Research on Concentricity Detection Method of Automobile Brake Piston Parts Based on Improved Canny Algorithm

Abstract

1. Introduction

2. Traditional Canny Algorithm and Its Improvement

2.1. Traditional Canny Algorithm

2.1.1. Algorithm Principle

- (1)

- Gaussian filtering: Firstly, the original image is smoothed by Gaussian to eliminate high-frequency noise and avoid interference in subsequent gradient calculation.

- (2)

- Gradient calculation and direction extraction: The Sobel operator (two small matrices) is used to calculate the gradient of the image in the horizontal (x) and vertical (y) directions, respectively. Based on the gradients in the x and y directions, calculate the gradient intensity (how sharp the edge is) and the direction (whether the edge is facing left/right/up/down) for each pixel. The gradient amplitude reflects the edge strength, and the direction indicates the potential direction of the edge.

- (3)

- Non-maximum suppression: The amplitude is locally compared in the gradient direction, only the pixels with the largest amplitude are retained, and the edge width is refined to the single pixel level to eliminate redundant responses.

- (4)

- Double threshold detection and edge connection: Candidate edges are screened by high and low thresholds: strong edges are determined by high thresholds, weak edges are retained by low thresholds, and weak edges are connected to strong edges in combination with connectivity analysis to ensure the continuity and integrity of edges.

2.1.2. Limitations

2.2. Improved Canny Algorithm

2.2.1. Bilateral Filtering

2.2.2. Multi-Scale Analysis

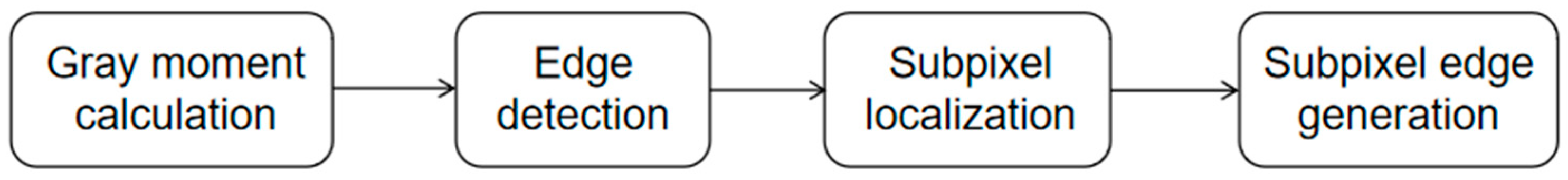

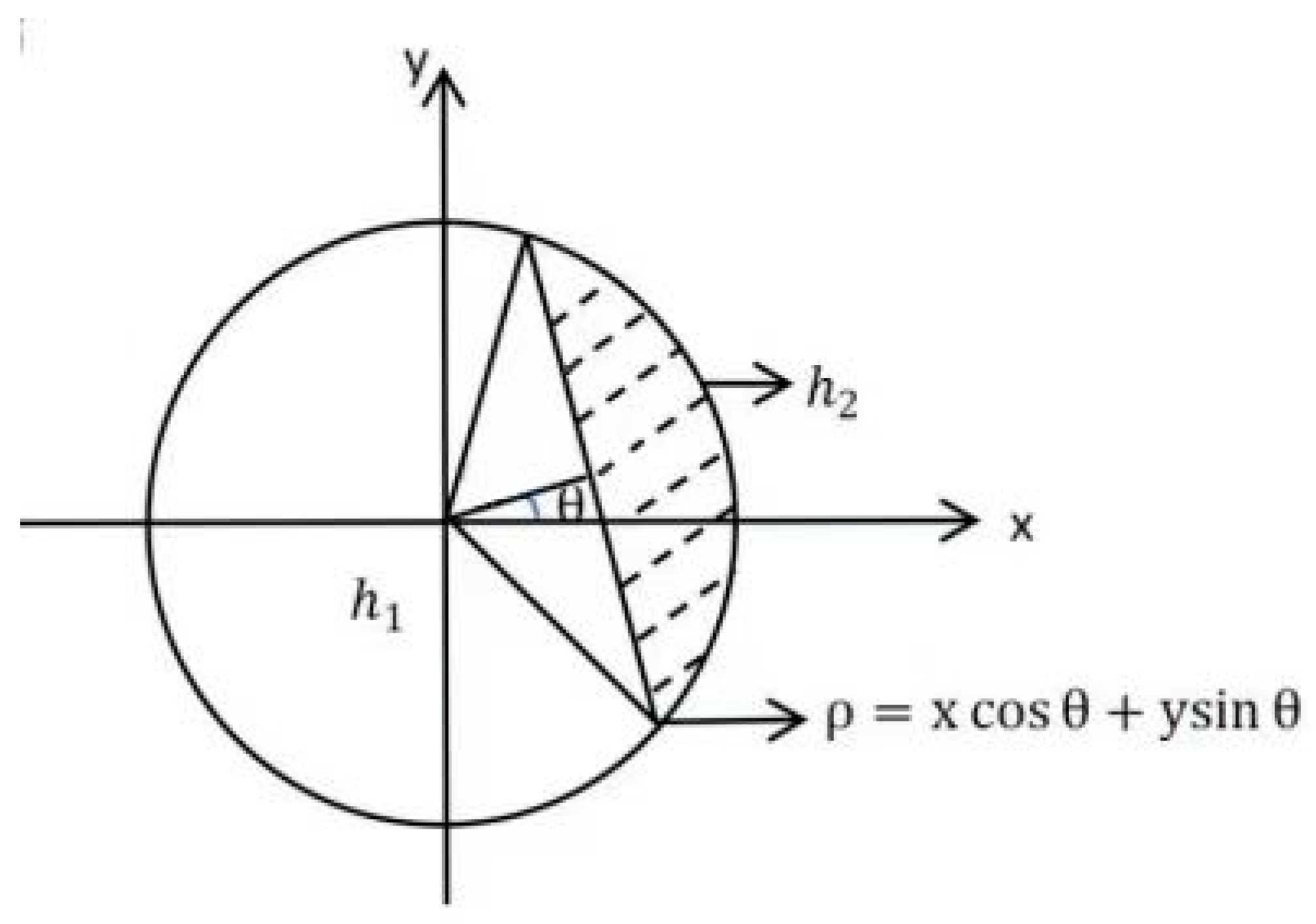

2.2.3. Gray Moment Sub-Pixel Edge Detection Algorithm

Calculation of Gray Moments

3. RANSAC Algorithm

4. Experimental Objects and Analysis of Results

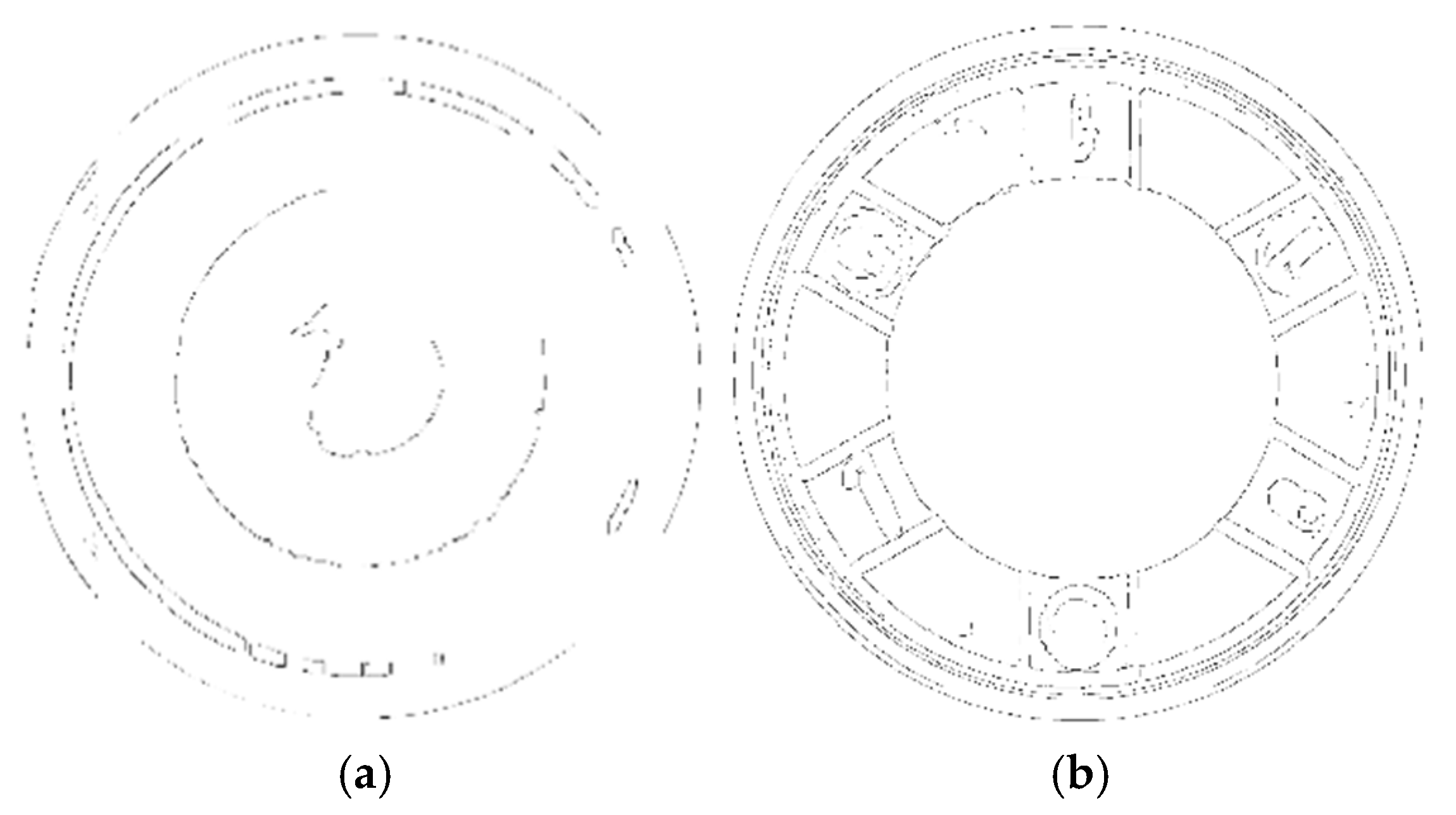

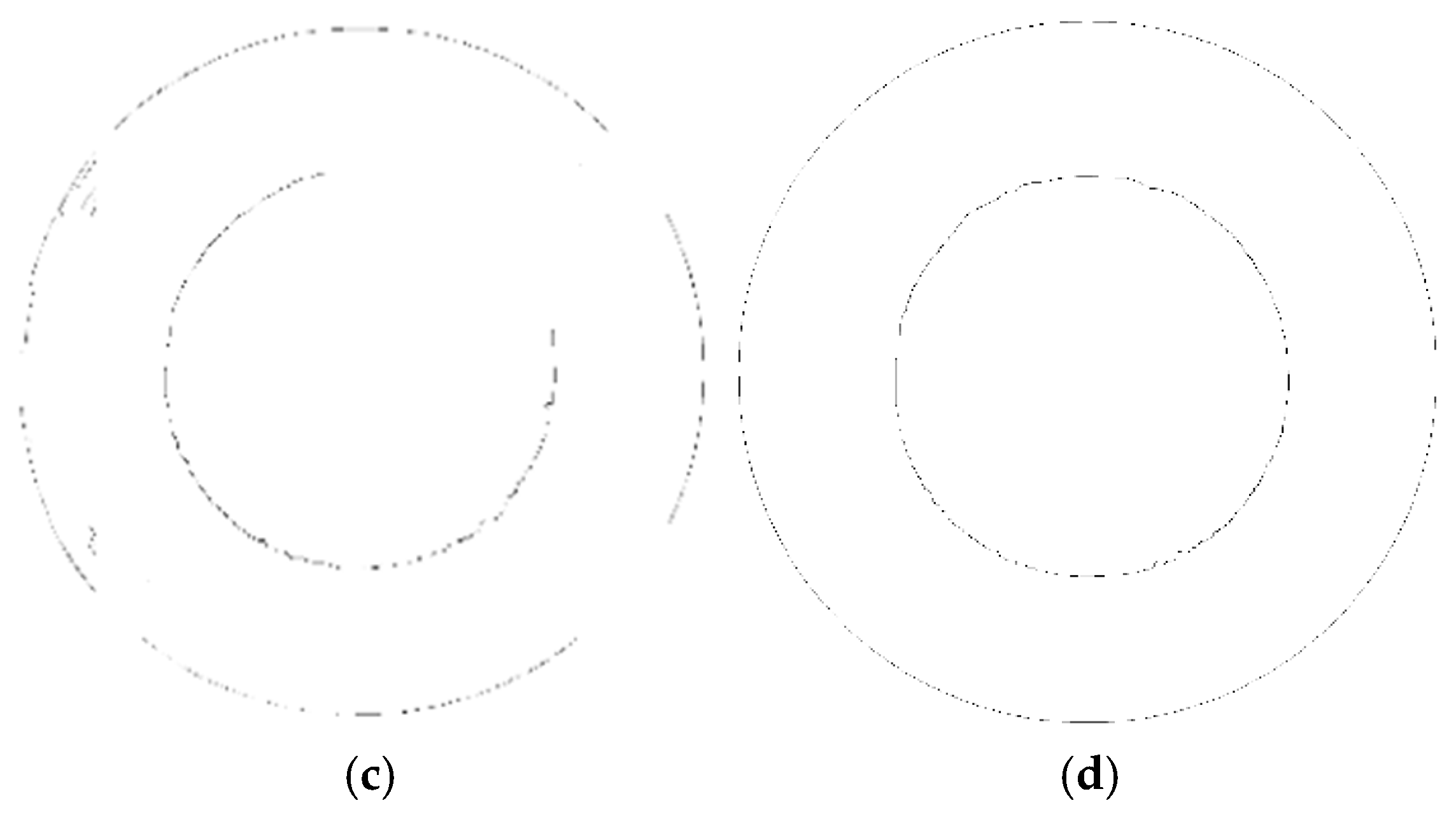

4.1. First Piston Component

4.2. Edge Image Extraction

4.3. Analysis of Fitting Results

5. Conclusions

- (1)

- Algorithm improvement: The two-sided filter is applied to the Canny algorithm to solve the problem of image edge information loss during image preprocessing. Multi-scale analysis is introduced, an image pyramid is constructed, and the problem of detail loss caused by the Sobel operator in the Canny algorithm in a single-scale edge detection is solved, and thus the edge detection accuracy is improved.

- (2)

- Measurement performance: The concentricity detection error in the laboratory environment is less than ±0.01 mm, which meets the ISO 1938-2015 standard [20]. The deviation is reduced by 4%, and the repeatability is significantly better than manual detection.

- (3)

- Application potential: The method is compatible with the existing structure of the riveting machine testing station and has the engineering conditions of non-contact real-time measurement. It provides a reliable technical solution to replace manual eye inspection. The next step will be to carry out the adaptation verification of the production line.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviation

| RANSAC | Random Sampling Consistency |

References

- Guo, Z. Research and Application of Circle Center Location Technology Based on Sub-Pixel Edge Detection. Master’s Thesis, Nanchang University, Nanchang, China, 2023. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, J.; Dian, S. Design of coaxiality detection and fine-tuning system based on machine vision. J. Transducer Microsyst. Technol. 2022, 41, 94–98+102. [Google Scholar]

- Wang, J.; Wang, X.; Cheng, B.; Dong, Z.; Zhai, Z.; Yang, L. Circle detection method based on moving sine fitting. J. China Instrum. 2021, 9, 56–61. [Google Scholar]

- Peng, Y.; Xiao, J.; Mao, J.; Dai, Y.; Zhang, M. A multi-bottle-mouth positioning algorithm based on DBSCAN random circle detection. J. Electron. Meas. Instrum. 2021, 35, 43–52. [Google Scholar]

- Zhao, C.; Fan, C.; Zhao, Z. The center of the circle fitting optimization algorithm based on the hough transform for crane. Appl. Sci. 2022, 12, 10341. [Google Scholar] [CrossRef]

- Guo, J.; Yang, J. An iterative procedure for robust circle fitting. Commun. Stat.-Simul. Comput. 2019, 48, 1872–1879. [Google Scholar] [CrossRef]

- Michałowska, M.; Rapiński, J.; Janicka, J. Tree position estimation from TLS data using hough transform and robust least-squares circle fitting. Remote Sens. Appl. Soc. Environ. 2023, 29, 100863. [Google Scholar] [CrossRef]

- Ou, Y.; Deng, H.; Liu, Y.; Zhang, Z.; Ruan, X.; Xu, Q.; Peng, C. A fast circle detection algorithm based on information compression. Sensors 2022, 22, 7267. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Wang, Y.; Zhu, Q.; Zhang, H.; Chen, Q. Circle detection with model fitting in polar coordinates for glass bottle mouth localization. Int. J. Adv. Manuf. Technol. 2022, 120, 1041–1051. [Google Scholar] [CrossRef]

- Guo, S.; Yang, S.; Zhang, P. A circle detection algorithm based on ellipse removal. J. Image Process. Theory Appl. 2021, 4, 42–50. [Google Scholar]

- Guo, P. Detection technology and application of parallelism and coaxiality of wind tower flanges based on laser measuring instrument. Electr. Appar. Ind. 2024, 10, 19–21+30. [Google Scholar]

- Qing, Y.; Yanru, Z.; Wen, L. Design of Dynamic Parameter Acquisition Module of Field CMM. Meas. Control Technol. 2014, 33, 45–47+51. [Google Scholar]

- Chen, Z.; Liu, Z. Research on underwater image edge detection method based on improved canny and gray-level moment. J. Agric. Equip. Veh. Eng. 2024, 62, 107–110+120. [Google Scholar]

- van Kempen, G.M.P.; van Vliet, L.J.; Verveer, P.J.; van der Voort, H.T.M. A quantitative evaluation of image sharpness criteria for microscope autofocusing. IEEE Trans. Instrum. Meas. 2018, 67, 309–320. [Google Scholar]

- Du, X.; Chen, D.; Ma, Z.; Liu, F. Improved image edge detection algorithm based on canny operator. Comput. Digit. Eng. 2022, 50, 410–413, 457. [Google Scholar]

- Wang, D.; Tang, C.; E, S.; Gao, C.; Ge, B. Image edge detection based on guided filter Retinex and adaptive Canny. J. Opt. Precis. Eng. 2021, 29, 443–451. [Google Scholar] [CrossRef]

- Zhang, M. Research on Sub-Pixel Edge Detection Technology. Master’s Thesis, Shenyang Ligong University, Shenyang, China, 2013. [Google Scholar]

- Ren, Y.; Tu, D.; Han, S. Diesel engine cylinder liner size detection based on machine vision. J. Modul. Mach. Tool Autom. Manuf. Technol. 2020, 9, 151–153. [Google Scholar]

- Shang, H.; Han, X.; Ji, C.; Peng, X. Application of circle fitting algorithm based on RANSAC in threaded hole detection. J. Mod. Manuf. Eng. 2024, 2, 112–119. [Google Scholar]

- ISO 1938-2015; Geometrical Product Specifications (GPS)—Dimensional Measuring Equipment. ISO: Geneva, Switzerland, 2015.

| Fitting Times | Original Image 1 | Original Image 2 | Original Image 3 | Original Image 4 | Original Image 5 |

|---|---|---|---|---|---|

| First time | 0.61872 | 0.66529 | 0.70329 | 0.63603 | 0.64464 |

| Second time | 0.78596 | 0.50514 | 0.65660 | 0.61228 | 0.59718 |

| Third time | 0.60205 | 0.64223 | 0.65253 | 0.61342 | 0.63857 |

| Fourth time | 0.72609 | 0.60871 | 0.63906 | 0.64046 | 0.40322 |

| Fifth time | 0.61912 | 0.64333 | 0.57418 | 0.61936 | 0.64323 |

| Sixth time | 0.66031 | 0.69923 | 0.60923 | 0.64542 | 0.65148 |

| Seventh time | 0.61843 | 0.60355 | 0.74016 | 0.61078 | 0.50514 |

| Eighth time | 0.66968 | 0.66274 | 0.63218 | 0.62800 | 0.89484 |

| Ninth time | 0.48028 | 0.71846 | 0.65326 | 0.76218 | 0.81706 |

| Tenth time | 0.65196 | 0.70728 | 0.68641 | 0.72281 | 0.65236 |

| Average of ten times | 0.64326 | 0.6456 | 0.65469 | 0.64907 | 0.64477 |

| Overall average | 0.6475 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Zhao, W.; Cheng, S.; Ji, Y. Research on Concentricity Detection Method of Automobile Brake Piston Parts Based on Improved Canny Algorithm. Appl. Sci. 2025, 15, 4397. https://doi.org/10.3390/app15084397

Li Q, Zhao W, Cheng S, Ji Y. Research on Concentricity Detection Method of Automobile Brake Piston Parts Based on Improved Canny Algorithm. Applied Sciences. 2025; 15(8):4397. https://doi.org/10.3390/app15084397

Chicago/Turabian StyleLi, Qinghua, Wanting Zhao, Siyuan Cheng, and Yi Ji. 2025. "Research on Concentricity Detection Method of Automobile Brake Piston Parts Based on Improved Canny Algorithm" Applied Sciences 15, no. 8: 4397. https://doi.org/10.3390/app15084397

APA StyleLi, Q., Zhao, W., Cheng, S., & Ji, Y. (2025). Research on Concentricity Detection Method of Automobile Brake Piston Parts Based on Improved Canny Algorithm. Applied Sciences, 15(8), 4397. https://doi.org/10.3390/app15084397