Abstract

Geotextile bags are widely used in revetment engineering due to their simple fabrication and cost-effectiveness. However, prolonged exposure to natural environments can lead to aging and damage, compromising their performance. To enhance the durability of geotextile bags in practical applications, this study conducted microscopic examinations and strength tests, employing a slurry spraying method to form a protective surface layer. Adhesion tests and orthogonal experiments were performed to evaluate the impact of spraying parameters on performance. The optimal parameter combination was determined through range analysis, variance analysis, and projection pursuit regression (PPR) analysis, with the durability improvement verified by accelerated aging tests. Results demonstrated that sediment significantly reinforced the internal fibers and mechanical properties of the geotextile. Artificial slurry spraying effectively adhered to the geotextile surface, with clay slurry exhibiting the strongest adhesion. By integrating range analysis, variance analysis, and PPR analysis, the key influencing factors were identified as spraying thickness, geotextile thickness, and clay content. The optimal parameter combination was selected for accelerated aging tests and electron microscopy observation, revealing that the spraying treatment significantly improved the geotextile’s strength retention rate, delayed performance degradation under UV and high-temperature conditions, and protected the fiber structure. These findings provide valuable insights in terms of enhancing the durability of geotextile bags.

1. Introduction

A geotextile is a permeable textile made from synthetic fibers through processes such as needle punching or weaving. Due to its excellent performance in reinforcement, filtration, and drainage functions [1,2,3], it has become an indispensable material in many major projects, including water conservancy, highways, and environmental protection. Geotextile bags, made from geotextiles, are widely used in coastal and riverbank protection due to their significant deformation coordination ability, low cost, convenient construction, and eco-friendliness [4,5]. Currently, geotextile bag technology has been applied in coastal and riverbank projects in many countries and regions, including China, Europe, the United States, Canada, Japan, India, Bangladesh, and Australia [6,7,8,9]. A summary of domestic and international research on the application of geotextile bags reveals that the technology is primarily used in road and building foundation reinforcement, retaining wall engineering, and coastal and riverbank erosion protection [10,11]. However, geotextiles, as polymer materials, inevitably undergo aging during use. Studies have shown [12,13,14] that light and temperature are the main factors contributing to geotextile aging. As usage time increases, the material’s performance declines, leading to a loss of functionality. The aging performance of geotextile bags directly affects the reliability and safety of revetment projects, making their durability an urgent issue that requires further research [15,16,17,18,19].

Domestic and foreign scholars have conducted extensive research on the durability of geotextiles. Bao Weiguo [20] conducted a 450-day aging test on geotextiles covered with 5 cm of sand, and the results showed that the 5 cm sand cover improved the durability of the geotextiles. Hornsey et al. [21] developed a composite geotextile, and the results indicated that an outer layer with sand-collecting functionality could effectively enhance the durability of the inner geotextile. Yang et al. [22] found that under relatively low ultraviolet (UV) irradiation intensities and outdoor exposure, carboxylic acid carbonyl groups formed on the surface of the samples, showing a strong correlation between the two test methods. However, under high-UV irradiation intensity, ester carbonyl groups and low-molecular-weight acids appeared, and the correlation between the two was poor. Carneiro et al. [14] conducted aging tests on polypropylene (PP) non-woven geotextiles and found that UV radiation significantly reduced the strength of the geotextiles. Under 35 MJ/m2 of UV radiation, the performance of ordinary geotextiles declined noticeably, while that of geotextiles with added light stabilizers remained largely unchanged. Valentin et al. [23] studied the UV aging performance of PP geotextiles and found that UV radiation affected the fibers, altering both strength and elongation. Carneiro et al. [24] investigated the aging patterns of polyethylene terephthalate (PET) filament-reinforced PP non-woven geotextiles under different weathering conditions. The results showed that UV radiation was the primary cause of geotextile degradation and the extent of aging was closely related to temperature, UV radiation intensity, and exposure time. Richaud et al. [25] used three accelerated aging methods to explore the thermal oxidation performance of PP geotextiles and compare the effectiveness of stabilizers under different aging conditions. They found that stabilizers were more effective under high oxygen pressure and water immersion, indicating that stabilizers could effectively inhibit material aging under specific environmental conditions. Karademir et al. [26] studied the relationship between the tensile properties of single-PP-filament geotextiles and temperature, as well as the effect of titanium dioxide (TiO2) addition on PP material performance. The results showed that the yield strength of PP filaments decreased with the increasing temperature, while the addition of TiO2 significantly improved their thermal stability and crystallinity [27]. Although domestic and foreign scholars have conducted extensive research on the durability and anti-aging measures of geotextiles, most studies have focused on the aging mechanisms, influencing factors, and durability testing of geotextiles. There is still a need for the in-depth exploration of the aging and durability enhancement measures of geotextile bags in practical engineering applications.

In light of this, this paper focuses on the durability issues of geotextile bags used in the revetment projects of the Tarim River. A convenient and economical “sprayed slurry” geotextile bag method is adopted, which involves spraying slurry onto pure geotextiles to form a physical protective layer on the surface. The slurry is primarily composed of local sand, with small amounts of clay or cement added. Adhesion tests were conducted based on the factors affecting the geotextile bags in the field. Orthogonal experiments were then carried out, and range analysis was used to identify the sensitive factors affecting the protective performance. Variance analysis was employed to determine the significance of each factor’s impact on the protective performance. A projection pursuit regression (PPR) model was established to predict the protective performance reliably, and the optimal parameter combination was obtained. The selected optimal solution was subjected to accelerated aging tests to verify its effectiveness. The research results provide references and guidance for improving the durability of geotextile bags.

2. Materials and Methods

2.1. Microscopic Morphology Observation

2.1.1. Test Materials

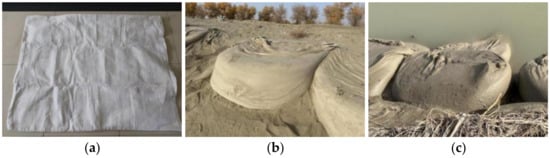

The test samples were all made of polyester filament non-woven geotextiles with a surface density of 300 g/m2 and a thickness of 2.2 mm. The samples were collected from different locations: we utilized unused geotextiles from the Usman Warehouse of the Tarim River in Xinjiang, geotextiles from the top of the embankment slope at K135 of the Tarim River Water Conveyance Dike, and geotextiles covered in mud from the water-level zone. The K135 geotextile bag revetment was constructed in May 2019 and the samples from the slope top and mud-covered areas were collected in November 2023. The details are illustrated in Figure 1.

Figure 1.

Three working conditions of geotextile at k135 of Tarim River: (a) brand-new unused geotextile; (b) geotextile from the top of the revetment slope; (c) geotextile covered in mud in the water level zone.

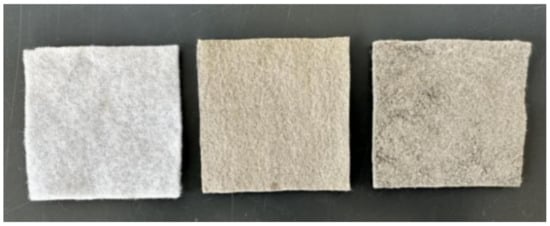

2.1.2. Test Materials and Operating Procedures

The three types of geotextiles were cut into 5 mm × 5 mm specimens, as shown in Figure 2. A scanning electron microscope (SEM, model Zeiss Supra55 VP, Oberkochen, Germany) was employed to investigate the microscopic characteristics of the fibers under different usage conditions. The samples were adhered to an aluminum sample stage using conductive adhesive, coated with gold for 60 s, and then placed into the vacuum chamber of the microscope. After evacuating the chamber, observations were conducted at magnifications of 100×, 300×, and 500× to analyze the microstructural features of the fibers.

Figure 2.

The geotextile samples for SEM analysis under three working conditions of Tarim River geotextile bag revetment (from left to right: brand-new geotextile; aged geotextile from the top of the revetment slope; geotextile covered in mud).

2.2. Sampling Strength Test

To further investigate and evaluate the durability of geotextile bags under the natural climatic conditions of southern Xinjiang, we collected samples of geotextiles exposed to the natural environment along the main stream of the Tarim River. The residual strength of these samples was tested to assess their performance. The test samples are illustrated in Figure 3. The sampling site was located at K135 of the Tarim River, characterized by a dry and sun-exposed environment. Samples were taken from the end of the geotextile bags, where the stress was greatest. Each sample was divided into six test strips for tensile testing. The tensile strength of the samples from the Usman Hub Station warehouse was used as the reference baseline (100%) for comparison.

Figure 3.

Geotextile testing samples.

2.3. Adhesion Test Design

2.3.1. Test Materials and Equipment

(1) Geotextile material: For the slurry adhesion test, a cost-effective white non-woven geotextile (polypropylene, PP) with a tensile strength of 7.5 kN/m and an O95 of 0.06 mm was used. To align with practical applications and provide reference for future projects, polyester geotextiles with specifications of 300 g/m2, 400 g/m2, and 500 g/m2 were selected for subsequent tests. All geotextiles were filament non-woven types.

(2) Test material: The sand from the Tarim River bank, primarily composed of silt and fine sand, was collected from the K135 water conveyance embankment. The particle size ranged from 0.075 mm to 0.25 mm, characterized by small and uniformly distributed particles. Detailed properties are listed in Table 1.

Table 1.

Physical property indicators of sand on the bBanks of Tahe River.

Ordinary Portland cement with a grade of 42.5 was used; the clay was obtained from nearby river channels, and the main physical properties of the clay are listed in Table 2 below.

Table 2.

Physical properties of clay particles.

(3) Test equipment: The equipment included an air compressor with a power rating of 3000 kW, an exhaust capacity of 270 m3/min, and a pressure of 0.8 MPa, as well as a 1500 W × 2 − 50 L air compressor. A TL-6C model slurry spray gun with a 1 cm nozzle was used for the spraying process.

2.3.2. Spray Test Design

The primary material for the slurry coating was locally sourced riverbank sand, supplemented with small amounts of clay, clay–cement mixture, and cement. Through preliminary tests, five mix ratios with a binder content ranging from 14.29% to 21.74% were identified as having suitable fluidity and viscosity. The experiment was designed with 15 sample groups, combining three types of slurry and five mix ratios. Each sample was prepared with dimensions of 200 mm × 200 mm and a single spray layer of approximately 2 mm thickness. The detailed experimental design is presented in Table 3.

Table 3.

Mix design of sprayed mortar materials.

Under the current experimental conditions, a black PVC (polyvinyl chloride) board was selected as the base plate for the test. The geotextile was secured under a white frame, and the slurry was sprayed onto the geotextile surface. To ensure uniformity during the spraying process, the geotextile and the spray gun were maintained in a parallel position. After the slurry coating solidified, the samples were cut to the required dimensions. The setup is illustrated in Figure 4.

Figure 4.

Schematic diagram of geotextile pulp hanging.

2.3.3. Adhesive Testing Design

(1) Artificial trampling: The method of artificial trampling is used to simulate compaction or compression situations that may be encountered in the hanging slurry layer in practical applications. Different parameters are tested 10 times, 20 times, and 30 times for each sprayed slurry sample.

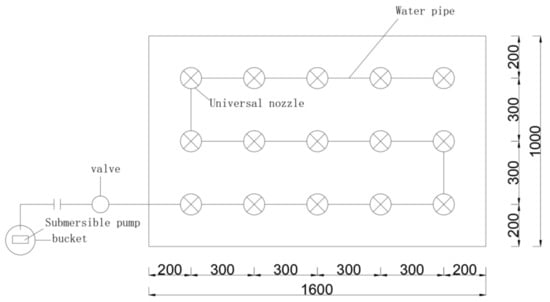

(2) Artificial rainfall: A device for simulating real rainfall conditions is shown in Figure 5. It was found that the maximum rainfall intensity of the revetment section in the past 40 years was 51.8 mm/h. Based on this, two experimental parameters of 55 mm/h and 60 mm/h were added, and the testing time was set to 60 min. Before the experiment, a rain gauge was used to measure the rainfall and calibrate the rainfall intensity. The rainfall uniformity was measured to be around 90%, which meets the requirement of greater than 80% [28].

Figure 5.

Schematic diagram of self-made artificial rainfall device (unit: mm).

(3) Wind resistance test: The historical maximum instantaneous wind speed in the Tarim River section reaches 40 m/s. Test parameters were set at 30 m/s, 35 m/s, and 40 m/s, with a test duration of 60 min. A high-power blower was used to simulate wind conditions, and the wind speed was calibrated using an anemometer before testing.

(4) After the tests, the adhesion degree S of the sprayed sample (the mass ratio of the sample before and after the test) is used as the basis for judging the adhesion of the sprayed sample, and the adhesion degree of the sprayed sample is calculated according to Equation (1).

In the formula, ma represents the mass of the sprayed sample after testing, mf represents the mass of the sprayed sample before testing, and g represents the mass of the geotextile.

2.4. Orthogonal Design

To investigate the influence of different test parameters on the experimental indicators and to distinguish between primary and secondary influencing factors, which is crucial for guiding construction, three key factors were selected: geotextile density (thickness) (A), binder content (B), and slurry coating thickness (C). Each factor was designed with three levels. The experimental indicators included light transmittance and thermal insulation temperature. Light transmittance reflects the light-blocking performance of the geotextile, while thermal insulation temperature was evaluated based on the temperature difference across a 5 cm sand layer [20] covered by the geotextile, serving as a durability criterion. The selected factors and their levels are detailed in Table 4. A three-factor, three-level orthogonal array L9 (34) was adopted, with the last column left blank as the error column. The specific experimental design is presented in Table 5.

Table 4.

Test factors and level design.

Table 5.

Orthogonal experimental design scheme.

2.5. Aging Test and Strength Test

2.5.1. Fluorescent UV Lamp Aging Test

The UV aging test was conducted in accordance with the geotextile aging standard [29]. Specimens measuring 75 mm × 200 mm were prepared according to the fixture size requirements. The aging conditions were set as follows based on the testing standard: continuous UV exposure with a constant wavelength of 340 nm and irradiance of 0.76 W/m2, temperature maintained at (60 ± 3) °C, for a duration of 144 h. These test parameters (irradiance and temperature) were established according to the testing standard and represent relatively extreme environmental conditions. The testing equipment used was model LU-8047-TM.

2.5.2. Strength Testing and Durability Qualification Standards

In accordance with the geotextile tensile testing standard [30], the tensile strength of the aged specimens was tested. The grip separation was set to (100 ± 3) mm. The tensile testing machine was activated and operated continuously until the specimen fractured, and the maximum load was recorded. The durability qualification criteria referenced GB/T 17639-2023 [31], which stipulates that the strength retention rate after UV aging tests must be ≥80% to meet the durability requirements.

3. Results and Discussion

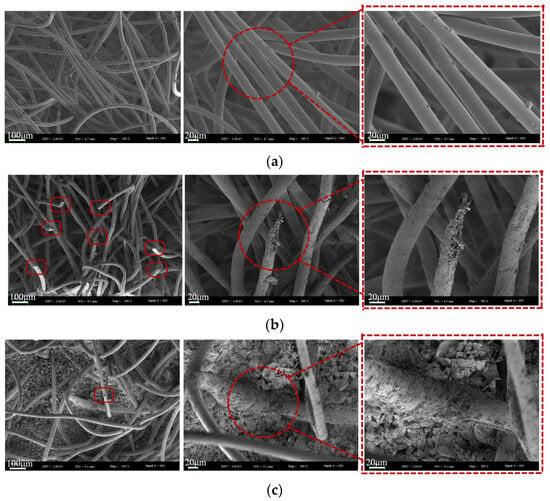

3.1. Microscopic Morphology Analysis

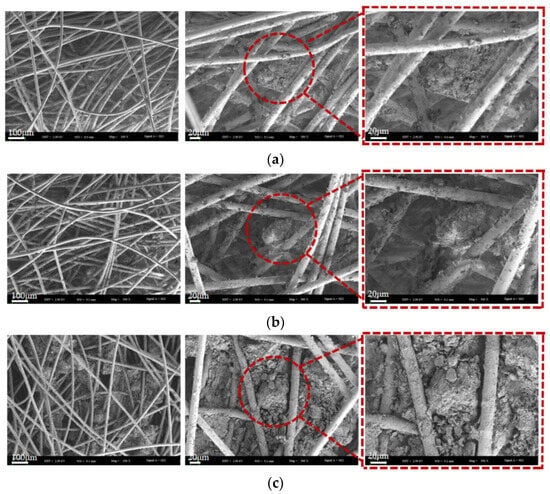

We used scanning electron microscopy (SEM) to observe the fiber internal structure of three types of geotextiles: new unused (referred to as X), top of slope protection (referred to as D), and covered in mud (referred to as N). This is shown in Figure 6. The fiber structure of the X geotextile is relatively complete, with no cracks or fractures on the surface. There are no signs of aging, discoloration, or chemical reactions. The surface of geotextile fibers is relatively rough, and there is a phenomenon of darkening in color. This color change is the result of the material undergoing ultraviolet oxidation reaction under long-term exposure to light. As the usage time increases, the fiber filaments break and crack, causing longer fibers to gradually decompose into shorter fibers. The surface of N geotextile fibers is covered with large areas of irregular soil particles, with a small amount of breakage and damage, indicating a slow rate of ultraviolet oxidation reaction and a relatively mild degree of aging.

Figure 6.

SEM scanning photos of geotextile samples under three working conditions at K135 of Tarim River: (a) new unused geotextile (X); (b) top geotextile for slope protection (D); (c) mud-covered geotextile (N).

Through sampling and scanning electron microscope (SEM) observations of the three types of geotextiles, it is evident that the fibers of the D geotextile (slope top) exhibit significant signs of aging, including surface roughness, wear, and noticeable darkening, indicating severe degradation. In contrast, the fibers of the N geotextile (mud-covered) show only minor roughness and wear, with the mud particles covering the surface significantly slowing down the aging process. These findings highlight the protective effect of mud coverage against environmental degradation.

3.2. Sampling Intensity Testing in Natural Environments

As shown in Table 6, the thickness of the geotextile sheets decreases to varying degrees over time, indicating the presence of aging and wear. From the changes in sheet strength, it is evident that the mud layer’s attachment on the geotextile surface effectively mitigates aging. Except for the transverse strength retention rate of 61% observed in the 2-year-old sheets, the strength retention rates of sheets with different usage durations, both longitudinally and transversely, remain at or above 100%. Notably, even after 5 years of continuous exposure to sunlight, geotextile bags retain 105% of their original strength.

Table 6.

Residual strength values of geotextile sampling samples (at K135 on the north bank).

Figure 7 shows the actual situation when sand adheres to the surface of the geotextile bag in the water level zone. It can be seen that the surface of the geotextile bag has been covered with a layer of mud, accompanied by the attachment of other aquatic plants. This situation is in sharp contrast to the geotextile bag at the top. The sand mixed in the internal fibers provides additional protective effect.

Figure 7.

Sand adheres to the surface of the geotextile bag in the water level zone (19 May 2023): (a) geotextile bag revetment at K135; (b) geotextile bag revetment at K169.

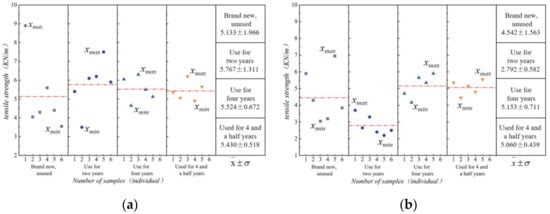

As shown in Figure 8, the longitudinal and transverse strength values of the unused geotextile exhibit significant variability (σ). However, as the usage time of geotextile bags increases, the strength retention rate shows minimal changes. Based on the reduction in sheet thickness, it was inferred that the fibers themselves aged, transitioning from their original long-filament state to a shorter-filament state. In the tensile strength tests, the unused geotextile was tested in its original form, while the sampled sheets from used bags were tested as a combination of thinner geotextile and sand. The presence of sand enhances the strength of the geotextile to some extent, resulting in only minor variations in the strength retention rate.

Figure 8.

Longitudinal and transverse tensile strength deviation: (a) longitudinal tensile strength; (b) transverse tensile strength.

The test data reveal significant variability in the tensile strength values across different sections of the same geotextile. Based on the data presented in Table 6 and Figure 8, the following conclusions can be drawn: (1) The material’s strength values exhibit considerable inherent variability, which may be attributed to factors such as product quality and variations in the working conditions of the geotextile bags. It is challenging to isolate the extent of influence from each factor. (2) The tensile strength values of different sections of the same geotextile show relatively high levels of dispersion. The thickness of the geotextile sheets may decrease to some extent due to external environmental factors. (3) In sun-exposed conditions, the geotextile bags retain relatively high residual strength after use. Although the material thickness decreases, the sand embedded within the fibers contributes to the overall strength of the geotextile.

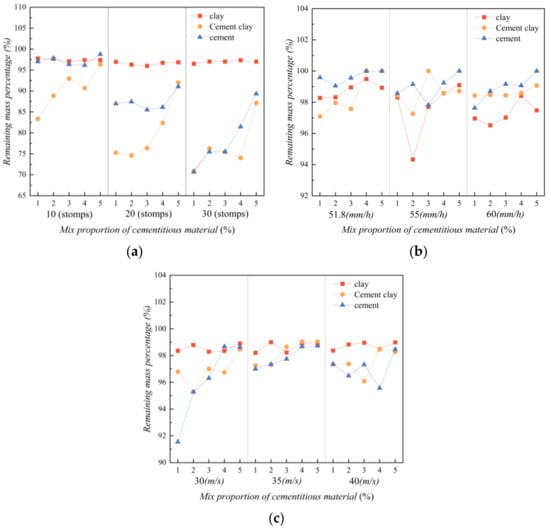

3.3. Adhesion Testing Analysis

Figure 9 presents test results for the adhesion performance of the slurry-coated geotextiles. From Figure 9a, it can be observed that the clay coating demonstrates the best adhesion under trampling conditions. The trampling force effectively enhances the compaction of the coating, reducing internal pores and voids, thereby increasing the contact area and adhesion between the slurry coating and the geotextile surface. In contrast, coatings containing cement tend to crack under external forces as the number of force applications increases, leading to a reduction in adhesion. Figure 9b shows that all coated samples maintained their adhesion performance without significant decline after exposure to high-intensity rainfall, indicating strong water resistance and resistance to detachment under extreme rainfall conditions. From Figure 9c, it is evident that the adhesion degree of the slurry coatings remains between 95% and 99%, demonstrating that the coatings retain excellent adhesion performance, even under wind force. These results highlight the robustness of the coatings in various environmental conditions.

Figure 9.

Adhesion test of shotcrete coating: (a) artificial trampling test; (b) artificial rainfall test; (c) wind test.

From the test results, it can be seen that these sprayed coatings can exhibit good adhesion under both simulated extreme environments and daily use conditions. Based on the above analysis, clay spray coating is more in line with practical application situations.

3.4. Analysis of Orthogonal Experiment Results

3.4.1. Range Analysis

Range analysis uses range Rj to determine the sensitivity order of each experimental parameter and find the optimal level combination. The range value of a factor intuitively reflects the fluctuation range experienced by the experimental indicator when the factor changes at different levels. The higher the range value, the greater the influence of the factor on the experimental indicators, which can be used to evaluate the sensitivity of each factor and further determine the optimal parameter combination. The results are shown in Table 7.

Table 7.

Range analysis results.

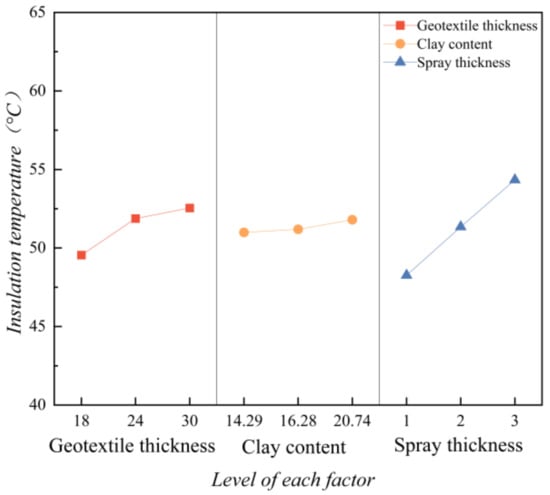

According to the data in the table above, the light transmittance values measured for all nine experimental groups were 0, indicating that the slurry coating layer can completely block light. Previous studies have shown that a 5 cm sand covering is sufficient to maintain the strength of geotextiles [20]. Using the thermal insulation performance of a 5 cm sand layer as a benchmark, while maintaining the upper surface temperature at 60 °C, the thermal insulation temperature of the sand layer’s upper and lower surfaces was measured to be around 25 °C. In comparison, the thermal insulation temperature of the slurry-sprayed geotextile ranged from 15.22 °C to 18.67 °C, achieving 61% to 75% of the thermal insulation effect of the 5 cm sand layer. This demonstrates that the slurry-spraying process can effectively block most of the heat. Analysis of the thermal insulation temperature data reveals that the influences for each factor are ranked as follows: slurry thickness (C) > geotextile thickness (A) > clay content (B). Therefore, the sensitivity of thermal insulation temperature to each factor is in the order of C—A—B. The optimal parameter combination is a geotextile surface density of 500 g/m2 (corresponding to a thickness of 3.4 mm), a clay content of 18.18%, and a slurry thickness of 3 layers (6 mm).

To more clearly illustrate the trend of each factor’s influence on the thermal insulation temperature, a trend chart was used for analysis, with thermal insulation temperature on the vertical axis and the different levels of each factor on the horizontal axis, as shown in Figure 10. The trend of the experimental indicators shows that the degree of influence of each factor follows the order [clay content < geotextile thickness < slurry thickness], and the thermal insulation temperature increases with the level of each factor.

Figure 10.

Direct view of influencing factors of test indexes.

3.4.2. Analysis of Variance

Analysis of variance is the estimation of the magnitude of errors and the significance of factors affecting experimental results. It is necessary to take the blank column as the error column, compare the sum of squared deviations of parameters with the sum of squared errors, and perform an F-test to determine the significance level of each parameter. Specifically, the significance level of factors is divided into four levels: (1) when F ≥ F0.01, the factor is considered to have a highly significant impact on the experimental results, marked as “* *”; (2) when F0.01 > F ≥ F0.05, the factor is considered to have a significant impact on the experimental results, marked as “* *”; (3) when F0.05 > F ≥ F0.1, the factor is considered to have a less significant impact on the experimental results, but still has a certain impact, marked as “*”; (4) when F < F0.1, the factor is considered to have no significant impact on the experimental results, marked as “*”. The analysis results are shown in Table 8. It is evident that slurry thickness is a highly significant influencing factor, while the geotextile thickness is a moderately significant factor and the clay content is a non-significant factor.

Table 8.

Analysis of variance results.

In summary, for the thermal insulation temperature of slurry-coated samples, the slurry thickness is the primary influencing factor. As the slurry thickness increases, its thermal resistance also enhances, leading to improved insulation performance. Geotextile thickness is a moderately significant factor, indicating its limited impact on insulation’s effectiveness. The clay content shows no significant influence, suggesting that its effect on thermal insulation may have reached saturation within a broad range, resulting in a relatively minor impact on insulation performance.

3.5. A Protection Effect Prediction Model Based on Projection Pursuit (PPR) Analysis Method

3.5.1. Introduction to the Principles of the PPR Model

The principle of projection pursuit regression (PPR) involves using computer algorithms to project high-dimensional experimental data into a low-dimensional subspaces (typically 1-3 dimensions), thereby achieving effective data dimensionality reduction. By systematically analyzing the reduced-dimension data, the method identifies characteristic projection directions that preserve the essential structural features of the original high-dimensional data. These optimal projections then serve as the basis for constructing regression models, ultimately enabling effective research and analysis of high-dimensional datasets [32].

The mathematical expression of the projection pursuit regression (PPR) model is given as follows [33]:

denotes the m-th ridge function; represents the weighting coefficient, indicating the contribution of the m-th ridge function to the output; is the argument of the ridge function, representing the projection of the P-dimensional input vector X onto the direction ; is the j-th component of the m-th projection direction vector ; and p denotes the dimensionality of the input space. Requirement .

Projection pursuit regression (PPR) analysis hinges on identifying optimal projection directions, with genetic algorithms currently being the predominant method for optimizing both projection directions and ridge function parameters. The solution procedure [34] is as follows:

(1) Given an initial projection direction α, compute , xj, j = 1, L, n. by projecting the independent variables onto direction α, yielding n one-dimensional projection values.

(2) The ridge function f1 is estimated via least squares minimization of the residual sum of squares .

(3) Iteratively repeat steps (1)–(2) until convergence is achieved, obtaining the optimal projection direction α1 and ridge function f1 to globally minimize Q.

(4) Verify whether the model meets convergence criteria. If satisfied, terminate computation; otherwise, proceed with subsequent calculations.

(5) Sequentially identify subsequent ridge functions by replacing the dependent variable with residuals and re-establishing relationships with independent variables. Repeat steps (1)–(3) iteratively until obtaining the m-th optimal projection direction α1 and corresponding optimal ridge function f1.

(6) Iteratively repeat steps (4)–(5) until the model satisfies all convergence criteria and performance requirements.

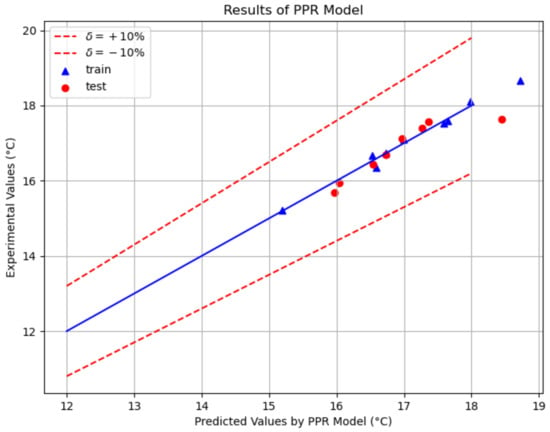

3.5.2. Establishment and Analysis of the PPR Model

This study employed a dataset comprising nine groups for model construction, while reserving eight independent groups for validation. To evaluate model performance, we first applied the projection pursuit regression (PPR) algorithm to analyze the modeling samples. The relative errors between measured and fitted values were then calculated using the “reverse fitting” method, with an acceptance criterion of |δ| < 10% [35]. Upon confirming that the modeling samples met the required qualification rate, we subsequently tested the PPR model using the reserved eight validation datasets. When the validation samples similarly satisfied the predetermined criteria, the PPR model was confirmed to demonstrate robust reliability and stability.

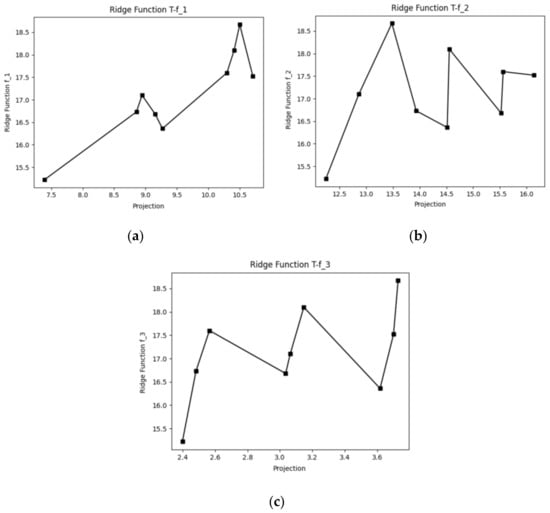

During model operation, five critical projection parameters must be specified: P = 3: number of influencing factors (independent variables); Q = 1: number of response variables (dependent variables); S = 0.1: smoothing coefficient (range: 0–1), where smaller values indicate higher model sensitivity to data variations; M = 5: maximum allowable number of ridge functions; Mu = 3: optimal number of ridge functions. The combination of M and Mu determines the model’s precision in capturing the underlying data structure. The derived projection directions obtained through computational modeling are given in Equation (3), the corresponding weight coefficients (β) are listed in Equation (4), and the ridge functions are visualized in Figure 11.

Figure 11.

Ridge function diagram of PPR model: (a) ridge function T-f1; (b) ridge function T-f2; (c) Ridge function T-f3.

Additionally, the PPR program was used to calculate the thermal insulation performance of the slurry-coated geotextiles. The contribution weight coefficients of each influencing factor to the thermal insulation temperature were determined as follows: geotextile thickness = 1.208, clay content = 1.105, and slurry thickness = 1.408. This indicates that the order of contribution weights of the three factors to thermal insulation temperature is as follows: slurry thickness > geotextile thickness > clay content.

Based on the PPR calculation results, the predictive model formula for the thermal insulation temperature of slurry-coated geotextiles is as follows:

In the formula, S is the predicted value of insulation temperature; f represents the ridge function; α is the projection direction; and x is the horizontal factor.

As illustrated in Figure 12, based on the aforementioned PPR modeling process, the predicted thermal insulation temperatures for both the modeling and validation samples demonstrate that the relative error (δ) between the predicted and measured values remains within 10%. This outcome robustly validates the reliability of the PPR model. Consequently, this model can be utilized to accurately predict the thermal insulation temperature of slurry-coated geotextile bags in untested conditions and to analyze the optimal parameter configurations for thermal insulation performance across different scenarios.

Figure 12.

PPR modeling calculation results.

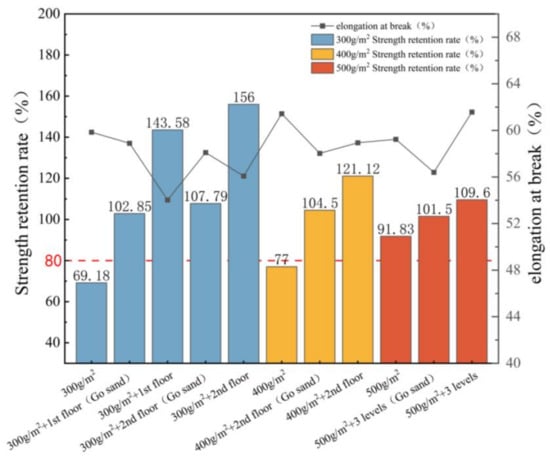

3.6. Aging Test Results and Electron Microscopy Microscopic Analysis

Based on the above analysis, the influence of clay content on the experimental values is relatively small, and a clay slurry content of 14.29% is selected as the unified choice for the experimental plan. We developed four different testing plans, namely, a blank group (300 g/m2, 400 g/m2, 500 g/m2), the most economical group (300 g/m2 + 1 layer slurry, 300 g/m2 + 2 layer slurry), the intermediate group (400 g/m2 + 5 layer slurry), and the safest group (500 g/m2 + 3 layer slurry).

According to Figure 13, after 144 h of fluorescent UV lamp aging testing, the strength retention rates of geotextiles with specifications of 300 g/m2 and 400 g/m2 were 69.18% and 77%, respectively, which did not meet the standard qualification requirement of 80%. The strength retention rate of the same specification of sprayed geotextile fabric is significantly higher than 100%, and the strength retention rate can also reach over 100% when the mud layer is scraped off for testing. This indicates that the spraying method has good protection for geotextiles, and the sand immersed in the fibers can also improve the overall tensile strength to a certain extent. Although the 500 g/m2 geotextile meets the standard in the aging test, its cost-effectiveness is not outstanding due to cost considerations.

Figure 13.

Test results of aging test.

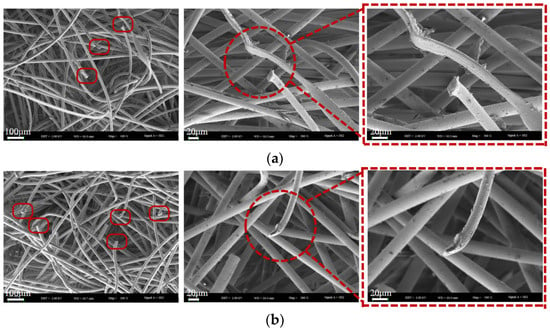

The internal fiber structures of three types of geotextiles—aged geotextiles (referred to as L) and slurry-coated geotextiles after aging tests (referred to as J)—were observed using a scanning electron microscope (SEM).

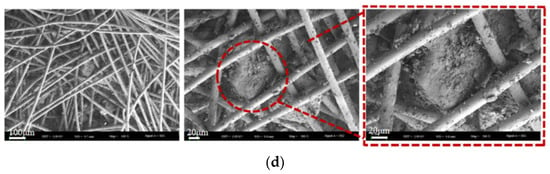

Figure 14 presents the SEM images of the L geotextile samples. The images reveal that the fiber structures of the geotextiles with three specifications (300 g/m2, 400 g/m2, and 500 g/m2) suffered varying degrees of damage under prolonged exposure to ultraviolet (UV) radiation and high temperatures. This damage manifested as multiple fractures in the fibers, including thermal decomposition, melting, and deformation. High temperatures exacerbated the aging effects of UV radiation on the geotextiles, making the fibers more brittle. These observations align closely with the aging state of fibers in geotextiles sampled from the K135 site under natural environmental conditions, further confirming that UV radiation and high temperatures are critical factors in the aging process of geotextiles.

Figure 14.

SEM images of virgin geotextile (sample L) after aging tests: (a) specification 300 g/m2 geotextile; (b) specification 400 g/m2 geotextile; (c) specification 500 g/m2 geotextile.

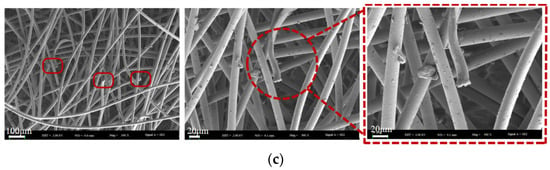

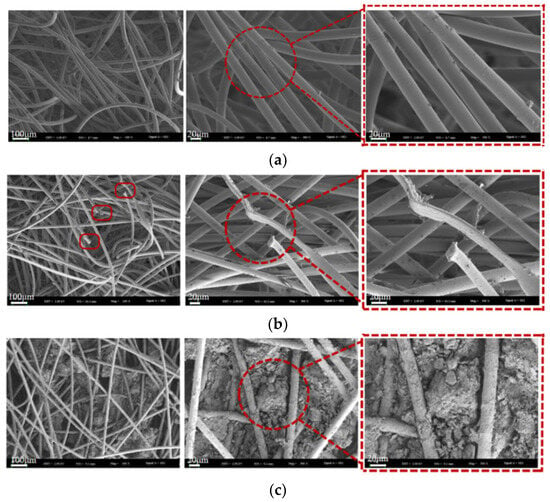

Figure 15 shows a scanning electron microscope image of the J geotextile sample. In that figure, it can be seen that after the accelerated aging test, the geotextile fibers treated with spraying showed good durability. There are many fine sand particles attached to the fibers, as well as many small slurry particles. The presence of these fine sand particles and small slurry particles will help improve overall wear and erosion resistance. Whether a process involves spraying one layer, two layers, or three layers, it has a significant protective effect on the geotextile. The presence of the sprayed layer effectively reduces the direct erosion of geotextile fibers by ultraviolet rays and other environmental factors, thereby extending the service life of geotextiles. This observation result is highly similar to the fibrous state of the mud soil bags in the water level zone of the K135 revetment under electron microscopy scanning.

Figure 15.

SEM images of spray-coated geotextile (sample J) post-aging tests: (a) 300 g/m2 + 1-layer sprayed geotextile; (b) 300 g/m2 + 2-layer sprayed geotextile; (c) 400 g/m2 + 2-layer sprayed geotextile; (d) 500 g/m2 + 3-layer sprayed geotextile.

Figure 16 presents comparative scanning electron microscopy (SEM) images of geotextiles before and after aging tests, including slurry-coated samples. The images reveal that, regarding (a) untreated geotextile (pre-aging), the fibers exhibit an intact structure with no cracks, fractures, or signs of aging, discoloration, or chemical degradation. (b) The untreated geotextile (post-aging): after prolonged exposure to UV radiation and high temperatures, the fiber structure shows varying degrees of damage, including multiple fractures. (c) Regarding slurry-coated geotextile (post-aging), a significant amount of sediment particles adhere to the fibers, enhancing their resistance to abrasion and erosion.

Figure 16.

SEM images of untreated and slurry-coated geotextiles: (a) pristine geotextile before aging test, (b) untreated geotextile after aging test, and (c) slurry-coated geotextile after aging test.

By comparing the fiber conditions in (a), (b), and (c), it is evident that the slurry coating effectively mitigates damage caused by UV exposure and high temperatures, thereby extending the geotextile’s service life.

In summary, the SEM observations not only confirm the damaging effects of ultraviolet (UV) radiation and high temperatures on the fiber structure of geotextiles but also demonstrate the significant effectiveness of slurry coating in enhancing the durability of geotextiles.

4. Conclusions

This study, conducted within the context of the geotextile bag revetment project along Xinjiang’s Tarim River, systematically investigates both the microstructural characteristics and macroscopic performance of geotextile bags in practical engineering applications. By implementing a slurry coating protection method and subjecting optimized samples to accelerated aging tests, the protective efficacy was thoroughly validated. The principal findings are as follows:

(1) Microscopic examination using electron microscopy coupled with mechanical strength testing revealed that sediment deposition significantly enhances both fiber integrity and the mechanical properties of geotextile bags employed in the Tarim River water conveyance embankment. Building upon this discovery, a manual slurry coating protection method was developed. Subsequent adhesion tests demonstrated that a clay-based slurry exhibits superior bonding performance with geotextile bags compared to alternative compositions.

(2) When targeting the two primary aging factors, UV radiation and temperature, the experimental results confirmed that the slurry coating serves as an effective light barrier while substantially reducing heat transfer under simulated high-temperature conditions, exhibiting remarkable thermal insulation properties.

(3) Comprehensive analysis employing range analysis, variance analysis, and projection pursuit regression (PPR) for thermal insulation performance evaluation established the following parameter significance hierarchy: slurry thickness > geotextile thickness > clay content. The PPR-derived predictive model (Equation (5)) enables the accurate estimation of thermal insulation performance under untested parameter combinations.

(4) The performance validation of optimally slurry-coated samples through accelerated aging tests and electron microscopy observations yielded significant results: the coating treatment markedly improved geotextile strength retention rates, effectively mitigating performance degradation in both UV-exposed and high-temperature environments. Microscopic analysis conclusively verified the slurry layer’s protective effect on fiber microstructure preservation.

Author Contributions

T.C.: software, validation, formal analysis, investigation, writing—original draft preparation; X.L.: conceptualization, methodology, writing—review and editing, supervision, funding acquisition; Y.Q.: conceptualization, writing—review and editing, supervision; H.W.: validation, investigation, writing—review and editing; supervision. All authors have read and agreed to the published version of the manuscript.

Funding

Xinjiang Uygur Autonomous Region Natural Science Foundation General Project: “Research on the Stability Characteristics and Protection Mechanism of Bottom Soil Bags for Fen Xi Sha River Embankment Engineering” (2022D01A183); Financial support provided by the research project “Xinjiang Key Laboratory of Water Conservancy Engineering Safety and Water Disaster Prevention and Control” for graduate students in 2022 (ZDSYS-YJS-2022-05).

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

We sincerely thank the Xinjiang Uygur Autonomous Region Natural Science Foundation General Project: “Research on the Stability Characteristics and Protection Mechanism of Bottom Soil Bags for Fen Xi Sha River Embankment Engineering” (2022D01A183); Financial support provided by the research project “Xinjiang Key Laboratory of Water Conservancy Engineering Safety and Water Disaster Prevention and Control” for graduate students in 2022 (ZDSYS-YJS-2022-05).

Conflicts of Interest

The authors have no relevant financial or non-financial interests to disclose.

References

- Grubb, D.G.; Diesing, W.E., III; Cheng, S.C.; Sabanas, R.M. Comparison of the Durability of Geotextiles in an Alkaline Mine Tailings Environment. Geosynth. Int. 2001, 8, 49–80. [Google Scholar] [CrossRef]

- Khachan, M.M.; Bhatia, S.K. The efficacy and use of small centrifuge for evaluating geotextile tube dewatering performance. Geotext. Geomembr. 2017, 45, 280–293. [Google Scholar] [CrossRef]

- Kim, H.J.; Dinoy, P.R.; Kim, H.S. Tension force analysis of geotextile tubes by half cross—Section test. Geotext. Geomembr. 2020, 48, 243–256. [Google Scholar] [CrossRef]

- Corbella, S.; Stretch, D.D. Geotextile sand filled containers as coastal defence: South African experience. Geotext. Geomembr. 2012, 35, 120–130. [Google Scholar] [CrossRef]

- Saathoff, F.; Oumeraci, H.; Restall, S. Australian and German experiences on the use of geotextile containers. Geotext. Geomembr. 2007, 25, 251–263. [Google Scholar] [CrossRef]

- Li, Y.Q.; You, Z.J.; Shi, H.Y.; Ren, B. Construction of in-situ coastal experimental station to continue assessing shoreline protection performance of geotextile sandbags. J. Coast. Res. 2020, 95, 267–271. [Google Scholar] [CrossRef]

- Oberhagemann, K.; Hossain, M.M. Geotextile bag revetments for large rivers in Bangladesh. Geotext. Geomembr. 2011, 29, 402–414. [Google Scholar] [CrossRef]

- Dong, Z.; Liu, Q.; Li, X. Efficiency and Economic Analysis of Revetment Structure Types in the Main Stream of the Tarim River. Henan Water Resour. South North Water Divers. 2022, 51, 18–19. [Google Scholar]

- Dong, Z.; Li, X. Suitability Analysis of Geotextile Bag Revetment Technology in the Main Stream of the Tarim River. Water Resour. Plan. Des. 2022, 7, 108–111. [Google Scholar]

- Liu, S.H.; Jia, F.; Chen, X.L.; Li, L.J. Experimental study on seismic response of soilbags-built retaining wall. Geotext. Geomembr. 2020, 48, 603–613. [Google Scholar] [CrossRef]

- Kudale, M.D.; Mahalingaiah, A.V.; Tayade, B.R. Use of sand-filled geotextile tubes for sustainable coastal protection-case studies in Indian scenario. Indian J. Mar. Sci. 2014, 43, 1241–1246. [Google Scholar]

- Tisinger, L.G.; Peggs, I.D.; Dudzik, B.E.; Winfree, J.P.; Carraher, C.E., Jr. Microstructural Analysis of a Polypropylene Geotextile After Long-Term Outdoor Exposure. Geosynth. Test. Waste Contain. Appl. 1990, 1081, 335. [Google Scholar]

- Aparicio-Ardila, M.A.; Pedroso, G.O.; Kobelnik, M.; Valentin, C.A.; da Luz, M.P.; Lins da Silva, J. Evaluating the Degradation of a Nonwoven Polypropylene Geotextile Exposed to Natural Weathering for 3 Years. Int. J. Geosynth. Ground Eng. 2021, 7, 1–11. [Google Scholar] [CrossRef]

- Carneiro, J.R.; Almeida, P.J.; Lopes, M.D. Evaluation of the Resistance of a Polypropylene Geotextile Against Ultraviolet Radiation. Microsc. Microanal. 2019, 25, 196–202. [Google Scholar] [CrossRef] [PubMed]

- Suits, L.D.; Hsuan, Y.G. Assessing the photo-degradation of geosynthetics by outdoor exposure and laboratory weatherometer. Geotext. Geomembr. 2003, 21, 111–122. [Google Scholar] [CrossRef]

- Hsieh, C.; Wang, J.B.; Chiu, Y.F. Weathering properties of geotextiles in ocean environments. Geosynth. Int. 2006, 13, 210–217. [Google Scholar] [CrossRef]

- Methacanon, P.; Weerawatsophon, U.; Sumransin, N.; Prahsarn, C.; Bergado, D.T. Properties and potential application of the selected natural fibers as limited life geotextiles. Carbohydr. Polym. 2010, 82, 1090–1096. [Google Scholar] [CrossRef]

- Clinton, M.; Rowe, R.K. Long-term durability of two HDPE geomembranes formulated with polyethylene of raised temperature resistance (PE-RT). Geotext. Geomembr. Off. J. Int. Geosynth. Soc. 2024, 52, 15. [Google Scholar] [CrossRef]

- Lavoie, F.L.; Kobelnik, M.; Valentin, C.A.; de Lurdes Lopes, M.; Palmeira, E.M.; da Silva, J.L. Service life of some HDPE geomembranes. Case Stud. Constr. Mater. 2023, 18, e02212. [Google Scholar] [CrossRef]

- Bao, W. Research on the Aging Performance of Polypropylene Geosynthetics. In Chinese Society of Hydropower Engineering, Proceedings of the 6th National Conference on Geosynthetics; Modern Knowledge Press: Truganina, Australia, 2004; p. 4. [Google Scholar]

- Hornsey, W.P.; Carley, J.T.; Coghlan, I.R.; Cox, R.J. Geotextile sand container shoreline protection systems: Design and application. Geotext. Geomembr. 2011, 29, 425–439. [Google Scholar] [CrossRef]

- Yang, X.; Ding, X. Prediction of outdoor weathering performance of polypropylene filaments by accelerated weathering tests. Geotext. Geomembr. 2006, 24, 103–109. [Google Scholar] [CrossRef]

- Valentin, C.A.; Kobelnik, M.; Franco, Y.B.; Lavoie, F.L.; Silva, J.L.; Luz, M.P. Study of the Ultraviolet Effect and Thermal Analysis on Polypropylene Nonwoven Geotextile. Materials 2021, 14, 1080. [Google Scholar] [CrossRef] [PubMed]

- Carneiro, J.R.; Miranda Carlos, D.; de Lurdes Lopes, M. Laboratory Degradation of a Reinforcement PET-PP Geocomposite Under Accelerated Weathering Conditions. Int. J. Geosynth. Ground Eng. 2021, 7, 1–11. [Google Scholar] [CrossRef]

- Richaud, E.; Farcas, F.; Divet, L.; Benneton, J.P. Accelerated ageing of polypropylene geotextiles, the effect of temperature, oxygen pressure and aqueous media on fibers—Methodological aspects. Geotext. Geomembr. 2008, 26, 71–81. [Google Scholar] [CrossRef]

- Karademir, T.; Frost, J.D. Micro-scale tensile properties of single geotextile polypropylene filaments at elevated temperatures. Geotext. Geomembr. 2014, 42, 201–213. [Google Scholar] [CrossRef]

- Chaudhari, S.B.; Shaikh, T.N.; Patel, B.H.; Pandey, P. Influence on thermal and dyeing characteristics of polypropylene filament on reindoring TiO2 nanoparticles. In Proceedings of the International conference on Application of Nano-Materials in Textile, Rome, Italy, 27–30 July 2015. [Google Scholar]

- GB/T 50085-2007; Technical Code for Sprinkler Engineering. Ministry of Construction of the People’s Republic of China, General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. China Planning Press: Beijing, China, 2007.

- GB/T 16422.3-2022; Plastics—Methods of Exposure to Laboratory Light Sources—Part 3: Fluorescent UV Lamps. The Standardization Administration of the People’s Republic of China: Beijing, China, 2022.

- 20130720-T-608; Geosynthetics—Wide-Width Tensile Test Method. National Technical Committee for Standardization of Industrial Textiles: Beijing, China, 2013.

- GB/T 17639-2023; Geosynthetics—Filament-Spunbonded Needle-Punched Nonwoven Geotextiles. State Administration for Market Regulation, National Standardization Administration: Beijing, China, 2023.

- Zheng, Z.G.; Liu, D.X. Projection pursuit autoregression and multidimensional hybrid regression models with application to flood forecasting in large river systems. J. China Hydrol. 1994, 4, 6–10+65. [Google Scholar]

- Zheng, Z.G. Projection pursuit autoregression model and its application to long-term precipitation forecasting during spring drought in Xinjiang. J. Bayi Agric. Coll. 1993, 2, 1–7. [Google Scholar]

- Jones, M. What is Projection Pursuit (with discussion). J. R. Stat. Soc. Ser. A 1987, 150, 1–18. [Google Scholar] [CrossRef]

- Phetchuay, C.; Horpibulsuk, S.; Arulrajah, A.; Suksiripattanapong, C.; Udomchai, A. Strength development in soft marine clay stabilized by fly ash and calcium carbide residue based geopolymer. Appl. Clay Sci. 2016, 127–128, 134–142. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).