jets From Multi-Nozzle Oxygen Lance in Steelmaking BOF. Steel Res. Int. 2015, 86, 1517–1529. [Google Scholar] [CrossRef]

- Bhattacharya, T.; Zhan, L.; Chukwulebe, B. Design Considerations of Supersonic Oxygen Lances for a Basic Oxygen Furnace (BOF). ResearchGate 2016. Available online: https://www.researchgate.net/publication/305612005 (accessed on 13 March 2025).

- Kärnä, A.; Järvinen, M.P.; Fabritius, T. CFD Modeling of a Supersonic Top Blown Lance in a CAS-OB Process: Development of Gas Heat and Mass Transfer Correlation. Steel Res. Int. 2015, 86, 1370–1378. [Google Scholar] [CrossRef]

- Alam, M.; Naser, J.; Brooks, G. Computational Fluid Dynamics Simulation of Supersonic Oxygen Jet Behavior at Steelmaking Temperature. Metall. Mater. Trans. B 2010, 41, 636–645. [Google Scholar] [CrossRef]

- Sumi, I.; Kishimoto, Y.; Kikuchi, Y.; Igarashi, H. Effect of High-Temperature Field on Supersonic Oxygen Jet Behavior. ISIJ Int. 2006, 46, 1312–1317. [Google Scholar] [CrossRef]

- Li, M.; Li, Q.; Li, L.; He, Y.; Zou, Z. Effect of Operation Parameters on Supersonic Jet Behaviour of BOF Six-Nozzle Oxygen Lance. Ironmak. Steelmak. 2014, 41, 699–709. [Google Scholar] [CrossRef]

- Tago, Y.; Higuchi, Y. Fluid Flow Analysis of Jets from Nozzles in Top Blown Process. ISIJ Int. 2003, 43, 209–215. [Google Scholar] [CrossRef]

- Naito, K.; Ogawa, Y.; Inomoto, T.; Kitamura, S.; Yano, M. Characteristics of Jets from Top-Blown Lance in Converter. ISIJ Int. 2000, 40, 23–30. [Google Scholar] [CrossRef]

- Sambasivam, R.; Durst, F. Characteristics of Supersonic Jets in LD Steelmaking. Ironmak. Steelmak. 2010, 37, 195–203. [Google Scholar] [CrossRef]

- Wang, W.; Yuan, Z.; Matsuura, H.; Zhao, H.; Dai, C.; Tsukihashi, F. Three-Dimensional Compressible Flow Simulation of Top-Blown Multiple Jets in Converter. ISIJ Int. 2010, 50, 491–500. [Google Scholar] [CrossRef]

- Li, M.; Li, Q.; Kuang, S.; Zou, Z. Transferring Characteristics of Momentum/Energy during Oxygen Jetting into the Molten Bath in BOFs: A Computational Exploration. Steel Res. Int. 2016, 87, 288–300. [Google Scholar] [CrossRef]

- Liu, F.; Zhu, R.; Dong, K.; Hu, S. Flow Field Characteristics of Coherent Jet with Preheating Oxygen under Various Ambient Temperatures. ISIJ Int. 2016, 56, 1519–1528. [Google Scholar] [CrossRef]

- Yin, Z.; Lu, J.; Li, L.; Wang, T.; Wang, R.; Fan, X.; Lin, H.; Huang, Y.; Tan, D. Optimized Scheme for Accelerating the Slagging Reaction and Slag–Metal–Gas Emulsification in a Basic Oxygen Furnace. Appl. Sci. 2020, 10, 5101. [Google Scholar] [CrossRef]

- Odenthal, H.-J.; Falkenreck, U.; Schlüter, J. CFD Simulation of Multiphase Melt Flows in Steelmaking Converters. In Proceedings of the European Conference on Computational Fluid Dynamics ECCOMAS CFD, Egmond aan Zee, The Netherlands, 5–8 September 2006. [Google Scholar]

- Kadrolkar, A.; Dogan, N. Model Development for Refining Rates in Oxygen Steelmaking: Impact and Slag-Metal Bulk Zones. Metals 2019, 9, 309. [Google Scholar] [CrossRef]

- Li, Q.; Li, M.; Kuang, S.; Zou, Z. Numerical Simulation of the Interaction Between Supersonic Oxygen Jets and Molten Slag–Metal Bath in Steelmaking BOF Process. Metall. Mater. Trans. B 2015, 46, 1494–1509. [Google Scholar] [CrossRef]

- Cao, L.; Wang, Y.; Liu, Q.; Feng, X. Physical and Mathematical Modeling of Multiphase Flows in a Converter. ISIJ Int. 2018, 58, 573–584. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, J.; Lin, W.; Cao, L.; Feng, X.; Liu, Q. Effect of Impact Cavity Shape Induced by Supersonic Oxygen Jet on the Dynamic Characteristics of Molten Bath in Converter. Steel Res. Int. 2021, 92, 2100179. [Google Scholar] [CrossRef]

- Lv, M.; Zhu, R.; Guo, Y.-G.; Wang, Y.-W. Simulation of Flow Fluid in the BOF Steelmaking Process. Metall. Mater. Trans. B 2013, 44, 1560–1571. [Google Scholar] [CrossRef]

- Liu, G.; Liu, K.; Han, P. Metallurgical Performance of Innovative Double-Parameter Oxygen Lance in BOF Steelmaking. Ironmak. Steelmak. 2020, 48, 437–446. [Google Scholar] [CrossRef]

- Yuan, Z.; Yang, X.; Lu, Z.; Huang, J.; Pan, Y.; Ma, E. Jet Behavior and Metallurgical Performance of Innovated Double-Parameter Oxygen Lance in BOF. J. Iron Steel Res. Int. 2007, 14, 1–5. [Google Scholar] [CrossRef]

- Li, J.; Zeng, Y.; Wang, J.; Han, Z. Simulation of Flow Field of Oxygen Lance Gas Jet Utilized for 50 t Converter. J. Iron Steel Res. Int. 2011, 18, 11–18. [Google Scholar] [CrossRef]

- Zhong, L.; Zhu, Y.; Jiang, M.; Qu, Z.; Za, Y.; Bao, X. Cold Modelling of Slag Splashing in LD Furnace by Oxygen Lance with Twisted Nozzle Tip. Steel Res. Int. 2005, 76, 611–615. [Google Scholar] [CrossRef]

- Higuchi, Y.; Tago, Y. Effect of Nozzle Twisted Lance on Jet Behavior and Spitting Rate in Top Blown Process. ISIJ Int. 2003, 43, 1410–1414. [Google Scholar] [CrossRef]

- Liu, F.; Sun, D.; Zhu, R.; Zhao, F.; Ke, J. Effect of Nozzle Twisted Oxygen Lance on Flow Field and Dephosphorisation Rate in Converter Steelmaking Process. Ironmak. Steelmak. 2017, 44, 640–648. [Google Scholar] [CrossRef]

- Li, L.; Li, M.; Shao, L.; Li, Q.; Zou, Z. Physical and Mathematical Modeling of Swirling Gas Jets Impinging onto a Liquid Bath Using a Novel Nozzles-Twisted Lance. Steel Res. Int. 2020, 91, 1900684. [Google Scholar] [CrossRef]

- Li, J.; Ma, Z.; Chen, C.; Zhang, J.; Wang, B. Behavior of Top-Blown Jet under a New Cyclone Oxygen Lance during BOF Steelmaking Process. Processes 2022, 10, 507. [Google Scholar] [CrossRef]

- Bahtli, T.; Hopa, D.Y.; Bostanci, V.M.; Ulvan, N.S.; Yasti, S.Y. Corrosion Behaviours of MgO–C Refractories: Incorporation of Graphite or Pyrolytic Carbon Black as a Carbon Source. Ceram. Int. 2018, 44, 6780–6785. [Google Scholar] [CrossRef]

- Anan, K. Wear of Refractories in Basic Oxygen Furnaces (BOF). J. Tech. Assoc. Refract. Jpn. 2001, 21, 241–246. [Google Scholar]

- Xiao, J.; Chen, J.; Wei, Y.; Zhang, Y.; Zhang, S.; Li, N. Oxidation Behaviors of MgO–C Refractories with Different Si/SiC Ratio in the 1100–1500 °C Range. Ceram. Int. 2019, 45, 21099–21107. [Google Scholar] [CrossRef]

- Zanotelli, V.H.; Ribas, L.L.; Bragança, S.R. Evaluation of Oxidation Resistance of MgO–C Bricks in Oxy-Combustion and Air-Combustion. Int. J. Appl. Ceram. Technol. 2021, 18, 1392–1403. [Google Scholar] [CrossRef]

- Ghosh, N.K.; Ghosh, D.N.; Jagannathan, K.P. Oxidation Mechanism of MgO–C in Air at Various Temperatures. Br. Ceram. Trans. 2000, 99, 124–128. [Google Scholar] [CrossRef]

- Faghihi-Sani, M.-A.; Yamaguchi, A. Oxidation Kinetics of MgO–C Refractory Bricks. Ceram. Int. 2002, 28, 835–839. [Google Scholar] [CrossRef]

- Liu, Z.; Yu, J.; Yang, X.; Jin, E.; Yuan, L. Oxidation Resistance and Wetting Behavior of MgO–C Refractories: Effect of Carbon Content. Materials 2018, 11, 883. [Google Scholar] [CrossRef]

- Hashemi, B.; Nemati, Z.A.; Sadrnezhaad, S.K.; Moghimi, Z.A. Kinetic Parameters Estimation of MgO–C Refractory by Shrinking Core Model. J. Mater. Sci. Technol. 2006, 22, 826–832. [Google Scholar]

- Mahato, S.; Behera, S.K. Oxidation Resistance and Microstructural Evolution in MgO–C Refractories with Expanded Graphite. Ceram. Int. 2016, 42, 7611–7619. [Google Scholar] [CrossRef]

- Bavand-Vandchali, M.; Golestani-Fard, F.; Sarpoolaky, H.; Rezaie, H.R.; Aneziris, C.G. The Influence of in Situ Spinel Formation on Microstructure and Phase Evolution of MgO–C Refractories. J. Eur. Ceram. Soc. 2008, 28, 563–569. [Google Scholar] [CrossRef]

- Luz, A.P.; Souza, T.M.; Pagliosa, C.; Brito, M.A.M.; Pandolfelli, V.C. In Situ Hot Elastic Modulus Evolution of MgO–C Refractories Containing Al, Si or Al–Mg Antioxidants. Ceram. Int. 2016, 42, 9813–9836. [Google Scholar] [CrossRef]

- Hu, S.; Zhu, R.; Liu, R.; Dong, K. Decarburisation Behaviour of High-Carbon MgO–C Refractories in O2-CO2 Oxidising Atmospheres. Ceram. Int. 2018, 44, 20641–20647. [Google Scholar] [CrossRef]

- Moliné, M.N.; Galliano, P.G.; Tomba Martinez, A.G. Chemical Degradation of Magnesia–Carbon Refractories by Different Gaseous Atmospheres. Carbon Trends 2024, 14, 100320. [Google Scholar] [CrossRef]

- Li, Z.; Mukai, K.; Tao, Z. Reactions Between MgO–C Refractory, Molten Slag and Metal. ISIJ Int. 2000, 40, 101–105. [Google Scholar] [CrossRef]

- Mukai, K.; Li, Z.; Tao, Z. Bubble Generation in MgO–C Crucible Charged with Slag and Metal in Relation to Local Corrosion. High Temp. Mater. Process. 2001, 20, 255–262. [Google Scholar] [CrossRef]

- Asahara, N.; Naito, K.; Kitagawa, I.; Matsuo, M.; Kumakura, M.; Iwasaki, M. Fundamental Study on Interaction between Top Blown Jet and Liquid Bath. Steel Res. Int. 2011, 82, 587–594. [Google Scholar] [CrossRef]

- Sambasivam, R.; Lenka, S.; Durst, F.; BOCK, M.; Chandra, S.; Ajmani, S. A New Lance Design for BOF Steelmaking. Metall. Mater. Trans. B 2007, 38, 45–53. [Google Scholar] [CrossRef]

- Treatise on Process Metallurgy, Volume 3: Industrial Processes. In Treatise on Process Metallurgy; Seetharaman, S., Ed.; Elsevier: Boston, MA, USA, 2014; Volume 3: Industrial Processes; pp. 231–250. ISBN 978-0-08-096988-6. [Google Scholar]

- Lee, W.E.; Zhang, S. Melt Corrosion of Oxide and Oxide–Carbon Refractories. Int. Mater. Rev. 1999, 44, 77–104. [Google Scholar] [CrossRef]

- Surendranathan, A.O. An Introduction to Ceramics and Refractories; CRC Press: Boca Raton, FL, USA, 2015; ISBN 978-0-429-06832-4. [Google Scholar]

- Jansson, S.; Brabie, V.; Jönsson, P. Corrosion Mechanism and Kinetic Behaviour of MgO–C Refractory Material in Contact with CaO–Al2O3–SiO2–MgO Slag. Scand. J. Metall. 2005, 34, 283–292. [Google Scholar] [CrossRef]

- Banerjee, S. Monolithic Refractories: A Comprehensive Handbook; American Ceramic Society: Westerville, OH, USA; World Scientific: River Edge, NJ, USA, 1998; ISBN 978-981-02-3120-0. [Google Scholar]

- Bruckhaus, R.; Fiedler, V.; Lachmund, V. Improvement of the BOF Process by Use of a Radar Measurement at the Dillinger Hütte. Rev. Met. Paris 2001, 98, 553–559. [Google Scholar] [CrossRef]

- Manchisi, J.; Matinde, E.; Rowson, N.A.; Simmons, M.J.H.; Simate, G.S.; Ndlovu, S.; Mwewa, B. Ironmaking and Steelmaking Slags as Sustainable Adsorbents for Industrial Effluents and Wastewater Treatment: A Critical Review of Properties, Performance, Challenges and Opportunities. Sustainability 2020, 12, 2118. [Google Scholar] [CrossRef]

- Kemminger, A.; Krause, F.; Odenthal, H.-J. CFD Simulation of Top-Blown Converters. In Proceedings of the 9th EOSC European Oxygen Steelmaking Conference, Aachen, Germany, 17–21 October 2022. [Google Scholar]

- Li, M.; Li, Q.; Kuang, S.; Zou, Z. Determination of Cavity Dimensions Induced by Impingement of Gas Jets onto a Liquid Bath. Metall. Mater. Trans. B 2016, 47, 116–126. [Google Scholar] [CrossRef]

- Ersson, M.; Tilliander, A. Review on CFD Simulation and Modeling of Decarburization Processes. Steel Res. Int. 2018, 89, 1700108. [Google Scholar] [CrossRef]

- Luomala, M.J.; Fabritius, T.M.J.; Härkki, J.J. The Effect of Bottom Nozzle Configuration on the Bath Behaviour in the BOF. ISIJ Int. 2004, 44, 809–816. [Google Scholar] [CrossRef]

- Jia, H.; Li, Y.; Han, P.; Liu, K.; Han, H.; Feng, L. Turbulence Calculations of a Dual-Structure Oxygen Lance for Converter Based on Hydrodynamics. Math. Probl. Eng. 2021, 2021, e5785889. [Google Scholar] [CrossRef]

- Hu, J.; Yang, Q.; Yang, S.; Yu, H.; Wang, H. Enhanced Impingement Characteristics of Supersonic Oxygen Jets on Molten Bath Using a Multi-Nozzle Oxygen Lance in a Converter. ISIJ Int. 2024, 64, 773–784. [Google Scholar] [CrossRef]

- Bhattacharya, T.; Zhan, L.; Chukwulebe, B. A Numerical Test Bench for Supersonic Oxygen Nozzles and Its Application to the BOF Process. AISTech Iron Steel Technol. Conf. Proc. 2014, 1, 1149–1158. [Google Scholar]

- Park, J.M.; Ha, C.S. Recent Improvement of BOF Refining at Kwangyang Works. Rev. Met. Paris 2000, 97, 729–735. [Google Scholar] [CrossRef]

- Lee, M.S.; O’Rourke, S.L.; Molloy, N.A. Oscillatory Flow in the Steelmaking Vessel. Scand. J. Metall. 2003, 32, 281–288. [Google Scholar] [CrossRef]

- Sabah, S.; Brooks, G. Splashing in Oxygen Steelmaking. ISIJ Int. 2014, 54, 836–844. [Google Scholar] [CrossRef]

- Kalifa, R.B.; Hamza, S.B.; Saïd, N.M.; Bournot, H. Fluid Flow Phenomena in Metals Processing Operations: Numerical Description of the Fluid Flow Field by an Impinging Gas Jet on a Liquid Surface. Int. J. Mech. Sci. 2020, 165, 105220. [Google Scholar] [CrossRef]

- Altohami, A.M.; Omer, A.A. Fluid Flow, Heat Transfer, Mixing Time and Inclusion Motion in Molten Steel Continuous Casting Tundish. Int. J. Eng. Trends Technol. IJETT. 2017, 49, 231–243. [Google Scholar]

- Iguchi, M.; Ilegbusi, O.J. Basic Transport Phenomena in Materials Engineering; Springer Japan: Tokyo, Japan, 2014; ISBN 978-4-431-54019-9. [Google Scholar]

- Amano, S.; Sato, S.; Takahashi, Y.; Kikuchi, N. Effect of Top and Bottom Blowing Conditions on Spitting in Converter. Eng. Rep. 2021, 3, e12406. [Google Scholar] [CrossRef]

- Li, Q.; Li, M.; Kuang, S.B.; Zou, Z. Understanding Characteristic of Abrasion of Refractory Lining Caused by Bath Oscillation in BOF Steelmaking. JOM 2016, 68, 3126–3133. [Google Scholar] [CrossRef]

- He, Q.L.; Standish, N. A Model Study of Residence Time of Metal Droplets in the Slag in BOF Steelmaking. ISIJ Int. 1990, 30, 356–361. [Google Scholar] [CrossRef]

- Deo, B.; Overbosch, A.; Snoeijer, B.; Das, D.; Srinivas, K. Control of Slag Formation, Foaming, Slopping, and Chaos in BOF. Trans. Indian Inst. Met. 2013, 66, 543–554. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, B.; Liu, C.; Jiang, M. A Novel Modeling Method of Slag Foaming in BOF. Metall. Mater. Trans. B 2020, 51, 1941–1946. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, B.; Hu, C.; Liu, C.; Jiang, M. Study on Splashing Mechanism in Basic Oxygen Furnace Based on Slag Foaming Modeling. Steel Res. Int. 2022, 93, 2100318. [Google Scholar] [CrossRef]

- Liu, Z.; Yuan, L.; Jin, E.; Yang, X.; Yu, J. Wetting, Spreading and Corrosion Behavior of Molten Slag on Dense MgO and MgO–C Refractory. Ceram. Int. 2019, 45, 718–724. [Google Scholar] [CrossRef]

- Martinsson, J.; Glaser, B.; Sichen, D. The Structure of Foaming BOF-Converter Slag. Ironmak. Steelmak. 2019, 46, 777–781. [Google Scholar] [CrossRef]

- Martinsson, J.; Glaser, B.; Sichen, D. Lime Dissolution in Foaming BOF Slag. Metall. Mater. Trans. B 2018, 49, 3164–3170. [Google Scholar] [CrossRef]

- Jiang, R.; Fruehan, R.J. Slag Foaming in Bath Smelting. Metall. Trans. B 1991, 22, 481–489. [Google Scholar] [CrossRef]

- Ito, K.; Fruehan, R.J. Slag Foaming in Smelting Reduction Processes. Steel Res. 1989, 60, 151–156. [Google Scholar] [CrossRef]

- Yao, L.; Zhu, R.; Tang, Y.; Wei, G.; Dong, K. Effect of Furnace Gas Composition on Characteristics of Supersonic Oxygen Jets in the Converter Steelmaking Process. Materials 2020, 13, 3353. [Google Scholar] [CrossRef]

- Li, M.; Li, Q.; Li, L.; Feng, M.; Zhang, Z.; Zou, Z. Numerical Study on Behavior of Top-Blown Supersonic Jets and Their Interaction with Bath in BOF Steelmaking Convertor. In Proceedings of the 8th Pacific Rim International Congress on Advanced Materials and Processing, Waikoloa, HI, USA, 4–9 August 2013; Marquis, F., Ed.; Springer International Publishing: Cham, Switzerland, 2016; pp. 3033–3040. [Google Scholar]

- Cao, L.L.; Liu, Q.; Wang, Z.; Li, N. Interaction Behaviour between Top Blown Jet and Molten Steel during BOF Steelmaking Process. Ironmak. Steelmak. 2016, 45, 239–248. [Google Scholar] [CrossRef]

| Chemical Composition (wt.%) | MgO in magnesia | min. 98.0 | |

| SiO2 in magnesia | max. 0.4 | ||

| CaO in magnesia | min. 1.2 | ||

| Fe2O3 in magnesia | max. 0.5 | ||

| Magnesia content | 86.5 | ||

| Residual carbon content | 13.5 | ||

| Physical Parameters | Volumetric mass | min. 2920 kg.m−3 | |

| Cold compressive strength | min. 27 MPa | ||

| Apparent porosity | max. 4% | ||

| Chemical Composition (wt.%) | MgO | 87.8 |

| CaO | 7.7 | |

| P2O5 | 2.7 | |

| SiO2 | 1.3 | |

| Al2O3 | 0.4 | |

| Fe2O3 | 0.1 | |

| Physical Parameters | Operating temperature | 1750 °C |

| Granularity | 0–3 mm | |

| Volumetric mass | 2200 kg·m−3 |

| Technical Parameter | Value |

|---|---|

| Oxygen lance length | 22.795 m |

| Amount of oxygen blown | max. 650 m3 |

| Pressure of blowing oxygen | max. 1.6 MPa |

| Purity of blown oxygen | min. 99.5% |

| Amount of cooling water | 190 m3·h−1 |

| Temperature difference in the cooling water | max. 15 °C |

| Number of nozzles on the tip | 5-hole |

| Critical nozzle diameter | 34.9 mm |

| Inclination angle | 14° |

| Impact area | 1.67 m2 |

| Diameter of impact | 1.27 m |

| BOF Lining Field | Zone Label | Affected Angle | Share in the Total Consumption % | Overall Consumption % |

|---|---|---|---|---|

| Trunnion zone | S3 | (75–105°) | 1.34 | 18.13 |

| Trunnion zone | S9 | (225–285°) | 16.79 | |

| Slag line zone | S3 | (75–105°) | 44.83 | 44.93 |

| Slag line zone | S9 | (225–285°) | 0.10 | |

| Other zones (charge pad, tap pad, tap hole, cone area) | - | - | 36.94 | 36.94 |

| Number of the Nozzles on the Copper Tip | The Value of the Rotation During Tip Replacement |

|---|---|

| 4-hole | 45° |

| 5-hole | 36° |

| 6-hole | 30° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Demeter, J.; Buľko, B.; Demeter, P.; Hrubovčáková, M.; Chudíková, D. Effect of Oxygen Lance Copper Tip Position Management on Corrosion of MgO–C Refractory Lining in Basic Oxygen Furnace During Campaign. Appl. Sci. 2025, 15, 5109. https://doi.org/10.3390/app15095109

Demeter J, Buľko B, Demeter P, Hrubovčáková M, Chudíková D. Effect of Oxygen Lance Copper Tip Position Management on Corrosion of MgO–C Refractory Lining in Basic Oxygen Furnace During Campaign. Applied Sciences. 2025; 15(9):5109. https://doi.org/10.3390/app15095109

Chicago/Turabian StyleDemeter, Jaroslav, Branislav Buľko, Peter Demeter, Martina Hrubovčáková, and Dáša Chudíková. 2025. "Effect of Oxygen Lance Copper Tip Position Management on Corrosion of MgO–C Refractory Lining in Basic Oxygen Furnace During Campaign" Applied Sciences 15, no. 9: 5109. https://doi.org/10.3390/app15095109

APA StyleDemeter, J., Buľko, B., Demeter, P., Hrubovčáková, M., & Chudíková, D. (2025). Effect of Oxygen Lance Copper Tip Position Management on Corrosion of MgO–C Refractory Lining in Basic Oxygen Furnace During Campaign. Applied Sciences, 15(9), 5109. https://doi.org/10.3390/app15095109