Abstract

Bread is a staple food and can be enriched with a variety of deficient nutrients in the human diet. This study evaluated the impact of buckwheat hull addition on the mineral content of toasted bread made with wheat bread flour and wholemeal bread made with the addition of wholemeal wheat flour. Bread samples were prepared with different levels of buckwheat hull addition (1.5%, 3.0%, and 4.5%) and compared with a nonenriched control sample. The impact of buckwheat hull addition on mineral content was determined using atomic absorption spectrometry. In the tested bread samples, the macroelements, in terms of determined quantities, can be ordered as follows: potassium (K) > phosphorus (P) > calcium (Ca) > sodium (Na) > magnesium (Mg); microelements can be ordered as follows: zinc (Zn) > iron (Fe) > manganese (Mn) > copper (Cu). Statistical analysis showed a significant increase (p < 0.05) in the manganese content in all enriched breads samples, but the most important changes were observed between 1.5 and 4.5% of husk addition. Significant increases were also observed in the Zn, Mg, Ca, Na and K contents depending on the bread type and the level of husk concentration. This study showed the role of food processing methods, such as food enrichment with a functional ingredient—buckwheat husk—in enhancing the nutritional quality of bread. Buckwheat hull addition to bread increased the coverage of daily requirements for several minerals crucial for the proper functioning of the human body. The consumption of a 100 g portion of husk-enriched (4.5%) wholemeal bread makes it possible to cover up to almost 70% of the daily requirement for manganese in the adult diet.

1. Introduction

The growing consumer demand for health-promoting foods has led the baking industry to focus on fortifying and improving the nutritional quality of baked products by incorporating natural, nutrient-dense ingredients [1]. Food fortification, which has been utilized as a public health strategy to increase nutritional intakes over the last century, has effectively reduced the risk of nutrient deficiency illnesses [2]. Bread is one of the most popular foods consumed by the majority of people around the world. Most bread manufactured with refined flour is low in minerals, vitamins, fiber, and antioxidants since bran and germ are removed during grain manufacturing, milling, and grinding processes. Furthermore, bread dough requires a heating procedure to improve digestibility, palatability, and physical and nutritional qualities, resulting in further decreases or losses of bioactive components. As a result, bread can be low in nutrients and does not meet consumers’ nutritional and health requirements.

The success of bread as a basic food can be attributed to two key factors: its ease of preparation and component selection, as well as the variety of grains that can be used in its production. The fundamental ingredients of bread are flour, water, yeast, and salt, which are combined, fermented, and baked to create bread. Breads available on the food market differ in composition and nutritional value. Particularly, wholegrain bread is an important source of dietary fiber, minerals, B-group vitamins, complex carbohydrates and proteins. Improving bread composition in terms of functional components, such as protein, fiber, minerals, vitamins, and antioxidant content may offer additional health benefits for customers, as well as give marketing opportunities for food manufacturers in a competitive retail scenario [3,4,5]. In addition to well-known plant-based additives such as sunflower seeds, caraway seeds, pumpkin seeds, flax seeds and fruit additives, breads with unusual, new additives such as nigella, chia seeds and even vegetable additives (carrot, tomato, beetroot or broccoli) have also found places in commercial offerings [6]. These additives increase the levels of minerals in bread to a degree depending on their content of a specific raw material. For example, Zlateva et al. [7] showed that bread with 10% pumpkin seed flour had a 6.7 times higher iron content (8.98 mg/kg) compared with the control (1.34 mg/kg). Additionally, the contents of magnesium, phosphorus, and zinc increased with higher levels of pumpkin seed flour substitution, with zinc increasing from 5.09 mg/kg in the control to 12.7 mg/kg in bread with 10% pumpkin seed flour. Czarnowska-Kujawska et al. [8] observed significant (p < 0.05) increases in Fe, Mg, Ca and K in breads fortified with 20% and 40% additions of fresh spinach. The most spectacular increase was reported for Ca—73% and 97%—and K—52% and 116%—in breads with 20% and 40% spinach addition, respectively, compared with the control. The same authors [8] proved that a 20% addition of fresh kale to bread dough significantly (p < 0.05) increased the levels of Mn, Fe, Mg, K and Ca in the final product. In the study of Purkiewicz et al. [9], the effect of adding other vegetables on bread mineral composition was tested. The highest increase was reported for Ca, ranging from 51% to 113% in bread samples enriched with 10% and 20% carrot and pumpkin powders. In terms of microelements, the addition of these powders to wheat bread caused the largest changes in Cu (46–150% increase) and Mn (25–99% increase) contents.

An interesting and innovative additive to bread that does not require cultivation and can be obtained very easily is buckwheat husk. It is a byproduct obtained in large quantities during the production of buckwheat groats. It is popular in many countries, and its purchase and storage are more economical and convenient than the plant additives discussed above. Over the years, buckwheat hull has been used in non-food industries as a filling for mattresses and pillows, and there have been attempts to use it as a biofuel [10]. Meanwhile, the husk, due to its health-promoting properties resulting from its high bioactive contents, can be successfully used to enrich various food products [11]. In the available literature, only a few articles on enriching bread with buckwheat husk are available, and they are mainly concerned with husk addition’s effect on bread structure [11,12]. Ground buckwheat hulls, available in food markets, are a dusty product and cannot be consumed on their own as they can cause choking and suffocation; they can only be used as an addition to food. Buckwheat husk’s high fiber content, which is well known for its ability to improve digestive health, increase satiety and help with weight management, is one of its most notable qualities. The husk is a rich source of various mineral compounds, and their contents primarily depend on the variety of buckwheat and the method of removing the husk during buckwheat groat production. Moreover, it was indicated that when added to wheat bread products, buckwheat components enhanced the microbiological properties of bread and modified its sensory qualities without affecting customer approval [13].

In previous research, we have shown that the addition of buckwheat husk to bread can improve its sensory properties, and, depending on the size and method of addition, it can increase its phenolic content and antioxidant activity [14,15]. While existing research has shown the nutritional benefits of buckwheat groats and flour, there is a notable gap regarding the mineral fortification potential of buckwheat hulls in bread formulations. However, it can be hypothesized that the addition of buckwheat husk to bread formulations will lead to a significant increase in the overall mineral content of the bread. This can enhance bread nutritional value and potentially contribute to the meeting of daily mineral requirements through its consumption. The aim of the study was to determine the degree of mineral content modification in bread after adding the functional ingredient of buckwheat husk. The test material consisted of two types of bread, wholemeal and toasted, which were baked in laboratory conditions with various additions of commercially available ground buckwheat husk.

2. Materials and Methods

2.1. Bread Preparation

The bread ingredients (Table 1) utilized in this study (sunflower oil, salt, sugar, powdered milk, wholemeal wheat flour, special wheat bread flour, and dried baker’s yeast) were bought in a local supermarket in the Northeast of Poland. Ground buckwheat husk was bought from an online store in Poland. Two types of wheat bread were prepared, toasted and wholemeal. Breads were enriched with buckwheat husk at 1.5%, 3%, and 4.5%. Control bread samples without husk were also prepared. The selected levels of buckwheat husk addition (1.5%, 3%, and 4.5%) were chosen based on a balance between nutritional enhancement and maintaining desirable sensory and functional properties of the bread. The amount of buckwheat husk incorporated in this study was determined based on preliminary, unpublished research that assessed the elasticity and compactness of breadcrumb. This research helped ensure that the texture and baking properties of the bread were not adversely affected by the addition of husk while allowing for significant modifications to the mineral contents. Lower levels (1.5%) ensured minimal impact on texture and flavor while providing measurable mineral fortification, whereas higher levels (3% and 4.5%) allowed for the evaluation of the maximum enrichment potential before adverse effects on bread quality may occur. These percentages also aligned with the ranges explored in previous fortification studies.

Table 1.

Tested breads formulae.

Altogether, eight variations of bread were prepared: TB 0—toasted bread without buckwheat husk; TB 1.5%, TB 3.0%, and TB 4.5%—toasted breads with 1.5%, 3.0%, and 4.5% buckwheat husk addition, respectively; WB 0—wholemeal bread without buckwheat husk; and WB 1.5%, WB 3.0%, and WB 4.5%—wholemeal breads with 1.5%, 3.0%, and 4.5% buckwheat husk addition, respectively. For the preparation of bread, an automated bread machine (Tefal PF6118 bread maker 1600W, Is-sur-Tille, France) was used. After the baking process (200 °C) was completed, the loaves were left to cool at room temperature and then crumbled in a high-speed vacuum blender (Philips HR3752/00, München, Germany) and collected for mineral analysis. Higher concentrations of buckwheat hull resulted in a denser, firmer and softer crumb. As the husk addition increased, the typical bread flavor was less intense and the crumb was darker.

2.2. Chemicals and Reagents

Deionized water used throughout the experiment with resistivity > 18.2 MΩ. cm was obtained with a Synergy water deionizer (Merck, Darmstadt, Germany). Cu, Mn, Fe, Zn, Mg, K, Na, and Ca standards with a concentration of 1 mg/cm3 were purchased from J.T. Baker (Deventer, The Netherlands), and a P standard (concentration of 1000 mg PO4) was purchased from Merck (Darmstadt, Germany). Hydrated lanthanum chloride used in the mineral content determination was purchased from Merck (Darmstadt, Germany). Ammonium molybdate VI, sodium sulfate IV, hydroquinone and other reagents used in the study were purchased from “POCH” S. A. (Gliwice, Poland).

2.3. Mineral Determination

After being weighed in borosilicate glass tubes, the bread samples were mineralized in a 3:1 (v:v) solution of nitric and perchloric acids. The temperature was progressively raised from 100 °C to 180 °C over the course of a few hours in an electric aluminum heating block (VELP DK 20, Scientifica, East Sussex, UK) used for the mineralization process. The resulting colorless mineralizate was poured into a 50 cm3 volumetric flask and filled to the appropriate level with deionized water.

The flame atomic absorption spectrometry (acetylene–air flame) technique was used to determine copper (Cu), manganese (Mn), iron (Fe), zinc (Zn), magnesium (Mg), and calcium (Ca) using a Thermo iCE 3000 Series (Madison, WI, USA) atomic absorption spectrometer equipped with a Glite data station, background correction (deuterium lamp), and appropriate cathode lamps [16]. To determine Ca, a 10% aqueous solution of lanthanum chloride was added to each measured solution in a proportion that ensured a final La+3 concentration of 1%. The selected elements were determined using the following wavelengths: 324.8 nm (Cu), 279.5 nm (Mn), 248.3 nm (Fe), 213.9 nm (Zn), 285.2 nm (Mg), and 422.7 nm (Ca). The emission technique (acetylene–air flame) was used to determine sodium (Na) and potassium (K) using a Thermo iCE 3000 Series atomic absorption spectrometer (Waltham, MA, USA), which was equipped with a Glite data station and operated in an emission system. Minerals were measured at wavelengths of 589.0 nm (Na) and 766.5 nm (K). The phosphorus content was determined using the colorimetric method with ammonium molybdate (VI), sodium sulfate (IV), and hydroquinone. Ammonium molybdate was transformed into phosphomolybdates, which were then reduced to phosphomolybdenum blue using sodium sulphate and hydroquinone. Analysis was performed using a VIS 6000 spectrophotometer (KRÜSS-OPTRONIC, Hamburg, Germany) set at 610 nm. Individual mineral content was expressed as the mean of three replicates with standard deviation in 100 g of fresh bread samples. The percentage coverage of daily demand for selected minerals was calculated based on recommended daily allowance, RDA [17], and individual mineral contents determined in the tested bread sample.

2.4. Statistical Analysis

The data were evaluated using the Statistica software package version 13.1 (StatSoft, Krakow, Poland, 2016). The minerals’ mean contents were compared using a one-way ANOVA with Duncan’s post hoc test at a significance level of p < 0.05. The correlation coefficients between analyzed components were determined with Pearsons’s correlation analysis at the p < 0.05 confidence level.

3. Results and Discussion

3.1. Mineral Contents in the Tested Bread Samples

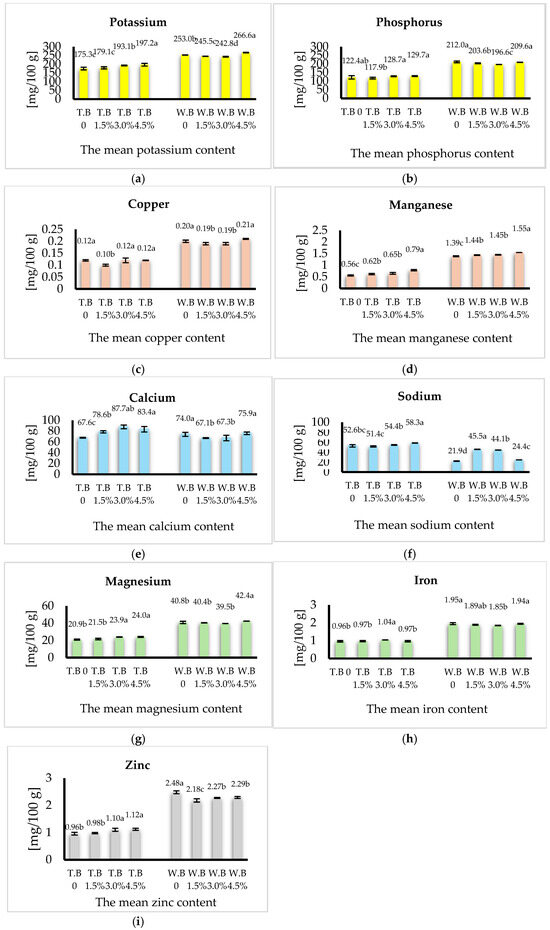

The results showed that potassium and phosphorus were the most abundant minerals in both the enriched and non-enriched breads (Figure 1a,b). Their contents ranged, depending on the addition of buckwheat husk, from 175.3 to 197.2 mg/100 g and from 122.4 to 129.7 mg/100 g in toasted bread, while in wholemeal bread, they ranged from 253.0 to 266.6 mg/100 g and from 212.0 to 209.6 mg/100 g, respectively. Copper and manganese were found in the lowest amounts ranging from 0.10 to 0.12 mg/100 g and from 0.56 to 0.79 mg/100 g in toasted bread and from 0.19 to 0.21 mg/100 g and from 1.39 to 1.55 mg/100 g in wholemeal bread (Figure 1c,d), respectively. The calcium content in both types of analyzed breads ranged from approx. 67 to 88 mg/100 g (Figure 1e), while the sodium and magnesium levels (Figure 1f,g) were several times lower and ranged from approx. 20 to 59 mg/100 g. The iron and zinc contents were detected in significantly lower amounts, from approximately 1 to 2.5 mg/100 g (Figure 1h,i). Similar contents of mineral components, especially a high level of potassium and phosphorus and low amounts of copper and manganese in various types of breads, were indicated by Torrinha et al. [18] and Ertl et al. [19]. Their studies confirmed that the levels of minerals in bread depend not only on the type of grain from which the flour was obtained but also on the method applied for grain milling, the flour extract, and other ingredients used in the baking process. In our study, for almost all elements that were tested, the quantities present in the wholemeal breads were superior to the quantities measured in the toasted breads with and without the addition of buckwheat husk. Wholemeal bread without buckwheat husk contained higher levels of chromium (Cu), manganese (Mn), iron (Fe), zinc (Zn), magnesium (Mg), and potassium (K) in comparison with nonenriched toasted bread. This is largely due to the retention of the bran and germ, which are naturally rich in minerals in wholemeal flour during its processing. In comparison with wholemeal flour, white wheat flour (used in toasted bread preparation) undergoes milling processes that remove these nutrient-dense components.

Figure 1.

Effects of different buckwheat hull additions on individual mineral contents in toasted and wholemeal breads. Values are expressed as means (n = 3) ± standard deviations. Mean values for the individual mineral contents of tested toasted and wholemeal breads with different lowercase letters are statistically different (p < 0.05) according to the Duncan’s test. TB 0—toasted bread without buckwheat husk; TB 1.5%, TB 3.0%, and TB 4.5%—toasted breads with 1.5%, 3.0%, and 4.5% buckwheat husk addition, respectively; WB 0—wholemeal bread without buckwheat husk; WB 1.5%, WB 3.0%, and WB 4.5%—wholemeal breads with 1.5%, 3.0%, and 4.5% buckwheat husk addition, respectively.

Analyzing the effect of husk addition on the levels of elements determined in the toasted bread showed that it caused a systematic increase in the levels of potassium, manganese, zinc, and magnesium (Figure 1a,d,g,i). The potassium content increased from the level of 175.3 mg/100 g in the control sample to 197.2 mg/100 g in the sample with the highest, 4.5%, husk addition; the manganese, zinc, and magnesium contents increased from 0.56 to 0.79 mg/100 g, from 0.96 to 1.12 mg/100 g, and from 20.9 to 24.0 mg/100 g, respectively (Figure 1a,d,g,i). The addition of 3% and 4.5% husk also caused an increase in the sodium content, while the lowest addition of husk resulted in a decrease in this element’s level (Figure 1f). The calcium level was significantly (p < 0.05) affected by husk addition at all levels of enrichment, increasing from 67.6 mg/100 g in the control sample to the highest content of 87.7 mg/100 g in TB 3.0% (Figure 1e). On the contrary, the addition of buckwheat husk did not significantly increase (p < 0.05) the copper and phosphorus levels, which were slightly reduced by the 1.5% husk addition (Figure 1c,b). Also, no significant (p < 0.05) difference in the content of iron was observed after husk addition in the tested toasted breads (Figure 1h).

In the case of the wholemeal bread, the addition of buckwheat husk affected the levels of the mineral components to a much less noticeable extent than in toasted bread (Figure 1a–i). The only element whose level systematically increased, although in a small range starting from the smallest 1.5% addition of husk, was manganese (Figure 1d). In the control sample, this element was determined at the level of 1.39 mg/100 g; after the 1.5% addition of husk, this content increased to 1.44 mg/100 g; it did not significantly change (p < 0.05) with the 3% husk addition; and after adding 4.5% of husk, it increased to 1.55 mg/100 g (Figure 1d). The sodium content at 1.5 and 3% of husk addition increased almost twice (from 22 mg/100 g in WB 0 to approx. 45 mg/100 g in WB 1.5% and WB 3.0%), while at the highest husk addition of 4.5%, it decreased to 24.4 mg/100 g (Figure 1f). For other elements, changes due to husk addition were less noticeable (Figure 1a–c,e,g–i), except for significant (p < 0.05) increases in potassium and magnesium in WB 4.5% (Figure 1a,g). There is a lack of information in the available literature on the influence of the addition of buckwheat hull on bread composition. Only data on the content of selected ingredients in husk-enriched pasta were found. A study by Milićević et al. [20] showed that the addition of buckwheat husk significantly enhances the potassium and phosphorus contents of pasta. However, the copper and manganese contents were relatively low in the tested samples with lower percentages of buckwheat husk. Our results are in agreement with the results obtained by Milićević et al. [20], showing that buckwheat addition increased certain mineral levels, although thermal processes may be a factor in reducing their contents. The incorporation of buckwheat, whether in the form of husk for bread or flour from starchy endosperm for pasta, generally improves the mineral content of the final product. However, the extent of this improvement and the impact of cooking vary for different minerals [21]. Salejda et al. [22] reported that buckwheat husk can be also added into frankfurter-type sausages, which was proven to have a substantial effect on mineral content. The authors indicated that the addition of this non-meat byproduct raised the levels of manganese, calcium, potassium, and magnesium, with the first trace element increasing nearly sixfold and the last by more than 40%. This comparison showed that buckwheat husk enrichment generally increases the potassium and phosphorus contents in different food matrices, with little variations in mineral content depending on the type of product and percentage of husk addition. It should be noted that in industrial practice, buckwheat hulls are obtained with slightly different compositions and properties due to the different courses of the dehulling process. The peeling elements of some machines cause parts of the buckwheat seeds to crack. This results in the transfer to the husk fraction of not only the seed coat but also cotyledon fragments together with the embryo and aleurone layer, which contain completely different mineral compounds than the outer parts of the seeds [23,24]. The granulation of the buckwheat husk produced in different groats also varies, which influences the differences in its properties. Regardless, buckwheat husk is a valuable food additive that positively influences the nutritional value and often also the sensory properties of food products. [11,24]. For instance, in the study of Amini et al. [25], it was shown that the enrichment of bread with whole green banana flour significantly improved its nutritional profile, particularly in terms of macrominerals like potassium, calcium, sodium, phosphorus, and magnesium. This observed increase is in agreement with our findings, which proved that buckwheat husk addition improved the contents of macrominerals like potassium and magnesium. In contrast to our study on buckwheat husk addition to breads, Amini et al. [25] did not observe significant changes in the levels of microminerals such as iron, zinc, and manganese. This may have resulted from the different mineral compositions of the additives used for enrichment. Buckwheat hull is rich in trace minerals, which explains the increase in manganese and copper in the enriched bread we analyzed, while green banana flour is richer in macrominerals.

Although the mechanism of the observed changes in the profile of minerals in the tested breads samples was not analyzed in this study, our previous studies results [26,27] and literature data allowed us to make certain conclusions. During food preparation processes including cooking, processing and storage, mineral components can undergo various changes that affect their bioavailability and the final composition of the product [26,28,29]. During food processing, mineral components can interact with other food components, making them unavailable for digestion. Fiber, particularly soluble fiber, can bind certain minerals, potentially affecting their absorption in the digestive tract [30]. The binding effect depends on the type of fiber and its concentrations [31]. The insoluble fraction of this component mainly consists of non-fermentable cellulose, hemicellulose and lignin, while the soluble fiber is composed of easily fermentable pectins, gums and mucilages. Cellulose and lignin have been shown to have a high metal binding capacity, but the NDF (neutral detergent) and ADF (acid detergent) fractions act at a physiological level to improve digestibility and mineral availability, as well as influencing a range of nutrient interactions [29,32]. Baye et al. [33] add that many in vitro studies have not shown a negative effect of fiber on mineral bioavailability and in some cases have even reported an increase in mineral absorption. This may be due to the fermentation of some fiber fractions occurring in the intestines, resulting in the release of previously bound minerals and their absorption in the large intestine. Both the wholemeal flour and buckwheat husk used in the present study for bread preparation were rich in fiber [34]. Fiber can form complexes with minerals such as calcium, iron, and zinc, which may reduce their bioavailability [31], which was also confirmed in our study. Moreover, plant products also contain elements other than fiber such as phytates and some fractions of polyphenols, which are often more potent inhibitors of mineral absorption. This makes the question of the bioavailability of minerals in plant products even more complex [35,36]. In our previous study [24,37], we showed that the interactions between these components significantly depend on the heat treatment parameters of buckwheat grains. A high temperature can inactivate endogenous phytase, which prevents the breakdown of phytates and the release of many minerals. On the other hand, phytates can be degraded during hydrothermal treatment, which releases minerals and increases their bioavailability [37,38]. Phenolic compounds also undergo thermal degradation, resulting in additional mineral release. The intensity of these changes is greater at higher heating temperatures [35]. The influence of thermal processes is equally important in the context of buckwheat hull extraction, since the process of dehulling the seeds under industrial conditions takes place after heating (intensively in the production of roasted buckwheat and gently in the case of unroasted buckwheat). We indicated that a shorter hydrothermal process conducted at a lower temperature was significantly more beneficial for the availability of buckwheat minerals (especially Mn and Mg) than a longer roasting process conducted at a higher temperature (which had particularly adverse effects on Zn and Cu) [37]. Equally important is the effect of the heat treatment applied during bread baking on the availability of minerals, as well as on their structure and their interactions (including synergism and antagonism). High temperatures and prolonged baking can lead to the breakdown of some organic compounds that minerals are bound to, resulting in their release or change in form, with varying degrees depending on the type of heat treatment and form of the minerals [30,31]. The final mineral contents of the baked bread will also depend on the used ingredients, such as flour, salt, and additives, as well as the baking time and temperature. Different baking methods can impact the degree to which minerals are retained in the unchanged form.

Analyzing the correlations between the elements determined in the tested breads (Table 2), it should be noted that minerals such as copper, manganese, iron, zinc, magnesium, potassium and phosphorus showed strong positive correlations with each other, meaning that an increase in one element’s content tends to coincide with increases in the others. These correlations may indicate the similarity of the chemical bonds elements such as these form in wheat grains and/or products derived from them. On the other hand, sodium showed significant negative correlations with these elements, indicating that as sodium levels increased, the content of these minerals decreased. This may indicate a problem of too-low contents of beneficial minerals for the human organism found in raw plant materials grown on soils with high salinity, as pointed out by Li et al. [39].

Table 2.

Correlation between determined minerals in tested bread samples.

Calcium showed weaker and less consistent correlations, being moderately negatively correlated with most other elements except sodium (Table 2). These correlations suggest that the reason for the correlations is the interplay between mineral absorption and retention during the bread-making process, in which the presence or concentration of one mineral may affect the others. Such relationships were also pointed out by Rousseau et al. [40], who emphasized that the extent and direction of mineral interactions depended to a large extent on the matrix of food products, in particular interactions with components such as fiber, phytates, oxalates and phenolic compounds.

3.2. Evaluation of the Coverage of Daily Demand for Selected Minerals

Minerals are ingredients that humans cannot synthesize, so they must be supplied with food. These compounds are classified into two groups based on the size of the daily demand and the amount of the element in the body: macroelements, whose daily requirement is greater than 100 mg/ person and whose content in alive organisms is at a level above 0.01%, and microelements, often known as trace elements, for which the daily requirement is less than 100 mg/person and less than 0.01% in alive organisms [27].

Table 3 presents the recommended daily allowance of the determined minerals in our study and the percentage coverage of daily requirements for individual minerals through the consumption of 100 g (approximately three slices) of the tested breads. Such a portion of bread allowed for the greatest coverage of the daily demand for manganese, approximately 60% in the case of wholemeal bread, up to 67% in the WB 4.5%, and approximately 30% in toasted enriched breads. The presented results of daily manganese demand coverage are worth paying attention to due to the importance of this element’s role in the human diet. It is necessary for the proper metabolism of proteins, lipids and carbohydrates. Moreover, manganese plays an important role in the processes of tissue growth and regeneration, and it also affects the functioning of the nervous system [41,42]. The tested breads, the wholemeal breads in particular, were proven to be an important source of phosphorus, copper and zinc, similarly to the case of manganese. The consumption of 100 g of wholemeal bread can cover 30% of the recommended daily intake of phosphorus and 20% of the recommended daily intake of copper and zinc.

Table 3.

The coverage of the daily demand for selected minerals after consuming a 100 g portion of the tested bread samples.

Many authors have pointed out the importance of bread consumption in supplementing the human population’s diet with minerals [43,44]. The values they have indicated for covering the daily requirements for individual minerals depend to a large extent on the type of bread and the additives used during the baking process, as well as the established standards for the recommended daily intake of individual elements in different countries. Many authors [45,46] have also confirmed the higher value of whole grain bread in providing minerals to human organisms compared with toasted bread derived from white flour [45,47]. The nutritional and physiological benefits of whole grain wheat flour have made it a popular addition in bread recipes. In addition to minerals, whole wheat flour contains more nutrients than flour without the outer parts of grain, especially antioxidants, fiber (such as arabinoxylans and other non-starch polysaccharides), vitamins and other phytochemicals like flavonoids, phenolic acids, and carotenoids [47,48,49]. Eating whole grain products is associated with a variety of health benefits, including a lower risk of mortality from non-communicable chronic diseases such as diabetes, cancer, obesity and cardiovascular disease [46,47,48].

The consumption of bread, especially white bread, has significantly declined in Western countries over the past few decades. This change in consumer preferences seems to be due to the quality of bread. Consumers’ perception of bread is linked to trends, such as a gluten-free diet, which corresponds to their purchasing decisions. In countries with low fiber intake and high salt intake, an increase in the consumption of wholemeal bread, which contains more fiber and is perceived as a healthier option, has been observed [46]. Thus, the inclusion of buckwheat hull, whose ingredients can have a positive impact on health, in the preparation of foods such as bread with increased nutritional value appears to be an attractive option for consumers.

4. Conclusions

We demonstrated that the mineral composition of bread can be significantly modified by incorporating buckwheat husk, showing its potential as a functional ingredient to enhance the nutritional profile of both toasted and wholemeal bread. The degree of mineral content changes in fortified breads depends on the amount of buckwheat hull added, as well as the type of bread. The extent of the observed changes may also have resulted from mutual interactions between the mineral components, as indicated by the high and statistically significant values of the correlation coefficients determined between them.

Considering the levels of the determined contents of minerals in the tested breads, it is worth noting that bread can be their significant source in the human diet, especially manganese, phosphorus, copper and zinc. This is confirmed by the high values of the estimated degree of coverage of the daily requirement for the analyzed elements by a 100 g portion of the tested breads, which is particularly noticeable in the case of bread baked from wholegrain flour compared with white flour without a seed coat.

A limitation of our study was the lack of a detailed analysis of the influence of various baking parameters on the bioavailability of the minerals determined not only in terms of the amount of buckwheat hull added but also in terms of the method of its removal and granulation. We also did not quantify the relationship between the levels of minerals and the contents of components that limit their digestion and absorption in the body, such as fiber, phytates and polyphenolics. This will certainly be a goal of our future research, as will a detailed sensory analysis of bread baked with the addition of husk.

We have analyzed all the indicated limitations in detail in the text of our article. This allows us to state unequivocally that an important outcome of our research is the identification of an easy way to enrich bread with buckwheat hulls, which is practically unused in the food industry, cheap, and easy to obtain and store. In addition to the minerals we analyzed, the husks are also a rich source of fiber and antioxidants, the consumption of which is still too low.

It is worth emphasizing that bread enriched with buckwheat husk gains the status of a functional food that can be produced not only by bakeries and other food plants but also by consumers baking bread at home. Groat factories may also be interested in such solutions, as they will gain a new market for buckwheat husks that are mainly sold for non-food purposes, which can not only improve their financial result and diversify the food market offer but also contribute to supporting ecological solutions based on the wider use of waste products from the food industry.

Author Contributions

W.M.: conceptualization, experiment performance, methodology and validation, data analysis, formal analysis, review, and writing—original draft preparation; J.K.: conceptualization, writing—original draft, review and editing, supervision, and funding acquisition; M.C.-K.: conceptualization, writing—original draft, review and editing, and supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Minister of Science under “the Regional Initiative of Excellence Program”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

Acknowledgement for technical support during the implementation of the study to Elżbieta Tońska from the Department of Commodity and Food Analysis.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Boukid, F.; Zannini, E.; Carini, E.; Vittadini, E. Pulses for Bread Fortification: A Necessity or a Choice? Trends Food Sci. Technol. 2019, 88, 416–428. [Google Scholar] [CrossRef]

- Dwyer, J.T.; Wiemer, K.L.; Dary, O.; Keen, C.L.; King, J.C.; Miller, K.B.; Philbert, M.A.; Tarasuk, V.; Taylor, C.L.; Gaine, P.C.; et al. Fortification and Health: Challenges and Opportunities. Adv. Nutr. 2015, 6, 124–131. [Google Scholar] [CrossRef]

- De Boni, A.; Pasqualone, A.; Roma, R.; Acciani, C. Traditions, Health and Environment as Bread Purchase Drivers: A Choice Experiment on High-Quality Artisanal Italian Bread. J. Clean. Prod. 2019, 221, 249–260. [Google Scholar] [CrossRef]

- Edwards, W.P. The Science of Bakery Products; The Royal Society of Chemistry: Cambridge, UK, 2007; Volume 382. [Google Scholar] [CrossRef]

- Ibrahim, U.K.; Salleh, R.M.; Maqsood-ul-Haque, S.N.S. Bread towards Functional Food: An Overview. ETP Int. J. Food Eng. 2015, 1, 39–43. [Google Scholar] [CrossRef][Green Version]

- Ranawana, V.; Raikos, V.; Campbell, F.; Bestwick, C.; Nicol, P.; Milne, L.; Duthie, G. Breads Fortified with Freeze-Dried Vegetables: Quality and Nutritional Attributes. Part 1: Breads Containing Oil as an Ingredient. Foods 2016, 5, 19. [Google Scholar] [CrossRef]

- Zlateva, D.; Stefanova, D.; Chochkov, R.; Ivanova, P. Study on the Impact of Pumpkin Seed Flour on Mineral Content of Wheat Bread. Food Sci. Appl. Biotechnol. 2022, 5, 131–139. [Google Scholar] [CrossRef]

- Czarnowska, M.; Starowicz, M.; Barišić, V.; Kujawski, W. Health-Promoting Nutrients and Potential Bioaccessibility of Breads Enriched with Fresh Kale and Spinach. Foods 2022, 11, 3414. [Google Scholar] [CrossRef] [PubMed]

- Purkiewicz, A.; Gul, F.H.; Pietrzak-Fiećko, R. The Utilization of Vegetable Powders for Bread Enrichment—The Effect on the Content of Selected Minerals, Total Phenolic and Flavonoid Content, and the Coverage of Daily Requirements in the Human Diet. Appl. Sci. 2024, 14, 10022. [Google Scholar] [CrossRef]

- Guo, X.-D.; Wu, C.-S.; Ma, Y.-J.; Parry, J.; Xu, Y.-Y.; Liu, H.; Wang, M.J. Comparison of Milling Fractions of Tartary Buckwheat for Their Phenolics and Antioxidant Properties. Food Res. Int. 2012, 49, 53–59. [Google Scholar] [CrossRef]

- Gutiérrez, Á.L.; Villanueva, M.; Rico, D.; Harasym, J.; Ronda, F.; Martín-Diana, A.B.; Caballero, P.A. Valorisation of Buckwheat By-Product as a Health-Promoting Ingredient Rich in Fibre for the Formulation of Gluten-Free Bread. Foods 2023, 12, 2781. [Google Scholar] [CrossRef]

- Wang, L.; Li, Y.; Guo, Z.; Wang, H.; Wang, A.; Li, Z.; Chen, Y.; Qiu, J. Effect of Buckwheat Hull Particle-Size on Bread Staling Quality. Food Chem. 2022, 405, 134851. [Google Scholar] [CrossRef] [PubMed]

- Wronkowska, M.; Zieliński, H.; Szmatowicz, B.; Ostaszyk, A.; Lamparski, G.; Majkowska, A. Effect of Roasted Buckwheat Flour and Hull Enrichment on the Sensory Qualities, Acceptance and Safety of Innovative Mixed Rye/Wheat and Wheat Bakery Products. J. Food Process. Preserv. 2019, 43, e14025. [Google Scholar] [CrossRef]

- Klepacka, J. Determining the Possibility of Using Buckwheat Hulls in the Food Industry. Food Ind. 2023, 12, 36–38. [Google Scholar] [CrossRef]

- Klepacka, J.; Czarnowska-Kujawska, M. An Evaluation of the Possibility of Using Buckwheat Hulls as an Addition to Bread. Proceedings 2023, 91, 347. [Google Scholar] [CrossRef]

- Whiteside, P.; Miner, B. Pye Unicam Atomic Absorption Data Book; Pye Unicam Ltd.: Cambridge, UK, 1984. [Google Scholar]

- Jarosz, M. Nutrition Standards for the Polish Population; Food and Nutrition Institute: Warsaw, Poland, 2017; Available online: http://zywnosc.com.pl/wp-content/uploads/2017/12/normy-zywienia-dla-populacji-polski-2017-1.pdf (accessed on 30 August 2022).

- Torrinha, Á.; Oliveira, M.; Marinho, S.; Paíga, P.; Delerue-Matos, C.; Morais, S. Mineral Content of Various Portuguese Breads: Characterization, Dietary Intake, and Discriminant Analysis. Molecules 2019, 24, 2787. [Google Scholar] [CrossRef]

- Ertl, K.; Goessler, W. Grains, Whole Flour, White Flour, and Some Final Goods: An Elemental Comparison. Eur. Food Res. Technol. 2018, 244, 2065–2075. [Google Scholar] [CrossRef]

- Milićević, N.; Sakač, M.; Mandić, A.; Psodorov, D.; Jambrec, D.; Pestorić, M.; Sedej, I.; Tamara; Hadnadev, D. Rheological Properties and Mineral Content of Buckwheat Enriched Wholegrain Wheat Pasta. Chem. Ind. Chem. Eng. Q. 2014, 20, 135–142. [Google Scholar] [CrossRef]

- Jachimowicz, K.; Winiarska-Mieczan, A.; Baranowska-Wójcik, E.; Bąkowski, M. Pasta as a Source of Minerals in the Diets of Poles: Effect of Culinary Processing of Pasta on the Content of Minerals. Foods 2021, 10, 2131. [Google Scholar] [CrossRef] [PubMed]

- Salejda, A.M.; Olender, K.; Zielińska-Dawidziak, M.; Mazur, M.; Szperlik, J.; Miedzianka, J.; Zawiślak, I.; Kolniak-Ostek, J.; Szmaja, A. Frankfurter-Type Sausage Enriched with Buckwheat By-Product as a Source of Bioactive Compounds. Foods 2022, 11, 674. [Google Scholar] [CrossRef]

- Steadman, K.J.; Burgoon, M.S.; Lewis, B.A.; Edwardson, S.E.; Obendorf, R.L. Minerals, Phytic Acid, Tannin and Rutin in Buckwheat Seed Milling Fractions. J. Sci. Food Agric. 2001, 81, 1094–1100. [Google Scholar] [CrossRef]

- Klepacka, J.; Najda, A. Effect of Commercial Processing on Polyphenols and Antioxidant Activity of Buckwheat Seeds. Int. J. Food Sci. Technol. 2021, 56, 661–670. [Google Scholar] [CrossRef]

- Amini, K.A.; Kebede, B.; Birch, J.; Bekhit, A.E.-D.A. The Effect of Bread Fortification with Whole Green Banana Flour on Its Physicochemical, Nutritional and In Vitro Digestibility. Foods 2020, 9, 152. [Google Scholar] [CrossRef]

- Johnson, P.E. Effect of Food Processing and Preparation on Mineral Utilization. Adv. Exp. Med. Biol. 1991, 289, 483–498. [Google Scholar] [CrossRef] [PubMed]

- Klepacka, J.; Tońska, E.; Rafałowski, R.; Czarnowska, M.; Opara, B. Tea as a Source of Biologically Active Compounds in the Human Diet. Molecules 2021, 26, 1487. [Google Scholar] [CrossRef] [PubMed]

- Ward, T.A.; Reichert, R.D. Comparison of the Effect of Cell Wall and Hull Fiber from Canola and Soybean on the Bioavailability for Rats of Minerals, Protein and Lipid. J. Nutr. 1986, 116, 233–241. [Google Scholar] [CrossRef] [PubMed]

- Miller, M.D.; Kokko, C.; Ballard, C.S.; Dann, H.M.; Fustini, M.; Palmonari, A.; Formigoni, A.; Cotanch, K.W.; Grant, R.J. Influence of Fiber Degradability of Corn Silage in Diets with Lower and Higher Fiber Content on Lactational Performance, Nutrient Digestibility, and Ruminal Characteristics in Lactating Holstein Cows. J. Dairy Sci. 2020, 104, 1728–1743. [Google Scholar] [CrossRef]

- Baye, K.; Guyot, J.-P.; Mouquet-Rivier, C. The Unresolved Role of Dietary Fibers on Mineral Absorption. Crit. Rev. Food Sci. Nutr. 2015, 57, 949–957. [Google Scholar] [CrossRef]

- Lattimer, J.M.; Haub, M.D. Effects of dietary fiber and its components on metabolic health. Nutrients 2010, 2, 1266–1289. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Triki, T.; Tlahig, S.; Benabderrahim, M.A.; Elfalleh, W.; Mabrouk, M.; Bagues, M.; Yahia, H.; Belhouchette, K.; Guasmi, F.; Loumerem, M. Variation in Phenolic, Mineral, Dietary Fiber, and Antioxidant Activity across Southern Tunisian Pearl Millet Germplasm. J. Food Qual. 2022, 2022, 1437306. [Google Scholar] [CrossRef]

- Juśkiewicz, J.; Fotschki, B.; Stępniowska, A.; Cholewińska, E.; Napiórkowska, D.; Marzec, A.; Ognik, K. Dietary Fiber with Functional Properties Counteracts the Thwarting Effects of Copper Nanoparticles on the Microbial Enzymatic Activity and Short-Chain Fatty Acid Production in the Feces of Rats. Pol. J. Food Nutr. Sci. 2024, 74, 363–375. [Google Scholar] [CrossRef]

- Gębski, J.; Jeżewska-Zychowicz, M.; Szlachciuk, J.; Kosicka-Gębska, M. Impact of Nutritional Claims on Consumer Preferences for Bread with Varied Fiber and Salt Content. Food Qual. Prefer. 2019, 76, 91–99. [Google Scholar] [CrossRef]

- Torre, M.; Rodriguez, A.R.; Saura-Calixto, F. Effects of Dietary Fiber and Phytic Acid on Mineral Availability. Crit. Rev. Food Sci. Nutr. 1991, 30, 1–22. [Google Scholar] [CrossRef] [PubMed]

- Petry, N.; Egli, I.; Zeder, C.; Walczyk, T.; Hurrell, R. Polyphenols and Phytic Acid Contribute to the Low Iron Bioavailability from Common Beans in Young Women. J. Nutr. 2010, 140, 1977–1982. [Google Scholar] [CrossRef] [PubMed]

- Klepacka, J.; Najda, A.; Klimek, K. Effect of Buckwheat Groats Processing on the Content and Bioaccessibility of Selected Minerals. Foods 2020, 9, 832. [Google Scholar] [CrossRef]

- Pongrac, P.; Potisek, M.; Fraś, A.; Likar, M.; Budic, B.; Myszka, K.; Boros, D.; Necemer, M.; Kelemen, M.; Vavpetič, P.; et al. Composition of Mineral Elements and Bioactive Compounds in Tartary Buckwheat and Wheat Sprouts as Affected by Natural Mineral-Rich Water. J. Cereal Sci. 2016, 69, 10. [Google Scholar] [CrossRef]

- Li, C.; Gao, X.; Li, S.; Bundschuh, J. A Review of the Distribution, Sources, Genesis, and Environmental Concerns of Salinity in Groundwater. Environ. Sci. Pollut. Res. 2020, 27, 41157–41174. [Google Scholar] [CrossRef]

- Rousseau, S.; Kyomugasho, C.; Celus, M.; Hendrickx, M.; Grauwet, T. Barriers Impairing Mineral Bioaccessibility and Bioavailability in Plant-Based Foods and the Perspectives for Food Processing. Crit. Rev. Food Sci. Nutr. 2019, 60, 826–843. [Google Scholar] [CrossRef]

- Chen, P.; Bornhorst, J.B.; Aschner, M. Manganese Metabolism in Humans. Front. Biosci. (Landmark Ed) 2018, 23, 1655–1679. [Google Scholar] [CrossRef]

- Harischandra, D.; Ghaisas, S.; Zenitsky, G.; Jin, H.; Kanthasamy, A.; Anantharam, V.; Kanthasamy, A. Manganese-Induced Neurotoxicity: New Insights Into the Triad of Protein Misfolding, Mitochondrial Impairment, and Neuroinflammation. Front. Neurosci. 2019, 13, 654. [Google Scholar] [CrossRef]

- Mesta-Corral, M.; Gómez-García, R.; Balagurusamy, N.; Torres-León, C.; Hernández-Almanza, A.Y. Technological and Nutritional Aspects of Bread Production: An Overview of Current Status and Future Challenges. Foods 2024, 13, 2062. [Google Scholar] [CrossRef]

- Kaim, U.; Goluch, Z.S. Health Benefits of Bread Fortification: A Systematic Review of Clinical Trials According to the PRISMA Statement. Nutrients 2023, 15, 4459. [Google Scholar] [CrossRef] [PubMed]

- Jonnalagadda, S.S.; Harnack, L.; Liu, R.H.; McKeown, N.; Seal, C.; Liu, S.; Fahey, G.C. Putting the Whole Grain Puzzle Together: Health Benefits Associated with Whole Grains—Summary of American Society for Nutrition 2010 Satellite Symposium. J. Nutr. 2011, 141, 1011S–1022S. [Google Scholar] [CrossRef] [PubMed]

- Sajdakowska, M.; Gębski, J.; Żakowska-Biemans, S.; Jeżewska-Zychowicz, M. Willingness to Eat Bread with Health Benefits: Habits, Taste and Health in Bread Choice. Public Health 2019, 167, 78–87. [Google Scholar] [CrossRef] [PubMed]

- Jacobs, D.R., Jr.; Meyer, K.A.; Kushi, L.H.; Folsom, A.R. Whole-Grain Intake May Reduce the Risk of Ischemic Heart Disease Death in Postmenopausal Women: The Iowa Women’s Health Study. Am. J. Clin. Nutr. 1998, 68, 248–257. [Google Scholar] [CrossRef]

- Slavin, J. Whole Grains and Human Health. Nutr. Res. Rev. 2004, 17, 99–110. [Google Scholar] [CrossRef]

- Zhou, K.; Su, L.; Yu, L. Phytochemicals and Antioxidant Properties in Wheat Bran. J. Agric. Food Chem. 2004, 52, 6108–6114. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).