Dynamic Monitoring of Goaf Stress Field and Rock Deformation Driven by Optical Diber Sensing Technology

Abstract

1. Introduction

2. Pressure Inversion Model for Gob Areas Driven by Optical Fiber Monitoring Data

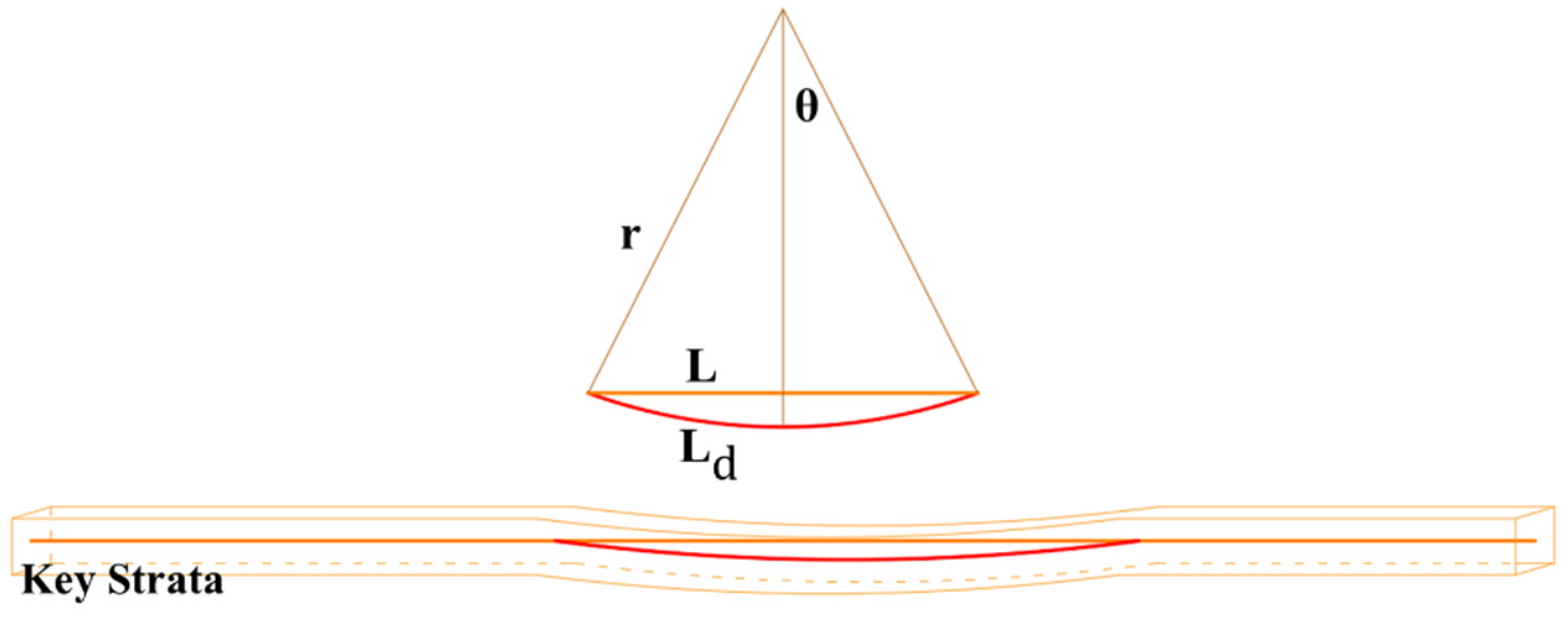

2.1. Distributed Optical Fiber Representation and Calculation Method for Subsidence of Key Strata

- (1)

- Before fracture of the key strata.

- (2)

- After the fracture of the key strata.

2.2. The Inversion Method for Pressure Distribution in the Gob Area

3. The Experiment of Similar Physical Models

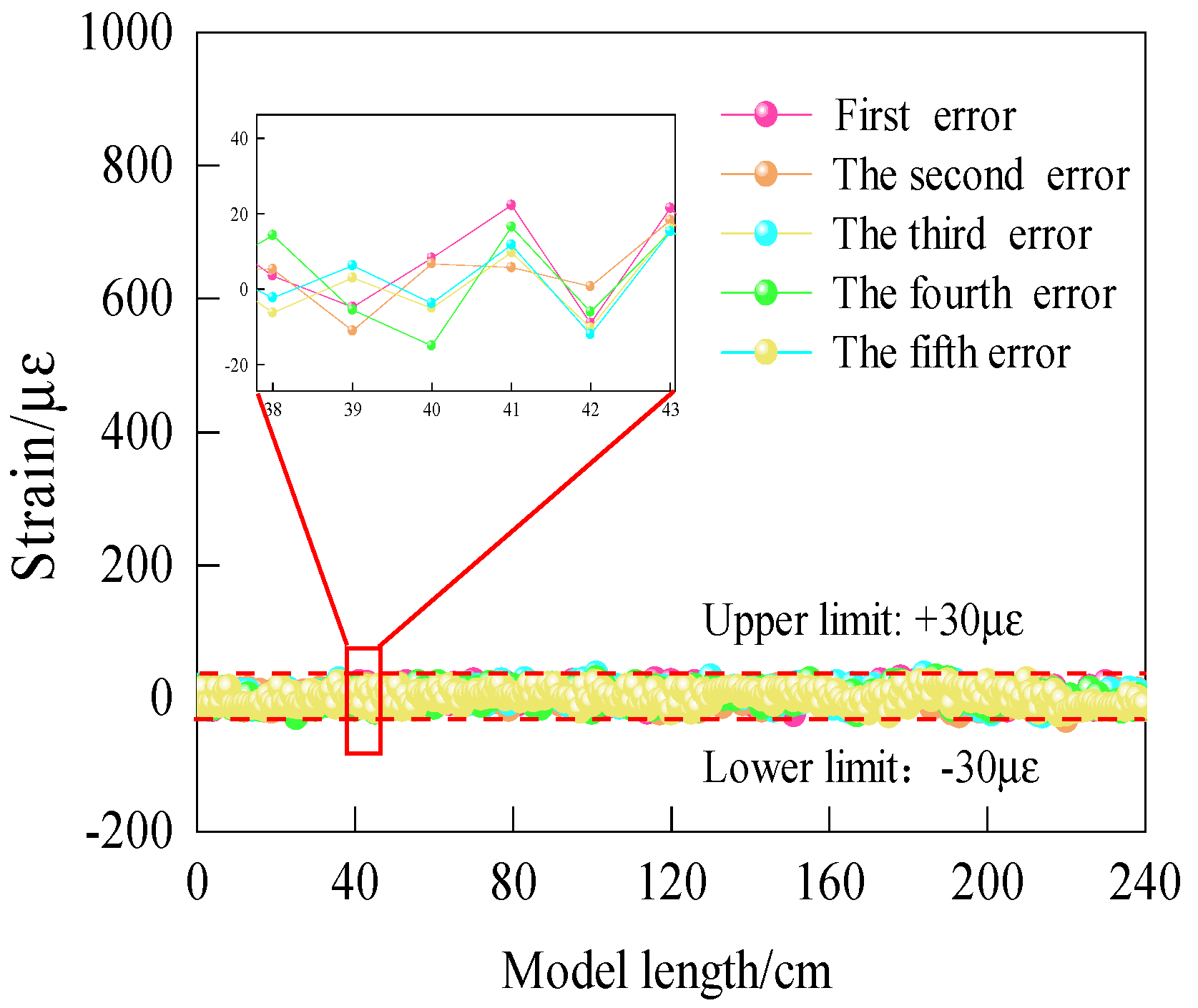

3.1. Overview of the Model

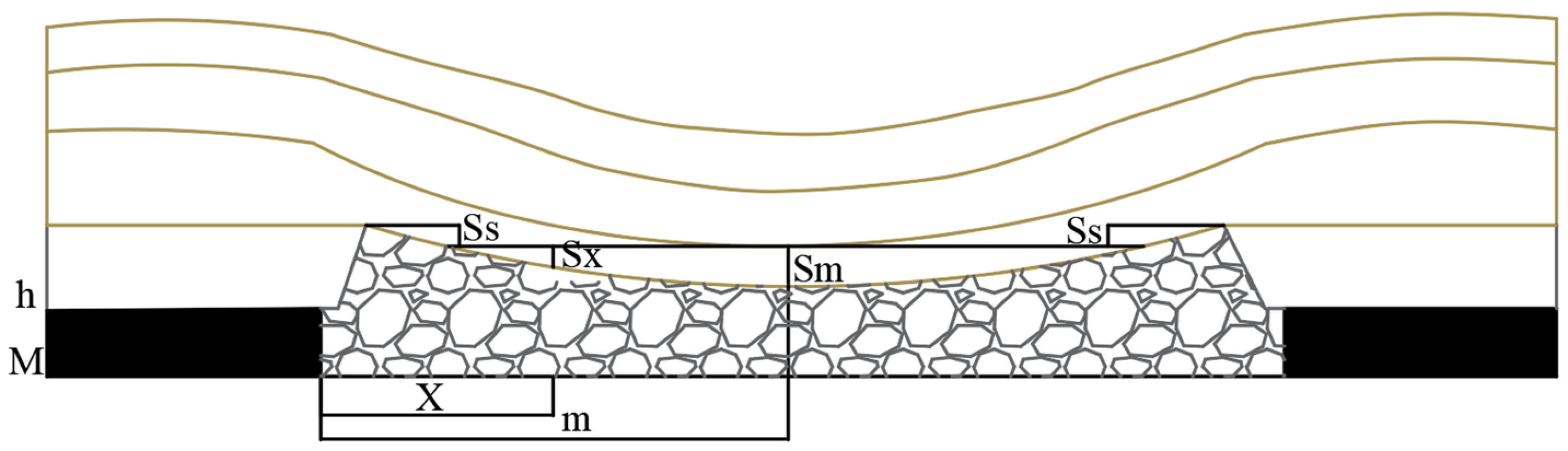

3.2. Layout of the Monitoring System

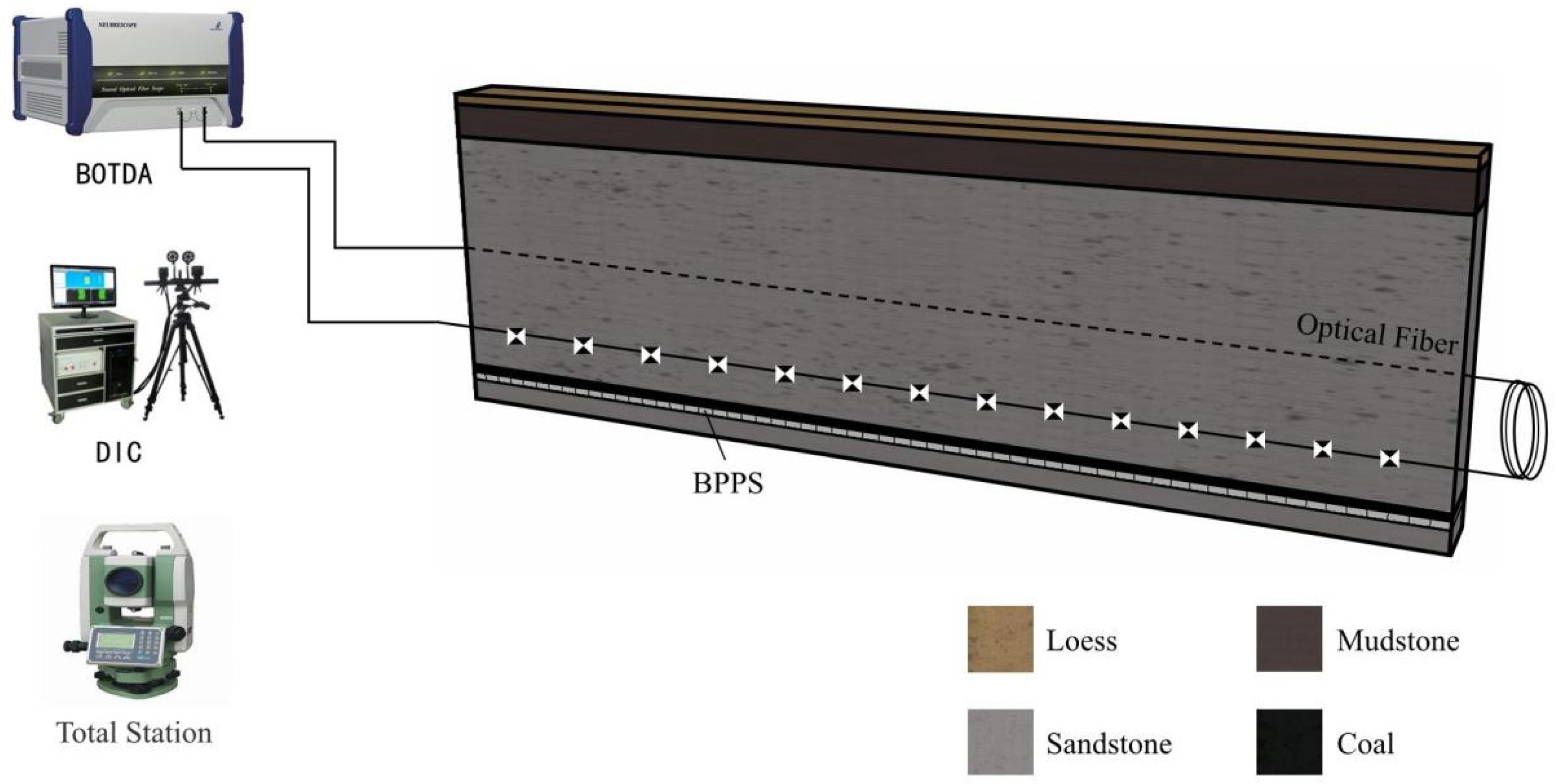

3.3. Fiber Optic Test System Accuracy

4. Analysis of Test Results

4.1. The Main Test Phenomenon

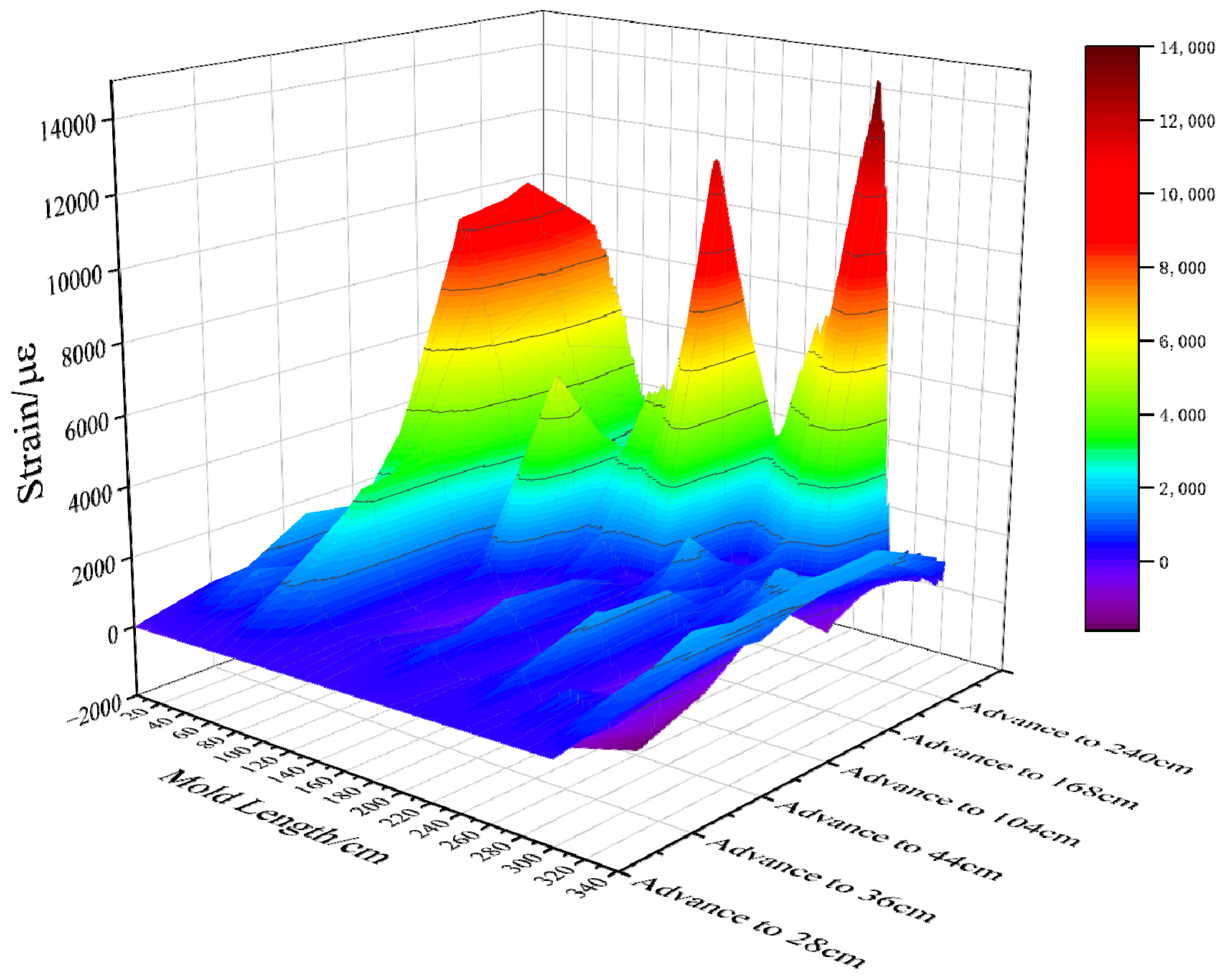

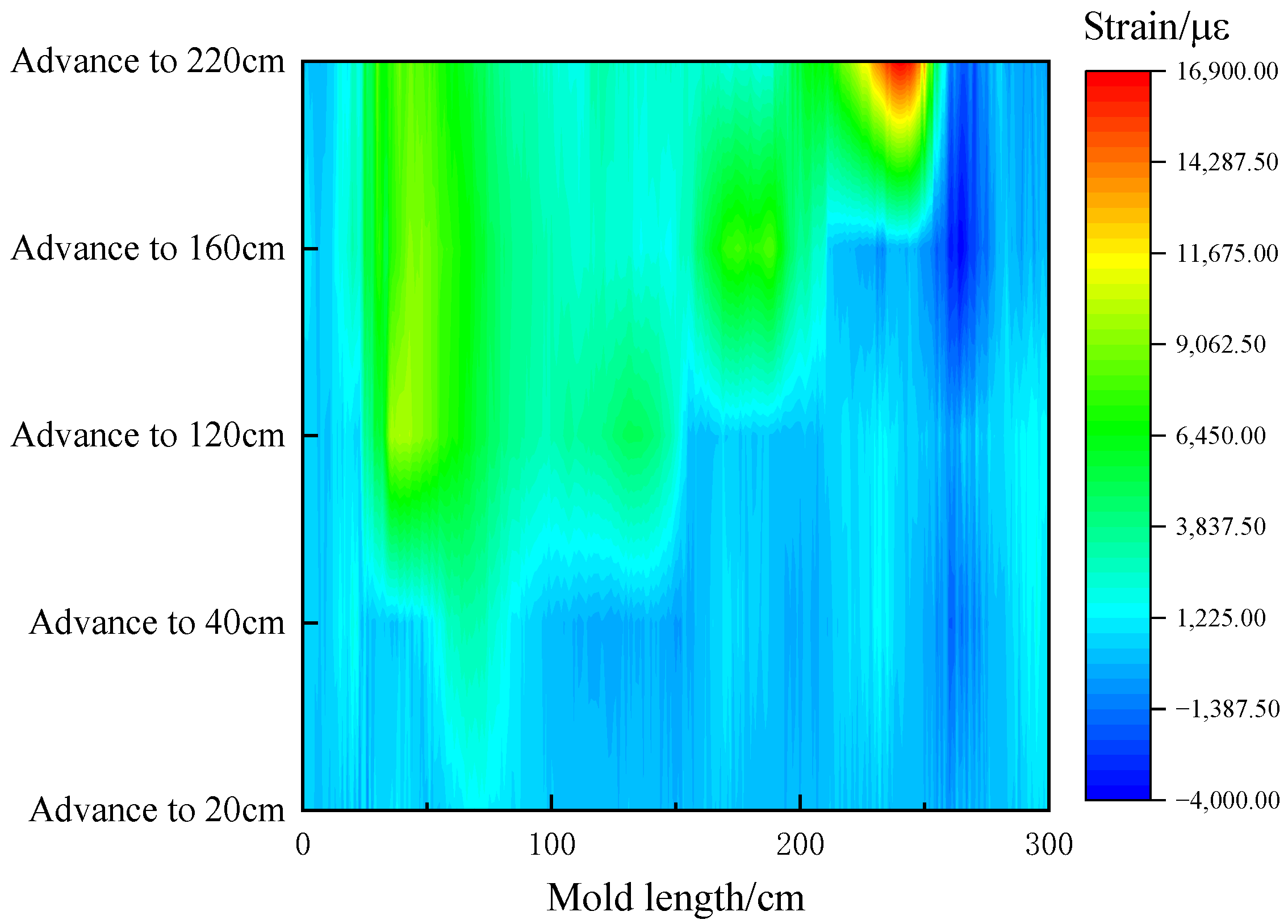

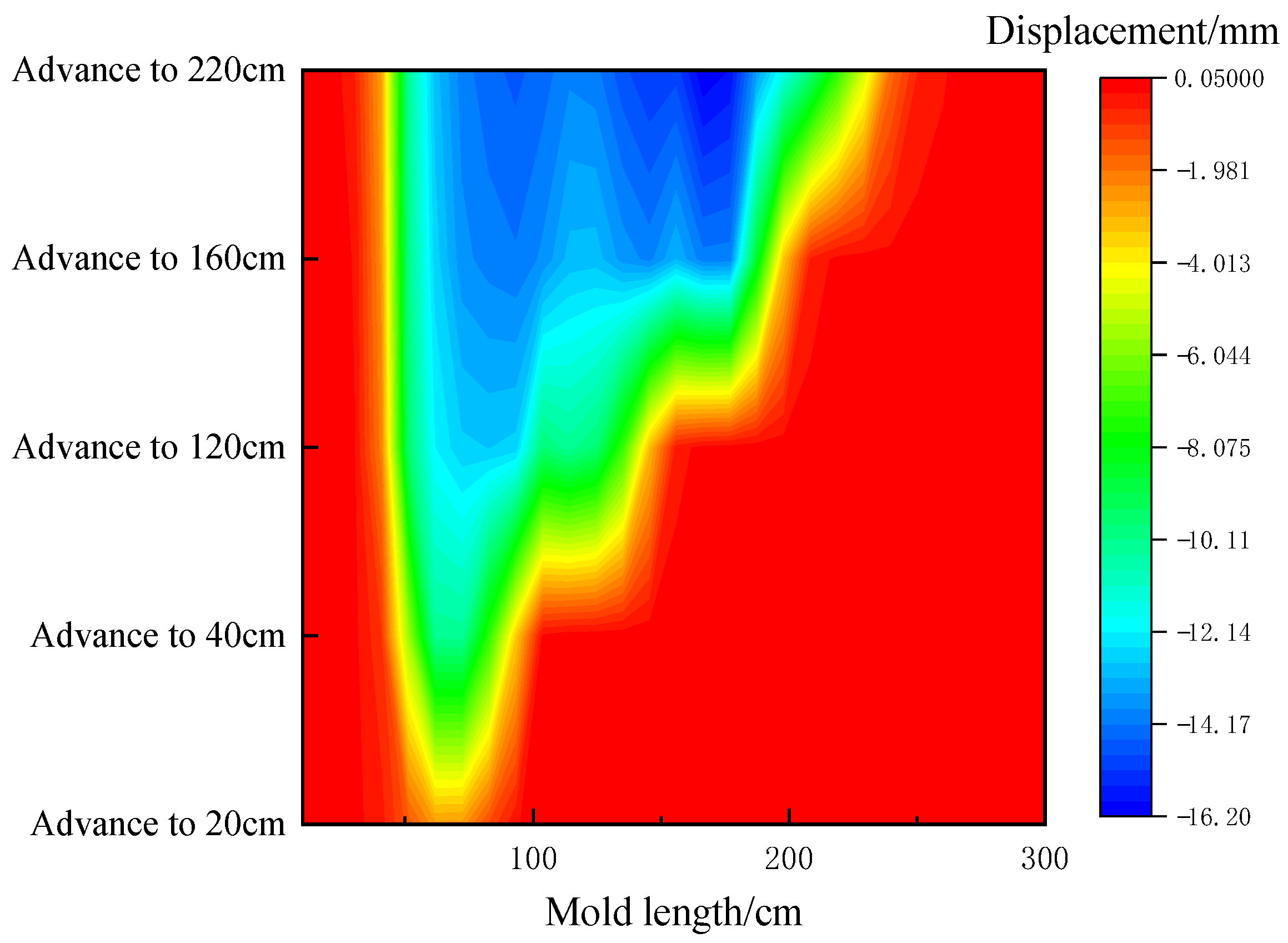

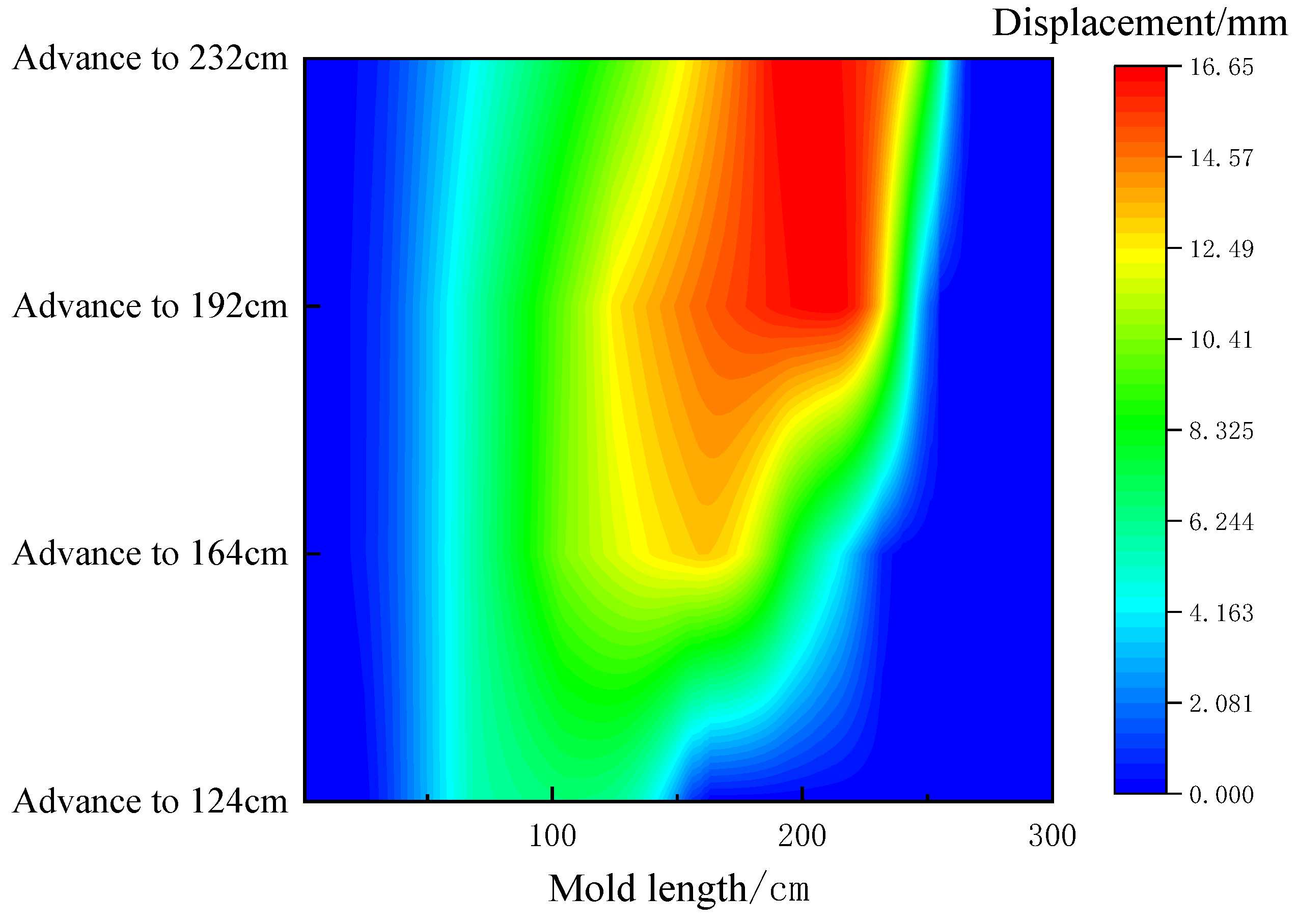

4.2. Spatial Distribution Characteristics of Goaf Pressure

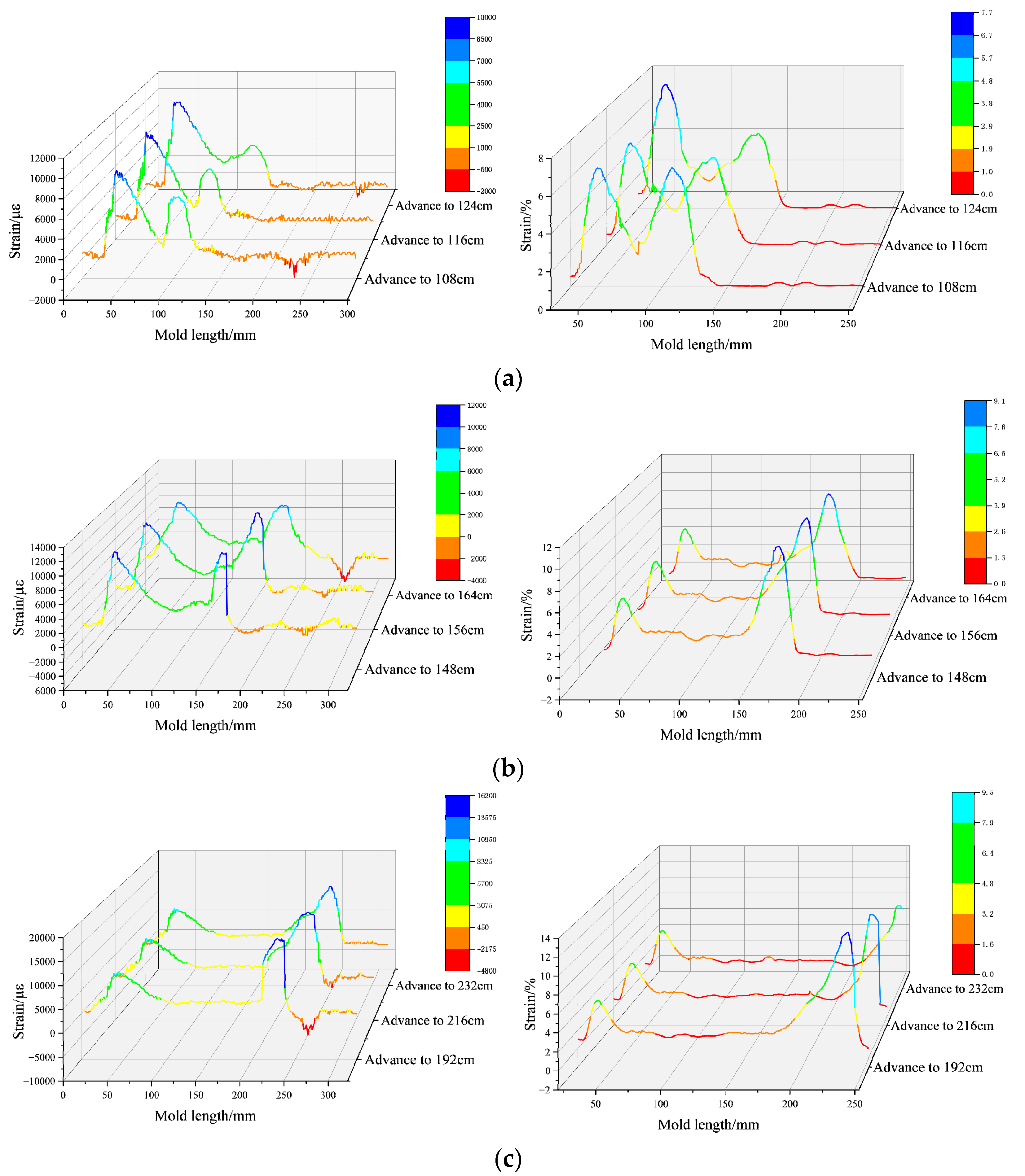

4.2.1. Critical Layer Deformation

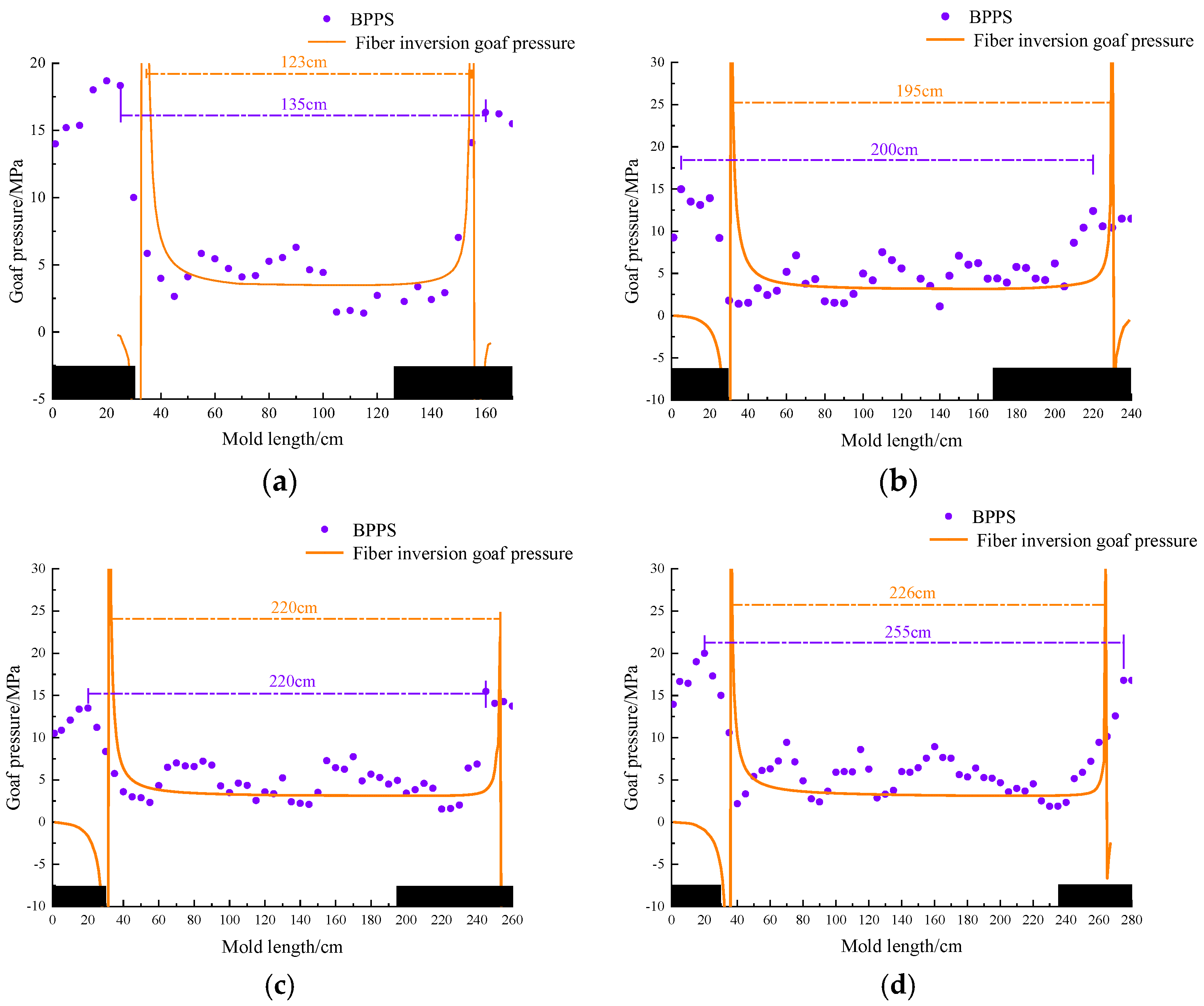

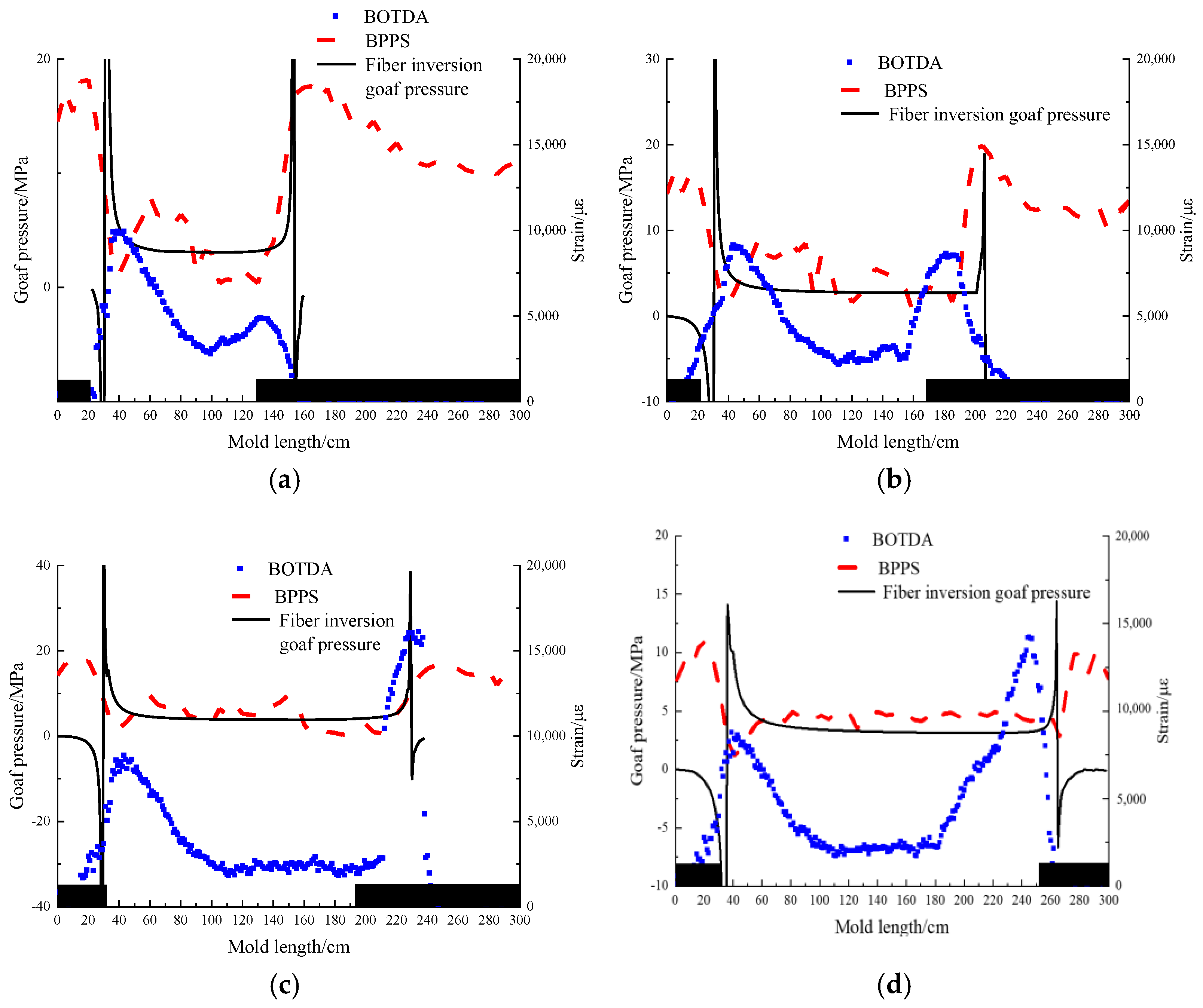

4.2.2. Goaf Pressure Inversion Analysis

5. Discussion

6. Conclusions

- (1)

- A pioneering goaf pressure inversion model has been developed, driven by distributed optical fiber monitoring data, which effectively characterizes critical layer subsidence through distinct pre-fracture and post-fracture phases. The sophisticated mathematical framework captures the intricate coupling relationship between optical fiber sensors and rock mass deformation, revealing a definitive correlation between key stratum failure locations and peak stress positions within the goaf area. This fundamental understanding substantially advances our knowledge of the internal mechanisms governing rock mass deformation and stress redistribution patterns during mining operations.

- (2)

- The innovative implementation of a dual monitoring system, integrating BOTDA and DIC technologies, demonstrates exceptional reliability in predicting overburden rock fracture patterns and quantifying critical deformation thresholds. Through rigorous experimental investigations, we have conclusively established a critical strain threshold of 4000 με for key stratum fracture initiation, with pre-fracture rock mass strain consistently maintaining values below this threshold. This precise quantitative parameter marks a significant advancement in mining safety monitoring, enabling the development of accurate early warning systems and facilitating proactive risk management through continuous, real-time strain measurements.

- (3)

- Through systematic physical model experiments, we have comprehensively validated the effectiveness of our optical fiber monitoring data inversion methodology in characterizing both spatial distribution and temporal evolution of goaf stress patterns. The experimental results conclusively demonstrate a characteristic “U-shaped” pressure distribution across the goaf area, with measurement deviations consistently maintained within 8.88% across various advancement stages. This thorough validation not only confirms the theoretical framework’s accuracy but also provides crucial insights into the dynamic evolution of mining-induced stress fields. These findings establish a robust foundation for enhanced mining safety assessment and control strategies, offering immediate practical applications in real-world mining operations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Han, D.; Hu, S.; Zhang, A.; Hao, G.; Hu, L. Study on void age distribution regulation and formation mechanism of crushed rock mass in gob. Coal Sci. Technol. 2020, 48, 113–120. [Google Scholar]

- Chen, S.; Li, R. Study on safe and rapid face reduction technology of fully-mechanized top-coal caving face with lower knife handle in contugous fully-mechanized goaf. Coal Sci. Technol. 2022, 50, 1–7. [Google Scholar]

- Wang, J.; Zhang, C.; Zheng, D.; Song, W.; Ji, X. Stability analysis of roof in goaf considering time effect. J. Min. Strat. Control Eng. 2020, 2, 47–55. [Google Scholar]

- Luo, S.; Tian, C.; Wu, Y.; Xie, P.; Wang, H. Characteristics of loading and failure of overlying rock at working face advancing direction in longwall mining of steeply inclined seam. J. China Coal Soc. 2021, 46, 2227–2236. [Google Scholar]

- Chai, J.; Ma, Z.; Du, W.; Gao, J.; Huang, Z.; Zhang, D.; Yang, J. Dynamic evolution law analysis of overburden separation and water flowing fracture under mining based on distributed optical fiber and information entropy theory. Opt. Fiber Technol. 2023, 80, 103408. [Google Scholar] [CrossRef]

- Ren, Y.; Yuan, Q.; Chen, J.; Wang, Z.; Zhang, D.; Li, S. Evolution characteristics of mining-induced fractures in overburden strata under close-multi coal seams mining based on optical fiber monitoring. Eng. Geol. 2024, 343, 107802. [Google Scholar] [CrossRef]

- Wang, L.; Cao, H.; Jiang, Z.; Wang, T. Influence of Gangue Compaction Process on Coal Pillar Supporting Pressure in Goaf. Saf. Coal Mines 2020, 51, 62–68. [Google Scholar]

- Zhang, J.; Wang, B.; Bai, W.; Chen, C.; Zhang, J. Stability study of the double-arch structure formed by short-distance discontinuous mining in shallow strata. J. China Univ. Min. Technol. 2021, 50, 598–605. [Google Scholar]

- Qian, M.; Li, H. The law of overlying strata movement and its influence on the pressure of mine. J. Coal Sci. 1982, 2, 1–8. [Google Scholar]

- Jiang, L.; Wu, Q.; Li, X.; Ding, N. Numerical simulation on coupling method between mining-induced stress and goaf compression. J. China Coal Soc. 2017, 42, 1951–1959. [Google Scholar]

- Sui, W.; Shen, W.; Di, Q. Engineering geological analysis and finite element simulation of stress deformation and failure of over burden in shallow goaf. J. China Coal Soc. 1990, 3, 76–81. [Google Scholar]

- Tu, H.; Tu, S.; Yuan, Y.; Wang, F.; Wang, C. Theoretical criterion of concentrated stress influence scope with thick coal seam left-over goaf. J. China Coal Soc. 2013, 38, 1345–1351. [Google Scholar]

- Wang, Z.; Liu, H. Consistency between stress in goaf area, movement law of overlying strata and stress effect of roof and floor rock. Coal Min. Technol. 1993, 8, 38–44. [Google Scholar]

- Xie, J.; Qu, Q.; Zhu, W.; Wang, X.; Xu, J.; Ning, S.; Hou, T.; Luo, X. Distributed strain monitoring of overburden delamination propagation at a deep longwall mine. Int. J. Rock Mech. Min. Sci. 2023, 171, 105589. [Google Scholar] [CrossRef]

- Hao, H.; Chai, J.; Ouyang, Y.; Zhang, D.; Gao, J.; Wang, J.; Huang, Z. Accurate monitoring of coal pillar deformation based on distributed optical fiber. Opt. Fiber Technol. 2024, 84, 103748. [Google Scholar] [CrossRef]

- Jing, C.; Zhicheng, H.; Wulin, L.; Dingding, Z.; Jianfeng, Y.; Chenyang, M.; Gang, H.; Mingyue, W. The application of distributed fiber-optic sensing technology in monitoring the loose zone in the floor of stoping roadway. Rock Mech. Rock Eng. 2024, 58, 723–744. [Google Scholar] [CrossRef]

- Xie, X.; Fang, X.; Liu, H.; Xing, X.; Liang, M.; Wu, G.; Chen, N. Development and application of a borehole stress meter in rocks surrounding the roadway, based on optical-fiber sensing technology. Front. Earth Sci. 2023, 10, 1122579. [Google Scholar] [CrossRef]

- Yang, J.; Ren, Y.; Chai, J.; Zhang, D.; Liu, Y. Adit deformation prediction based on ICEEMDAN dispersion entropy and LSTM-BP. Opt. Fiber Technol. 2023, 79, 103364. [Google Scholar] [CrossRef]

- Vu, T.T.; Do, S.A. Determination of the rock mass displacement zone by numerical modeling method when exploiting the longwallat the Nui Beo Coal Mine, Vietnam. Min. Miner. Depos. 2023, 17, 59–66. [Google Scholar] [CrossRef]

- Nowak, S.; Sherizadeh, T.; Esmaeelpour, M.; Brooks, P.; Guner, D.; Karadeniz, K.; Wurst, G.; Kirmaci, A. Geomechanical Monitoring of an Underground Bulk Mining Operation Using a Novel Distributed Optical Fiber Strain Sensing Method. Min. Metall. Explor. 2024, 41, 1553–1565. [Google Scholar] [CrossRef]

- Yumba, J.; Ferentinou, M.; Grobler, M. Experimental Study of Sinkhole Propagation Induced by a Leaking Pipe Using Fibre Bragg Grating Sensors. Sens. Sens. 2024, 24, 6215. [Google Scholar] [CrossRef]

- Doonechaly, N.G.; Reinicke, A.; Hertrich, M.; Plenkers, K.; Obermann, A.; Fischli, F.; Maurer, H.; Wiemer, S.; Giardini, D. Multiphysics monitoring of cementation operation: Implications for wellbore integrity and hydrogeological characterization. Environ. Earth Sci. 2024, 83, 146. [Google Scholar] [CrossRef]

- Anjana, K.; Herath, M.; Epaarachchi, J. Optical fibre sensors for geohazard monitoring—A review. Measurement 2024, 235, 114846. [Google Scholar] [CrossRef]

- Gao, S.; Du, W.; Liu, Y.; Chai, J.; Gao, D.; Ma, C.; Chen, J. Reasonable top coal thickness for large cross-section open-off cut in lower-layer mining. Front. Earth Sci. 2023, 11, 1301595. [Google Scholar] [CrossRef]

- Chai, J.; Ouyang, Y.; Liu, J.; Zhang, D.; Du, W.; Lei, W. Experimental study on a new method to forecasting goaf pressure based key strata deformation detected using optic fiber sensors. Opt. Fiber Technol. 2021, 67, 102706. [Google Scholar] [CrossRef]

- Wen, L.; Xue, L.; Hao, R.W. Evolution analysis of research on disaster-causing mechanism and prevention technology of mine goaf disaster. Environ. Sci. Pollut. Res. 2023, 30, 93388–93406. [Google Scholar]

- Ratnayake, R.; Ghassemi, A. Modeling of Fiber Optic Strain Responses to Shear Deformation of Fractures. Energies 2024, 17, 2142. [Google Scholar] [CrossRef]

- Zuo, Q.; Wang, Y.; Li, J. Study on the oxidation and heating characteristics of residual coal in goafs under different air-leakage conditions. Therm. Sci. 2021, 25, 3293–3302. [Google Scholar] [CrossRef]

- Cheng, G.; Wang, Z.; Shi, B.; Zhu, W.; Li, T. Research on a Space–Time Continuous Sensing System for Overburden Deformation and Failure during Coal Mining. Sensors 2023, 23, 5947. [Google Scholar] [CrossRef]

- Li, J.; He, Z.; Piao, C.; Chi, W.; Lu, Y. Research on Subsidence Prediction Method of Water-Conducting Fracture Zone of Overlying Strata in Coal Mine Based on Grey Theory Model. Water 2023, 15, 4177. [Google Scholar] [CrossRef]

- Ma, L.; Liu, C.; Zhao, G. Study on Coal Pillar Setting and Stability in Downward Mining Section of Close Distance Coal Seam. Energies 2024, 17, 5441. [Google Scholar] [CrossRef]

- Zou, J.; Chen, W.; Yuan, J.; Yang, D.; Yang, J. 3-D numerical simulation of hydraulic fracturing in a CBM reservoir. J. Nat. Gas Sci. Eng. 2017, 37, 386–396. [Google Scholar] [CrossRef]

- Wang, S.; Huang, Q.; Fan, L.; Yang, Z.; Shen, T. Study on overburden aquclude and water protection mining regionazation in the ecological fragile mining area. J. China Coal Soc. 2010, 1, 7–14. [Google Scholar]

- Yu, Y. Deformation Characteristics and Permeability Evolution Laws of Strata on Stope Boundary. Ph.D. Thesis, China University of Mining & Technology, Xuzhou, China, 2020. [Google Scholar]

- Gao, Z. Research on the Law of Overlying Rock Failure in the Goaf of Coal Mine. Ph.D. Thesis, Chang’an University, Xi’an, China, 2021. [Google Scholar]

- Yu, B.; Zhang, Z.; Kuang, T.; Liu, J. Stress Changes and Deformation Monitoring of Longwall Coal Pillars Located in Weak Ground. Rock Mech. Rock Eng. 2016, 49, 3293–3305. [Google Scholar] [CrossRef]

- Zhu, S.; Feng, Y.; Jiang, F. Determination of Abutment Pressure in Coal Mines with Extremely Thick Alluvium Stratum: A Typical Kind of Rockburst Mines in China. Rock Mech. Rock Eng. 2015, 49, 1943–1952. [Google Scholar] [CrossRef]

- Qi, T.Y.; Zhang, F.; Pei, X.M.; Feng, G.R.; Wei, H.R. Simulation research and application on response characteristics of detectingwater-filled goaf by transient electromagnetic method. Int. J. Coal Sci. Technol. 2022, 9, 167–192. [Google Scholar] [CrossRef]

- Wang, W.; Wang, S.; Liu, H.; Jiang, T. The space and time characteristics of the cover stress restablishment of the fractured rock mass in the goaf after coal mining. J. Min. Saf. Eng. 2017, 34, 127–133. [Google Scholar]

- Kang, H.; Lou, J.; Gao, F.; Yang, J.; Li, J. A physical and numerical investigation of sudden massive roof collapse during longwall coal retreat mining. Int. J. Coal Geol. 2018, 188, 25–36. [Google Scholar] [CrossRef]

- Chai, J.; Ouyang, Y.; Liu, J.; Zhang, D.; Du, W. Experimental evaluation of precise monitoring of multi-scale deformation failure of rock mass based on distributed optical fiber. Measurement 2022, 199, 111381. [Google Scholar] [CrossRef]

| Layer Number | Lithology | Model Thickness/cm | Mix Number | Sand/kg | Gypsum/kg | CaCO3/kg | Remarks |

|---|---|---|---|---|---|---|---|

| 1 | Loess | 3.33 | 1019 | 238.25 | 2.38 | 21.44 | Topsoil |

| 2 | mudstone | 10 | 919 | 82.89 | 0.92 | 8.29 | |

| 3 | Siltstone | 14.66 | 837 | 119.53 | 4.48 | 10.46 | |

| 4 | Medium sand | 20 | 837 | 159.47 | 5.98 | 13.95 | |

| 5 | Siltstone | 5.33 | 937 | 37.63 | 1.25 | 2.93 | |

| 6 | Medium sand | 6.66 | 828 | 55.24 | 1.38 | 5.52 | |

| 7 | Fine sandstone | 4.66 | 837 | 36.33 | 1.36 | 3.18 | |

| 8 | Siltstone | 4 | 828 | 21.08 | 0.53 | 2.11 | |

| 9 | Fine sandstone | 9.33 | 828 | 61.01 | 1.53 | 6.1 | Key stratum |

| 10 | Fine sandstone | 8.66 | 937 | 12.13 | 0.27 | 1.08 | Immediate roof |

| 11 | Coal seam | 2 | 12.48 | 0.47 | 3.12 | coal seam | |

| 12 | Siltstone | 4 | 937 | 19.88 | 0.66 | 1.55 | |

| 13 | Fine sandstone | 5.33 | 837 | 48.26 | 1.81 | 4.22 |

| Parameter | DOFS Monitoring | Traditional Stress Monitoring Methods |

|---|---|---|

| Accuracy | High accuracy due to the use of advanced signal processing techniques and multi-parameter sensing capabilities | Generally lower accuracy compared to DOFS, limited by the point measurement nature and susceptibility to environmental factors |

| Data Resolution | High spatial resolution (can be as fine as 1 meter or less) along the entire length of the fiber | Lower spatial resolution and typically limited to point measurements at specific locations |

| Practicality | Suitable for long-distance and large-scale monitoring, immune to electromagnetic interference, and can operate in harsh environments | Limited to shorter distances and smaller scales, susceptible to electromagnetic interference, and may require more maintenance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chai, J.; Yan, Z.; Ouyang, Y.; Zhang, D.; Yang, J.; Yang, G.; Ma, C. Dynamic Monitoring of Goaf Stress Field and Rock Deformation Driven by Optical Diber Sensing Technology. Appl. Sci. 2025, 15, 4393. https://doi.org/10.3390/app15084393

Chai J, Yan Z, Ouyang Y, Zhang D, Yang J, Yang G, Ma C. Dynamic Monitoring of Goaf Stress Field and Rock Deformation Driven by Optical Diber Sensing Technology. Applied Sciences. 2025; 15(8):4393. https://doi.org/10.3390/app15084393

Chicago/Turabian StyleChai, Jing, Zhe Yan, Yibo Ouyang, Dingding Zhang, Jianfeng Yang, Gaoyi Yang, and Chenyang Ma. 2025. "Dynamic Monitoring of Goaf Stress Field and Rock Deformation Driven by Optical Diber Sensing Technology" Applied Sciences 15, no. 8: 4393. https://doi.org/10.3390/app15084393

APA StyleChai, J., Yan, Z., Ouyang, Y., Zhang, D., Yang, J., Yang, G., & Ma, C. (2025). Dynamic Monitoring of Goaf Stress Field and Rock Deformation Driven by Optical Diber Sensing Technology. Applied Sciences, 15(8), 4393. https://doi.org/10.3390/app15084393