Meta-Analytical Analysis of Competitiveness in Small- and Medium-Sized Manufacturing Enterprises: The Role of Technology and Quality

Abstract

1. Introduction

2. Literary Review

2.1. Integration of Advanced Methodologies and Emerging Technologies

2.2. Digitalization and Digital Transformation in PYMES

2.3. Information Systems and Their Relationship to Competitiveness

2.4. Total Quality Management (TQM) and Competitiveness

2.5. Quality and Its Relation to Competitiveness in PYMES

2.6. Competitive Strategies and Business Performance

3. Methodology

3.1. Selection Criteria

3.2. Study Selection Process

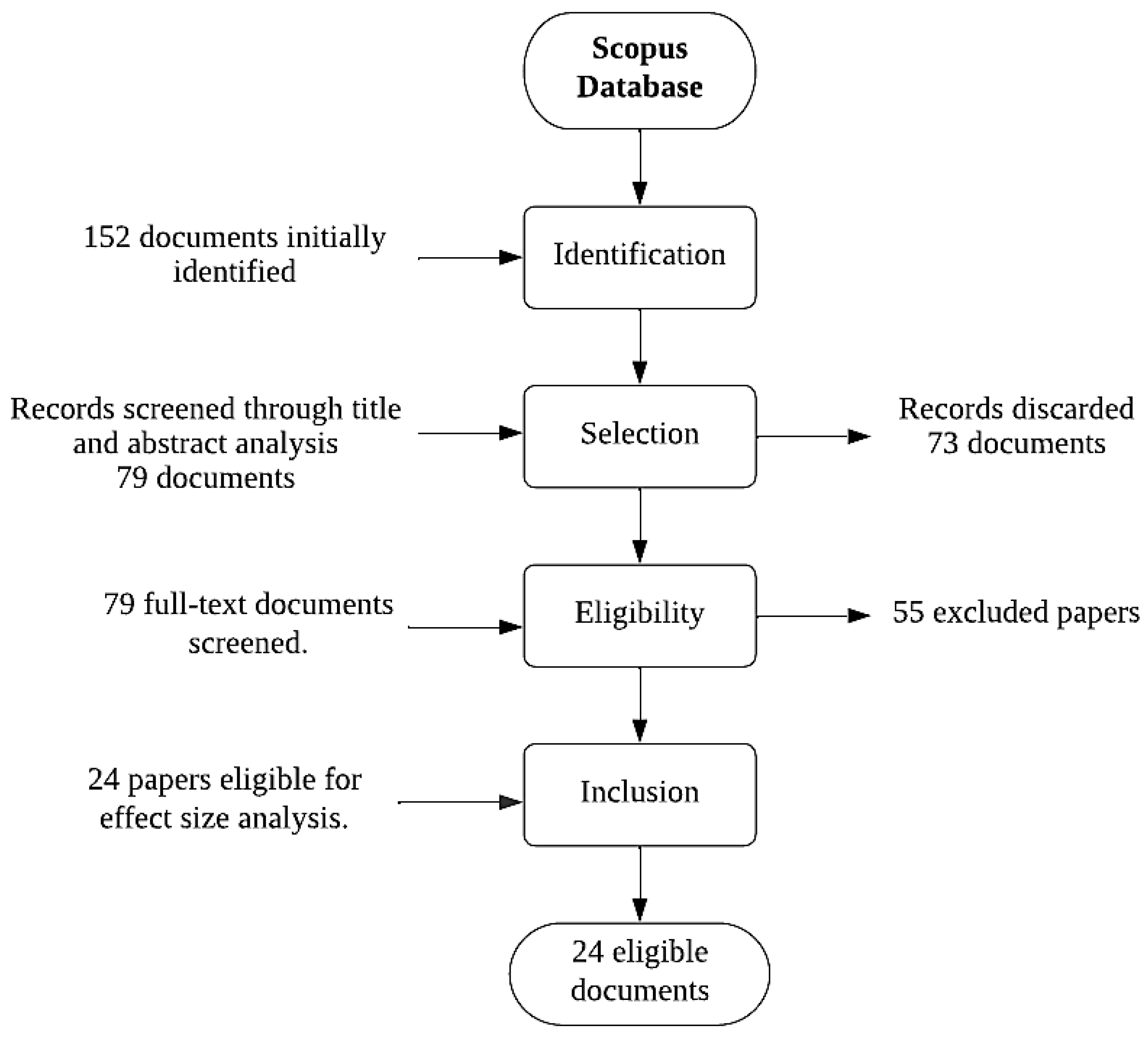

- Identification: a total of 152 documents were identified through searches in the Scopus database.

- Selection: of these, 79 documents were selected for further analysis according to title and abstract, and 73 documents were discarded at the initial stage.

- Eligibility: The remaining 79 papers were reviewed in full text to determine eligibility. At this stage, 55 papers that did not meet the specific inclusion criteria were excluded.

- Inclusion: 24 papers were included in the final analysis and were finally considered eligible.

3.3. Rationale

4. Meta-Analysis

4.1. Search and Selection of Studies

4.2. Data Extraction and Data Conversion

- Conversion of offset coefficients: an overall offset coefficient was calculated using Fisher’s z-transform, which facilitated the aggregation of results.

- Conversion of effect sizes: beta and R2 values were adjusted to a format comparable with the compensation coefficients.

4.3. Statistical Analysis

- I2: proportion of variability attributed to between-study heterogeneity.

- H2: absolute measure of heterogeneity.

- Tau2: variance of effects in a random-effects model.

4.4. Visualization of Results

4.5. Study Matrix

4.6. Topical Analysis

- Handling of ambiguous terms: Lemmatization and lemmatization techniques were implemented to reduce words to their base form and avoid unnecessary variations. In addition, a thesaurus was used to unify equivalent terms, and a manual revision of keywords was performed to ensure their correct interpretation in the context of the analysis.

- Tokenization: The tidytext package was used to divide the text into analyzable units, and terms shorter than three characters were eliminated to reduce noise in the analysis. Then, additional filters were applied to avoid affecting proper names or irrelevant terms.

- Topic Modeling with LDA: Dirichlet’s latent topic assignment (LDA) model was applied using the topic models package in R. This mixed model assumes that each document is a mixture of a small number of topics and that each word in the document is assigned to one of the topics. The selection of LDA was based on its ability to identify latent patterns in text collections, which was key to exploring recurrent approaches related to innovation, quality and competitiveness in manufacturing PYMES.

4.7. Software and Libraries Used

- Meta-analysis: meta, metafor, esc.

- Text analysis: tm, topicmodels, tidytext, dplyr, tidyr.

- Visualization: gplot2.

5. Results

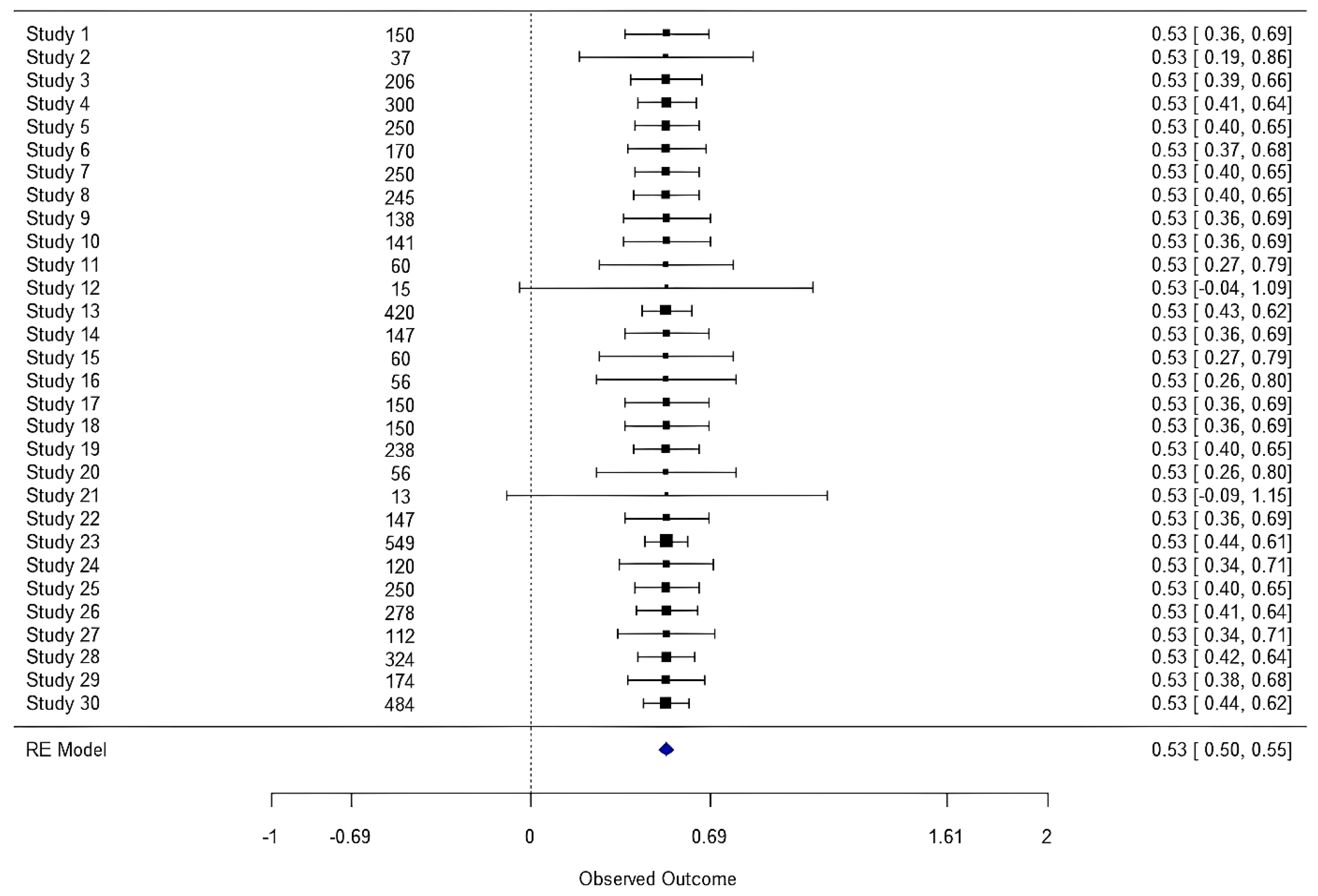

5.1. Meta-Analysis

5.2. Heterogeneity Analysis

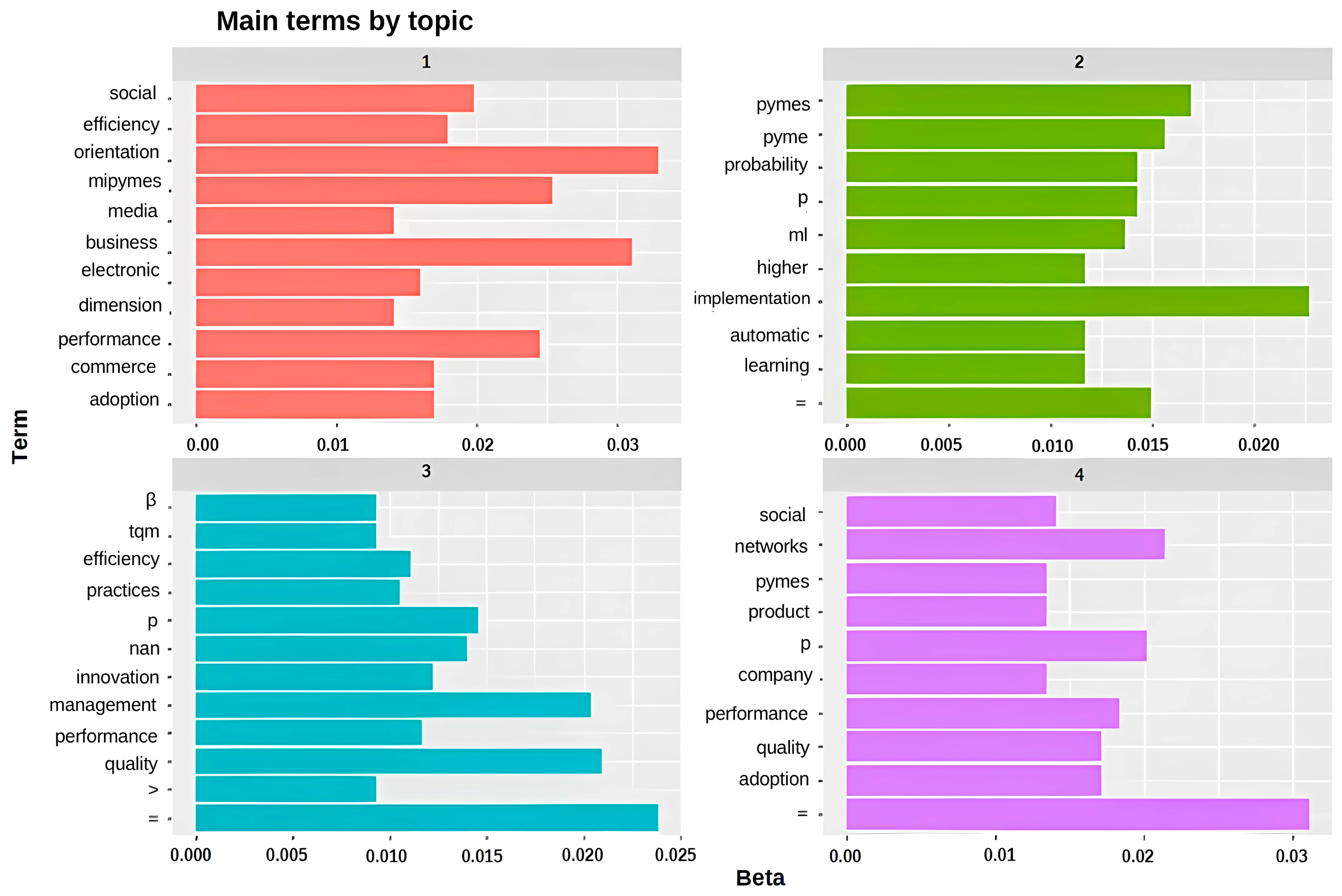

5.3. Topical Analysis (LDA)

- Topic 1: This topic focuses on terms such as “social”, “performance”, “orientation”, “MiPYMES”, “media”, “entrepreneurial”, “electronic”, “dimension”, “performance”, “trade” and “adoption”. It focuses on the relationship between social networks and SME performance, emphasizing the importance of entrepreneurial orientation and the adoption of e-technology and e-commerce. “Size” and “Performance” indicate a consideration of firm size and market performance.

- Topic 2: Predominant terms in this topic include “PYMES”, “probability”, “ml”, “major”, “implementation”, “automatic” and “learning”. This topic discusses the implementation of machine learning in small- and medium-sized enterprises. The terms “probability” and “p” relate to the statistical techniques used in these studies. The “implementation” of “machine learning” indicates a focus on the adoption of these technologies and their potential results, emphasizing the importance of advanced technologies to improve business processes.

- Topic 3: This topic includes terms such as “tqm”, “performance”, “practices”, “innovation”, “management”, “performance” and “quality”. This topic analyzes the implementation of machine learning in small- and medium-sized companies. The terms “probability” and “p” relate to the statistical techniques used in these studies. It is relevant to TQM and performance practices in PYMES. “β” and “p” are statistical terms that indicate the relationship between variables and their significance. The inclusion of “innovation” and “management” demonstrates how the emphasis on TQM practices and innovation management affects the performance and quality of PYMES.

- Topic 4: The main terms are “social”, “networks”, “PYMES”, “product”, “enterprise”, “performance”, “quality” and “adoption”. It focuses on the use of social networks and product quality in small- and medium-sized enterprises. The terms “social” and “network” suggest a strong relationship with the adoption of social communication technologies. “Product” and “quality” indicate that the focus of the discussion is also on how PYMES manage product quality to improve business performance.

6. Discussion

7. Limitations and Future Lines of Research

7.1. Limitations

- The low heterogeneity observed in the meta-analysis indicates that the included studies share similar methodological and contextual approaches. This uniformity may restrict the understanding of how external factors, such as industry sector, level of digitization or access to finance, influence the relationship between technology, quality and competitiveness.

- Topic analysis based on the latent Dirichlet allocation (LDA) model allowed the identification of thematic patterns in the literature reviewed. However, this technique has limitations in capturing more complex semantic relationships and contextual variations within the texts analyzed.

- Although this study identifies technological and financial barriers that limit the adoption of innovative and quality strategies, it does not delve into the impact of public policies and financial incentives on the modernization of manufacturing PYMES.

7.2. Future Lines of Research

- The application of meta-regression and moderator analysis is necessary to evaluate how contextual variables, such as country of origin, industry type and firm size, impact the competitiveness of manufacturing PYMES.

- The implementation of advanced natural language processing models, such as latent semantic analysis (LSA) or neural networks, is also recommended to improve the identification of emerging trends in the academic discourse on innovation and quality in PYMES.

- It is suggested that the role of government financing and technological support programs be analyzed, with the objective of identifying effective strategies that facilitate the digital transformation and competitive growth of PYMES in different economic and regulatory contexts.

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Joshi, S.; Sharma, M.; Bartwal, S.; Joshi, T.; Prasad, M. Critical Challenges of Integrating OPEX Strategies with I4.0 Technologies in Manufacturing SMEs: A Few Pieces of Evidence from Developing Economies. TQM J. 2024, 36, 108–138. [Google Scholar] [CrossRef]

- Nowak, M.; Martineau, S.; Sobottka, T.; Ansari, F.; Schlund, S. An Indicator Scheme for Improving Measurability of Sustainable Development Goals in Manufacturing Enterprises. Procedia Comput. Sci. 2024, 232, 655–664. [Google Scholar] [CrossRef]

- Albhirat, M.M.; Zulkiffli, S.N.A.; Salleh, H.S.; Zaki, N.A.M. The Moderating Role of Social Capital in the Relationship Between Green Supply Chain Management and Sustainable Business Performance: Evidence from Jordanian SMEs. Int. J. Sustain. Dev. Plan. 2023, 18, 1733–1747. [Google Scholar] [CrossRef]

- Soleimani, M.; Mollaei, E.; Beinabaj, M.H.; Salamzadeh, A. Evaluating the Enablers of Green Entrepreneurship in Circular Economy: Organizational Enablers in Focus. Sustainability 2023, 15, 11253. [Google Scholar] [CrossRef]

- Ali, R.; Leifu, G.; Rehman, R. The Impact of Technology Orientation and Customer Orientation on Firm Performance: Evidence Form Chinese Firms. Int. J. Manag. Mark. Res. 2016, 9, 1–11. [Google Scholar]

- Brynjolfsson, E.; Hitt, L.M. Beyond the Productivity Paradox. Commun. ACM 1998, 41, 49–55. [Google Scholar] [CrossRef]

- Oyaque Mora, S.M. Productividad Como Factor de Competitividad Empresarial: Un Estudio de Revisión Sistemática. Religación 2024, 9, e2401217. [Google Scholar] [CrossRef]

- Iansiti, M.; Favaloro, G.; Utzschneider, J.; Richards, G. Why IT Matters in Midsized Firms. 2005. Available online: https://www.hbs.edu/ris/Publication%20Files/06-013.pdf (accessed on 25 March 2025).

- Forootani, S.; Abdolvand, N.; Harandi, S.R. Factors Affecting the Adoption of Cloud-Based CRM in Small and Medium Enterprises. Int. J. Serv. Technol. Manag. 2022, 28, 120–140. [Google Scholar] [CrossRef]

- Digalwar, A.K.; Singh, S.R.; Pandey, R.; Sharma, A. Industry 4.0 Implementation: Evidence from Indian Industries. In IFIP Advances in Information and Communication Technology; Springer: Cham, Switzerland, 2024; Volume 699, pp. 23–34. [Google Scholar] [CrossRef]

- Coba, E.; Díaz, J.; Tapia, E.; Aranguren, W. La Información Gerencial y Los Sistemas de Información En Las PyMES; Universidad de Carabobo: Carabobo, Venezuela, 2017. [Google Scholar]

- Levy, M.; Powell, P. Strategies for Growth in SMEs; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar] [CrossRef]

- Antoncic, B.; Hisrich, R.D. Intrapreneurship: Construct Refinement and Cross-Cultural Validation. J. Bus. Ventur. 2001, 16, 495–527. [Google Scholar] [CrossRef]

- Martínez, A. Industria 4.0 en México; Plaza y Valdés, SA de CV: Ciudad de México, Mexico, 2020. [Google Scholar]

- Hsu, W.-S.; Chang, P.-L. Promoting Technological Capabilities of Small and Medium-Sized Enterprises through Industry-University Cooperation: Case Study of Taiwan Machine Tool Industry. Int. J. Manuf. Technol. Manag. 2000, 1, 257–270. [Google Scholar] [CrossRef]

- Gramegna, N.; Greggio, F.; Bonollo, F. Smart Factory Competitiveness Based on Real Time Monitoring and Quality Predictive Model Applied to Multi-Stages Production Lines. In Proceedings of the IFIP Advances in Information and Communication Technology, Novi Sad, Serbia, 30 August–3 September 2020; Volume 592, pp. 185–196. [Google Scholar] [CrossRef]

- Habib, L. Presencia de Los Pilares de La Industria 4.0 En La Formación de Ingenieros En El Noreste de México. Rev. Cuba. Educ. Super. 2022, 41, 19. [Google Scholar]

- Nieto, S.R.L. Impacto de La Tecnología En La Generación de La Industria 4.0 En Las Pymes: Estudio Diagnóstico En Empresas de La Ciudad de Puebla. RICEA Rev. Iberoam. Contad. Econ. Adm. 2023, 12, 32–55. [Google Scholar] [CrossRef]

- Erbay, H.; Ylldlrlm, N. Combined Technology Selection Model for Digital Transformation in Manufacturing: A Case Study From the Automotive Supplier Industry. Int. J. Innov. Technol. Manag. 2022, 19, 2250023. [Google Scholar] [CrossRef]

- Park, B.; Kim, T.; Jong-Pil, J. AI-Smart Factory: Design and Verification of Korean SME AI Smart Factory Using Level Diagnosis System. Procedia Comput. Sci. 2023, 224, 169–179. [Google Scholar] [CrossRef]

- Nimfa, D.T.; Uzir, M.U.H.; Maimako, L.N.; Eneizan, B.; Latiff, A.S.A.; Wahab, S.A. The Impact of Innovation Competitive Advantage on Product Quality for Sustainable Growth among SMEs: An Empirical Analysis. Int. J. Bus. Sci. Appl. Manag. 2021, 16, 39–62. [Google Scholar] [CrossRef]

- Tikakul, C.T.; Thomson, A. Knowledge Management Practice: Case Study of Thai SMEs in the Manufacturing Sector. In Proceedings of the 17th European Conference on Knowledge Management, (ECKM 2016), Coleraine, UK, 1–2 September 2016; pp. 1099–1108. Available online: https://pureportal.strath.ac.uk/en/publications/knowledge-management-practice-case-study-of-thai-smes-in-the-manu (accessed on 25 March 2025).

- Institute of Electrical and Electronics. 2004 2nd IEEE International Conference on Industrial Informatics: Collaborative Automation—One Key for Intelligent Industrial Environments, Berlin, Germany, 24–26 June 2004; Filos, E., Ed.; IEEE: Piscataway, NJ, USA, 2004. [Google Scholar]

- Mishra, M.; Chaubey, A.; Khatwani, R.; Nair, K. Overcoming Barriers in Automotive SMEs to Attain International Competitiveness: An ISM Approach Modelling. J. Bus. Ind. Mark. 2023, 38, 2713–2730. [Google Scholar] [CrossRef]

- Shuaib, K.M.; He, Z. Mediating Effects of Organisational Learning on the Relationship between TQM, Innovation and Business Performance: Evidence from Manufacturing SMEs in Nigeria. Int. J. Bus. Perform. Manag. 2023, 25, 94–127. [Google Scholar] [CrossRef]

- Burggräf, P.; Steinberg, F.; Sauer, C.R.; Nettesheim, P. Machine Learning Implementation in Small and Medium-Sized Enterprises: Insights and Recommendations from a Quantitative Study. Prod. Eng. 2024, 18, 751–764. [Google Scholar] [CrossRef]

- Nolasco-Mamani, M.A.; Vidaurre, S.M.E.; Choque-Salcedo, R.E. Innovación y Transformación Digital en la Empresa; ACVENISPROH Académico: Maracay, Venezuela, 2023. [Google Scholar] [CrossRef]

- Chicaiza, P.M.; Guanoluisa, M.C.; Cobos, M.C.; Toscano, D.G. Transformación Digital En Las Empresas: Una Revisión Conceptual. J. Sci. Res. 2023, 7, 756–769. [Google Scholar] [CrossRef]

- Chen, G. Design of Intelligent Protection Device Based on Numerical Control Tool. In Proceedings of the 2022 3rd International Conference on Robotics Systems and Vehicle Technology (RSVT), Singapore, 22–24 July 2022; ACM: Singapore, 2022; pp. 36–39. [Google Scholar] [CrossRef]

- Mendoza Pérez, M.A.; Cuellar, S. Industry 4.0: Latin America SMEs Challenges. In Proceedings of the 2020 Congreso Internacional de Innovación y Tendencias en Ingeniería (CONIITI), Bogota, Colombia, 30 September–2 October 2020; IEEE: Bogota, Colombia, 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Szopa, Ł.; Cyplik, P. The Concept of Building a Digital Transformation Model for Enterprises from the SME Sector. Logforum 2020, 16, 593–601. [Google Scholar] [CrossRef]

- Brundl, P.; Stoidner, M.; Nguyen, H.G.; Baechler, A.; Franke, J. Digitalization and Adoption of Industry 4.0 in Engineer-to-Order Small and Medium-Sized Manufacturing Companies: An Empirical Analysis. In Proceedings of the 2023 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 18–21 December 2023; pp. 908–912. [Google Scholar] [CrossRef]

- Tian, G.; Li, B.; Cheng, Y. Does Digital Transformation Matter for Corporate Risk-Taking? Finance Res. Lett. 2022, 49, 103107. [Google Scholar] [CrossRef]

- Oduro, S.; De Nisco, A.; Mainolfi, G. Do Digital Technologies Pay off? A Meta-Analytic Review of the Digital Technologies/Firm Performance Nexus. Technovation 2023, 128, 102836. [Google Scholar] [CrossRef]

- Rodríguez, O.A.G. Transformación Digital: Una Agenda de Oportunidades Para La Investigación y La Práctica. Rev. Perspect. Empres. 2021, 7, 3–6. [Google Scholar] [CrossRef]

- Gao, F.; Lin, C.; Zhai, H. Digital Transformation, Corporate Innovation, and International Strategy: Empirical Evidence from Listed Companies in China. Sustainability 2022, 14, 8137. [Google Scholar] [CrossRef]

- Muna, N.; Yasa, N.N.K.; Ekawati, N.W.; Wibawa, I.M.A. A Dynamic Capability Theory Perspective: Borderless Media Breakthrough to Enhance SMEs Performance. Int. J. Data Netw. Sci. 2022, 6, 363–374. [Google Scholar] [CrossRef]

- García, M.L.S.; Adame, M.E.C.; García, M.E.S. Competitividad de Las Pyme y Su Relación Con Los Sistemas de Información. Cuad. Contab. 2019, 20, 1–25. [Google Scholar] [CrossRef]

- Colomina Climent, E. Adopción de Sistemas de Información en las PYME: Teoría y Evidencia Empírica. Ph.D. Thesis, Universidad de Alicante, Alicante, Spain, 1998. Available online: http://hdl.handle.net/10045/3393 (accessed on 25 March 2025).

- Neil Baily, M.; Lawrence, R.Z. Do We Have an Economy? Am. Econ. Rev. 2001, 9, 308–312. [Google Scholar]

- Tarutė, A.; Gatautis, R. ICT Impact on SMEs Performance. Procedia-Soc. Behav. Sci. 2014, 110, 1218–1225. [Google Scholar] [CrossRef]

- Lim, J.; Richardson, V.J.; Roberts, T.L. Information Technology Investment and Firm Performance: A Meta-Analysis. In Proceedings of the 37th Annual Hawaii International Conference on System Sciences, Big Island, HI, USA, 5–8 January 2004; IEEE: Piscataway, NJ, USA, 2004; p. 10. [Google Scholar] [CrossRef]

- Mahmood, M.A.; Mann, G.J. Information Technology Investments and Organizational Productivity and Performance: An Empirical Investigation. J. Organ. Comput. Electron. Commer. 2005, 15, 185–202. [Google Scholar] [CrossRef]

- Bayraktar, E.; Demirbag, M.; Koh, S.C.L.; Tatoglu, E.; Zaim, H. A Causal Analysis of the Impact of Information Systems and Supply Chain Management Practices on Operational Performance: Evidence from Manufacturing SMEs in Turkey. Int. J. Prod. Econ. 2009, 122, 133–149. [Google Scholar] [CrossRef]

- Rodriguez, O.J.S.; De Lema, D.G.P.; García, J.J.B. Influencia de La Implementación Del Sistema de Información Sobre El Rendimiento En Pequeñas y Medianas Empresas: Un Estudio Empírico En Colombia. Cuad. Adm. 2014, 30, 31–43. [Google Scholar] [CrossRef]

- Abrego-Almazán, D.; Medina-Quintero, J.M.; Sánchez-Tovar, Y. La calidad de los Sistemas de Información en la eficiencia de las Pymes. Rev. Cuba. Cienc. Inform. 2016, 10, 27–41. [Google Scholar]

- Demirbag, M.; Tatoglu, E.; Tekinkus, M.; Zaim, S. An Analysis of the Relationship between TQM Implementation and Organizational Performance: Evidence from Turkish SMEs. J. Manuf. Technol. Manag. 2006, 17, 829–847. [Google Scholar] [CrossRef]

- Lehyani, F.; Zouari, A.; Ghorbel, A.; Tollenaere, M. Do KM and TQM Have an Impact on Employee Effectiveness and Supply Chain Performance? Int. J. Lean Six Sigma 2024, 15, 733–762. [Google Scholar] [CrossRef]

- Benzaquen-De Las Casas, J.; Pérez-Cepeda, M. El ISO 9001 y TQM en Las Empresas de Ecuador. J. Glob. Compet. Governability 2016, 10, 153–176. [Google Scholar] [CrossRef]

- Jum’a, L.; Alkalha, Z.; Al Mandil, K.; Alaraj, M. Exploring the Influence of Lean Manufacturing and Total Quality Management Practices on Environmental Sustainability: The Moderating Role of Quality Culture. Int. J. Lean Six Sigma 2023, 14, 1626–1654. [Google Scholar] [CrossRef]

- García, M.L.S.; Adame, M.E.C.; Sánchez, B.T. Calidad Para La Competitividad En Las Micro, Pequeñas y Medianas Empresas, de La Ciudad de México. Rev. Venez. Gerenc. 2017, 22, 551–575. [Google Scholar]

- Calvo, J.C.A.; Ortiz, R.F.; Menorca, M.L.G. Technological Capacities and Quality Certifications. An Empirical Application to La Rioja Family SMEs. Cuad. Gest. 2004, 4, 69–82. [Google Scholar] [CrossRef]

- Camisón, C.; Boronat Navarro, M.; Villar López, A. Estructuras Organizativas, Estrategias Competitivas y Ventajas Estratégicas de Las PYMES. Econ. Ind. 2010, 375, 89–100. [Google Scholar]

- Rubio, A.; Aragón, A. Recursos Críticos y Estrategia En La Pyme Industrial. Rev. ICE Trib. Econ. 2009, 17, 193–212. [Google Scholar]

- Rubio, A.; Aragón, A. Recursos Estratégicos En Las Pymes. Rev. Eur. Dir. Econ. Empresa 2008, 17, 103–126. [Google Scholar]

- Powell, T.C. Total Quality Management as Competitive Advantage: A Review and Empirical Study. Strateg. Manag. J. 1995, 16, 15–37. [Google Scholar] [CrossRef]

- OEA-GTZ. Gestión de La Calidad En Pequeñas y Medianas Empresas; Memoria del Proyecto Copatrocinado por OEA y GTZ; OEA: Bogotá, Colombia, 2001. [Google Scholar]

- Aguilasocho, D.; Galeana, E.; Guerra, J. Factores Que Afectan La Competitividad de Las Pymes Agrocítricas Manufactureras En Michoacán. Dialnet 2014, 15, 45–69. [Google Scholar] [CrossRef]

- Demuner-Flores, M.R.; Mercado Salgado, P. Gestión de Calidad En PyMEs Manufactureras Certificadas Con ISO 9001-2000. Rev. Cent. Inv. 2011, 9, 79–97. [Google Scholar]

- Hung, S.-C.; Hung, S.-W.; Lin, M.-J.J. Are Alliances a Panacea for SMEs? The Achievement of Competitive Priorities and Firm Performance. Total Qual. Manag. Bus. Excell. 2015, 26, 190–202. [Google Scholar] [CrossRef]

- Li, R.; Li, R.; Lin, S. The Embedding Path of Design Innovation in Garment Enterprises’ High-Quality Development. J. Silk 2022, 59, 80–88. [Google Scholar] [CrossRef]

- Lamatinulu; Dahlan, M.; Rauf, N.; Nusran, M. Interpretive structural modeling of performance improvement strategies on perspective of customers. Int. J. Tech. Phys. Probl. Eng. 2023, 15, 106–114. [Google Scholar]

- Niyi Anifowose, O.; Ghasemi, M.; Olaleye, B.R. Total Quality Management and Small and Medium-Sized Enterprises’ (SMEs) Performance: Mediating Role of Innovation Speed. Sustainability 2022, 14, 8719. [Google Scholar] [CrossRef]

- Olaleye, B.R.; Ali-Momoh, B.O.; Herzallah, A.; Sibanda, N.; Ahmed, A.F. Dimensional Context of Total Quality Management Practices and Organizational Performance of SMEs in Nigeria: Evidence from Mediating Role of Entrepreneurial Orientation. Int. J. Oper. Quant. Manag. 2021, 27, 399–415. [Google Scholar] [CrossRef]

- Ahmad, F.; Hamid, N.A.; Ahmad, A.N.A.; Nawi, M.N.M.; Rahman, N.A.A.A.; Hamid, N.A.A. The impact of tqm on business performances based on balanced scorecard approach in Malaysia SMEs. Int. J. Qual. Res. 2022, 16, 231–242. [Google Scholar] [CrossRef]

- Teplická, K.; Hurná, S. New Approach of Costs of Quality According Their Trend of during Long Period in Industrial Enterprises in SMEs. Manag. Syst. Prod. Eng. 2021, 29, 20–26. [Google Scholar] [CrossRef]

- Yang, C.-C. The Effectiveness Analysis of the Practices in Five Quality Management Stages for SMEs. Total Qual. Manag. Bus. Excell. 2020, 31, 955–977. [Google Scholar] [CrossRef]

- Silviana; Hardianto, A.; Fuhaid, N.; Hermawan, D. Designing the Ergonomic Press and Molding Machine of Cassava Chips for Sustainable Development in Smes. Pertanika J. Sci. Technol. 2021, 29, 1595–1608. [Google Scholar] [CrossRef]

- Hariastuti, N.L.P.; Pratikto, P.; Santoso, P.B.; Tama, I.P. Analyzing the Drivers of Sustainable Value Creation, Partnership Strategies, and Their Impact on Business Competitive Advantages of Small & Medium Enterprises: A PLS-Model. East.-Eur. J. Enterp. Technol. 2021, 2, 55–66. [Google Scholar] [CrossRef]

- Borenstein, M.; Hedges, L.V.; Higgins, J.P.T.; Rothstein, H.R. Introduction to Meta-Analysis; Nachdr.; Wiley: Chichester, UK, 2009. [Google Scholar]

- Hedges, L.V.; Olkin, I. Statistical Methods for Meta-Analysis. J. Educ. Stat. 1988, 13, 75. [Google Scholar] [CrossRef]

- Liu, W. Accuracy of Funding Information in Scopus: A Comparative Case Study. Scientometrics 2020, 124, 803–811. [Google Scholar] [CrossRef]

- Vengadesh, S.; Chinna, P.R.; Aravindaraj, K. A Bibliometric Analysis of Research Trends in Goods Transportation Using the Scopus Database. Bus. Perspect. Res. 2023, 227853372211488. [Google Scholar] [CrossRef]

- Falagas, M.E.; Pitsouni, E.I.; Malietzis, G.A.; Pappas, G. Comparison of PubMed, Scopus, Web of Science, and Google Scholar: Strengths and Weaknesses. FASEB J. 2008, 22, 338–342. [Google Scholar] [CrossRef]

- Martín-Martín, A.; Orduna-Malea, E.; Thelwall, M.; Delgado López-Cózar, E. Google Scholar, Web of Science, and Scopus: A Systematic Comparison of Citations in 252 Subject Categories. J. Informetr. 2018, 12, 1160–1177. [Google Scholar] [CrossRef]

- Nguyen, P.T.; Timilsina, B. Sources of Sustainable Competitive Advantage and Direction of Development: A Study on Pharmaceutical SMEs. Acta Logist. 2023, 10, 331–344. [Google Scholar] [CrossRef]

- Higgins, J.P.T.; Thompson, S.G.; Deeks, J.J.; Altman, D.G. Measuring Inconsistency in Meta-Analyses. BMJ 2003, 327, 557–560. [Google Scholar] [CrossRef] [PubMed]

- Sterne, J.A.C.; Sutton, A.J.; Ioannidis, J.P.A.; Terrin, N.; Jones, D.R.; Lau, J.; Carpenter, J.; Rucker, G.; Harbord, R.M.; Schmid, C.H.; et al. Recommendations for Examining and Interpreting Funnel Plot Asymmetry in Meta-Analyses of Randomised Controlled Trials. BMJ 2011, 343, d4002. [Google Scholar] [CrossRef] [PubMed]

- Stanley, T.D.; Doucouliagos, H. Meta-Regression Analysis in Economics and Business; Routledge: London, UK, 2012. [Google Scholar] [CrossRef]

| Inclusion Criteria | Exclusion Criteria |

|---|---|

| 1. Relevance of the Topic: studies that specifically analyze the relationship between innovation, quality and competitiveness in manufacturing PYMES will be included. | 1. Irrelevance of the Topic: studies that do not directly address the relationship between innovation, quality and competitiveness in manufacturing PYMES. |

| 2. Type of Company: They will focus exclusively on small- and medium-sized enterprises (PYMES) in the manufacturing sector. | 2. Type of Company: studies that focus on large companies, microenterprises or sectors other than manufacturing. |

| 3. Temporal dimension: studies published between 2019 and 2024 will be included to ensure the timeliness of the data. | 3. Publication Date: studies published before 2019. |

| 4. Language: studies must be written in English or Spanish. | 4. Language: studies written in languages other than English or Spanish. |

| 5. Type of Study: both qualitative and quantitative studies will be considered, including empirical research, case studies and systematic reviews. | 5. Type of Study: non-systematic narrative reviews, editorials, opinions and comments will be excluded. |

| 6. Available Data: studies that provide sufficient data for meta-analysis, such as sample sizes, correlation coefficients, values of beta, R2, Chi-square (χ2) and F2. | 6. Lack of Data: studies that do not provide sufficient data for meta-analysis. |

| 7. Accessibility: studies accessible through recognized academic databases. | 7. Accessibility: studies that are not accessible through recognized academic databases or that require paid access without the possibility of obtaining them by other legal means. |

| Authors | Year | Document | Title | Study Method | Sample | Effect Size |

|---|---|---|---|---|---|---|

| Gabriela Citlalli Lopez-Torres, Giovanni Schiuma, Jaime Muñoz-Arteaga, Francisco Javier Alvarez-Torres | 2024 | Article | Unveiling the relationships between visibility, information technologies and innovation management for sustainability performance: an empirical study | Quantitative, cross-sectional study using a variance-based structural equation model (SEM) approach, processed with the partial least squares (PLS) regression method. | 141 | β (Visibility − Sustainable Performance) = 0.690, β (IT − Visibility) = 0.293, β (Innovation Management ? Visibility) = 0.462 |

| Peter Burggräf, Fabian Steinberg, Carl René Sauer, Philipp Nettesheim | 2024 | Article | Machine learning implementation in small and medium-sized enterprises: insights and recommendations from a quantitative study | Quantitative, multiple linear regressions (MLRs). | 60 | β (WTP) = 0.33, β (DMR) = 0.27, β (IMT) = 0.44 |

| Burggraf, Peter; Steinberg, Fabián; Sauer, Carl René; Nettesheim, Philipp | 2024 | Article | Implementing Machine Learning in Small and Medium-Sized Enterprises: Insights and Recommendations from a Quantitative Study | Quantitative: An empirical study was carried out where a quantitative survey was carried out using a web survey in which professionals from PYMES in Europe were interviewed. The survey was created with the help of the SoSci-Survey tool. Based on extensive bibliographic research, it was feasible to formulate questions relevant to the content, which completely maps the dependent variable. | 56 | 65% of the variance of the predictors was explained during the examined combination of independent variables (Corr. R2 = 0.65). This shows that the result did not arise by chance, nor was there a negative trade-off between the criteria and the predictors. |

| Patrick Bründl, Micha Stoidner, Huong Giang Nguyen, Andreas Baechler, Jörg Franke | 2023 | Article | Digitalization and Adoption of Industry 4.0 in Engineer-to-order Small and Medium-sized Manufacturing Companies: An Empirical Analysis | Quantitative: web survey based on 37 complete responses out of 856 invitations sent. | 37 | r = 0.526 for the relationship between digitalization and business performance. |

| Fatma Lehyani, Alaeddine Zouari, Ahmed Ghorbel, Michel Tollenaere | 2023 | Article | Do KM and TQM have an impact on employee effectiveness and supply chain performance? | Quantitative: survey with 206 responses from Tunisian companies. | 206 | β = 0.599: TQM -> EE, β = 0.469 KM -> β = 0.573: EE, KM -> SCP, β = 0.435: EE -> SCP |

| Mahima Mishra, Akriti Chaubey, Ritesh Khatwani, Kiran Nair | 2023 | Article | Overcoming barriers in automotive PYMES to attain international competitiveness: an ISM approach modelling | Mixed, interpretative structural modeling (ISM) and Delphi method with MICMAC analysis. | 15 | LMP: Kanban: β = −0.002; batch size reduction: β = 0.285; preparation time reduction: β = −0.110; JIT programming: β = −0.087. TQM: customer focus: β = 0.290; product design: β = 0.277; statistical process control: β = 0.089. Moderating effect of quality culture: quality culture in LMPs: β = 0.024; quality culture in TQM: β = −0.177. |

| Muath Maqbool Albhirat, Siti Nur ‘Atikah Zulkiffli, Hayatul Safrah Salleh, Nur Amalina Mohamad Zaki | 2023 | Article | The Moderating Role of Social Capital in the Relationship Between Green Supply Chain Management and Sustainable Business Performance | Quantitative, partial least squares survey (PLS). | 420 | INT-GSCM: F-sq = 0.13, EXT-GSCM: F-sq = 0.04. |

| Yacob, Syahmardi; Sulistiyo, Urip; Marzal, Jefri; Siregar, Ade Perdana; Mukminin, Amirul; | 2023 | Article | An investigation of entrepreneurial orientation, social network adoption and e-commerce on the business performance of MPYMES: an empirical study in Indonesia. | Quantitative: the study employed both quantitative and qualitative approaches, using in-depth interviews, focus group discussions (DGF) and observation for qualitative data and the partial least squares (PLS) method for quantitative data. | 150 | The R-squared value of MPYMES performance during the pandemic was 0.700 and R2 = 0.480 for entrepreneurial orientation. This suggests a substantial effect of social networking and e-commerce adoption on business performance. |

| Yakuttinah Marjan, Uswatun Hasanah, Yurilla Endah Muliatie, Indrianawati Usman | 2022 | Article | Logistic Capability and Total Quality Management Practice on PYMES Performance | Quantitative: hierarchical multiple regression analysis. | 250 | R2 of logistics capacity = 0.490; R2 of practices TQM = 0.446; R2 of non-financial performance = 0.521. |

| Sara Forootani, Neda Abdolvand, Saeedeh Rajaei Harandi | 2022 | Article | Factors affecting the adoption of cloud-based CRM in small and medium enterprises | Quantitative: structural equation model. | 170 | R2 of perceived utility = 0.224, R2 of perceived ease of use = 0.342, R2 of CRM adoption = 0.189 |

| Jiju Antony, Michael Sony, Olivia McDermott, Raja Jayaraman, David Flynn | 2022 | Article | An exploration of organizational readiness factors for Quality 4.0: an intercontinental study and future research directions | Quantitative: online survey. | 147 | β = (leadership) = 0.777; Exp(β) (leadership) = 2.175. |

| Muna, N., Yasa, NNK, Ekawati, NW, Wibawa, IMA | 2022 | Article | A Dynamic Capability Theory Perspective: Borderless Media Advancement For Improving PYMES Performance. | Data for this cross-sectional study were collected from artisanal jewelry PYMES in Bali, Indonesia. | 238 | H1 is rejected: p = 0.900, no significant impact on the company’s performance. H2 is accepted: p = 0.000, given that the adoption of social networks influenced product innovation. H3 is accepted: p = 0.000, the adoption of social networks influenced the quality of business networks. H4 is accepted: p = 0.013, a product innovation suggestively predicted the firm’s performance. H5 acceptance: p = 0.031, the significant effect of the quality of business networks on firm performance. The mediational analysis posited to accept H6, that product innovation significantly impacts the relationship between social media adoption and firm performance. These results lead to the acceptance of H7. |

| Chang Muñoz, E., Guarín García, AF, Nieto Parejo, A., ... Gallego-Nicholls, JF, Huyke Taboada, AP | 2022 | Article | Human-Computer Interaction Activities as a Basis for the Development of In-Process Innovations: The Case of Colombian Exporting PYMES | Quantitative: survey to collect data on different innovation variables covering both the activities and processes of 56 exporting PYMES. | 56 | (p-value = 0.005 χ2 = 12.67), with the implementation of a significant and improved distribution method (p-value = 0.001 χ2 = 15.59) and the implementation of a new production method (p-value = 0.030 χ2 = 7.014). Likewise, there is evidence of a significant positive association between investment in research, development and innovation (R+D) and the number of significantly improved product distribution methods (p-value = 0.019 χ2 = 9.9). |

| Mahima Mishra, Akriti Chaubey, Ritesh Khatwani, Kiran Nair | 2022 | Article | Small Business Strategic Management Practices and Performance: A Configurational Approach | Quantitative: descriptive. | 13 | Not provided. |

| Niyi Anifowose, Oluwaseun; Ghasemi, Matina; Olaleye, Banji Rildwan | 2022 | Article | Total Quality Management and Performance of Small and Medium-sized Enterprises (PYMES): The Mediating Role of Innovation Speed | Quantitative: a quantitative cross-sectional survey was conducted with the help of an adapted survey that had been prepared and was easy to administer to acquire relevant information. | 484 | r: 0.43, relationship between innovation velocity (IS) and operational performance (OP); r: 0.05, relationship between innovation velocity (IS) and total quality management (TQM); r: 0.30, relationship between total quality management (TQM) and operational performance (OP). |

| Ye Feng, Kunmeng Liu, Liyang Lyu, Guojun Sun, Yuanjia Hu | 2021 | Article | The Financial Impact of Patents on PYMES in China: Empirical Evidence from Pharmaceutical Sector | Quantitative: data from 300 pharmaceutical PYMES in China, 1555 observations in different time periods. | 300 | β = 50,055 for patents added annually with a one-year delay. |

| Patricia Nicole Ramos, Maryl Louise B. Enteria, Marvin I. Noroña | 2021 | Article | Readiness Model Development in the Adoption of Internet of Things (IoT) among Philippine Manufacturing PYMES Using Force Field Analysis Approach and Structural Equation Modelling | Quantitative, SEM and FFA | 250 | SCV W = 0.332, OI W = 0.303, PR W = 0.322, EM W = 0.508. |

| Danjuma Tali Nimfa, Md Uzir Hossain Uzir, Livinus Nkuri Maimako, Bilal Eneizan, Ahmad Shaharudin Abdul Latiff, Sazali Abdul Wahab | 2021 | Article | The Impact of Innovation Competitive Advantage on Product Quality for Sustainable Growth among PYMES: An Empirical Analysis | Quantitative: PLS-SEM with SmartPLS 3.0 | 245 | R2 (product quality) = 0.480, R2 (technology adoption) = 0.400. |

| Olaleye, Banji Rildwan; Ali-Momoh, Betty Oluwayemisi; Herzallah, Ahmad; Sibanda, Nomazwe; Ahmed, Aminat Favor | 2021 | Article | Dimensional Context of Total Quality Management Practices and Organizational Performance of PYMES in Nigeria: Evidence of the Mediating Role of Business Orientation | Quantitative research was employed using cross-sectional surveys, with the help of an adopted, designed and appropriately administered survey to collect related information from specific respondents. | 549 | The sizes of the effects (f2 = 0.02, 0.15 and 0.35). |

| Hariastuti, Ni Luh Putu; Pratikto; Santoso, Purnomo Budi; Tama, Ishardita Pambudi | 2021 | Article | Analysis of the drivers of sustainable value creation, partnership strategies and their impact on the business competitive advantages of small and medium-sized enterprises: a PLS model | Quantitative: the partial least squares (PLS) approach to structural equation modeling (SEM) is used to evaluate relationships and effects based on survey data from small- and medium-sized industries. | 120 | The effect of sustainable value creation on sustainable competitiveness is fully moderated by the partnership strategy (β = 0.179; ρ = 0.03), especially in technology, equipment and human resources. |

| Patricia Nicole Ramos, Maryl Louise B. Enteria, Marvin I. Noroña | 2021 | Article | Developing Internet of Things (IoT) Adoption Readiness Models Among Philippine Manufacturing PYMES Using a Force Field Analysis and Structural Equation Modeling Approach | Quantitative: using force field analysis and structural equation modeling (SEM). | 250 | Ease of management has a strong trade-off with readiness to adopt IoT (β: 0.508, p = 0.001). |

| Honggeng Zhou, Ling Li | 2020 | Article | The impact of supply chain practices and quality management on firm performance: Evidence from China’s small and medium manufacturing enterprises | Quantitative: multiple hierarchical regression analysis. | 138 | β (quality management ? market share performance) = 0.638; β (specific investment in suppliers ? market share performance) = 0.262; β (quality management ? innovation performance) = 0.492; β (specific investment in suppliers ? innovation performance) = 0.163. |

| Al-Hyari, Khalil | 2020 | Article | Lean Packages in Jordanian Manufacturing PYMES and Their Effect on Business Performance | Quantitative: this study uses the quantitative scientific approach based primarily on a structured survey questionnaire. | 278 | The evaluation coefficients for the investigated variables were reasonably high between (0.718) and (0.560). |

| Lucie Kaňovská | 2020 | Article | Are smart service manufacturing providers different in innovation cooperation and flexibility, in innovation performance and business performance from non-smart service manufacturing providers? | Quantitative: online surveys and regression analysis. | 112 | Not provided. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zúñiga-Santillán, X.; Tapia-Núñez, D.; Espinoza-Toalombo, R.; Romero-Cárdenas, E.; Carrasquero-Rodríguez, E. Meta-Analytical Analysis of Competitiveness in Small- and Medium-Sized Manufacturing Enterprises: The Role of Technology and Quality. Appl. Sci. 2025, 15, 4124. https://doi.org/10.3390/app15084124

Zúñiga-Santillán X, Tapia-Núñez D, Espinoza-Toalombo R, Romero-Cárdenas E, Carrasquero-Rodríguez E. Meta-Analytical Analysis of Competitiveness in Small- and Medium-Sized Manufacturing Enterprises: The Role of Technology and Quality. Applied Sciences. 2025; 15(8):4124. https://doi.org/10.3390/app15084124

Chicago/Turabian StyleZúñiga-Santillán, Xiomara, Diego Tapia-Núñez, Rosa Espinoza-Toalombo, Erika Romero-Cárdenas, and Edwuin Carrasquero-Rodríguez. 2025. "Meta-Analytical Analysis of Competitiveness in Small- and Medium-Sized Manufacturing Enterprises: The Role of Technology and Quality" Applied Sciences 15, no. 8: 4124. https://doi.org/10.3390/app15084124

APA StyleZúñiga-Santillán, X., Tapia-Núñez, D., Espinoza-Toalombo, R., Romero-Cárdenas, E., & Carrasquero-Rodríguez, E. (2025). Meta-Analytical Analysis of Competitiveness in Small- and Medium-Sized Manufacturing Enterprises: The Role of Technology and Quality. Applied Sciences, 15(8), 4124. https://doi.org/10.3390/app15084124