Supply Chain Management in Renewable Energy Projects from a Life Cycle Perspective: A Review

Abstract

1. Introduction

2. Materials and Methods

Inclusion and Exclusion Criteria

- Peer-reviewed journal articles, technical reports, and international assessments published between 2010 and 2025.

- Empirical and review studies focusing on LCA applications in RE technologies (e.g., solar, wind, biomass).

- Studies addressing the use of critical raw materials (e.g., neodymium, dysprosium, silicon).

- Literature incorporating environmental indicators such as carbon footprint, water use, energy demand, and waste generation.

- Publications unrelated to RE or LCA frameworks.

- Studies lacking methodological transparency or quantitative environmental data.

- Non-peer-reviewed sources without institutional validation (e.g., blogs, opinion pieces, or unverified repositories).

3. Results

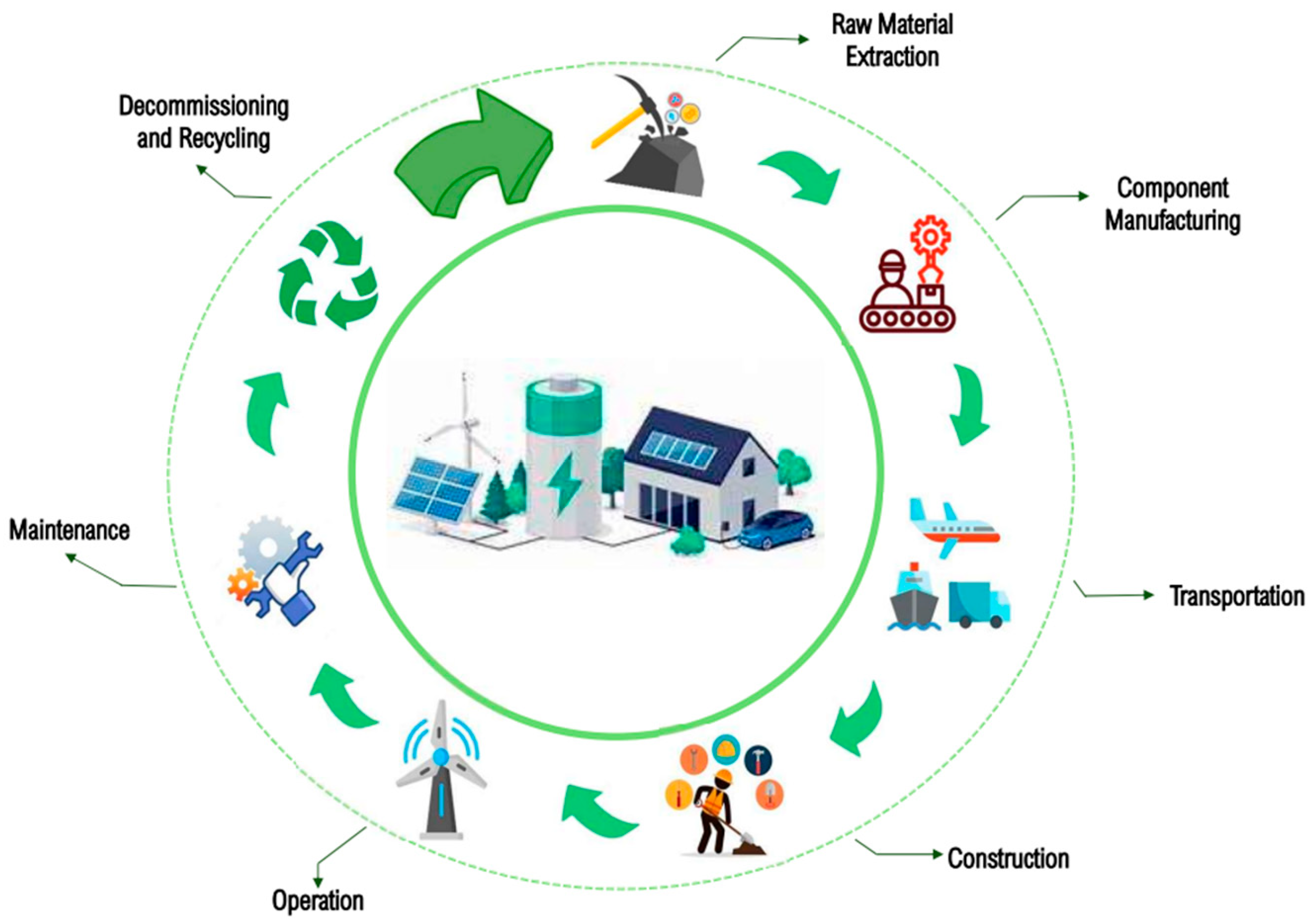

Key Phases of the Renewable Energy Supply Chain

- Extraction and Processing of Materials: This phase involves obtaining essential natural resources for the manufacturing of RE components. It includes mining, refining, and purification of various materials. Critical materials are essential for manufacturing batteries used in RE storage [147,148,149]. Rare earth elements are essential components in high-efficiency wind turbines and electric vehicles. China currently controls approximately 70% of global production, raising concerns about the long-term security of supply. It is important to emphasize that the environmental benefits of electric vehicles are only fully realized when the electricity that powers them is generated from RE sources such as wind, hydro, or solar energy [150,151,152,153,154,155]. Otherwise, the transition from internal combustion engines to electric mobility may merely shift CO2 and other GHG emissions from vehicle tailpipes to fossil fuel-based power plants. From this perspective, the contribution of electric mobility to climate change mitigation is significant only when accompanied by a broader energy transition toward clean electricity generation [156,157,158,159,160].

- Component Manufacturing: After obtaining raw materials, the manufacturing of various components necessary for RE systems takes place. This process includes the production of solar panels, wind turbines, batteries, inverters, and other essential elements for the generation and storage of renewable energy [161,162,163].

- Transportation and Construction: This stage covers the transportation of the manufactured components to the installation site and their assembly. In photovoltaic systems, this involves the installation of solar panels and the integration of balance-of-system (BOS) components, such as mounting structures and wiring. In wind energy, in addition to the installation of turbines, the construction of foundations is required, which often involves significant use of cement and steel reinforcement [164]. This phase can generate emissions due to the transportation of materials and the use of heavy machinery during installation [165].

- Operation and Maintenance: These activities are carried out during the operational life of RE installations to ensure their efficiency and functionality. These activities include regular cleaning of solar panels, technical inspections, adjustments to electrical systems, and proper lubrication of moving parts [166,167,168,169,170,171,172,173].

- Decommissioning and End of Life: At the end of the operational life of RE installations, proper decommissioning is essential. This process includes the removal of equipment, recycling, and the potential recovery of land [174,175,176,177,178]. Efficient management of this phase is key to minimizing environmental impact and maximizing the use of recyclable materials. However, the recycling of certain RE components remains a technological and logistical challenge at present [179,180,181,182].

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- NASA. Evidence—NASA Science. Available online: https://science.nasa.gov/climate-change/evidence/ (accessed on 28 February 2025).

- Filonchyk, M.; Peterson, M.P.; Zhang, L.; Hurynovich, V.; He, Y. Greenhouse gases emissions and global climate change: Examining the influence of CO2, CH4, and N2O. Sci. Total. Environ. 2024, 935, 173359. [Google Scholar] [CrossRef]

- Fawzy, S.; Osman, A.I.; Doran, J.; Rooney, D.W. Strategies for mitigation of climate change: A review. Environ. Chem. Lett. 2020, 18, 2069–2094. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Integrating Solar and Wind: Global Experience and Emerging Lessons; IEA: Paris, France, 2020. [Google Scholar]

- IPCC. Sixth Assessment Report—IPCC. Available online: https://www.ipcc.ch/assessment-report/ar6/ (accessed on 28 February 2025).

- IEA. Executive Summary—Energy Efficiency 2024—Analysis. Available online: https://www.iea.org/reports/energy-efficiency-2024/executive-summary (accessed on 11 December 2024).

- Our World in Data. 30% of the World’s Electricity Came from Renewable Sources in 2023. Available online: https://ourworldindata.org/data-insights/renewable-electricity-2023 (accessed on 1 March 2025).

- Conventional Energy—An Overview. ScienceDirect Topics. Available online: https://www.sciencedirect.com/topics/engineering/conventional-energy (accessed on 2 March 2025).

- United Nations Framework Convention on Climate Change (UNFCCC). The Paris Agreement. 2016. Available online: https://unfccc.int/sites/default/files/resource/parisagreement_publication.pdf (accessed on 27 March 2025).

- Owusu, P.A.; Asumadu-Sarkodie, S. A review of renewable energy sources, sustainability issues and climate change mitigation. Cogent Eng. 2016, 3, 1167990. [Google Scholar] [CrossRef]

- Ember. Global Electricity Review 2024. Available online: https://ember-energy.org/latest-insights/global-electricity-review-2024 (accessed on 1 March 2025).

- Al-Shetwi, A.Q.; Abidin, I.Z.; Mahafzah, K.A.; Hannan, M. Feasibility of future transition to 100% renewable energy: Recent progress, policies, challenges, and perspectives. J. Clean. Prod. 2024, 478, 143942. [Google Scholar] [CrossRef]

- Villares, M.; Işıldar, A.; van der Giesen, C.; Guinée, J. Does ex ante application enhance the usefulness of LCA? A case study on an emerging technology for metal recovery from e-waste. Int. J. Life Cycle Assess. 2017, 22, 1618–1633. [Google Scholar] [CrossRef]

- Gielen, D.; Lyons, M. Critical Materials for the Energy Transition: Rare Earth Elements. International Renewable Energy Agency (IRENA), Abu Dhabi. 2022. Available online: https://www.irena.org/-/media/Irena/Files/Technical-papers/IRENA_Rare_Earth_Elements_2022.pdf (accessed on 23 April 2025).

- Onu, P.; Pradhan, A.; Mbohwa, C. The potential of industry 4.0 for renewable energy and materials development—The case of multinational energy companies. Heliyon 2023, 9, e20547. [Google Scholar] [CrossRef]

- Gielen, D.; Boshell, F.; Saygin, D.; Bazilian, M.D.; Wagner, N.; Gorini, R. The role of renewable energy in the global energy transformation. Energy Strategy Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Cheilas, P.; Christou, T.; Karkalakos, S.; Kottaridi, C.; Michaelides, P.G. Rare earth elements and the US renewable economy: A causality exploration between critical materials and clean energy. Resour. Policy 2025, 101, 105491. [Google Scholar] [CrossRef]

- Kim, J.; Guillaume, B.; Chung, J.; Hwang, Y. Critical and precious materials consumption and requirement in wind energy system in the EU 27. Appl. Energy 2015, 139, 327–334. [Google Scholar] [CrossRef]

- Abbasi, T.; Abbasi, S. Biomass energy and the environmental impacts associated with its production and utilization. Renew. Sustain. Energy Rev. 2010, 14, 919–937. [Google Scholar] [CrossRef]

- Tejeda, R.C.R.; Valdés, Y.M. Environmental and Ecological Flows for Sustainability. In Clean Water and Sanitation; Filho, W.L., Azul, A.M., Brandli, L., Salvia, A.L., Wall, T., Eds.; Springer: Cham, Swizterland, 2020; pp. 1–10. [Google Scholar] [CrossRef]

- Abbasi, S.; Abbasi, N. The likely adverse environmental impacts of renewable energy sources. Appl. Energy 2000, 65, 121–144. [Google Scholar] [CrossRef]

- Laner, D.; Rechberger, H. Material Flow Analysis. In Special Types of Life Cycle Assessment; Finkbeiner, M., Ed.; Springer: Dordrecht, The Netherlands, 2016; pp. 293–332. [Google Scholar] [CrossRef]

- Guidi, G.; Violante, A.C.; De Iuliis, S. Environmental Impact of Electricity Generation Technologies: A Comparison between Conventional, Nuclear, and Renewable Technologies. Energies 2023, 16, 7847. [Google Scholar] [CrossRef]

- Sayed, E.T.; Wilberforce, T.; Elsaid, K.; Rabaia, M.K.H.; Abdelkareem, M.A.; Chae, K.-J.; Olabi, A. A critical review on environmental impacts of renewable energy systems and mitigation strategies: Wind, hydro, biomass and geothermal. Sci. Total. Environ. 2021, 766, 144505. [Google Scholar] [CrossRef]

- Soukka, R.; Väisänen, S.; Grönman, K.; Uusitalo, V.; Kasurinen, H. Life Cycle Assessment. In Encyclopedia of Sustainable Management; Idowu, S.O., Schmidpeter, R., Capaldi, N., Zu, L., Del Baldo, M., Abreu, R., Eds.; Springer: Cham, Switzerland, 2023; pp. 2218–2228. [Google Scholar] [CrossRef]

- Arent, D.; Pless, J.; Mai, T.; Wiser, R.; Hand, M.; Baldwin, S.; Heath, G.; Macknick, J.; Bazilian, M.; Schlosser, A.; et al. Implications of high renewable electricity penetration in the U.S. for water use, greenhouse gas emissions, land-use, and materials supply. Appl. Energy 2014, 123, 368–377. [Google Scholar] [CrossRef]

- Speirs, J.; Gross, R.; Contestabile, M.; Candelise, C.; Houari, Y.; Gross, B. Materials Availability for Low-Carbon Technologies: An Assessment of the Evidence, UKERC Technology & Policy Assessment. 2014. Available online: https://ukerc.rl.ac.uk/UCAT/PUBLICATIONS/Materials_Availability_for_Low_Carbon_Technologies.pdf (accessed on 17 April 2025).

- Liang, Y.; Kleijn, R.; Tukker, A.; van der Voet, E. Material requirements for low-carbon energy technologies: A quantitative review. Renew. Sustain. Energy Rev. 2022, 161, 112334. [Google Scholar] [CrossRef]

- Osman, A.I.; Chen, L.; Yang, M.; Msigwa, G.; Farghali, M.; Fawzy, S.; Rooney, D.W.; Yap, P.-S. Cost, environmental impact, and resilience of renewable energy under a changing climate: A review. Environ. Chem. Lett. 2022, 21, 741–764. [Google Scholar] [CrossRef]

- Motamedisedeh, O.; Omrani, S.; Karim, A.; Drogemuller, R.; Walker, G. A comprehensive review of optimum integration of photovoltaic-based energy systems. Renew. Sustain. Energy Rev. 2024, 207, 114935. [Google Scholar] [CrossRef]

- Lian, J.; Zhang, Y.; Ma, C.; Yang, Y.; Chaima, E. A review on recent sizing methodologies of hybrid renewable energy systems. Energy Convers. Manag. 2019, 199, 112027. [Google Scholar] [CrossRef]

- Pandey, A.; Tyagi, V.; Selvaraj, J.A.; Rahim, N.; Tyagi, S. Recent advances in solar photovoltaic systems for emerging trends and advanced applications. Renew. Sustain. Energy Rev. 2016, 53, 859–884. [Google Scholar] [CrossRef]

- Karali, N.; Shah, N. Bolstering supplies of critical raw materials for low-carbon technologies through circular economy strategies. Energy Res. Soc. Sci. 2022, 88, 102534. [Google Scholar] [CrossRef]

- Chen, L.; Gao, L.; Xing, S.; Chen, Z.; Wang, W. Zero-carbon microgrid: Real-world cases, trends, challenges, and future research prospects. Renew. Sustain. Energy Rev. 2024, 203, 114720. [Google Scholar] [CrossRef]

- Mobarakeh, M.R.; Kienberger, T. Climate neutrality strategies for energy-intensive industries: An Austrian case study. Clean. Eng. Technol. 2022, 10, 100545. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration (EIA). EIA Projects Nearly 50% Increase in World Energy Use by 2050, Led by Growth in Renewables. Available online: https://www.eia.gov/todayinenergy/detail.php?id=49876 (accessed on 2 March 2025).

- Koltsaklis, N.E.; Knápek, J. Assessing flexibility options in electricity market clearing. Renew. Sustain. Energy Rev. 2022, 173, 113084. [Google Scholar] [CrossRef]

- Statista. World Energy Consumption by Energy Source 2050. Available online: https://www.statista.com/statistics/222066/projected-global-energy-consumption-by-source/ (accessed on 2 March 2025).

- Kurz, D.; Bugała, A.; Głuchy, D.; Kasprzyk, L.; Szymenderski, J.; Tomczewski, A.; Trzmiel, G. The Use of Renewable Energy Sources in Road Construction and Public Transport: A Review. Energies 2024, 17, 2141. [Google Scholar] [CrossRef]

- Kılkış, Ş.; Krajačić, G.; Duić, N.; Rosen, M.A.; Al-Nimr, M.A. Sustainable development of energy, water and environment systems in the critical decade for climate action. Energy Convers. Manag. 2023, 296, 117644. [Google Scholar] [CrossRef]

- Moreno, J.; Moreno, J.; Campagnolo, L.; Campagnolo, L.; Boitier, B.; Boitier, B.; Nikas, A.; Nikas, A.; Koasidis, K.; Koasidis, K.; et al. The impacts of decarbonization pathways on Sustainable Development Goals in the European Union. Commun. Earth Environ. 2024, 5, 1–14. [Google Scholar] [CrossRef]

- Alizadeh, M.; Moghaddam, M.P.; Amjady, N.; Siano, P.; Sheikh-El-Eslami, M. Flexibility in future power systems with high renewable penetration: A review. Renew. Sustain. Energy Rev. 2016, 57, 1186–1193. [Google Scholar] [CrossRef]

- European Commission. Critical Raw Materials. Available online: https://single-market-economy.ec.europa.eu/sectors/raw-materials/areas-specific-interest/critical-raw-materials_en (accessed on 11 April 2025).

- UNEP. Global Environment Outlook 7. Available online: http://www.unep.org/geo/global-environment-outlook-7 (accessed on 11 April 2025).

- IEA. World Energy Outlook 2023—Analysis. Available online: https://www.iea.org/reports/world-energy-outlook-2023 (accessed on 11 April 2025).

- IRENA. End-of-Life Management Solar Photovoltaic Panels. Available online: https://www.irena.org/publications/2016/Jun/End-of-life-management-Solar-Photovoltaic-Panels (accessed on 20 March 2025).

- Lambert, D.M. (Ed.) Supply Chain Management: Processes, Partnerships, Performance, 4th ed.; Supply Chain Management Institute: Ponte Vedra Beach, FL, USA, 2014. [Google Scholar]

- Rajendra, K.; Garg, D.; Agarwal, A. Understanding of supply chain: A literature review. Int. J. Eng. Sci. Technol. 2011, 3, 2059–2072. [Google Scholar]

- Tracey, M.; Lim, J.; Vonderembse, M.A. The impact of supply-chain management capabilities on business performance. Supply Chain Manag. Int. J. 2005, 10, 179–191. [Google Scholar] [CrossRef]

- Heikkilä, J. From supply to demand chain management: Efficiency and customer satisfaction. J. Oper. Manag. 2002, 20, 747–767. [Google Scholar] [CrossRef]

- Tan, K.C. A framework of supply chain management literature. Eur. J. Purch. Supply Manag. 2001, 7, 39–48. [Google Scholar] [CrossRef]

- Jüttner, U.; Christopher, M.; Baker, S. Demand chain management-integrating marketing and supply chain management. Ind. Mark. Manag. 2007, 36, 377–392. [Google Scholar] [CrossRef]

- Mentzer, J.T.; DeWitt, W.; Keebler, J.S.; Min, S.; Nix, N.W.; Smith, C.D.; Zacharia, Z.G. Defining Supply Chain Management. J. Bus. Logist. 2001, 22, 1–25. [Google Scholar] [CrossRef]

- Chopra, S.; Meindl, P.; Kalra, D.V. Supply Chain Management: Strategy, Planning, and Operation; Pearson: Upper Saddle River, NJ, USA, 2005. [Google Scholar]

- Rexhausen, D.; Pibernik, R.; Kaiser, G. Customer-facing supply chain practices—The impact of demand and distribution management on supply chain success. J. Oper. Manag. 2012, 30, 269–281. [Google Scholar] [CrossRef]

- Boon-Itt, S.; Wong, C.Y.; Wong, C.W. Service supply chain management process capabilities: Measurement development. Int. J. Prod. Econ. 2017, 193, 1–11. [Google Scholar] [CrossRef]

- Zhang, J.; Yalcin, M.G.; Hales, D.N. Elements of paradoxes in supply chain management literature: A systematic literature review. Int. J. Prod. Econ. 2021, 232, 107928. [Google Scholar] [CrossRef]

- Lee, N.C.-A. Reconciling integration and reconfiguration management approaches in the supply chain. Int. J. Prod. Econ. 2021, 242, 108288. [Google Scholar] [CrossRef]

- Zaid, M.; Farooqi, R.; Azmi, S.N. Driving sustainable supply chain performance through digital transformation: The role of information exchange and responsiveness. Cogent Bus. Manag. 2024, 12, 2443047. [Google Scholar] [CrossRef]

- Wulf, C.; Zapp, P.; Schreiber, A.; Kuckshinrichs, W. Setting Thresholds to Define Indifferences and Preferences in PROMETHEE for Life Cycle Sustainability Assessment of European Hydrogen Production. Sustainability 2021, 13, 7009. [Google Scholar] [CrossRef]

- Lu, Z.; Li, Y. A Multi-Criteria Framework for Sustainability Evaluation of Hydrogen-Based Multi-Microgrid Systems under Triangular Intuitionistic Fuzzy Environment. Sustainability 2023, 15, 3708. [Google Scholar] [CrossRef]

- Sindi, S.; Roe, M. The Evolution of Supply Chains and Logistics. In Strategic Supply Chain Management: The Development of a Diagnostic Model; Sindi, S., Roe, M., Eds.; Springer: Cham, Switzerland, 2017; pp. 7–25. [Google Scholar] [CrossRef]

- Hu, S.J. Evolving Paradigms of Manufacturing: From Mass Production to Mass Customization and Personalization. Procedia CIRP 2013, 7, 3–8. [Google Scholar] [CrossRef]

- Lele, V.; Ajmeri, Y. Supply Chain Integration and Collaboration. In From Source to Shelf: Orchestrating a Supply Chain Symphony; Apress: Berkeley, CA, USA, 2024; pp. 83–117. [Google Scholar] [CrossRef]

- Ragatz, G. Success factors for integrating suppliers into new product development. J. Prod. Innov. Manag. 1997, 14, 190–202. [Google Scholar] [CrossRef]

- De Stefano, M.C.; Montes-Sancho, M.J. Supply chain environmental R&D cooperation and product performance: Exploring the network dynamics of positional embeddedness. J. Purch. Supply Manag. 2018, 24, 288–303. [Google Scholar] [CrossRef]

- Parast, M.M. The impact of R&D investment on mitigating supply chain disruptions: Empirical evidence from U.S. firms. Int. J. Prod. Econ. 2020, 227, 107671. [Google Scholar] [CrossRef]

- Becker, W.; Dietz, J. R&D cooperation and innovation activities of firms—Evidence for the German manufacturing industry. Res. Policy 2004, 33, 209–223. [Google Scholar] [CrossRef]

- Ambulkar, S.; Blackhurst, J.; Grawe, S. Firm’s resilience to supply chain disruptions: Scale development and empirical examination. J. Oper. Manag. 2015, 33–34, 111–122. [Google Scholar] [CrossRef]

- Jajja, M.S.S.; Chatha, K.A.; Farooq, S. Impact of supply chain risk on agility performance: Mediating role of supply chain integration. Int. J. Prod. Econ. 2018, 205, 118–138. [Google Scholar] [CrossRef]

- Alam, A.; Uddin, M.; Yazdifar, H.; Shafique, S.; Lartey, T. R&D investment, firm performance and moderating role of system and safeguard: Evidence from emerging markets. J. Bus. Res. 2020, 106, 94–105. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Feng, J. Identifying supply chain R&D partners via multilayer institutional cooperation network and tailored link prediction. Comput. Ind. Eng. 2025, 201, 110887. [Google Scholar] [CrossRef]

- Raygoza-Limón, M.E.; Jiménez-Sánchez, R.; Orduño-Osuna, H.; Mercado-Herrara, A.; Murrieta-Rico, F.N. Management of public and fiscal policies for the energy transition and sustainable development in Mexico. Rev. De Cienc. Tecnol. 2023, 6, e290. [Google Scholar] [CrossRef]

- Hall, J. Environmental Supply Chain Innovation. In Greening the Supply Chain; Sarkis, J., Ed.; Springer: London, UK, 2006; pp. 233–249. [Google Scholar] [CrossRef]

- Ehie, I.C.; Olibe, K. The effect of R&D investment on firm value: An examination of US manufacturing and service industries. Int. J. Prod. Econ. 2010, 128, 127–135. [Google Scholar] [CrossRef]

- Xu, X.; Liu, Z.; Liu, W.; Pei, C.; Wu, X.; Nie, Z. A sustainable development benchmarking framework for energy companies based on topic mining and knowledge graph: The case of oil and gas industry. Renew. Sustain. Energy Rev. 2024, 196, 114350. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Lim, M.K.; Wu, K.-J. Improving the benefits and costs on sustainable supply chain finance under uncertainty. Int. J. Prod. Econ. 2019, 218, 308–321. [Google Scholar] [CrossRef]

- Abdel-Basset, M.; Mohamed, R.; Sallam, K.; Elhoseny, M. A novel decision-making model for sustainable supply chain finance under uncertainty environment. J. Clean. Prod. 2020, 269, 122324. [Google Scholar] [CrossRef]

- Shang, M.; Luo, J. The Tapio Decoupling Principle and Key Strategies for Changing Factors of Chinese Urban Carbon Footprint Based on Cloud Computing. Int. J. Environ. Res. Public Health 2021, 18, 2101. [Google Scholar] [CrossRef]

- Zheng, J.; Liang, Z.-T.; Li, Y.; Li, Z.; Wu, Q.-H. Multi-Agent Reinforcement Learning with Privacy Preservation for Continuous Double Auction-Based P2P Energy Trading. IEEE Trans. Ind. Inform. 2024, 20, 6582–6590. [Google Scholar] [CrossRef]

- Hui, H.; Bao, M.; Ding, Y.; Meinrenken, C.J. Incorporating Multi-Energy Industrial Parks Into Power System Operations: A High-Dimensional Flexible Region Method. IEEE Trans. Smart Grid 2024, 16, 463–477. [Google Scholar] [CrossRef]

- Gu, M.; Yang, L.; Huo, B. The impact of information technology usage on supply chain resilience and performance: An ambidexterous view. Int. J. Prod. Econ. 2021, 232, 107956. [Google Scholar] [CrossRef]

- Das, S.; Hassan, H.K. Impact of sustainable supply chain management and customer relationship management on organizational performance. Int. J. Prod. Perform. Manag. 2021, 71, 2140–2160. [Google Scholar] [CrossRef]

- Nayal, K.; Raut, R.D.; Yadav, V.S.; Priyadarshinee, P.; Narkhede, B.E. The Impact of Sustainable Development Strategy on Sustainable Supply Chain Firm Performance in the Digital Transformation Era. Bus. Strateg. Environ. 2024, 33, 4974–4975. [Google Scholar] [CrossRef]

- Feizabadi, J. Machine learning demand forecasting and supply chain performance. Int. J. Logist. Res. Appl. 2021, 24, 245–262. [Google Scholar] [CrossRef]

- Carbonneau, R.; Laframboise, K.; Vahidov, R. Application of machine learning techniques for supply chain demand forecasting. Eur. J. Oper. Res. 2008, 184, 1140–1154. [Google Scholar] [CrossRef]

- Bin Rashid, A.; Kausik, A.K. AI revolutionizing industries worldwide: A comprehensive overview of its diverse applications. Hybrid Adv. 2024, 7, 100277. [Google Scholar] [CrossRef]

- Douaioui, K.; Oucheikh, R.; Benmoussa, O.; Mabrouki, C. Machine Learning and Deep Learning Models for Demand Forecasting in Supply Chain Management: A Critical Review. Appl. Syst. Innov. 2024, 7, 93. [Google Scholar] [CrossRef]

- Zhang, J.; Yuyang, W.; Zidu, W. Enhancing Supply Chain Forecasting with Machine Learning: A Data-Driven Approach to Demand Prediction, Risk Management, and Demand-Supply Optimization. J. Fintech Bus. Anal. 2024, 2, 1–5. [Google Scholar] [CrossRef]

- Raygoza-L, M.E.; Orduño-Osuna, J.H.; Anaya-Romo, M.; López-Linares, A.A.; Jimenez-Macias, R.V.; Herrera, A.M.; Murrieta-Rico, F.N. Energetic Efficiency and Sustainability: Artificial Intelligence in the Design of Public Policies. In Public Governance Practices in the Age of AI; IGI Global Scientific Publishing: Hershey, PA, USA, 2025; pp. 355–376. [Google Scholar] [CrossRef]

- Ma, K.; Yu, Y.; Yang, B.; Yang, J. Demand-Side Energy Management Considering Price Oscillations for Residential Building Heating and Ventilation Systems. IEEE Trans. Ind. Inform. 2019, 15, 4742–4752. [Google Scholar] [CrossRef]

- Martins, C.L.; Pato, M.V. Supply chain sustainability: A tertiary literature review. J. Clean. Prod. 2019, 225, 995–1016. [Google Scholar] [CrossRef]

- Parvathy, S.U.; Kolil, V.K.; Raman, R.; Vinuesa, R.; Achuthan, K. Integrating Sustainable Development Goals into Life Cycle Thinking: A Multidimensional Approach for Advancing Sustainability. Environ. Dev. Sustain. 2025, 27, 123–145. [Google Scholar] [CrossRef]

- Karmaker, C.L.; Al Aziz, R.; Ahmed, T.; Misbauddin, S.; Moktadir, A. Impact of industry 4.0 technologies on sustainable supply chain performance: The mediating role of green supply chain management practices and circular economy. J. Clean. Prod. 2023, 419, 138249. [Google Scholar] [CrossRef]

- Birkel, H.; Müller, J.M. Potentials of industry 4.0 for supply chain management within the triple bottom line of sustainability—A systematic literature review. J. Clean. Prod. 2021, 289, 125612. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Q.; Liu, J. Innovating Sustainability: VQA-Based AI for Carbon Neutrality Challenges. J. Organ. End User Comput. 2024, 36, 1–22. [Google Scholar] [CrossRef]

- Yozgat, S.; Erol, S. Sustainable Closed-Loop Supply Chain Network Design and Optimization. In Proceedings of the 16th International Conference on Management Science and Engineering Management—Volume 1; Xu, J., Ed.; Springer: Cham, Switzerland, 2022; pp. 705–726. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Lim, M.K.; Wu, K.-J.; Peng, W.-W. Improving sustainable supply chain capabilities using social media in a decision-making model. J. Clean. Prod. 2019, 227, 700–711. [Google Scholar] [CrossRef]

- Dossou, P.-E. Impact of Sustainability on the supply chain 4.0 performance. Procedia Manuf. 2018, 17, 452–459. [Google Scholar] [CrossRef]

- Kristal, M.M.; Huang, X.; Roth, A.V. The effect of an ambidextrous supply chain strategy on combinative competitive capabilities and business performance. J. Oper. Manag. 2010, 28, 415–429. [Google Scholar] [CrossRef]

- Bui, T.-D.; Tsai, F.M.; Tseng, M.-L.; Tan, R.R.; Yu, K.D.S.; Lim, M.K. Sustainable supply chain management towards disruption and organizational ambidexterity: A data driven analysis. Sustain. Prod. Consum. 2021, 26, 373–410. [Google Scholar] [CrossRef]

- Abdallah, A.B.; Al-Ghwayeen, W.S. Green supply chain management and business performance. Bus. Process. Manag. J. 2019, 26, 489–512. [Google Scholar] [CrossRef]

- Nayeri, S.; Sazvar, Z.; Heydari, J. Towards a responsive supply chain based on the industry 5.0 dimensions: A novel decision-making method. Expert Syst. Appl. 2023, 213, 119267. [Google Scholar] [CrossRef]

- Web of Science Core Collection. An Analysis of Metrics Used to Measure Performance in Green and Sustainable Supply Chains. Available online: https://www.webofscience.com/wos/woscc/full-record/WOS:000347501000037 (accessed on 25 March 2025).

- Negri, M.; Cagno, E.; Colicchia, C.; Sarkis, J. Integrating sustainability and resilience in the supply chain: A systematic literature review and a research agenda. Bus. Strat. Environ. 2021, 30, 2858–2886. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J. The design of a responsive sustainable supply chain network under uncertainty. Int. J. Adv. Manuf. Technol. 2015, 80, 427–445. [Google Scholar] [CrossRef]

- Earles, J.M.; Halog, A. Consequential life cycle assessment: A review. Int. J. Life Cycle Assess. 2011, 16, 445–453. [Google Scholar] [CrossRef]

- Caiado, R.G.G.; De Freitas Dias, R.; Mattos, L.V.; Quelhas, O.L.G.; Filho, W.L. Towards sustainable development through the perspective of eco-efficiency—A systematic literature review. J. Clean. Prod. 2017, 165, 890–904. [Google Scholar] [CrossRef]

- Beamon, B.M. Designing the green supply chain. Logist. Inf. Manag. 1999, 12, 332–342. [Google Scholar] [CrossRef]

- Ali, I.; Gölgeci, I. Where is supply chain resilience research heading? A systematic and co-occurrence analysis. Int. J. Phys. Distrib. Logist. Manag. 2019, 49, 793–815. [Google Scholar] [CrossRef]

- Hellweg, S.; Benetto, E.; Huijbregts, M.A.J.; Verones, F.; Wood, R. Life-cycle assessment to guide solutions for the triple planetary crisis. Nat. Rev. Earth Environ. 2023, 4, 471–486. [Google Scholar] [CrossRef]

- Rink, D.R.; Swan, J.E. Product life cycle research: A literature review. J. Bus. Res. 1979, 7, 219–242. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B. Life Cycle Assessment of construction materials: Methodologies, applications and future directions for sustainable decision-making. Case Stud. Constr. Mater. 2023, 19, e02326. [Google Scholar] [CrossRef]

- De Bhowmick, G.; Sarmah, A.K.; Sen, R. Zero-waste algal biorefinery for bioenergy and biochar: A green leap towards achieving energy and environmental sustainability. Sci. Total. Environ. 2019, 650, 2467–2482. [Google Scholar] [CrossRef] [PubMed]

- Kandpal, V.; Jaswal, A.; Gonzalez, E.D.R.S.; Agarwal, N. The Economics of Sustainable Energy Transition and the Circular Economy. In Sustainable Energy Transition: Circular Economy and Sustainable Financing for Environmental, Social and Governance (ESG) Practices; Springer: Cham, Switzerland, 2024; pp. 53–87. [Google Scholar] [CrossRef]

- Chen, B.; Xiong, R.; Li, H.; Sun, Q.; Yang, J. Pathways for sustainable energy transition. J. Clean. Prod. 2019, 228, 1564–1571. [Google Scholar] [CrossRef]

- Bošković, G.; Cvetanović, A.M.; Jovičić, N.; Jovanović, A.; Jovičić, M.; Milojević, S. Digital Technologies for Advancing Future Municipal Solid Waste Collection Services. In Digital Transformation and Sustainable Development in Cities and Organizations; IGI Global: Hershey, PA, USA, 2024; p. 26. [Google Scholar] [CrossRef]

- Liu, K.; Luo, J.; Faridi, M.Z.; Nazar, R.; Ali, S. Green shoots in uncertain times: Decoding the asymmetric nexus between monetary policy uncertainty and renewable energy. Energy Environ. 2025. [Google Scholar] [CrossRef]

- Gong, Q.; Wu, J.; Jiang, Z.; Hu, M.; Chen, J.; Cao, Z. An integrated design method for remanufacturing scheme considering carbon emission and customer demands. J. Clean. Prod. 2024, 476, 143681. [Google Scholar] [CrossRef]

- Xu, A.; Wang, W.; Zhu, Y. Does smart city pilot policy reduce CO2 emissions from industrial firms? Insights from China. J. Innov. Knowl. 2023, 8, 100367. [Google Scholar] [CrossRef]

- Energy.gov.au. General Manufacturing. Available online: https://www.energy.gov.au/business/sector-guides/manufacturing/general-manufacturing (accessed on 19 March 2025).

- Pan, S.Y.; Du, M.A.; Huang, I.T.; Liu, I.H.; Chang, E.E.; Chiang, P.C. Strategies on implementation of waste-to-energy (WTE) supply chain for circular economy system: A review. J. Clean. Prod. 2015, 108, 409–421. [Google Scholar] [CrossRef]

- Barbosa-Póvoa, A.P.; da Silva, C.; Carvalho, A. Opportunities and challenges in sustainable supply chain: An operations research perspective. Eur. J. Oper. Res. 2018, 268, 399–431. [Google Scholar] [CrossRef]

- Hülagü, S.; Dullaert, W.; Eruguz, A.S.; Heijungs, R.; Inghels, D. Integrating life cycle assessment into supply chain optimization. PLoS ONE 2025, 20, e0316710. [Google Scholar] [CrossRef]

- Carvalho, H.; Govindan, K.; Azevedo, S.G.; Cruz-Machado, V. Modelling green and lean supply chains: An eco-efficiency perspective. Resour. Conserv. Recycl. 2017, 120, 75–87. [Google Scholar] [CrossRef]

- Jiménez-Sánchez, R.; Raygoza-L, M.E.; Orduño-Osuna, J.H.; Limón-Molina, G.M.; Murrieta-Rico, F.N. Towards a Sustainable Supply Chain Management: Strategies and Challenges in the Era of Industry 4.0. In Advances in Logistics, Operations, and Management Science; Ramakrishna, Y., Srivastava, B., Eds.; IGI Global: Hershey, PA, USA, 2024; pp. 57–73. [Google Scholar] [CrossRef]

- Luthra, S.; Mangla, S.K. Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process Saf. Environ. Prot. 2018, 117, 168–179. [Google Scholar] [CrossRef]

- Tjahjono, B.; Esplugues, C.; Ares, E.; Pelaez, G. What does Industry 4.0 mean to Supply Chain? Procedia Manuf. 2017, 13, 1175–1182. [Google Scholar] [CrossRef]

- Nilsson, F.; Göransson, M. Critical factors for the realization of sustainable supply chain innovations—Model development based on a systematic literature review. J. Clean. Prod. 2021, 296, 126471. [Google Scholar] [CrossRef]

- Steubing, B.; Mutel, C.; Suter, F.; Hellweg, S. Streamlining scenario analysis and optimization of key choices in value chains using a modular LCA approach. Int. J. Life Cycle Assess. 2016, 21, 510–522. [Google Scholar] [CrossRef]

- Life Cycle Assessment. Interdisciplinary Life Cycle Assessment Laboratory. Available online: https://ilcal.uplb.edu.ph/life-cycle-assessment/ (accessed on 8 March 2025).

- Barkhordar, Z.A.; Fakouriyan, S.; Sheykhha, S. The role of energy subsidy reform in energy efficiency enhancement: Lessons learnt and future potential for Iranian industries. J. Clean. Prod. 2018, 197, 542–550. [Google Scholar] [CrossRef]

- García-Gusano, D.; Iribarren, D.; Martín-Gamboa, M.; Dufour, J. Life Cycle Sustainability Assessment of Electricity Generation from Renewable Energy Sources in the Spanish Context. Energies 2022, 15, 9173. [Google Scholar] [CrossRef]

- Farajzadeh, R.; Glasbergen, G.; Karpan, V.; Mjeni, R.; Boersma, D.M.; Eftekhari, A.A.; Casquera Garcia, A.; Bruining, J. Improved Oil Recovery Techniques and Their Role in Energy Efficiency and Reducing CO2 Footprint of Oil Production. J. Clean. Prod. 2022, 369, 133308. [Google Scholar] [CrossRef]

- Kiehbadroudinezhad, M.; Hosseinzadeh-Bandbafha, H.; Tajuddin, S.A.F.S.A.; Tabatabaei, M.; Aghbashlo, M. A critical review of life cycle assessment of renewable agricultural systems. Sustain. Energy Technol. Assess. 2024, 73, 104100. [Google Scholar] [CrossRef]

- Stindt, D. A generic planning approach for sustainable supply chain management—How to integrate concepts and methods to address the issues of sustainability? J. Clean. Prod. 2017, 153, 146–163. [Google Scholar] [CrossRef]

- Mandade, P.; Bakshi, B.R.; Yadav, G.D. Ethanol from Indian agro-industrial lignocellulosic biomass—A life cycle evaluation of energy, greenhouse gases, land and water. Int. J. Life Cycle Assess. 2015, 20, 1649–1658. [Google Scholar] [CrossRef]

- Cheirsilp, B.; Maneechote, W.; Srinuanpan, S.; Angelidaki, I. Microalgae as tools for bio-circular-green economy: Zero-waste approaches for sustainable production and biorefineries of microalgal biomass. Bioresour. Technol. 2023, 387, 129620. [Google Scholar] [CrossRef]

- Chopra, J.; Rangarajan, V.; Rathnasamy, S.; Dey, P. Life Cycle Assessment as a Key Decision Tool for Emerging Pretreatment Technologies of Biomass-to-Biofuel: Unveiling Challenges, Advances, and Future Potential. BioEnergy Res. 2024, 17, 857–876. [Google Scholar] [CrossRef]

- Kandpal, V.; Jaswal, A.; Gonzalez, E.D.R.S.; Agarwal, N. Environmental Impact Assessment and Sustainable Energy Transition. In Sustainable Energy Transition: Circular Economy and Sustainable Financing for Environmental, Social and Governance (ESG) Practices; Springer: Cham, Switzerland, 2024; pp. 273–288. [Google Scholar]

- Gohla-Neudecker, B.; Bowler, M.; Mohr, S. Battery 2nd Life: Leveraging the Sustainability Potential of EVs and Renewable Energy Grid Integration. In Proceedings of the 2015 International Conference on Clean Electrical Power (ICCEP), Taormina, Italy, 16–18 June 2015; ISBN 978-1-4799-8704-7. [Google Scholar]

- Nami, A.; Zare, F.; Ghosh, A. Multilevel Inverter Topology for Renewable Energy Grid Integration. IEEE Trans. Ind. Electron. 2013, 60, 4797–4808. [Google Scholar] [CrossRef]

- Edenhofer, O.; Pichs-Madruga, R.; Sokona, Y.; Farahani, E.; Kadner, S.; Seyboth, K.; Adler, A.; Baum, I.; Brunner, S.; Eickemeier, P.; et al. Technical Summary. In Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2014; pp. 33–107. [Google Scholar] [CrossRef]

- Zhang, J. Energy access challenge and the role of fossil fuels in meeting electricity demand: Promoting renewable energy capacity for sustainable development. Geosci. Front. 2024, 15, 101873. [Google Scholar] [CrossRef]

- Nwagu, C.N.; Ujah, C.O.; Kallon, D.V.; Aigbodion, V.S. Integrating solar and wind energy into the electricity grid for improved power accessibility. Unconv. Resour. 2025, 5, 100129. [Google Scholar] [CrossRef]

- Wang, J.; Chen, X.; Zhuang, M.; Li, Y.; Ruan, Z.; Wang, Y.; Zhang, N.; Song, J.; He, K.; Lu, X. Accelerating exploitation and integration of global renewable energy resources. Innovation 2025, 6, 100873. [Google Scholar] [CrossRef]

- Mignone, B.K.; Clarke, L.; Edmonds, J.A.; Gurgel, A.; Herzog, H.J.; Johnson, J.X.; Mallapragada, D.S.; McJeon, H.; Morris, J.; O’rourke, P.R.; et al. Drivers and implications of alternative routes to fuels decarbonization in net-zero energy systems. Nat. Commun. 2024, 15, 3938. [Google Scholar] [CrossRef]

- Naqvi, A.; Ali, A.; Altabey, W.A.; Kouritem, S.A. Energy Harvesting from Fluid Flow Using Piezoelectric Materials: A Review. Energies 2022, 15, 7424. [Google Scholar] [CrossRef]

- Obiuto, N.C.; Olajiga, O.K.; Adebayo, R.A. The Role of Nanomaterials in Energy Storage: A Comparative Review of USA and African Development. World J. Adv. Res. Rev. 2024, 18, 144–161. [Google Scholar] [CrossRef]

- Pranto, J.A.; Kadir, M.; Khan, Y.A. A Comprehensive Study of the Importance of Materials for Renewable Energy Generation. Control. Syst. Optim. Lett. 2024, 2, 310–316. [Google Scholar] [CrossRef]

- Wang, S.; Yang, L. Mineral resource extraction and resource sustainability: Policy initiatives for agriculture, economy, energy, and the environment. Resour. Policy 2024, 89, 104657. [Google Scholar] [CrossRef]

- Yi, X.; Lu, T.; Li, Y.; Ai, Q.; Hao, R. Collaborative planning of multi-energy systems integrating complete hydrogen energy chain. Renew. Sustain. Energy Rev. 2024, 210, 115147. [Google Scholar] [CrossRef]

- Wang, P.; Chen, L.-Y.; Ge, J.-P.; Cai, W.; Chen, W.-Q. Incorporating critical material cycles into metal-energy nexus of China’s 2050 renewable transition. Appl. Energy 2019, 253, 113612. [Google Scholar] [CrossRef]

- Kis, Z.; Pandya, N.; Koppelaar, R.H. Electricity generation technologies: Comparison of materials use, energy return on investment, jobs creation and CO2 emissions reduction. Energy Policy 2018, 120, 144–157. [Google Scholar] [CrossRef]

- Depraiter, L.; Goutte, S. The role and challenges of rare earths in the energy transition. Resour. Policy 2023, 86, 104137. [Google Scholar] [CrossRef]

- Li, J.; Peng, K.; Wang, P.; Zhang, N.; Feng, K.; Guan, D.; Meng, J.; Wei, W.; Yang, Q. Critical Rare-Earth Elements Mismatch Global Wind-Power Ambitions. One Earth 2020, 3, 116–125. [Google Scholar] [CrossRef]

- Skrúcaný, T.; Kendra, M.; Stopka, O.; Milojević, S.; Figlus, T.; Csiszár, C. Impact of the Electric Mobility Implementation on the Greenhouse Gases Production in Central European Countries. Sustainability 2019, 11, 4948. [Google Scholar] [CrossRef]

- IEA. The Role of Critical Minerals in Clean Energy Transitions. World Energy Outlook Special Report. 2021. Available online: https://www.iea.org/reports/the-role-of-critical-minerals-in-clean-energy-transitions (accessed on 23 April 2025).

- Dong, X.; Yu, M. Green bond issuance and green innovation: Evidence from China’s energy industry. Int. Rev. Financ. Anal. 2024, 94, 103281. [Google Scholar] [CrossRef]

- Dong, X.; Yu, M. Time-varying effects of macro shocks on cross-border capital flows in China's bond market. Int. Rev. Econ. Financ. 2024, 96, 103720. [Google Scholar] [CrossRef]

- Huang, Z.; Zhou, Y.; Lin, Y.; Zhao, Y. Resilience evaluation and enhancing for China’s electric vehicle supply chain in the presence of attacks: A complex network analysis approach. Comput. Ind. Eng. 2024, 195, 110416. [Google Scholar] [CrossRef]

- Hashmi, G.; Miettunen, K.; Peltola, T.; Halme, J.; Asghar, I.; Aitola, K.; Toivola, M.; Lund, P. Review of materials and manufacturing options for large area flexible dye solar cells. Renew. Sustain. Energy Rev. 2011, 15, 3717–3732. [Google Scholar] [CrossRef]

- Sun, C.; Wang, Y.; McMurtrey, M.D.; Jerred, N.D.; Liou, F.; Li, J. Additive manufacturing for energy: A review. Appl. Energy 2021, 282, 116041. [Google Scholar] [CrossRef]

- Kumar, M.; Sharma, S. Renewable Energy and Sustainable Transportation. In Role of Science and Technology for Sustainable Future; Sobti, R.C., Ed.; Springer Nature: Singapore, 2024; pp. 375–414. [Google Scholar] [CrossRef]

- UNEP. Building Materials and the Climate: Constructing a New Future. Available online: https://www.unep.org/resources/report/building-materials-and-climate-constructing-new-future (accessed on 19 March 2025).

- Sanz-Bobi, M.A. (Ed.) Use, Operation and Maintenance of Renewable Energy Systems: Experiences and Future Approaches; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar] [CrossRef]

- Abdulla, H.; Sleptchenko, A.; Nayfeh, A. Photovoltaic systems operation and maintenance: A review and future directions. Renew. Sustain. Energy Rev. 2024, 195, 114342. [Google Scholar] [CrossRef]

- Leite, G.d.N.P.; Araújo, A.M.; Rosas, P.A.C. Prognostic techniques applied to maintenance of wind turbines: A concise and specific review. Renew. Sustain. Energy Rev. 2018, 81, 1917–1925. [Google Scholar] [CrossRef]

- Ding, F.; Tian, Z.; Zhao, F.; Xu, H. An integrated approach for wind turbine gearbox fatigue life prediction considering instantaneously varying load conditions. Renew. Energy 2018, 129, 260–270. [Google Scholar] [CrossRef]

- Pinciroli, L.; Baraldi, P.; Ballabio, G.; Compare, M.; Zio, E. Optimization of the Operation and Maintenance of renewable energy systems by Deep Reinforcement Learning. Renew. Energy 2022, 183, 752–763. [Google Scholar] [CrossRef]

- Scaife, A.D. Improve predictive maintenance through the application of artificial intelligence: A systematic review. Results Eng. 2023, 21, 101645. [Google Scholar] [CrossRef]

- Iftikhar, H.; Sarquis, E.; Branco, P.J.C. Why Can Simple Operation and Maintenance (O&M) Practices in Large-Scale Grid-Connected PV Power Plants Play a Key Role in Improving Its Energy Output? Energies 2021, 14, 3798. [Google Scholar] [CrossRef]

- Keisang, K.; Bader, T.; Samikannu, R. Review of Operation and Maintenance Methodologies for Solar Photovoltaic Microgrids. Front. Energy Res. 2021, 9, 730230. [Google Scholar] [CrossRef]

- Invernizzi, D.C.; Locatelli, G.; Velenturf, A.; Love, P.E.; Purnell, P.; Brookes, N.J. Developing policies for the end-of-life of energy infrastructure: Coming to terms with the challenges of decommissioning. Energy Policy 2020, 144, 111677. [Google Scholar] [CrossRef]

- Ove Arup & Partners Ltd.; UK Department of Business, Energy and Industrial Strategy. Cost Estimation and Liabilities in Decommissioning Offshore Wind Installations. 2018. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/725316/Cost_and_liabilities_of_OWF_decommissioning_public_report.pdf (accessed on 19 March 2025).

- Wyatt, J. Repowering and Decommissioning: End of Life for Renewable Energy; Great Plains Institute: Minneapolis, MN, USA, 2020; Available online: https://www.betterenergy.org/wp-content/uploads/2020/10/Repowering-and-Decommisioning.pdf (accessed on 23 April 2025).

- Amrollahi Biyouki, Z.; Zaman, A.; Marinova, D.; Minunno, R.; Askari Shayegan, M. Solar Photovoltaics Value Chain and End-of-Life Management Practices: A Systematic Literature Review. Sustainability 2024, 16, 7038. [Google Scholar] [CrossRef]

- Pinciroli, L.; Baraldi, P.; Ballabio, G.; Zio, E. Propuesta de una estrategia de mantenimiento optimizada para sistemas de energía renovable utilizando aprendizaje profundo por refuerzo. Renew. Energy 2022, 183, 752–763. [Google Scholar] [CrossRef]

- Habib, K.; Hamelin, L.; Wenzel, H. A dynamic perspective of the geopolitical supply risk of metals. J. Clean. Prod. 2016, 133, 850–858. [Google Scholar] [CrossRef]

- Caetano, N.S.; Martins, F.F.; Oliveira, G.M. Life cycle assessment of renewable energy technologies. In The Renewable Energy-Water-Environment Nexus; Elsevier: Amsterdam, The Netherlands, 2024; pp. 37–79. [Google Scholar] [CrossRef]

- International Renewable Energy Agency; IEA-PVPS. End-of-Life Solar PV Panels. 2016. Available online: https://iea-pvps.org/key-topics/irena-iea-pvps-end-of-life-solar-pv-panels-2016/ (accessed on 20 March 2025).

- Heffron, R.J. Energy law for decommissioning in the energy sector in the 21st century. J. World Energy Law Bus. 2018, 11, 189–195. [Google Scholar] [CrossRef]

- Xia, Y.; Huang, Y.; Fang, J. A generalized Nash-in-Nash bargaining solution to allocating energy loss and network usage cost of buildings in peer-to-peer trading market. Sustain. Energy Grids Netw. 2025, 42, 101628. [Google Scholar] [CrossRef]

- Curran, M.A. Life Cycle Assessment: A review of the methodology and its application to sustainability. Curr. Opin. Chem. Eng. 2013, 2, 273–277. [Google Scholar] [CrossRef]

- Ekvall, T. Attributional and Consequential Life Cycle Assessment. In Sustainability Assessment at the 21st Century; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- Baz, K.; Zhu, Z. Life cycle analysis of green technologies: Assessing the impact of environmental policies on carbon emissions and energy efficiency. Geosci. Front. 2025, 16, 102004. [Google Scholar] [CrossRef]

- Singh, A.; Olsen, S.I.; Pant, D. Importance of Life Cycle Assessment of Renewable Energy Sources. In Life Cycle Assessment of Renewable Energy Sources. Green Energy and Technology; Singh, A., Pant, D., Olsen, S., Eds.; Springer: London, UK, 2013; pp. 1–11. [Google Scholar] [CrossRef]

- Song, G.; Lu, Y.; Liu, B.; Duan, H.; Feng, H.; Liu, G. Photovoltaic panel waste assessment and embodied material flows in China, 2000–2050. J. Environ. Manag. 2023, 338, 117675. [Google Scholar] [CrossRef]

- Chowdhury, M.S.; Rahman, K.S.; Chowdhury, T.; Nuthammachot, N.; Techato, K.; Akhtaruzzaman, M.; Tiong, S.K.; Sopian, K.; Amin, N. An overview of solar photovoltaic panels’ end-of-life material recycling. Energy Strat. Rev. 2020, 27, 100431. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). Solar PV Recycling Offers Significant Untapped Business Opportunity—New Report Shows. 2016. Available online: https://www.irena.org/news/pressreleases/2016/Jun/Solar-PV-Recycling-Offers-Significant-Untapped-Business-Opportunity-New-Report-Shows (accessed on 21 March 2025).

- Tan, V.; Deng, R.; Egan, R. Solar photovoltaic waste and resource potential projections in Australia, 2022–2050. Resour. Conserv. Recycl. 2023, 202, 107316. [Google Scholar] [CrossRef]

- Al Zaabi, B.; Ghosh, A. Managing photovoltaic Waste: Sustainable solutions and global challenges. Sol. Energy 2024, 283, 112985. [Google Scholar] [CrossRef]

- Heath, G.; Weckend, S.; Wade, A. End-of-Life Management: Solar Photovoltaic Panels; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2016. Available online: https://research-hub.nrel.gov/en/publications/end-of-life-management-solar-photovoltaic-panels-2 (accessed on 21 March 2025).

- Viebahn, P.; Lechtenböhmer, J.; Samadi, J.; Vallentin, A.; Fischedick, J. Materials, Energy, Water, and Emissions Nexus Impacts on the Future Contribution of PV Solar Technologies to Global Energy Scenarios. Sci. Rep. 2019, 9, 55853. Available online: https://www.nature.com/articles/s41598-019-55853-w (accessed on 24 March 2025).

- Saad, A.M.H. Analyzing the Lifecycle of Solar Panels Including Raw Material Sourcing, Manufacturing, and End-of-Life Disposal. World J. Adv. Eng. Technol. Sci. 2024, 13, 966–978. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Al-Othman, A.; Kafiah, F.; Abdelsalam, E.; Almomani, F.; Alkasrawi, M. Environmental impacts of solar photovoltaic systems: A critical review of recent progress and future outlook. Sci. Total. Environ. 2021, 759, 143528. [Google Scholar] [CrossRef]

- Baldassarre, B.; Carrara, S. Critical raw materials, circular economy, sustainable development: EU policy reflections for future research and innovation. Resour. Conserv. Recycl. 2024, 215, 108060. [Google Scholar] [CrossRef]

- Pell, R.; Tijsseling, L.; Goodenough, K.; Wall, F.; Dehaine, Q.; Grant, A.; Deak, D.; Yan, X.; Whattoff, P. Towards sustainable extraction of technology materials through integrated approaches. Nat. Rev. Earth Environ. 2021, 2, 665–679. Available online: https://www.nature.com/articles/s43017-021-00211-6 (accessed on 18 March 2025). [CrossRef]

- Ludin, N.A.; Mustafa, N.I.; Hanafiah, M.M.; Ibrahim, M.A.; Teridi, M.A.M.; Sepeai, S.; Zaharim, A.; Sopian, K.; Fthenakis, A.A.; Kim, H.C. Prospects of life cycle assessment of renewable energy from solar photovoltaic technologies: A review. Renew. Sustain. Energy Rev. 2018, 96, 11–28. [Google Scholar] [CrossRef]

- Shannak, S.; Cochrane, L.; Bobarykina, D. Strategic analysis of metal dependency in the transition to low-carbon energy: A critical examination of nickel, cobalt, lithium, graphite, and copper scarcity using IEA future scenarios. Energy Res. Soc. Sci. 2024, 118, 103773. [Google Scholar] [CrossRef]

- Moore, K.R.; Marquis, E.; Shanks, K.; Wall, F. Mining of Primary Raw Materials as the Critical Foundation of ‘Sustainable’ Metals: A Wicked Problem for Technology Innovation Clusters. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2024, 382, 20230241. [Google Scholar] [CrossRef]

- Nicholson, S.; Heath, G. Life Cycle Greenhouse Gas Emissions from Electricity Generation: Update; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2021. Available online: https://www.nrel.gov/docs/fy21osti/80580.pdf (accessed on 23 April 2025).

- European Commission. Report from the Commission to the European Parliament and the Council on the Functioning of the European Carbon Market in 2023; COM(2024) 538 final; European Commission: Brussels, Belgium, 2024; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52024DC0538 (accessed on 25 March 2025).

- Life Cycle Assessment Harmonization. Available online: https://www.nrel.gov/analysis/life-cycle-assessment.html (accessed on 25 March 2025).

- Heath, G.; Warner, E.; O’Donoughue, P. Harmonization of Energy Generation Life Cycle Assessments (LCA): FY2010 LCA Milestone Report; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2010. Available online: https://www.nrel.gov/docs/gen/fy11/47492.pdf (accessed on 23 April 2025).

- U.S. EPA. E3 Sustainability Tools. Available online: https://www.epa.gov/e3/e3-sustainability-tools (accessed on 25 March 2025).

- U.S. Environmental Protection Agency (EPA). USEPA/ElectricityLCI (Python Repository). 2025. Available online: https://github.com/USEPA/ElectricityLCI (accessed on 25 March 2025).

- Nandwani, A.C. Remanufacturing. In Sustainable Manufacturing and Remanufacturing; Springer: Berlin/Heidelberg, Germany, 2024; Available online: https://link.springer.com/chapter/10.1007/978-3-031-77106-4_3 (accessed on 19 March 2025).

- Jafar, H.T.; Tavakoli, O.; Bidhendi, G.N.; Alizadeh, M. Sustainable electricity supply planning: A nexus-based optimization approach. Renew. Sustain. Energy Rev. 2024, 195, 114316. [Google Scholar] [CrossRef]

- International Energy Agency (IEA); IRENA. Life Cycle Inventories and Life Cycle Assessments of Photovoltaic Systems 2020, Task 12 PV Sustainability. 2020. Available online: https://www.researchgate.net/publication/347999880_Life_Cycle_Inventories_and_Life_Cycle_Assessments_of_Photovoltaic_Systems_2020_Task_12_PV_Sustainability (accessed on 13 April 2025).

- Schell, D. Wind LCA Harmonization (Fact Sheet); Natl. Renew. Energy Lab. (NREL): Applewood, Colorado, 2013. Available online: https://research-hub.nrel.gov/en/publications/wind-lca-harmonization-fact-sheet-nrel-national-renewable-energy- (accessed on 13 April 2025).

- European Environment Agency (EEA). Circular Economy Country Profile—Sweden; Report No. 2022/5; EEA: Copenhagen, Denmark, 2022; Available online: https://www.eionet.europa.eu/etcs/etc-ce (accessed on 13 April 2025).

| LCA Phases Renewable Energy | Supply Chain Stage | Similarities | Differences |

|---|---|---|---|

| Manufacturing | Production and Manufacturing | Both involve the creation of products, such as solar panels, wind turbines, or components within the supply chain. | Manufacturing RE equipment focuses on producing energy technology, while the supply chain encompasses a broader range of products. |

| Transport | Logistics and Distribution | Both involve the movement of products from the manufacturing site to the installation site. | Transport of renewable products focuses more on heavy, specific equipment, such as wind turbines, whereas the supply chain can involve products from various sectors. |

| Installation | Assembly and Installation | Both stages involve the installation of equipment on-site. | RE installation focuses specifically on implementing complex technological systems, while installation in the supply chain can be more general. |

| Operation and Maintenance | Operations and Inventory Management | Both stages focus on operational efficiency and the maintenance of systems or products. | In RE, operation refers to continuous energy generation, while inventory management in the supply chain refers more to the distribution of products. |

| Dismantling and End of Life | Dismantling and Recycling | Both involve handling products at the end of their life cycle. | RE dismantling focuses on waste management and recycling of specific materials, while the supply chain may have a broader focus on product recycling. |

| Metric | Unit of Measurement | Description |

|---|---|---|

| Carbon Footprint (CO2) | kg CO2-eq/kWh | Measures GHGs associated with each life cycle stage. |

| Energy Consumption | MJ or kWh | Indicates the amount of energy used in each life cycle phase. |

| Natural Resource Use | kg or tons | Evaluates the use of materials such as rare earths, metals, and water. |

| Water Footprint | m3 of water/kWh | Measures the water consumed or polluted throughout the system’s lifetime. |

| Waste Generation | kg/kWh | Quantifies waste generated during manufacturing, operation, and end of life. |

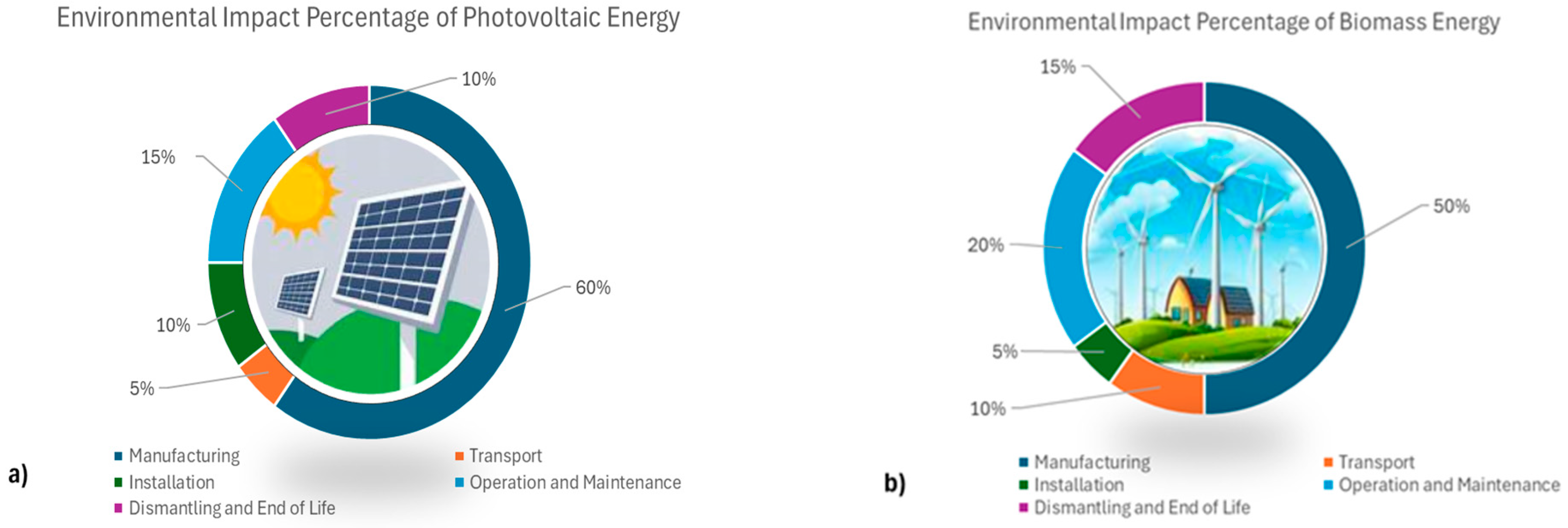

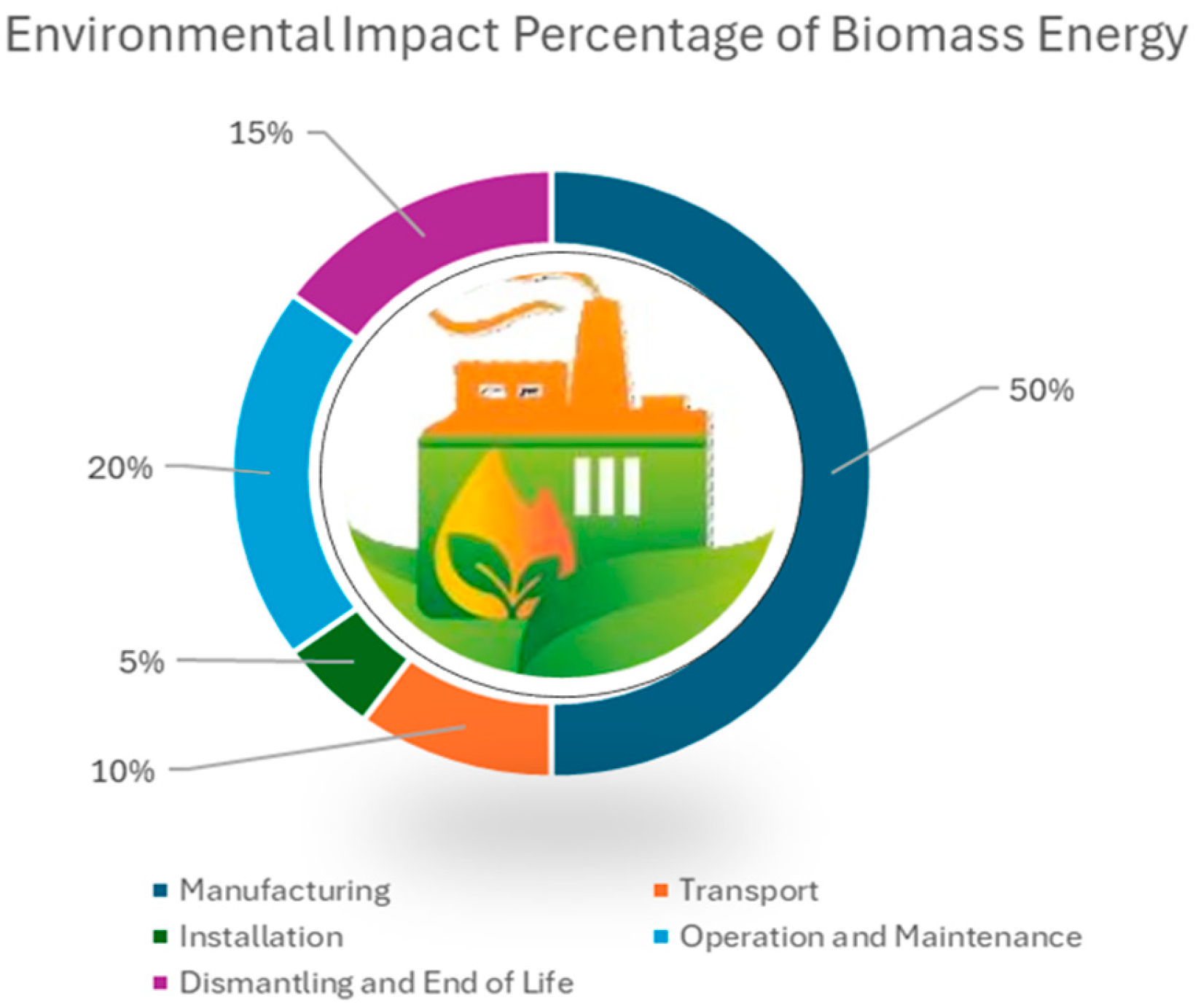

| Energy Type | Extraction and Processing of Materials | Component Manufacturing | Transport and Construction | Operation and Maintenance | Decommissioning and End of Life |

|---|---|---|---|---|---|

| Solar Energy | Emissions from the extraction of silica, silver, and other materials. Environmental impact: Land use and water consumption during material extraction | Emissions due to high energy demand in panel production; use of chemicals in manufacturing | Emissions of CO2 from the transportation of materials and panel installation | CO2 emissions are practically negligible during operation | Emissions from solar panel waste at the end of their life cycle; recycling is limited but under development |

| Wind Energy | Emissions from the extraction of metals such as steel, copper, and rare earth elements; mining impact | Emissions generated during the manufacturing of wind turbines, which requires energy-intensive processes and high-resistance materials | Emissions of CO2 from the transport of components and infrastructure construction | CO2 emissions during operation are practically negligible. Environmental impact: habitat disruption and increased mortality of birds due to turbines. | Emissions from turbine decommissioning, with partial material recycling; complex waste management |

| Biomass | Emissions from biomass cultivation, harvesting, and processing, impacting land and water use | Emissions from biomass conversion into biofuels or pellets, requiring industrial processes | Emissions from biomass transportation to power plants | Emissions are present during operation Environmental impact: CO2 emissions and other GHGs released during combustion | Emissions from ash and gas residues; possible reuse in fertilization or carbon capture. |

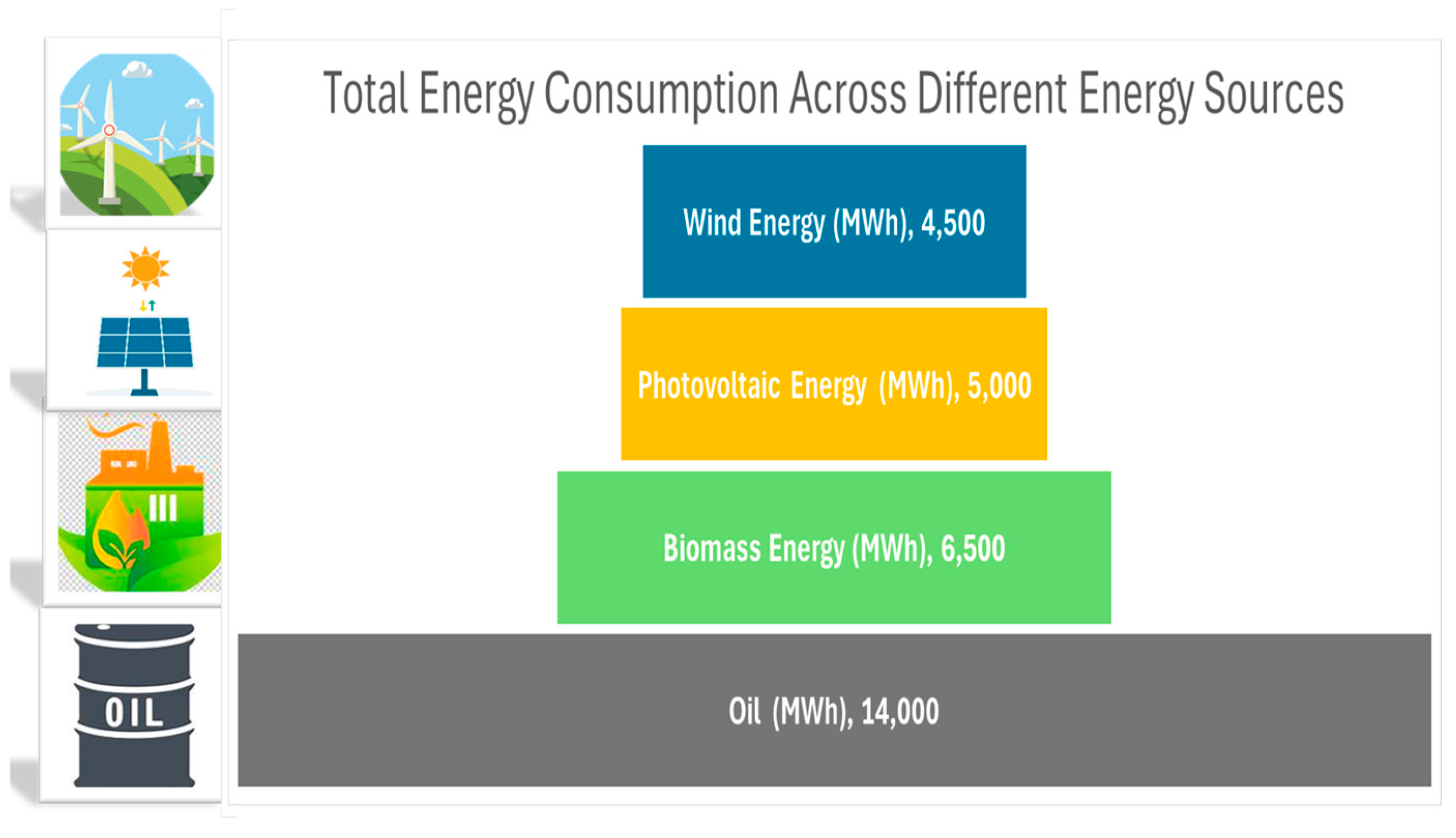

| Energy Source | Raw Material Extraction (kg CO2-eq/kWh) | Manufacturing (kg CO2-eq/kWh) | Transport (kg CO2-eq/kWh) | Installation (kg CO2-eq/kWh) | Operation & Maintenance (kg CO2-eq/kWh) | End of Life (kg CO2-eq/kWh) | Total CO2 in Life Cycle (kg CO2-eq/kWh) |

|---|---|---|---|---|---|---|---|

| Solar PV | 0.018–0.180 | 0.018–0.180 | 0–0.001 | 0–0.001 | 0.002–0.005 | 0.002–0.005 | 0.026–0.190 |

| Wind | 0.007–0.056 | 0.007–0.056 | 0–0.001 | 0–0.001 | 0.001–0.004 | 0.001–0.004 | 0.011–0.064 |

| Biomass | 0.130–0.420 | 0.130–0.420 | 0.050–0.100 | 0.050–0.100 | 0.010–0.050 | 0.010–0.050 | 0.230–0.620 |

| Oil | 0.510–1.170 | 0.510–1.170 | 0.050–0.100 | 0.050–0.100 | 0.150–0.220 | 0.100–0.200 | 0.650–1.300 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raygoza-Limón, M.E.; Orduño-Osuna, J.H.; Trujillo-Hernández, G.; Bravo-Zanoguera, M.E.; Amezquita Garcia, J.A.; Ramírez-Hernández, L.R.; Flores-Fuentes, W.; Antúnez-García, J.; Murrieta-Rico, F.N. Supply Chain Management in Renewable Energy Projects from a Life Cycle Perspective: A Review. Appl. Sci. 2025, 15, 5043. https://doi.org/10.3390/app15095043

Raygoza-Limón ME, Orduño-Osuna JH, Trujillo-Hernández G, Bravo-Zanoguera ME, Amezquita Garcia JA, Ramírez-Hernández LR, Flores-Fuentes W, Antúnez-García J, Murrieta-Rico FN. Supply Chain Management in Renewable Energy Projects from a Life Cycle Perspective: A Review. Applied Sciences. 2025; 15(9):5043. https://doi.org/10.3390/app15095043

Chicago/Turabian StyleRaygoza-Limón, María E., J. Heriberto Orduño-Osuna, Gabriel Trujillo-Hernández, Miguel E. Bravo-Zanoguera, José Alejandro Amezquita Garcia, Luis Roberto Ramírez-Hernández, Wendy Flores-Fuentes, Joel Antúnez-García, and Fabian N. Murrieta-Rico. 2025. "Supply Chain Management in Renewable Energy Projects from a Life Cycle Perspective: A Review" Applied Sciences 15, no. 9: 5043. https://doi.org/10.3390/app15095043

APA StyleRaygoza-Limón, M. E., Orduño-Osuna, J. H., Trujillo-Hernández, G., Bravo-Zanoguera, M. E., Amezquita Garcia, J. A., Ramírez-Hernández, L. R., Flores-Fuentes, W., Antúnez-García, J., & Murrieta-Rico, F. N. (2025). Supply Chain Management in Renewable Energy Projects from a Life Cycle Perspective: A Review. Applied Sciences, 15(9), 5043. https://doi.org/10.3390/app15095043