High-Performance Asphalt Binder Incorporating Trinidad Lake Asphalt and SBS Polymer for Extreme Climates

Abstract

1. Introduction

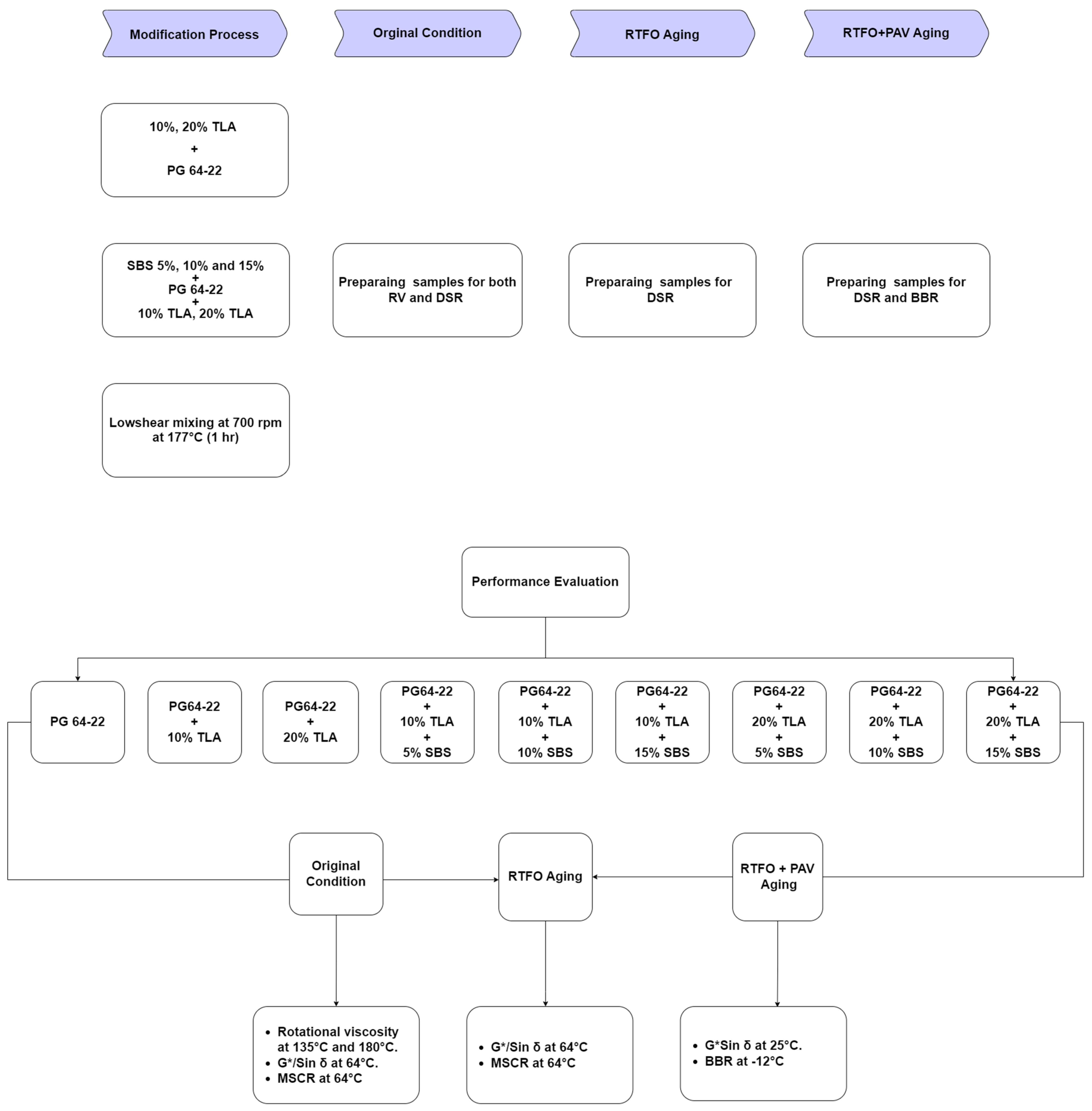

2. Materials and Experimental Methodology

2.1. Materials

2.2. Preparation of Samples

2.3. Physical Properties Test

2.4. Asphalt High Temperature Aging: Mechanisms of Short-Term (RTFO) and Extended Aging (PAV)

2.4.1. Short-Term Thermal Aging

2.4.2. Long-Term PAV Thermal Aging

2.5. Rheological Characteristics at High and Ambient Temperatures

2.6. Rheological Property at Low Temperature

2.7. Multiple Stress Creep and Recovery (MSCR) Examination

2.8. Statistical Analysis

3. Results and Discussion

3.1. Physical Properties

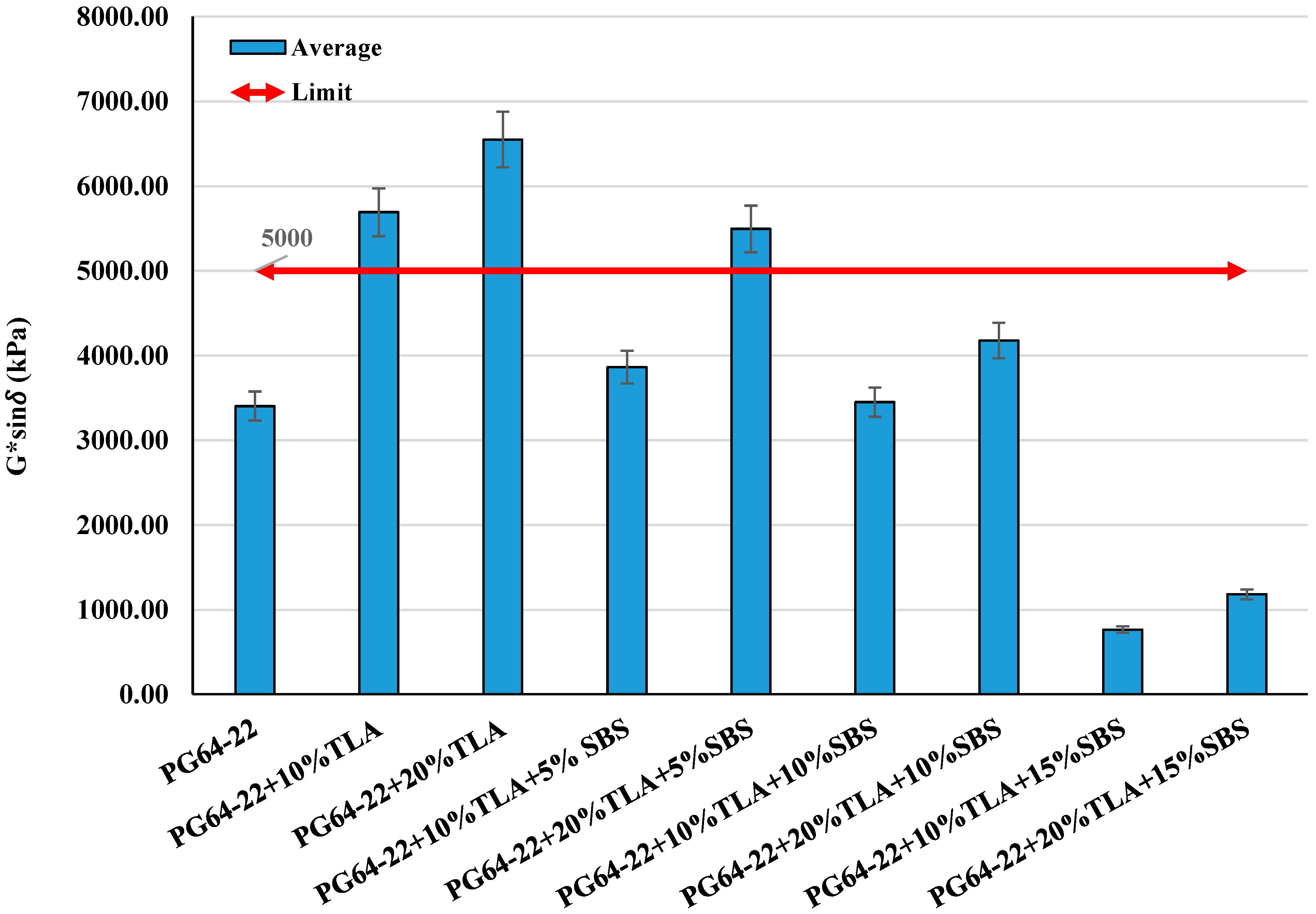

3.2. Rheological Characteristics at High Temperature

- PG64-22 + 10% TLA + 5% SBS achieved 10.10 kPa in the original condition and 19.70 kPa during the RTFO-aged condition.

- PG64-22 + 20% TLA + 5% SBS exhibited 14.54 kPa (original) and 25.18 kPa (RTFO). Statistical analysis confirms these improvements as significant compared to the PG64-22 and PG64-22 + TLA combinations, highlighting the effectiveness of SBS in enhancing binder performance.

- Further increasing SBS content to 10% and 15% showed remarkable gains as described below.

- PG64-22 + 10% TLA + 10% SBS reached 32.40 kPa (original) and 45.40 kPa (RTFO).

- PG64-22 + 20% TLA + 15% SBS recorded the highest values of 74.79 kPa (original) and 94.62 kPa (RTFO). Statistical analysis indicates that these combinations demonstrate significant differences (S) compared to all other binders, reinforcing the superiority of SBS-modified binders in achieving excellent rutting resistance.

3.3. Rheological Characteristics Results (Ambient Temperature)

3.4. Results of MSCR Test on Original and RTFO-Aged Binders

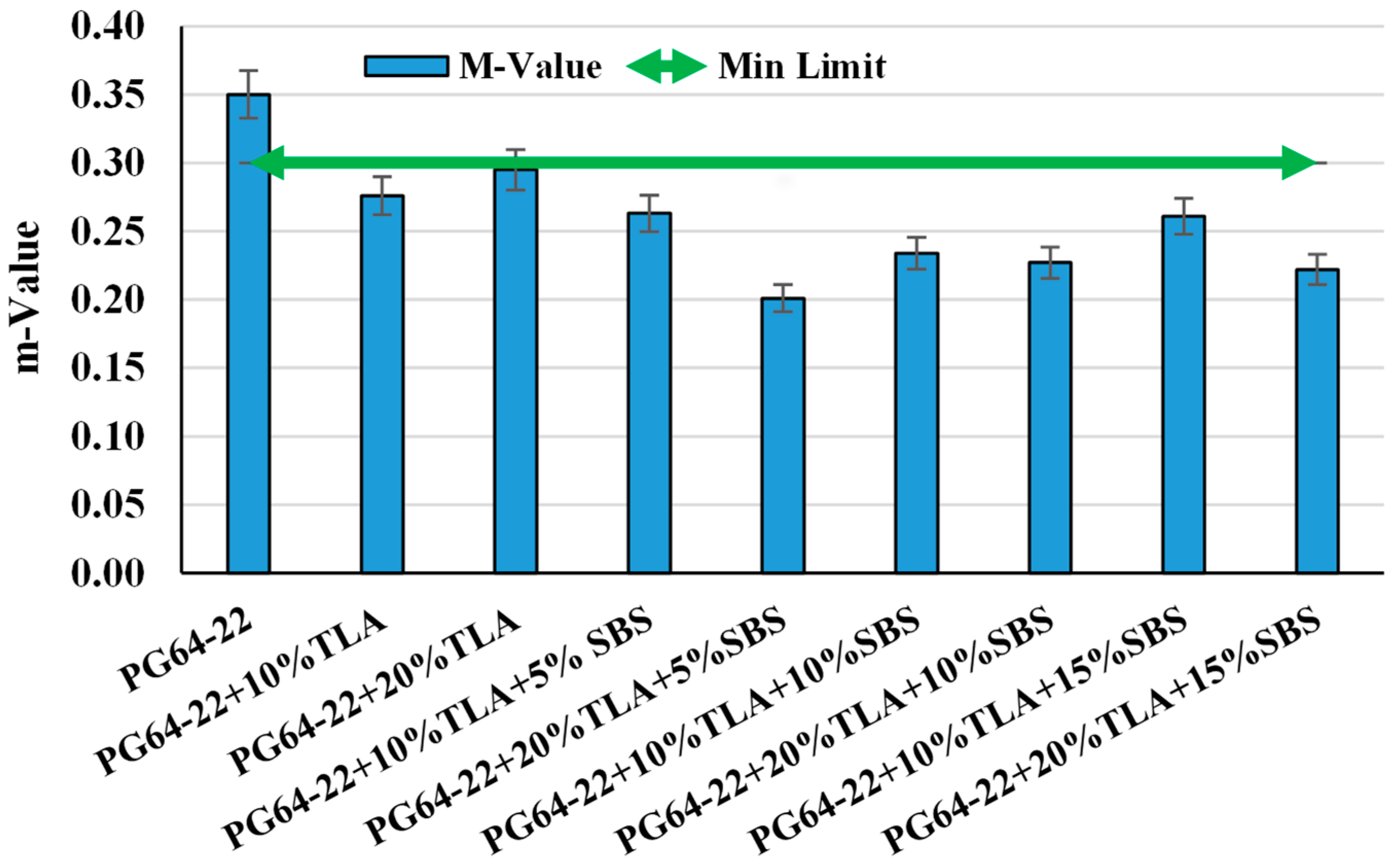

3.5. Rheological Characteristics Results (Low Temperature)

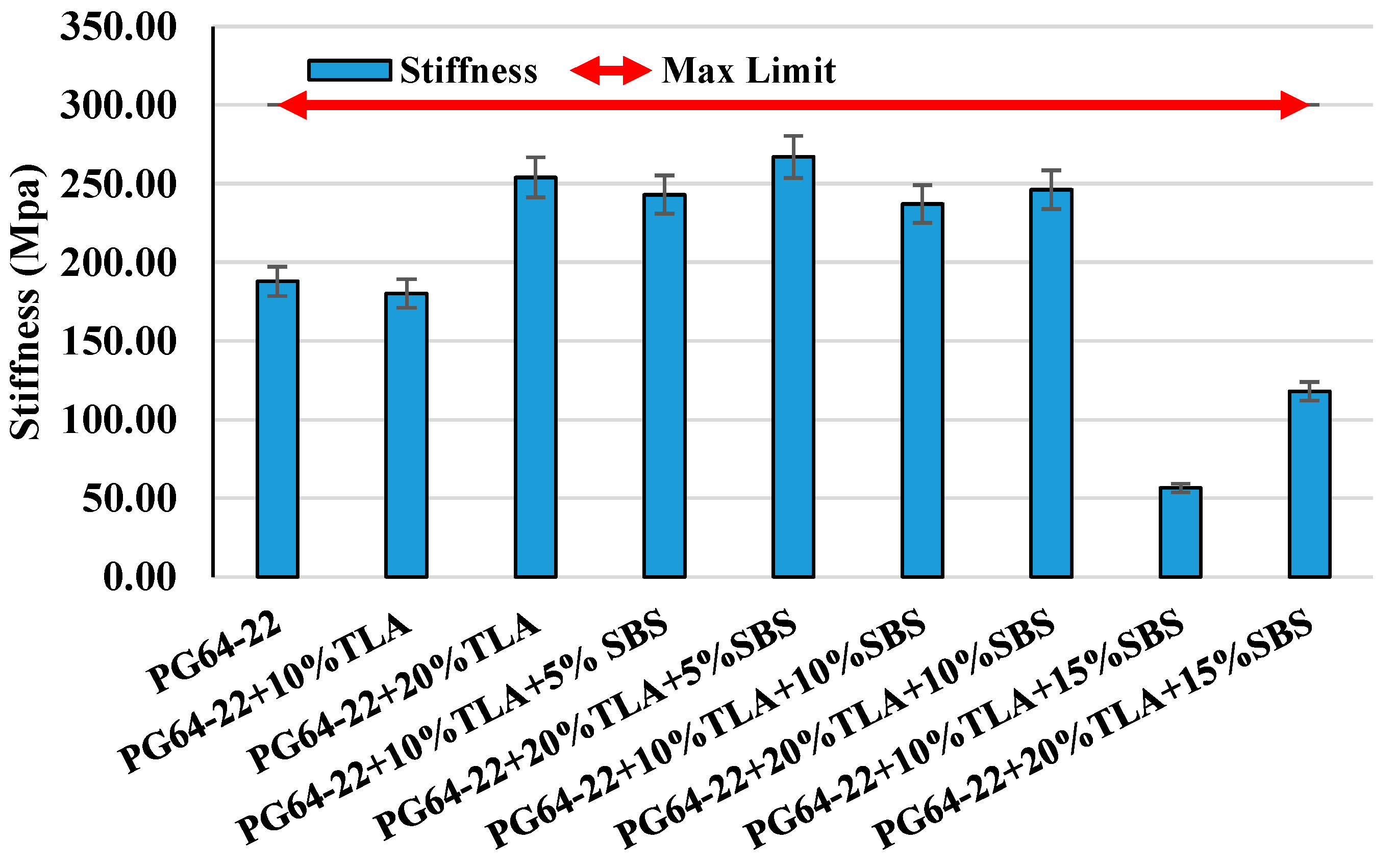

4. Conclusions

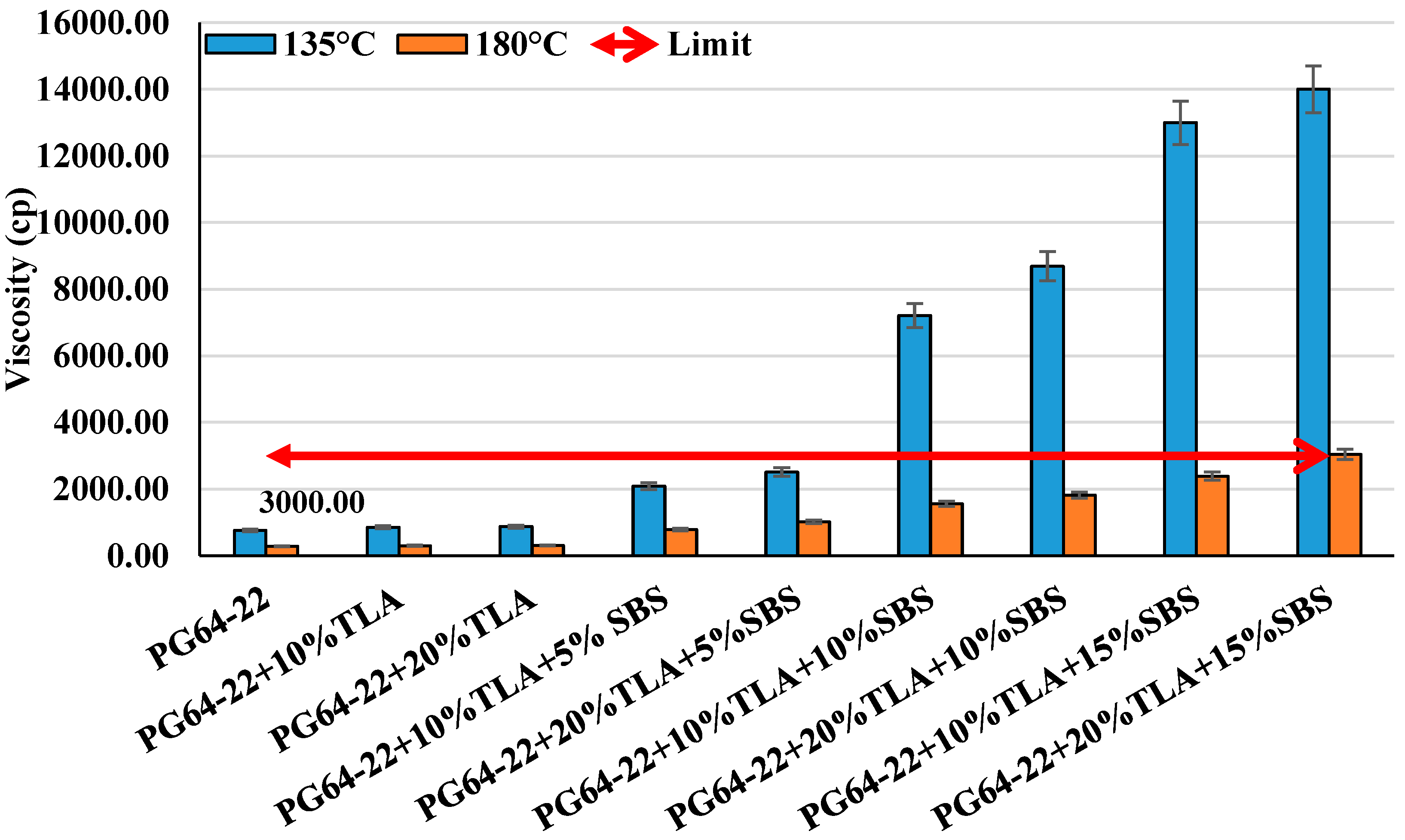

- The incorporation of TLA and SBS has a notable impact on binder viscosity. Moderate amounts of TLA (10–20%) combined with SBS (up to 5%) maintain satisfactory workability. However, a higher SBS content raises viscosity, reducing workability and necessitating increased mixing and compaction temperatures to address this issue.

- The DSR test results reveal substantial enhancements in rutting resistance with the addition of SBS, particularly at higher dosages. The optimal combination of 20% TLA and 15% SBS provides exceptional resistance to permanent deformation, making it a prime candidate for pavements subjected to high temperatures and heavy traffic loads.

- TLA increases stiffness and rutting resistance, but excessive rigidity is mitigated effectively by incorporating SBS. Moderate SBS levels restore flexibility while maintaining compliance with Superpave performance criteria, emphasizing the role of SBS in balancing stiffness and flexibility.

- The % recovery and non-recoverable compliance (Jnr) data indicate that binders with 15% SBS exhibit superior elastic recovery and minimal deformation under loading, even after RTFO aging. This confirms the suitability of these formulations for high-performance applications in heavy traffic and extreme climatic conditions.

- While an SBS above 7.5% is typically considered highly modified, this study investigated higher dosages (10–15%) due to the 20% TLA substitution limit. The results confirm that increasing SBS enhances elasticity and rutting resistance, with 15% SBS achieving >88% recovery and Jnr < 0.01 kPa−1. However, increased viscosity at higher SBS contents necessitates careful consideration of workability.

- The combination of 20% TLA with 10% SBS emerges as the optimal formulation, providing a balance between performance and practical usability for high-traffic, extreme climate pavements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, S.; Gong, F.; Ge, D.; You, Z.; Sousa, J.B. Use of Reacted and Activated Rubber in Ultra-Thin Hot Mixture Asphalt Overlay for Wet-Freeze Climates. J. Clean. Prod. 2019, 232, 369–378. [Google Scholar] [CrossRef]

- Zhu, Y.; Yi, J.; Xu, M.; Chen, Z.; Yang, S.-H.; Feng, D. Quantum Chemical Simulation and Laboratory Testing of the Curing Mechanism and Performance of Resin Bio-Oil. Int. J. Pavement Eng. 2021, 22, 1123–1142. [Google Scholar] [CrossRef]

- Liao, M.-C.; Chen, J.-S.; Airey, G.D.; Wang, S.-J. Rheological Behavior of Bitumen Mixed with Trinidad Lake Asphalt. Constr. Build. Mater. 2014, 66, 361–367. [Google Scholar] [CrossRef]

- Widyatmoko, I.; Elliott, R. Characteristics of Elastomeric and Plastomeric Binders in Contact with Natural Asphalts. Constr. Build. Mater. 2008, 22, 239–249. [Google Scholar] [CrossRef]

- Zou, G.; Xu, X.; Li, J.; Yu, H.; Wang, C.; Sun, J. The Effects of Bituminous Binder on the Performance of Gussasphalt Concrete for Bridge Deck Pavement. Materials 2020, 13, 364. [Google Scholar] [CrossRef] [PubMed]

- Hunter, R.N.; Self, A.; Read, J.; Hobson, E. The Shell Bitumen Handbook; Ice Publishing: London, UK, 2015; Volume 514. [Google Scholar]

- Ceratti, J.A.P.; Bernucci, L.L.B.; Soares, J.B. Utilização de Ligantes Asfálticos em Serviços de Pavimentação: Guia Técnico; Abeda: Rio de Janeiro, Brazil, 2015. [Google Scholar]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer Modification of Bitumen: Advances and Challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar]

- Su, M.; Zhou, J.; Lu, J.; Chen, W.; Zhang, H. Using Molecular Dynamics and Experiments to Investigate the Morphology and Micro-Structure of SBS Modified Asphalt Binder. Mater. Today Commun. 2022, 30, 103082. [Google Scholar]

- Chegenizadeh, A.; Tokoni, L.; Nikraz, H.; Dadras, E. Effect of Ethylene-Vinyl Acetate (EVA) on Stone Mastic Asphalt (SMA) Behaviour. Constr. Build. Mater. 2021, 272, 121628. [Google Scholar] [CrossRef]

- Zapién-Castillo, S.; Rivera-Armenta, J.L.; Chávez-Cinco, M.Y.; Salazar-Cruz, B.A.; Mendoza-Martínez, A.M. Physical and Rheological Properties of Asphalt Modified with SEBS/Montmorillonite Nanocomposite. Constr. Build. Mater. 2016, 106, 349–356. [Google Scholar] [CrossRef]

- Abduljabbar, N.; Al-Busaltan, S.; Dulaimi, A.; Al-Yasari, R.; Sadique, M.; Al Nageim, H. The Effect of Waste Low-Density Polyethylene on the Mechanical Properties of Thin Asphalt Overlay. Constr. Build. Mater. 2022, 315, 125722. [Google Scholar]

- Xu, X.; Yu, J.; Zhang, C.; Cao, Z.; Gu, Y.; Xue, L. Effect of Reactive Rejuvenators on Structure and Properties of UV-Aged SBS Modified Bitumen. Constr. Build. Mater. 2017, 155, 780–788. [Google Scholar]

- Wu, W.; Cavalli, M.C.; Jiang, W.; Kringos, N. Differing Perspectives on the Use of High-Content SBS Polymer-Modified Bitumen. Constr. Build. Mater. 2024, 411, 134433. [Google Scholar]

- Chen, M.; Geng, J.; Xia, C.; He, L.; Liu, Z. A Review of Phase Structure of SBS Modified Asphalt: Affecting Factors, Analytical Methods, Phase Models and Improvements. Constr. Build. Mater. 2021, 294, 123610. [Google Scholar] [CrossRef]

- Liang, M.; Xin, X.; Fan, W.; Luo, H.; Wang, X.; Xing, B. Investigation of the Rheological Properties and Storage Stability of CR/SBS Modified Asphalt. Constr. Build. Mater. 2015, 74, 235–240. [Google Scholar] [CrossRef]

- Rezaei, S.; Ziari, H.; Nowbakht, S. High-Temperature Functional Analysis of Bitumen Modified with Composite of Nano-Sio2 and Styrene Butadiene Styrene Polymer. Pet. Sci. Technol. 2016, 34, 1195–1203. [Google Scholar]

- Behnood, A.; Olek, J. Rheological Properties of Asphalt Binders Modified with Styrene-Butadiene-Styrene (SBS), Ground Tire Rubber (GTR), or Polyphosphoric Acid (PPA). Constr. Build. Mater. 2017, 151, 464–478. [Google Scholar]

- Rezaei, S.; Ziari, H.; Nowbakht, S. Low Temperature Functional Analysis of Bitumen Modified with Composite of Nano-Sio2 and Styrene Butadiene Styrene Polymer. Pet. Sci. Technol. 2016, 34, 415–421. [Google Scholar]

- Vigneswaran, S.; Yun, J.; Kim, H.; Lee, M.-S.; Lee, S.-J. Enhancing Asphalt Binder Performance and Storage Stability with Trinidad Lake Asphalt (TLA). Appl. Sci. 2024, 14, 6023. [Google Scholar] [CrossRef]

- Hemmati, N.; Vigneswaran, S.; Kim, H.H.; Lee, M.-S.; Lee, S.-J. Laboratory Evaluation of Asphalt Binders Containing Styrene-Butadiene-Styrene (SBS) and Processed Oil. Materials 2023, 16, 1235. [Google Scholar] [CrossRef] [PubMed]

- Jamrah, A.A.; Kutay, M.E. A New Rheological Approach to Evaluating the Aged Performance of Crumb Rubber Modified Binders. Int. J. Pavement Eng. 2022, 23, 1897–1910. [Google Scholar]

- ASTM D5-06; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D70-18a; Standard Test Method for Density of Semi-Solid Asphalt Binder (Pycnometer Method). ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D36/D36M-12; Standard Test Method for Softening Point of Bitumen (Ring-And Ball Apparatus). American Association of State and Highway Transportation Officials: Washington, DC, USA, 2014.

- ASTM D92-18; Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester. ASTM International: West Conshohocken, PA, USA, 2018.

- ISO 2781; Rubber, Vulcanized or Thermoplastic—Determination of Density. International Organization for Standardization (ISO): Geneva, Switzerland, 2002.

- ASTM D2240; Standard Test Method for Rubber Property—Durometer Hardness. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D445-18; Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity). ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D1416; Standard Test Methods for Rubber Property—Adhesion to Rigid Substrates. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D1925-17; Standard Test Method for Determining the Mechanical Properties of Natural and Artificial Weathering Wood. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D4402/D4402M-23; Standard Test Method for Viscosity Determination of Asphalt Binder Using Rotational Viscometer. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D2872-19; Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test). ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D6521-19; Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV). ASTM International: West Conshohocken, PA, USA, 2019.

- AASHTO T 315-12; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2012.

- AASHTO T 313-12; Standard Method of Test for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2012.

- AASHTO T350; Standard Method of Test for Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2019.

- Ott, R.L.; Longnecker, M. An Introduction to Statistical Methods and Data Analysis; Cengage Learning Inc.: Boston, MA, USA, 2010. [Google Scholar]

| Aging States | Test Properties | Test Result |

|---|---|---|

| Asphalt binder (before aging) | Viscosity @ 135 °C (cP) Viscosity @ 180 °C (cP) | 757 284 |

| G*/sin δ @ 64 °C (kPa) | 2.09 | |

| RTFO (short-term aged) | G*/sin δ @ 64 °C (kPa) | 6.00 |

| RTFO + PAV aged residual | G*sin δ @ 25 °C (kPa) | 3405 |

| Stiffness @ −12 °C (MPa) | 189 | |

| m-value @ −12 °C | 0.37 |

| Properties | Test Method | Test Result |

|---|---|---|

| Penetration (25 °C) | ASTM D5 [23] | 2–4 |

| Density | ASTM D70 [24] | 1.42–1.44 g/m3 |

| Softening point | ASTM D36 [25] | 94–100 °C |

| Flash point | ASTM D92 [26] | 257–268 °C |

| Fire point | ASTM D92 (Cleveland open cup) [26] | 308–312 °C |

| Parameter | Method | Test Result |

|---|---|---|

| Density | ISO 2781 [27] | 0.94 g/cm3 |

| Hardness | ASTM D2240 [28] | 79 Shore A |

| Toluene solution viscosity | ASTM D445 [29] | 13 cSt |

| Volatile matter | ASTM D1416 [30] | <0.7% |

| Yellow index | ASTM D1925 [31] | <7 |

| Viscosity at 135 °C and 180 °C | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 135C | 180C | ||||||||||||||||||

| Combination | P64-22 | PG64-22 + 10% TLA | PG64-22 + 20% TLA | PG64-22 + 10% TLA + 5% SBS | PG64-22 + 20% TLA + 5% SBS | PG64-22 + 10% TLA + 10% SBS | PG64-22 + 20% TLA + 10% SBS | PG64-22 + 10% TLA + 15% SBS | PG64-22 + 20% TLA + 15% SBS | PG64-22 | PG64-22 + 10% TLA | PG64-22 + 20% TLA | PG64-22 + 10% TLA + 5% SBS | PG64-22 + 20% TLA + 5% SBS | PG64-22 + 10% TLA + 10% SBS | PG64-22 + 20% TLA + 10% SBS | PG64-22 + 10% TLA + 15% SBS | PG64-22 + 20% TLA + 15% SBS | |

| 135 °C | PG64-22 | - | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S |

| PG64-22 + 10%TLA | - | - | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S | |

| PG64-22 + 20%TLA | - | - | - | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S | |

| PG64-22 + 10%TLA + 5% SBS | - | - | - | - | S | S | S | S | S | S | S | S | S | S | S | S | S | S | |

| PG64-22 + 20%TLA + 5%SBS | - | - | - | - | - | S | S | S | S | S | S | S | S | S | S | S | S | S | |

| PG64-22 + 10%TLA + 10%SBS | - | - | - | - | - | - | S | S | S | S | S | S | S | S | S | S | S | S | |

| PG64-22 + 20%TLA + 10%SBS | - | - | - | - | - | - | - | S | S | S | S | S | S | S | S | S | S | S | |

| PG64-22 + 10%TLA + 15%SBS | - | - | - | - | - | - | - | - | S | S | S | S | S | S | S | S | S | S | |

| PG64-22 + 20%TLA + 15%SBS | - | - | - | - | - | - | - | - | - | S | S | S | S | S | S | S | S | S | |

| 180 °C | PG64-22 | - | - | - | - | - | - | - | - | - | - | S | S | S | S | S | S | S | S |

| PG64-22 + 10%TLA | - | - | - | - | - | - | - | - | - | - | - | S | S | S | S | S | S | S | |

| PG64-22 + 20%TLA | - | - | - | - | - | - | - | - | - | - | - | - | S | S | S | S | S | S | |

| PG64-22 + 10%TLA + 5% SBS | - | - | - | - | - | - | - | - | - | - | - | - | - | S | S | S | S | S | |

| PG64-22 + 20%TLA + 5%SBS | - | - | - | - | - | - | - | - | - | - | - | - | - | - | S | S | S | S | |

| PG64-22 + 10%TLA + 10%SBS | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | S | S | S | |

| PG64-22 + 20%TLA + 10%SBS | - | - | - | - | - | - | - | - | - | - | - | - | - | - | S | S | |||

| PG64-22 + 10%TLA + 15%SBS | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | S | |

| PG64-22 + 20%TLA + 15%SBS | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

| Viscoelasticity Original and RTFO Condition at 64 °C | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Original | RTFO | ||||||||||||||||||

| Combination | PG64-22 | PG64-22 + 10% TLA | PG64-22 + 20% TLA | PG64-22 + 10% TLA + 5% SBS | PG64-22 + 20% TLA + 5% SBS | PG64- 22 + 10% TLA + 10% SBS | PG64- 22 + 20% TLA + 10% SBS | PG64-22 + 10% TLA + 15% SBS | PG64-22 + 20% TLA + 15% SBS | PG64-22 | PG64-22 + 10% TLA | PG64-22 + 20% TLA | PG64-22 + 10% TLA + 5% SBS | PG64-22 + 20% TLA + 5% SBS | PG64-22 + 10% TLA + 10% SBS | PG64-22 + 20% TLA + 10% SBS | PG64-22 + 10% TLA + 15% SBS | PG64- 22 + 20% TLA + 15% SBS | |

| Original | PG64-22 | - | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S |

| PG64-22 + 10%TLA | - | - | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S | |

| PG64-22 + 20%TLA | - | - | - | S | S | S | S | S | S | S | S | S | S | S | S | S | S | S | |

| PG64-22 + 10%TLA + 5% SBS | - | - | - | - | S | S | S | S | S | S | S | S | S | S | S | S | S | S | |

| PG64-22 + 20%TLA + 5%SBS | - | - | - | - | - | S | S | S | S | S | S | S | S | S | S | S | S | S | |

| PG64-22 + 10%TLA + 10%SBS | - | - | - | - | - | - | S | S | S | S | S | S | S | S | S | S | S | S | |

| PG64-22 + 20%TLA + 10%SBS | - | - | - | - | - | - | - | S | S | S | S | S | S | S | S | S | S | S | |

| PG64-22 + 10%TLA + 15%SBS | - | - | - | - | - | - | - | - | S | S | S | S | S | S | S | S | S | S | |

| PG64-22 + 20%TLA + 15%SBS | - | - | - | - | - | - | - | - | - | S | S | S | S | S | S | S | S | S | |

| RTFO | PG64-22 | - | - | - | - | - | - | - | - | - | - | S | S | S | S | S | S | S | S |

| PG64-22 + 10%TLA | - | - | - | - | - | - | - | - | - | - | - | S | S | S | S | S | S | S | |

| PG64-22 + 20%TLA | - | - | - | - | - | - | - | - | - | - | - | - | S | S | S | S | S | S | |

| PG64-22 + 10%TLA + 5% SBS | - | - | - | - | - | - | - | - | - | - | - | - | - | S | S | S | S | S | |

| PG64-22 + 20%TLA + 5%SBS | - | - | - | - | - | - | - | - | - | - | - | - | - | - | S | S | S | S | |

| PG64-22 + 10%TLA + 10%SBS | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | S | S | S | |

| PG64-22 + 20%TLA + 10%SBS | - | - | - | - | - | - | - | - | - | - | - | - | - | - | S | S | |||

| PG64-22 + 10%TLA + 15%SBS | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | S | |

| PG64-22 + 20%TLA + 15%SBS | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

| PAV Condition at 25 °C | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| RTFO + PAV | ||||||||||

| Combination | PG64-22 | PG64-22 + 10% TLA | PG64-22 + 20% TLA | PG64-22 + 10% TLA + 5% SBS | PG64-22 + 20% TLA + 5% SBS | PG64-22 + 10% TLA + 10% SBS | PG64-22 + 20% TLA + 10% SBS | PG64-22 + 10% TLA + 15% SBS | PG64-22 + 20% TLA + 15% SBS | |

| 25 °C | PG64-22 | - | S | S | S | S | S | S | S | S |

| PG64-22 + 10%TLA | - | - | S | S | S | S | S | S | S | |

| PG64-22 + 20%TLA | - | - | - | S | S | S | S | S | S | |

| PG64-22 + 10%TLA + 5% SBS | - | - | - | - | S | S | S | S | S | |

| PG64-22 + 20%TLA + 5%SBS | - | - | - | - | - | S | S | S | S | |

| PG64-22 + 10%TLA + 10%SBS | - | - | - | - | - | - | S | S | S | |

| PG64-22 + 20%TLA + 10%SBS | - | - | - | - | - | - | - | S | S | |

| PG64-22 + 10%TLA + 15%SBS | - | - | - | - | - | - | - | - | S | |

| PG64-22 + 20%TLA + 15%SBS | - | - | - | - | - | - | - | - | - | |

| PAV Condition at 25 °C | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| RTFO + PAV | ||||||||||

| Combination | PG64-22 | PG64-22 + 10% TLA | PG64-22 + 20% TLA | PG64-22 + 10% TLA + 5% SBS | PG64-22 + 20% TLA + 5% SBS | PG64-22 + 10% TLA + 10% SBS | PG64-22 + 20% TLA + 10% SBS | PG64-22 + 10% TLA + 15% SBS | PG64-22 + 20% TLA + 15% SBS | |

| 25 °C | PG64-22 | - | S | S | S | S | S | S | S | S |

| PG64-22 + 10%TLA | - | - | S | S | S | S | S | S | S | |

| PG64-22 + 20%TLA | - | - | - | S | S | S | S | S | S | |

| PG64-22 + 10%TLA + 5% SBS | - | - | - | - | S | S | S | S | S | |

| PG64-22 + 20%TLA + 5%SBS | - | - | - | - | - | S | S | S | S | |

| PG64-22 + 10%TLA + 10%SBS | - | - | - | - | - | - | S | S | S | |

| PG64-22 + 20%TLA + 10%SBS | - | - | - | - | - | - | - | S | S | |

| PG64-22 + 10%TLA + 15%SBS | - | - | - | - | - | - | - | - | S | |

| PG64-22 + 20%TLA + 15%SBS | - | - | - | - | - | - | - | - | - | |

| Stiffness at −12 °C | ||||||||

|---|---|---|---|---|---|---|---|---|

| RTFO + PAV | ||||||||

| Combination | PG64-22 | PG64-22 + 10%TLA | PG64-22 + 20%TLA | PG64-22 + 10%TLA + 5% SBS | PG64-22 + 20%TLA + 5% SBS | PG64-22 + 10%TLA + 10% SBS | PG64-22 + 20%TLA + 10% SBS | |

| RTFO + PAV | PG64-22 | - | S | S | S | S | S | S |

| PG64-22 + 10%TLA | - | - | S | S | S | S | S | |

| PG64-22 + 20%TLA | - | - | - | S | S | S | S | |

| PG64-22 + 10%TLA + 5% SBS | - | - | - | - | S | S | S | |

| PG64-22 + 20%TLA + 5% SBS | - | - | - | - | - | S | S | |

| PG64-22 + 10%TLA + 10% SBS | - | - | - | - | - | - | S | |

| PG64-22 + 20%TLA + 10% SBS | - | - | - | - | - | - | - | |

| m-Value at −12 °C | ||||||||

|---|---|---|---|---|---|---|---|---|

| RTFO + PAV | ||||||||

| Combination | PG64-22 | PG64-22 + 10%TLA | PG64-22 + 20%TLA | PG64-22 + 10%TLA + 5% SBS | PG64-22 + 20%TLA + 5% SBS | PG64-22 + 10%TLA + 10% SBS | PG64-22 + 20%TLA + 10% SBS | |

| RTFO + PAV | PG64-22 | - | S | S | S | S | S | S |

| PG64-22 + 10%TLA | - | - | S | N | S | S | S | |

| PG64-22 + 20%TLA | - | - | - | S | S | S | S | |

| PG64-22 + 10%TLA + 5% SBS | - | - | - | - | N | S | N | |

| PG64-22 + 20%TLA + 5% SBS | - | - | - | - | - | S | N | |

| PG64-22 + 10%TLA + 10% SBS | - | - | - | - | - | - | S | |

| PG64-22 + 20%TLA + 10% SBS | - | - | - | - | - | - | - | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vigneswaran, S.; Yun, J.; Lee, M.-S.; Lee, S.-J. High-Performance Asphalt Binder Incorporating Trinidad Lake Asphalt and SBS Polymer for Extreme Climates. Appl. Sci. 2025, 15, 3411. https://doi.org/10.3390/app15063411

Vigneswaran S, Yun J, Lee M-S, Lee S-J. High-Performance Asphalt Binder Incorporating Trinidad Lake Asphalt and SBS Polymer for Extreme Climates. Applied Sciences. 2025; 15(6):3411. https://doi.org/10.3390/app15063411

Chicago/Turabian StyleVigneswaran, Shyaamkrishnan, Jihyeon Yun, Moon-Sup Lee, and Soon-Jae Lee. 2025. "High-Performance Asphalt Binder Incorporating Trinidad Lake Asphalt and SBS Polymer for Extreme Climates" Applied Sciences 15, no. 6: 3411. https://doi.org/10.3390/app15063411

APA StyleVigneswaran, S., Yun, J., Lee, M.-S., & Lee, S.-J. (2025). High-Performance Asphalt Binder Incorporating Trinidad Lake Asphalt and SBS Polymer for Extreme Climates. Applied Sciences, 15(6), 3411. https://doi.org/10.3390/app15063411