Service Process Modeling in Practice: A Case Study in an Automotive Repair Service Provider

Abstract

1. Introduction

- Analyzing service processes in a holistic way, considering their interconnections and their impact on overall performance.

- Investigating the specific challenges and opportunities of the automotive sector and proposing context-specific solutions.

- Translating research results in concrete and applicable measures to improve performance in automotive service.

- Modeling service processes in an automotive repair service provider organization has a positive impact on efficiency and customer satisfaction.

- Optimizing resource allocation and customer communication positively influences the effectiveness of vehicle scheduling and reception processes.

- Ensuring technical competence and procedural compliance in the diagnosis and repair processes leads to improved service quality and reduced errors.

- Implementing a standardized handover process and actively collecting customer feedback enhances customer satisfaction and loyalty.

2. Theoretical Considerations

3. Materials and Methods

3.1. Research Design and Data Sources

- Data Collection:

3.2. Purpose of Research Stages

3.3. Analytical Tools

3.4. Case Study Description and Rationale

3.5. Theoretical Framework

4. Service Process Analysis and Modeling

4.1. Identifying and Analyzing the Main Service Processes

4.2. Critical Success Factors and Improvement Measures for Each Process

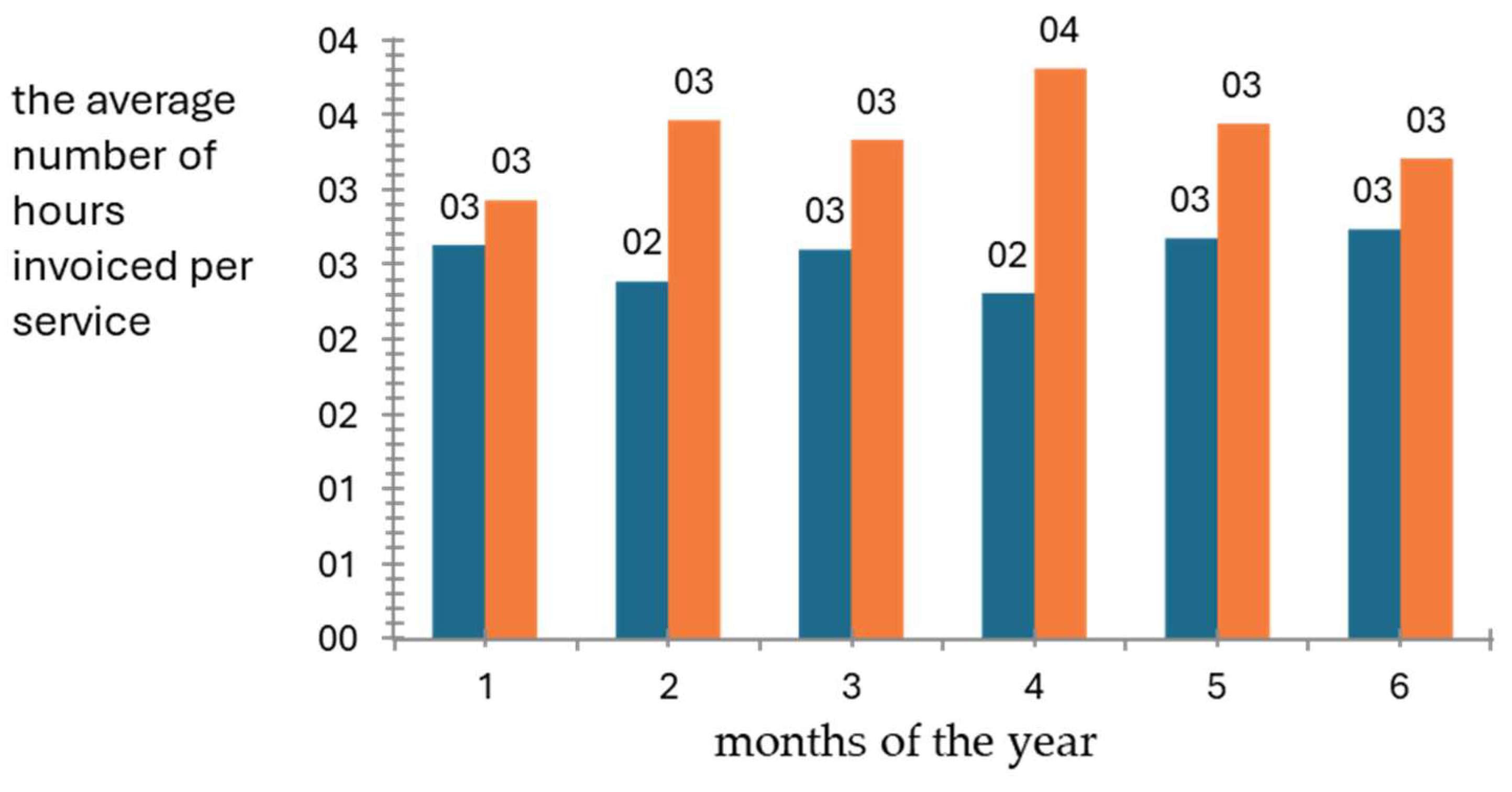

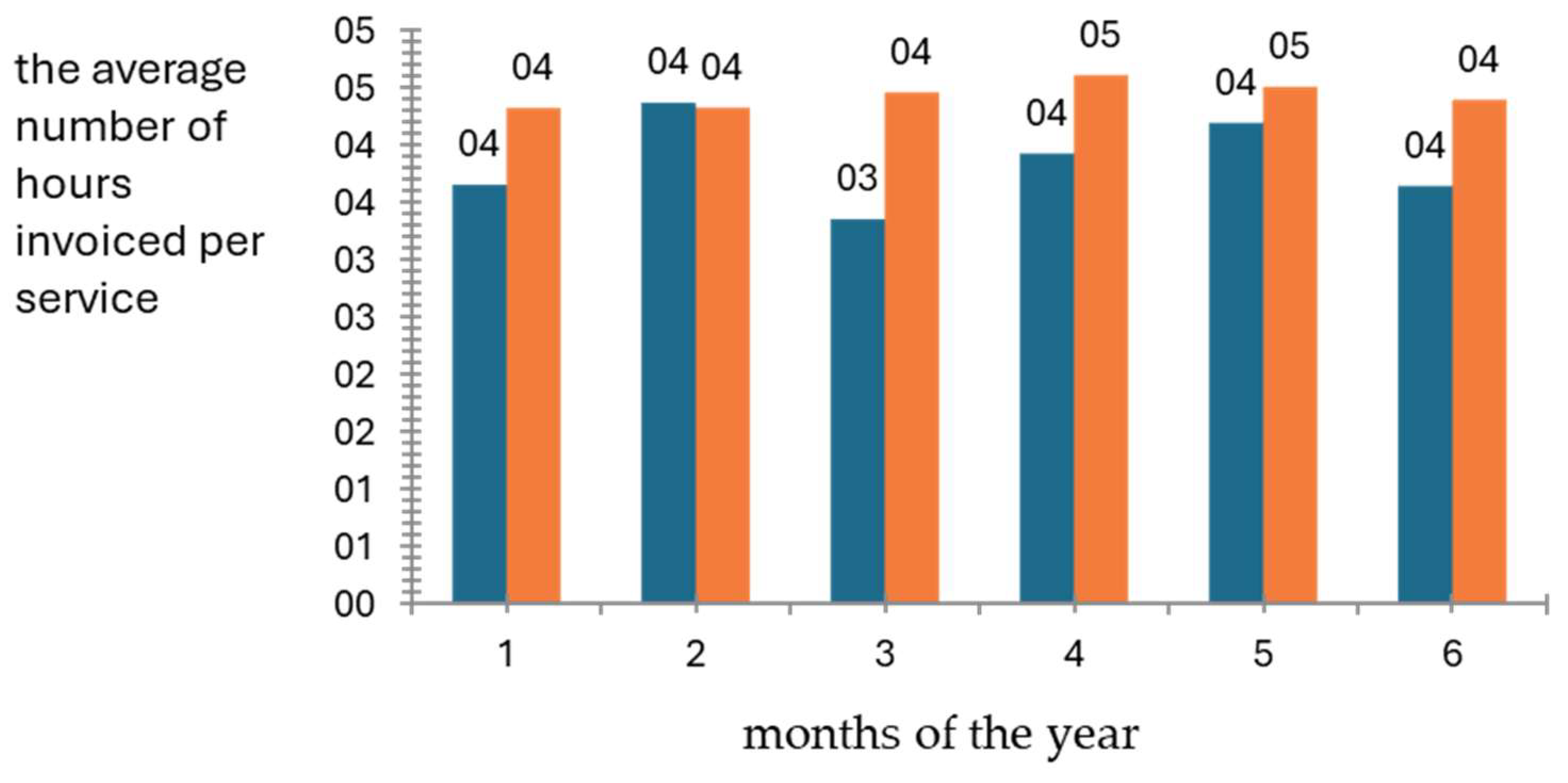

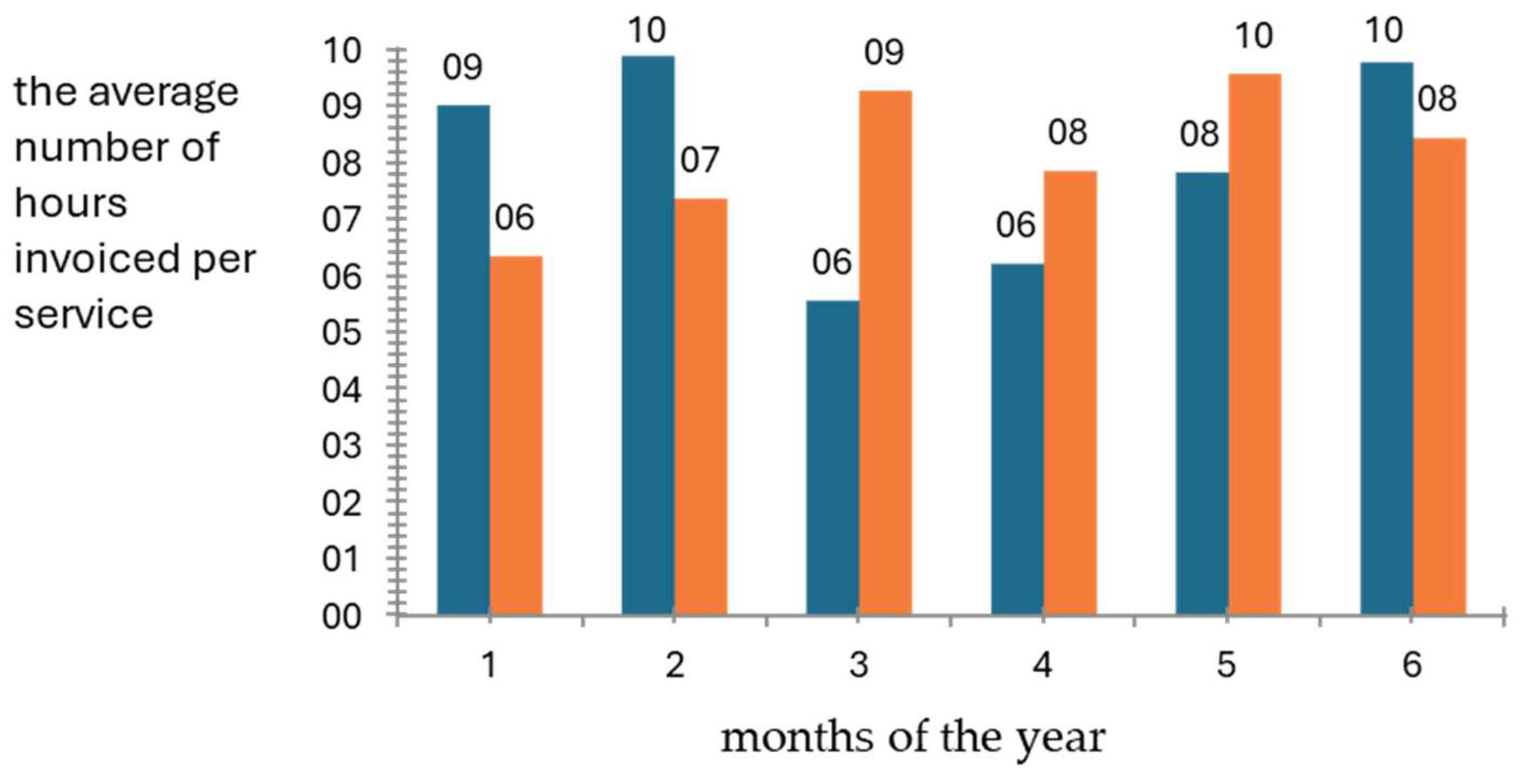

- passenger car service workshop (PKW)—3.5 h invoiced per passenger car;

- commercial vehicle service workshop (LKW)—5 h invoice per commercial vehicle;

- damaged vehicle service workshop (ATV)—10 h invoiced per damaged vehicle.

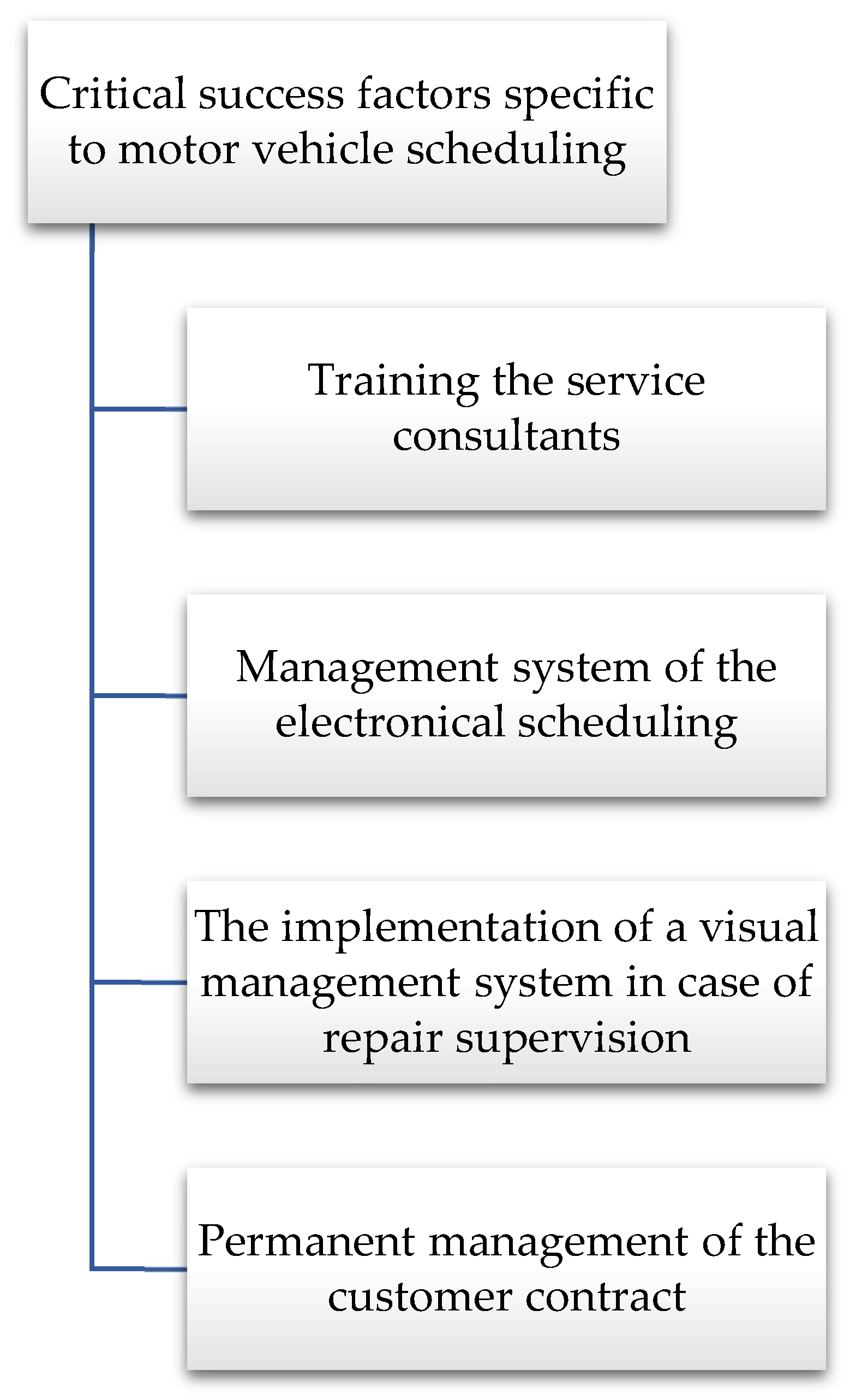

4.2.1. Vehicle Scheduling: Optimizing Resource Allocation and Customer Communication

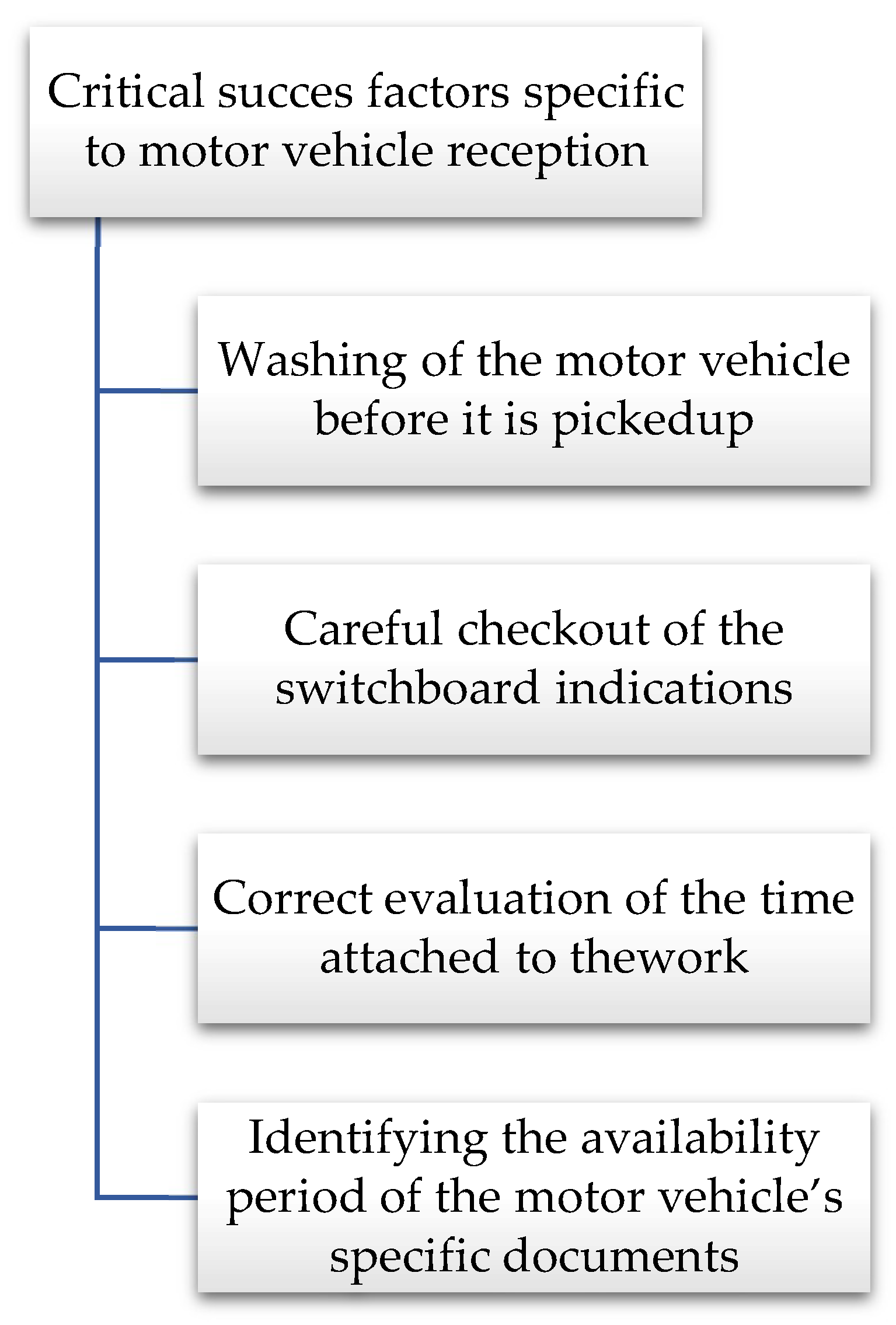

4.2.2. Vehicle Reception: Ensuring Effective Customer Intake and Communication

4.2.3. Diagnosis: Ensuring Technical Competence and Procedural Compliance

4.2.4. Repair: Optimizing the Repair Process and Ensuring Customer Satisfaction

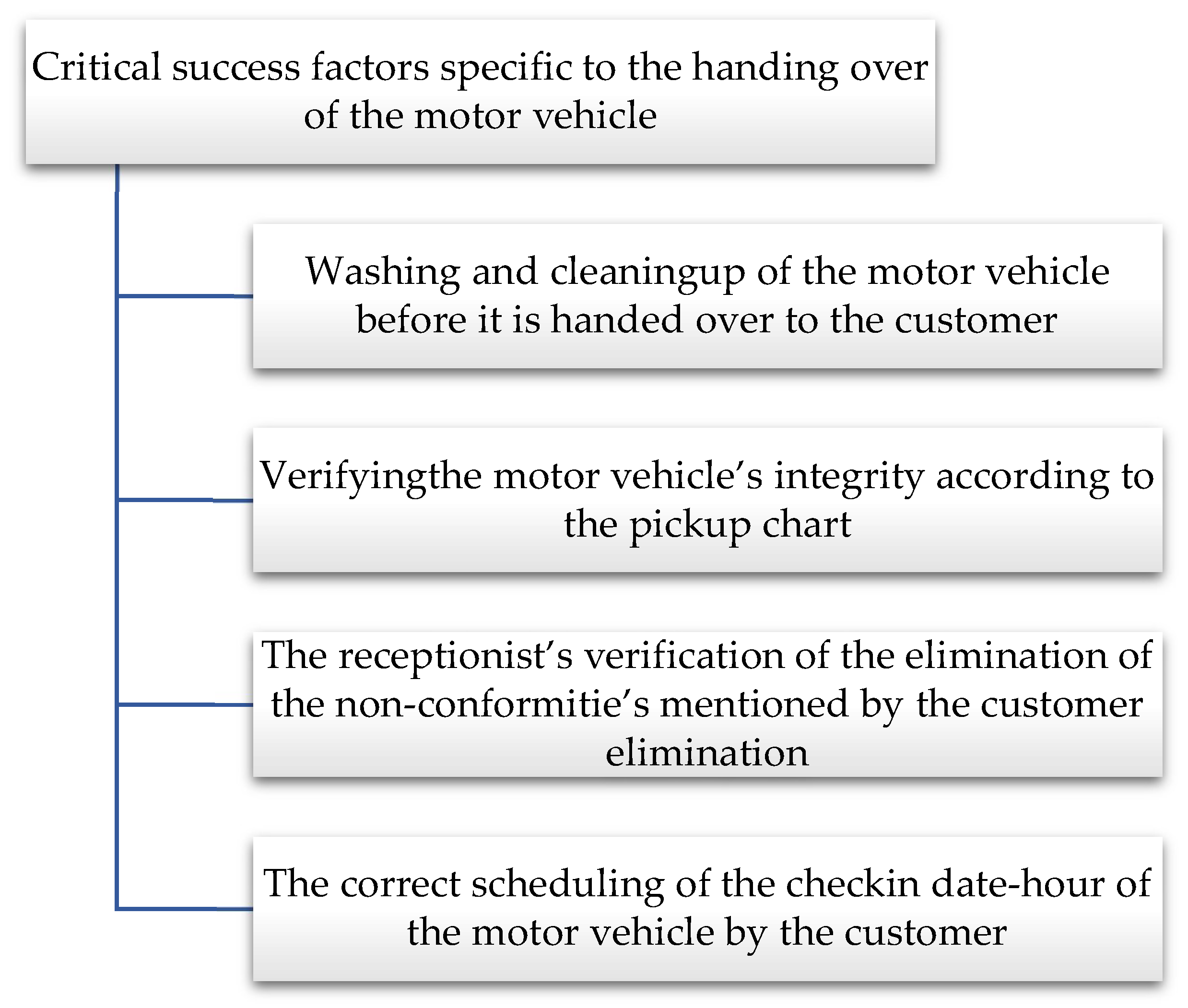

4.2.5. Vehicle Handover: Improving the Handover Process and Collecting Feedback

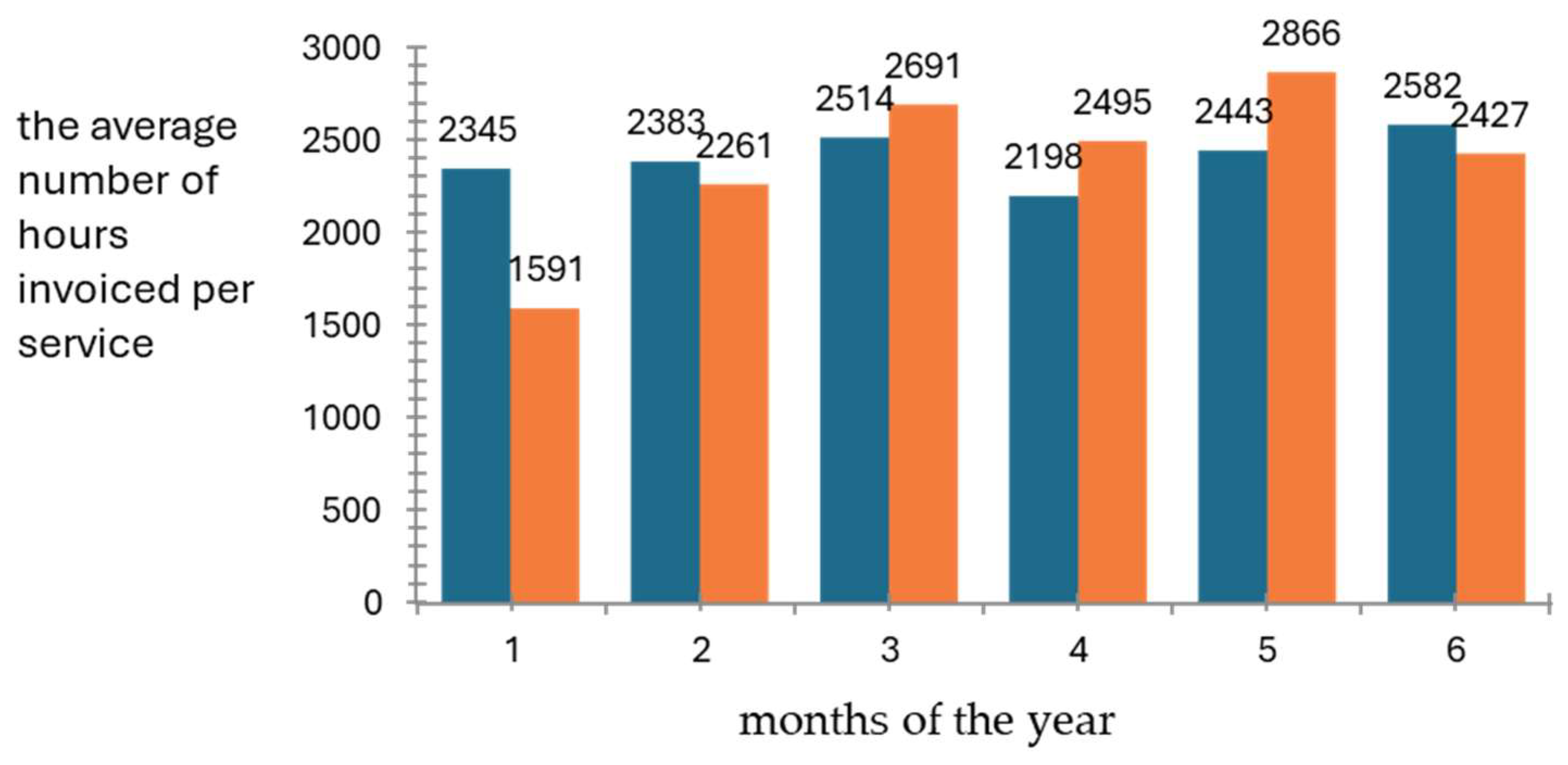

4.3. Performance Targets and the Need for Continuous Improvement

5. Results and Discussions

5.1. Enhanced Efficiency and Productivity Through Process Optimization

5.2. Improved Customer Satisfaction Through Effective Communication and Personalized Service

- -

- Technical Expertise: Possessing a strong understanding of automotive systems, repair procedures, and industry standards.

- -

- Communication Skills: Demonstrating excellent interpersonal and communication skills, including active listening, empathy, and clear articulation.

- -

- Customer Focus: Exhibiting a genuine commitment to customer satisfaction and a willingness to go the extra mile to meet their needs.

- -

- Problem-Solving Abilities: Having the ability to effectively address customer issues, resolve conflicts, and find solutions that meet both customer and organizational needs.

- -

- Technical Training: In-depth knowledge of vehicle systems, repair procedures, and industry standards.

- -

- Customer Service Training: Development of effective communication, active listening, and conflict resolution skills.

- -

- Sales and Marketing Training: Techniques for identifying customer needs, offering appropriate solutions, and promoting additional services.

- -

- Software and Systems Training: Proficiency in using the organization’s electronic management system and other relevant software tools.

5.3. Positive Impact on Financial Performance

5.4. Discussions

6. Conclusions

- How can service processes be modeled in an automotive repair service provider organization to increase performance and ensure customer satisfaction?

- What are the critical success factors for each service process, and how can they be optimized to achieve superior performance?

- Optimizing service processes, such as vehicle scheduling, acceptance, diagnosis, repair, and handover, has been shown to lead to significant improvements in efficiency, customer satisfaction, and profitability, as demonstrated by the increased number of hours billed and positive customer feedback (see Section 5.1, Section 5.2 and Section 5.3).

- Critical success factors for each service process include optimizing resource allocation and improving customer communication, which were addressed through measures such as implementing electronic scheduling systems and training service advisors (see Section 4.2).

- Implementing the proposed measures provides managers with a roadmap for achieving tangible benefits, such as reduced downtime and increased revenue from service and parts sales (see Section 5.1 and Section 5.3).

- Continuous staff training and investment in modern technology are key factors in ensuring superior performance and rapid, enabling service organizations to maintain a competitive edge (see Section 5.4)

- Single Case Study: This research focused on a single automotive repair service provider organization, which may limit the generalizability of the findings to other contexts. Future research could expand the scope to include multiple organizations to explore the potential influence of organizational size, structure, and culture on service process effectiveness.

- Focus on Operational and Financial Performance: This study primarily focused on the impact of process modeling on operational and financial performance, without exploring in detail the effects on other dimensions, such as employee satisfaction, environmental sustainability, and social responsibility. Future research could investigate these aspects to gain a more comprehensive understanding of the benefits of process modeling.

- Data Collection Period: The data collection period was limited to a specific timeframe, which may not capture the full range of seasonal or cyclical variations in service demand and performance. Future research could employ a longitudinal approach to track changes over a more extended period.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Crosby, D.A. Consciousness and Freedom: The Inseparability of Thinking and Doing; Lexington Books: Lanham, MD, USA, 2017. [Google Scholar]

- Collins, J. Excellence in Business; Curtea Veche Publishing House: Bucharest, Romania, 2010. [Google Scholar]

- Lawler, E.; Boudreau, J.W. Achieving Excellence in Human Resources Management: An Assessment of Human Resource Functions; Stanford University Press: Redwood City, CA, USA, 2020. [Google Scholar]

- Sevel, C.; Brown, P. Customers for Life; Public Publishing House: Bucharest, Romania, 2009. [Google Scholar]

- Fader, P. Customer Centricity: Focus on the Right Customers for Strategic Advantage; University of Pennsylvania Press: Philadelphia, PA, USA, 2020. [Google Scholar]

- Mostaghel, R.; Chirumalla, K. Role of customers in circular business models. J. Bus. Res. 2021, 127, 35–44. [Google Scholar] [CrossRef]

- Drucker, P. Decision and Efficiency; Meteor Press Publishing House: Bucharest, Romania, 2010. [Google Scholar]

- Lazarashouri, H.; Najafi, S.E. Enhancing emergency department efficiency through simulation and fuzzy multi-criteria decision-making integration. J. Operat. Strat. Anal. 2024, 2, 56–71. [Google Scholar] [CrossRef]

- Castro, D.M.; Silv Parreiras, F. A review on multi-criteria decision-making for energy efficiency in automotive engineering. Appl. Comput. Inform. 2021, 17, 53–78. [Google Scholar] [CrossRef]

- Jenson, R. The Pyramid of Success—Success Organization Through Success People; Codecs Publishing: Bucharest, Romania, 2010. [Google Scholar]

- Drigas, A.; Papoutsi, C.; Skianis, C. Metacognitive and metaemotional training strategies through the nine-layer pyramid model of emotional intelligence. Int. J. Recent Contrib. Eng. Sci. IT (IJES) 2021, 9, 58–76. [Google Scholar] [CrossRef]

- Bohórquez, E.; Caiche, W.; Benavides, V.; Benavides, A. Motivation and job performance: Human capital as a key factor for organizational success. In Congress in Sustainability, Energy and City; Springer International Publishing: Cham, Switzerland, 2021; pp. 123–133. [Google Scholar]

- Imai, M. Kaizen; Public Publishing House: Bucharest, Romania, 2005. [Google Scholar]

- Ohno, T. Toyota Production System—An Alternative to the Series Production; Finmedia Publishing House: Bucharest, Romania, 2005. [Google Scholar]

- Rusdiana, I.W.; Soediantono, D. Kaizen and implementation suggestion in the defense industry: A literature review. J. Ind. Eng. Manag. Res. 2022, 3, 35–52. [Google Scholar]

- Morell-Santandreu, O.; Santandreu-Mascarell, C.; García-Sabater, J. Sustainability and kaizen: Business model trends in healthcare. Sustainability 2020, 12, 10622. [Google Scholar] [CrossRef]

- Kumar, S.R.; Nathan, V.N.; Ashique, S.M.; Rajkumar, V.; Karthick, P.A. Productivity enhancement and cycle time reduction in toyota production system through jishuken activity—Case study. Mater. Today Proc. 2021, 37, 964–966. [Google Scholar] [CrossRef]

- Gil-Vilda, F.; Yaguee-Fabra, J.A.; Sunyer, A. From lean production to lean 4.0: A systematic literature review with a historical perspective. Appl. Sci. 2021, 11, 10318. [Google Scholar] [CrossRef]

- Oprean, C.; Titu, M. Quality Management in Economy and in the Organization Based on Knowledge; AGIR Publishing House: Bucharest, Romania, 2008. [Google Scholar]

- Fonseca, L.; Amaral, A.; Oliveira, J. Quality 4.0: The EFQM 2020 model and industry 4.0 relationships and implications. Sustainability 2021, 13, 3107. [Google Scholar] [CrossRef]

- Lăzăroiu, G.; Ionescu, L.; Andronie, M.; Dijmărescu, I. Sustainability management and performance in the urban corporate economy: A systematic literature review. Sustainability 2020, 12, 7705. [Google Scholar] [CrossRef]

- Shokouhyar, S.; Shokoohyar, S.; Safari, S. Research on the influence of after-sales service quality factors on customer satisfaction. J. Retail. Consum. Serv. 2020, 56, 102139. [Google Scholar] [CrossRef]

- Chen, T.; Peng, L.; Yin, X.; Rong, J.; Yang, J.; Cong, G. Analysis of user satisfaction with online education platforms in China during the COVID-19 pandemic. Healthcare 2020, 8, 200. [Google Scholar] [CrossRef]

- Oprean, C.; Tîtu, M.; Grecu, D. The scientific analysis of the competitive advantages provided by the production system Toyota—Just in time. In Proceedings of the Asian Conference on the Social Sciences, Osaka, Japan, 14–24 June 2010. [Google Scholar]

- Milewski, D. Managerial and economical aspects of the just-in-time system “lean management in the time of pandemic”. Sustainability 2022, 14, 1204. [Google Scholar] [CrossRef]

- Yang, J.; Xie, H.; Yu, G.; Liu, M. Achieving a just–in–time supply chain: The role of supply chain intelligence. Int. J. Prod. Econ. 2021, 231, 107878. [Google Scholar] [CrossRef]

- Kalbach, J. Mapping Experiences; O’Reilly Media: Sebastopol, CA, USA, 2020. [Google Scholar]

- Zingraff-Hamed, A.; Hüesker, F.; Lupp, G.; Begg, C.; Huang, J.; Oen, A.; Vojinovic, Z.; Kuhlicke, C.; Pauleit, S. Stakeholder mapping to co-create nature-based solutions: Who is on board? Sustainability 2020, 12, 8625. [Google Scholar] [CrossRef]

- Salido-Andres, N.; Rey-Garcia, M.; Alvarez-Gonzalez, L.I.; Vazquez-Casielles, R. Mapping the field of donation-based crowdfunding for charitable causes: Systematic review and conceptual framework. VOLUNTAS Int. J. Volunt. Nonprofit Organ. 2021, 32, 288–302. [Google Scholar] [CrossRef]

- Oprean, C.; Ţîţu, M.; Grecu, D.; Oprean, C. The Importance of Insuring Document Quality during the Process of Motor Vehicle Repair. In Proceedings of the IMECS 2011, Hong Kong, China, 16–18 March 2011. [Google Scholar]

- Hanafy, M.; Ming, R. Machine learning approaches for auto insurance big data. Risks 2021, 9, 42. [Google Scholar] [CrossRef]

- Uzair, M. Who is liable when a driverless car crashes? World Electr. Veh. J. 2021, 12, 62. [Google Scholar] [CrossRef]

- Oprean, C.; Ţîţu, M.; Grecu, D. Studies and Research on the Possibility of Cost Reduction within the Knowledge-based Organizations in the European Car Industry. In Proceedings of the IMECS 2011, Hong Kong, China, 16–18 March 2011. [Google Scholar]

- Bąk, I.; Wawrzyniak, K.; Oesterreich, M. Competitiveness of the regions of the European Union in a sustainable knowledge-based economy. Sustainability 2022, 14, 3788. [Google Scholar] [CrossRef]

- Evangelista, P.; Kianto, A.; Hussinki, H.; Vanhala, M.; Nisula, A.M. Knowledge-based human resource management, logistics capability, and organizational performance in small Finnish logistics service providers. Logistics 2023, 7, 12. [Google Scholar] [CrossRef]

- Krishnamurthi, R.; Kumar, A.; Gopinathan, D.; Nayyar, A.; Qureshi, B. An overview of IoT sensor data processing, fusion, and analysis techniques. Sensors 2020, 20, 6076. [Google Scholar] [CrossRef] [PubMed]

- Posada-Quintero, H.F.; Chon, K.H. Innovations in electrodermal activity data collection and signal processing: A systematic review. Sensors 2020, 20, 479. [Google Scholar] [CrossRef]

- Daniels, A.C. Managementul Performanţei—Strategii de Obţinere a Rezultatelor Maxime de la Angajaţi; Editura POLIROM: Bucharest, Romania, 2007. [Google Scholar]

- Maharana, K.; Mondal, S.; Nemade, B. A review: Data pre-processing and data augmentation techniques. Glob. Transit. Proc. 2022, 3, 91–99. [Google Scholar] [CrossRef]

- Kou, Y.; Liu, Y.; Li, G.; Hou, J.; Luan, L.; Wang, H. Design and Implementation of an Integrated Management System for Backfill Experimental Data. Adv. Civ. Eng. 2022, 2022, 1876435. [Google Scholar] [CrossRef]

- Munawar, H.S.; Qayyum, S.; Ullah, F.; Sepasgozar, S. Big data and its applications in smart real estate and the disaster management life cycle: A systematic analysis. Big Data Cogn. Comput. 2020, 4, 4. [Google Scholar] [CrossRef]

- Agrawal, N.; Rabiee, M.; Jabbari, M. Contextual relationships in Juran’s quality principles for business sustainable growth under circular economy perspective: A decision support system approach. Ann. Oper. Res. 2023, 342, 47–77. [Google Scholar] [CrossRef]

- Grecu, D. The Elaboration of the Evaluation Model of the Motor Vehicle’s After Sales Services Level of Quality; Rapport of the scientific research; Lucian Blaga University: Sibiu, Romania, 2011. [Google Scholar]

- Balinado, J.R.; Prasetyo, Y.T.; Young, M.N.; Persada, S.F.; Miraja, B.A.; Redi, A.A.N.P. The effect of service quality on customer satisfaction in an automotive after-sales service. J. Open Innov. Technol. Mark. Complex. 2021, 7, 116. [Google Scholar] [CrossRef]

- Durugbo, C.M. After-sales services and aftermarket support: A systematic review, theory, and future research directions. Int. J. Prod. Res. 2020, 58, 1857–1892. [Google Scholar] [CrossRef]

- Ţîţu, M.; Oprean, C.; Grecu, D. Managing the Activity of the After Sales Departments in an Organisation Which Has Implemented a System of Quality Management. In Proceedings of the 7th International Conference of the Management of Technological Changes, Alexandropolis, Greece, 1–3 September 2011. [Google Scholar]

- Permana, A.; Purba, H.H.; Rizkiyah, N.D. A systematic literature review of Total Quality Management (TQM) implementation in the organization. Int. J. Prod. Manag. Eng. 2021, 9, 25–36. [Google Scholar] [CrossRef]

- Tambare, P.; Meshram, C.; Lee, C.C.; Ramteke, R.J.; Imoize, A.L. Performance measurement system and quality management in data-driven Industry 4.0: A review. Sensors 2021, 22, 224. [Google Scholar] [CrossRef]

- Stawiarska, E.; Szwajca, D.; Matusek, M.; Wolniak, R. Diagnosis of the maturity level of implementing Industry 4.0 solutions in selected functional areas of management of automotive companies in Poland. Sustainability 2021, 13, 4867. [Google Scholar] [CrossRef]

- Chuenyindee, T.; Ong, A.K.S.; Ramos, J.P.; Prasetyo, Y.T.; Nadlifatin, R.; Kurata, Y.B.; Sittiwatethanasiri, T. Public utility vehicle service quality and customer satisfaction in the Philippines during the COVID-19 pandemic. Util. Policy 2022, 75, 101336. [Google Scholar] [CrossRef]

- Gelbrich, K.; Voigt, S.; Nazifi, A. Remedy management for product recalls in the automotive industry: How car dealers should time the repair and communicate its outcome. J. Bus. Res. 2023, 167, 114173. [Google Scholar] [CrossRef]

- Al Khoury, G.; Thrassou, A.; Papasolomou, I.; Vrontis, D. The requisite role of emotional intelligence in customer service in the retail banking sector. Int. J. Organ. Anal. 2023, 31, 3315–3347. [Google Scholar] [CrossRef]

- Babin, B.J.; Zhuang, W.; Borges, A. Managing service recovery experience: Effects of the forgiveness for older consumers. J. Retail. Consum. Serv. 2021, 58, 102222. [Google Scholar] [CrossRef]

- Soklaridis, S.; Geske, A.M.; Kummer, S. Key characteristics of perceived customer centricity in the passenger airline industry: A systematic literature review. J. Air Transp. Res. Soc. 2024, 3, 100031. [Google Scholar] [CrossRef]

- Van Looy, A. A quantitative and qualitative study of the link between business process management and digital innovation. Inf. Manag. 2021, 58, 103413. [Google Scholar] [CrossRef]

- Wang, K.L.; Pang, S.Q.; Zhang, F.Q.; Miao, Z.; Sun, H.P. The impact assessment of smart city policy on urban green total-factor productivity: Evidence from China. Environ. Impact Assess. Rev. 2022, 94, 106756. [Google Scholar] [CrossRef]

- Studer, S.; Bui, T.B.; Drescher, C.; Hanuschkin, A.; Winkler, L.; Peters, S.; Müller, K.R. Towards CRISP-ML (Q): A machine learning process model with quality assurance methodology. Mach. Learn. Knowl. Extr. 2021, 3, 392–413. [Google Scholar] [CrossRef]

- Kenny, E.M.; Ford, C.; Quinn, M.; Keane, M.T. Explaining black-box classifiers using post-hoc explanations-by-example: The effect of explanations and error-rates in XAI user studies. Artif. Intell. 2021, 294, 103459. [Google Scholar] [CrossRef]

- Khan, R.U.; Salamzadeh, Y.; Iqbal, Q.; Yang, S. The impact of customer relationship management and company reputation on customer loyalty: The mediating role of customer satisfaction. J. Relatsh. Mark. 2022, 21, 1–26. [Google Scholar] [CrossRef]

- Silva, M.J.; Leitão, J. Cooperation in innovation practices among firms in Portugal: Do external partners stimulate innovative advances? Int. J. Entrep. Small Bus. 2009, 7, 391–403. [Google Scholar] [CrossRef]

| Motor Service/Month | Cars Motor Service | Commercial Motor Vehicles Motor Service | Damaged Motor Vehicles Motor Service | Total of Motor Service Hours 2023 |

|---|---|---|---|---|

| January | 650 | 650 | 950 | 2250 |

| February | 850 | 800 | 1150 | 2800 |

| March | 930 | 850 | 1360 | 3140 |

| April | 930 | 850 | 1360 | 3140 |

| May | 930 | 900 | 1360 | 3190 |

| June | 930 | 950 | 1360 | 3240 |

| July | 930 | 950 | 1360 | 3240 |

| August | 930 | 950 | 1360 | 3240 |

| September | 930 | 950 | 1360 | 3240 |

| October | 930 | 950 | 1360 | 3240 |

| November | 930 | 950 | 1360 | 3240 |

| December | 750 | 750 | 100 | 2500 |

| Total in 2022 | 10,620 | 10,500 | 15,340 | 36,460 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Titu, A.M.; Grecu, D.; Pop, A.B.; Șugar, I.R. Service Process Modeling in Practice: A Case Study in an Automotive Repair Service Provider. Appl. Sci. 2025, 15, 4171. https://doi.org/10.3390/app15084171

Titu AM, Grecu D, Pop AB, Șugar IR. Service Process Modeling in Practice: A Case Study in an Automotive Repair Service Provider. Applied Sciences. 2025; 15(8):4171. https://doi.org/10.3390/app15084171

Chicago/Turabian StyleTitu, Aurel Mihail, Daniel Grecu, Alina Bianca Pop, and Ioan Radu Șugar. 2025. "Service Process Modeling in Practice: A Case Study in an Automotive Repair Service Provider" Applied Sciences 15, no. 8: 4171. https://doi.org/10.3390/app15084171

APA StyleTitu, A. M., Grecu, D., Pop, A. B., & Șugar, I. R. (2025). Service Process Modeling in Practice: A Case Study in an Automotive Repair Service Provider. Applied Sciences, 15(8), 4171. https://doi.org/10.3390/app15084171