Advances in Bio-Hydrogen Production: A Critical Review of Pyrolysis Gas Reforming

Abstract

1. Introduction

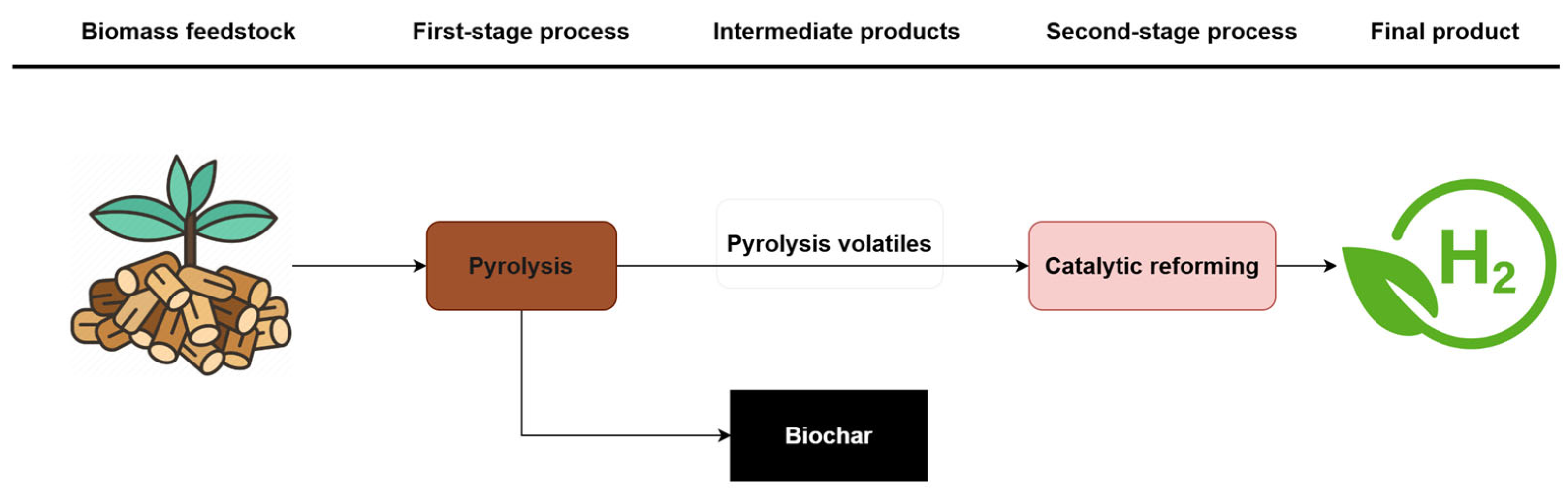

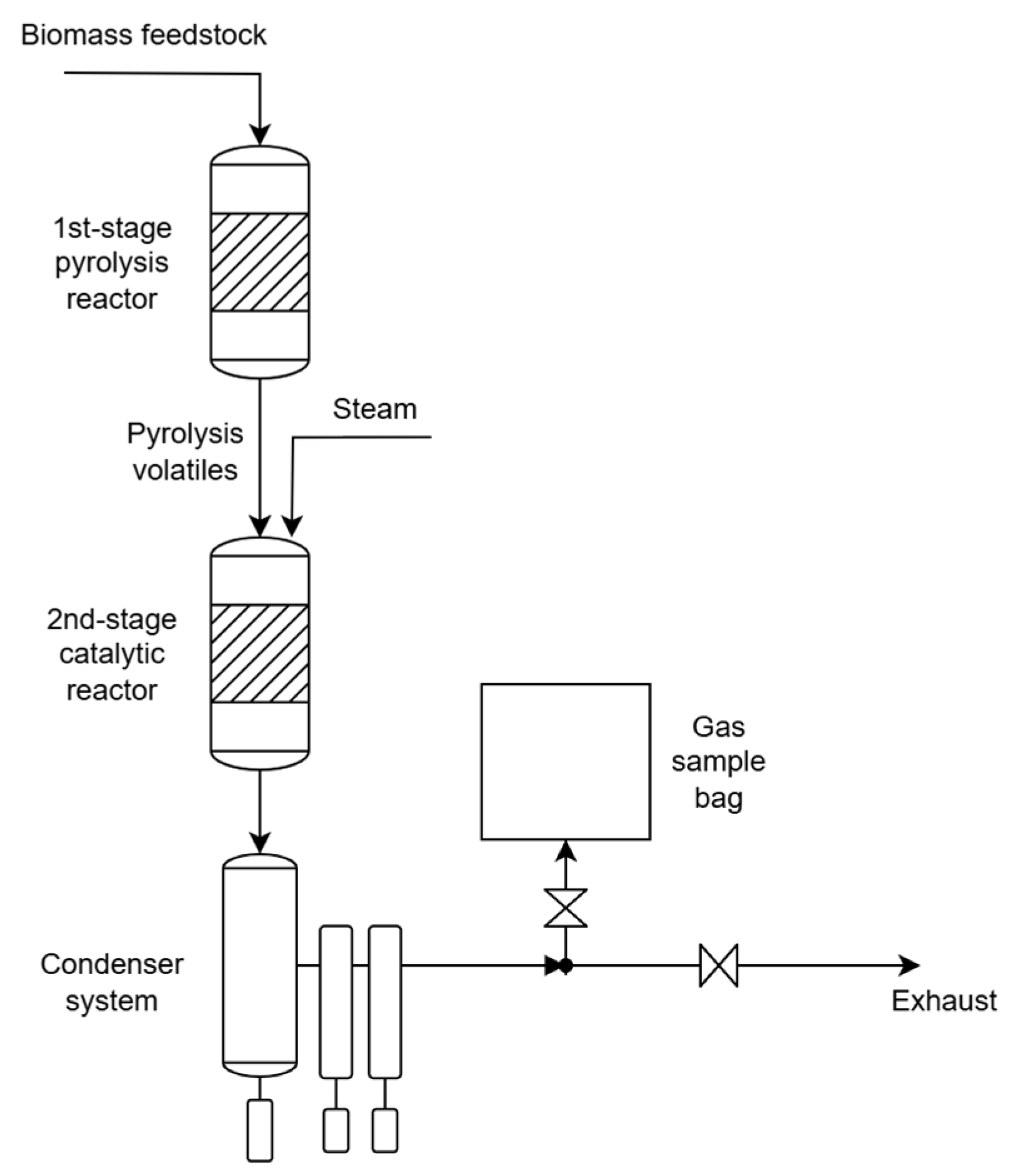

2. Hydrogen Production by Using Pyrolysis Process

3. Hydrogen Production by Catalytic Reforming of Pyrolysis Volatiles

3.1. Slow Pyrolysis

3.1.1. Pyrolysis Temperature

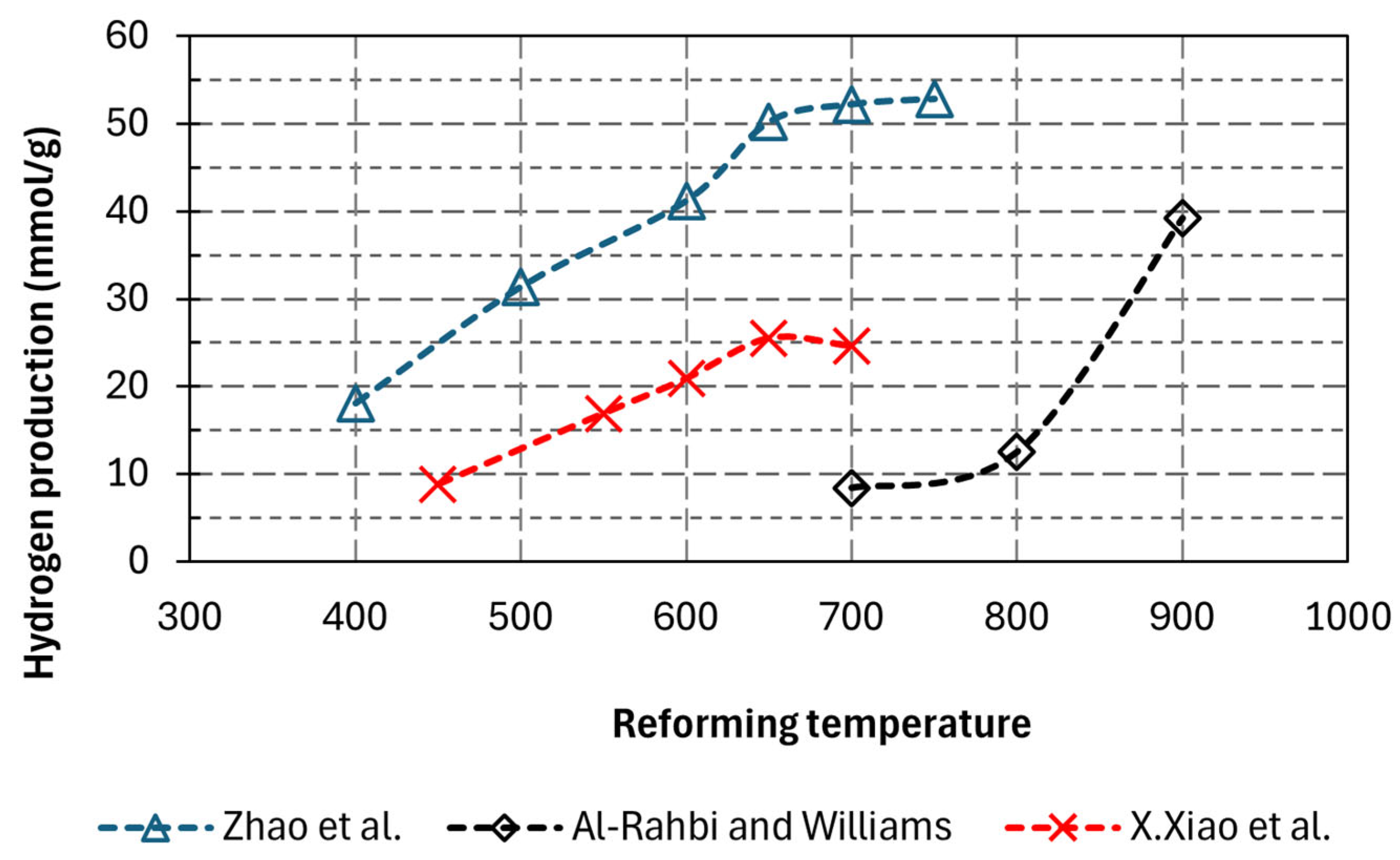

3.1.2. Reforming Temperature

3.1.3. Steam-to-Biomass Ratio

3.1.4. Space Velocity

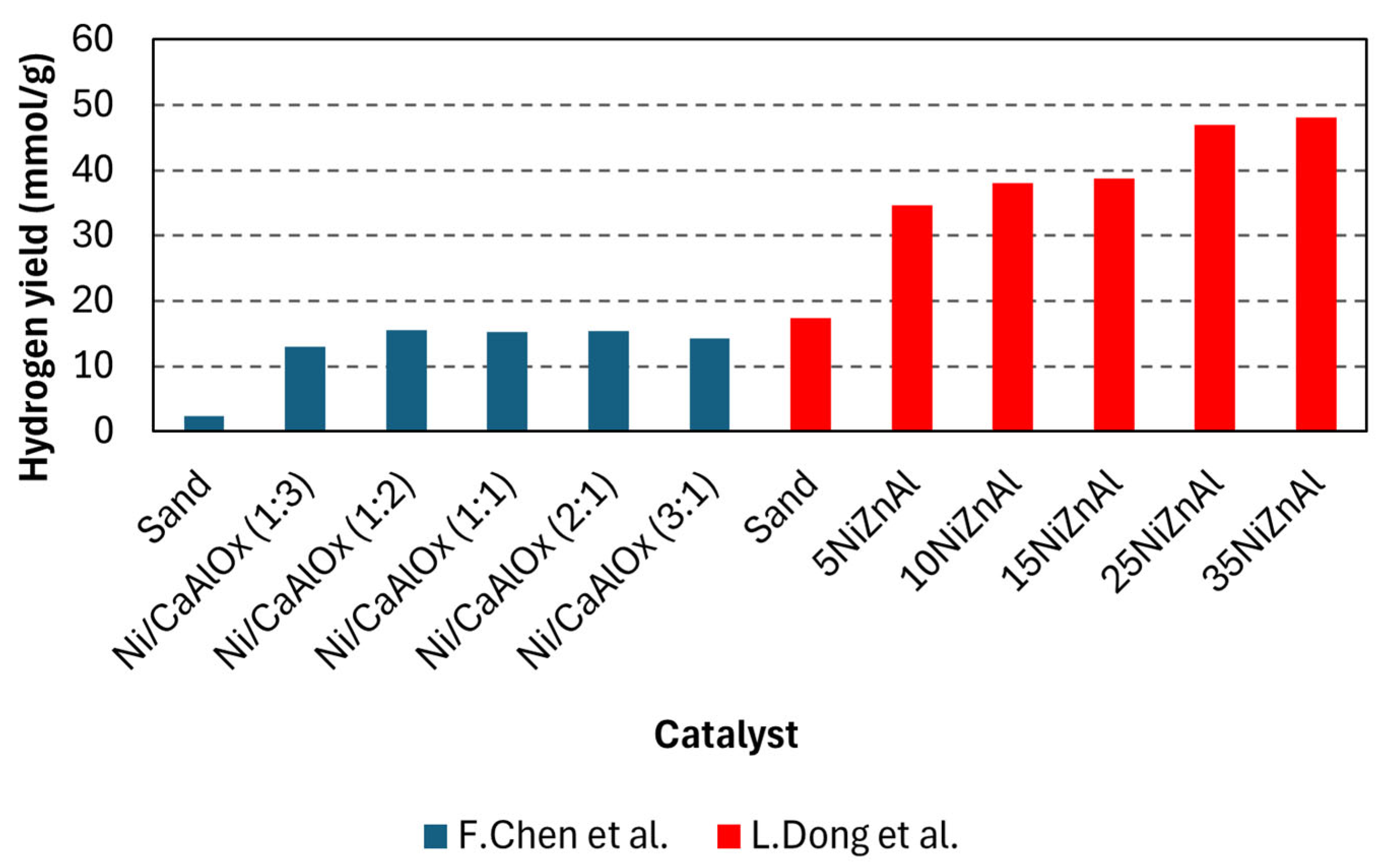

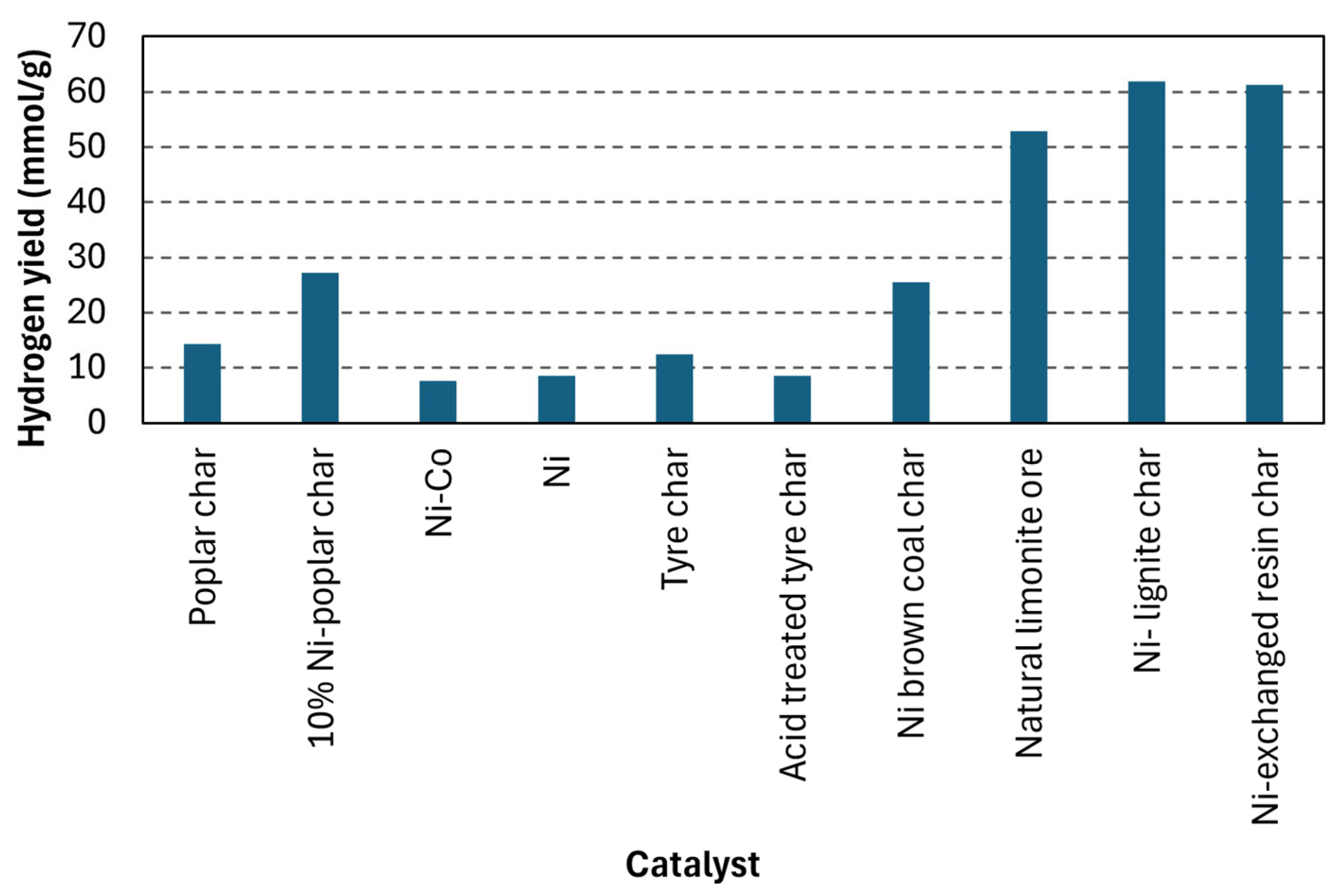

3.1.5. Catalyst Type

3.2. Intermediate and Fast Pyrolysis

4. Main Results

Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| GHG | Greenhouse gas |

| PEM | Polymer electrolyte membrane |

| SOE | Solid oxide electrolyzer |

| TRL | Technology readiness level |

| HTL | Hydrothermal liquefaction |

| S/B | Steam to biomass |

| RDF | Refuse-derived fuel |

References

- BP. Energy Outlook 2020 Edition. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/energy-outlook/bp-energy-outlook-2020.pdf (accessed on 15 December 2024).

- Share of Primary Energy Consumption from Fossil Fuels. 2023. Available online: https://ourworldindata.org/grapher/fossil-fuels-share-energy (accessed on 3 September 2024).

- Hassan, Q.; Viktor, P.; Al-Musawi, T.J.; Ali, B.M.; Algburi, S.; Alzoubi, H.M.; Al-Jiboory, A.K.; Sameen, A.Z.; Salman, H.M.; Jaszczur, M. The Renewable Energy Role in the Global Energy Transformations. Renew. Energy Focus 2024, 48, 100545. [Google Scholar] [CrossRef]

- Share of Primary Energy Consumption from Renewable Sources. 2023. Available online: https://ourworldindata.org/grapher/renewable-share-energy (accessed on 5 December 2024).

- Masson-Delmotte, V.; Zhai, P.; Pörtner, H.-O.; Roberts, D.; Skea, J.; Shukla, P.R.; Pirani, A.; Moufouma-Okia, W.; Péan, C.; Pidcock, R.; et al. Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C Above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty; Summary for Policymakers Edited by Science Officer Science Assistant Graphics Officer Working Group I Technical Support Unit; IPCC: Geneva, Switzerland, 2018. [Google Scholar]

- Dahiru, A.R.; Vuokila, A.; Huuhtanen, M. Recent Development in Power-to-X: Part I—A Review on Techno-Economic Analysis. J. Energy Storage 2022, 56, 105861. [Google Scholar] [CrossRef]

- Superchi, F.; Mati, A.; Carcasci, C.; Bianchini, A. Techno-Economic Analysis of Wind-Powered Green Hydrogen Production to Facilitate the Decarbonization of Hard-to-Abate Sectors: A Case Study on Steelmaking. Appl. Energy 2023, 342, 121198. [Google Scholar] [CrossRef]

- Hydrogen. Available online: https://www.irena.org/Energy-Transition/Technology/Hydrogen (accessed on 6 September 2024).

- da Silva Veras, T.; Mozer, T.S.; da Costa Rubim Messeder dos Santos, D.; da Silva César, A. Hydrogen: Trends, Production and Characterization of the Main Process Worldwide. Int. J. Hydrogen Energy 2017, 42, 2018–2033. [Google Scholar] [CrossRef]

- Global Hydrogen Review 2024—Analysis—IEA. Available online: https://www.iea.org/reports/global-hydrogen-review-2024 (accessed on 6 January 2025).

- Ursúa, A.; Gandía, L.M.; Sanchis, P. Hydrogen Production from Water Electrolysis: Current Status and Future Trends. Proc. IEEE 2012, 100, 410–426. [Google Scholar] [CrossRef]

- Gabriel, K.S.; El-Emam, R.S.; Zamfirescu, C. Technoeconomics of Large-Scale Clean Hydrogen Production—A Review. Int. J. Hydrogen Energy 2022, 47, 30788–30798. [Google Scholar] [CrossRef]

- Grigoriev, S.A.; Kuleshov, N.V.; Grigoriev, A.S.; Millet, P. Electrochemical Characterization of a High-Temperature Proton-Exchange Membrane Fuel Cell Using Doped-Poly Benzimidazole as Solid Polymer Electrolyte. J. Fuel Cell Sci. Technol. 2015, 12, 031004. [Google Scholar] [CrossRef]

- Sapountzi, F.M.; Gracia, J.M.; Fredriksson, H.O.; Niemantsverdriet, J.H. Electrocatalysts for the Generation of Hydrogen, Oxygen and Synthesis Gas. Prog. Energy Combust. Sci. 2017, 58, 1–35. [Google Scholar] [CrossRef]

- Carmo, M.; Fritz, D.L.; Mergel, J.; Stolten, D. A Comprehensive Review on PEM Water Electrolysis. Int. J. Hydrogen Energy 2013, 38, 4901–4934. [Google Scholar] [CrossRef]

- Ausfelder, F.; Bazzanella, A.M.; Wehrl, A. Roadmap Chemie 2050 Auf Dem Weg Zu Einer Treibhausgasneutralen Chemischen Industrie in Deutschland; FutureCamp Climate GmbH: Munich/Frankfurt, Germany, 2019; ISBN 9783897462236. [Google Scholar]

- Vidas, L.; Castro, R.; Cagno, E.; Soltani, M.; Pouresmaeil, E. Recent Developments on Hydrogen Production Technologies: State-of-the-Art Review with a Focus on Green-Electrolysis. Appl. Sci. 2021, 11, 11363. [Google Scholar] [CrossRef]

- Buffi, M.; Prussi, M.; Scarlat, N. Energy and Environmental Assessment of Hydrogen from Biomass Sources: Challenges and Perspectives. Biomass Bioenergy 2022, 165, 106556. [Google Scholar] [CrossRef]

- Li, G.; Yang, Y.; Yu, Q.; Ma, Q.; Lam, S.S.; Chen, X.; He, Y.; Ge, S.; Sonne, C.; Peng, W. Application of Nanotechnology in Hydrogen Production from Biomass: A Critical Review. Adv. Compos. Hybrid. Mater. 2024, 7, 17. [Google Scholar] [CrossRef]

- Sun, Y.; He, J.; Yang, G.; Sun, G.; Sage, V. A Review of the Enhancement of Bio-Hydrogen Generation by Chemicals Addition. Catalysts 2019, 9, 353. [Google Scholar] [CrossRef]

- Ni, M.; Leung, D.Y.C.; Leung, M.K.H.; Sumathy, K. An Overview of Hydrogen Production from Biomass. Fuel Process. Technol. 2006, 87, 461–472. [Google Scholar] [CrossRef]

- Gielen, D.; Boshell, F.; Saygin, D.; Bazilian, M.D.; Wagner, N.; Gorini, R. The Role of Renewable Energy in the Global Energy Transformation. Energy Strategy Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Aziz, M.; Darmawan, A.; Juangsa, F.B. Hydrogen Production from Biomasses and Wastes: A Technological Review. Int. J. Hydrogen Energy 2021, 46, 33756–33781. [Google Scholar] [CrossRef]

- Abdin, Z.; Zafaranloo, A.; Rafiee, A.; Mérida, W.; Lipiński, W.; Khalilpour, K.R. Hydrogen as an Energy Vector. Renew. Sustain. Energy Rev. 2020, 120, 109620. [Google Scholar] [CrossRef]

- Megia, P.J.; Vizcaino, A.J.; Calles, J.A.; Carrero, A. Hydrogen Production Technologies: From Fossil Fuels toward Renewable Sources. A Mini Review. Energy Fuels 2021, 35, 16403–16415. [Google Scholar] [CrossRef]

- Ong, H.C.; Chen, W.H.; Farooq, A.; Gan, Y.Y.; Lee, K.T.; Ashokkumar, V. Catalytic Thermochemical Conversion of Biomass for Biofuel Production: A Comprehensive Review. Renew. Sustain. Energy Rev. 2019, 113, 109266. [Google Scholar] [CrossRef]

- Zhang, Y.; Wan, L.; Guan, J.; Xiong, Q.; Zhang, S.; Jin, X. A Review on Biomass Gasification: Effect of Main Parameters on Char Generation and Reaction. Energy Fuels 2020, 34, 13438–13455. [Google Scholar] [CrossRef]

- Arregi, A.; Amutio, M.; Lopez, G.; Bilbao, J.; Olazar, M. Evaluation of Thermochemical Routes for Hydrogen Production from Biomass: A Review. Energy Convers. Manag. 2018, 165, 696–719. [Google Scholar] [CrossRef]

- Luo, S.; Xiao, B.; Guo, X.; Hu, Z.; Liu, S.; He, M. Hydrogen-Rich Gas from Catalytic Steam Gasification of Biomass in a Fixed Bed Reactor: Influence of Particle Size on Gasification Performance. Int. J. Hydrogen Energy 2009, 34, 1260–1264. [Google Scholar] [CrossRef]

- Fremaux, S.; Beheshti, S.M.; Ghassemi, H.; Shahsavan-Markadeh, R. An Experimental Study on Hydrogen-Rich Gas Production via Steam Gasification of Biomass in a Research-Scale Fluidized Bed. Energy Convers. Manag. 2015, 91, 427–432. [Google Scholar] [CrossRef]

- Zhang, Z.; Pang, S. Experimental Investigation of Biomass Devolatilization in Steam Gasification in a Dual Fluidised Bed Gasifier. Fuel 2017, 188, 628–635. [Google Scholar] [CrossRef]

- Liu, Q.; Zhong, Z.; Wang, S.; Luo, Z. Interactions of Biomass Components during Pyrolysis: A TG-FTIR Study. J. Anal. Appl. Pyrolysis 2011, 90, 213–218. [Google Scholar] [CrossRef]

- Akubo, K.; Nahil, M.A.; Williams, P.T. Pyrolysis-Catalytic Steam Reforming of Agricultural Biomass Wastes and Biomass Components for Production of Hydrogen/Syngas. J. Energy Inst. 2019, 92, 1987–1996. [Google Scholar] [CrossRef]

- Dhyani, V.; Bhaskar, T. A Comprehensive Review on the Pyrolysis of Lignocellulosic Biomass. Renew. Energy 2018, 129, 695–716. [Google Scholar] [CrossRef]

- Zhang, H.; Gao, Z.; Ao, W.; Li, J.; Liu, G.; Fu, J.; Ran, C.; Mao, X.; Kang, Q.; Liu, Y.; et al. Microwave-Assisted Pyrolysis of Textile Dyeing Sludge Using Different Additives. J. Anal. Appl. Pyrolysis 2017, 127, 140–149. [Google Scholar] [CrossRef]

- Chiaramonti, D.; Lotti, G.; Vaccari, F.P.; Sanei, H. Assessment of Long-Lived Carbon Permanence in Agricultural Soil: Unearthing 15 Years-Old Biochar from Long-Term Field Experiment in Vineyard. Biomass Bioenergy 2024, 191, 107484. [Google Scholar] [CrossRef]

- Demirbaş, A. Biomass Resource Facilities and Biomass Conversion Processing for Fuels and Chemicals. Energy Convers. Manag. 2001, 42, 1357–1378. [Google Scholar] [CrossRef]

- Phan, A.N.; Ryu, C.; Sharifi, V.N.; Swithenbank, J. Characterisation of Slow Pyrolysis Products from Segregated Wastes for Energy Production. J. Anal. Appl. Pyrolysis 2008, 81, 65–71. [Google Scholar] [CrossRef]

- Tinwala, F.; Mohanty, P.; Parmar, S.; Patel, A.; Pant, K.K. Intermediate Pyrolysis of Agro-Industrial Biomasses in Bench-Scale Pyrolyser: Product Yields and Its Characterization. Bioresour. Technol. 2015, 188, 258–264. [Google Scholar] [CrossRef] [PubMed]

- Bartocci, P.; D’Amico, M.; Moriconi, N.; Bidini, G.; Fantozzi, F. Pyrolysis of Olive Stone for Energy Purposes. Energy Procedia 2015, 82, 374–380. [Google Scholar] [CrossRef]

- Soni, B.; Karmee, S.K. Towards a Continuous Pilot Scale Pyrolysis Based Biorefinery for Production of Bio oil and Biochar from Sawdust. Fuel 2020, 271, 117570. [Google Scholar] [CrossRef]

- Dai, X.; Wu, C.; Li, H.; Chen, Y. The Fast Pyrolysis of Biomass in CFB Reactor. Energy Fuels 2000, 14, 552–557. [Google Scholar] [CrossRef]

- Nikolaidis, P.; Poullikkas, A. A Comparative Overview of Hydrogen Production Processes. Renew. Sustain. Energy Rev. 2017, 67, 597–611. [Google Scholar] [CrossRef]

- Bade, S.O.; Tomomewo, O.S.; Meenakshisundaram, A.; Ferron, P.; Oni, B.A. Economic, Social, and Regulatory Challenges of Green Hydrogen Production and Utilization in the US: A Review. Int. J. Hydrogen Energy 2024, 49, 314–335. [Google Scholar] [CrossRef]

- Younas, M.; Shafique, S.; Hafeez, A.; Javed, F.; Rehman, F. An Overview of Hydrogen Production: Current Status, Potential, and Challenges. Fuel 2022, 316, 123317. [Google Scholar] [CrossRef]

- Shah, J.; Valaki, J. Characterization of Bio-Oil, Bio-Char, and Pyro-Gas Derived from Cotton Stalk Slow Pyrolysis—As Sustainable Energy Sources. Indian J. Chem. Technol. 2022, 29, 380–389. Available online: http://blog.niscair.res.in/html/index.php/IJCT/article/view/60904 (accessed on 21 November 2024).

- Gheorghe, C.; Dinu, R.; Marculescu, C.; Badea, A.; Apostol, T. Two-Phase Pyrolysis Modelling Of Wooden Waste. WIT Trans. Ecol. Environ. 2008, 109, 31–38. [Google Scholar] [CrossRef]

- Sakhiya, A.K.; Anand, A.; Aier, I.; Vijay, V.K.; Kaushal, P. Suitability of Rice Straw for Biochar Production through Slow Pyrolysis: Product Characterization and Thermodynamic Analysis. Bioresour. Technol. Rep. 2021, 15, 100818. [Google Scholar] [CrossRef]

- Varma, A.K.; Thakur, L.S.; Shankar, R.; Mondal, P. Pyrolysis of Wood Sawdust: Effects of Process Parameters on Products Yield and Characterization of Products. Waste Manag. 2019, 89, 224–235. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Andries, J.; Spliethoff, H. Catalytic Pyrolysis of Biomass for Hydrogen Rich Fuel Gas Production. Energy Convers. Manag. 2003, 44, 2289–2296. [Google Scholar] [CrossRef]

- Alam, M.; Sarkar, I.; Chanda, N.; Ghosh, S.; Loha, C. Enhancing Syngas Production and Hydrogen Content in Syngas from Catalytic Slow Pyrolysis of Biomass in a Pilot Scale Fixed Bed Reactor. Biomass Convers. Biorefin 2025, 15, 6237–6249. [Google Scholar] [CrossRef]

- Al Arni, S. Comparison of Slow and Fast Pyrolysis for Converting Biomass into Fuel. Renew. Energy 2018, 124, 197–201. [Google Scholar] [CrossRef]

- Guizani, C.; Valin, S.; Billaud, J.; Peyrot, M.; Salvador, S. Biomass Fast Pyrolysis in a Drop Tube Reactor for Bio Oil Production: Experiments and Modeling. Fuel 2017, 207, 71–84. [Google Scholar] [CrossRef]

- Safdari, M.S.; Rahmati, M.; Amini, E.; Howarth, J.E.; Berryhill, J.P.; Dietenberger, M.; Weise, D.R.; Fletcher, T.H. Characterization of Pyrolysis Products from Fast Pyrolysis of Live and Dead Vegetation Native to the Southern United States. Fuel 2018, 229, 151–166. [Google Scholar] [CrossRef]

- Abou Rjeily, M.; Chaghouri, M.; Gennequin, C.; Abi Aad, E.; Randrianalisoa, J.H. Investigating Co-Production of Syngas, Biochar, and Bio-Oil from Flax Shives Biomass by Pyrolysis and in-Line Catalytic Hybrid Reforming. Biomass Convers. Biorefinery 2023, 14, 25599–25625. [Google Scholar] [CrossRef]

- Park, Y.; Namioka, T.; Sakamoto, S.; Min, T.J.; Roh, S.A.; Yoshikawa, K. Optimum Operating Conditions for a Two-Stage Gasification Process Fueled by Polypropylene by Means of Continuous Reactor over Ruthenium Catalyst. Fuel Process. Technol. 2010, 91, 951–957. [Google Scholar] [CrossRef]

- Wu, C.; Williams, P.T. Pyrolysis–Gasification of Plastics, Mixed Plastics and Real-World Plastic Waste with and without Ni–Mg–Al Catalyst. Fuel 2010, 89, 3022–3032. [Google Scholar] [CrossRef]

- Barbarias, I.; Lopez, G.; Artetxe, M.; Arregi, A.; Santamaria, L.; Bilbao, J.; Olazar, M. Pyrolysis and In-Line Catalytic Steam Reforming of Polystyrene through a Two-Step Reaction System. J. Anal. Appl. Pyrolysis 2016, 122, 502–510. [Google Scholar] [CrossRef]

- Barbarias, I.; Lopez, G.; Alvarez, J.; Artetxe, M.; Arregi, A.; Bilbao, J.; Olazar, M. A Sequential Process for Hydrogen Production Based on Continuous HDPE Fast Pyrolysis and In-Line Steam Reforming. Chem. Eng. J. 2016, 296, 191–198. [Google Scholar] [CrossRef]

- Pietraszek, A.; Koubaissy, B.; Roger, A.C.; Kiennemann, A. The Influence of the Support Modification over Ni-Based Catalysts for Dry Reforming of Methane Reaction. Catal. Today 2011, 176, 267–271. [Google Scholar] [CrossRef]

- Al-Rahbi, A.S.; Williams, P.T. Waste Ashes as Catalysts for the Pyrolysis–Catalytic Steam Reforming of Biomass for Hydrogen-Rich Gas Production. J. Mater. Cycles Waste Manag. 2019, 21, 1224–1231. [Google Scholar] [CrossRef]

- Jaffar, M.M.; Nahil, M.A.; Williams, P.T. Synthetic Natural Gas Production from the Three Stage (i) Pyrolysis (Ii) Catalytic Steam Reforming (Iii) Catalytic Hydrogenation of Waste Biomass. Fuel Process. Technol. 2020, 208, 106515. [Google Scholar] [CrossRef]

- Waheed, Q.M.K.; Williams, P.T. Hydrogen Production from High Temperature Pyrolysis/Steam Reforming of Waste Biomass: Rice Husk, Sugar Cane Bagasse, and Wheat Straw. Energy Fuels 2013, 27, 6695–6704. [Google Scholar] [CrossRef]

- Chen, F.; Wu, C.; Dong, L.; Vassallo, A.; Williams, P.T.; Huang, J. Characteristics and Catalytic Properties of Ni/CaAlOx Catalyst for Hydrogen-Enriched Syngas Production from Pyrolysis-Steam Reforming of Biomass Sawdust. Appl. Catal. B 2016, 183, 168–175. [Google Scholar] [CrossRef]

- Chen, F.; Wu, C.; Dong, L.; Jin, F.; Williams, P.T.; Huang, J. Catalytic Steam Reforming of Volatiles Released via Pyrolysis of Wood Sawdust for Hydrogen-Rich Gas Production on Fe–Zn/Al2O3 Nanocatalysts. Fuel 2015, 158, 999–1005. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, L.; Zhang, T.; Wang, Q. Hydrogen-Rich Syngas Production from Biomass Pyrolysis and Catalytic Reforming Using Biochar-Based Catalysts. Fuel 2022, 313, 123006. [Google Scholar] [CrossRef]

- Olaleye, A.K.; Adedayo, K.J.; Wu, C.; Nahil, M.A.; Wang, M.; Williams, P.T. Experimental Study, Dynamic Modelling, Validation and Analysis of Hydrogen Production from Biomass Pyrolysis/Gasification of Biomass in a Two-Stage Fixed Bed Reaction System. Fuel 2014, 137, 364–374. [Google Scholar] [CrossRef]

- Dong, L.; Wu, C.; Ling, H.; Shi, J.; Williams, P.T.; Huang, J. Promoting Hydrogen Production and Minimizing Catalyst Deactivation from the Pyrolysis-Catalytic Steam Reforming of Biomass on Nanosized NiZnAlOx Catalysts. Fuel 2017, 188, 610–620. [Google Scholar] [CrossRef]

- Jin, F.; Sun, H.; Wu, C.; Ling, H.; Jiang, Y.; Williams, P.T.; Huang, J. Effect of Calcium Addition on Mg-AlOx Supported Ni Catalysts for Hydrogen Production from Pyrolysis-Gasification of Biomass. Catal. Today 2018, 309, 2–10. [Google Scholar] [CrossRef]

- Al-Rahbi, A.S.; Williams, P.T. Hydrogen-Rich Syngas Production and Tar Removal from Biomass Gasification Using Sacrificial Tyre Pyrolysis Char. Appl. Energy 2017, 190, 501–509. [Google Scholar] [CrossRef]

- Abou Rjeily, M.; Chaghouri, M.; Gennequin, C.; Abi Aad, E.; Pron, H.; Randrianalisoa, J.H. Biomass Pyrolysis Followed by Catalytic Hybrid Reforming for Syngas Production. Waste Biomass Valorization 2023, 14, 2715–2743. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Ren, J.; Cao, J.P.; Wei, F.; Zhu, C.; Fan, X.; Zhao, Y.P.; Wei, X.Y. Catalytic Reforming of Volatiles from Biomass Pyrolysis for Hydrogen-Rich Gas Production over Limonite Ore. Energy Fuels 2017, 31, 4054–4060. [Google Scholar] [CrossRef]

- Xiao, X.; Cao, J.; Meng, X.; Le, D.D.; Li, L.; Ogawa, Y.; Sato, K.; Takarada, T. Synthesis Gas Production from Catalytic Gasification of Waste Biomass Using Nickel-Loaded Brown Coal Char. Fuel 2013, 103, 135–140. [Google Scholar] [CrossRef]

- García, L.; Salvador, M.L.; Arauzo, J.; Bilbao, R. Catalytic Steam Gasification of Pine Sawdust. Effect of Catalyst Weight/Biomass Flow Rate and Steam/Biomass Ratios on Gas Production and Composition. Energy Fuels 1999, 13, 851–859. [Google Scholar] [CrossRef]

- Cao, J.P.; Shi, P.; Zhao, X.Y.; Wei, X.Y.; Takarada, T. Catalytic Reforming of Volatiles and Nitrogen Compounds from Sewage Sludge Pyrolysis to Clean Hydrogen and Synthetic Gas over a Nickel Catalyst. Fuel Process. Technol. 2014, 123, 34–40. [Google Scholar] [CrossRef]

- Wang, B.S.; Cao, J.P.; Zhao, X.Y.; Bian, Y.; Song, C.; Zhao, Y.P.; Fan, X.; Wei, X.Y.; Takarada, T. Preparation of Nickel-Loaded on Lignite Char for Catalytic Gasification of Biomass. Fuel Process. Technol. 2015, 136, 17–24. [Google Scholar] [CrossRef]

- Cao, J.P.; Liu, T.L.; Ren, J.; Zhao, X.Y.; Wu, Y.; Wang, J.X.; Ren, X.Y.; Wei, X.Y. Preparation and Characterization of Nickel Loaded on Resin Char as Tar Reforming Catalyst for Biomass Gasification. J. Anal. Appl. Pyrolysis 2017, 127, 82–90. [Google Scholar] [CrossRef]

- Azhar Uddin, M.; Tsuda, H.; Wu, S.; Sasaoka, E. Catalytic Decomposition of Biomass Tars with Iron Oxide Catalysts. Fuel 2008, 87, 451–459. [Google Scholar] [CrossRef]

- Efika, C.E.; Wu, C.; Williams, P.T. Syngas Production from Pyrolysis–Catalytic Steam Reforming of Waste Biomass in a Continuous Screw Kiln Reactor. J. Anal. Appl. Pyrolysis 2012, 95, 87–94. [Google Scholar] [CrossRef]

- Koike, M.; Ishikawa, C.; Li, D.; Wang, L.; Nakagawa, Y.; Tomishige, K. Catalytic Performance of Manganese-Promoted Nickel Catalysts for the Steam Reforming of Tar from Biomass Pyrolysis to Synthesis Gas. Fuel 2013, 103, 122–129. [Google Scholar] [CrossRef]

- Yang, H.; Nurdiawati, A.; Gond, R.; Chen, S.; Wang, S.; Tang, B.; Jin, Y.; Zaini, I.N.; Shi, Z.; Wang, W.; et al. Carbon-Negative Valorization of Biomass Waste into Affordable Green Hydrogen and Battery Anodes. Int. J. Hydrogen Energy 2024, 49, 459–471. [Google Scholar] [CrossRef]

- Zaini, I.N.; Sophonrat, N.; Sjöblom, K.; Yang, W. Creating Values from Biomass Pyrolysis in Sweden: Co-Production of H2, Biocarbon and Bio-Oil. Processes 2021, 9, 415. [Google Scholar] [CrossRef]

- Arregi, A.; Lopez, G.; Amutio, M.; Barbarias, I.; Bilbao, J.; Olazar, M. Hydrogen Production from Biomass by Continuous Fast Pyrolysis and In-Line Steam Reforming. RSC Adv. 2016, 6, 25975–25985. [Google Scholar] [CrossRef]

- Arregi, A.; Santamaria, L.; Lopez, G.; Olazar, M.; Bilbao, J.; Artetxe, M.; Amutio, M. Appraisal of Agroforestry Biomass Wastes for Hydrogen Production by an Integrated Process of Fast Pyrolysis and in Line Steam Reforming. J. Environ. Manage 2023, 347, 119071. [Google Scholar] [CrossRef]

- Soria, J.; Li, R.; Flamant, G.; Mazza, G.D. Influence of Pellet Size on Product Yields and Syngas Composition during Solar-Driven High Temperature Fast Pyrolysis of Biomass. J. Anal. Appl. Pyrolysis 2019, 140, 299–311. [Google Scholar] [CrossRef]

- Pattanotai, T.; Watanabe, H.; Okazaki, K. Experimental Investigation of Intraparticle Secondary Reactions of Tar during Wood Pyrolysis. Fuel 2013, 104, 468–475. [Google Scholar] [CrossRef]

- Weldekidan, H.; Strezov, V.; Town, G.; Kan, T. Production and Analysis of Fuels and Chemicals Obtained from Rice Husk Pyrolysis with Concentrated Solar Radiation. Fuel 2018, 233, 396–403. [Google Scholar] [CrossRef]

- Mohammed, I.Y.; Abakr, Y.A.; Musa, M.; Yusup, S.; Singh, A.; Kazi, F.K. Valorization of Bambara Groundnut Shell via Intermediate Pyrolysis: Products Distribution and Characterization. J. Clean. Prod. 2016, 139, 717–728. [Google Scholar] [CrossRef]

- Mahmood, A.S.N.; Brammer, J.G.; Hornung, A.; Steele, A.; Poulston, S. The Intermediate Pyrolysis and Catalytic Steam Reforming of Brewers Spent Grain. J. Anal. Appl. Pyrolysis 2013, 103, 328–342. [Google Scholar] [CrossRef]

- Wang, X.; Kersten, S.R.A.; Prins, W.; Van Swaaij, W.P.M. Biomass Pyrolysis in a Fluidized Bed Reactor. Part 2: Experimental Validation of Model Results. Ind. Eng. Chem. Res. 2005, 44, 8786–8795. [Google Scholar] [CrossRef]

- Fernandez-Akarregi, A.R.; Makibar, J.; Lopez, G.; Amutio, M.; Olazar, M. Design and Operation of a Conical Spouted Bed Reactor Pilot Plant (25 Kg/h) for Biomass Fast Pyrolysis. Fuel Process. Technol. 2013, 112, 48–56. [Google Scholar] [CrossRef]

- Duanguppama, K.; Suwapaet, N.; Pattiya, A. Fast Pyrolysis of Contaminated Sawdust in a Circulating Fluidised Bed Reactor. J. Anal. Appl. Pyrolysis 2016, 118, 63–74. [Google Scholar] [CrossRef]

- Maliutina, K.; Tahmasebi, A.; Yu, J.; Saltykov, S.N. Comparative Study on Flash Pyrolysis Characteristics of Microalgal and Lignocellulosic Biomass in Entrained-Flow Reactor. Energy Convers. Manag. 2017, 151, 426–438. [Google Scholar] [CrossRef]

| Pyrolysis Process Type (Temperature) | Feedstock | H2 (vol%) | CO (vol%) | CO2 (vol%) | CH4 (vol%) | C2+ (vol%) | N2 (Vol%) | O2 (vol%) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Slow (650) | Waste wood | 7 | 30.5 | 44.7 | 14.7 | 3.1 | [38] | ||

| Cardboard | 13.4 | 36.6 | 32.4 | 15.3 | 2.3 | ||||

| Textile | 5.4 | 34.7 | 35.6 | 19.2 | 5.1 | ||||

| Slow (500) | Neem seed | 6.89 ± 1 | 0.46 ± 0.3 | 7.16 ± 1 | 15.87 ± 2 | 18.46 ± 2 | [39] | ||

| Pigeon pea | 4.66 ± 1 | 1.60 ± 1 | 8.93 ± 1 | 21.57 ± 2 | 14.58 ± 1 | ||||

| Yellow pea | 0.15± 0.1 | 1.30 ± 1 | 11.23 ± 1 | 24.77 ± 2 | 15.56 ± 2 | ||||

| Ground nut shell | 5.02 ± 1 | 10.16 ± 1 | 6.97 ± 1 | 13.21 ± 1 | 10.93 ± 1 | ||||

| Channa straw cicer | 4.36 ± 1 | 14.02 ± 1 | 6.94± 1 | 19.93 ± 2 | 10.58 ± 1 | ||||

| Soyabean Straw Glycine | 8.29 ± 1 | 13.85 ± 1 | 7.80± 1 | 18.53 ± 2 | 10.60 ± 1 | ||||

| Wheat straw | 7.05 ± 1 | 7.51 ± 1 | 5.62 ± 1 | 18.70 ± 2 | 13.38 ± 1 | ||||

| Sawdust | 7.11 ± 1 | 6.26 ± 1 | 4.93± 0.5 | 22.25 ± 2 | 15.40 ± 2 | ||||

| Slow (600) | Olive stone | 29.47 | 31.48 | 14.1 | 20.5 | 3.65 | 0.8 | [40] | |

| Fast (550) | Sawdust | 4.54 | 34.49 | 16.8 | 4.41 | 35.55 | 4.25 | [41] | |

| Fast (550) | Woody biomass | 7.01 | 24.13 | 36.35 | 4.41 | 28.1 | [42] |

| Process | Advantages | Disadvantages | Efficiency (%) |

|---|---|---|---|

| Steam methane reforming | Mature technology, low production cost | GHG emissions, fossil fuel resource depletion | 74–85 |

| Partial oxidation | Proven technology | GHG emissions, fossil fuel resource depletion | 60–75 |

| Electrolysis | Mature technology, no emissions, cheap and available feedstock, O2 byproduct | Low overall efficiency, high capital cost, corrosion challenges | 40–60 |

| Biomass pyrolysis | Cheap feedstock, CO2-neutral | Tar formation, seasonal availability of and impurities in feedstock | 35–50 |

| Biomass gasification | Cheap feedstock, CO2-neutral | Tar formation, seasonal availability of and impurities in feedstock | 35 |

| Reaction | Description |

|---|---|

| Biomass pyrolysis | |

| Catalytic tar cracking | |

| Tar steam reforming | |

| Hydrocarbon volatile steam reforming | |

| Tar dry reforming | |

| Hydrocarbon volatile dry reforming | |

| Water gas shift | |

| Char steam gasification | |

| Char CO2 gasification |

| Feedstock | Catalyst | H2 Yield (mmol/g) | Ref. |

|---|---|---|---|

| Corncob | Ni/Al2O3 | 51 | [72] |

| Sewage sludge | Ni/Al2O3 | 53 | [75] |

| Wood sawdust | Ni/Al2O3 | 11.01 | [67] |

| Corncob | Ni/Al2O3 | 21.2 | [76] |

| Rice husk | Ni–dolomite | 23.71 | [63] |

| Sugar cane | 21.18 | ||

| Wheat straw | 21.59 | ||

| Corncob | Ni–exchanged resin char | 25 | [77] |

| Poplar wood | Poplar char | 14.4 | [66] |

| Catalpa wood | Catalpa char | 17.1 | |

| Elm wood | Elm char | 15.7 | |

| Pine wood | Pine char | 14.4 | |

| Poplar wood | 5% Ni/poplar char | 21.4 | |

| Poplar wood | 10% Ni/poplar char | 27.2 | |

| Poplar wood | 15% Ni/poplar char | 18.9 | |

| Corncob | Natural limonite ore | 50.2 | [72] |

| Feedstock | Pyrolysis Temperature °C (Heating Rate °C/min) | Scale | Total Gas Yield (wt.%) | H2 Yield (vol%) | Ref. |

|---|---|---|---|---|---|

| Slow pyrolysis | |||||

| Pine | 1600 (50) | Lab scale | 55 | 41.7 | [85] |

| Cypress wood | 600 (30) | Lab scale | 11 | 14.4 | [86] |

| Sugar cane bagasse | 480 (20) | Lab scale | 25 | 9.6 | [52] |

| 780 (20) | 36 | 28.8 | |||

| Waste wood | 500 (30) | Lab scale | 63 | 40.6 | [47] |

| 550 (30) | 63.4 | 47.8 | |||

| 600 (30) | 65.6 | 52.5 | |||

| 650 (30) | 67.8 | 54.2 | |||

| 700 (30) | 71.3 | 53.6 | |||

| 750 (30) | 74.3 | 53.4 | |||

| 800 (30) | 76.5 | 52.5 | |||

| Rice husk | 800 (2) | Lab scale | 25.5 | 8.6 | [87] |

| Olive stone | 600 | Lab scale | 44.17 | 29.47 | [40] |

| Intermediate pyrolysis | |||||

| Agricultural residue | 500 (50) | Lab scale | 32 | 2.5 | [88] |

| Brewers spent grain | 450 (100) | Lab scale | 21 | 1.6 | [89] |

| Fast pyrolysis | |||||

| Sugar cane bagasse | 480 (120) | Lab scale | 14.12 | 8.7 | [52] |

| 580 (120) | 15.46 | 15.2 | |||

| 680 (120) | 17.94 | 45.3 | |||

| Beach wood | 350 (1000) | Lab scale | 10 | 0.9 | [90] |

| 400 (1000) | 18.4 | 1.4 | |||

| 450 (1000) | 10.1 | 0.8 | |||

| 500 (1000) | 17.7 | 2.3 | |||

| 550 (1000) | 20.5 | 3.4 | |||

| 800 (1000) | 56.9 | 13.8 | |||

| Pine | 550 (1000) | 17.9 | 6.9 | ||

| Bamboo | 500 (1000) | 19.1 | 1.5 | ||

| Pine wood | 440 (N.A) | Pilot scale | 61.5 | 4.2 | [91] |

| 460 (N.A) | 62.6 | 4.9 | |||

| 480 (N.A) | 65.9 | 6.1 | |||

| 510 (N.A) | 64 | 7 | |||

| 525 (N.A) | 63.4 | 9.1 | |||

| 565 (N.A) | 61.5 | 15.1 | |||

| Sawdust | 400 (N.A) | Lab scale | 23.7 | 10 | [92] |

| 450 (N.A) | 22.1 | 20 | |||

| 500 (N.A) | 15.2 | 24 | |||

| 550 (N.A) | 22.7 | 21 | |||

| 600 (N.A) | 26.7 | 19 | |||

| Flash pyrolysis | |||||

| Palm kernel shell | 600 (N.A) | Lab scale | 5 | 18.5 | [93] |

| 900 (N.A) | Lab scale | 32 | 26.6 | ||

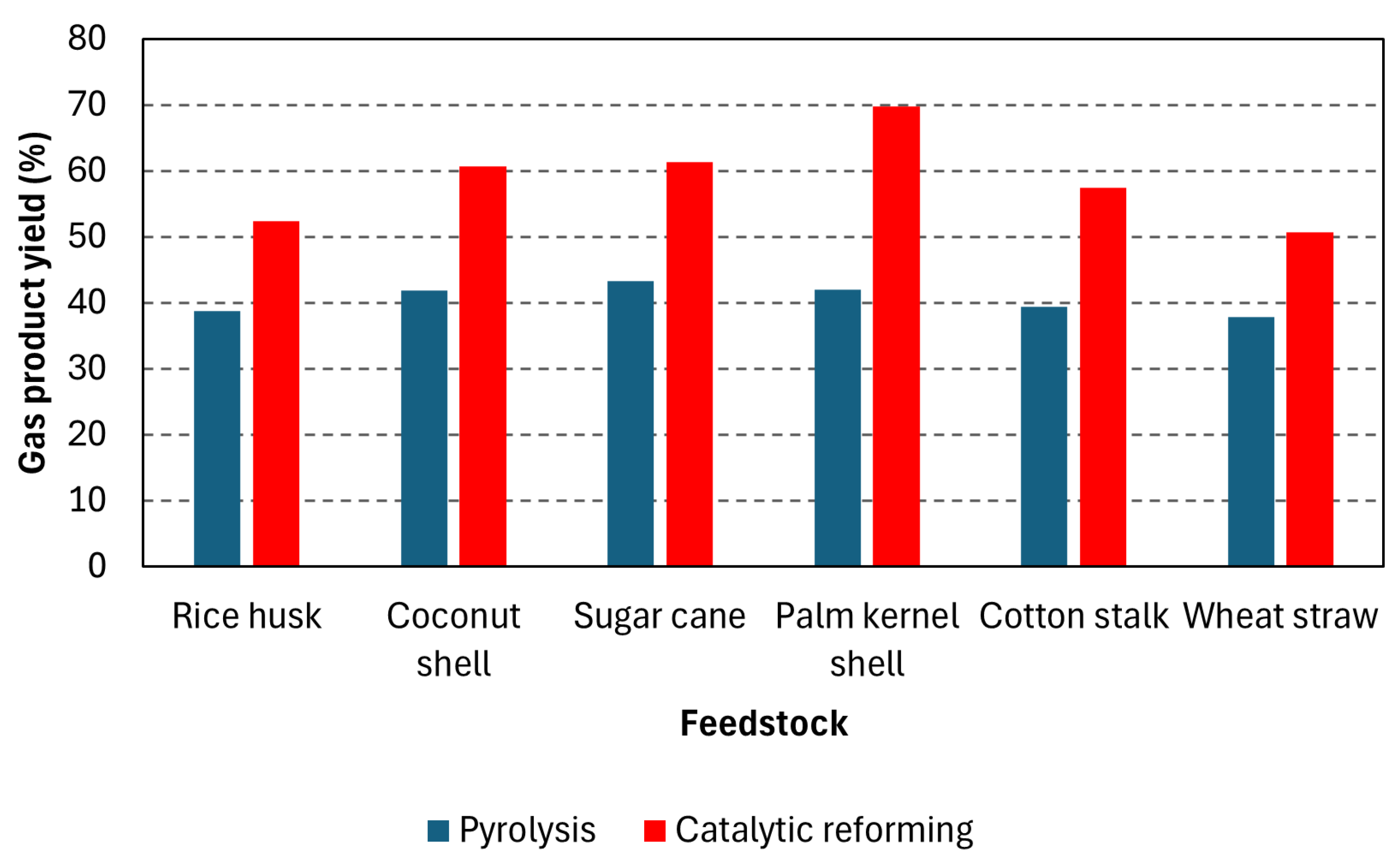

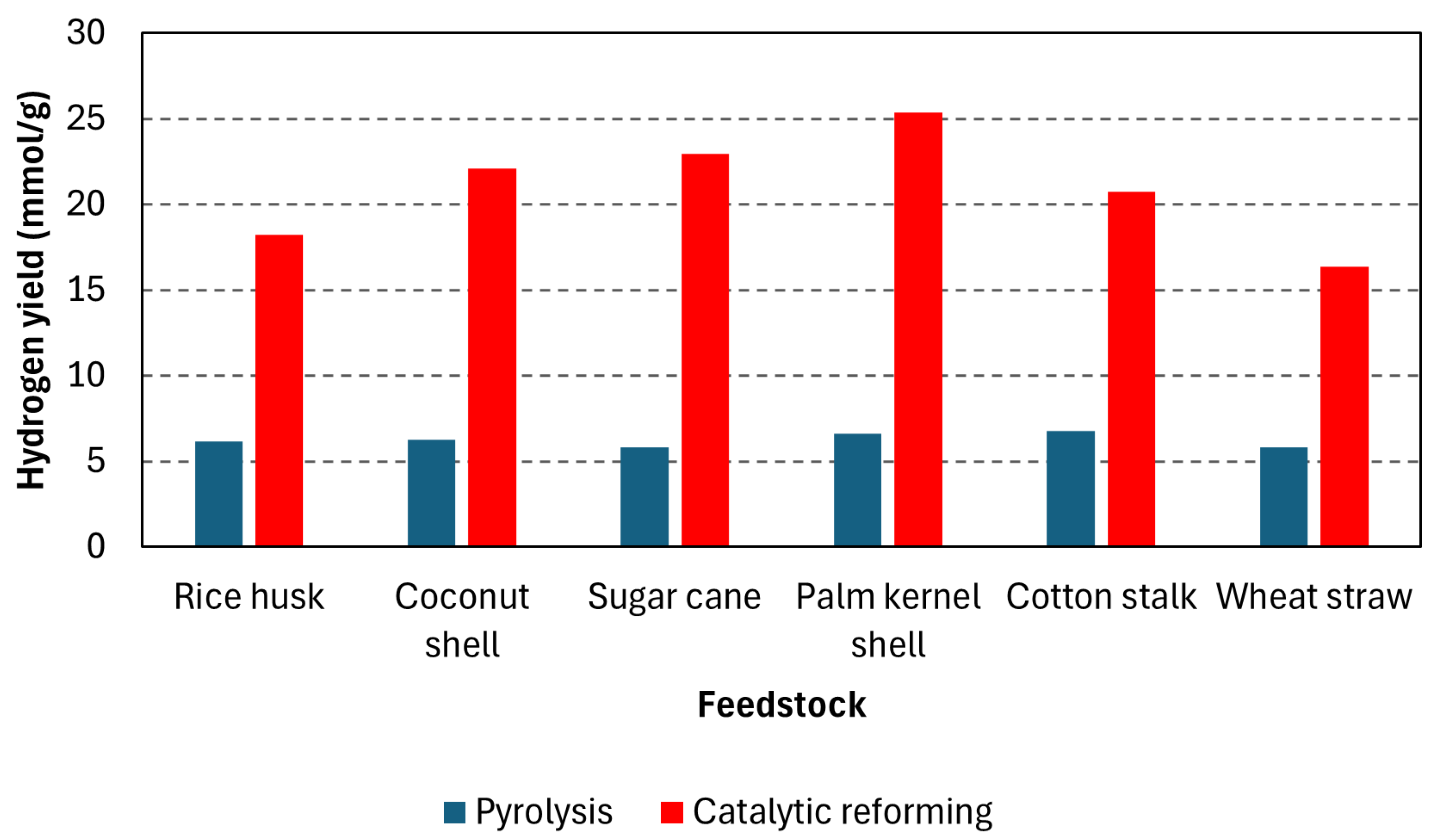

| Feedstock | Pyrolysis Temperature °C (Heating Rate °C/min) | Reforming Temperature °C | Catalyst | H2 Concentration (vol%) | H2 Yield (mmol/g) | Ref. |

|---|---|---|---|---|---|---|

| Rice husk | 950 (20) | 950 | 10 wt % Ni–dolomite | 59.32 | 25.44 | [63] |

| Sugar cane bagasse | 57.4 | 25.41 | ||||

| Wheat straw | 58.3 | 24.47 | ||||

| Rice husk | 550 (20) | 750 | 10 wt% NiAl2O3 | 57.63 | 18.22 | [33] |

| Coconut shell | 58.21 | 22.11 | ||||

| Sugar cane | 59.23 | 22.96 | ||||

| Palm kernel shell | 57.36 | 25.35 | ||||

| Cotton stalk | 57.95 | 20.74 | ||||

| Wheat straw | 54.06 | 16.38 | ||||

| Lignin | 64.02 | 25.25 | ||||

| Cellulose | 56.43 | 19.72 | ||||

| Xylan | 58.77 | 20.54 | ||||

| Corncob | 900 (10) | 650 | Ni–exchanged resin char (Ni/RC) | 72.5 | 61.2 | [77] |

| Wood pellets | 500 (40) | 700 | Tire char | 34.6 | 10.2 | [70] |

| 800 | Tire char | 38.2 | 15.1 | |||

| 900 | Tire char | 51.8 | 47.6 | |||

| 700 | Acid-treated tire char | 14.3 | 3.11 | |||

| 800 | Acid-treated tire char | 28.3 | 10.2 | |||

| 900 | Acid-treated tire char | 47.1 | 36.7 | |||

| Wood sawdust | 550 (40) | 800 | Blank | 23.2 | 6 | [69] |

| Ni-Ca-Mg-Al (1:1:1:1) | 52.3 | 18.2 | ||||

| Ni-Mg-Al | 35.1 | 10.4 | ||||

| Wood sawdust | 500 (40) | 800 | Sand | 17.5 | 2.4 | [65] |

| Fe-Zn/Al2O3 (1:1) | 40.6 | 9.65 | ||||

| Fe-Zn/Al2O3 (1:2) | 35.1 | 7.25 | ||||

| Fe-Zn/Al2O3 (1:3) | 35.6 | 6.79 | ||||

| Fe-Zn/Al2O3 (1:4) | 35.1 | 6.59 | ||||

| Waste wood | 500 (2400) | 760 | Sand | 18.2 | N.A | [80] |

| NiO/Al2O3 | 44.4 | N.A | ||||

| NiO/SiO2 | 38.7 | N.A | ||||

| NiO/CeO2/Al2O3 | 43.1 | N.A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zayer Kabeh, K.; Prussi, M.; Chiaramonti, D. Advances in Bio-Hydrogen Production: A Critical Review of Pyrolysis Gas Reforming. Appl. Sci. 2025, 15, 3995. https://doi.org/10.3390/app15073995

Zayer Kabeh K, Prussi M, Chiaramonti D. Advances in Bio-Hydrogen Production: A Critical Review of Pyrolysis Gas Reforming. Applied Sciences. 2025; 15(7):3995. https://doi.org/10.3390/app15073995

Chicago/Turabian StyleZayer Kabeh, Kaveh, Matteo Prussi, and David Chiaramonti. 2025. "Advances in Bio-Hydrogen Production: A Critical Review of Pyrolysis Gas Reforming" Applied Sciences 15, no. 7: 3995. https://doi.org/10.3390/app15073995

APA StyleZayer Kabeh, K., Prussi, M., & Chiaramonti, D. (2025). Advances in Bio-Hydrogen Production: A Critical Review of Pyrolysis Gas Reforming. Applied Sciences, 15(7), 3995. https://doi.org/10.3390/app15073995