Abstract

With increasing exterior temperature, steel corrosion and concrete disintegration in RC (reinforced concrete) are severe due to the increased transport of harmful ions. A durability design for the intended service life should be ensured for the changing exterior conditions. In this study, for the concrete used in a UAE (United Arab Emirates) nuclear power plant structure, the diffusion coefficient of sulfate ions affected by temperature was evaluated through a natural diffusion cell test, and the service life in the structure was calculated through deterministic and probabilistic methods. As the temperature increased from 20 °C to 50 °C, the results decreased rapidly due to an enlarged diffusion coefficient, and its variation significantly increased with unstable ion transport. In the probabilistic method, the effect of the mean and COV (coefficient of variation) for each design parameter on service life was analyzed, which suggested the importance of enough cover depth design with COV under 0.2.

1. Introduction

Service life in PSC (prestressed concrete) and RC (reinforced concrete) structures is very important for securing the performance of the structures during their use period, and each country plans these structures with consideration of the target performance and intended service life [1,2]. Concrete is a porous construction material, which partially permits the transport of moisture and harmful ions, and concrete structures have been exposed to various deterioration environments. In the deterioration of chloride attack and carbonation, embedded steel corrosion is initiated and accelerated through penetrated chloride ions and carbon dioxide from outside, so they are considered as major deterioration in each country [3,4,5]. Particularly, these two deterioration mechanisms have clear critical conditions since they accelerate reinforcement corrosion, and the service life can be evaluated or determined based on the critical threshold, such as critical chloride content, which initiates corrosion in outer steel and carbonation depth, which exceeds the cover depth.

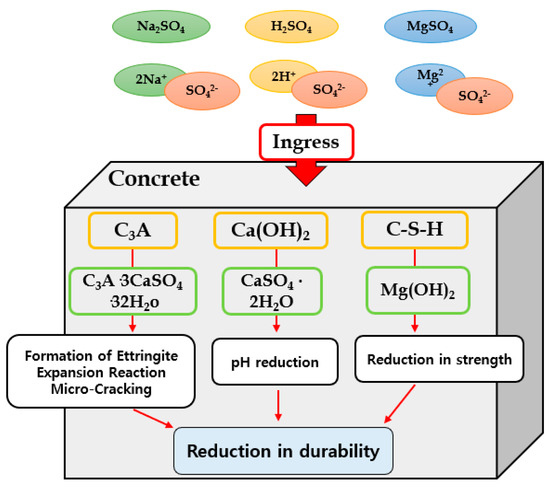

In the case of freezing–thawing action and chemical erosion for concrete, which cause the decomposition of the cement matrix, concrete strength and porosity play an important role in resistance to these deteriorations. In particular, chemical erosion, which is mainly caused by sulfate ions, leads to the penetration of sulfate ions, expansion of cement hydrates, micro cracking in the pore structure, and acceleration of deterioration. Sulfate ions from outside react with the cement hydrates to produce gypsum and ettringite, which results in the swelling and disintegration of the pore structure [6,7,8]. Many studies have been performed on these reactions, and various research results have been reported on deterioration modeling using thermodynamic equations, strength degradation modeling, and combined deterioration with freeze–thawing action [9,10,11].

For chloride attack and carbonation, many studies have been proposed for evaluating service life from semi-empirical models with experimental parameters to thermodynamic models considering moisture transport and ion reactions with absorption [3,5,12,13,14]; however, regarding sulfate attack, a clear model has not been adopted for international codes or specification. It is very difficult to quantify the deterioration in the design stage since the deteriorated concrete depth and sulfate diffusion change simultaneously, and the complex reactions between the cement hydrates and the sulfuric acid ions in liquid and gaseous phases occur with micro cracking at the same time [3,5,7,11]. For service life design at the meso-level, multilayer diffusion theory and the linear degradation depth method are widely used [15,16,17], where the diffusion coefficient and cover depth are recognized as key parameters.

In the former theory [15,16], the time-dependent diffusion of sulfate ions was assumed, and the intruded sulfate ions were compared with the critical concentration, like the evaluation technique for chloride penetration based on the skin depth theory [18]. In the latter theory [5,17], it is assumed that the deterioration depth due to sulfate ions linearly increases with the exposure period and diffusion coefficient, considering the reaction of cement component (Al2O3) and sulfate concentration. In previous studies and tests [6,7], several models were proposed with regression analysis of the test parameters, but it is difficult to apply them to various concrete mixtures and exposure conditions. The ion transport is greatly affected by exterior conditions and the deterioration depth due to sulfate ions and also varies with the temperature. The diffusion behavior trend with increasing temperature is known to follow the Arrhenius Law, and the variation in the measured diffusion coefficient significantly increases as well, which yields a change in service life [19,20,21]. For evaluating the service life in the target structure, it is very important to quantify not only the design parameters such as cover depth, diffusion coefficient, and mix conditions but also external environmental conditions such as external sulfate concentration and temperature.

The consideration of exterior temperature is significantly important since constant design parameters are changed with temperature and it gives an impact on service life. For this reason, the temperature effect on the diffusion coefficient, which is a key parameter for service life design, should be evaluated. For chloride ion and CO2 diffusion, research on temperature effects has been performed, but its effect on sulfate ions has barely been studied since sulfate ions are mainly considered in footing and foundation systems on the ground (soil). However, high sulfate ions in ground water or cooling water in drainage RC systems may have more severe durability problems due to high temperature. In the study, the service life of an RC drainage structure exposed to high sulfate ions was evaluated through a linear degradation depth model, considering the temperature-dependent diffusion coefficient. For this purpose, the diffusion coefficient of sulfate ions was experimentally evaluated through the natural diffusion cell test from 20 °C to 50 °C (10 °C interval), and the probabilistic parameters (mean and COV) were evaluated for each temperature. The activation energy of sulfate ions was derived based on the Arrhenius Law and utilized for the temperature-dependent diffusion coefficient. The changes in service life were evaluated through deterministic and probabilistic methods, and the effect of design parameters on service life was also investigated with the temperature effect.

2. Deterministic and Probabilistic Approach in Service Life Evaluation

Durability design can be classified into a deterministic method and a probabilistic method. When clear design variable definition and design formulas are ready, a deterministic method is reasonable, but the probabilistic method can be adopted for considering engineering uncertainties [22,23]. The deterministic method requires a clear critical condition, and it is determined by the physical governing equation. Regarding chloride attack, the durability design is usually followed by the procedure that the chloride concentration penetrated from the outside during the intended service life should be lower than the critical chloride concentration, which causes corrosion initiation at the outer steel [3,5,12]. In the case of carbonation, the increasing carbonation depth with period should be lower than the design cover depth during the intended service life [3,24]. Service life can be secured by enhancing cover depth, protective coating, and improving concrete mix conditions. In addition, a margin for safe design is considered through an environmental load coefficient of 1.1 to 1.3 for the deterioration value over time and an environmental reduction coefficient of 0.7 to 0.8 for the threshold value to be resisted [3,4].

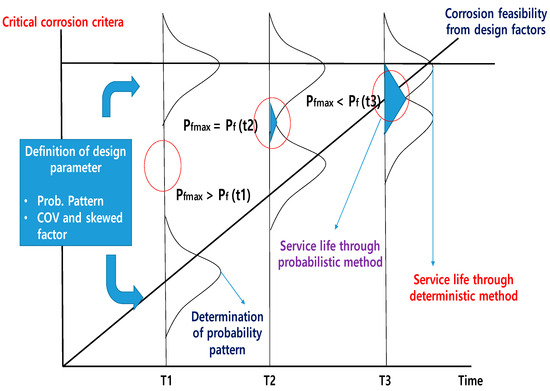

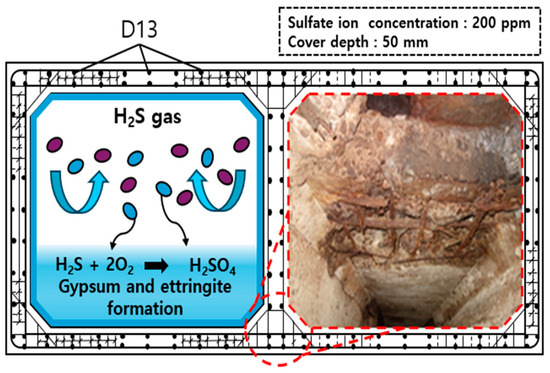

Probability random variables for design parameters and their patterns should be defined in the probabilistic method, and the probability of durability failure during the intended service period should be maintained below the target durability failure probability, around 0.08~0.10, which depends on the significance of the target structures and maintenance difficulties [4,22]. Currently, several models with degradation evaluation with spatial variability (time and space domain) are actively studied and applied to durability design [23]. Table 1 summarizes the engineering uncertainties considering sulfate attack, and a schematic diagram of deterministic and probabilistic models for the deterioration depth equation is shown in Figure 1. The deterioration mechanism from sulfate ions is shown in Figure 2 [11].

Table 1.

Engineering uncertainties for sulfate erosion.

Figure 1.

Schematic diagram for deterministic and probabilistic method.

Figure 2.

Deteriorated concrete from sulfate ion intrusion.

3. Evaluation of Service Life Using Different Design Approaches

3.1. Design Parameters and Governing Equations

External conditions like temperature and humidity have a great effect on the diffusion coefficient. For humidity, it is greatly reduced below 75% for chloride ions [25], so that the humidity inside is implemented as a function of saturation in the thermodynamic coupling model [13,14]. Considering the long-term service life, the average saturation and the external humidity become similar, so the change in humidity becomes a relatively small problem in the case of full saturated conditions like sea water. For the temperature effect on ion diffusion, it significantly varies with mixing proportions, materials to be used, coarse aggregate use, and test method types [26,27,28,29,30].

In this study, service life evaluation on sulfate erosion was performed focusing on the evaluation techniques and the temperature effect in sulfate ion diffusion. The technique of deterioration depth is listed in Equation (1) [16,17].

where R is the deterioration rate of concrete by sulfate ions, Zp is the predicted sulfate penetration depth, t is the exposure period, c0 is the external sulfate concentration, Di is the sulfate diffusion coefficient in concrete, E is the elastic modulus, α is the roughness coefficient of the area where performance deterioration occurs, B is the stress of 1 mol of sulfate ions that reacts in 1 m3 of concrete, γ is the required energy for the concrete surface fracture, ν is Poisson’s ratio, x is the cement content of the target structure, and φAl2O3 is the aluminum oxide content in the used cement [17].

The diffusion coefficient in Equation (1) can be modified with the effect of temperature, which can be explained by Arrhenius, as in Equation (2) [12,30].

where D(T) is the sulfate coefficient at temperature T; Dref, which can be assumed as Di in Equation (1), is the diffusion coefficient at reference Tref; U is the activation energy; R is the gas constant; and T is the absolute temperature (K). The service life can be considered to be when the deterioration depth from Equation (1) reaches the critical cover depth, which is defined as Equation (3).

where rp and φk are environment fact (1.10) and reduction factor (0.92) [3,4]. C and CK are design cover depth and outer steel diameter, respectively.

As previously explained in Section 2, the probabilistic method considers each design parameter not as a constant but as a random variable with a probabilistic function, so that the method induces the probability that increasing deterioration depth due to sulfate ions over using period is higher than cover depth should be lower than a given intended probability. The service life through the probabilistic method can be determined by Equations (4a) and (4b) considering the target durability failure probability.

where Tser and pfmax are the derived service life and maximum allowable probability (intended durability failure probability).

3.2. Diffusion Test with Changing Temperature

In previous studies, the effects of temperature on chloride diffusion and migration were comprehensively studied [19,31,32]; however, the effect on sulfate diffusion was studied less. In this work, a sulfate diffusion test was performed with changing room temperature from 20 °C to 50 °C, and probabilistic variables were obtained, like probabilistic pattern, mean, and COV (coefficient of variation). The mix proportions for the test are listed in Table 2, which are the same as the previous study, and the concrete samples with 91 curing days were selected for the natural diffusion test of sulfate ions [15,16].

Table 2.

Concrete mix proportions for the diffusion test.

The specified method for the evaluation of sulfate diffusion was not proposed, so the natural diffusion cell test suggested from previous studies [15,29,30] was adopted, which is listed in Equation (5).

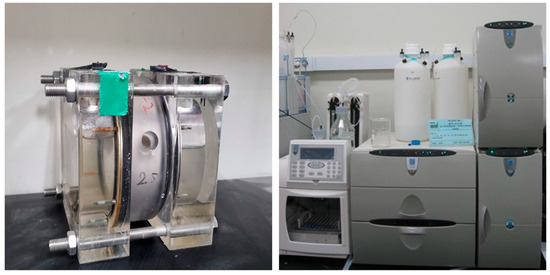

where is the diffusion of sulfate ions, is the volume of the diffusion cell, is increased sulfate ions in distilled water (kg/m3), is the surface area of concrete sample (m2), is the duration period of the test (s), is the thickness of the concrete slice (m), is the initial sulfate ion concentration (kg/m3), is the initial sulfate ion concentration in distilled water (kg/m3). The increasing ion concentration in the opposite cell was evaluated through IC (ion chromatography). The detailed dimensions of the equipment are shown in Figure 3, and photos for the diffusion cell and IC equipment are shown in Figure 4.

Figure 3.

Details of natural diffusion test for sulfate ion.

Figure 4.

Photo for diffusion cell and IC equipment.

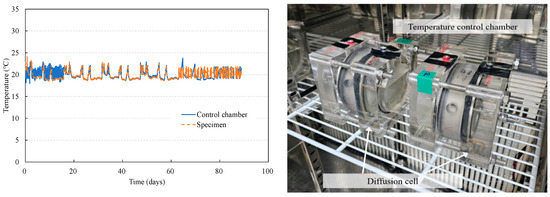

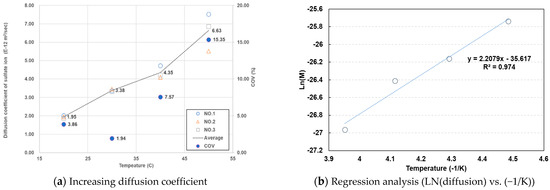

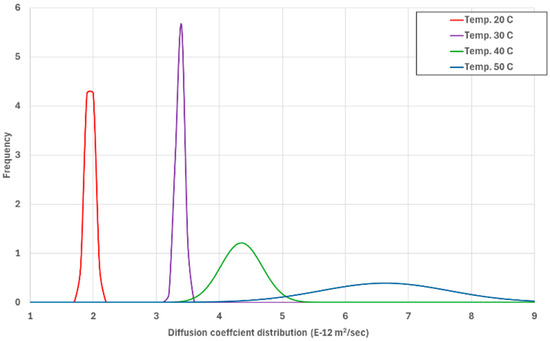

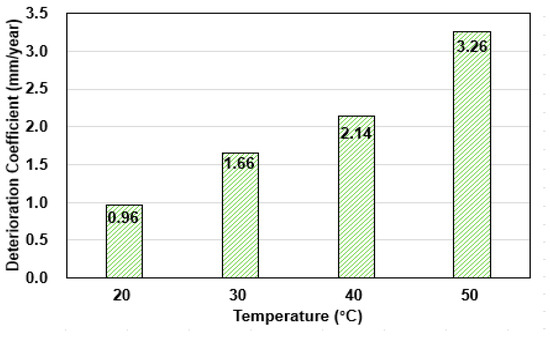

To test the elevation of temperature, the previously performed test was referred to. In the previous test [30], almost 13.3 h was taken for raising 20 °C to 40 °C in a control chamber, and 8.3 h was taken for elevating 5 °C. The diffusion cell and the sample were preheated independently, and the test started from −5 °C to the target temperature. The temperature changes in the diffusion cell and test setup are shown in Figure 5. The diffusion test results are summarized in Table 3, where the mean and COV were calculated from three samples. The test result and probabilistic patterns are shown in Figure 6 and Figure 7, assuming a normal distribution.

Figure 5.

Temperature-raising test in control chamber and test setup of diffusion cell.

Table 3.

Summary of sulfate diffusion test.

Figure 6.

Temperature effect of diffusion coefficient and regression analysis.

Figure 7.

Probability distributions of measured diffusion coefficients.

As shown in Figure 6 and Figure 7, the variation in the probability distribution increased with raising temperature, which showed the same trend as the results from the chloride diffusion test. With increasing the temperature to 50 °C, the diffusion coefficient nonlinearly increased to 3.4-times the control case (20 °C). The increasing COV with increasing temperature was also observed in the chloride diffusion test due to unsound ion transport and the dissociation of bound composition [30,33].

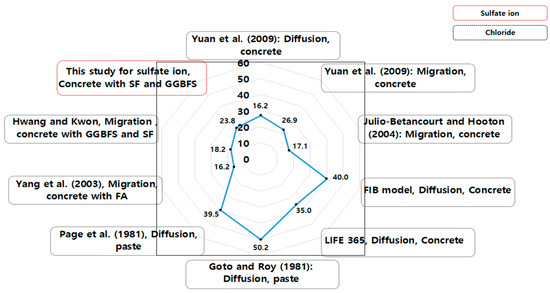

Furthermore, the derived activation energy had a similar level to the previous research results of chloride ions, and there was no significant difference from the those of the diffusion coefficient. The derived activation energy was 19.2~28.2 KJ/mol, and the average was 22.4 KJ/mol. A comparison with the previous results of chloride ions is plotted in Figure 8.

Figure 8.

Activation energy of sulfate ions with the previous studies on chloride ions.

3.3. Service Life Variation with Activation Energy-Deterministic Methods

The design parameters like mean and COV for service life evaluation are listed in Table 4 with the related references [15,16,17], and the target RC culvert is shown in Figure 9, which was constructed in UAE Barakah [34,35].

Table 4.

Durability design parameters for two evaluation methods.

Figure 9.

Schematic diagram of RC culvert under sulfate attack.

In Table 4, the average sulfate ion concentration was set to 200 ppm, which amounts to 96.06 g/L (mol of SO42−) since the annual average was reported to be low due to rainfall drainage [36]. The elastic modulus and Poisson’s ratio were assumed to be at the normal level, referring to ACI 318–95 and KS F 2438. The parameters of roughness, fracture energy, and linear parameter (B) are adopted from the previous results [17,37]. In the model, high-strength concrete may have a relatively rapid deteriorating rate due to the high elasticity and low Poisson’s ratio, but it has a very low diffusion coefficient of sulfate ions due to the dense pore structure. The concrete with GGBFS (ground-granulated blast furnace slag), which is very efficient for chemical erosion control, has a very low diffusion coefficient, but it has lots of Al2O3, over 10.0%. For controlling sulfate erosion, the effect of design parameters on the deteriorating rate should be considered comprehensively.

Through Equations (1)–(3), the deterioration depth with period was evaluated, which showed the service life was evaluated as being shortened due to enlarged diffusion with rising temperature. The environmental load factor (1.1) and reduction factor (0.94) were adopted, referring to the related codes. The results are shown in Figure 10, where, with increasing temperature from 20 °C to 50 °C, the service life was reduced to 9.57 years, which amounts to 29.4%. The enlarged diffusion coefficient with temperature was utilized in Equation (1) and linearly considered for the deterioration coefficient and service life.

Figure 10.

Reduced service life with increasing exterior temperature.

3.4. Service Life Variation with Random Variables (Probabilistic Methods)

3.4.1. Service Life from the Different Methods Considering Temperature Effect

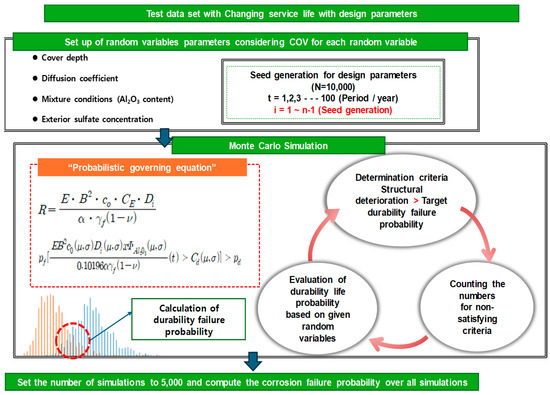

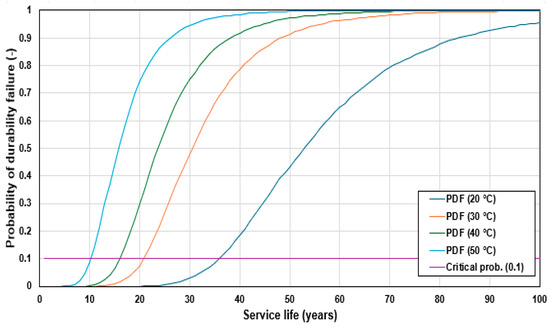

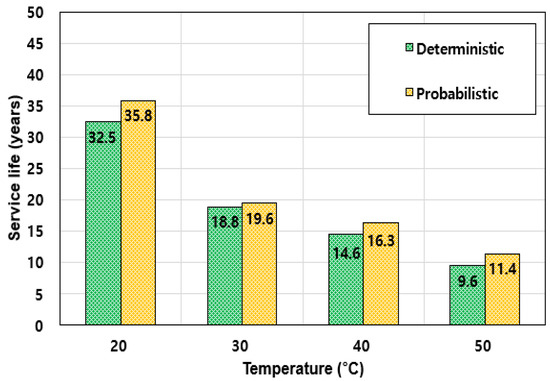

The random variables were defined as cover depth, diffusion coefficient, mixture conditions (Al2O3 content), and exterior sulfate concentration. Their probability patterns were assumed to be normal distributions, and the measured results (mean and COV) were adopted for the simulation. For seed generation, 10,000 simulations were performed for each case. A flowchart for MCS (Monte Carlo Simulation) is shown in Figure 11. The PDF (probability of durability failure) with increasing temperature and the comparison of service life from different methods are shown in Figure 12 and Figure 13, respectively.

Figure 11.

Flowchart for random generation and calculation of failure probability.

Figure 12.

PDF with increasing temperature.

Figure 13.

Temperature effect on service life from different evaluation methods.

The results in Figure 13 show a consistent trend, showing a gradual reduction in service life with temperature, and the results from the deterministic method provide more conservative results of 1~3 years. In the previous research, more conservative results (reduced service life) were evaluated for carbonation and chloride attack [12,22]; however, more conservative service life was observed in the deterministic method since the outer steel diameter (13.0 mm) was additionally excluded from cover depth in this simulation. Regarding the temperature effect on service life, the service life decreased to 30.0% for the deterministic method and 31.8% for the probabilistic method, which showed a similar reduction in the results since design parameters have a reasonable level of COV without the time effect.

The critical condition (maximum allowable PDF) was set to 10.0% in this study, which is the same as the case of chloride attack. So far, the international codes and specifications (EN, ACI, JSCE, and KCI) have provided a generalized design process without critical PDF since the critical condition for service life judgement can be changed for the importance and maintenance difficulty of the target structures. Regarding the design process, the deterministic method has a strong point with simple load and reduction factor; however, the probabilistic method has further engineering merit, like the consideration of the uncertainty of design parameters, such as the detailed quality condition of cover depth and material properties.

3.4.2. Service Life Simulation with Changing Variation

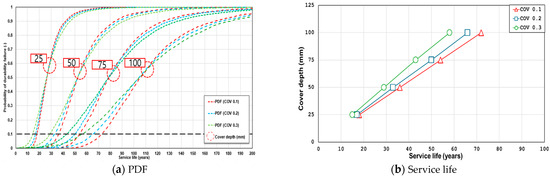

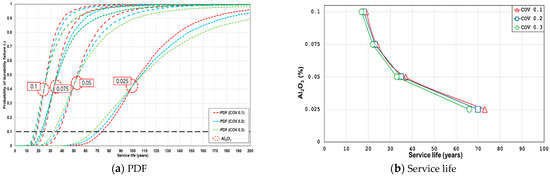

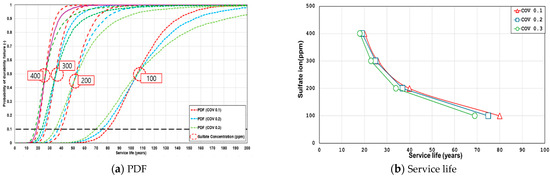

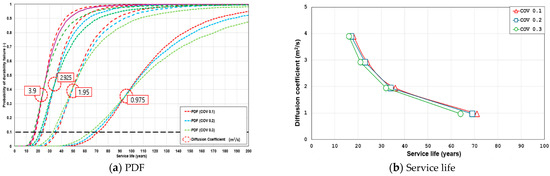

The mean and COV are very critical for evaluation, so four governing parameters, like cover depth, diffusion coefficient, cement component, and exterior sulfate concentration, were selected with their changing variations. For the cover depth effect, the input values were the same as in Table 4, and the cover depth with COV were altered. The effect of cover depth on failure probability is plotted in Figure 14a, and the evaluated service life is plotted in Figure 14b. Linearly increasing service life was observed with enlarged cover depth; however, increasing COV (over 0.2) showed more reduced service life, which is related to the significance of construction skill. With the same procedure, the effect of the remaining parameters with changing temperature is shown in Figure 15, Figure 16 and Figure 17, respectively.

Figure 14.

Simulation results and service life with changing cover depth and COVs.

Figure 15.

Simulation results and service life with changing cement component and COVs.

Figure 16.

Simulation results and service life with changing sulfate concentration and COVs.

Figure 17.

Simulation results and service life with changing diffusion coefficient and COVs.

The analysis results in Figure 14, Figure 15, Figure 16 and Figure 17 are those of PDF and service life with increasing COV from 0.1 to 0.3 and the multiplied design parameters from 0.5- to 2.0-times under the control condition in Table 4, where the exterior sulfate condition of 200 ppm was considered. Regarding cover thickness, the service life significantly decreased with increasing COV. For 75 mm and 100 mm of cover depth, the difference between COV 0.1 and 0.3 was 11 years and 14 years, respectively, which showed more than 10 years with increasing COV. It is very important to ensure reasonable variation for cover depth, which directly explains detailed construction skills since its COV greatly affects the service life.

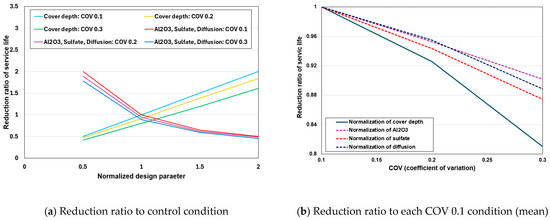

In the case of Al2O3 content, 37 years, 35 years, and 33 years of service life were evaluated with increasing COV to 0.3 for 0.05% of Al2O3. There was no significant difference compared to a COV of 0.1, and the service life decreased up to 89.2% with the largest COV (0.3). The effect of sulfate concentration and diffusion coefficient on service life also had a similar tendency to Al2O3 since the adopted governing equation used linearly proportional design parameters to the deteriorated depth. For the control condition of 200 ppm, 40 years, 37 years, and 34 years were evaluated with increasing COV, respectively, showing over 10.0% of the service life reduction ratio. Over 0.2 of COV, the service life reduction is evaluated to be relatively large, which meaningfully suggests that the quality control of concrete mixing and construction is very important. After normalization of the design parameters, the changing service life ratio is shown in Figure 18 with increasing COV.

Figure 18.

Reduction ratio of service life with changing normalized design parameters and COV.

LCC (life cycle cost) analysis for infrastructure has been studied widely. Before the construction stage, quantitative analysis for the priority of design parameters can be useful for cost–benefit analysis considering the exterior sulfate concentration.

4. Conclusions

In this study, the service life of RC structures affected by sulfate ingress was analyzed with a temperature-dependent diffusion coefficient and patterns of design parameters. Through obtaining activation energy based on the diffusion test results, two different design techniques were applied to the RC drainage structure, and the effects of design parameters (cover depth, component of cement, exterior sulfate concentration, and diffusion coefficient) and their variations were analyzed in terms of service life variation. The conclusions drawn from this work are as follows.

Through a natural diffusion cell test from 20 °C to 50 °C, the diffusion coefficient of sulfate ions was obtained, and the activation energy, which can be used for the temperature parameter, was derived based on the Arrhenius equation. With the increasing temperature to 50 °C, the service life of RC culvert was greatly reduced due to the enlarged diffusion coefficient and constant cover depth. The probabilistic pattern of the diffusion coefficient (mean and COV) showed higher mean and COV with increasing temperature due to unstable ion transport and the dissociation of bound ions. The service life from the probabilistic technique considering the temperature effect showed similar results to the deterministic technique since the design parameters have a reasonable level of COV and no consideration of the use period. When considering more marginal cover depth in the deterministic technique based on the design code, more conservative results were evaluated in the deterministic technique.

Among the four design parameters of cover depth, content of Al2O3, sulfate concentration, and diffusion coefficient, the cover depth greatly affected the service life since the three parameters, except for cover depth, in the governing equation were linearly proportional to the deteriorated depth due to sulfate penetration. Through the probabilistic simulation based on normal distribution, the COV over 0.2 yielded a large reduction in service life, and it was remarkably observed in the case of small cover depth.

In this study, a limited number of samples were tested in the different temperature conditions, and simple normal distributions of design parameters were assumed. For more reasonable durability design through the probabilistic approach, several further studies are required for the definition of time-dependent diffusion for sulfate ions, reasonable database construction for design parameters, and quantitative definition of exterior conditions, such as sulfate ion concentration, saturation, and temperature.

Author Contributions

Conceptualization, S.-J.K. and A.K.A.; methodology, S.-J.K. and A.K.A.; formal analysis, S.-J.K. and H.-W.L.; investigation, S.-J.K. and K.-H.Y.; resources, S.-J.K.; data curation, S.-J.K. and H.-W.L.; writing—original draft preparation, S.-J.K. and H.-W.L.; writing—review and editing, S.-J.K. and K.-H.Y.; supervision, S.-J.K. and K.-H.Y.; funding acquisition, S.-J.K. and A.K.A. All authors have read and agreed to the published version of the manuscript.

Funding

National Research Foundation of Korea (NRF), grant funded by the Korean government.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

This work was supported by the National Research Foundation of Korea (NRF), grant funded by the Korean government (MSIT) (No. RS-2024-00415881 and NRF-2022M2E9A3091898).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- American Concrete Institute. ACI 304.3R-20: Heavyweight Concrete: Measuring, Mixing, Transporting, and Placing; American Concrete Institute: Farmington Hills, MI, USA, 2020. [Google Scholar]

- Soave, F.; Ferrara, L. A durability-based design approach for structural applications with advanced cement-based materials. Case Stud. Constr. Mater. 2025, 22, e04294. [Google Scholar] [CrossRef]

- JSCE. Guidelines for Concrete 16, Standard Specification for Concrete Structures—Materials and Construction; Japan Society of Civil Engineering: Tokyo, Japan, 2016; pp. 81–92. [Google Scholar]

- EN-1992-1-1; Eurocode 2: Design of Concrete Structures. European Committee for Standardization (Comité Européen de Normalisation, CEN): Brussels, Belgium, 2004; pp. 8–22.

- ACI 201R-08; Guide to Durable Concrete. American Concrete Institute (ACI) Committee-201: Detroit, MI, USA, 2008; pp. 26–28.

- Qin, S.; Zou, D.; Liu, T.; Jivkov, A. A chemo-transport-damage model for concrete under external sulfate attack. Cem. Concr. Res. 2020, 132, 106048. [Google Scholar] [CrossRef]

- Sotiriadis, K.; Mácová, P.; Mazur Anton, A.S.; Viani, A.; Tolstoy, P.M.; Tsivilis, S. Long-term thaumasite sulfate attack on portland limestone cement concrete: A multi-technique analytical approach for assessing phase assemblage. Cem. Concr. Res. 2020, 130, 105995. [Google Scholar] [CrossRef]

- Wang, D.; Guan, F.; Feng, C.; Mathivanan, K.; Zhang, R.; Sand, W. Review on microbially influenced concrete corrosion. Microorganisms 2023, 11, 2076. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, L.M.; Guo, J.J.; Liu, W.L.; Chen, H.L. Mechanical properties and service life prediction of modified concrete attacked by sulfate corrosion. Adv. Civ. Eng. 2018, 2018, 8907363. [Google Scholar] [CrossRef]

- Rasheed, P.A.; Nayar, S.K.; Barsoum, I.; Alfantazi, A. Degradation of concrete structures in nuclear power plants: A review of the major causes and possible preventive measures. Energies 2022, 15, 8011. [Google Scholar] [CrossRef]

- Wu, L.; Huang, G.; Liu, W.V. Methods to evaluate resistance of cement-based materials against microbially induced corrosion: A state-of-the-art review. Cem. Concr. Compos. 2021, 123, 104208. [Google Scholar] [CrossRef]

- Thomas, M.D.A.; Bentz, E.C. Computer Program for Predicting the Service Life and Life-Cycle Costs of Reinforced Concrete Exposed to Chlorides; Life365 Manual; SFA: Lovettsville, VA, USA, 2002; pp. 12–56. [Google Scholar]

- Damrongwiriyanupap, N.; Limkatanyu, S.; Xi, Y. A thermo-hygro-coupled model for chloride penetration in concrete structures. Adv. Mater. Sci. Eng. 2015, 2015, 682940. [Google Scholar] [CrossRef]

- Park, S.S.; Kwon, S.J.; Jung, S.H. Analysis technique for chloride penetration in cracked concrete using equivalent diffusion and permeation. Constr. Build. Mater. 2012, 29, 183–192. [Google Scholar] [CrossRef]

- Yoon, H.S.; Yang, K.H.; Kwon, S.J. Service life of sewage culvert with bacteria coating from waste sludge and negative pressure method. J. Mater. Cycles Waste Manag. 2022, 24, 582–594. [Google Scholar] [CrossRef]

- Yoon, H.S.; Yang, K.H.; Lee, K.M.; Kwon, S.J. Service life evaluation for RC sewer structure repaired with bacteria mixed coating: Through probabilistic and deterministic method. Materials 2021, 14, 5424. [Google Scholar] [CrossRef]

- Atkinson, A.; Hearne, J.A. Mechanistic model for the durability of concrete barriers exposed to sulphate-bearing groundwaters. MRS OPL 1989, 176, 149. [Google Scholar] [CrossRef]

- Andrade, C.; Díez, J.M.; Alonso, C. Mathematical modeling of a concrete surface “skin effect” on diffusion in chloride contaminated media. Adv. Cem. Based Mater. 1997, 6, 39–44. [Google Scholar] [CrossRef]

- Care, S. Effect of temperature on porosity and on chloride diffusion in cement pastes. Constr. Build. Mater. 2008, 22, 1560–1573. [Google Scholar] [CrossRef]

- Samson, E.; Marchand, J. Modeling the effect of temperature on ionic transport in cementitious materials. Cem. Concr. Res. 2007, 37, 455–468. [Google Scholar] [CrossRef]

- Dousti, A.; Rashetnia, R.; Ahmadi, B.; Shekarchi, M. Influence of exposure temperature on chloride diffusion in concretes incorporating silica fume or natural zeolite. Constr. Build. Mater. 2013, 49, 393–399. [Google Scholar] [CrossRef]

- Kwon, S.J.; Na, U.J.; Park, S.S.; Jung, S.H. Service life prediction of concrete wharves with early-aged crack: Probabilistic approach for chloride diffusion. Struct. Saf. 2009, 31, 75–83. [Google Scholar] [CrossRef]

- Saassouh, B.; Lounis, Z. Probabilistic modeling of chloride-induced corrosion in concrete structures using first-and second-order reliability methods. Cem. Concr. Compos. 2012, 34, 1082–1093. [Google Scholar] [CrossRef]

- Jiang, C.; Gu, X.; Huang, Q.; Zhang, W. Carbonation depth predictions in concrete bridges under changing climate conditions and increasing traffic loads. Cem. Concr. Compos. 2018, 93, 140–154. [Google Scholar] [CrossRef]

- Saetta, A.V.; Scotta, R.V.; Vitaliani, R.V. Analysis of chloride diffusion into partially saturated concrete. Mater. J. 1993, 90, 441–451. [Google Scholar]

- Page, C.; Short, N.R.; EI Tarras, A. Diffusion of chloride ions in hardened cement pastes. Cem. Concr. Res. 1981, 11, 395–406. [Google Scholar] [CrossRef]

- Detwiler, R.J.; Kjellsen, K.O.; Gjorv, O.E. Resistance to chloride intrusion of corrosion cured at different temperatures-closure. ACI Mater. J. 1991, 88, 677–679. [Google Scholar]

- Dhir, R.K.; Jones, M.R.; Elghaly, A.E. PFA Concrete: Exposure temperature effects on chloride diffusion. Cem. Concr. Res. 1993, 23, 1105–1114. [Google Scholar] [CrossRef]

- So, H.S.; Choi, S.H.; Seo, J.S.; So, S.Y.; Seo, K.S. Influence of temperature on chloride ion diffusion of concrete. J. Korea Concr. Inst. 2014, 26, 71–78. (In Korean) [Google Scholar] [CrossRef]

- Yang, K.H.; Kwon, S.J.; Hwang, J.W.; Yoon, Y.S. Temperature effect on strength and chloride migration in nuclear power plant concrete. Constr. Build. Mater. 2023, 405, 13345. [Google Scholar] [CrossRef]

- Goto, S.; Roy, D.M. Diffusion of ions through hardened cement pastes. Cem. Concr. Res. 1981, 11, 751–757. [Google Scholar] [CrossRef]

- Yuan, Q.; Shi, C.; Schutter, G.D.; Audenaert, K. Effect of temperature on transport of chloride ions in concrete. In Concrete Repair, Rehabilitation and Retrofitting II; CRC Press: Boca Raton, FL, USA, 2008; pp. 177–178. [Google Scholar]

- Hwang, J.W.; Kwon, S.J. Temperature-dependent Diffusion Coefficient of Chloride Ion in UAE Concrete. J. Kor. Inst. Struct. Maint. Inspect. 2024, 28, 48–54. (In Korean) [Google Scholar]

- Ha, J.S.; Kim, S.Y.; Al Suwaidi, J.K.; Beeley, P. Development of a framework for establishment of risk-informed safety goals for nuclear power plants operation in the UAE. In Proceedings of the PSAM 2014—Probabilistic Safety Assessment and Management, Honolulu, HI, USA, 22–27 June 2014. [Google Scholar]

- An, K.H. Experimental investigation of sulfate attack on concrete in UAE’s nuclear power plants. In Proceedings of the Transactions of the Korean Nuclear Society Autumn Meeting, Changwon, Republic of Korea, 24–25 October 2024. [Google Scholar]

- Yoon, H.S.; Yang, K.H. Evaluation of effectiveness of concrete coated with bacterial glycocalix under simulated sewage environments. J. Rec. Const. Resour. 2020, 8, 97–104. (In Korean) [Google Scholar]

- Clifton, J.R.; Frohnsdorff, G.J.; Ferraris, C.C. Standards for Evaluating the Susceptibility of Cement-Based Materials to External Sulfate Attack. 1999, 29, 821–830. Available online: https://www.nist.gov/publications/standards-evaluating-susceptibility-cement-based-materials-external-sulfate-attack?pub_id=860169 (accessed on 19 March 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).