Investigation of Rock-Breaking Mechanisms Based on the Adaptive Matching Method for Drilling Loads

Abstract

:1. Introduction

2. Methodology

2.1. Particle Flow Code

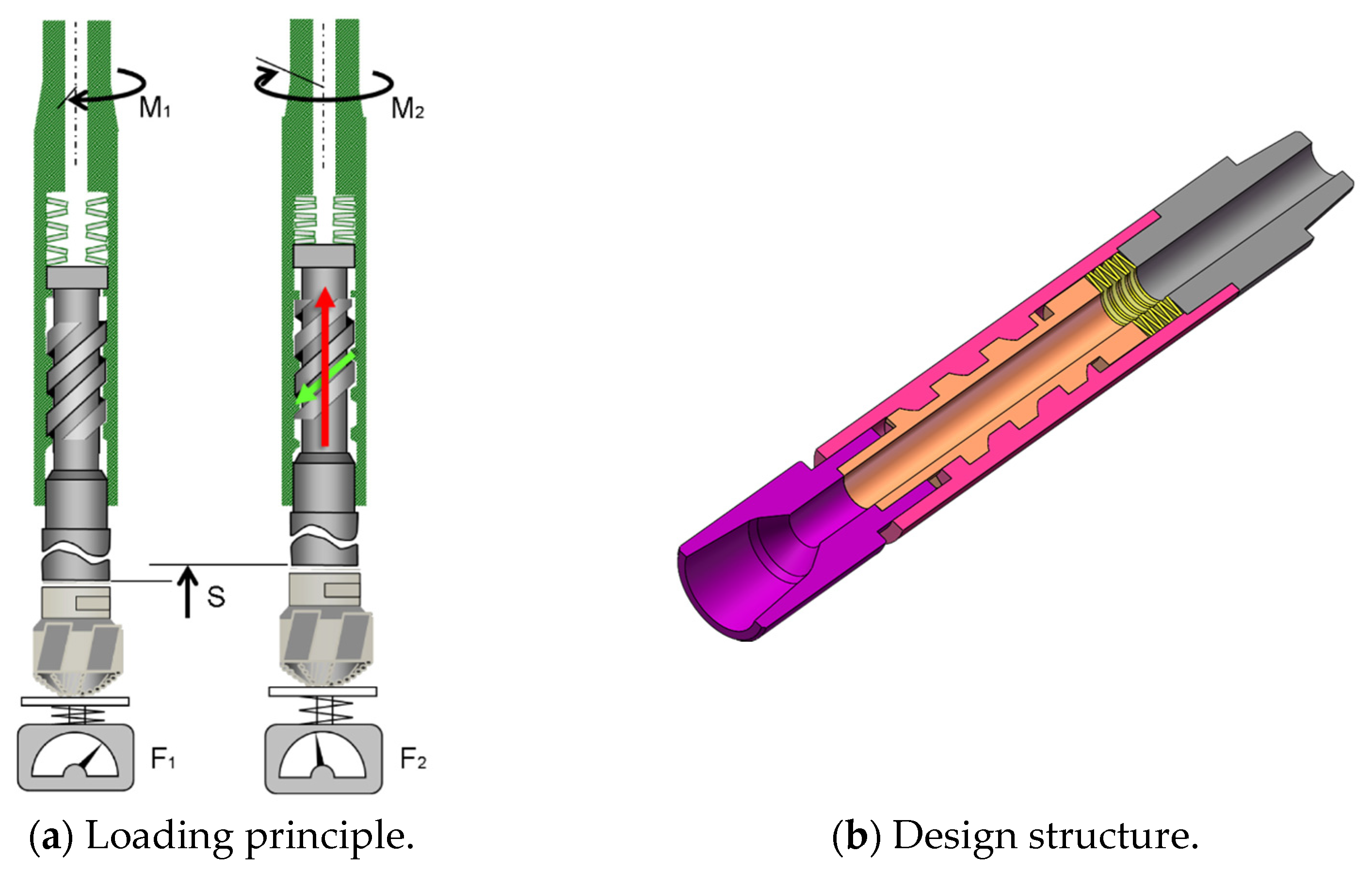

2.2. Loading Method for Adaptive Matching of Drilling Loads

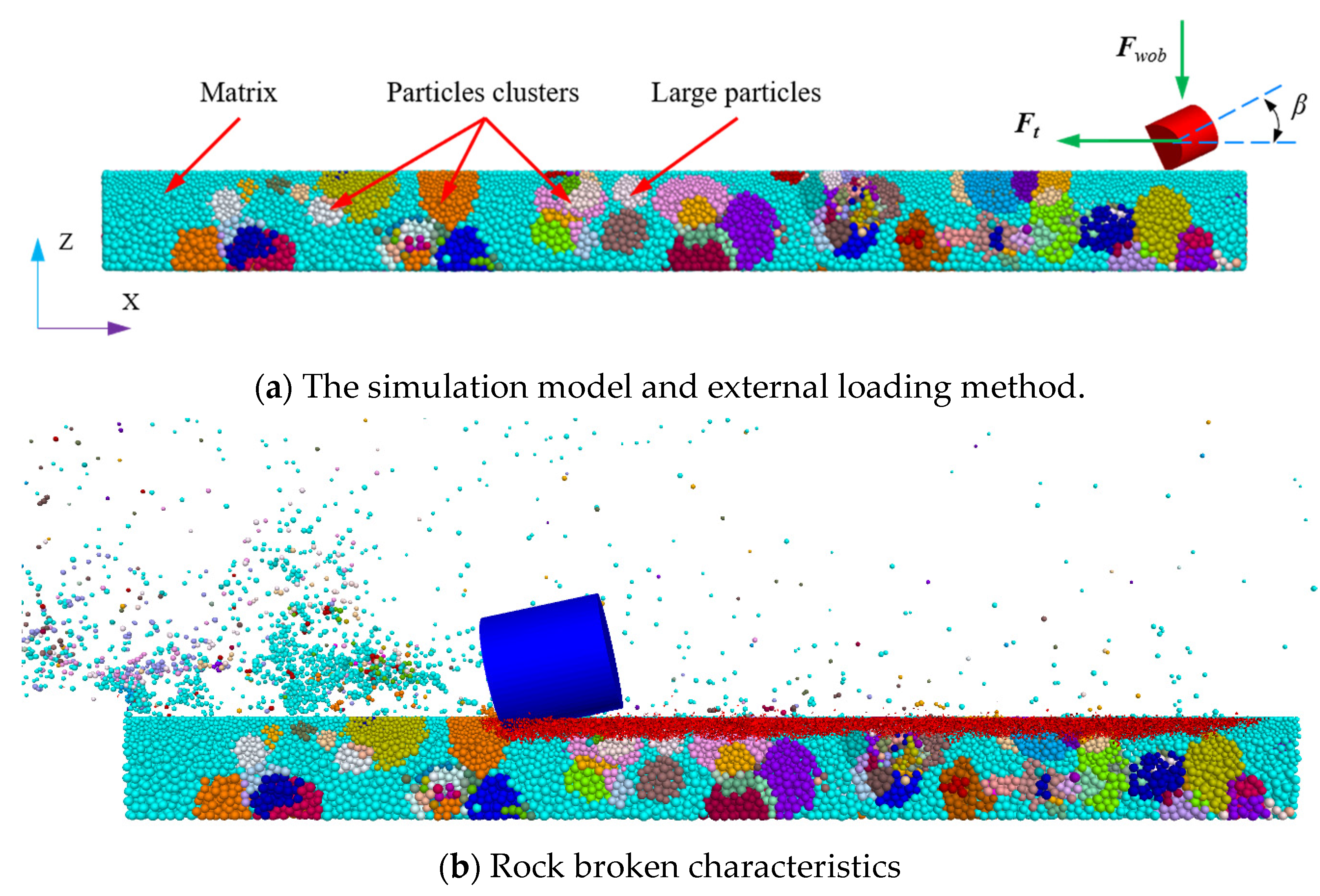

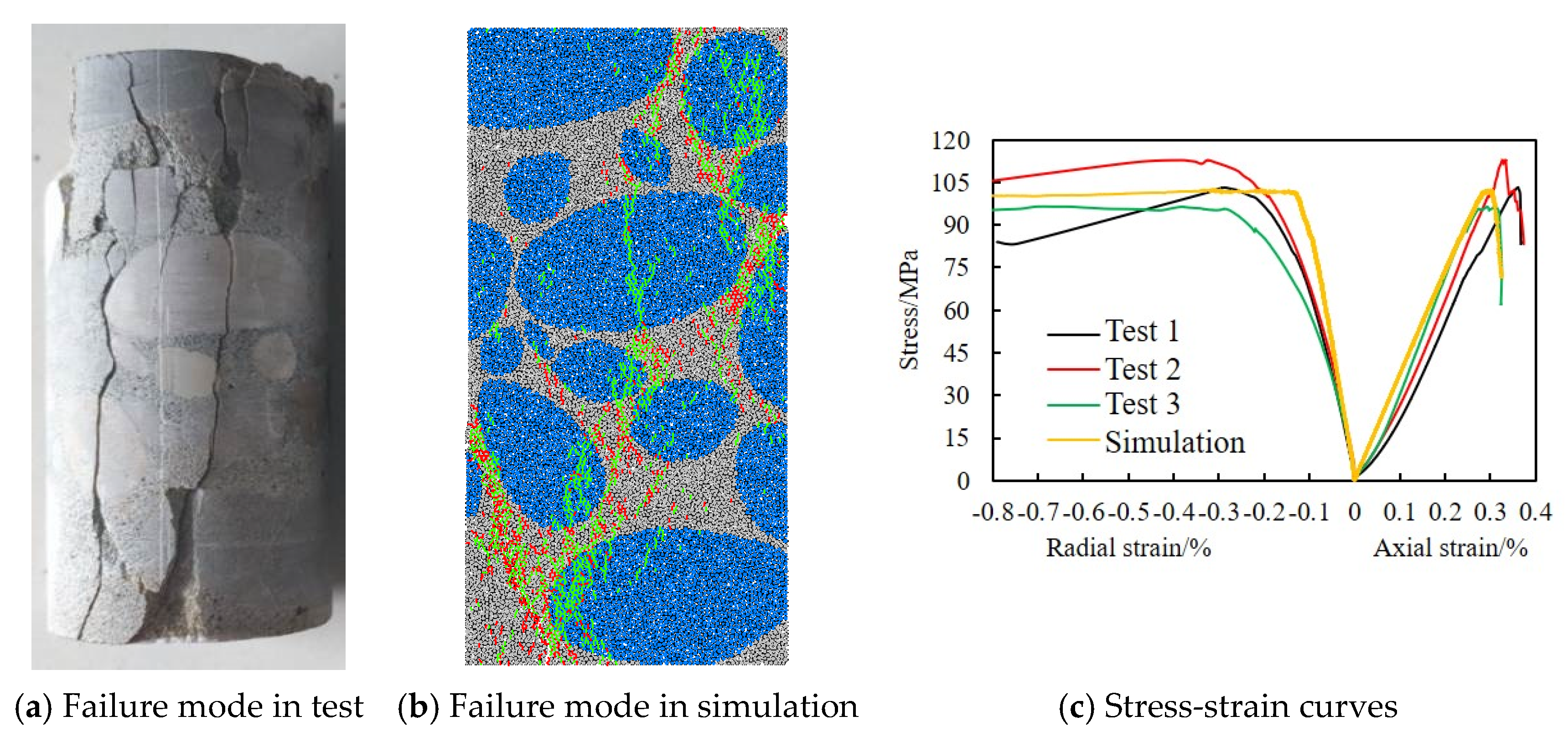

2.3. Modeling of the PDC Cutter Cutting Rock

3. Results and Discussion

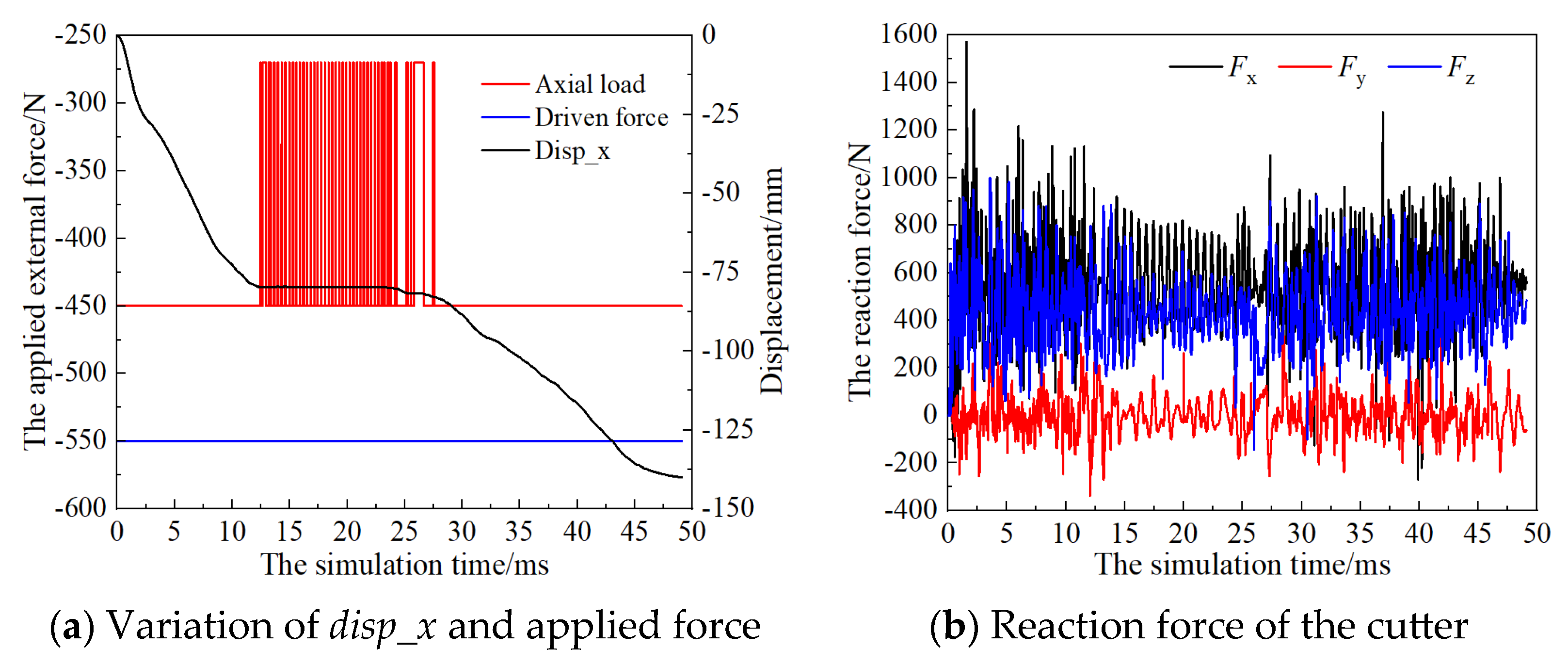

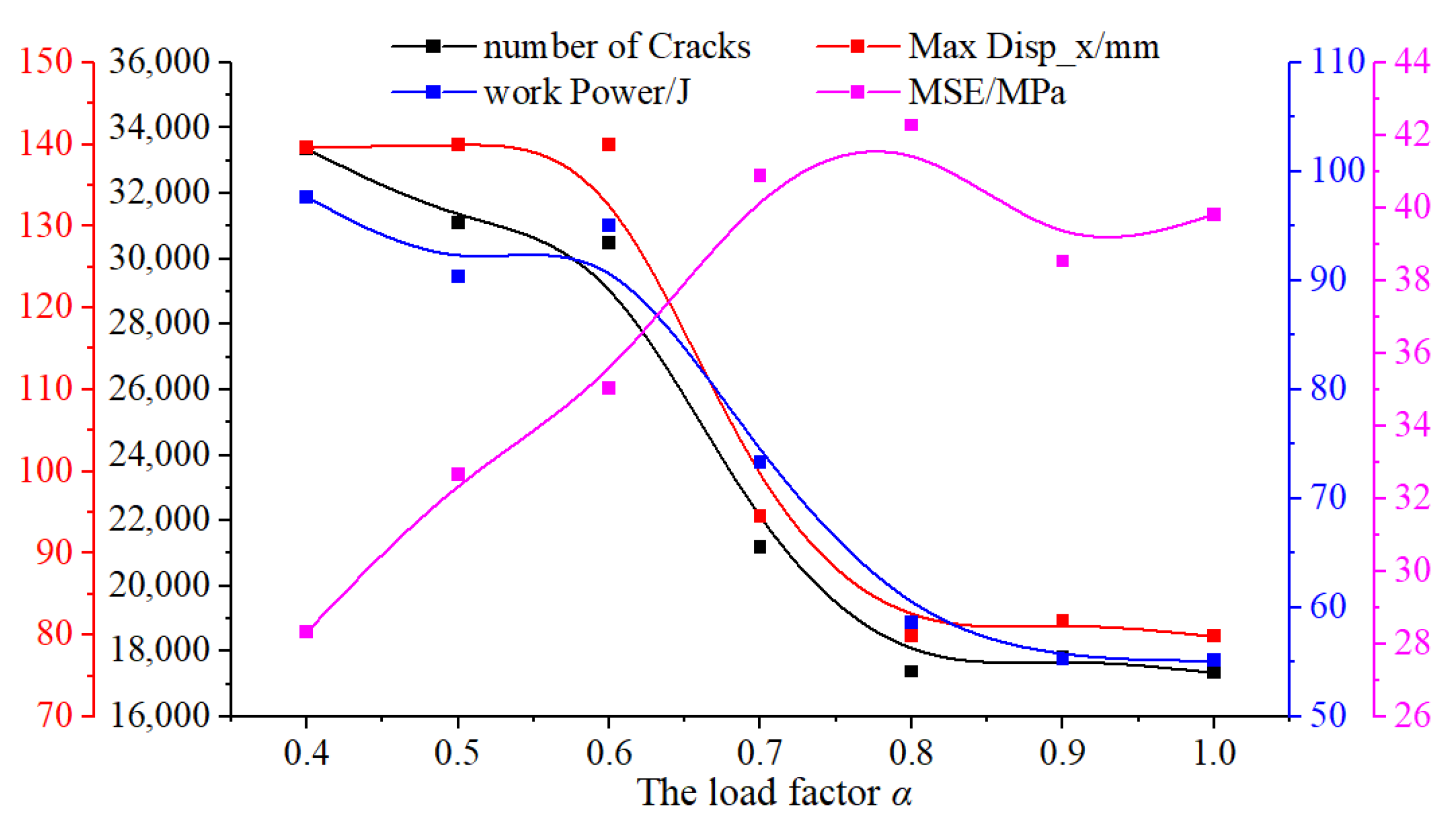

3.1. Effect of the Load Factor

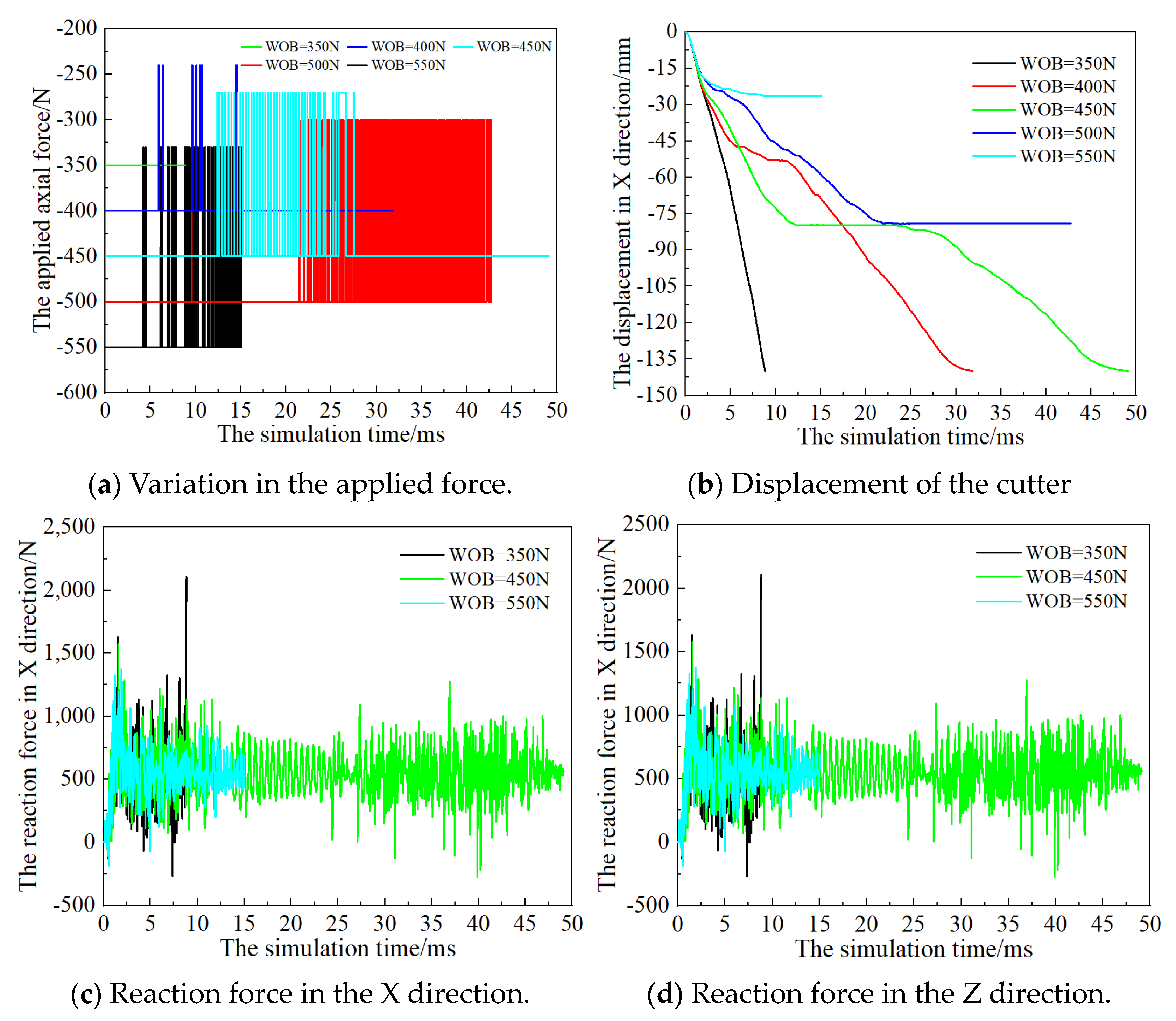

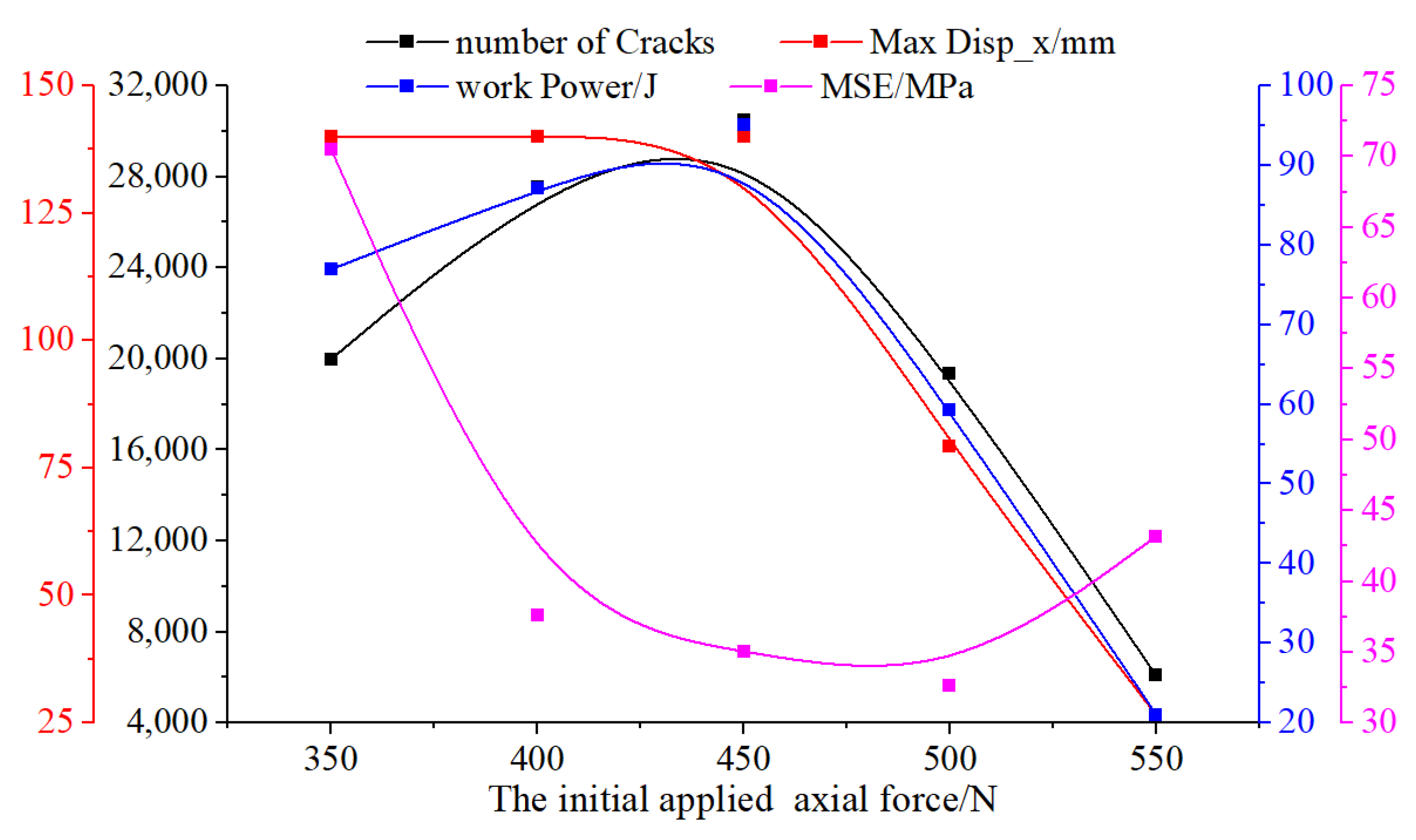

3.2. Effect of the Initial Axial Force

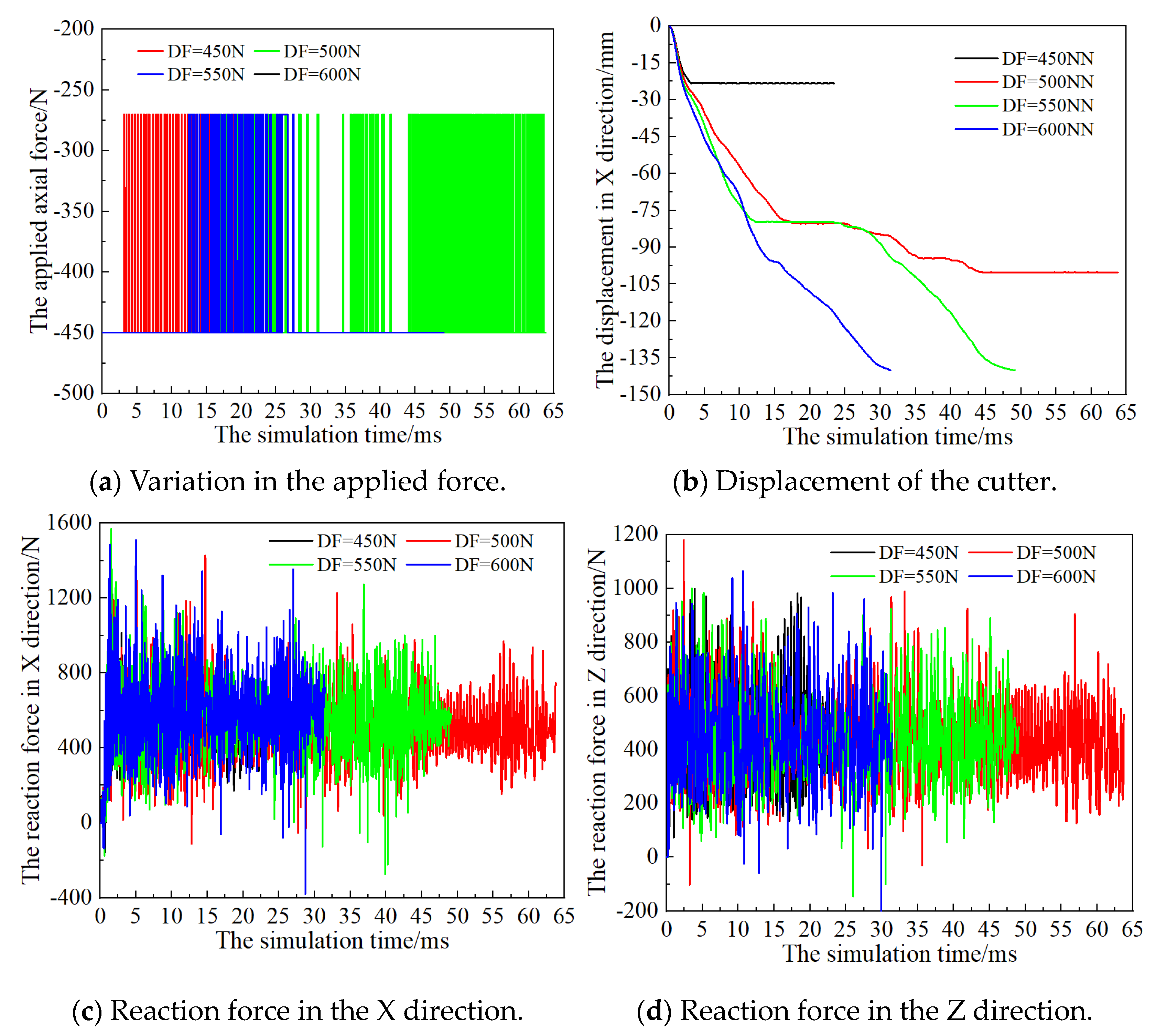

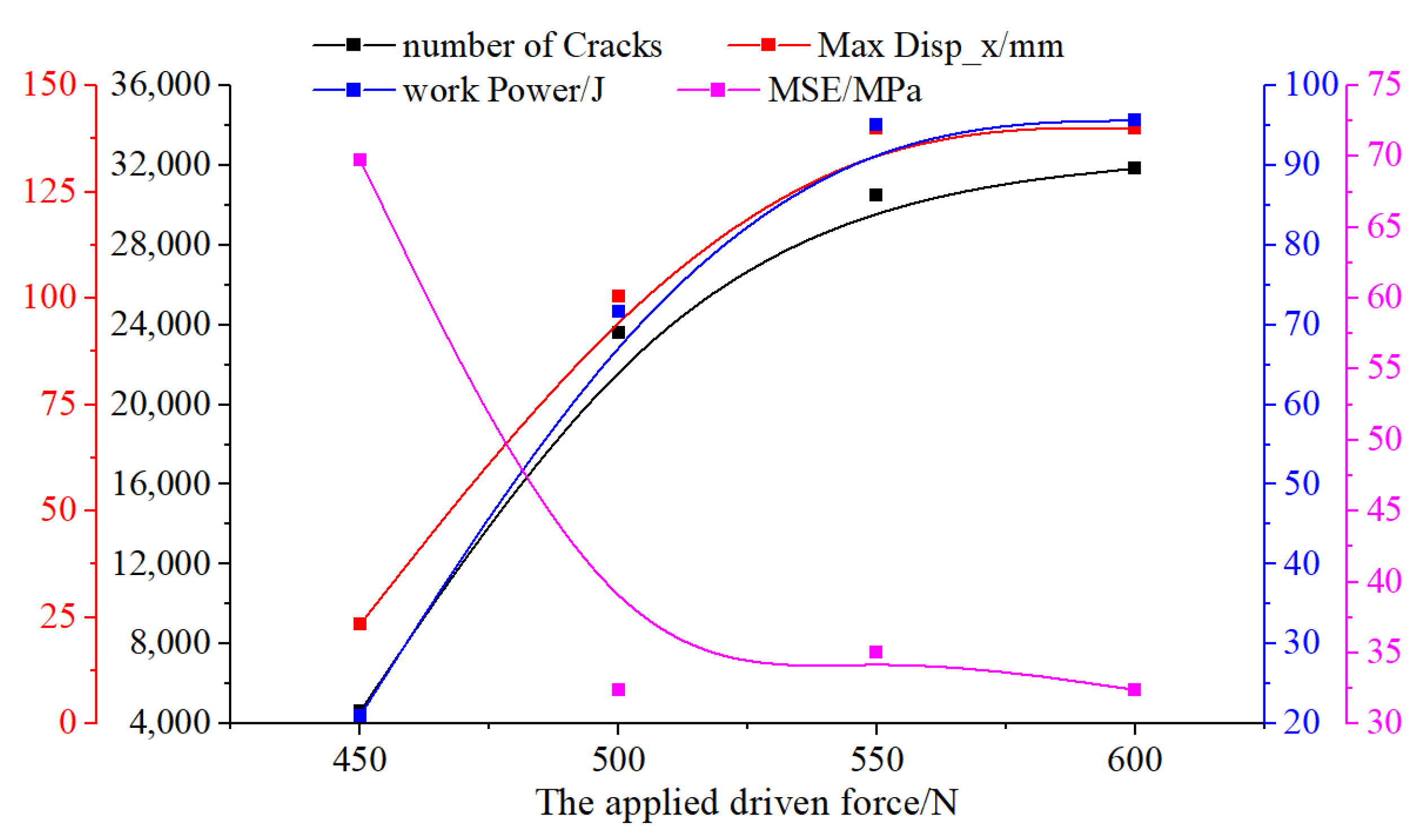

3.3. Effect of the Driven Force

4. Conclusions

- (1)

- This study proposes an adaptive matching method of drilling load acting on the PDC drill bit during the process of rock breaking in a bottomhole. The working principle and adjustment mechanism of this method are elaborated upon in detail, complemented by the detailed structural design of a purpose-built tool implementing this adaptive load control.

- (2)

- A kind of simulation model of rock breaking under the action of a PDC cutter based on the discrete element method (DEM) is established, incorporating the proposed adaptive matching method of drilling load to dynamically adjust applied axial force according to the reaction force monitored in the cutter. This simulation framework enables systematic investigation of the rock-breaking mechanism under adaptive load conditions.

- (3)

- The influential factors of load factor, initial axial force, and driven force on the kinematics and rock fragmentation behavior are clarified based on the proposed method. The use of the proposed method of this kind of tool can systematically decrease the reaction force in the cutting direction, while axial reaction force exhibits non-uniform fluctuations. The total crack count inversely correlates with MSE, and the tensile cracks account for 85% of total failures, consistent with the simulated rock’s tensile-dominated failure mode. The cracks generated a decrease while increasing the load factor, which increases linearly with the driven force and follows a parabolic trend with the initial axial force acting on the PDC cutter.

- (4)

- The proposed adaptive matching method of drilling load strategy improves the mechanics of PDC cutter–rock contact, thereby enhancing drilling efficiency and the working life through reduced drillstring vibration and reaction force mitigation. This innovation offers a viable solution for optimizing penetration rates in highly heterogeneous formations or soft–hard interbedded formations by dynamically balancing cutting loads and energy consumption.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, H.; Ge, Y.; Lin, S. Technologies in deep and ultra-deep well drilling: Present status, challenges and future trend in the 13th Five-Year Plan period (2016–2020). Nat. Gas. Ind. B 2017, 4, 319–326. [Google Scholar] [CrossRef]

- Caicedo, H.; Calhoun, W.; Ewy, R. Unique ROP predictor using bit-specific coefficient of sliding friction and mechanical efficiency as a function of confined compressive strength impacts drilling performance. In Proceedings of the SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 23–25 February 2005; Society of Petroleum Engineers: Calgary, AB, Canada, 2005. [Google Scholar]

- Jain, J.R.; Ricks, G.; Baxter, B.; Vempati, C.; Peters, V.; Bilen, J.-M.; Spencer, R.; Stibbe, H. A Step Change in Drill Bit Technology with Self-Adjusting PDC Bits. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Fort Worth, TX, USA, 1–3 March 2016; SPE-178815. Society of Petroleum Engineers: Calgary, AB, Canada, 2016. [Google Scholar]

- Kenneth, E.; Russell, S.C. Innovative Ability to Change Drilling Responses of a PDC Bit at the Rig Site Using Interchangeable Depth of Cut Control Features. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Fort Worth, TX, USA, 1–3 March 2016; SPE-178808. Society of Petroleum Engineers: Calgary, AB, Canada, 2016. [Google Scholar]

- Si, N.; Deng, H.; Li, J.; Pi, G. Self-adjusting PDC bit of Baker Hughes. Fault-Block Oil Gas Field 2017, 24, 125–130. [Google Scholar]

- Hu, H.; Huang, H.; Wang, H. New Progress and Development Trends of PDC Bits in China and Abroad. China Pet. Mach. 2024, 52, 1–10. [Google Scholar]

- Hu, H. Research on Influence Factors of Rock-Breaking Efficiency and Physical Design of Wob Self-Adjusting PDC Bit; China University of Petroleum: Qingdao, China, 2021. [Google Scholar]

- Hu, H.; Guan, Z.; Zhang, B.; Xu, Y.; Liu, Y.; Wang, B. Structure design of weight-on-bit self-adjusting PDC bit based on stress field analysis and experiment evaluation. J. Pet. Sci. Eng. 2021, 196, 107692. [Google Scholar] [CrossRef]

- Hu, H.; Guan, Z.; Wang, B.; Liang, D.; Sun, M.; Wang, X.; Chen, W. Weight-on-Bit Self-Adjusting Dual-Diameter Bit Leads a Step Change in Drilling Bit Technology. In Proceedings of the International Petroleum Technology Conference, Beijing, China, 26–28 March 2019; Society of Petroleum Engineers: Calgary, AB, Canada, 2019. [Google Scholar]

- Jain, J.R.; Ricks, G.; Ledgerwood, L.W.; Phillips, A. Mitigating Drilling Dysfunctions and Enhancing Performance with Self-Adjusting Bit Technology: Analytical and Experimental Case Studies. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, The Hague, The Netherlands, 14–16 March 2017; SPE-184736-MS. Society of Petroleum Engineers: Calgary, AB, Canada, 2017. [Google Scholar]

- Bai, B.; Zeng, Y.; Lu, X.; Zhang, J.; Tao, L. An ROP Improvement Technology Based on Adaptive Matching Between the Rock-Breaking Energy of Bits and Rock Features. Pet. Drill. Tech. 2023, 51, 30–36. [Google Scholar]

- Selnes, K.S.; Clemmensen, C.C.; Reimers, N. Drilling Difficult Formations Efficiently with the Use of an Antistall Tool. In Proceedings of the IADC/SPE Drilling Conference, Orlando, FL, USA, 4–6 March 2008. [Google Scholar]

- Dagestad, V.; Mykkeltvedt, M.; Eide, K.; Reimers, N. First field results for extended-reach ct-drilling tool. In Proceedings of the SPE/ICoTA Coiled Tubing and Well Intervention Conference and Exhibition, Woodlands, TX, USA, 4–5 April 2006. [Google Scholar]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Geotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Cundall, P.A.; Hart, R.D. Numerical modelling of discontinua. Eng. Comput. 1992, 9, 101–113. [Google Scholar] [CrossRef]

- Potyondy, D.O. The bonded-particle model as a tool for rock mechanics research and application: Current trends and future directions. Geosyst. Eng. 2015, 18, 1–28. [Google Scholar] [CrossRef]

- Itasca Consulting Group. Particle Flow Code in Two Dimensions; Itasca Consulting Group, Inc.: Minneapolis, MN, USA, 1999. [Google Scholar]

- Lei, S.T.; Kaitkay, P. Distinct Element Modeling of Rock Cutting under Hydrostatic Pressure. Key Eng. Mater. 2003, 250, 110–117. [Google Scholar] [CrossRef]

- Itasca Consulting Group, Inc. PFC (Particle Flow Code in 2 and 3 Dimensions); Version 5.0; Itasca Consulting Group, Inc.: Minneapolis, MN, USA, 2016. [Google Scholar]

- Wei, J.; Liao, H.; Huang, B.; Li, N.; Liang, H.; Zhou, B.; Zhang, Q.; Chen, L.; Feng, H. Effect of the random distribution of gravel particles on the mechanical behaviors of conglomerate. Arab. J. Geosci. 2023, 16, 485. [Google Scholar] [CrossRef]

- Luo, S.; Ge, H.; Wang, J.; Zhou, W.; Shen, Y.; Liu, P.; Liu, J. Numerical simulation study on the crack propagation of conglomerate. R. Soc. Open Sci. 2021, 8, 202178. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Li, J.; Gao, D.; Guo, H.; Lian, W.; Yang, H.; Gao, R. Analysis on Rock Breaking Mechanism and Adaptability of PDC Bit in Conglomerate Formation. China Pet. Mach. 2023, 51, 51–67. [Google Scholar]

- Liu, X.; Zou, D.; Chen, Y.; Huang, Y.; Wang, Q. Analysis of PDC cutter cutting broken conglomerate based on the discrete element method. Energy Sci. Eng. 2022, 10, 3580–3591. [Google Scholar] [CrossRef]

- Yang, H.; Deng, Q.; Ye, B.; Liu, J.; Huang, A. Simulation on Microscopic Damage of PDC Cutter During Conglomerate Cutting. China Pet. Mach. 2024, 52, 1–10. [Google Scholar]

| Description | Parameter | Matrix | Particles | Bond |

|---|---|---|---|---|

| Ball density/kg·m−3 | 2500 | 2875 | / | |

| Ball–ball contact modulus/GPa | Ec | 11.4 | 25.2 | 12.6 |

| Ball stiffness ratio | kn/ks | 2.21 | 1.52 | 0.76 |

| Parallel bond Young’s modulus/GPa | 11.4 | 25.2 | 12.6 | |

| Particle contact’s normal to shear stiffness ratio | 2.21 | 1.52 | 0.76 | |

| Parallel bond normal strength/MPa | 31.1 | 45.4 | 22.7 | |

| Parallel bond cohesion/MPa | 31.1 | 45.4 | 22.7 | |

| Parallel bond frictional angle/° | 38 | 49 | 24.5 | |

| Ball friction coefficient | 0.31 | 0.24 | 0.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, H.; Ji, G.; Shao, F.; Zhang, L.; Wei, K. Investigation of Rock-Breaking Mechanisms Based on the Adaptive Matching Method for Drilling Loads. Appl. Sci. 2025, 15, 4320. https://doi.org/10.3390/app15084320

Hu H, Ji G, Shao F, Zhang L, Wei K. Investigation of Rock-Breaking Mechanisms Based on the Adaptive Matching Method for Drilling Loads. Applied Sciences. 2025; 15(8):4320. https://doi.org/10.3390/app15084320

Chicago/Turabian StyleHu, Huaigang, Guodong Ji, Fangyuan Shao, Liling Zhang, and Kai Wei. 2025. "Investigation of Rock-Breaking Mechanisms Based on the Adaptive Matching Method for Drilling Loads" Applied Sciences 15, no. 8: 4320. https://doi.org/10.3390/app15084320

APA StyleHu, H., Ji, G., Shao, F., Zhang, L., & Wei, K. (2025). Investigation of Rock-Breaking Mechanisms Based on the Adaptive Matching Method for Drilling Loads. Applied Sciences, 15(8), 4320. https://doi.org/10.3390/app15084320