Study of Various Types of Glazing in a Building Constructed Using Hybrid Technology with a Large Window Area

Abstract

1. Introduction

1.1. Scientific Studies Using the Building Energy Simulation Method

- It is recommended to use glazing with a low heat transfer coefficient, because it significantly reduces energy consumption for heating and at the same time does not significantly change the energy demand for cooling;

- The SHGC coefficient, which determines how much solar radiation falling on a window is transmitted into the room, has a key influence on the energy demand for cooling;

- The most effective way to reduce cooling demand is to use shading devices.

1.2. Analyses Based Only on Modelling of Heat Transfer Through Window

1.3. Summary of Literature Reviews

1.4. Scientific Objective of the Current Analysis

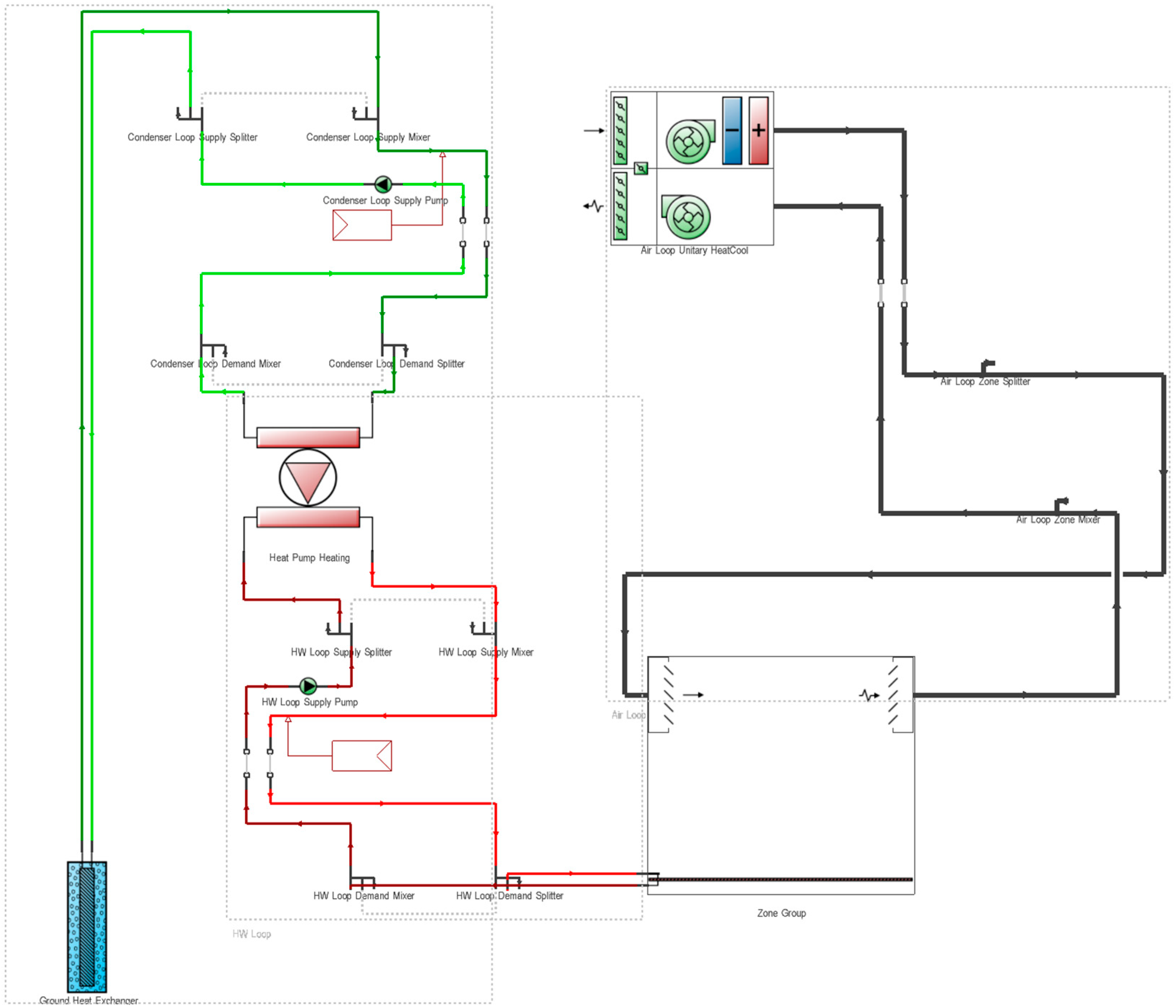

2. Materials and Methods

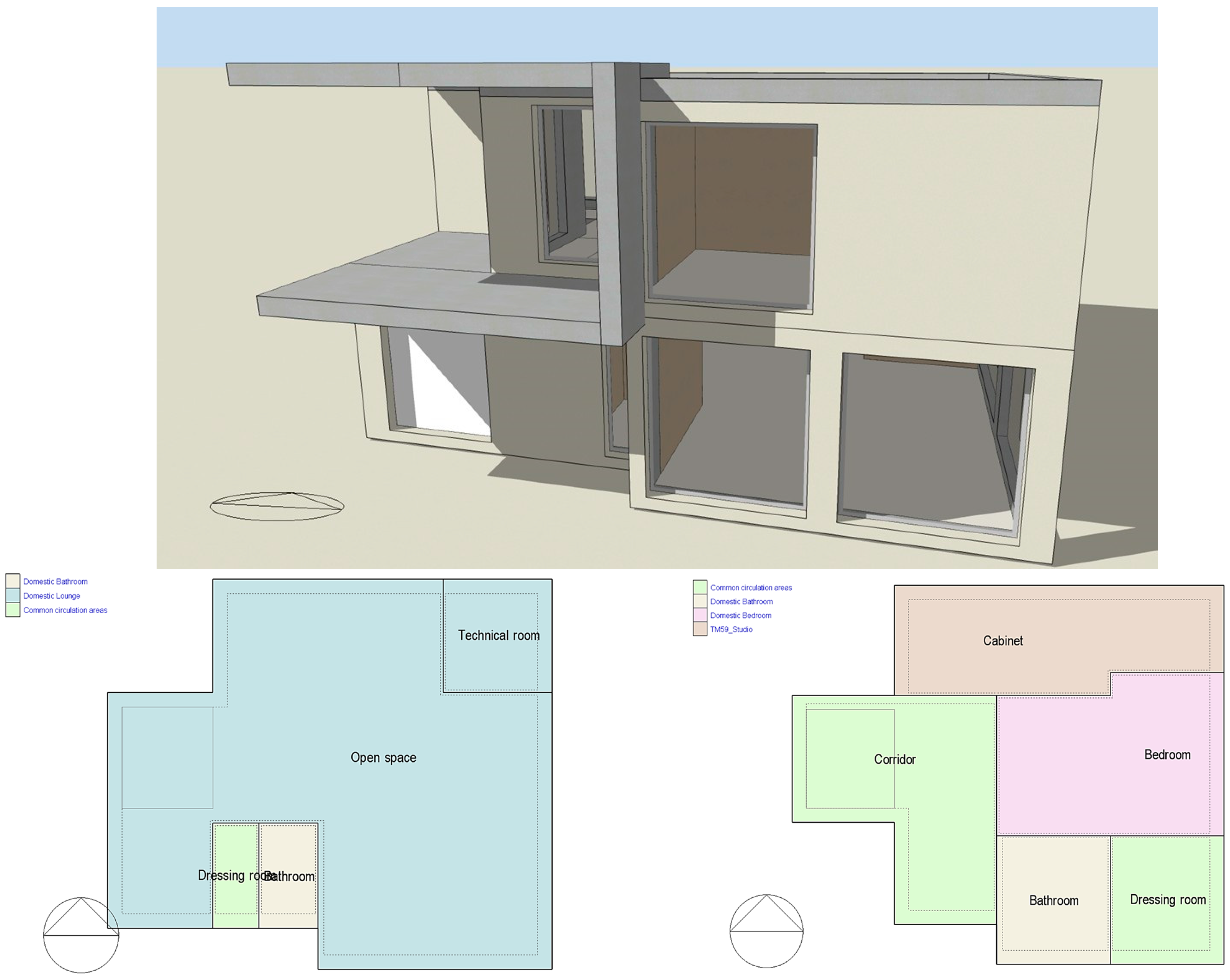

2.1. Key Characteristics of Test Building and Weather Conditions

2.2. Assumptions Made in Building Energy Modelling

- The simulation period was one year, and the calculations used meteorological data for TMY—POL_BIALYSTOK_IMGW and SWE_KIRUNA_IWEC—Kiruna [28];

- It was assumed that 4 people lived in the reference building;

- Schedules for occupant behaviour were implemented as typical for residential spaces;

- Blinds with highly reflective slats placed inside provided shading for the windows;

- Activity in the form of light manual work, clothing thermal resistance in summer—0.5 clo, and in winter—1 clo were assumed in order to estimate the PMV index;

- Linear controlled lighting was used. It consisted of a linear change in artificial lighting intensity depending on the change in daylight intensity;

- Energy-saving lighting was used: “surface-mount” type with a visible fraction of 0.84 and a normalised power density of 2 Wm2-100 lux;

- Mechanical ventilation with heat recovery with an efficiency of 0.7 at design flow and 0.75 at 75% airflow;

- A ground-source heat pump was used to heat the building with an average COP of around 4;

- The rooms were cooled using a single-speed DX cooling coil with a gross rated COP coefficient of 3;

- The set air temperature during heating was 20 °C in the rooms and 24 °C in the bathroom, while the cooling process started when the air temperature exceeded 25 °C;

- Underfloor heating system made of pipes with an internal diameter of 13 mm and regulated by variable flow.

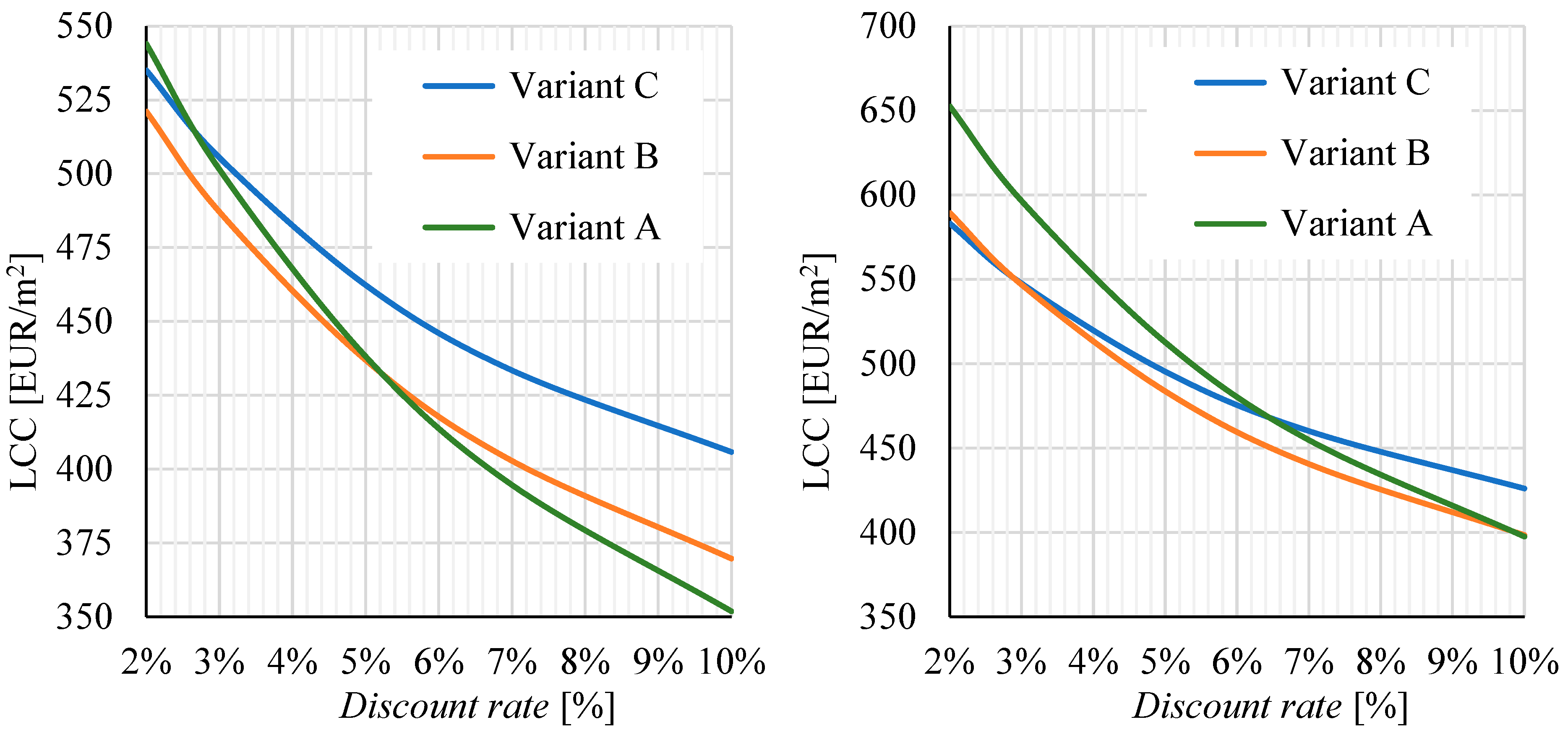

2.3. Key Assumptions Used in the Financial Cost Analysis

- IC—initial cost [EUR/m2];

- T—life cycle period [year];

- OC—annual operational costs [EUR/m2];

- r—discount rate [%];

- DC—disposal cost [EUR/m2].

3. Results

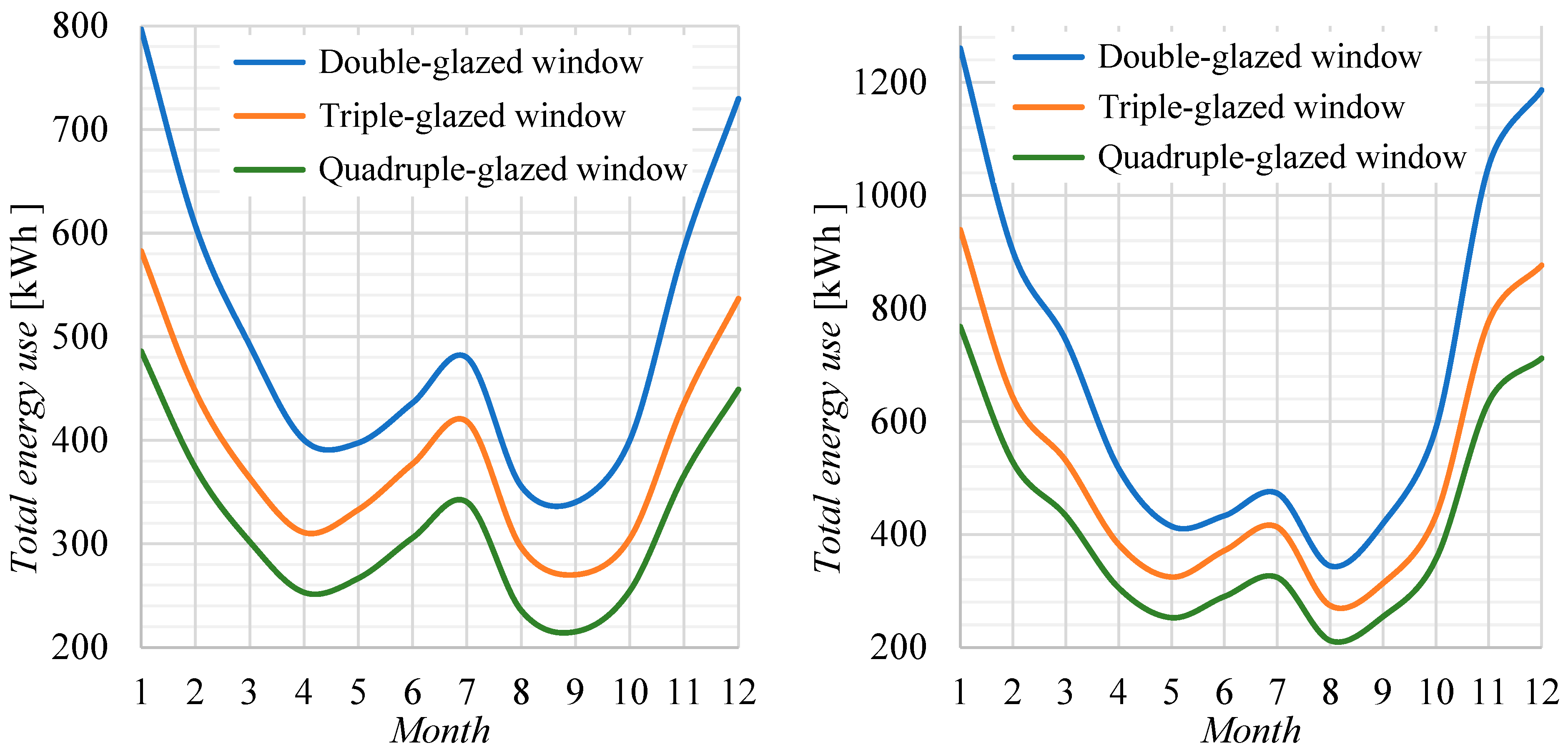

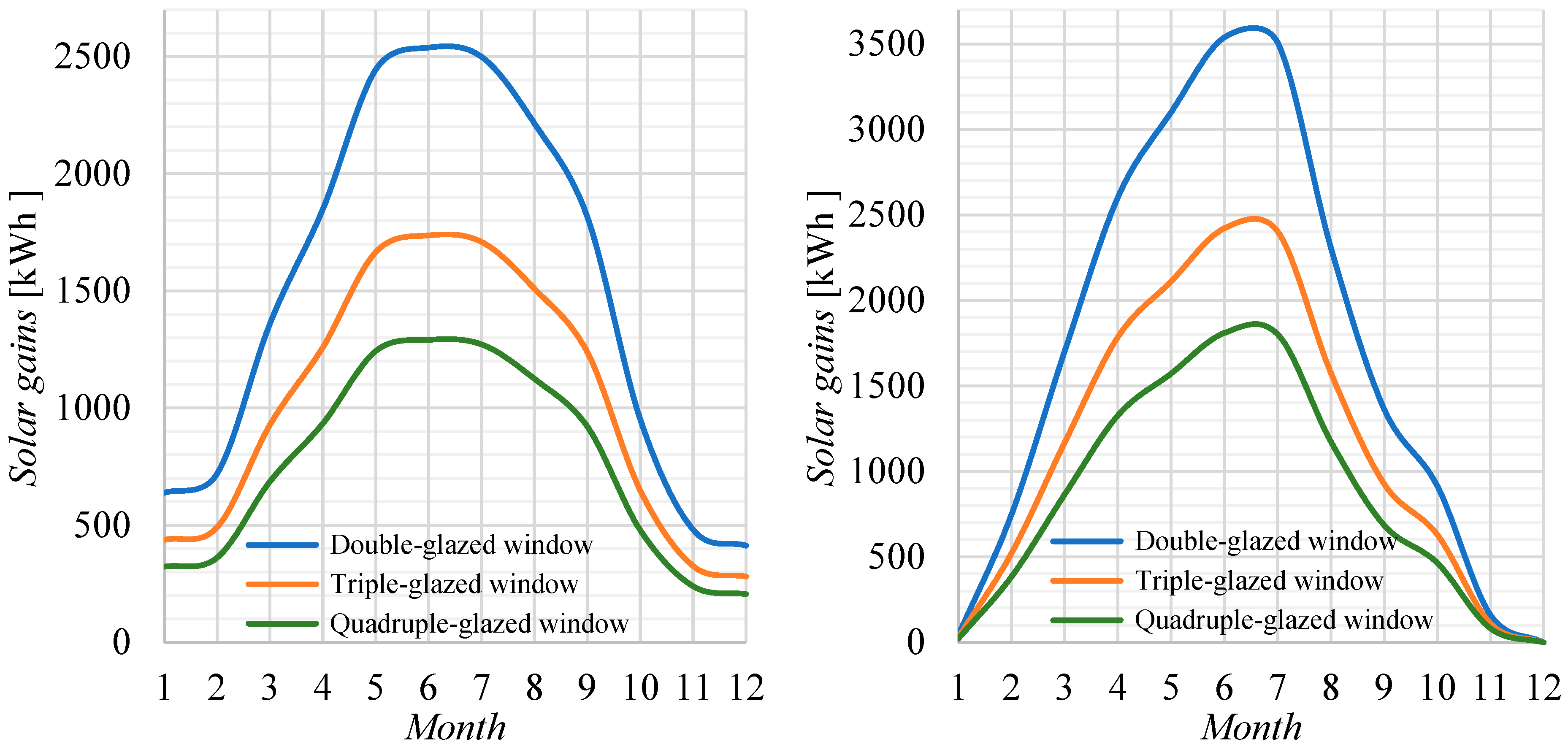

3.1. Results of Building Energy Simulations

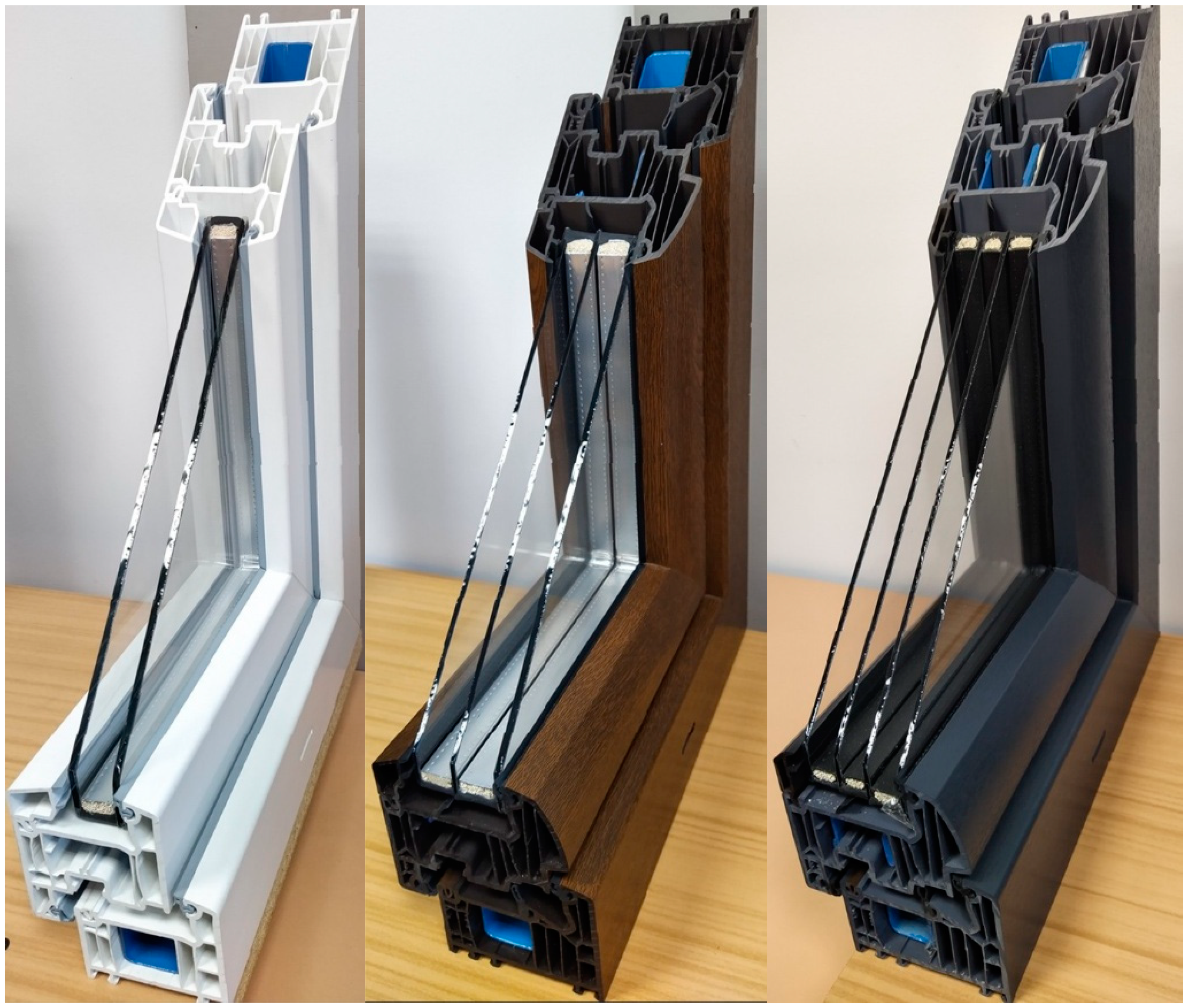

- Variant A—double-glazed system;

- Variant B—triple-glazed system;

- Variant C—quadruple-glazed system.

3.2. Thermal Comfort Assessment Results

3.3. Discussion of the Influence of Glazing Type on Artificial Lighting

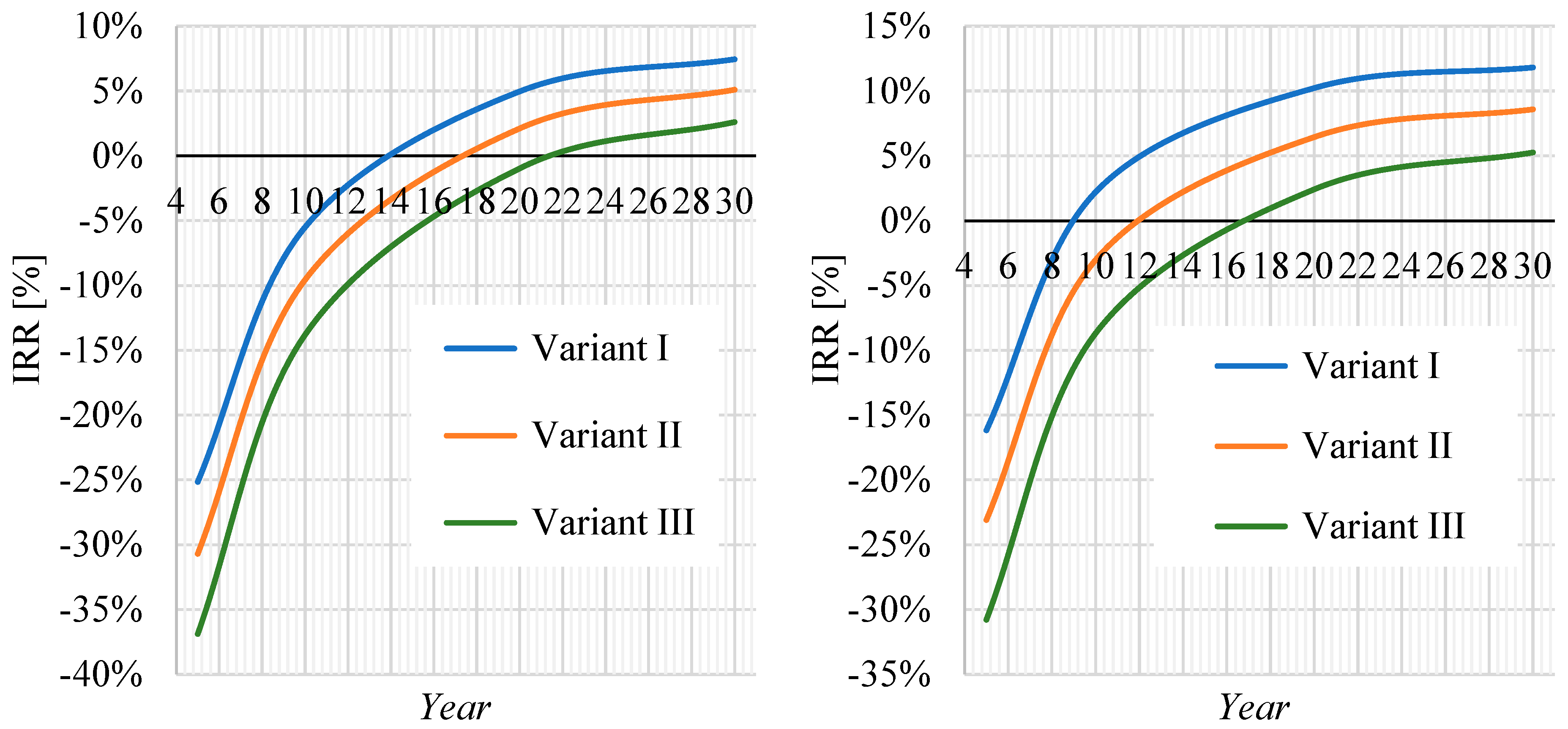

3.4. Results of the Economic Analyses and Their Discussion

- Variant I—replacing a double-glazed window with a triple-glazed one;

- Variant II—replacing a double-glazed window with a quadruple-glazed window;

- Variant III—replacing a triple-glazed window with a quadruple-glazed window.

4. Summary and Conclusions

4.1. Conclusions Related to the Energy Efficiency of the Building

4.2. Conclusions Related to Thermal Comfort

4.3. Conclusions Related to Economic Analysis

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Phillips, R.; Troup, L.; Fannon, D.; Eckelman, M.J. Triple bottom line sustainability assessment of window-to-wall ratio in US office buildings. Build. Environ. 2020, 182, 107057. [Google Scholar] [CrossRef]

- Elkington, J. Accounting for the triple bottom line. Meas. Bus. Excell. 1998, 2, 18–22. [Google Scholar] [CrossRef]

- Jaber, S.; Ajib, S. Thermal and economic windows design for different climate zones. Energy Build. 2011, 43, 3208–3215. [Google Scholar] [CrossRef]

- Tokarik, M.S.; Richman, R.C. Life cycle cost optimization of passive energy efficiency improvements in a Toronto house. Energy Build. 2016, 118, 160–169. [Google Scholar] [CrossRef]

- Elkhayat, Y.O.; Ibrahim, M.G.; Tokimatsu, K.; Ali, A.A.M. Life cycle cost analysis on three high-performance glazing systems for an office building in New Cairo, Egypt. Archit. Eng. Des. Manag. 2020, 17, 131–145. [Google Scholar] [CrossRef]

- Saadatian, S.; Rodrigues, C.; Freire, F.; Simões, N. Key drivers of life-cycle environmental and cost assessment of windows for different European climate zones. J. Build. Eng. 2022, 50, 104206. [Google Scholar] [CrossRef]

- ISO 13791; Thermal Performance of Buildings—Calculation of Internal Temperatures of a Room in Summer Without Mechanical Cooling—General Criteria and Validation Procedures. International Organization for Standardization: Geneva, Switzerland, 2004.

- Mahmoodzadeh, M.; Gretka, V.; Blue, A.; Adams, D.; Dallimore, B.; Mukhopadhyaya, P. Evaluating thermal performance of vertical building envelopes: Case studies in a Canadian university campus. J. Build. Eng. 2021, 40, 102712. [Google Scholar] [CrossRef]

- Poirazis, H.; Blomsterberg, Å.; Wall, M. Energy simulations for glazed office buildings in Sweden. Energy Build. 2008, 40, 1161–1170. [Google Scholar] [CrossRef]

- Kim, R.; Tae, S.; Roh, S. Development of low carbon durability design for green apartment buildings in South Korea. Renew. Sustain. Energy Rev. 2017, 77, 263–272. [Google Scholar] [CrossRef]

- Thalfeldt, M.; Kurnitski, J.; Voll, H. Detailed and simplified window model and opening effects on optimal window size and heating need. Energy Build. 2016, 127, 242–251. [Google Scholar] [CrossRef]

- Van Gulck, L.; Van de Putte, S.; Van Den Bossche, N.; Steeman, M. Comparison of an LCA and LCC for façade renovation strategies designed for change. E3S Web Conf. 2020, 172, 18005. [Google Scholar] [CrossRef]

- Delghust, M. Improving the Predictive Power of Simplified Residential Space Heating Demand Models: A Field Data and Model Driven Study. Ph.D. Thesis, Ghent University, Ghent, Belgium, 2016. [Google Scholar]

- Feehan, A.; Nagpal, H.; Marvuglia, A.; Gallagher, J. Adopting an integrated building energy simulation and life cycle assessment framework for the optimisation of facades and fenestration in building envelopes. J. Build. Eng. 2021, 43, 103138. [Google Scholar] [CrossRef]

- Jezierski, W.; Zukowski, M. Evaluation of the Impact of Window Parameters on Energy Demand and CO2 Emission Reduction for a Single-Family House. Energies 2023, 16, 4429. [Google Scholar] [CrossRef]

- Zavala-Guillén, I.; Barrera-Román, D.; Noh-Pat, F.; Sidón, M.; García-Pérez, D.; Rodriguez-Ake, A. Thermal analysis of multi-layered glazed window under Mexican climate. Energy Build. 2025, 329, 115259. [Google Scholar] [CrossRef]

- Kralj, A.; Drev, M.; Žnidaršič, M.; Černe, B.; Hafner, J.; Jelle, B.P. Investigations of 6-pane glazing: Properties and possibilities. Energy Build. 2019, 190, 61–68. [Google Scholar] [CrossRef]

- Saadatian, S.; Simões, N.; Freire, F. Integrated environmental, energy and cost life-cycle analysis of windows: Optimal selection of components. Build. Environ. 2021, 188, 107516. [Google Scholar] [CrossRef]

- Sadooghi, P.; Kherani, N.P. Influence of slat angle and low-emissive partitioning radiant energy veils on the thermal performance of multilayered windows for dynamic facades. Renew. Energy 2019, 143, 142–148. [Google Scholar] [CrossRef]

- Arıcı, M.; Karabay, H.; Kan, M. Flow and heat transfer in double, triple and quadruple pane windows. Energy Build. 2015, 86, 394–402. [Google Scholar] [CrossRef]

- Salazar, S.L.; Simá, E.; Vargas-López, R.; Yang, R.; Li, D.; Hernández-López, I. Assessing different glazing types for energy savings and CO2 reduction in a tropical climate: A comparative study. J. Build. Eng. 2024, 82, 108188. [Google Scholar] [CrossRef]

- Tükel, M.; Mumcuoğlu, K.; Arıcı, M.; Karabay, H. Analysis of fluid flow and heat transfer characteristics in multiple glazing roofs with a special emphasis on the thermal performance. Appl. Therm. Eng. 2019, 148, 694–703. [Google Scholar] [CrossRef]

- Arıcı, M.; Kan, M. An investigation of flow and conjugate heat transfer in multiple pane windows with respect to gap width, emissivity and gas filling. Renew. Energy 2015, 75, 249–256. [Google Scholar] [CrossRef]

- Huang, Y.; El Mankibi, M.; Cantin, R.; Coillot, M. Application of fluids and promising materials as advanced inter-pane media in multi-glazing windows for thermal and energy performance improvement: A review. Energy Build. 2021, 253, 111458. [Google Scholar] [CrossRef]

- ISO 10292:1994; Glass in Building—Calculation of Steady-State U Values (Thermal Transmittance) of Multiple Glazing. International Organization for Standardization: Geneva, Switzerland, 1994.

- EN 673:2024; Glass in Building—Determination of Thermal Transmittance (U Value)—Calculation Method. British Standards Institution: London, UK, 2024.

- ISO 6946:2017; Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Methods. International Organization for Standardization: Geneva, Switzerland, 2017.

- Weather Data by Location Europe (WMO Region 6) EnergyPlus. Available online: https://energyplus.net/weather-region/europe_wmo_region_6/POL (accessed on 14 February 2025).

- Zukowski, M. Multi-aspect analysis of measures to reduce the building’s energy demand. J. Build. Eng. 2024, 91, 109758. [Google Scholar] [CrossRef]

- ISO 15686-5:2017; Buildings and Constructed Assets—Service Life Planning, Part 5: Life-Cycle Costing. International Organization for Standardization: Geneva, Switzerland, 2017.

| Window Parameters | Double-Glazed Window | Triple-Glazed Window | Quadruple-Glazed Window |

|---|---|---|---|

| U-value (ISO 10292 [25], EN 673 [26]) [W/m2-K] | 1.634 | 1.072 | 0.806 |

| Total solar transmission (SHGC) [-] | 0.691 | 0.579 | 0.466 |

| Direct solar transmission [-] | 0.624 | 0.458 | 0.338 |

| Light transmission [-] | 0.744 | 0.698 | 0.624 |

| Total | North | East | South | West | |

|---|---|---|---|---|---|

| Gross Window–Wall Ratio [%] | 38.87 | 28.49 | 50.23 | 33.85 | 45.07 |

| Ground Wall Area [m2] | 261.08 | 69.54 | 61.00 | 69.54 | 61.00 |

| Window Opening Area [m2] | 101.48 | 19.81 | 30.64 | 23.54 | 27.49 |

| Parameter | Year | Winter Period | Warm Period |

|---|---|---|---|

| Bialystok | |||

| Outside dry-bulb temperature [°C] | 6.87 | 0.36 | 13.38 |

| Wind velocity [m/s] | 2.53 | 2.94 | 2.12 |

| Wind direction [°] | 175.00 | 188.51 | 161.49 |

| Direct normal solar irradiance [W/m2] | 38.95 | 16.38 | 61.52 |

| Diffuse horizontal solar irradiance [W/m2] | 51.63 | 23.61 | 79.66 |

| Kiruna | |||

| Outside dry-bulb temperature [°C] | −1.15 | −8.44 | 6.15 |

| Wind velocity [m/s] | 3.79 | 3.88 | 3.69 |

| Wind direction [°] | 187.19 | 187.10 | 187.28 |

| Direct normal solar irradiance [W/m2] | 45.58 | 21.30 | 69.85 |

| Diffuse horizontal solar irradiance [W/m2] | 41.56 | 9.16 | 73.96 |

| Variant | Month | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | Sum | |

| Bialystok | |||||||||||||

| Heating energy [kWh] | |||||||||||||

| A | 646 | 470 | 327 | 166 | 43 | 17 | 12 | 28 | 74 | 232 | 442 | 580 | 3037 |

| B | 452 | 328 | 221 | 108 | 24 | 9 | 7 | 15 | 43 | 160 | 311 | 407 | 2085 |

| C | 376 | 273 | 184 | 90 | 20 | 8 | 6 | 12 | 35 | 135 | 260 | 339 | 1738 |

| Cooling energy [kWh] | |||||||||||||

| A | 1 | 3 | 17 | 94 | 211 | 282 | 326 | 184 | 126 | 21 | 0 | 0 | 1266 |

| B | 1 | 2 | 15 | 81 | 185 | 250 | 289 | 158 | 106 | 17 | 0 | 0 | 1104 |

| C | 1 | 1 | 9 | 59 | 142 | 198 | 232 | 119 | 78 | 12 | 0 | 0 | 851 |

| Energy used by fans [kWh] | |||||||||||||

| A | 136 | 123 | 136 | 132 | 136 | 132 | 136 | 136 | 132 | 136 | 132 | 136 | 1606 |

| B | 117 | 106 | 117 | 113 | 117 | 113 | 117 | 117 | 113 | 117 | 113 | 117 | 1381 |

| C | 98 | 88 | 98 | 94 | 98 | 94 | 98 | 98 | 94 | 98 | 94 | 98 | 1149 |

| Energy used by pumps [kWh] | |||||||||||||

| A | 13 | 11 | 11 | 9 | 7 | 5 | 5 | 7 | 8 | 11 | 12 | 13 | 112 |

| B | 12 | 11 | 11 | 9 | 7 | 5 | 5 | 7 | 8 | 11 | 12 | 13 | 109 |

| C | 12 | 11 | 11 | 9 | 7 | 6 | 5 | 7 | 8 | 11 | 12 | 13 | 111 |

| Kiruna | |||||||||||||

| Heating energy [kWh] | |||||||||||||

| A | 1100 | 757 | 562 | 293 | 118 | 31 | 17 | 70 | 246 | 423 | 899 | 1026 | 5543 |

| B | 796 | 514 | 368 | 183 | 66 | 15 | 9 | 36 | 160 | 286 | 640 | 734 | 3807 |

| C | 651 | 423 | 304 | 151 | 53 | 13 | 9 | 29 | 132 | 238 | 522 | 595 | 3119 |

| Cooling energy [kWh] | |||||||||||||

| A | 0 | 1 | 25 | 74 | 143 | 256 | 305 | 122 | 23 | 9 | 0 | 0 | 959 |

| B | 0 | 1 | 23 | 66 | 123 | 227 | 270 | 102 | 20 | 8 | 0 | 0 | 839 |

| C | 0 | 0 | 15 | 46 | 88 | 172 | 207 | 73 | 13 | 4 | 0 | 0 | 618 |

| Energy used by fans [kWh] | |||||||||||||

| A | 145 | 131 | 145 | 140 | 145 | 140 | 145 | 145 | 140 | 145 | 140 | 145 | 1709 |

| B | 129 | 116 | 129 | 125 | 129 | 125 | 129 | 129 | 125 | 129 | 125 | 129 | 1516 |

| C | 103 | 93 | 103 | 100 | 103 | 100 | 103 | 103 | 100 | 103 | 100 | 103 | 1216 |

| Energy used by pumps [kWh] | |||||||||||||

| A | 16 | 13 | 12 | 9 | 8 | 5 | 5 | 7 | 10 | 11 | 14 | 15 | 126 |

| B | 14 | 11 | 11 | 9 | 8 | 5 | 5 | 7 | 10 | 11 | 13 | 14 | 118 |

| C | 14 | 11 | 11 | 9 | 8 | 6 | 5 | 8 | 10 | 11 | 13 | 13 | 118 |

| Variant | Month | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | Sum | |

| Bialystok | |||||||||||||

| A | −0.99 | −0.89 | −0.65 | −1.21 | −0.55 | −0.06 | 0.01 | −0.51 | −0.91 | −0.61 | −0.91 | −1 | −0.69 |

| B | −0.97 | −0.87 | −0.63 | −1.2 | −0.55 | −0.07 | 0 | −0.51 | −0.92 | −0.6 | −0.9 | −0.98 | −0.68 |

| C | −0.98 | −0.89 | −0.67 | −1.29 | −0.68 | −0.23 | −0.15 | −0.63 | −1.02 | −0.63 | −0.91 | −0.99 | −0.76 |

| Kiruna | |||||||||||||

| A | −1.32 | −1.08 | −0.79 | −1.46 | −1 | −0.29 | −0.16 | −1.02 | −1.82 | −0.83 | −1.22 | −1.27 | −1.02 |

| B | −1.21 | −1.03 | −0.76 | −1.42 | −0.98 | −0.27 | −0.13 | −0.99 | −1.79 | −0.81 | −1.13 | −1.15 | −0.97 |

| C | −1.2 | −1.05 | −0.79 | −1.51 | −1.1 | −0.43 | −0.29 | −1.08 | −1.82 | −0.82 | −1.12 | −1.14 | −1.03 |

| Variant | Month | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | Sum | |

| Electricity consumption for artificial lighting [kWh] | |||||||||||||

| Bialystok | |||||||||||||

| A | 73.8 | 65.1 | 67.3 | 52.9 | 49.9 | 43.8 | 48.4 | 51.8 | 59.0 | 69.6 | 70.5 | 74.3 | 726.4 |

| B | 74.1 | 65.4 | 67.6 | 54.2 | 50.3 | 44.6 | 48.9 | 52.7 | 59.6 | 70.4 | 70.9 | 74.7 | 733.3 |

| C | 74.3 | 65.7 | 68.2 | 55.0 | 50.9 | 44.7 | 49.5 | 52.9 | 60.0 | 71.2 | 71.3 | 75.0 | 738.7 |

| Kiruna | |||||||||||||

| A | 80.04 | 67.87 | 64.57 | 43.3 | 31.83 | 21.17 | 23.51 | 39.89 | 54.43 | 72.46 | 76.04 | 80.49 | 655.60 |

| B | 80.11 | 68.04 | 65.29 | 44.28 | 33.26 | 21.56 | 24.83 | 41.01 | 56.19 | 73.07 | 76.18 | 80.49 | 664.31 |

| C | 80.13 | 68.24 | 66.23 | 45.4 | 34.47 | 22.98 | 25.22 | 41.69 | 57.49 | 73.37 | 76.33 | 80.49 | 672.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zukowski, M. Study of Various Types of Glazing in a Building Constructed Using Hybrid Technology with a Large Window Area. Appl. Sci. 2025, 15, 4488. https://doi.org/10.3390/app15084488

Zukowski M. Study of Various Types of Glazing in a Building Constructed Using Hybrid Technology with a Large Window Area. Applied Sciences. 2025; 15(8):4488. https://doi.org/10.3390/app15084488

Chicago/Turabian StyleZukowski, Miroslaw. 2025. "Study of Various Types of Glazing in a Building Constructed Using Hybrid Technology with a Large Window Area" Applied Sciences 15, no. 8: 4488. https://doi.org/10.3390/app15084488

APA StyleZukowski, M. (2025). Study of Various Types of Glazing in a Building Constructed Using Hybrid Technology with a Large Window Area. Applied Sciences, 15(8), 4488. https://doi.org/10.3390/app15084488