Research on the Influence of the Defects of Materials on Thermal Runaway in Microwave Hybrid Heating for Sintering Processes

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Non-Uniformity and Defects in Crude Sample

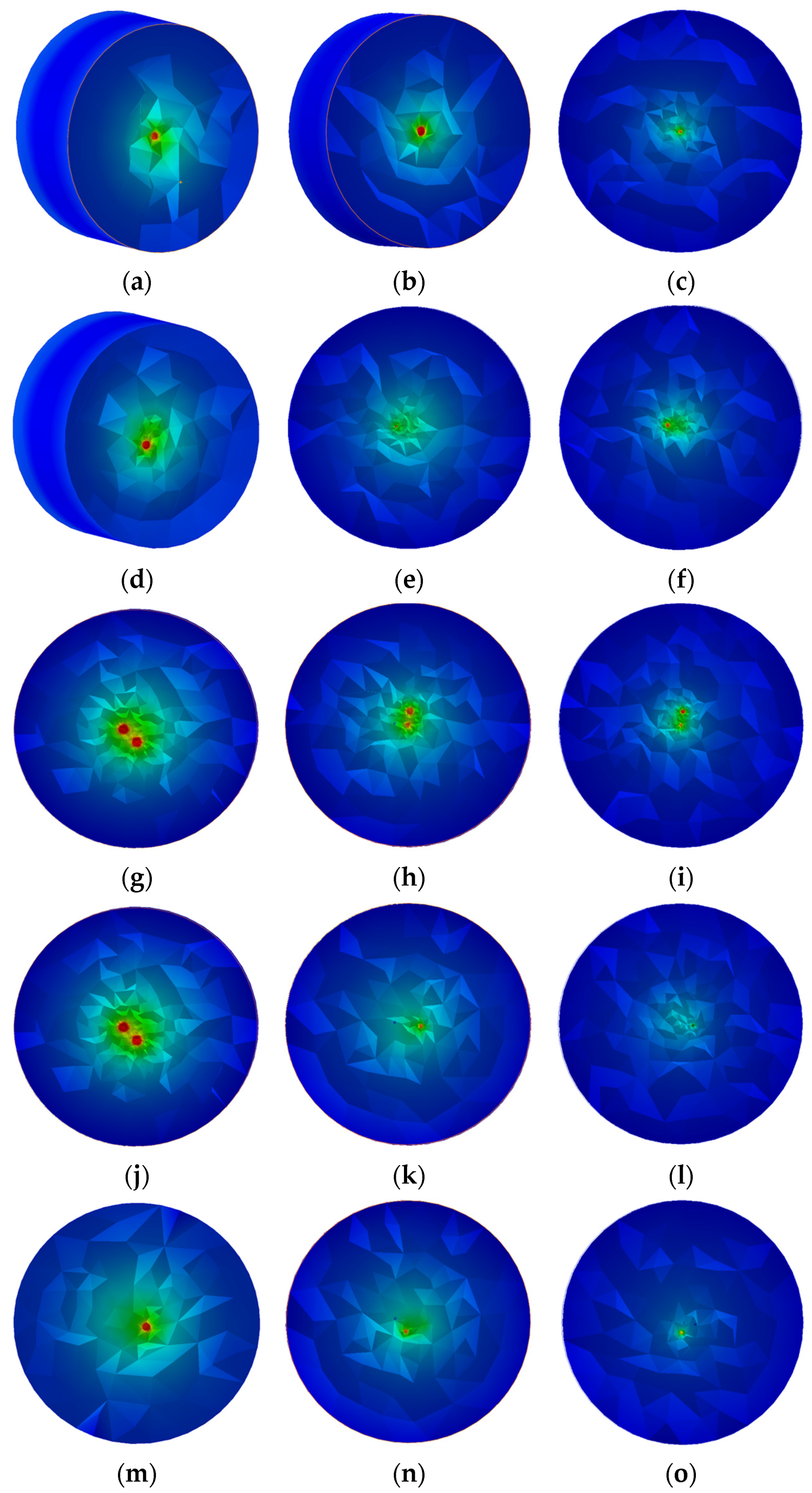

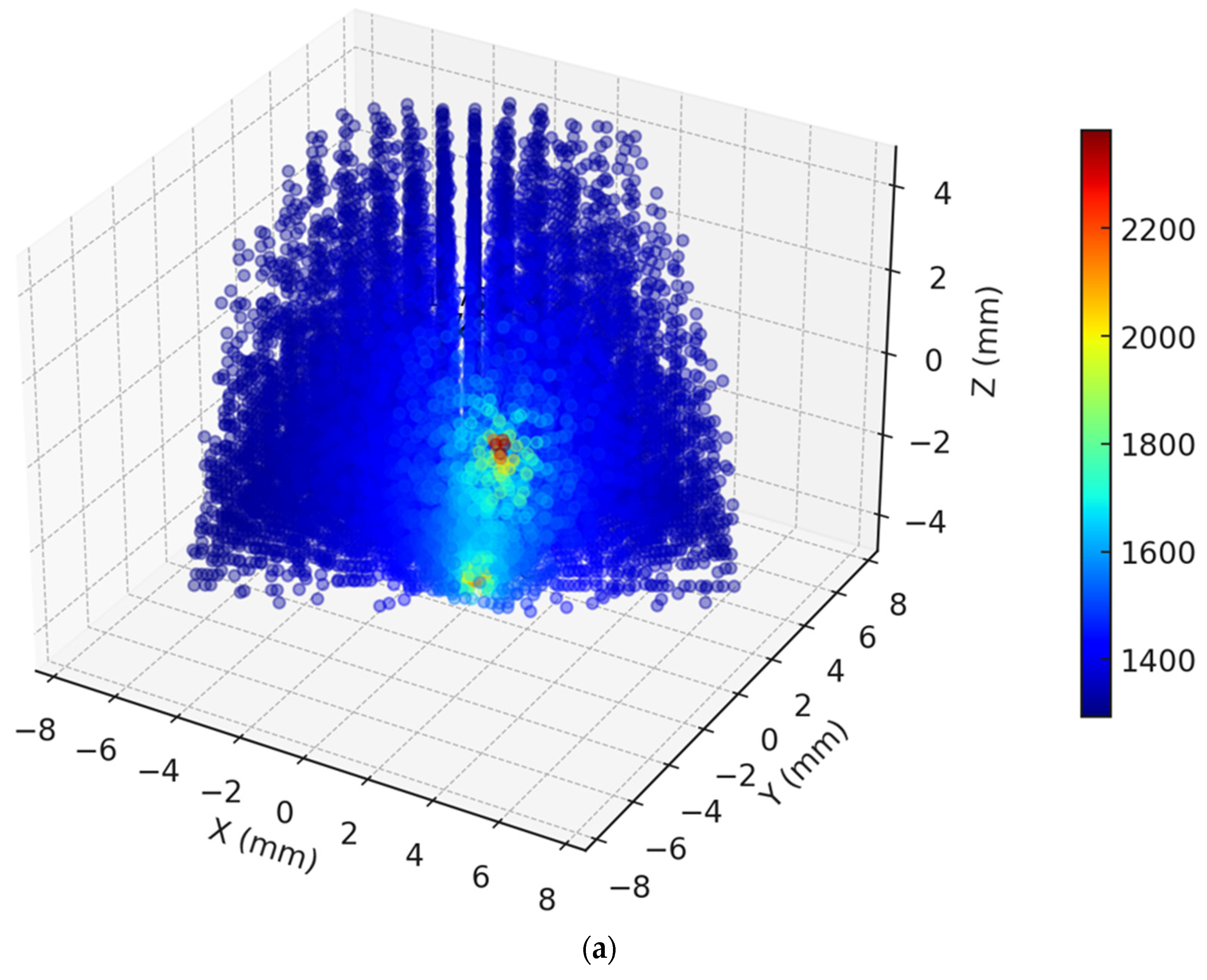

2.2. Simulation of the Temperature Distribution and the Local Overheating

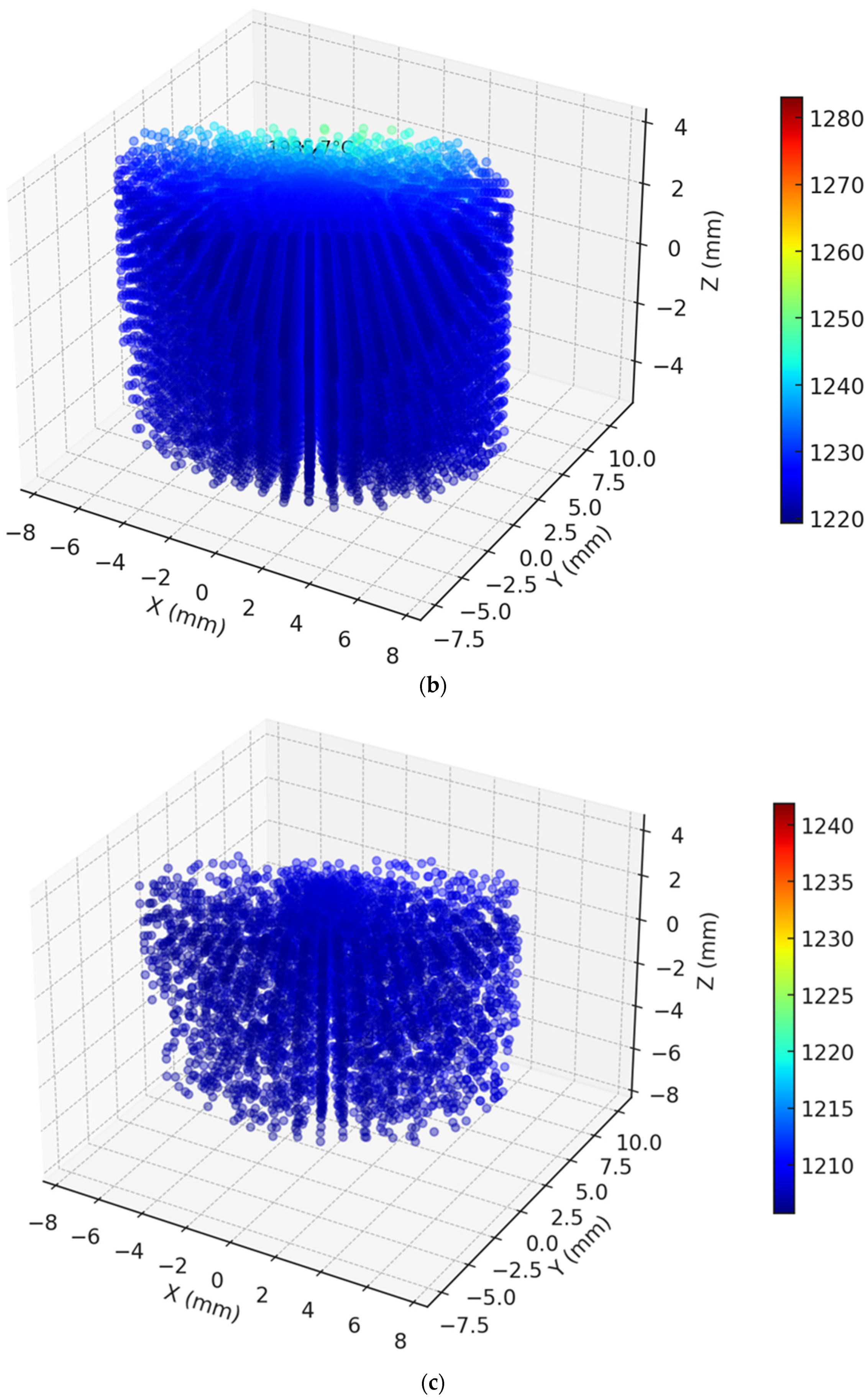

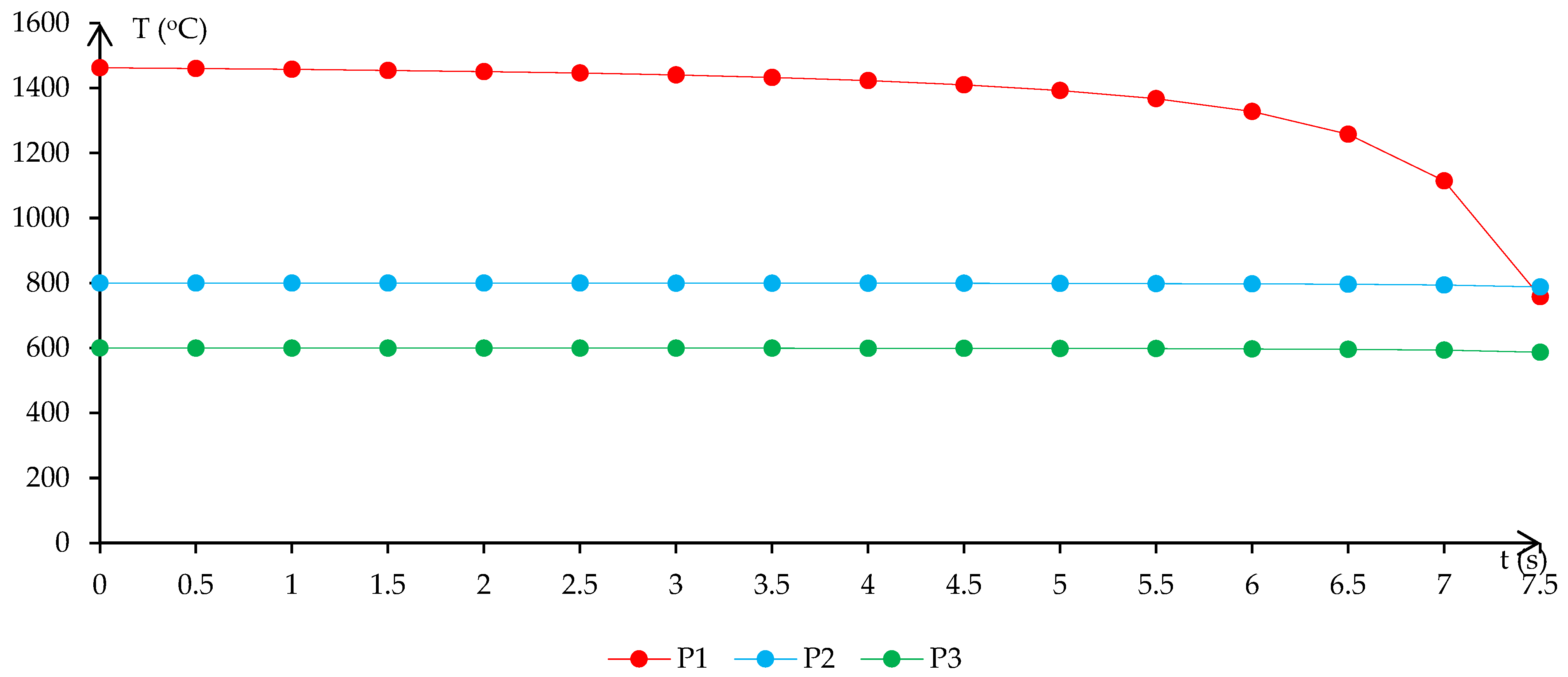

- Taking into consideration the irregular shape of the holes inside the samples, for the temperature distribution model, it is considered that holes can be approximated as spheres containing air.

- The holes in the Barium Ferrite W-type sample act as thermal concentration points where the temperature can be higher than the average values of the sample temperatures due to the reflection coefficient of microwaves and local absorption.

- The temperatures change in time and the distribution of absorbed power is uniform with a conversion rate of 60% of the microwave injected power.

- The thermal transfer in ceramic materials can be evaluated using the thermal diffusion equation presented in Equation (2) [21]:

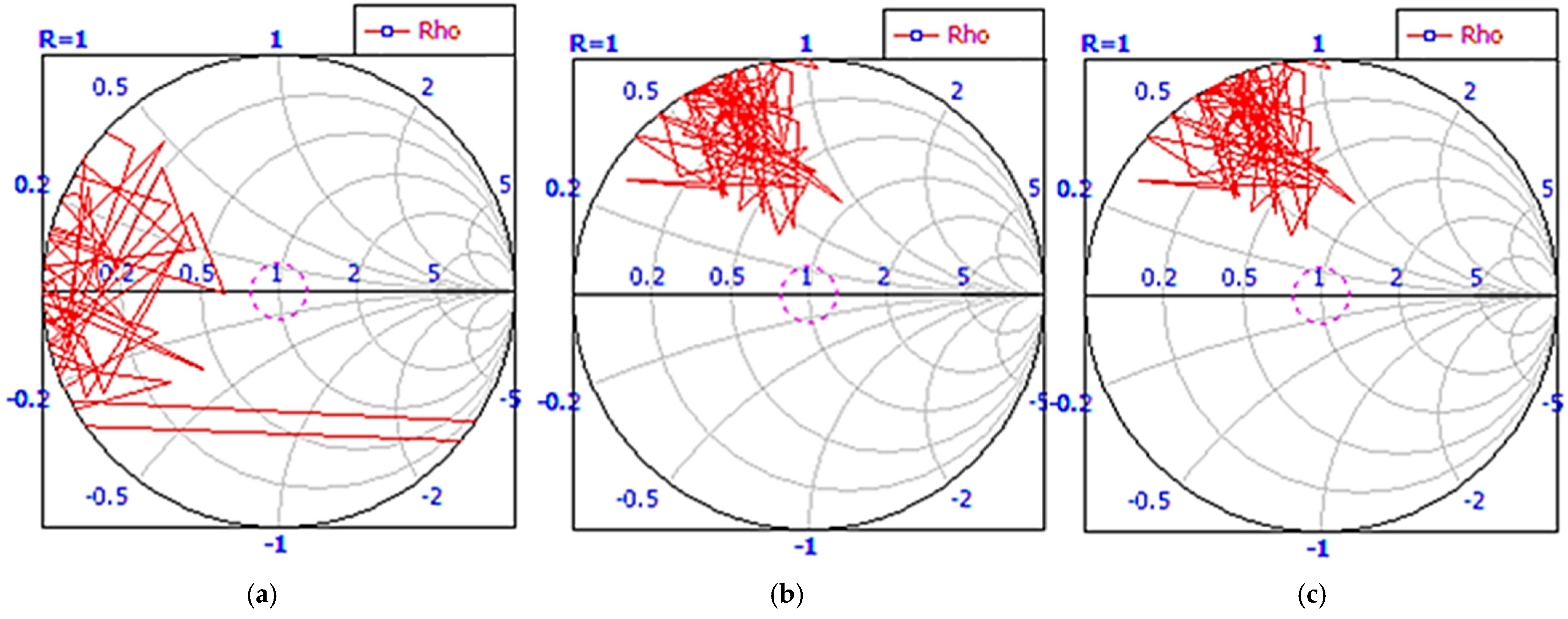

2.3. Modeling and Simulation of Thermal Runaway in MHH Process

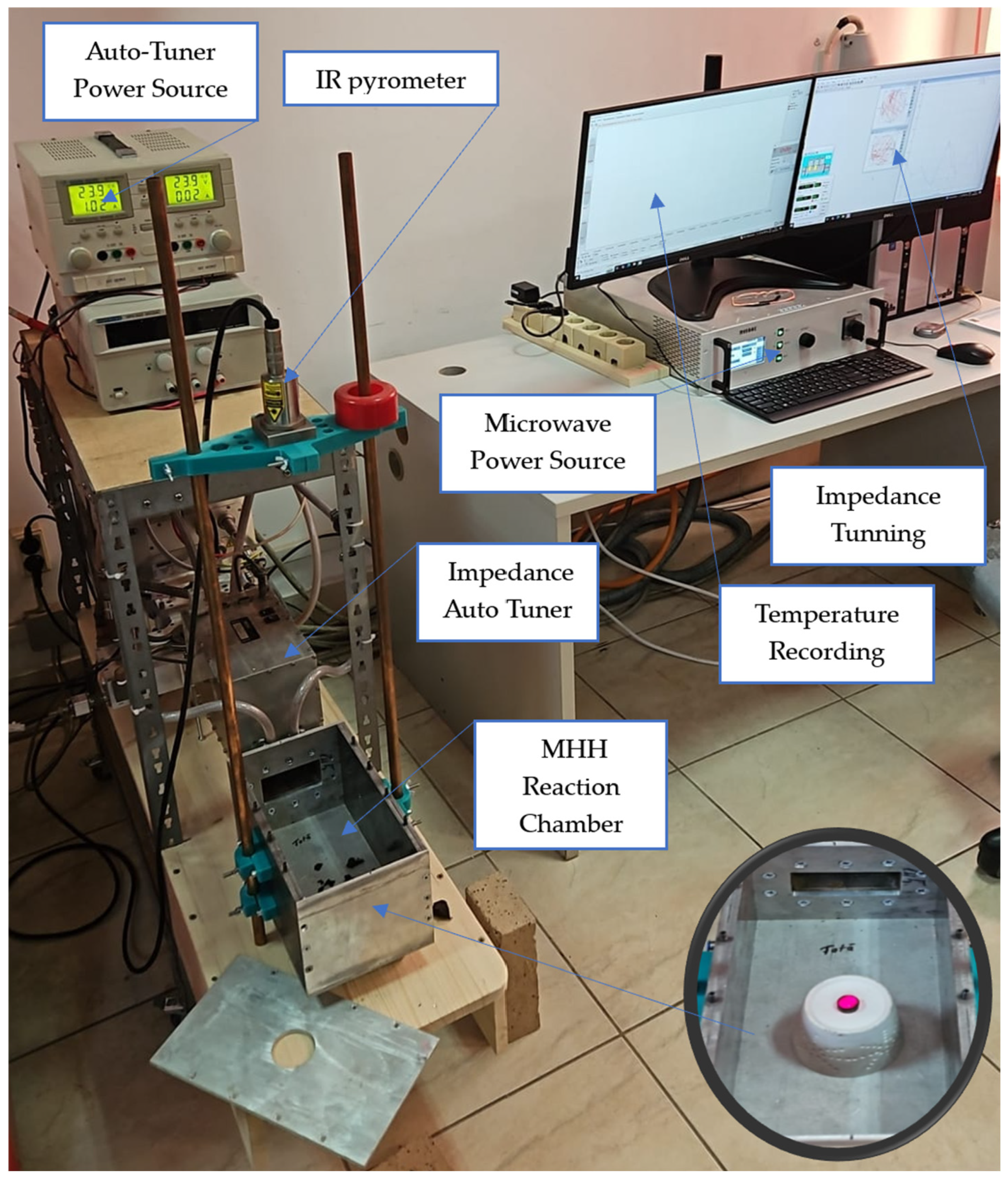

2.4. Experimental Processing of Barium Ferrite W-Type Samples Using MHH

3. Results and Discussion

4. Conclusions

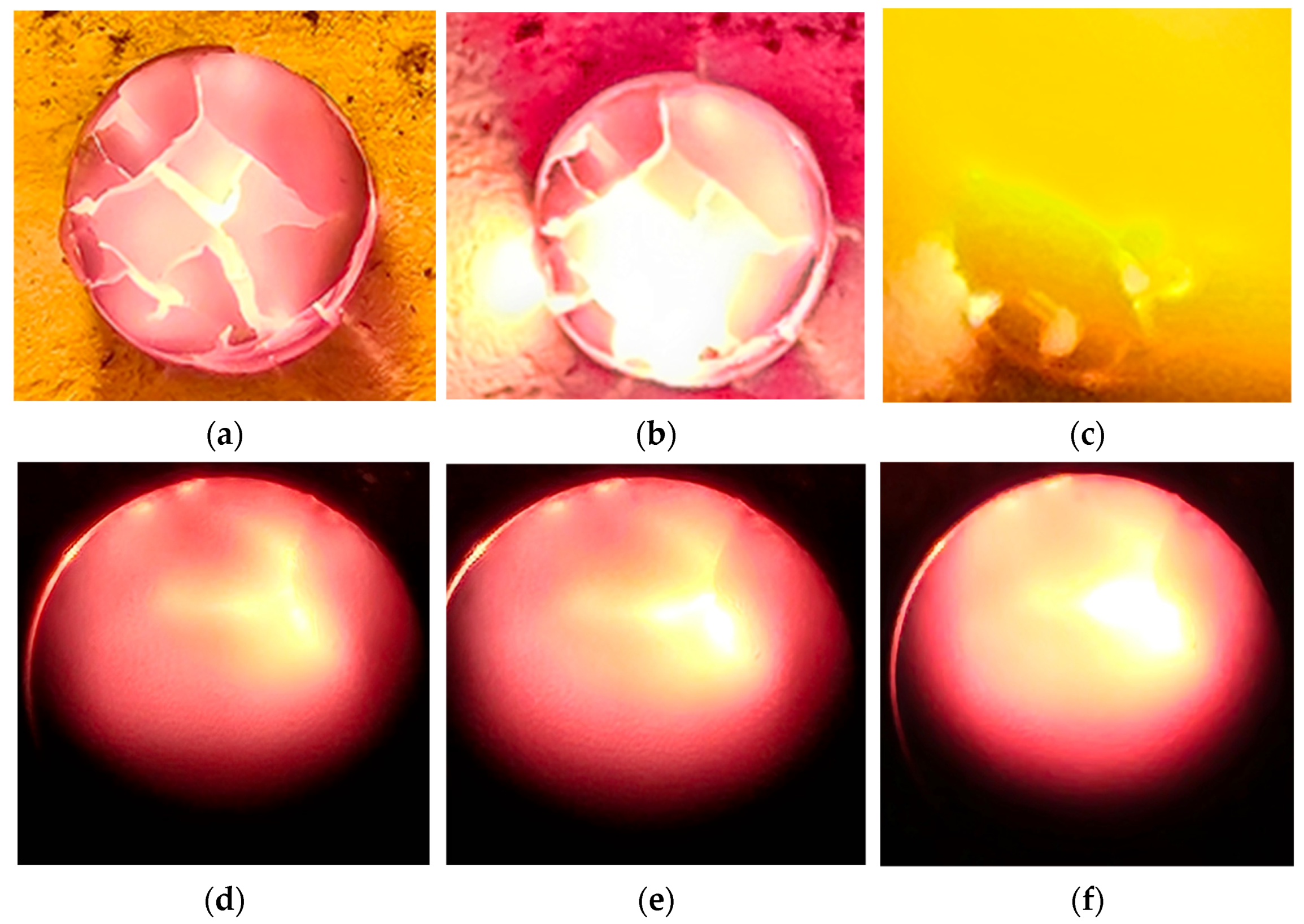

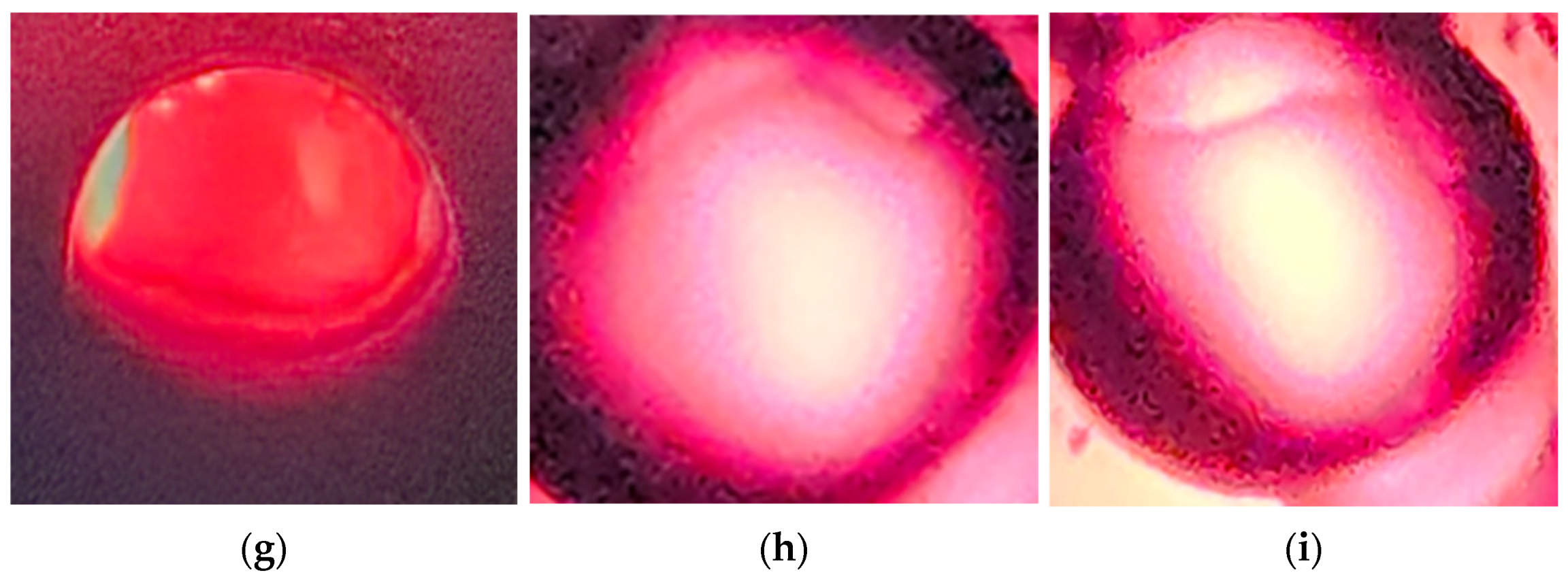

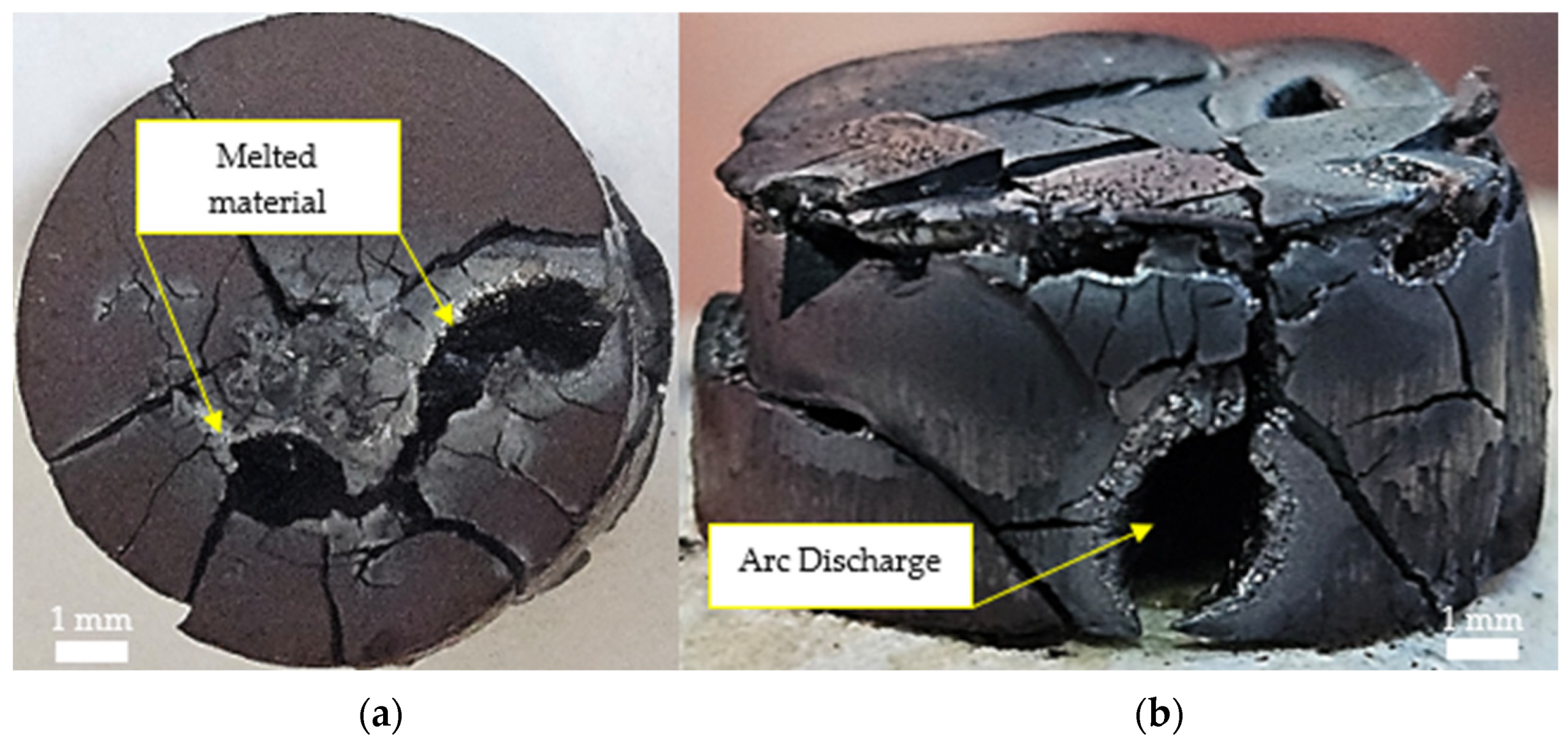

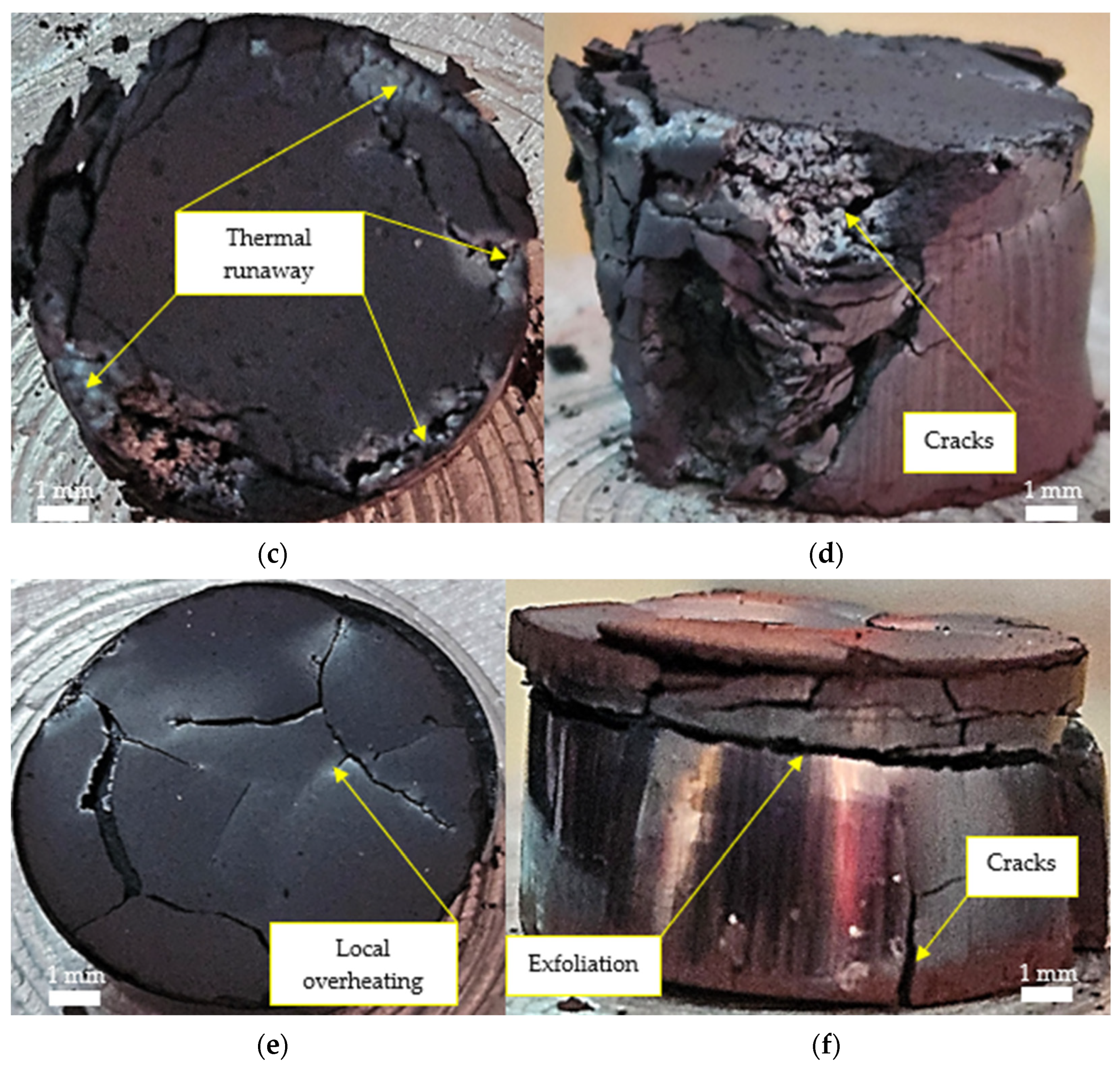

- Barium Ferrite W-type powders should be compacted at higher pressure forces in order to reduce the size of the defects in the materials.

- The MHH process can be suitable for microwave sintering if matching load impedance tuning is used. However, the level of microwave injected power should be decreased to below 300 W, taking into consideration the aggressivity of the thermal runaway phenomenon. In addition, the heating time should be increased in order to facilitate the uniform distribution of the temperature in samples by dissipating the heat from the local overheating near the defects.

- Local overheating leads to major cracks and arc discharge in the case of samples compacted at low pressure forces. It is recommended to cool the surface of the samples using compressed air in order to avoid the thermal runaway phenomenon and arc discharge.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ojo, O.O.; Olutomilola, E.O.; Oyerinde, A.Y.; Afolabi, A.F.; Abioye, T.E.; Oladele, A.Y.; Alaneme, K.K. Advancements in microwave welding: Susceptor-assisted microwave hybrid-heating technique for metals and polymers. Mater. Today Commun. 2025, 43, 111653. [Google Scholar] [CrossRef]

- Said, M.; Salleh, N.A.; Nazeri, M.F.M.; Akbulut, H.; Kheawhom, S.; Mohamad, A.A. Microwave hybrid heating for lead-free solder: A review. J. Mater. Res. Technol. 2023, 26, 6220–6243. [Google Scholar] [CrossRef]

- Zhang, S.; Qin, S.; Wan, W.; Li, J.; Liu, S.; Paik, K.-W.; He, P.; Zhang, S. Investigation on electromagnetic and heat transfer coupling of heating susceptor for selective microwave hybrid soldering: 3D multi-physics simulation and experiment. Appl. Therm. Eng. 2024, 225, 124047. [Google Scholar] [CrossRef]

- Zhang, S.; Qiu, Q.; Zeng, C.; Paik, K.W.; He, P.; Zhang, S. A review on heating mechanism, materials and heating parameters of microwave hybrid heated joining technique. J. Manuf. Process. 2024, 116, 176–191. [Google Scholar] [CrossRef]

- Savio, S.G.; Babu, D.A.; Ramakrishna, B.; Singh, S.; Vanitha, C. Influence of sintering process on microstructure and mechanical properties of alumina ceramics: Spark plasma and microwave hybrid sintering. Ceram. Int. 2024, 50, 11730–11742. [Google Scholar] [CrossRef]

- Mohapatra, P.P.; Singh, H.K.; Dobbidi, P. Advancements in electromagnetic microwave absorbers: Barium Ferrite W-types and carbonaceous materials. Adv. Colloid Interface Sci. 2025, 337, 103381. [Google Scholar] [CrossRef]

- Mudasar, M.; Xu, Z.H.; Lian, S.Y.; Li, X.; Wang, J.; Cheng, X. Featuring heterogeneous composite of W-type hexagonal Barium Ferrite W-type with 2D vanadium carbide MXene for wideband microwave absorption. J. Mater. Res. Technol. 2024, 28, 2699–2713. [Google Scholar] [CrossRef]

- Krikkis, R.N. Microwave heating of ceramic fibers. From multistability to thermal runaway. Int. J. Therm. Sci. 2025, 211, 109686. [Google Scholar] [CrossRef]

- Shen, L.; Zhou, J.; Zhang, X. In situ investigation of the thermal characteristics of microwave resonance-induced focused hotspots in dimers for improving microwave heating uniformity. Case Stud. Therm. Eng. 2024, 54, 104052. [Google Scholar] [CrossRef]

- Patel, D.K.; Mohanty, A.; Panigrahi, S.K. A sustainable waveguide-based design strategy for improving the energy efficiency of microwave hybrid heating systems: A combined theoretical and multi-physics simulation approach. Therm. Sci. Eng. Prog. 2024, 56, 103054. [Google Scholar] [CrossRef]

- Savu, I.D.; Savu, S.V.; Benga, G.C. Thermal Runaway of the BaCO3 + Fe2O3 homogenous mixture and mechanical alloys at the microwave heating. Adv. Mater. Res. 2014, 837, 185–189. [Google Scholar] [CrossRef]

- Wang, X.; Huang, F.; Du, J.; Su, H.; Li, Y.; Qu, M.; Tang, X. Low-temperature sintering and microwave dielectric properties of Ca2+ substituted Ba0.8-xCaxSr0.2CuSi2O6 ceramics. Ceram. Int. 2025; in press, corrected proof. [Google Scholar]

- Li, H.; Li, X.; Yang, J.; Liu, F.; Liu, S. Rapid preparation of MgTiO3–CaTiO3 microwave ceramics with high quality factor Q via microwave-assisted sintering. Ceram. Int. 2024, 22, 44928–44934. [Google Scholar] [CrossRef]

- Metaxas, A.C. Microwave heating. Power Eng. 1991, 5, 237–247. [Google Scholar] [CrossRef]

- Garcia-Baños, B.; Catalá-Civera, J.M.; Peñaranda-Foix, F.L.; Plaza-González, P.; Llorens-Vallés, G. In Situ Monitoring of Microwave Processing of Materials at High Temperatures through Dielectric Properties Measurement. Materials 2016, 9, 349. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.; Li, Y.; Li, L.; Su, X.; Hu, Y.; Xu, X. One-step synthesis and low-temperature rapid sintering of alumina-zirconia ceramics by flash sintering combined with phase transformation. Mater. Charact. 2024, 209, 113771. [Google Scholar] [CrossRef]

- Wang, C.; Lu, Y.; Ma, W.; Zhou, X.; Liu, J.; Xiao, J.; Guo, X.; Song, Y.; Ye, S.; Tran, N.M.A.; et al. Enhanced Mechanical Performance via Al2O3 Whisker Reinforcing and Microwave Sintering in 3Y-TZP Ceramics. Ceram. Int. 2025; in press, corrected proof. [Google Scholar]

- Chen, W.; Yin, Z.; Yuan, J. Microwave sintering of WC-HEA cemented carbide: Sintering process, microstructure and mechanical properties. Int. J. Refract. Met. Hard Mater. 2024, 123, 106789. [Google Scholar] [CrossRef]

- Yu, Y.; Cheng, D.; Dong, J.; Yao, Z.; Zhang, L.; Xu, Y.; Shen, Y.; Zhao, J.; Liu, H.; Shi, F.; et al. Crystal structures, lattice vibrational characteristics, and dielectric responses of ZnWO4 microwave dielectric ceramics sintered at different temperatures. Mater. Sci. Eng. B 2024, 309, 117647. [Google Scholar] [CrossRef]

- Mohamad, Y.S.; Yu, M.; Felder, M.; Meunier, V.; Litster, J.; Salman, A.D. Systematic study to improve the powder feeding performance and reducing the percentage of fines in roller compactor. Powder Technol. 2024, 446, 120158. [Google Scholar] [CrossRef]

- Bai, Q.; Liang, Z.; Liu, Y.; Lai, H.; Zhang, K. Heat transfer, crystallization and properties of Bayan Obo tailings-based nanocrystalline glass-ceramics processed with microwave radiation. Mater. Today Commun. 2024, 38, 108005. [Google Scholar] [CrossRef]

- Yang, J.; Liu, G.; Zheng, W. Study on hydrogen diffusion behavior during welding of heavy plate. Materials 2020, 13, 3887. [Google Scholar] [CrossRef]

- TokioBarium Ferrite W-Type Webpage. Sintered Magnet: Physical and Mechanical Property Table. Available online: https://tokyoferrite-ho.co.jp/en/product/sinter/sinter.html (accessed on 9 March 2025).

- Silva, K.B.M.S.; Araujo, C.J.; Delgado, J.M.P.Q.; Gomez, R.S.; Magalhaes, H.L.F.; Figueredo, M.J.; Figueiroa, J.A.; Brito, M.K.T.; Neto, J.N.O.; Pereira, A.B.C.; et al. Heat and Mass Transfer in Structural Ceramic Blocks: An Analytical and Phenomenological Approach. Energies 2022, 15, 7150. [Google Scholar] [CrossRef]

- MakeItfrom.com Webpage. Barium Ferrite W-Type. Available online: https://www.makeitfrom.com/material-properties/Ferrite (accessed on 8 March 2025).

| P1 (100 MPa) | P2 (200 MPa) | P3 (300 MPa) | |||

|---|---|---|---|---|---|

| Defect Size (μm) | Z-Axis (mm) | Defect Size (μm) | Z-Axis (mm) | Defect Size (μm) | Z-Axis (mm) |

| 420 | 1.390 | 488 | 10.050 | 170 | 19.016 |

| 489 | 2.165 | 137 | 11.830 | 188 | 19.620 |

| 515 | 5.266 | 376 | 13.090 | 194 | 20.365 |

| 503 | 5.170 | 197 | 15.099 | 110 | 21.496 |

| 443 | 7.790 | 198 | 17.797 | 154 | 22.889 |

| P1 (100 MPa) | P2 (200 MPa) | P3 (300 MPa) | |||

|---|---|---|---|---|---|

| dmax_H (μm) | kNU | dmax_H (μm) | kNU (mm) | dmax_H (μm) | kNU (mm) |

| 420 | 8.55 | 488 | 9.94 | 170 | 3.46 |

| 489 | 9.96 | 137 | 2.79 | 188 | 3.83 |

| 515 | 10.49 | 376 | 7.66 | 194 | 3.95 |

| 503 | 10.24 | 197 | 4.01 | 110 | 2.24 |

| 443 | 9.02 | 198 | 4.03 | 154 | 3.14 |

| P1 (100 MPa) | P2 (200 MPa) | P3 (300 MPa) | |||

|---|---|---|---|---|---|

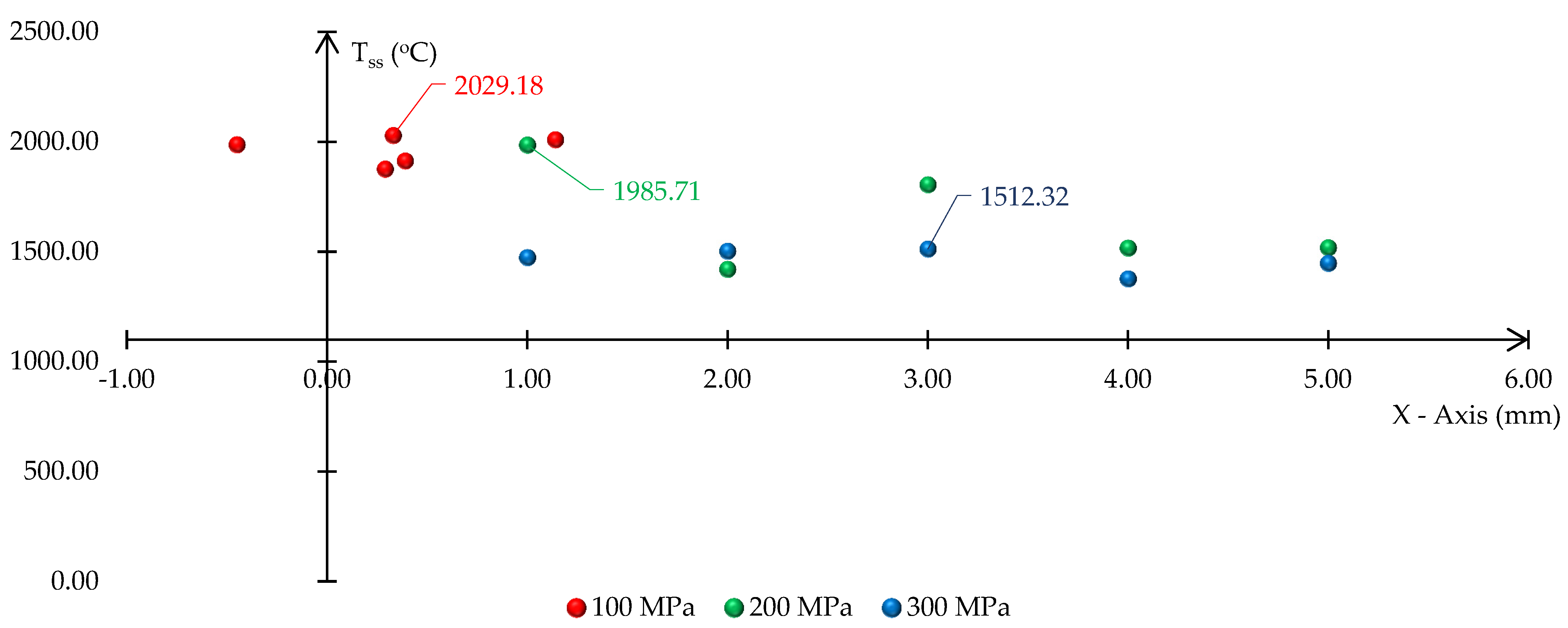

| dmax_H (μm) | Tmax (°C) | dmax_H (μm) | Tmax (°C) | dmax_H (μm) | Tmax (°C) |

| 420 | 1106 | 488 | 1212 | 170 | 1186 |

| 489 | 1210 | 137 | 1195 | 188 | 1121 |

| 515 | 1210 | 376 | 1201 | 194 | 1196 |

| 503 | 1211 | 197 | 1199 | 110 | 1160 |

| 443 | 1207 | 198 | 1200 | 154 | 1180 |

| Phenomenon | Local Overheating | Thermal Runaway | Arc Discharge | |||

|---|---|---|---|---|---|---|

| Sample | t (s) | Tss (°C) | t (s) | Tss (°C) | t (s) | Tss (°C) |

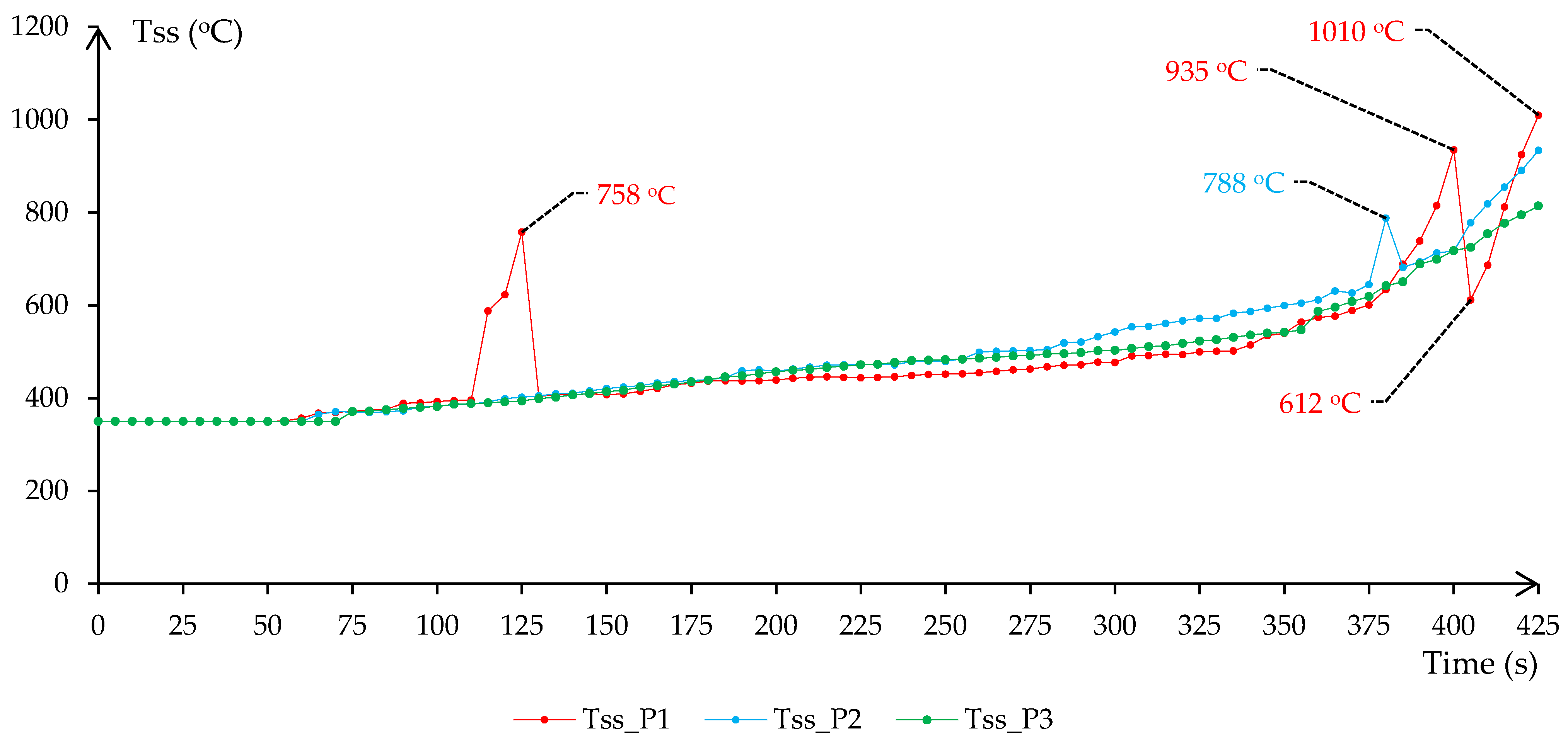

| P1 | 125 | 758 | 400 | 935 | 425 | 1010 |

| P2 | 260 | 486 | 380 | 788 | 425 | 934 |

| P3 | 360 | 587 | 390 | 689 | 425 | 816 |

| Sample | Densities (g/cm3) | |

|---|---|---|

| Before MHH | After MHH | |

| P1 | 2.26 | 2.99 |

| P2 | 2.97 | 3.76 |

| P3 | 3.09 | 4.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Savu, S.V.; Tarniță, D.; Stefan, I.; Benga, G.C.; Savu, I.D.; Sîrbu, N.-A.; Dumitru, I.; Ciungu, M.A.; Ursu, M.; Cosma, C. Research on the Influence of the Defects of Materials on Thermal Runaway in Microwave Hybrid Heating for Sintering Processes. Appl. Sci. 2025, 15, 4115. https://doi.org/10.3390/app15084115

Savu SV, Tarniță D, Stefan I, Benga GC, Savu ID, Sîrbu N-A, Dumitru I, Ciungu MA, Ursu M, Cosma C. Research on the Influence of the Defects of Materials on Thermal Runaway in Microwave Hybrid Heating for Sintering Processes. Applied Sciences. 2025; 15(8):4115. https://doi.org/10.3390/app15084115

Chicago/Turabian StyleSavu, Sorin Vasile, Daniela Tarniță, Iulian Stefan, Gabriel Constantin Benga, Ionel Danut Savu, Nicușor-Alin Sîrbu, Ilie Dumitru, Marin Andretti Ciungu, Mihai Ursu, and Cristian Cosma. 2025. "Research on the Influence of the Defects of Materials on Thermal Runaway in Microwave Hybrid Heating for Sintering Processes" Applied Sciences 15, no. 8: 4115. https://doi.org/10.3390/app15084115

APA StyleSavu, S. V., Tarniță, D., Stefan, I., Benga, G. C., Savu, I. D., Sîrbu, N.-A., Dumitru, I., Ciungu, M. A., Ursu, M., & Cosma, C. (2025). Research on the Influence of the Defects of Materials on Thermal Runaway in Microwave Hybrid Heating for Sintering Processes. Applied Sciences, 15(8), 4115. https://doi.org/10.3390/app15084115