Alignment Optimization of Elastically Supported Submarine Propulsion Shafting Based on Dynamic Bearing Load Influence Numbers

Abstract

1. Introduction

- An equivalent line-surface method was proposed, in order to effectively solve the problem of difficult measurement of elastic bearing displacement induced by elastic deformation of supporting foundations.

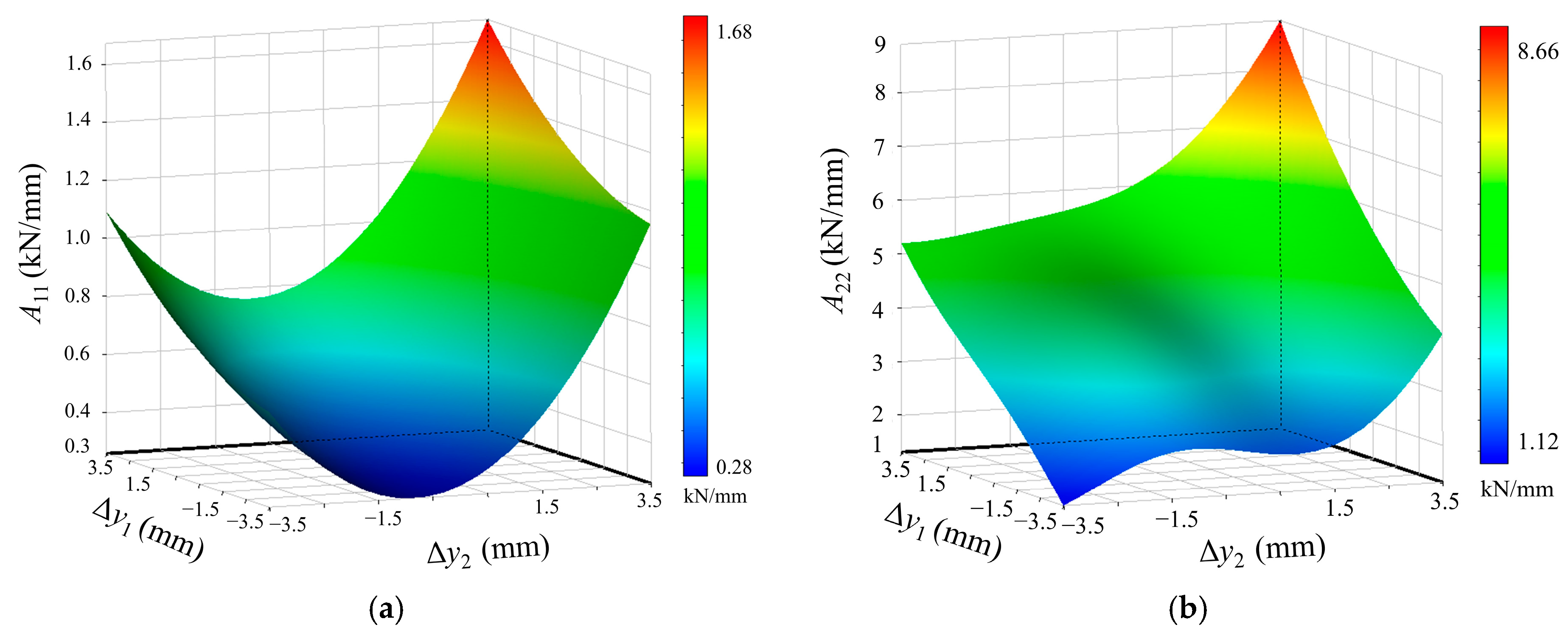

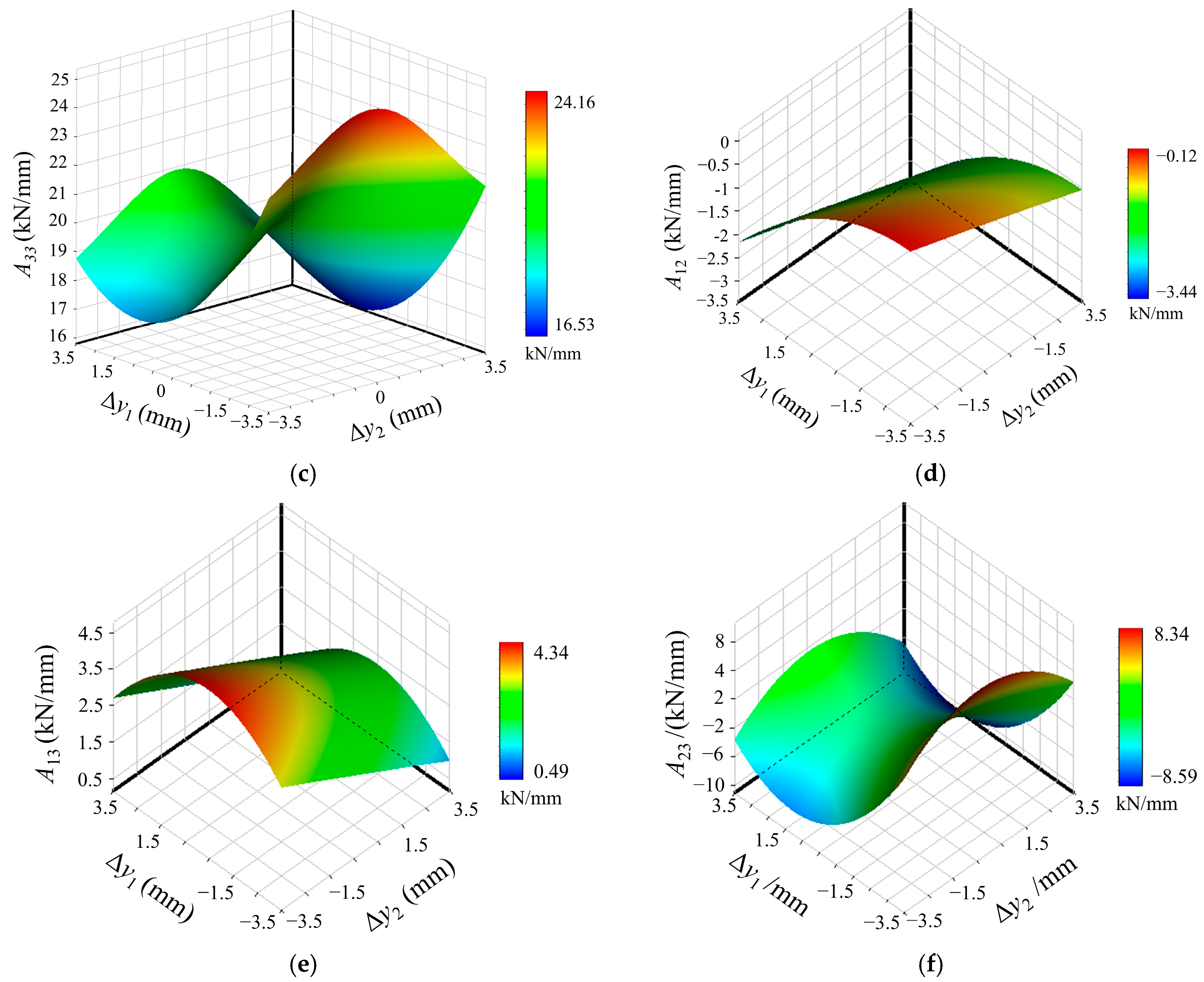

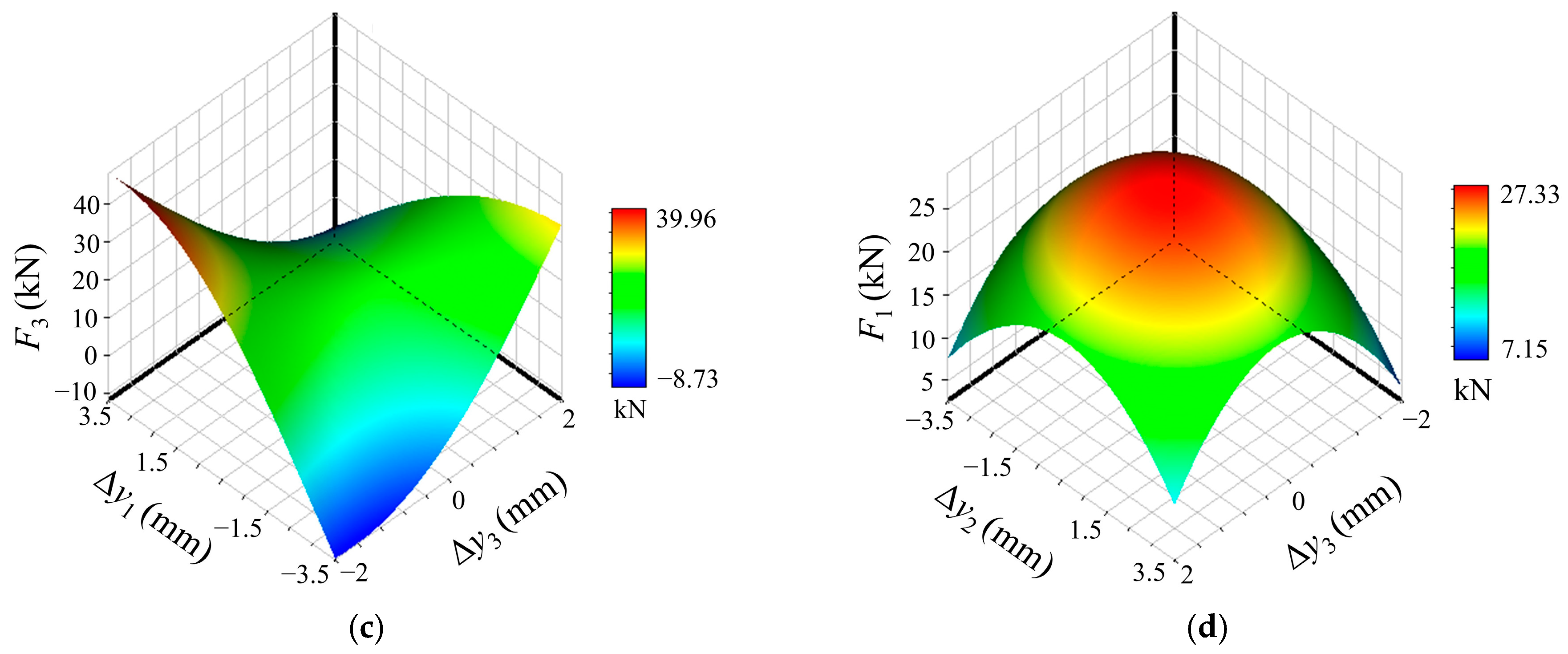

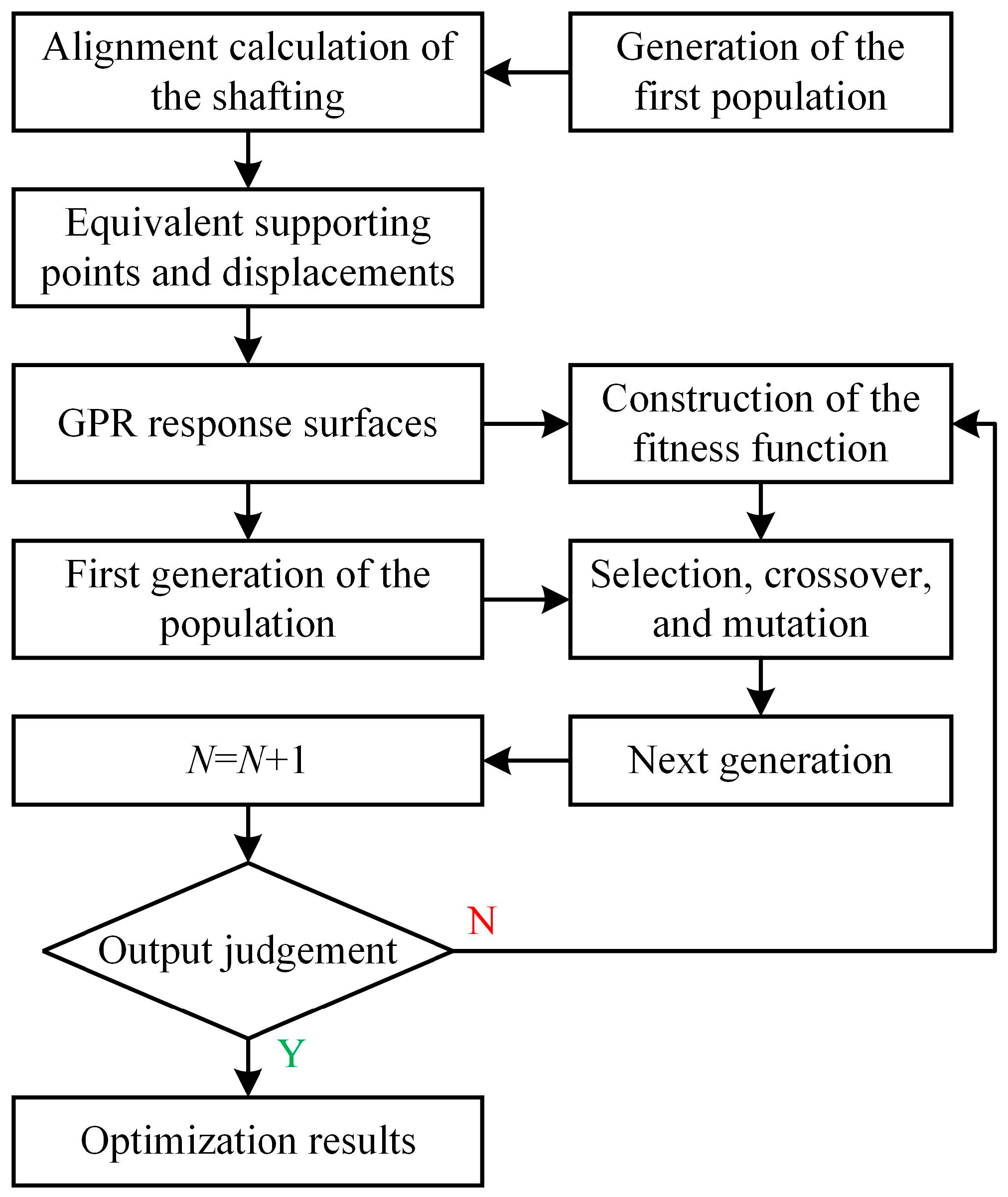

- The influence of elastic deformation of supporting foundations on the BLINs matrix was analyzed, and the concept of the dynamic BLINs was proposed. In order to use the BLINs for alignment optimization, the response surface method based on GPR was used to establish the mapping relationship between the elastic bearing displacement and the dynamic BLINs.

- Combining the response surfaces of the dynamic BLINs with the genetic algorithm, the alignment optimization of the shafting was realized. A new method has been developed for the analysis and optimization of the alignment of elastically supported marine propulsion shafting.

2. Alignment Calculation Model

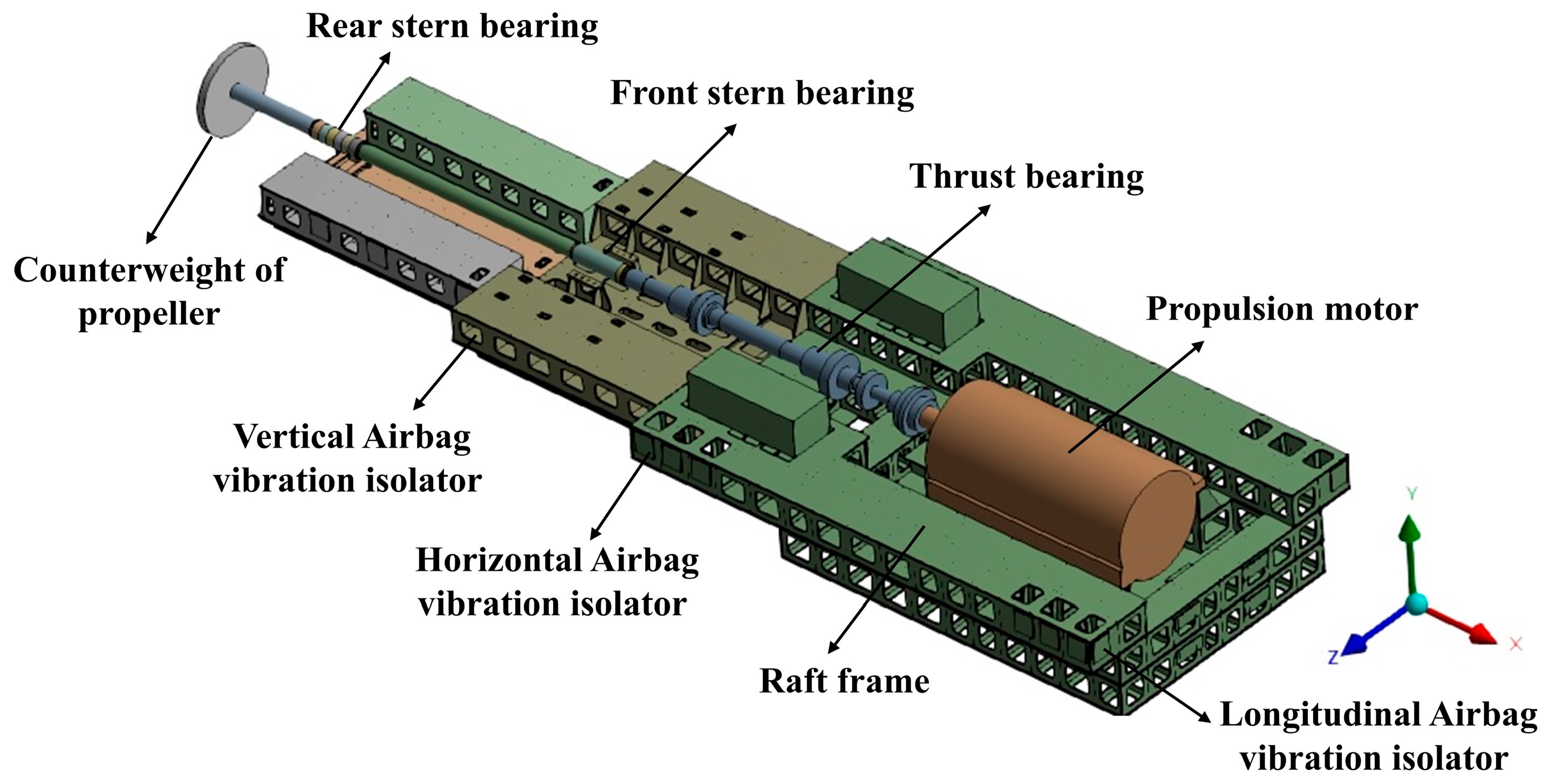

2.1. Numerical Model

- Shaft segments are treated as uniform-diameter stepped shafts with homogeneous distributions of density, modulus, and stiffness. The cross-section changes between flanges, couplings, and shaft segments are disregarded, and the propeller was equivalent to a homogeneous disc.

- Each bearing is supported by multiple points. The equivalent supporting point for the rear stern bearing is set at the rear one-third of the axial bearing length, while those of the front stern bearing and the thrust bearing are set at the midpoint [20].

- The radial stiffness of each support point is simplified into two orthogonal components in the y direction (vertical) and z direction (horizontal), and the coupling stiffness between these two orthogonal directions, which exhibits negligible influence on shafting alignment calculation, is neglected here. The stiffness of each bearing equals the parallel stiffness of the spring elements it contains, and the axial stiffness of the thrust bearing is simulated using an axial spring.

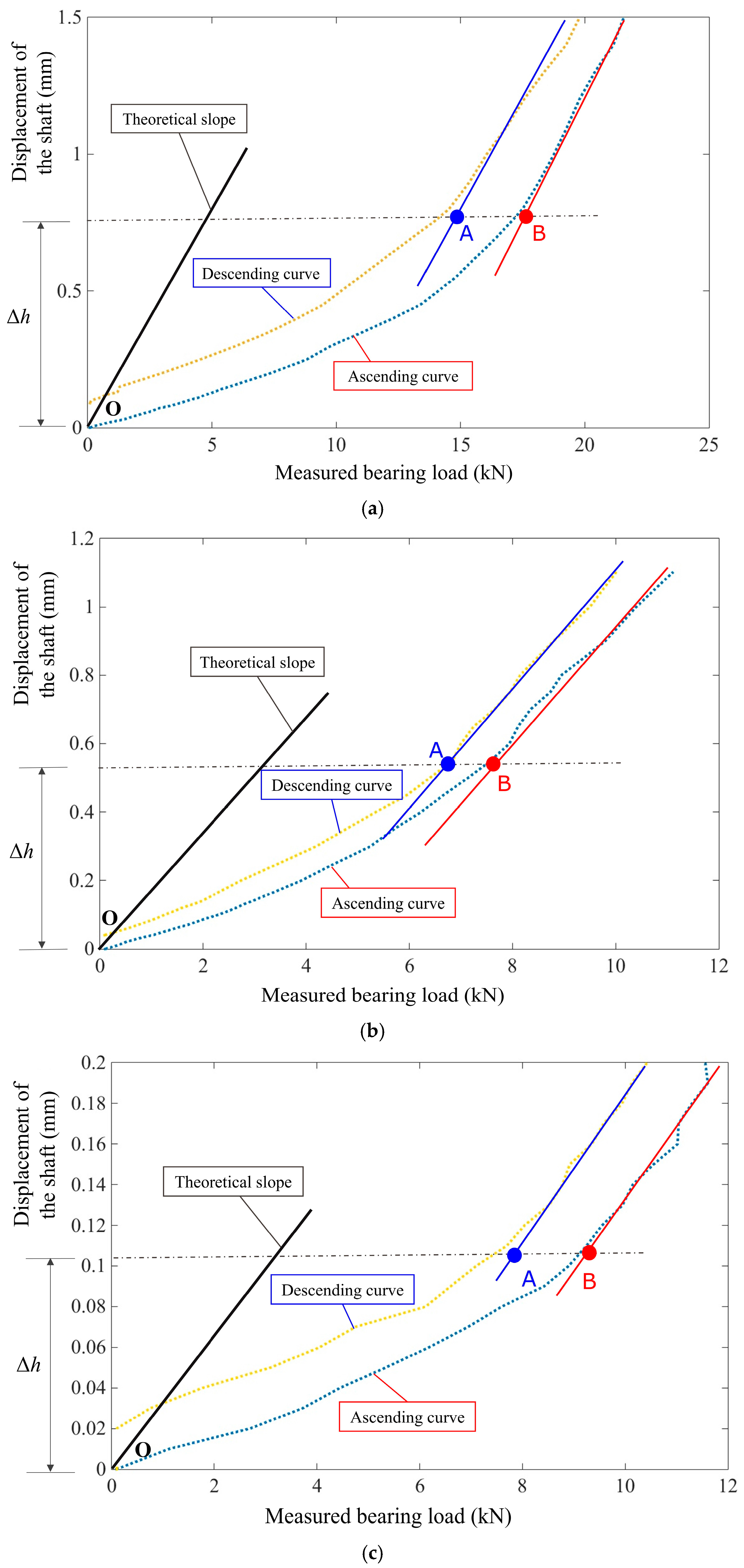

2.2. Experiment of Model Validation

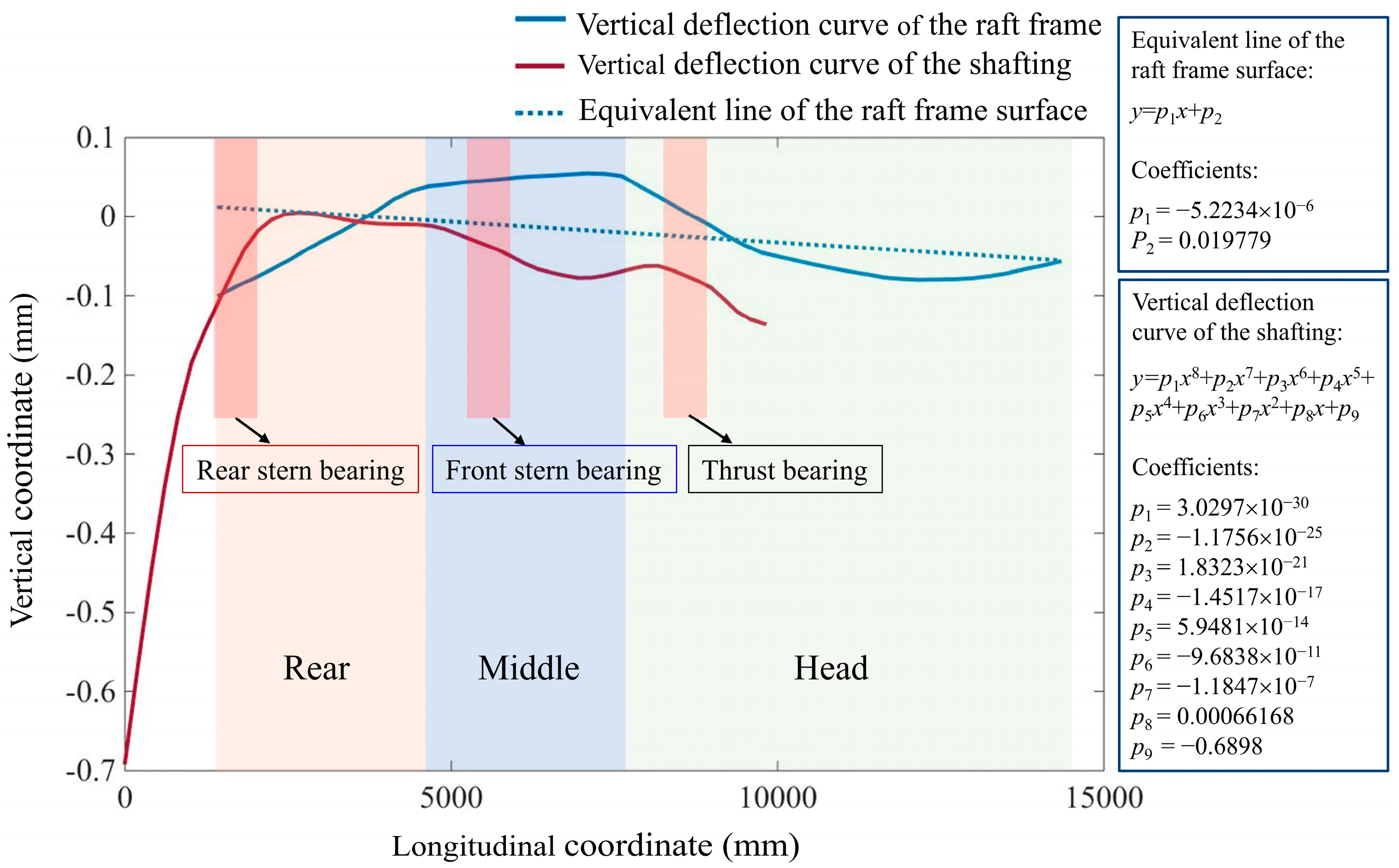

3. Measurement of Elastic Displacement

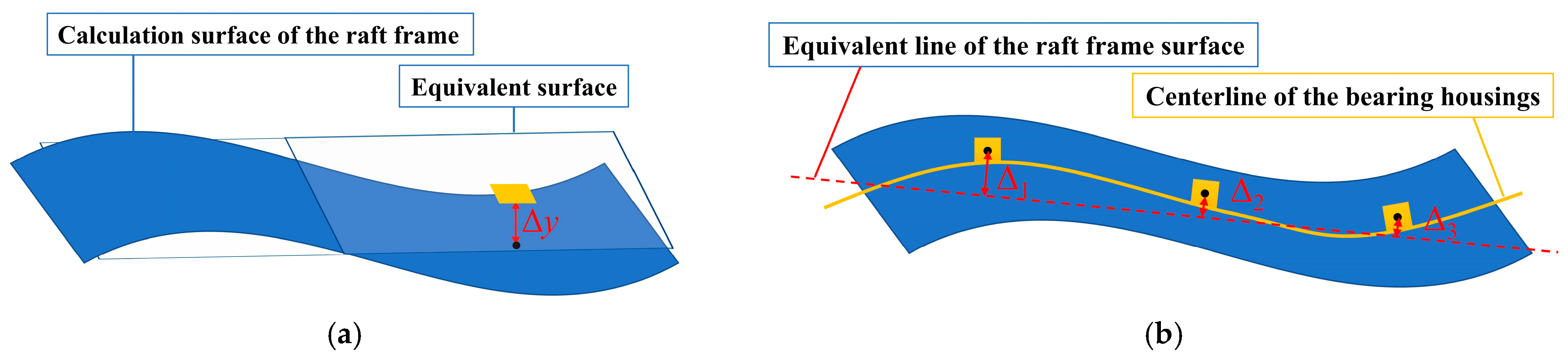

3.1. Elastic Displacement Increment

- The EDI may yield substantial deviation between calculated and actual displacement values when used to measure the displacement change of a certain point;

- The EDIs at a given point under different system deformation states may be equivalent, so it cannot correctly reflect the deflection of both the shafting and its supporting foundation, as shown in Figure 4c.

3.2. Equivalent Line-Surface Method

4. Dynamic BLINs Based on Response Surface Method

4.1. BLINs Considering Elastic Deformation

4.2. Response Surface Method Using GPR

- Randomly sample within the feasible ranges of the bearings’ equivalent displacement using the Latin hypercube sampling method, and generate the initial training sample set via the numerical model of the shafting.

- Use the GPR to train the regression equation, and test the accuracy of the training model with newly generated sample points. The test method is used to calculate the average relative error of each bearing load, with the requirement that the load error of the stern bearings should not exceed 5%, while that of the thrust bearing should not exceed 1%.

- If the accuracy of the training model is not satisfied, the newly generated sample points will be aggregated into the training set to improve the training quality.

- When the training accuracy meets the requirements, the local sample points at the feasible region boundary will be predicted and compared with the numerical calculation results. If the errors are unacceptable, the process will return to Step (3). When the errors are acceptable, the GPR response surfaces will be output.

5. Alignment Optimization

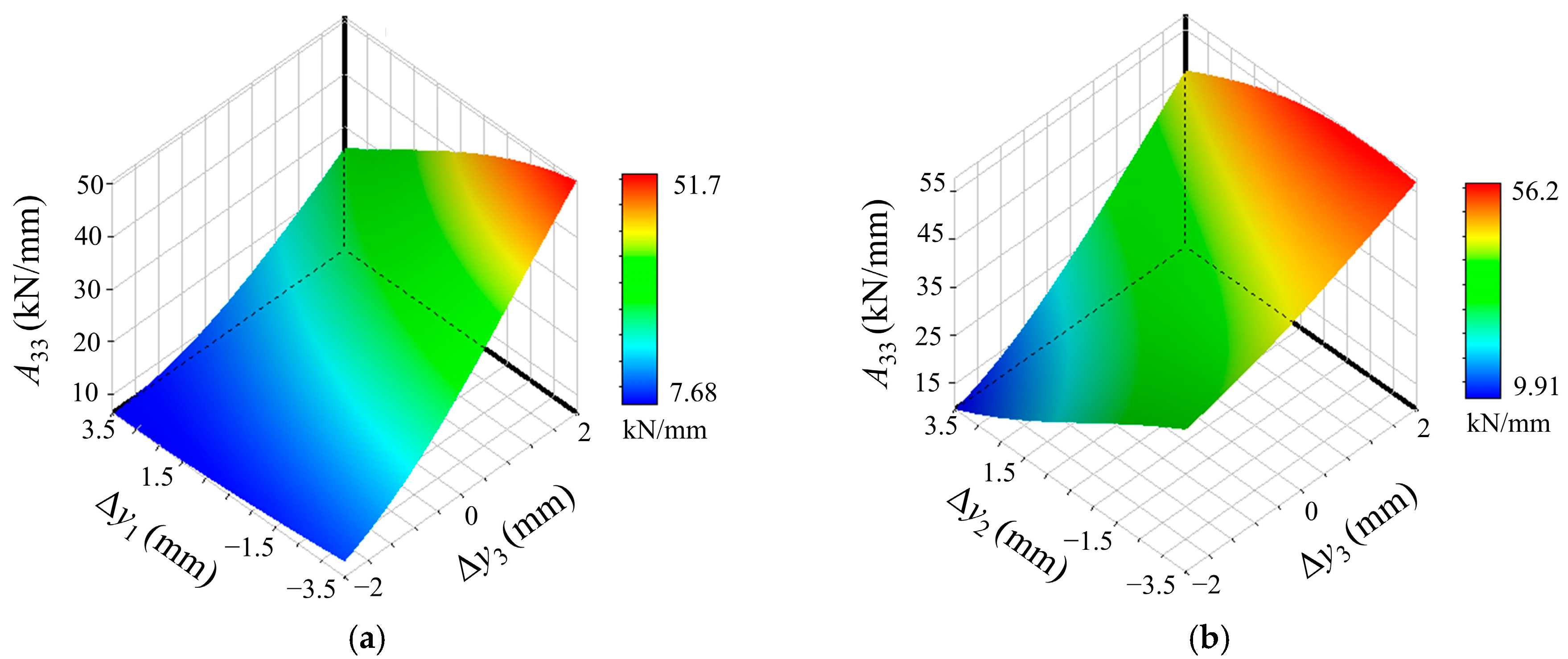

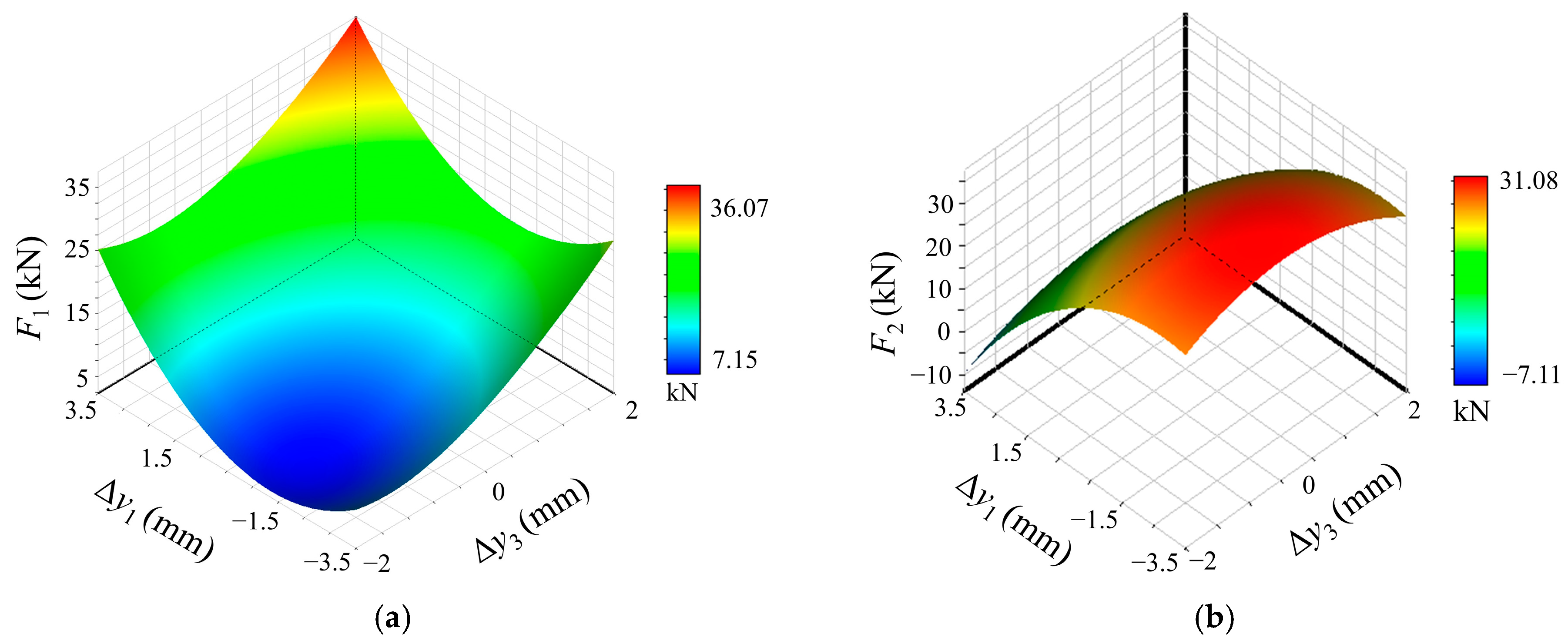

5.1. Response Surfaces of the Dynamic BLINs

- The load of the rear stern bearing is too large, and prolonged operation under this condition may lead to abnormal wear of the stern shaft segments and bearings, compromising the safety and stability of the shafting.

- The BLINs of the thrust bearing is much larger than that of the stern bearings, so, influenced by elastic deformation, vertical displacement of the thrust bearing will greatly change its load. Therefore, even-load distribution of the bearings should be taken into account to avert the instability of the thrust bearing caused by excessive displacement during the process of alignment optimization.

5.2. Alignment Optimization Based on GPR Response Surfaces

6. Conclusions

- To address the measurement challenges of elastic deformation in elastically supported shafting, an equivalent line-surface method was proposed to measure the elastic bearing displacement, and the concept of the dynamic BLINs was elicited considering elastic deformation.

- Using the GPR response surfaces, the mapping relationship between the elastic displacement and the dynamic BLINs was established, and the dynamic BLINs caused by elastic deformation were acquired.

- According to the analysis results of the straight-line alignment and the response surfaces, the optimization objective functions were defined and the genetic algorithm was used for alignment optimization. After optimization, the load of the rear stern bearing and the load difference between two stern bearings were reduced. The load distribution among the bearings became more even.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, G.; Zeng, F. Modern Marine Engineering, 1st ed.; National University of Defense Science and Technology Press: Changsha, China, 2001; pp. 545–546. ISBN 7-81024-734-4. [Google Scholar]

- Zhang, Y.; Xu, W.; Li, Z.; Yin, L. Alignment and safety analysis of marine propulsion shafting using intelligent raft system. J. Mar. Sci. Technol. 2021, 26, 323–330. [Google Scholar] [CrossRef]

- Sharma, S.K.; Sharma, R.C.; Lee, J. Modelling and simulation of MR damper characterization and uncertainty assessment in marine engine vibration isolation with FLPID control. Int. J. Model. Simul. 2024, 1–11. [Google Scholar] [CrossRef]

- Liu, S.; Shi, L.; Xu, W.; Hu, Z. Digital-twin driven alignment control method for marine shafting with air spring vibration isolation system. Sci. Rep. 2025, 15, 1065. [Google Scholar] [CrossRef]

- Deliporanides, G. Finite element shaft alignment on elastic foundation. Int. Shipbuild. Prog. 1992, 39, 391–397. [Google Scholar] [CrossRef]

- Murawski, L. Shaft line alignment analysis taking ship construction flexibility and deformations into consideration. Mar. Struct. 2005, 18, 62–84. [Google Scholar] [CrossRef]

- Murawski, L. The influence of shaft line alignment accuracy on the operational reliability of marine propulsion systems. J. KONES 2016, 23, 247–254. [Google Scholar] [CrossRef][Green Version]

- Zhou, R. The Theoretic Studies on the Propulsion Shafting Alignment of Ultra-Large Vessels. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 2005. [Google Scholar]

- Khalyavkin, A.A.; Makeev, S.A.; Loshadkin, D.V.; Mamontov, V.A.; Auslender, A.Y. Analysis of influence of elastic properties of deadwood bearings on shaft line operability. Vestn. Astrakhan State Tech. Univ. Ser. Mar. Eng. Technol. 2021, 2, 7–15. [Google Scholar] [CrossRef]

- Gu, Z.; Fu, Y.; Li, Z.; Yang, P. Shafting alignment calculation of large span propeller shafts. J. Ship. Mech. 2024, 28, 435–441. [Google Scholar] [CrossRef]

- Murawski, L. Thermal interaction between main engine body and ship hull. Ocean Eng. 2018, 147, 107–120. [Google Scholar] [CrossRef]

- Seo, C.O.; Jeong, B.U.; Kim, J.R.; Song, M.H.; Noh, J.H.; Lee, J.U. Determining the influence of ship hull deformation caused by draught change on shaft alignment application using FE analysis. Ocean Eng. 2020, 210, 107488. [Google Scholar] [CrossRef]

- Avgouleas, K.; Sarris, E.; Gougoulidis, G. Practical Aspects of Propulsion Shaft Alignment. In Proceedings of the 7th International Symposium on Ship Operations, Management & Economics, Athens, Greece, 6–7 April 2021. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, J.; Li, R.; Liu, Y. A novel 4-DOF marine stern bearing support model considering discrete distribution effects. Ocean Eng. 2024, 312, 119072. [Google Scholar] [CrossRef]

- Nickabadi, S.; Hosseini, S.M.; Bathaee, H.; Alirezaeipour, S. Marine shaft optimization using surrogate models and multi-objective optimization. Structures 2024, 63, 106415. [Google Scholar] [CrossRef]

- Magalhães, D.L.; Martins, D.H.C.S.S.; Castro, B.M.; Vaz, L.A.; Monteiro, U.A.; Gutiérrez, R.H.R. Machine learning performance comparison for main propulsive shafting systems alignment. Ocean Eng. 2023, 280, 114556. [Google Scholar] [CrossRef]

- Lai, G.; Lei, J.; Liu, J.; Cao, S.; Qin, H.; Zeng, F.; Zhou, R. Numerical and experimental study on comprehensive optimization for the KPIs of ship propulsion shafting design based on MDO. Ocean Eng. 2021, 222, 108624. [Google Scholar] [CrossRef]

- Li, R.; Wang, J.; Chen, Z.; Wang, F.; Liu, Y. Study on the Methods of Measurement, Optimization and Forecast of Propulsion Shaft Bearing Load of Ships. J. Mar. Sci. Eng. 2023, 11, 1324. [Google Scholar] [CrossRef]

- Bsiso, R.M.; Ripin, Z.M. Optimizing the bearing vertical offset of a marine propeller shaft system. Proc. IMechE Part M J. Eng. Mar. Environ. 2024, 14750902241277260. [Google Scholar] [CrossRef]

- Sun, J.S.; Kim, Y.G.; Kim, U.K. Study on shaft alignment of propulsion shafting system depending on single reaction force supporting position of aft stern tube bearing. J. Mar. Sci. Technol. 2021, 26, 1340–1357. [Google Scholar] [CrossRef]

- Zhou, R.; Xu, L.; Zhang, S.; Huang, Z. Study on some technical problems in alignment of ship propulsion shafting. Ship. Eng. 2004, 26, 48–52. [Google Scholar] [CrossRef]

- Zhao, X.; Shuai, C.; Xu, W.; Li, Z. Research on bearings load-increment in integrated vibration isolation system of ship stern. Eng. Mech. 2019, 36, 311–315. [Google Scholar] [CrossRef]

- Schaffrin, B.; Lee, I.; Choi, Y.; Felus, Y. Total Least-Squares (TLS) for geodetic straight-line and plane adjustment. Boll. Geod. Sci. Affini 2006, 65, 141–168. [Google Scholar]

- Liu, Z.; Li, M.; Lu, J. Cylindrical Fitting of Point Cloud Data Based on Robust Weighted Total Least Squares. Mod. Surv. Mapp. 2018, 41, 39–42. [Google Scholar] [CrossRef]

- Sebastian, T.B.; Klein, P.N.; Kimia, B.B. On aligning curves. IEEE Trans. Pattern. Anal. Mach. Intell. 2003, 25, 116–125. [Google Scholar] [CrossRef]

- Liu, J.; Gu, Z.; Liu, S. Research on MDO of ship propulsion shafting dynamics considering the coupling effect of a propeller-shafting-hull system. Pol. Marit. Res. 2023, 30, 86–97. [Google Scholar] [CrossRef]

- Lu, L.; Li, G.; Xing, P.; Gao, L.; Song, Y.; Zhang, H. Numerical calculation and experimental investigation of the dynamic alignment of ship propulsion shafting based on Latin hypercube stochastic finite element. Ocean Eng. 2024, 296, 116935. [Google Scholar] [CrossRef]

- Nguyen, A.H.; Rath, M.; Leitinger, E.; Nguyen, K.V.; Witrisal, K. Gaussian Process Modeling of Specular Multipath Components. Appl. Sci. 2020, 10, 5216. [Google Scholar] [CrossRef]

- Singf, S.K.; Mali, H.S.; Unune, D.R.; Wojciechowski, S.; Wilczyński, D. Application of Generalized Regression Neural Network and Gaussian Process Regression for Modelling Hybrid Micro-Electric Discharge Machining: A Comparative Study. Processes 2022, 10, 755. [Google Scholar] [CrossRef]

| Bearing | A | B | Measured Load | Calculated Load | B − A |

|---|---|---|---|---|---|

| Rear stern bearing | 14.89 | 17.41 | 16.15 | 16.69 | 2.52 |

| Front stern bearing | 6.82 | 7.92 | 7.37 | 7.18 | 1.10 |

| Thrust bearing | 7.83 | 9.79 | 8.81 | 8.22 | 1.96 |

| Bearing | Relative Deflection (mm) | Bearing Load (kN) | Rotation Angle (Rad) |

|---|---|---|---|

| Rear stern bearing | 0.198 | 17.94 | 9.79 × 10−4 |

| Front stern bearing | −0.076 | 7.14 | −3.31 × 10−4 |

| Thrust bearing | −0.095 | 8.31 | −2.54 × 10−4 |

| Bearing | (mm) | Bearing Load (kN) | Rotation Angle (Rad) |

|---|---|---|---|

| Rear stern bearing | −0.57 | 14.95 | 7.86 × 10−4 |

| Front stern bearing | 0.14 | 9.15 | −3.25 × 10−4 |

| Thrust bearing | 0.05 | 8.01 | 2.27 × 10−4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Gu, Z.; He, J.; Cao, S. Alignment Optimization of Elastically Supported Submarine Propulsion Shafting Based on Dynamic Bearing Load Influence Numbers. Appl. Sci. 2025, 15, 4348. https://doi.org/10.3390/app15084348

Liu J, Gu Z, He J, Cao S. Alignment Optimization of Elastically Supported Submarine Propulsion Shafting Based on Dynamic Bearing Load Influence Numbers. Applied Sciences. 2025; 15(8):4348. https://doi.org/10.3390/app15084348

Chicago/Turabian StyleLiu, Jinlin, Zheng Gu, Junhui He, and Shijie Cao. 2025. "Alignment Optimization of Elastically Supported Submarine Propulsion Shafting Based on Dynamic Bearing Load Influence Numbers" Applied Sciences 15, no. 8: 4348. https://doi.org/10.3390/app15084348

APA StyleLiu, J., Gu, Z., He, J., & Cao, S. (2025). Alignment Optimization of Elastically Supported Submarine Propulsion Shafting Based on Dynamic Bearing Load Influence Numbers. Applied Sciences, 15(8), 4348. https://doi.org/10.3390/app15084348