Abstract

Internal-condition sensing for road structures is crucial for road service safety, performance assessments, and maintenance. In recent years, new technologies for monitoring structural conditions of roads have been updated, significantly improving road-sensing capabilities. Most of these techniques use a new generation of sensors and monitoring systems by means of buried sensors in roads to obtain the accurate mechanical status of road-internal structures. This paper presents an exhaustive and systematic literature review of in situ sensing technology for the internal-structure conditions of pavements in the past 20 years. The principles, advantages, and disadvantages of existing monitoring sensors, such as fiber-optic grating sensors and resistive strain gauges, and their applicability in pavement monitoring are reviewed. Meanwhile, sensing technology based on conductive sensitive materials (CSMs) are shown to have broad application prospects, and the details of conductive polymer compositions, preparation processes, and sensing performance factors are discussed. Lastly, further opportunities and challenges for using polymer CSMs for in situ road monitoring are highlighted.

1. Introduction

Asphalt pavements are widely used in the construction of high-grade highways due to their good performance, such as good surface smoothness, no joints, small vibrations, low noise, driving comfort, and convenient maintenance [1,2]. However, due to the negative impact of increasing traffic flows; heavy vehicle loads; extreme weather; and long-term exposure to temperatures, humidity, and other factors, asphalt pavement damage has become the main technical problem in the service period and maintenance stage of roads. The mechanical response of layered pavements, such as strain, stress, and so on, can reflect the occurrence of early pavement damage, but the stress and stain state of pavements from calculation results by the layered elastic theory are quite different from the actual service status of pavements due to the neglect of the inhomogeneity, anisotropy, and nonlinear stress–strain relationship of pavement materials. Therefore, mechanical state monitoring of pavements is crucial to acquire reliable data on mechanical servicing of pavements, which is important for the reasonable design, scientific maintenance, and safe operation of roads [3,4].

In recent years, the mechanical parameter of pavement structures is mainly evaluated by the bending of a Falling Weight Deflectometer (FWD). A large amount of research has been carried out on the modulus inversion and modulus analysis of pavement structures based on the results of FWDs at home and abroad in order to scientifically evaluate the mechanical state of layered pavement structures. Nevertheless, the reliability of modulus inversion results has always been a core concern in the industry [5]. For obtaining the accurate mechanical state of pavement structures, mechanical detection technology for the surface of pavement structures has been developed successively, which has made important contributions to the scientific evaluation of pavement structures [6,7,8]. As an external detection method, technology for detecting pavement surfaces is not only time-consuming but also cannot involve full-time detection for the internal layered structure states. In many cases, damage of a pavement is often detected after the road disease has occurred by the current detection technology, which is generally an after-the-fact detection method.

Pavement monitoring by means of in situ sensing technology has attracted the attention of many road researchers [9]. The monitoring process of internal deformation and the damage of civil engineering structures is generally known as structural health monitoring (SHM) [10]. Active monitoring systems can identify different defects and monitor damage, strain, and temperature in real time, which is crucial for optimal maintenance of the structure [3]. In general, a typical SHM system consists of three main components: the sensor system; the data processing system (including data acquisition, storage, and transmission systems); and the status assessment system (including information management and diagnostic algorithms, etc.) [11,12], as shown in Figure 1. A sensor system is used to bury the different sensors in a certain layer or a key position inside the civil engineering structure so as to form a distributed sensor network. At the same time, data recorded by the sensor are collected and transmitted. The collected data are analyzed and displayed by the remote server and data processing system so as to evaluate the health status of the civil structure. The structural health monitoring system involves interdisciplinarity, including the sensor network, real-time data signal transmission, signal processing, software development, and structural evaluation.

Figure 1.

Road structure health monitoring.

2. Research Progress in In Situ Road Health Monitoring Technology

Strain is one of the important parameters of mechanical analysis and evaluation systems in the civil engineering field. At present, asphalt pavement damage (such as rutting, cracking, potholes, etc.) is caused by a variety of factors, and a few causes can be identified through an intuitive observation and analysis of the surface, but most distresses originate from the coupling of various forces on the surface layer and substructure. Repeated traffic loads cause large tensile strain at the bottom of the asphalt layer, leading to an overall decrease in the pavement bearing capacity of fatigue. The repeated compression of vehicles leads to the rutting of pavements, which causes permanent deformation. Therefore, it is necessary to understand the mechanical parameters, such as the mechanical response and strain under a combined action of various factors, of pavement structures. The assumptions made during pavement designs can be verified by monitoring and analyzing the response of different layers of the pavement under moving loads over time [13,14]. At the same time, this may predict the occurrence of fatigue or rutting so as to provide empirical support for the effective evaluation of the service condition of pavements, early damage detection, estimations of the remaining working life, and the design of pavement maintenance [11,15,16].

Over the past many years, researchers have made great efforts to monitor the strain status of asphalt pavements. The harsh construction process of asphalt pavements leads to the easy inactivation of ordinary sensors during installations or loads. The sensors need to be able to withstand high temperatures (up to 150–170 °C), humidity, high pressure, and repeated overloading. It must be noted that most conventional sensors used in other civil structures cannot be used directly for the interior structures of pavements [16]. In recent years, scholars have carried out a lot of research on optical fiber Bragg grating sensors (FBGs), strain gauges, piezoelectric sensing elements, embedded vibrating string strain gauges, and other sensors in the field of mechanical property monitoring for pavement structures. Different sensors have various abilities for sensing physicochemical parameters related to the health of civil structures. At present, sensors used for deformation monitoring are generally designed based on the principles of strain measurements.

2.1. Fiber-Optic Grating Sensors

In 1978, Hill [17] successfully invented the world’s first fiber-optic grating (FBG) technology. The working principle of the optical fiber grating strain gauge involves the deformation of an optical fiber when the load changes, which leads to the intensity, amplitude, phase, frequency, or polarization state of the light. Then, the demodulated optical fiber grating is used to detect the strain of the measured object. The central wavelength of a fiber grating is affected by strain and temperature conditions [18]:

in which ΔλB is changes in the fiber grating; neff is the effective refractive index; Λ is the fiber grating period; ε and ΔT are strain and temperature changes, respectively; and μ, αδ, ζδ, p11, and p12 represent the Poisson ratio, thermal expansion coefficient, and thermal light coefficient of the optical fiber and the bounce light coefficient of the optical fiber grating, respectively.

Optical fiber grating strain gauges have been widely used in civil engineering structures, the aerospace industry, the shipping industry, the petrochemical industry, the electric power industry, the nuclear industry, medicine, and other aspects of civil engineering structures due to their advantages of high strain-detection accuracy, strong anti-environmental interference ability, and small size [19]. Fiber grating sensors have been applied in the field of civil engineering safety monitoring, especially in the field of bridge engineering monitoring [20,21]. Generally, according to the configuration and structure of fiber monitoring, fiber sensors can be divided into three types: discrete, quasi-distributed, and distributed. Generally, the sensor is embedded in the road surface for monitoring, which can be realized in two ways. One is to place the processed optical fiber sensor in the core sample or in the groove and then backfill it; the other is to bury and compact it simultaneously with the pavement construction process. But the latter is extremely prone to cause sensor damage [22].

Mustafa et al. [23,24] embedded distributed fiber-optic sensors in experimental rutting boards and existing road surfaces using the slotting and embedding method to identify external load information. They conducted experiments by comparing three embedding depths (10, 30, and 40 mm) and three moving loads (pedestrians, cars, and trucks) to study the applicability and sensitivity of distributed fiber-optic sensors in obtaining moving load information on road surfaces at different depths.

However, it must be noted that due to the fragility of fiber grating sensors and the complexity of road construction environments and service conditions, fiber grating sensors are difficult to be directly used for field monitoring and are extremely easily damaged under load conditions. In order to improve their survival rate, it is necessary to carry out encapsulation research and research on installation protection methods. In 2018, for the first time in Flanders, Kara et al. [25] conducted a pre-construction monitoring study on the bottom of asphalt pavements with different layers (surface and base). By embedding the fiber grating and installing it in the prefabricated base and asphalt layer groove, a cross-sectional strain measurement was obtained, as shown in Figure 2.

Figure 2.

Embedded FBG sensor installed in prefabricated base (a) and asphalt layer groove (b) [25].

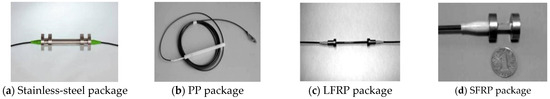

With the gradual maturity and stability of optical fiber communication technology and optical fiber sensing technology, research has gradually shifted from the development of new optical fiber demodulation principles and structures to the practical packaging of existing optical fiber sensors to meet different monitoring needs, as shown in Figure 3. Grakovski et al. [26] used a fiber-optic sensor that responds to deformation, and then, this information is further used for the estimation of the vehicle wheel’s speed, contact width, and length and the axle’s weight while in motion. Recorded signals from a truck passing over a group of fiber-optic sensors with various speeds and known weights are used as input data. Dong et al. [27] and Tan et al. [28] combined strain measurements and finite element simulations. A dynamic modulus test was therefore used to first obtain the viscoelastic characteristics of asphalt mixtures. The similarity theory with embedded fiber Bragg grating (FBG) sensors was used to develop a small-scale laboratory loading test. Studies were then carried out for measured strain validations in conjunction with a finite element method model. They also employed a fiber grating strain gauge that was based on polypropylene (PP) and fiber reinforced plastic (FRP) materials, and they embedded the calibrated fiber grating strain gauge in the asphalt concrete trabecular with conducted strain testing in static and dynamic loading modes. However, the FRP package sensor was separated from the matrix, and the range of the tests needs to be expanded to further verify the effectiveness of the measured strain of the fiber grating sensor [29,30]. At the same time, by using the detection data of optical fiber grating strain gauges combined with the Burgers viscoelastic model, the permanent deformation of asphalt pavements can be calculated [31,32,33].

Figure 3.

Fiber grating strain gauge based on different material packages [29].

R. Li [34] deployed fiber-optic sensors on the prestressed tendons of bridge box girders to monitor the mechanical properties of bridge structures during construction and service periods. Although the monitoring survival time is longer compared to surface-mounted strain gauges, further research is needed on the durability of fiber-optic sensors. Qian et al. [35,36,37] buried Bridgman–Wigner Time-Domain Analysis (BOTDR) distributed fiber-optic sensing technology in asphalt pavement layers to monitor cracks in asphalt concrete pavements. The results of experimental simulations and on-site monitoring indicate that the application of BOTDR technology has good monitoring accuracy and stability in monitoring the temperature, residual deformation, and cracks of actual road surfaces.

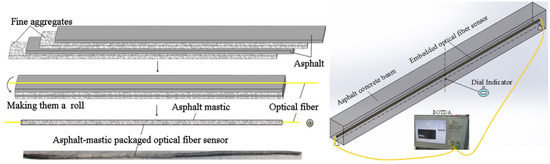

Xiang et al. [38] developed a flexible asphalt-encapsulated fiber-optic sensor for monitoring the distributed strain of asphalt pavements by curling the fiber-optic sensor into asphalt and fine aggregates and analyzed the strain transfer theory of the fiber-optic sensor, as shown in Figure 4. Through an experimental test of an asphalt concrete beam and a field performance test under urban temperature and traffic loads of asphalt pavements, the designed fiber sensor can effectively detect the strain distribution of asphalt pavements, but the effectiveness of the monitoring data needs to be further verified. Researchers have also used optical fiber Bragg grating sensors for monitoring asphalt concrete strain tests combined with the requirements of pavement construction, and the monitoring performance of the sensor is tested by weight static loading and dynamic rut loading experiments, respectively [39,40].

Figure 4.

Diagram of flexible asphalt-encapsulated fiber sensors and indoor tests [38].

The above research provides high-precision optical fiber grating sensing technology for pavement structure detection. However, FBG and BOTDA optical fiber sensors still have the following defects: (1) The maximum ultimate tensile strain is only about 1.5% for quartz optical fibers of ordinary communication, which results in an optic grating strain gauge with poor shear resistance that has the problems of low survival rates and poor durability, especially in the harsh construction and working environments of the asphalt pavement structure layer. (2) FBG technology has a low spectral utilization rate, and the number of measuring points is limited. (3) The matching degree of FBG sensors and asphalt materials gradually decrease with working time, leading to irregular monitoring strains. These problems pose a great challenge to the stability of FBG monitoring sensors [41].

2.2. Resistance-Type Strain Gauges

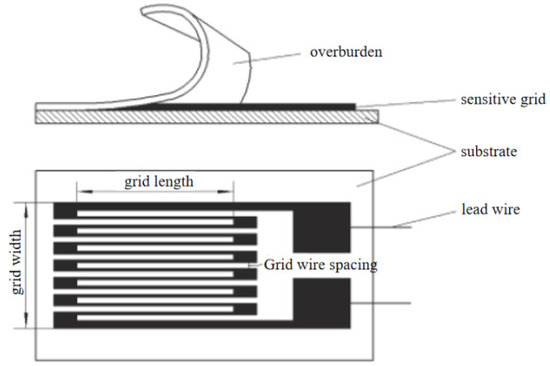

Resistance strain gauges have the advantages of a light weight, a small size, high measurement accuracy, high fatigue resistance, and good stability. Therefore, a resistance strain gauge with corresponding elastic elements is widely used in the aerospace, electric power, and civil construction engineering fields [42]. The detection technique involves measuring the strain of the strain gauge on the measured structure by changing the strain on the measured structure of the strain gauge on the structure of the measured structure, as shown in Figure 5. When applied in civil structures, the strain is generally measured by sticking to the surface of the bridge or other cement concrete with a smooth surface. The quality of the gauge paste directly affects the accuracy and reliability of the test, resulting in a high degree of empirical control and the lack of reuse [43,44]. In terms of asphalt pavements, due to the concealment of the monitoring position of the asphalt pavement structure layer, it is difficult to directly paste the strain patch. Under the harsh construction conditions and complex service environments of asphalt pavements, it is difficult for directly buried unpackaged strain patch elements to survive. On the other hand, the stiffness of a resistance strain gauge sensor is quite different from the stiffness of asphalt concrete, and the interface compatibility between the strain gauge and asphalt pavement material is poor, which affects the detection accuracy and reliability. Therefore, it is necessary to take the resistance strain gauge as the core element and to carry out research on the packaging and protection process to match the complex mechanical state of asphalt concrete.

Figure 5.

Typical structure of a resistance strain gauge.

In road engineering, the ASG (asphalt strain gauge) asphalt pavement resistance strain gauge developed by CTL (Hico, TX, USA) and the TML (Tokyo, Japan) asphalt strain gauge are relatively mature, with many engineering applications, as shown in Figure 6. According to the monitoring direction, the ASG asphalt strain gauge is divided into a horizontal asphalt strain gauge (I-shape) and a vertical asphalt strain gauge. The strain gauge involves sticking the resistance strain gauge on a threaded nylon rod member. Both ends of the nylon rod are connected to an aluminum rod to measure the axial strain. In the monitoring element area, polysulfur polymer and silicon butyl rubber materials are used to package and protect the strain sheet to adapt to the construction conditions and working environments of asphalt pavements. By collecting the output voltage of the sensor, the corresponding strain can be converted, as shown in Equation (2). The embedded asphalt strain gauge KM-100HAS of TML (Tokyo, Japan) also adopts an I-shaped structure with an aluminum rod at each end, which is used to fix the intermediate axial shaft. In order to make coordinate deformation of the strain gauge and the asphalt mixture, the middle axial rod of the strain gauge is selected, and the asphalt mixture modulus is equivalent to the material, with high temperature, moisture, and other properties of the material.

where Usc and U0 represent the excitation voltage and output voltage in V and mV, respectively, and GF is the sensitivity coefficient of the strain gauge. It is generally considered that the sensitivity coefficient of the resistive strain gauge is considered to be about 2.0; ε is the strain in με, and μ is the Poisson ratio of the nylon rod.

Figure 6.

ASG asphalt strain gauge produced by CTL from the USA and TML asphalt strain gauge from Japan.

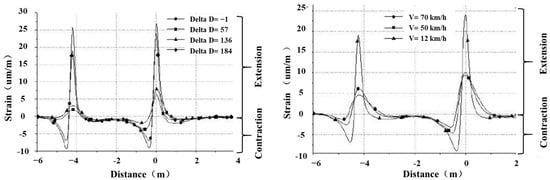

Due to the relatively stable performance of the above asphalt strain gauges and their high detection accuracy, they have been widely used in the study of the structural mechanics of asphalt concrete pavements or airport runways at home and abroad [45,46,47]. In 1998, as a pioneer case in the field of road monitoring, Al-Qadi et al. [48] buried pressure boxes, asphalt strain gauges, thermocouples, humidity probes, and vibrating wire strain gauges in a road of 3.2 km in Virginia, USA. They simulated the impact of different loads and driving speeds on the dynamic response of the road by passing through the sensor burial area with different numbers of passengers and speeds on trucks with known axle loads. In France, in the A41N highway [46], 47 strain sensors, 12 temperature sensors, and 2 fiber sensors were buried in the wearing layer, base course, and sub-base course. Trucks with known axle weights were driven at three different travel speeds and three different trajectories, and the signals were collected at 600 Hz to study the effect of two variables on the structural strain of the road, as shown in Figure 7. Cook et al.’s [49] study of debonding slips at the top of the HMA surface and the bottom of the HMA overlay of a runway using ASG strain gauges at Newark International Airport. Correia et al. [50] studied the mechanical properties of flexible asphalt pavements reinforced by geogrids using ASG strain gauges. Duong et al. [51] buried of TML strain gauges (Tokyo, Japan) in the asphalt layer to monitor the transverse and longitudinal strains, respectively, under different loading conditions. The corresponding mechanical responses were analyzed with the classical multi-layer linear elastic pavement model and the viscoelastic pavement model, respectively, and a comparison concluded that the viscoelastic model had better predictions.

Figure 7.

Longitudinal strain response under different running tracks and speeds [52].

In China, Wang et al. [53] utilized ASG asphalt strain gauges for monitoring the dynamic strain response of asphalt pavements and investigated the setting of data acquisition frequencies and signal processing methods through experiments. Ai, C. [54] measured the effects of temperature, vehicle speed, and axle load on the dynamic response of the bottom of the asphalt layer by comparing and contrasting actual measurements and proposed a prediction model for the strain response of the bottom of the asphalt layer based on the three parameters of temperature, vehicle speed, and axle load, respectively, by adopting the method of multivariate regression analysis. However, this work only considered several factors affecting the strain response of the asphalt layer, and there are many control factors in actual working conditions, so further research is needed to better understand and analyze the measured strain response of the asphalt layer. Luan et al. [55] monitored a construction road by burying a vibrating wire strain gauge and compared the measured data with calculated values based on the elastic layer theory. The comparison results show that there was a certain deviation between the theoretically calculated values and the measured data. Lin et al. [56] buried KM-100HAS of TML (Tokyo, Japan) into asphalt mixture beamlets and verified the synergistic deformation of the sensor and asphalt concrete using two modes of step-by-step loading and dynamic loading. Yang et al. [57] and Chuan et al. [58] also used ASG asphalt strain gauges to detect the strain of asphalt pavements to analyze the mechanical state of durable pavements. Commonly used asphalt strain gauge parameters are shown in Table 1. However, this kind of mature resistance strain gauge detection system is generally more expensive, which is difficult to promote and apply at a large scale in road monitoring and intelligent road construction.

Table 1.

Summary of parameters of resistive asphalt strain gauges.

In addition to asphalt strain gauges, in order to improve the durability and detection accuracy of strain gauges, scholars are also constantly exploring new encapsulation technologies for resistance strain gauges. According to the different packaging structures, these can be divided into tube encapsulation, substrate encapsulation, clamp encapsulation, embedded encapsulation, surface metalized encapsulation, etc. According to the different encapsulation materials, they can be divided into single-material encapsulation and mixed-material encapsulation [5]. Nie et al. [59] proposed a simple, cost-effective strain sensor based on synergetic conductive networks constituted by double-layer microstructures with multi-walled carbon nanotubes and elastomers. However, the above technologies lack research on asphalt pavement monitoring in engineering applications.

2.3. Conductive Concrete Composite Materials

Conductive concrete is mixed with conductive fillers to prepare conductive concrete so that for the conductive concrete with varying external loads (pressure and strain), temperatures, and other changes, its output electrical signal also changes accordingly, that is, it is a self-sensing material. The application of self-sensing materials in mechanical detection in the engineering field is mainly divided into two categories: composite materials with commonly used civil materials, such as matrix and polymer compounds, as the matrix [60,61]. The commonly used composite materials in civil engineering include cement-based concrete composite materials and asphalt-based concrete composite materials, as shown in Figure 8. The conductive materials of these two types of conductive composite materials are usually graphite, CB, CNTs, carbon fiber, or metal powder. With respect to cement bases and asphalt concrete composite materials, research on their detection technology mainly focuses on the mix ratio of material designs; composite piezoelectric resistance tests (including stress, strain-resistance, temperature-resistance correlation, etc.); and their conductive mechanism analysis and the establishment of a related model. At the same time, these materials have been employed in research on structural engineering, road engineering, and engineering applications [62,63].

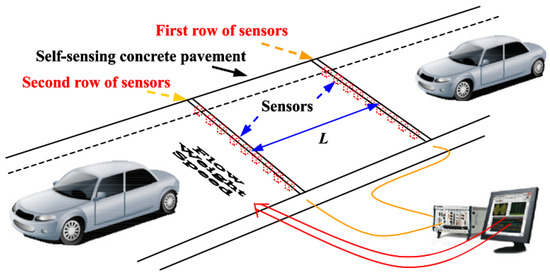

Figure 8.

Signal monitoring based on cement-based conductive concrete [64].

Cement-based conductive concrete composite materials have good piezoresistance performance and can be used for strain detection in cement concrete engineering [65,66]. Nalon et al. [67] prepared CB nanoparticle cement conductive concrete with different specific surface areas, and the superior conductivity of the CB nanoparticles with specific structures was verified by conducted piezoresistive and mechanical performance tests. Han et al. [64] successfully prepared materials with piezoresistive effects by adding specific conductive materials to traditional cement mortar and conducted targeted research on the use of cement-based conductive concrete materials for stress–strain sensing and in situ monitoring. Han et al. [68] used water-reducing agents, dispersants, and defoamers to improve the dispersibility of carbon fibers and prepared carbon fiber cement-based conductive concrete. The effects of the carbon fiber length and dosage on conductivity and changes in compressive resistance were investigated. However, the compatibility and deformation coordination of cement-based conductive concrete composite materials and asphalt materials were poor. It was difficult for the deformation of the two types of materials to be consistent for strain detection, so they cannot be applied for mechanical state detection of asphalt pavements.

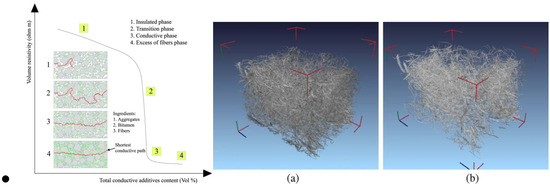

Asphalt-based conductive concrete composite materials and asphalt materials have good deformation consistency [69]. García et al. [70] analyzed the changes in conductivity of carbon fiber conductive asphalt mixtures with the addition of conductive fillers and combined them with nano CT scanning images to analyze the situation of carbon fibers participating in the connection of conductive asphalt mixtures, as shown in Figure 9. Liu et al. [71,72,73] prepared conductive asphalt concrete with good diagnostic abilities for strain caused by external stress by adding graphite to asphalt concrete. They verified pressure-sensitive effects and phased electrical signal changes for monitoring internal damage of asphalt concrete. Yan et al. [74] investigated the water stability, crack resistance, strength performance, and force electric sensitivity characteristics of composite conductive asphalt concrete with graphite and short-cut carbon fiber. It was found that the addition of graphite reduces the road performance of asphalt concrete, while carbon fiber can improve the road performance of asphalt concrete. Moreover, strain and electrical resistivity show a good correlation with an extension of the loading time under indirect tensile creep mode. The authors also carried out research on the pressure-sensitive properties of conductive asphalt mortar with an electrical conductivity up to the order of 10−4 S/cm by incorporation of graphite with carbon fiber [75]. The pressure sensitivity and reversibility of materials under cyclic loading mode were studied, and the change rates of resistivity under different cyclic loading times were analyzed. Asphalt-based conductive asphalt concrete has significant sticky elastic plastic due to the characteristics of asphalt viscoelastic itself. Plastic deformation is non-negligible at high temperatures and fatigue loads, leading to poor resistance output signal repeatability and an obvious hysteresis effect.

Figure 9.

Change of resistivity of conductive asphalt concrete with volume fraction of conductive filler and CT scan diagram (a) all the fibers (b) and only the connected fber [70].

2.4. Piezoelectric Sensing Elements

In recent years, the development of sensitive polymer composite materials has provided a new method for solving the problems of poor deformation coordination and insufficient working performance of strain sensors. Sensitive polymer composite materials are mainly composed of a polymer compound matrix and conductive material. They are a new type of functional material with self-perception of external factors, such as force, deformation, temperature, and humidity [67,76,77]. Due to their good adaptability to complex environments, material compatibility, piezoresistance performance, strain sensitivity, durability, and good repeatability, they have gained significant research attention in recent years and have shown good engineering application prospects.

In addition, piezoelectric film sensors, piezoelectric quartz, and piezoelectric ceramics can also be used in situ to monitor civil engineering structures. A piezoelectric film sensor is a sensor based on polyvinylidene fluoride (PVDF) film, in which the core is the VDF-TrFE piezoelectric polymer located in the middle layer, composed of a repetitive monomer (-CH2-CF2-). By polarizing the piezoelectric material in a strong electric field, the noncrystalline polymer takes on a semi-crystalline form and has linear piezoelectric properties for stress or strain. Bai, S. [78] studied the dynamic strain sensing characteristics of PVDF piezoelectric films by encapsulating them with polytetrafluoroethylene and validated a device for health monitoring on offshore platforms. Ding et al. [79] applied PVDF piezoelectric thin films onto copper sheets and designed a testing device to verify the strain sensing characteristics of thin piezoelectric films. Ju et al. [80] studied the sensitivity and linearity of thin PVDF piezoelectric films by pasting thin piezoelectric films on civil engineering structures, where the high sensitivity and resolution in strain monitoring were verified. Du et al. [81] effectively monitored the initiation and propagation process of cracks using thin PVDF piezoelectric films. Li et al. [82] and Sha et al. [83] used lead zirconate titanate (PZT) powder and PVDF to prepare sheet-like composite materials. They also used a 3D-printed cylindrical structure to encapsulate sheet-like composite materials and prepared piezoelectric sensing devices, which were embedded in asphalt mixtures. The effectiveness of the sensing signal output was tested by simulating vehicle loads. However, the application of PVDF and piezoelectric films in asphalt pavements is still in the exploratory stage at present. Song et al. [84] prepared “smart aggregates” by encapsulating PZT piezoelectric ceramic sheets after waterproofing with silicone gel for consistent monitoring of concrete structures. The authors of this paper have also carried out related explorations and research on the optimization, encapsulation, signal analysis, and monitoring system of PVDF piezoelectric films in recent years.

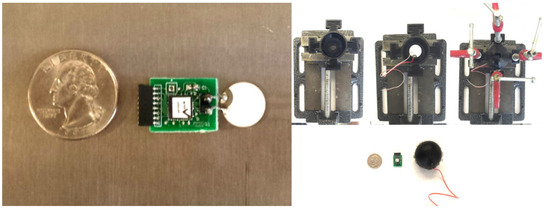

2.5. Wireless Sensing Elements

With the development of network communication technology, wireless sensing technologies came into being. Their low price, small size, high reliability wireless sensor, and their network have become a research focus in recent years [85]. Amiir, H.A. [12] designed and studied self-sensing powered wireless sensors (SWSs), whose structural and encapsulating forms are shown in Figure 10. This piezoelectric sensor consists of a piezoelectric transducer, a sensor piezoelectric electronic device, a terminal board, etc. Under the action of traffic load, the piezoelectric transducer is pressurized to generate an electrical signal to supply power to the sensor piezoelectric electronic device through the circuit board, and the signal of the sensor piezoelectric electronic device is used for the diagnosis of structural damage. In the encapsulation process, the spherical packaging shell was prepared using 3D-printed technology with openings reserved at its top and six fixed anchors in 3 directions. The wireless sensor was sealed by injecting polyurethane glue TU-981, since the stiffness of glue TU-981 is similar to that of asphalt concrete. The final encapsulated sensor had a similar size with asphalt concrete aggregates. Communication between the wireless sensor and the vehicle is performed using radio frequency identification (RFID) technology. It was shown [86] that data from such unembedded sensors can be read from 16 inches using the RFID method. For the sensing system embedded in the asphalt sample, the thickness of the asphalt layer affected the accuracy of the transmission and recovery signal. In this case, the sensor and the RFID scanner commutated at a distance of approximately 12 inches. Therefore, they proposed a sustainable long-term health monitoring and analysis system using the developed SWSs and verified the system with finite element simulations and the three-point bending-beam experiment method, respectively. With the wireless sensor signal output values as the basic data, the system obtained the probability density function (PDF) from the strain distribution provided by each sensor in the system. Thus, the cumulative density distribution (CDF) was calculated by the characteristic factors μ and σ so as to predict the damage rate and damage location of road damage. However, instead of directly monitoring the absolute values of the strain, the system uses the relative strain distribution to infer the strain trend. Abdulkarem et al. [87] also explored network communication protocols, network designs, and integration technology in wireless monitoring technology. However, wireless sensing technology for monitoring the mechanical state of asphalt pavements is still in its early stages.

Figure 10.

Diagram of wireless sensing elements and packages [12].

This paper further makes a comparison between optical fiber sensors, wireless sensors, and cameras/radars in the field of road engineering, as shown in Table 2.

Table 2.

Comparison of different sensors.

3. Pavement Self-Sensing Technology Based on Conductive Polymer Composite Materials

With the development of advanced materials and the improvement of test methods, a new technology of polymer-based composites with self-sensing functions has shown good advantages for monitoring engineering structures. In particular, it provides a new method for solving technical difficulties such as the poor coordination of sensor deformation and insufficient long-term work performance of civil monitoring [10,88,89]. Polymer matrix composite materials present different electrical changes, electromagnetic changes, and other changes when subject to different pressures, strains, temperatures, or other external factors. In recent years, extensive research [90,91,92,93,94,95,96,97] on new sensitive polymer-based composite materials has been used for various applications, such as human motion detection, posture recognition, life prediction, and self-repairing.

Piezoresistive strain sensors based on conductive composites often have higher sensitivity and a tunable strain range. Compared with capacitive strain sensors or piezoelectric strain sensors, piezoresistance strain sensors have a wider pressure range, known as multifunctional strain sensors, which are capable of detecting compression, stretch, shear and extrusion strain, etc. More importantly, they are easy to produce and are able to adjust resistance strain sensitivity and measurable strain or stress ranges [90]. Many scholars [91,92,93,94] have carried out research on sensitive polymer-based composite materials, mainly focusing on the design of sensitive composite materials, piezoelectric resistance characteristic analysis, and conductive mechanism research. Rocker, S.N. [91] prepared polymer composites by adding multi-walled carbon nano-tubes (MWCNTs) and ammonium perchlorate (AP) crystals to polydimethylsiloxane (PDMS). Tests on mechanical properties and piezoresistive responses under monotonic uniaxial and cyclic compression damage were carried out, which validated the application of embedded CNT sensing networks for structural health monitoring (SHM) under cyclic loading. Shin et al. [92] utilized polyurethane (PU) solutions to infiltrate three-dimensional networks formed by MWCNT-aligned arrays to form conductive polymer composites and monitored the electrical signals under monotonic stretching and cyclic loading at many ranges of strains (0–300%). Hu et al. [93] investigated the mechanical and electrical properties of carbon nanofiller/epoxy composites using a combination of numerical simulations and experimental methods. The effects of doping, the diameter, the conductivity of the CNT, preparation process parameters (including stirring speed and curing temperature), and the polymer matrix barrier height on the sensitivity of the strain sensors of the resin/CNT composites were investigated, as shown in Figure 11.

Figure 11.

Physical picture and SEM image of carbon nanofiller/epoxy resin composites [95].

Qi et al. [94] prepared carbon nanofiber polyurethane-based composite materials by mechanical high-speed blending and tested the conductive, pressure-sensitive, and piezoelectric properties of the specimens at different ratios. Qu et al. [95] prepared thin films of CNTs by floating catalytic chemical vapor deposition and introduced glass fiber-reinforced composites to achieve material damage detection and verified the localization of the penetration hole damage up to millimeter-level accuracy. In recent years, Yao et al. [75,96,97] used polyethylene terephthalate (PET) as the substrate to prepare sensitive mortar or sensitive materials doped with graphite, nickel powder, carbon fiber, CB, and other conductive materials, respectively. The stress-resistance correlation of PET-based sensitive materials was studied, which was further applied to test the structural mechanics of asphalt pavements. It was verified that PET-based sensitive materials have good deformation of asphalt pavements, in line with the characteristics of the material compatibility. However, the accuracy of PET-based sensitive materials is low when used to detect small strains in asphalt pavement structures, and the sensing characteristics, engineering properties, and electric force response mechanism of PET composite materials need to be further investigated.

3.1. Factors Affecting the Electrical Conductivity of Polymer Composites

3.1.1. Polymer Matrix

Polymer matrices commonly used in polymer matrix composites are broadly categorized into thermosets (e.g., resins [98]), thermoplastics, and elastomers (e.g., rubbers [99] and PDMS [100]). In the preparation of composite materials, a rational choice can be made based on the scope of application of the material and the purpose of research and development. Among them, resins are often used as the matrix because of their better force-sensitive properties and durability. Resin polymers mainly include epoxy resins, nylon (PA), polypropylene (PP), polyethylene (PE), high-density polyethylene (HDPE), ethylene glycol ethanedioic acid ester, polyethylene terephthalate (PET), and so on [101]. Oladele et al. [88] prepared two types of polymer composites using carbon fiber mats as the conductive material and two types of resins, flexible resin and 3201 vinyl resin (rigid resin), as the polymer matrix and comparatively investigated the effects of resin types on strain resistivity. The results show that due to the difference in Poisson’s ratio, the spacing between the transverse joints of the flexible resin decreases to a greater extent, which slows down the magnitude of the increase in resistivity. Because epoxy resin has the advantages of high reactivity and strong cohesion, and its strength is adjustable and controllable, it can coordinate with the stiffness of asphalt pavements. Therefore, epoxy resin is an ideal matrix of sensitive polymer composites for road-monitoring applications.

3.1.2. Conductive Fillers

Commonly used conductive materials include metal and carbon, metal conductive materials mainly include gold, silver, nickel, copper, etc. Carbon conductive materials are widely used in the development of sensitive composite materials for better binding with polymer compounds, and the most commonly used ones are CNTs [100,102], CB, carbon fiber [103], and the GNP [104] class. The physicochemical properties of various carbon materials vary greatly due to their structural and scale differences. During the development process of composites, single-carbon materials or compound-carbon materials can be flexibly selected according to the needs and can be combined with different polymer materials. Nanoscale conductive fillers, due to their special nanoscale size effect and large specific surface area, cause the polymer matrix and conductive fillers to have a large area of direct or indirect interaction between them, which in turn causes a series of interfacial interaction changes and novel mechanical and electrical phenomena.

CNTs have been widely used in research on self-sensing composites as conductive materials and structural reinforcement components due to their excellent mechanical and electrical properties. Due to the structure of carbon nanotubes and the lamellar structure of graphite, their axial conductivity is extremely superior, and they have an ultra-high aspect ratio, which is a very ideal conductive filler. In general, theory predicts that its electrical conductivity depends on the helicity of the arrangement of its layers of carbon atoms, i.e., the pipe diameter and the helix angle of the pipe wall (n, m). On the one hand, when the integer multiple of n/m is 3, it is easy to show a metal-like conductivity; on the other hand, when the diameter of CNTs is n < 6 nm, CNTs can be regarded as a one-dimensional quantum wire with good conductivity performance, and when the diameter of CNTs is n > 6 nm, the conductivity gradually decreases. In addition, according to the number of structural layers, CNTs can be categorized into single-walled CNTs and multi-walled CNTs, and the performance of SWCNTs is generally better than that of MWCNTs, but they are very expensive due to their more complex preparation. However, both SWCNTs and MWCNTs have extremely high Young’s modulus and tensile strength values, and when they are subjected to mechanical deformation by external forces, they produce corresponding changes in the corresponding electrical signals, which also provides good application prospects for their participation in the preparation of sensing components.

Nanoscale fillers have high specific surface energies, resulting in a low dispersion of CNTs in polymer matrices and common solvents, which are prone to aggregation. The conjugated and hyperconjugated electronic systems and hollow structures in the internal structure of CNTs in turn provide a basis for their further expansion, i.e., surface functionalization, such as amination [105], carboxylation [106,107], macromolecule functionalization [108], and the modification of silane coupling agents [109]. Surface-functionalized CNTs help to reduce the repulsive forces between carbon CNTs, thus facilitating dispersion.

Carbon black (CB), as spherical particles with sizes at the millimeter, micrometer, and nanometer scale, depending on the preparation process [76], has good electrical conductivity and low cost and is also widely used in the preparation of composite materials. However, due to the limitation of its shape, generally, CB has a high conductive value over penetration. Graphene is a conductive filler with a lamellar structure, which is a newly emerging material in recent years. The planar structure and ultra-high specific surface area of graphene allow for better transfer of stress to the matrix during the loading process, resulting in higher mechanical properties in polymer composites [110]. In addition, compound conductors composed of conductive fillers of different shapes or sizes often exhibit synergistic or antagonistic effects due to the interaction of their structures and shapes. Bisht et al. [111] determined that the addition of carbon CNTs to graphene had a synergistic enhancement effect on a polymer matrix, as CNTs inhibited stacking of the graphene sheets, thus providing a nanophase with a larger surface area in to bind to the polymer matrix and provide mechanical support by sharing loads and inhibiting crack extensions. Zakaria et al. [112] comparatively investigated the effects of graphene and MWCNT on the mechanical, thermal, and dielectric properties of epoxy composites at different filler amounts, and the results show that graphene-filled epoxy nanocomposites had higher thermal and dielectric properties but slightly lower mechanical properties compared to MWCNT-filled epoxy composites. The tensile strength, flexural strength, thermal conductivity, and dielectric constant of the graphene-filled epoxy composites increased by 11%, 17%, 126%, and 171%, respectively, and those of the MWCNT-filled epoxy nanocomposites increased by 26%, 29%, 60% and 73%, respectively.

Asphalt pavement strain monitoring focuses on the internal structural layer of micro-strain-level changes, especially within the core of 100 με, where the conductive material is not only a sensitive composite material with electrical conductivity, sensitivity, and self-sensing abilities but also the core of the development of monitoring elements. Therefore, in order to obtain materials with higher response accuracy, it is recommended to use nano-conductive fillers, such as CNTs, nano-carbon black, graphene, etc.

3.2. Preparation Methods of Conductive Polymer Composite Materials

One of the pursuits of composite material research is determining ways to use the lowest possible content of conductive nanoparticles to obtain high mechanical strength and high electrical conductivity. On the one hand, good filler/polymer interfacial interactions are very important for load transfers between the filler and the polymer matrix; on the other hand, the dispersion of conductive fillers in the polymer matrix has great influence on the mechanical properties, electrical conductivity, and piezoresistive properties of composites. The more uniform and better dispersed the conductive carbon filler is in the system, the better the mechanical properties of the polymer matrix will be. However, too high a content of a conductive carbon filler can cause agglomeration, forming stress concentration points, which become defects and reduce the tensile strength of the material. However, it is difficult to realize the uniform dispersion of conductive fillers in the polymer matrix. The dispersion of conductive fillers in the polymer matrix largely depends on conditions such as its viscosity, dispersion method, shear stress, and mixing time.

Currently, commonly used methods for the preparation of polymer-based conductive composites include mechanical methods, liquid-phase blending composite methods, chemical modification methods, solid-phase eutectic composite methods, in situ polymerization methods, mixed curing agent-assisted stacking methods, sol–gel methods, etc. The degree of dispersion of conductive fillers with large specific surface areas in polymers can be facilitated by the above methods. Mechanical methods, generally utilizing ultrasonic vibration and magnetic or mechanical stirring, can assist in the dispersion of nanoparticles in dilute solutions. Liquid-phase co-compounding methods are generally aided by mixing the conductive particles in a dilute solution, which facilitates the acceleration of the wetting and penetration processes and reduces the strength of the agglomerates. In addition, the dispersion of the conductive particles in the polymer can also be facilitated by the introduction of chemical modification groups on the surface of the conductive particles that promote compatibility or linkage branching groups with the polymer, as described in Section 3.1.2.

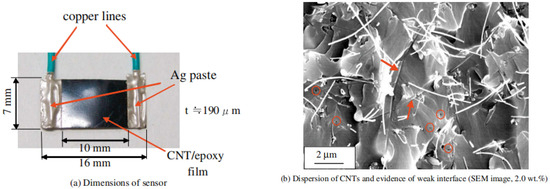

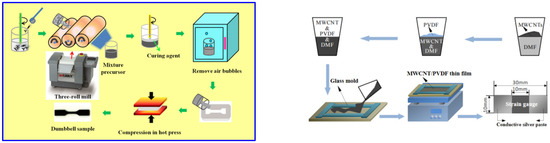

Tanabi et al. [113] found that the conductivity of CNT-filled nanocomposites prepared by different dispersion processes may differ by two orders of magnitude at the same CNT concentration. Chen et al. [114] synthesized epoxy resin/CNT nanocomposites using various methods to investigate the effects of dispersion methods on their properties. Firstly, CNTs were subjected to three methods: untreated, activated in HNO3, and activated with coupling agents in HNO3. Then, CNTs were dispersed and mixed into the resin using asymmetric centrifugation, ultrasound, and manual mixing methods. The results show that ultrasound combined with double asymmetric centrifugation was more effective for unpretreated CNTs. Dispersion with ultrasound is no longer recommended for CNTs pretreated with HNO3, as ultrasound may destroy the pretreated CNTs. Li et al. [115] dispersed mechanical mixtures of conductive hybrid materials and particles separately using a three-roll mill and subsequently dispersed them proportionally into epoxy resins, which were degassed and cured under high pressure (10 MPa). Sharma et al. [116] utilized a N, N-dimethylformamide (DMF) solvent to promote the dispersion of CNTs in the polymer matrix material PVDF and molded the composite material on a glass substrate to introduce a conductive silver paste, as shown in Figure 12. Zhang et al. [117] prepared conductive composites by depositing MWCNT on the surface of electrically insulating glass fibers by electrophoresis or impregnation, followed by embedding single or multiple MWCNT glass fibers into an epoxy matrix.

Figure 12.

Composite materials prepared by three mill methods and solvent methods [115,116].

3.3. Research on Epoxy Resin-Based Conductive Composites

Epoxy resins are substances containing two or more epoxy groups (-CH-O-CH-) in the molecule. Based on the advantages of higher reactivity, adjustable and controllable strength of epoxy resins, the special volume effect, the tunneling effect, and the quantum size effect of conductive fillers, such as CNTs, epoxy resin-based conductive composites exhibit excellent mechanical [118], electrical [119,120,121], thermodynamic [122], optical, and other properties. In recent years, preparing sensitive polymer composite materials with epoxy resin and CNTs as conductive materials has become a hot research topic.

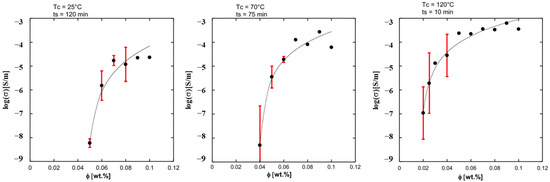

Lachman et al. [118] and Chang et al. [119] investigated the effects of different functionalized CNTs, such as pristine CNTs, carboxylated CNTs, and amine-based CNTs, on the mechanical properties of epoxy matrix composites and explored the potential correlation between different functionalized CNTs due to their different interfacial adhesion abilities and material mechanics, especially toughness, by combining them with the classical pull-out energy model. Monti et al. [120] investigated the electrical (shown in Figure 13) and dielectric properties of multi-walled CNT epoxy composites prepared with different process parameters (ultrasonication time and curing temperature) by using both DC and AC methods to analyze the seepage behavior of the composites and to study the correlation between the network of CNTs generated during the preparation process and the final properties.

Figure 13.

Percolation behavior under different preparation parameters [122].

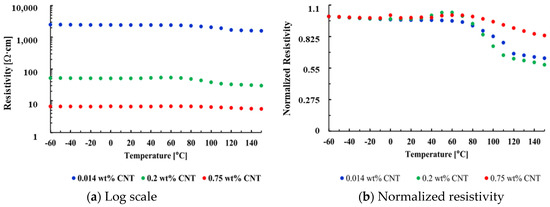

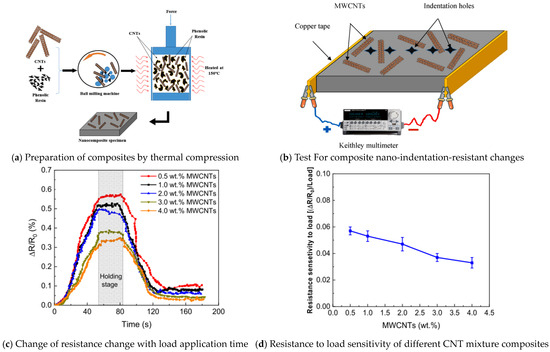

Earp et al. [121] investigated the electrical behavior of CNT epoxy composites in different temperature environments using a convection oven thermal vacuum chamber by determining the apparent resistance values and by normalizing the resistance values, which showed that CNT epoxy composites showed a small change in resistance values in the range of −60 °C to 60 °C, but beyond 60 °C, the resistance values showed a significant decreasing trend. Upon reaching 150 °C, the resistance value decreased to 40%, as shown in Figure 14. Factors that have been verified in the relevant literature to cause changes in electrical resistance include, among others, the temperature dependence of composite matrix materials, differences in the thermal expansion of matrix constituents, the thermal activation/thermal fluctuation-induced tunneling of carriers at elevated temperatures [122], and interactions with the atmosphere [123,124]. Al-Bahrani et al. [125,126] prepared self-sensing nanoresin composites based on CNTs by the hot-pressing method (as shown in Figure 15a) and found that overdiffusion of electrical rates occurs up to 1.0 wt% CNT doping, and material conductivity reaches a maximum when the doping level is 4.0 wt%. Meanwhile, resistance changes in the composite material when compressed in the micro-zone was tested using nano-indentation experiments (shown in Figure 15b) to verify the piezoelectric sensing properties of the material (shown in Figure 15c), the law of the resistance with micro-zone indentation damage was established, and a simple micro-scale model for predicting changes in the rate of change of the electrical resistance caused by the micro-indentation damage was proposed.

Figure 14.

Variations in resistivity recorded when samples were exposed to 10−6 mmHg [121].

Figure 15.

Self-sensing nanoresin composites developed by Al-Bahrani [126].

Hu et al. [127] prepared resistive strain sensors with metal-coated carbon nanofillers (CNFs)/epoxy resins. Two types of nanofillers were used, i.e., multi-walled CNTs and nickel-, copper-, and silver-coated vapor-phase-grown carbon fibers. The results show that the metal-loaded novel sensors have higher strain sensitivity, up to about 80 times that of metal foil strain gauges, compared to sensors made of nanomaterials that are not metal-loaded and compared to conventional strain gauges. Kim et al. [128] investigated the effects of MWCNT conductive fillers on the electrical conductivity and dielectric and piezoelectric properties of ceramic–epoxy nanocomposite films. Their study was based on the permeation theory, whereby CNTs act as a conductive bridge between piezoelectric ceramic particles, and a small amount of CNTs dispersed in the nanocomposite film can significantly improve the dielectric and piezoelectric properties of the film, e.g., the piezoelectric coefficient of the ceramic–epoxy nanocomposite film with the addition of 0.07 wt% of CNTs was 2.5 times higher than that of the original composite film. Liang et al. [129] designed an integrated system for road traffic information sensing, monitoring, and energy harvesting with the PVDF/PZT/CNTS piezoelectric sensor, which was successfully applied to a real highway (Jinan-Weifang Expressway, China). Precise control and loading tests of the vehicle’s front and rear axle weights were achieved at the design speeds of 30 km/h and 60 km/h and with rear axle weights of the test vehicle of 5 t (0.35 MPa), 10 t (0.7 MPa), and 15 t (1.05 MPa).

Summarizing the status of available research, it can be concluded that in situ road-monitoring technology based on conductive sensitive polymer composites shows great application prospects, which provides a reliable approach for the development of monitoring sensors, but polymer the electric force response of conductive composites, their sensing characteristics, their long-term service performance, the deformation characteristics of road structures, and other issues still need to be further clarified.

4. Future Research Directions for Smart Sensing Technologies in Civil Engineering

- (1)

- Multi-Modal Sensor Fusion and Hybrid Sensing Architectures

Future research should focus on integrating multi-modal sensor networks (e.g., combining fiber optics, wireless sensors, and radars) to achieve comprehensive structural health monitoring. For instance, fiber-optic sensors excel in long-term strain and temperature monitoring, while wireless sensors provide flexibility in dynamic load detection. Hybrid systems leveraging AI-driven data fusion algorithms (e.g., deep learning for anomaly detection) could enhance accuracy and reduce false alarms. A priority is to develop low-power, high-sensitivity sensor nodes capable of cross-modal data synchronization in harsh environments (e.g., underwater tunnels or extreme climates).

- (2)

- Self-Powered and Energy-Harvesting Sensors

Advancing self-sustaining sensing systems is critical for large-scale infrastructure monitoring. Current battery-dependent wireless sensors face limitations in longevity and maintenance costs. Research should explore energy harvesting from ambient sources (e.g., piezoelectric materials for vibration energy conversion and solar-powered sensors for surface structures). For example, bio-inspired materials like cellulose nanofiber composites could enable biodegradable sensors with integrated energy storage. Additionally, optimizing energy-efficient communication protocols (e.g., LoRaWAN for long-range transmission) is essential.

- (3)

- Edge Computing and Distributed Intelligence

To address latency and bandwidth constraints in real-time monitoring, edge computing frameworks must be prioritized. Embedding AI models directly on sensor nodes (e.g., TinyML for crack detection) can reduce reliance on centralized cloud systems. Future studies should investigate lightweight algorithms for edge devices, such as compressed neural networks tailored for structural data. Distributed intelligence also requires robust fault-tolerant mechanisms to ensure reliability in sensor networks.

5. Conclusions and Challenges

In this paper, the existing research on in situ sensing technology for the internal conditions of layered road structures in the past 20 years was extensively reviewed and compared. The monitoring approach of the internal conditions of the road structures mainly involves buried sensors, which can obtain the accurate mechanical state of a road structure. These sensors mainly include fiber-optic grating sensors, resistive strain gauges, electrically conductive concrete composites, piezoelectric sensing elements, etc. This paper discussed in detail the principles, advantages, and disadvantages of each monitoring sensor and its applicability in road monitoring. Sensing technology based on conductive polymer self-sensing materials has broad application prospects. Meanwhile, the details of conductive polymer compositions, preparation processes, and sensing performance factors were discussed. Lastly, the application of epoxy-based conductive sensitive materials for in situ road-monitoring techniques was emphasized.

Current sensors used for internal condition monitoring of road structures include fiber-optic grating sensors, resistive strain gauges, sensors based on conductive concrete composites, piezoelectric sensors, and wireless sensing elements. These sensors can acquire mechanical and environmental parameters, such as strain, stress, temperature, humidity, etc., of layered road structures by burying them inside the road. The monitoring accuracy of fiber grating sensors is very good, and the monitoring accuracy can reach ±1 με, but it is not suitable for large deformation monitoring. The available research focuses on encapsulation for fiber gratings in order to adapt to the complex service environment of roads. Resistive strain gauges have better monitoring accuracy, but water and humidity have a greater effect on resistive sensors. Sensors based on conductive concrete composites are mainly used in monitoring the condition of structural concrete and are not suitable for road monitoring. Piezoelectric sensors can obtain the road surface stress state and vehicle axle weight and other information, while wireless sensing elements are mainly made of the encapsulation of microelectronic devices, which can be used as wireless road monitoring of the “smart rock”. However, most of the sensors currently used in road engineering have been transplanted directly from structural engineering and other fields. Current sensors are less compatible with flexible pavement structures, resulting in distorted sensor test data.

Sensitive polymer composite materials have good adaptability to complex engineering environments, material compatibility, strain sensitivity, use of durability, and other advantages. Considering the harshness of pavement monitoring environments, conductive sensitive polymer composites provide a reliable approach for the development of pavement monitoring sensors, and sensitive polymer composite-based sensors show good durability and weather resistance. For conductive polymer sensing materials for road monitoring, it is recommended to use epoxy resin, nylon, and other polymer matrices with similar modulus properties to the road material. Nanoconductive fillers, such as CNTs, graphene, etc., are conducive to improving the response accuracy of composite materials. Meanwhile, the preparation process has a huge impact on the strain resistance effect of conductive composite materials, and it is recommended to use a combination of mechanical mixing and ultrasonic dispersion to prepare polymer conductive composite materials. Sensors based on epoxy conductive composites and in situ monitoring technology for roads show great application prospects.

However, the current research on composite materials and sensors in the field of road engineering is relatively limited and mainly has the following urgent problems. The electric force response and sensing characteristics of polymer conductive composites still need to be further studied, especially given the lack of research on the electric force response under small strain conditions. The long-term service performance of polymer conductive composite sensors in complex road environments, the deformation characteristics of buried sensors and layered road structures, and the durability effects of buried polymer conductive composite sensors on road structures and materials are understudied. Finally, the encapsulation technology for polymer conductive composites adapted to the road service environment still needs further research.

Author Contributions

X.X.: writing—review and editing. J.H.: conceptualization. L.C.: investigation. M.L.: conceptualization. Z.Y.: conceptualization. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Shandong Provincial Natural Science Foundation (ZR2024QE383).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The Researcher would like to thank the University of Jinan and Shandong University for financial support.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Liu, Y.; Su, P.; Li, M.; You, Z.; Zhao, M. Review on evolution and evaluation of asphalt pavement structures and materials. J. Traffic Transp. Eng. (Engl. Ed.) 2020, 7, 573–599. [Google Scholar]

- Liang, M.; Liang, P.; Fan, W.; Qian, C.; Xin, X.; Shi, J.; Nan, G. Thermo-rheological behavior and compatibility of modified asphalt with various styrene–butadiene structures in SBS copolymers. Mater. Des. 2015, 88, 177–185. [Google Scholar]

- Abdo, M. Structural Health Monitoring, History, Applications and Future. A Review Book; Open Science: Charlottesville, VA, USA, 2014. [Google Scholar]

- Liu, G. Review and Prospect of Research on Structural Health Monitoring Technology for Bridges. J. Arch. Res. Dev. 2024, 8, 156–161. [Google Scholar]

- Dong, Z.; Ma, X.; Shao, X. Airport pavement responses obtained from wireless sensing network upon digital signal processing. Int. J. Pavement Eng. 2018, 19, 381–390. [Google Scholar]

- Ko, J.M.; Ni, Y.Q. Technology developments in structural health monitoring of large-scale bridges. Eng. Struct. 2005, 27, 1715–1725. [Google Scholar]

- Han, W.; Yang, G.; Chen, S.; Zhou, K.; Xu, X. Research progress on intelligent operation and maintenance of bridges. J. Traffic Transp. Eng. (Engl. Ed.) 2024, 11, 173–187. [Google Scholar]

- Liu, H.; Ge, W.; Pan, Q.; Hu, R.; Lv, S.; Huang, T. Characteristics and analysis of dynamic strain response on typical asphalt pavement using Fiber Bragg Grating sensing technology. Constr. Build. Mater. 2021, 310, 125242. [Google Scholar]

- Soong, T.T.; Cimellaro, G.P. Future directions in structural control. Struct. Control Health Monit. 2009, 16, 7–16. [Google Scholar]

- Rana, S.; Fangueiro, R.; Correia, A.G. A review on smart self-sensing composite materials for civil engineering applications. AIMS Mater. Sci. 2016, 3, 357–379. [Google Scholar]

- Barriera, M.; Pouget, S.; Lebental, B.; Van Rompu, J. In situ pavement monitoring: A review. Infrastructures 2020, 5, 18. [Google Scholar] [CrossRef]

- Alavi, A.H.; Hasni, H.; Lajnef, N.; Chatti, K. Continuous health monitoring of pavement systems using smart sensing technology. Constr. Build. Mater. 2016, 114, 719–736. [Google Scholar]

- Moghaddam, T.B.; Karim, M.R.; Abdelaziz, M. A review on fatigue and rutting performance of asphalt mixes. Sci. Res. Essays 2011, 6, 670–682. [Google Scholar]

- Selvaraj, S.I. Review on the use of instrumented pavement test data in validating flexible pavement mechanistic load response models. Procedia-Soc. Behav. Sci. 2012, 43, 819–831. [Google Scholar] [CrossRef][Green Version]

- Wang, N.; Han, T.; Cheng, H.; Li, T.; Fu, J.; Ma, T.; Fu, Y.; Chen, F.; Zhang, Y. Monitoring structural health status of asphalt pavement using intelligent sensing technology. Constr. Build. Mater. 2022, 352, 129025. [Google Scholar]

- Chu, W.; Xiong, L.H. A review on pavement distress and structural defects detection and quantification technologies using imaging approaches. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 135–150. [Google Scholar] [CrossRef]

- Friebele, E.J. Fiber Bragg grating strain sensors: Present and future applications in smart structures. Opt. Photonics News 1998, 9, 33. [Google Scholar] [CrossRef]

- Fu, D.; Zhang, Y.N.; Zhang, A.; Han, B.; Wu, Q.; Zhao, Y. Novel fiber grating for sensing applications. Phys. Status Solidi A 2019, 216, 1800820. [Google Scholar]

- Grattan, K.T.; Sun, T. Fiber optic sensor technology: An overview. Sens. Actuators A Phys. 2000, 82, 40–61. [Google Scholar] [CrossRef]

- Wang, J.; Han, Y.; Cao, Z.; Xu, X.; Zhang, J.; Xiao, F. Applications of optical fiber sensor in pavement Engineering: A review. Constr. Build. Mater. 2023, 400, 132713. [Google Scholar] [CrossRef]

- Di Graziano, A.; Marchetta, V.; Cafiso, S. Structural health monitoring of asphalt pavements using smart sensor networks: A comprehensive review. J. Traffic Transp. Eng. (Engl. Ed.) 2020, 7, 639–651. [Google Scholar] [CrossRef]

- Deng, L.; Cai, C.S. Applications of fiber optic sensors in civil engineering. Struct. Eng. Mech. 2007, 25, 577–596. [Google Scholar]

- Mustafa, S.; Sekiya, H.; Maeda, I.; Takaba, S.; Hamajima, A. Identification of external load information using distributed optical fiber sensors embedded in an existing road pavement. Opt. Fiber Technol. 2021, 67, 102705. [Google Scholar]

- Mustafa, S.; Sekiya, H.; Morichika, S.; Maeda, I.; Takaba, S.; Hamajima, A. Monitoring internal strains in asphalt pavements under static loads using embedded distributed optical fibers. Opt. Fiber Technol. 2022, 68, 102829. [Google Scholar]

- De Maeijer, P.K.; Van den bergh, W.; Vuye, C. Fiber Bragg grating sensors in three asphalt pavement layers. Infrastructures 2018, 3, 16. [Google Scholar] [CrossRef]

- Grakovski, A.; Pilipovec, A.; Kabashkin, I.; Petersons, E. Weight-in-motion estimation based on reconstruction of tyre footprint’s geometry by group of fibre optic sensors. Transp. Telecommun. J. 2014, 15, 97–110. [Google Scholar]

- Dong, Z.; Tan, Y.; Cao, L.; Liu, H. Combining strain measurement and FEM simulation to obtain dynamic response of asphalt pavement. Int. J. Pavement Res. Technol. 2009, 2, 231–235. [Google Scholar]

- Tan, Y.; Wang, H.; Ma, S.; Xu, H. Quality control of asphalt pavement compaction using fibre Bragg grating sensing technology. Constr. Build. Mater. 2014, 54, 53–59. [Google Scholar]

- Tan, Y.; Wang, H.; Sun, Z.; Li, Y.; Shi, X. Calibration method of FBG sensor based on asphalt pavement indoor small size test. In Proceedings of the 2011 International Conference on Transportation, Mechanical, and Electrical Engineering (TMEE), Beijing, China, 23–24 October 2011. [Google Scholar]

- Tan, Y.; Chen, F.C.; Dong, Z.; Liu, H. Calculation method of permanent deformation for asphalt pavement based on fiber bragg grating sensing technology. J. Dalian Marit. Univ. 2008, 11, 119–122. [Google Scholar]

- Dong, Z.; Tan, Y.; Chen, F. Preliminary design of testing segment for Accelerated Loading Facility based on Finite Element Simulation Analysis. Asphalt Material Characterization, Accelerated Testing, and Highway Management. In Proceedings of the 2009 GeoHunan International Conference, Changsha, China, 16–18 October 2009. [Google Scholar]

- Dong, Z.; Ma, X.; Gong, X.; Oeser, M. Theoretical evaluation of the measurement accuracy of fiber Bragg grating strain sensors within randomly filled asphalt mixtures based on finite element simulation. Struct. Control Health Monit. 2018, 25, 2057. [Google Scholar]

- Tan, Y.; Liang, Z.; Xu, H.; Xing, C. Research on rutting deformation monitoring method based on intelligent aggregate. IEEE Trans. Intell. Transp. Syst. 2022, 23, 22116–22126. [Google Scholar]

- Li, R. Research and development status of intelligent sensing materials, sensors and health monitoring systems for civil engineering structures. Archit. Eng. Technol. Des. 2016, 1, 72–76. [Google Scholar]

- Qian, Z.; Huang; Guan, Y.; Han, G. BOTDA Application in the crack monitoring of asphalt concrete pavement layer. J. Southeast Univ. (Nat. Sci. Ed.) 2008, 38, 799–803. [Google Scholar]

- Qian, Z.; Han, G.; Huang; Guan, Y.; Yin, Z. Study on crack fatigue expansion of steel bridge deck pavement based on BOTDA. J. Civ. Eng. 2009, 42, 132–136. [Google Scholar]

- Hu, J.; Qian, Z.; Chen, L. Fracture behavior of epoxy asphalt pavement on steel bridges based on optical fiber sensing technology and numerical simulation. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2014, 29, 858–862. [Google Scholar]

- Xiang, P.; Wang, H. Optical fibre-based sensors for distributed strain monitoring of asphalt pavements. Int. J. Pavement Eng. 2016, 19, 842–850. [Google Scholar]

- Liu, Z.; Gu, X.; Wu, C.; Ren, H.; Zhou, Z.; Tang, S. Studies on the validity of strain sensors for pavement monitoring: A case study for a fiber Bragg grating sensor and resistive sensor. Constr. Build. Mater. 2022, 321, 126085. [Google Scholar]

- Al-Tarawneh, M.A. Traffic Monitoring System Using in-Pavement Fiber Bragg Grating Sensors. Ph.D. Dissertation, North Dakota State University, Fargo, ND, USA, 2019. [Google Scholar]

- Bado, M.F.; Casas, J.R. A review of recent distributed optical fiber sensors applications for civil engineering structural health monitoring. Sensors 2021, 21, 1818. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, Y.; Li, Y.; Hao, Q. Development and application of resistance strain force sensors. Sensors 2020, 20, 5826. [Google Scholar] [CrossRef]

- Ni, Y.; Xia, H.; Wong, K.; Ko, J. In-service condition assessment of bridge deck using long-term monitoring data of strain response. J. Bridge Eng. 2012, 17, 876–885. [Google Scholar]

- Regier, R.; Hoult, N. Distributed strain behavior of a reinforced concrete bridge: Case study. J. Bridge Eng. 2014, 19, 05014007. [Google Scholar]

- Li, Q.; Cary, C.; Combs, S.; Garg, N. Evaluation of asphalt concrete layer response using asphalt strain gauges and fiber optic strain gauges. In Proceedings of the International Conference on Transportation and Development 2016, Houston, TX, USA, 26–29 June 2016. [Google Scholar]

- Swett, L.; Mallick, R.B.; Humphrey, D.N. A study of temperature and traffic load related response in different layers in an instrumented flexible pavement. Int. J. Pavement Eng. 2008, 9, 303–316. [Google Scholar] [CrossRef]

- Islam, M.R.; Tarefder, R.A. Field measurement of vertical strain in asphalt concrete. Int. J. Sci. Eng. Res. 2013, 4, 1–6. [Google Scholar]

- Al-Qadi, I.L.; Loulizi, A.; Elseifi, M.; Lahouar, S. The Virginia Smart Road: The impact of pavement instrumentation on understanding pavement performance. J. Assoc. Asph. Paving Technol. 2004, 73, 427–465. [Google Scholar]

- Cook, K.; Garg, N.; Singh, A.; Flynn, M. Detection of delamination in the HMA layer of runway pavement structure using asphalt strain gauges. J. Transp. Eng. 2016, 142, 04016047. [Google Scholar] [CrossRef]

- Correia, N.S.; Zornberg, J.G. Mechanical response of flexible pavements enhanced with geogrid-reinforced asphalt overlays. Geosynth. Int. 2016, 23, 183–193. [Google Scholar] [CrossRef]

- Duong, N.S.; Blanc, J.; Hornych, P.; Bouveret, B.; Carroget, J.; Le Feuvre, Y. Continuous strain monitoring of an instrumented pavement section. Int. J. Pavement Eng. 2019, 20, 1435–1450. [Google Scholar] [CrossRef]

- Gaborit, P.; Sauzéat, C.; Di Benedetto, H.; Pouget, S.; Olard, F.; Claude, A. Investigation of highway pavements using in-situ strain sensors. In Sustainability, Eco-Efficiency, and Conservation in Transportation Infrastructure Asset Management; Academia.edu: San Francisco, CA, USA, 2014; pp. 331–337. [Google Scholar]

- Wang, L.; Wei, J.; Wu, W.; Zhang, X.; Xu, X.; Yan, X. Technical development and long-term performance observations of long-life asphalt pavement: A case study of Shandong Province. J. Road Eng. 2022, 2, 369–389. [Google Scholar] [CrossRef]

- Ai, C.; Rahman, A.; Xiao, C.; Yang, E.; Qiu, Y. Analysis of measured strain response of asphalt pavements and relevant prediction models. Int. J. Pavement Eng. 2017, 18, 1089–1097. [Google Scholar] [CrossRef]

- Luan, L.; Guo, Z.; Lu, X. Loading response analysis of the pavement of Fuzhou freeway test road. Highw. Eng. 2012, 37, 229–233. [Google Scholar]

- Lin, S.; Ling, Y. Adaptation of buried strain gages for asphalt concrete pavement. Shanghai Highw. 2019, 1, 25–29. [Google Scholar]

- Yang, Y.; Wang, L.; Gao, X.; Jia, H.; Wei, J. Analysis of perpetual pavement strain distribution and fatigue damage. J. Shandong Univ. (Eng. Sci.) 2009, 39, 118–124. [Google Scholar]

- Chuan, X. Evaluation of measured strain responses to in situ vehicular loading for typical asphalt pavements. Eng. Trans. 2019, 67, 55–73. [Google Scholar]

- Nie, M.; Ren, X.; Wen, L.; Han, L.; Wang, J.; Su, S. Highly sensitive and large range strain sensor based on synergetic effects with double conductive layer structures. Sens. Actuators A Phys. 2021, 318, 112515. [Google Scholar] [CrossRef]

- Han, M.; Muhammad, Y.; Wei, Y.; Zhu, Z.; Huang, J.; Li, J. A review on the development and application of graphene based materials for the fabrication of modified asphalt and cement. Constr. Build. Mater. 2021, 285, 122885. [Google Scholar] [CrossRef]

- Ding, S.; Ruan, Y.; Yu, X.; Han, B.; Ni, Y. Self-monitoring of smart concrete column incorporating CNT/NCB composite fillers modified cementitious sensors. Constr. Build. Mater. 2019, 201, 127–137. [Google Scholar] [CrossRef]

- Yu, X.; Kwon, E. A carbon nanotube/cement composite with piezoresistive properties. Smart Mater. Struct. 2009, 18, 055010. [Google Scholar] [CrossRef]

- Parveen, S.; Rana, S.; Fangueiro, R. A review on nanomaterial dispersion, microstructure, and mechanical properties of carbon nanotube and nanofiber reinforced cementitious composites. J. Nanomater. 2013, 2013, 710175. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Kwon, E. A self-sensing carbon nanotube/cement composite for traffic monitoring. Nanotechnology 2009, 20, 445501. [Google Scholar] [CrossRef]

- Sun, M.Q.; Liew, R.J.; Zhang, M.H.; Li, W. Development of cement-based strain sensor for health monitoring of ultra high strength concrete. Constr. Build. Mater. 2014, 65, 630–637. [Google Scholar] [CrossRef]

- Baeza, F.J.; Galao, O.; Zornoza, E.; Garcés, P. Effect of aspect ratio on strain sensing capacity of carbon fiber reinforced cement composites. Mater. Des. 2013, 51, 1085–1094. [Google Scholar] [CrossRef]

- Nalon, G.H.; Ribeiro, J.C.L.; de Araújo, E.N.D.; Pedroti, L.G.; de Carvalho, J.M.F.; Santos, R.F.; Aparecido-Ferreira, A. Aparecido-Ferreira. Effects of different kinds of carbon black nanoparticles on the piezoresistive and mechanical properties of cement-based composites. J. Build. Eng. 2020, 32, 101724. [Google Scholar]

- Han, B.; Guan, X.; Ou, J. Experimental research of electrical conductivity and pressure sensitivity of carbon fiber reinforced cement. Mater. Sci. Technol. 2006, 14, 1–4. [Google Scholar]

- Chen, Z.; Liu, R.; Hao, P.; Li, G.; Su, J. Developments of conductive materials and characteristics on asphalt concrete: A review. J. Test. Eval. 2020, 48, 2144–2161. [Google Scholar]

- García, Á.; Schlangen, E.; van de Ven, M.; Liu, Q. Electrical conductivity of asphalt mortar containing conductive fibers and fillers. Constr. Build. Mater. 2009, 23, 3175–3181. [Google Scholar]

- Liu, X.; Wu, S. Study on the piezoresistivity character of electrically conductive asphalt concrete. Adv. Mater. Res. 2011, 233, 1756–1761. [Google Scholar]

- Liu, X.; Wu, S. Research on the conductive asphalt concrete’s piezoresistivity effect and its mechanism. Constr. Build. Mater. 2009, 23, 2752–2756. [Google Scholar]

- Liu, X.; Liu, W.; Wu, S.; Wang, C. Effect of carbon fillers on electrical and road properties of conductive asphalt materials. Constr. Build. Mater. 2014, 68, 301–306. [Google Scholar]

- Yan, D. Study of road performance and force-electrical sensitivity characteristics of conducting asphalt concretes. Highway 2019, 64, 33–37. [Google Scholar]

- Yao, Z.; Han, J.; Shang, Q.; Ge, Z.; Zhang, X.; Cui, H. Research on pressure sensitivity of the conductive asphalt mortar with carbon fiber and graphite powders. J. Shandong Univ. (Eng. Sci.) 2013, 43, 80–85. [Google Scholar]