Experimental Study on Horizontal Pipeline Transportation Characteristics of Coarse Particle

Abstract

1. Introduction

2. Methodology

2.1. Theory of Solid–Liquid Two Phase Flow Model

2.2. Flow Morphology of Coarse Particle Group in Pipes

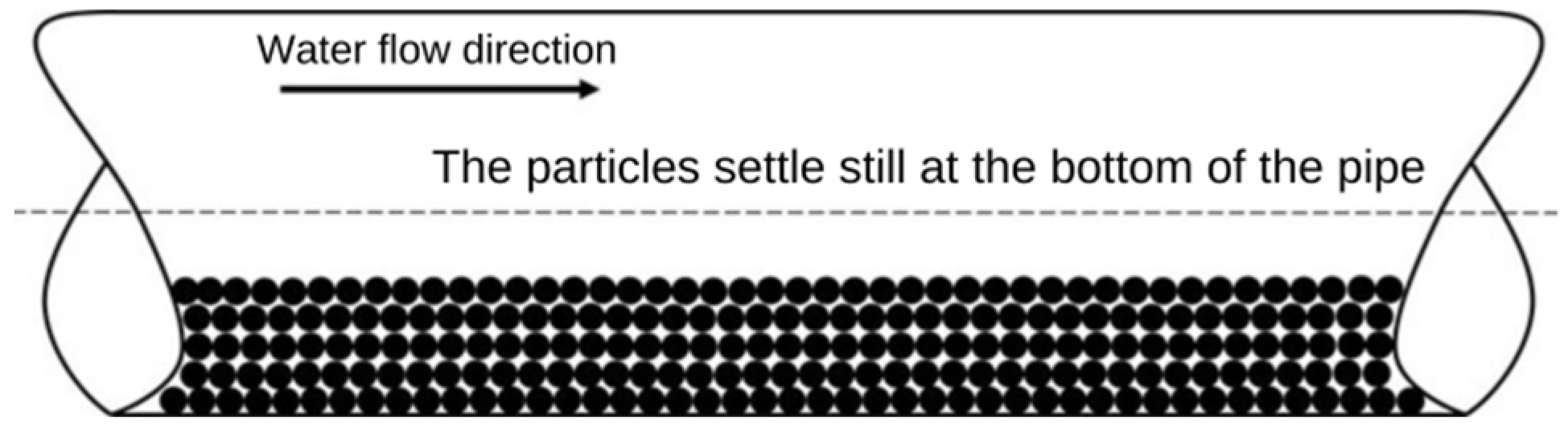

- Sedimentary Bed Type: In this type, particles accumulate statically at the bottom of the pipeline, forming a sedimentary bed, as illustrated in Figure 1.

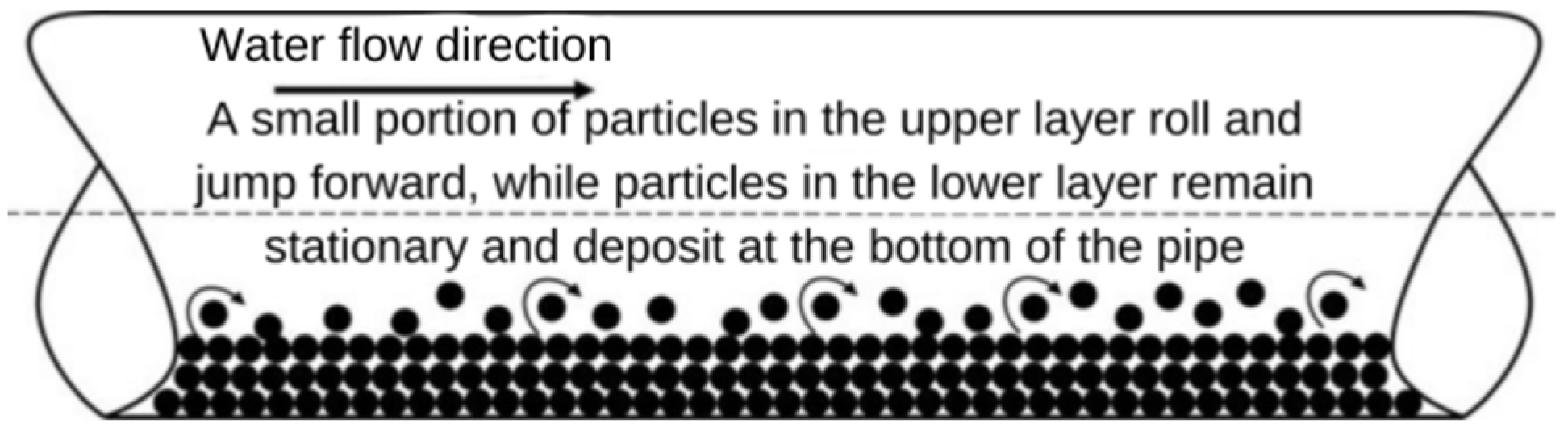

- Sedimentary Bed Type with Jumping/Rolling Particles: Here, some particles detach from the sedimentary bed and move forward by rolling or jumping, as depicted in Figure 2.

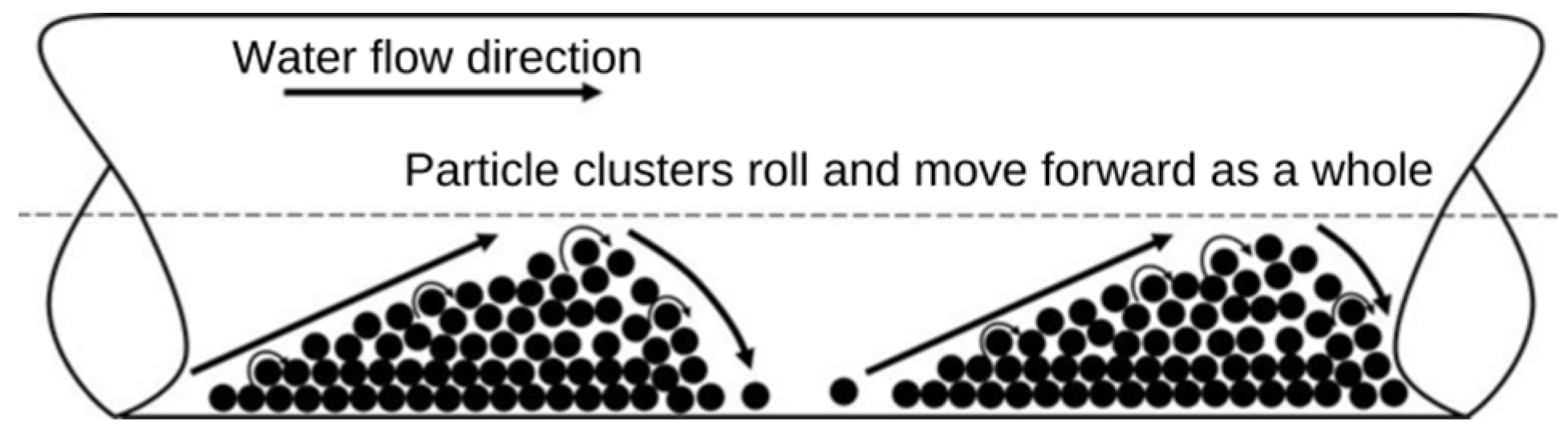

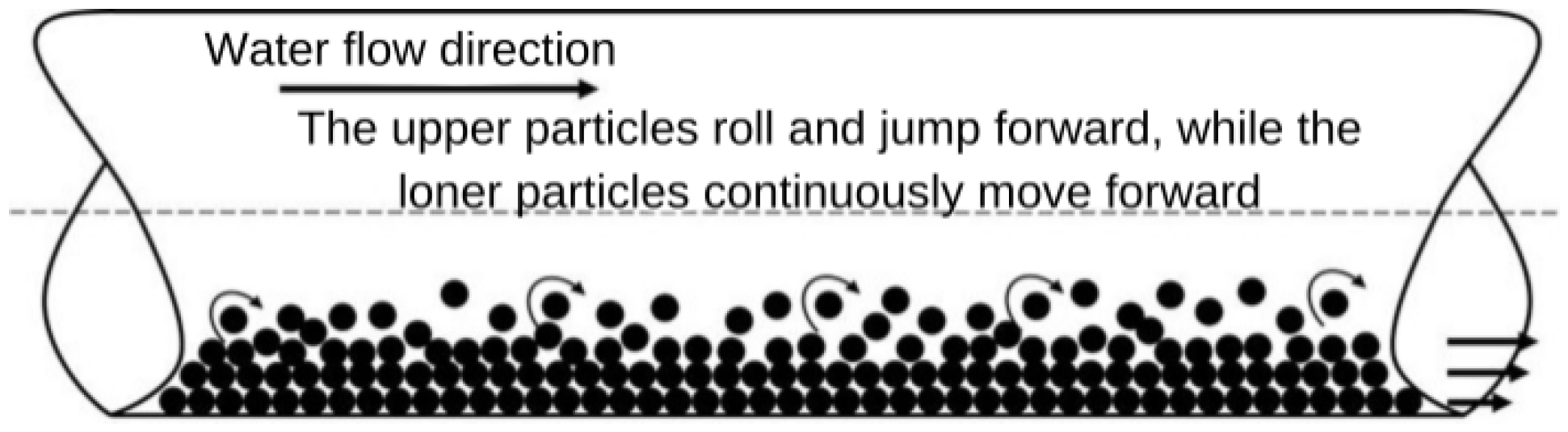

- Nudging Movement: In this category, all particles participate in the two-phase flow movement, with the solid particles’ motion dominated by nudging. This type is further divided into the following:

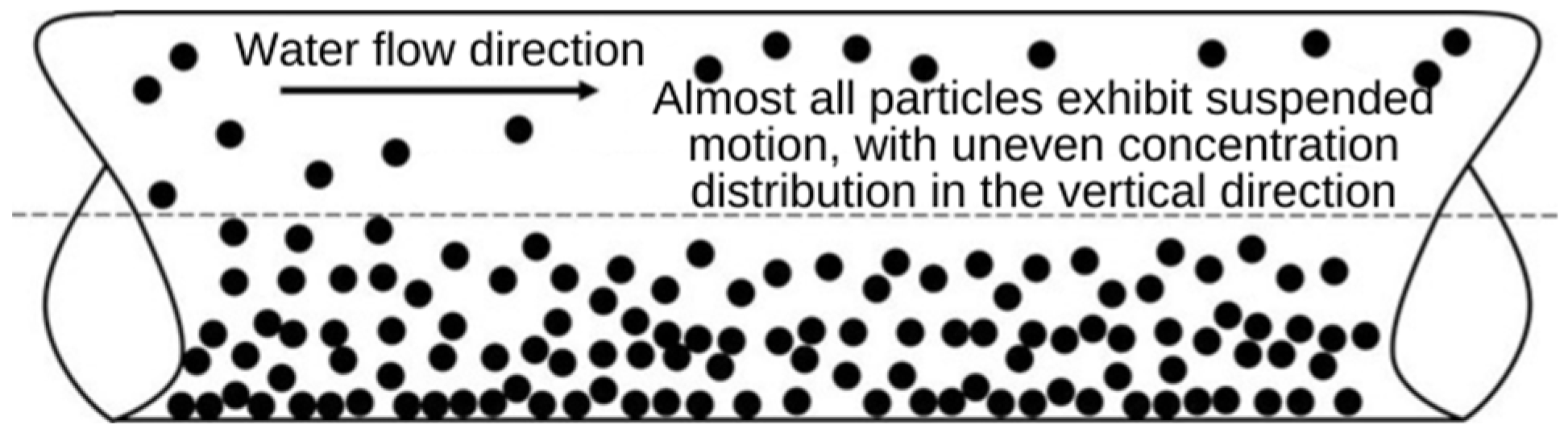

- Non-Homogeneous Flow Suspension Movement: In this state, all solid particles are suspended and moving, but the concentration distribution of particles within the group is non-uniform. The fluid is treated as a non-Newtonian fluid, as illustrated in Figure 5.

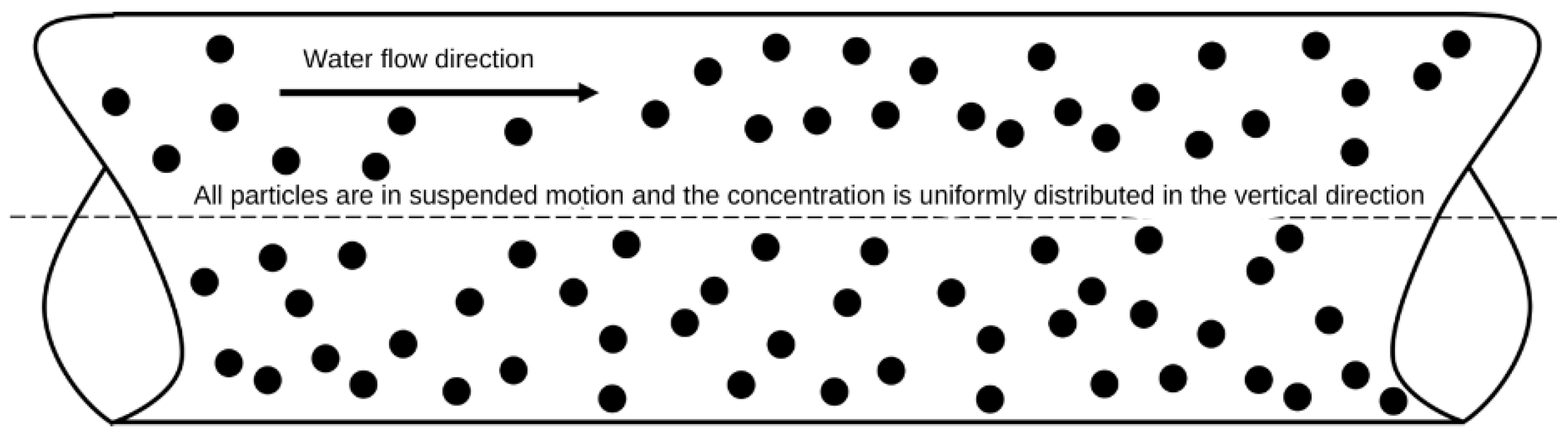

- Pseudo-Homogeneous Flow Suspension Movement: Here, all particles are suspended and moving, with a relatively uniform concentration distribution. The two-phase flow fluid is considered a single fluid, behaving as a Newtonian fluid, as shown in Figure 6.

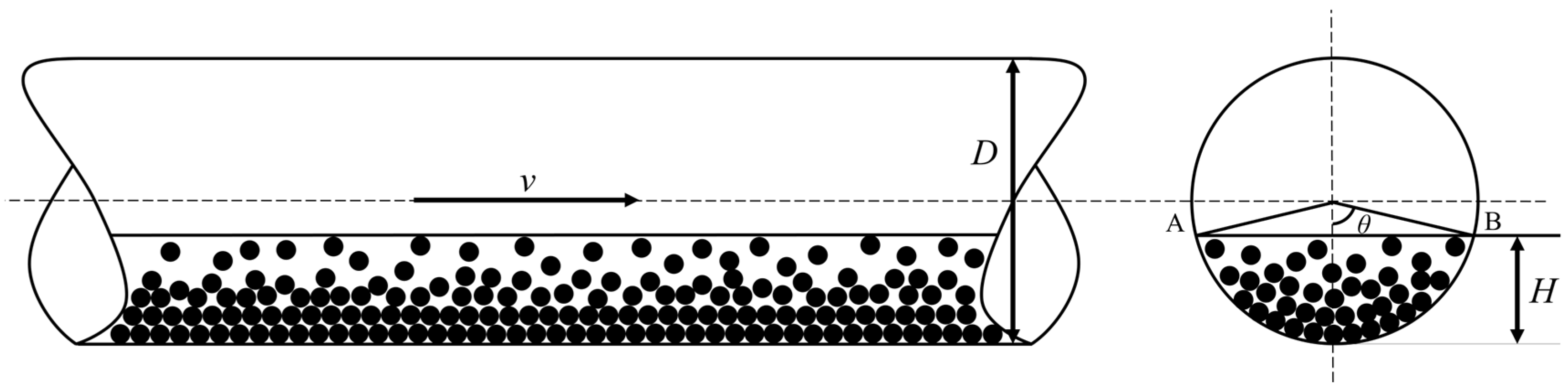

2.3. Granular Beds

3. Experimental Preparation

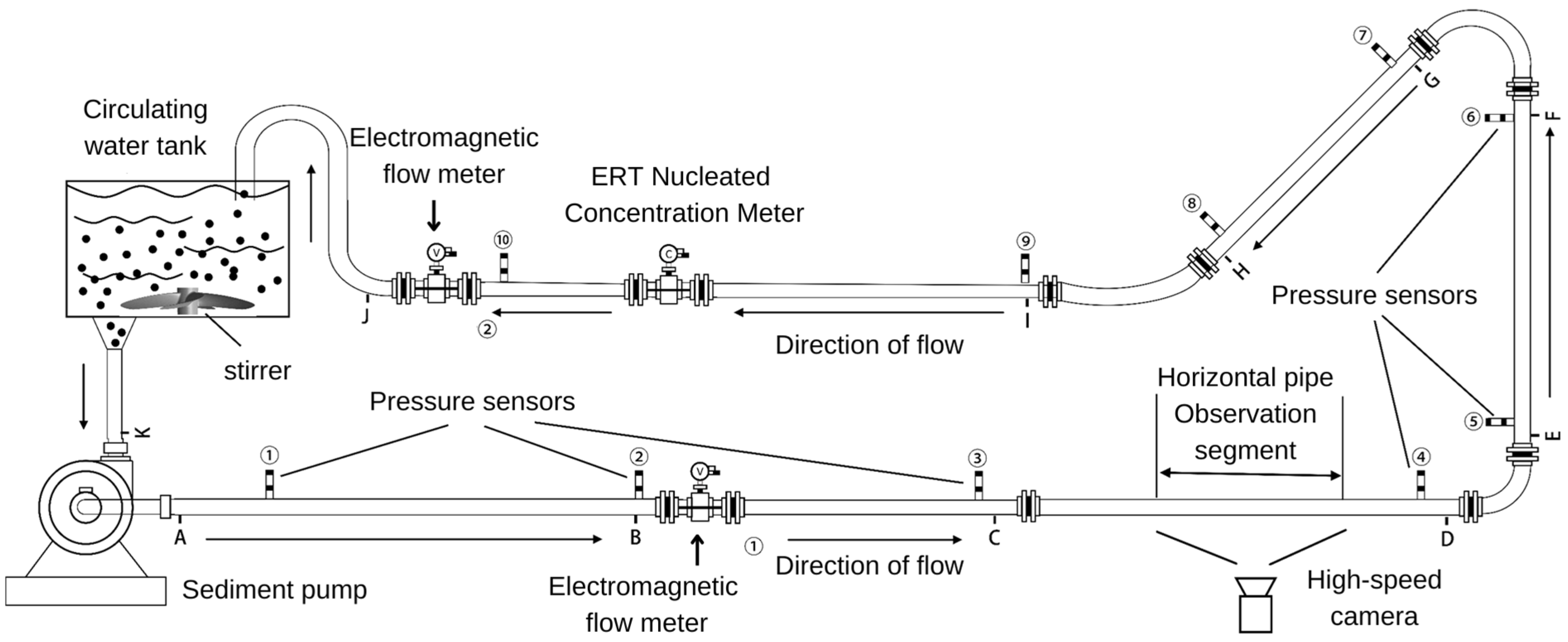

3.1. Experiment Setup

3.2. Design of Experiments

- (1)

- Pre-Experiment Preparation Stage.

- (2)

- Equipment operation stage.

- (3)

- Experimental data collection and screening.

4. Results and Discussion

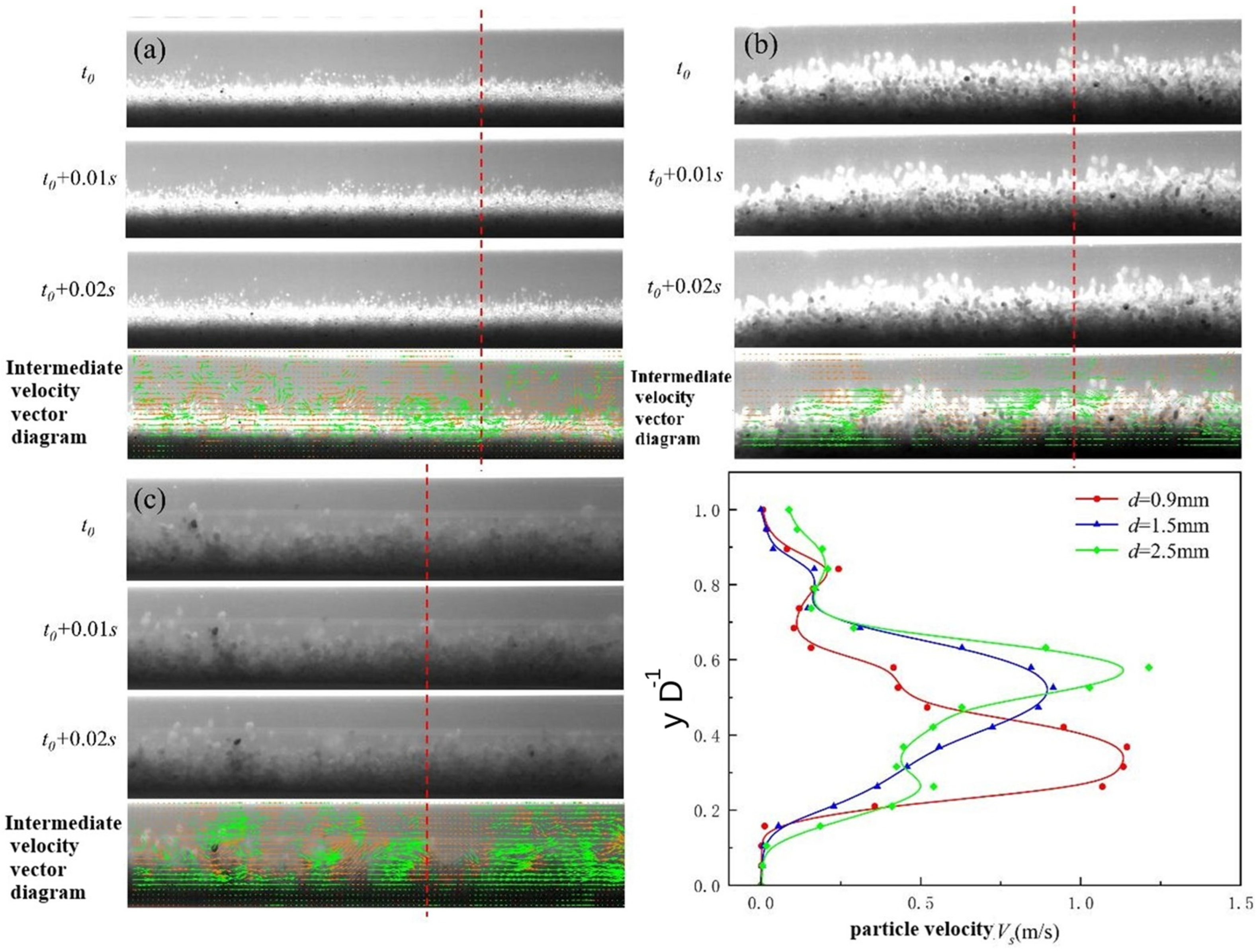

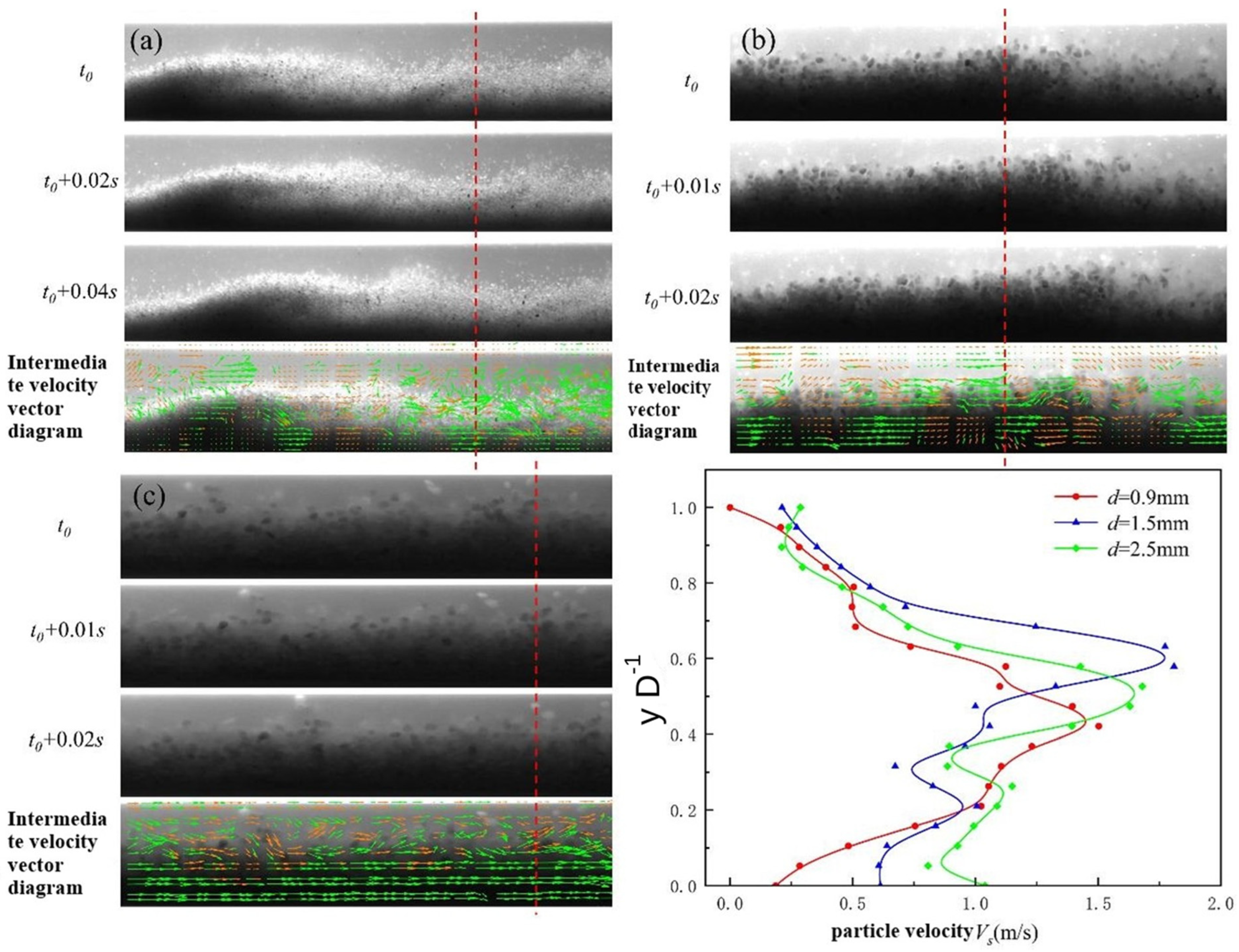

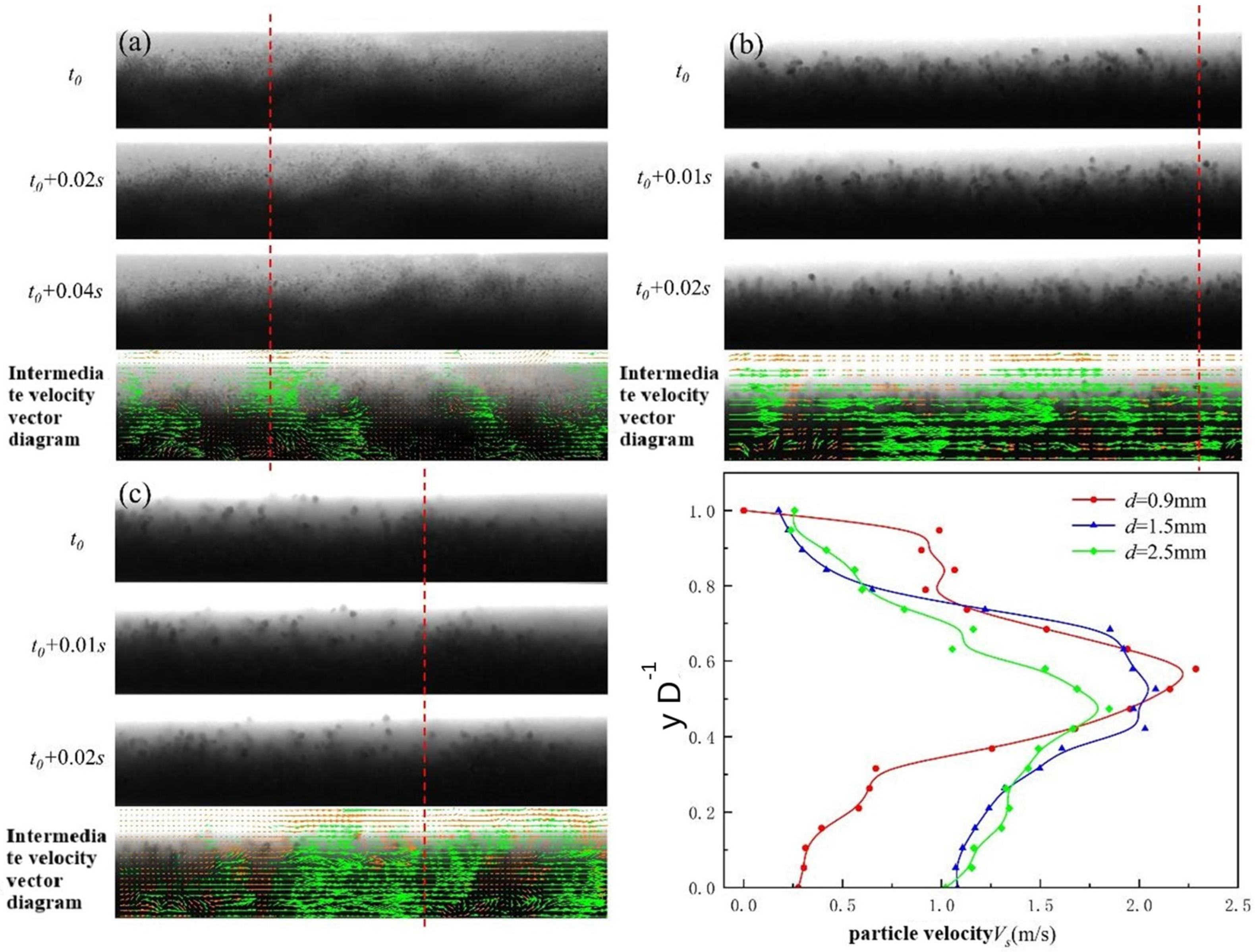

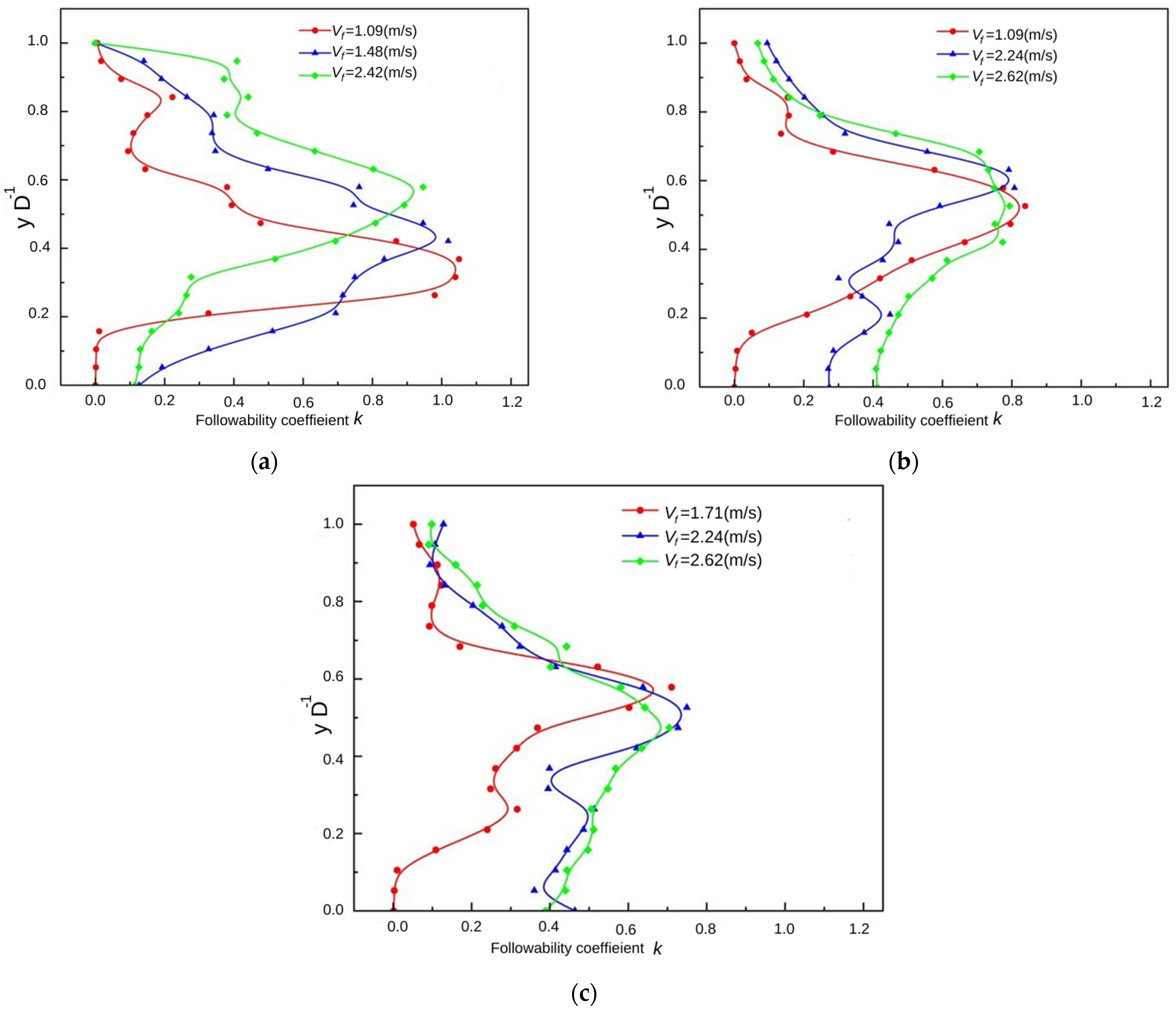

4.1. Velocity Distribution Characteristics of Different Coarse Particle Group Flow Patterns

- (1)

- Sedimentary bed type with jumping and rolling particles

- (2)

- Moving Movement

- (3)

- Heterogeneous flow suspension motion

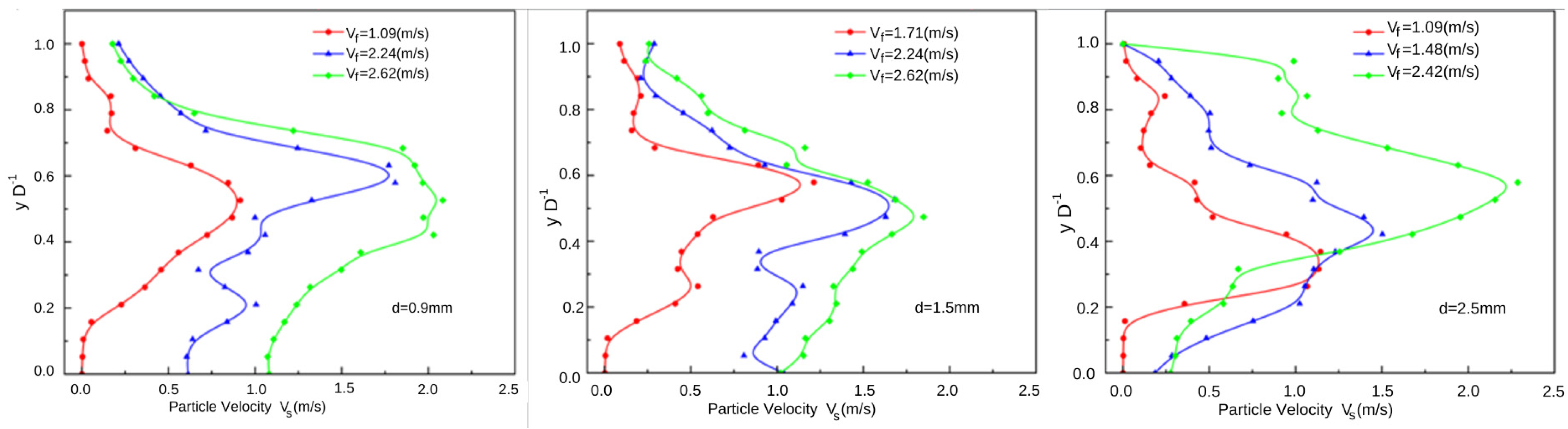

4.2. The Influence of Particle Diameter on the Velocity Distribution of Coarse Particle Groups

4.3. Analysis of Coarse Particle Flow Characteristics

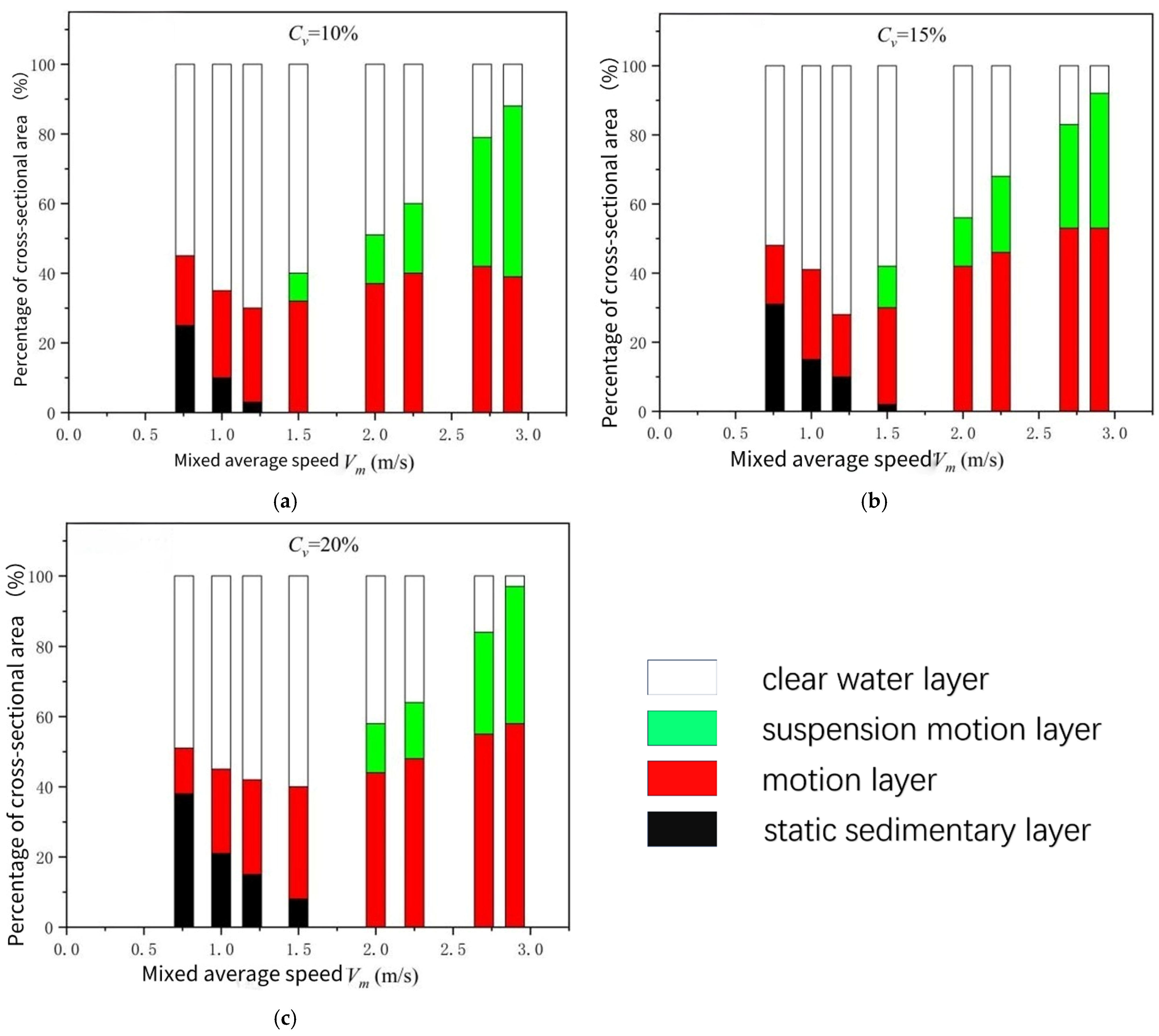

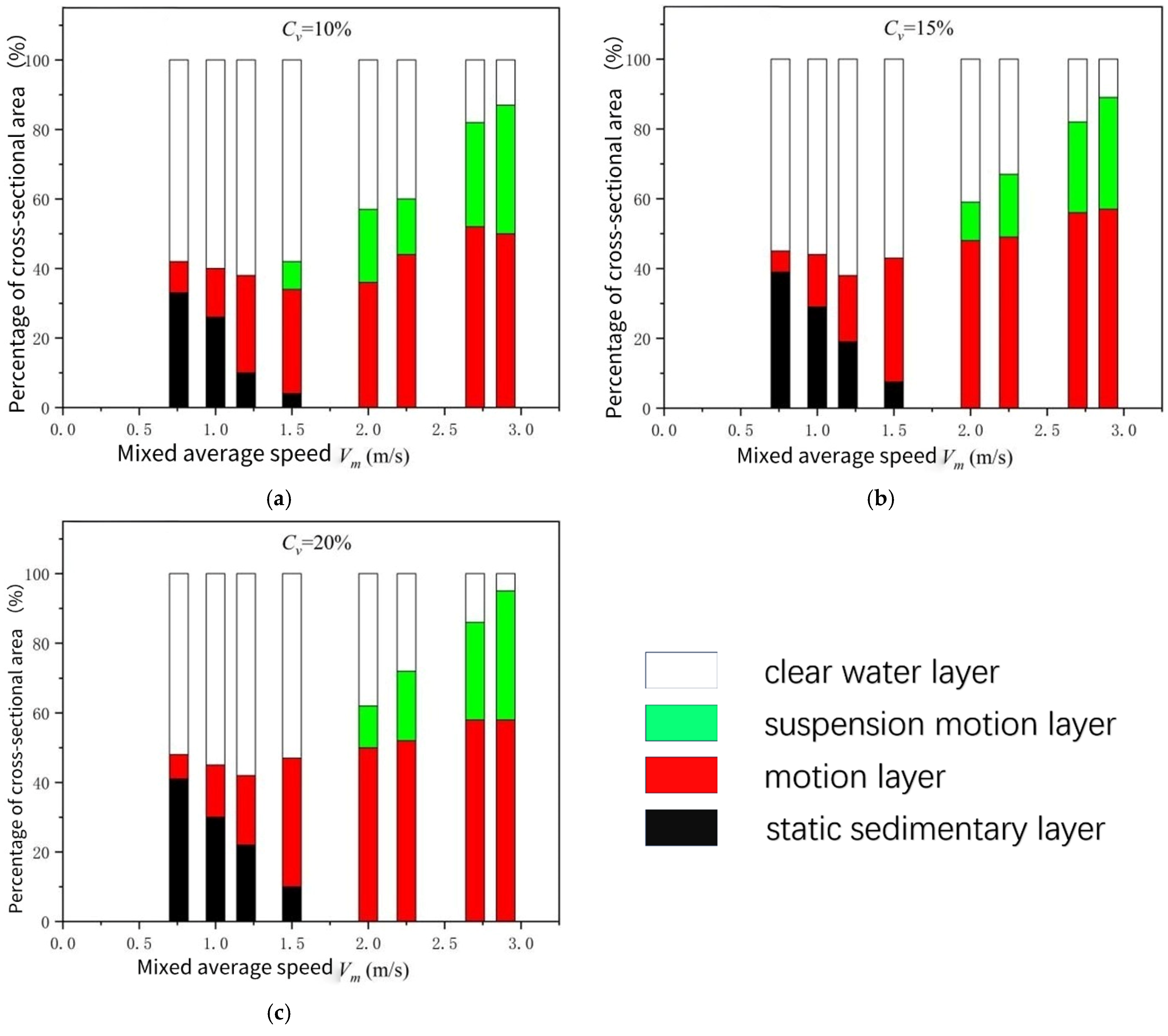

4.4. The Influence of Particle Bed Types on the Flow Pattern of Coarse Particle Clusters in Various Motion States

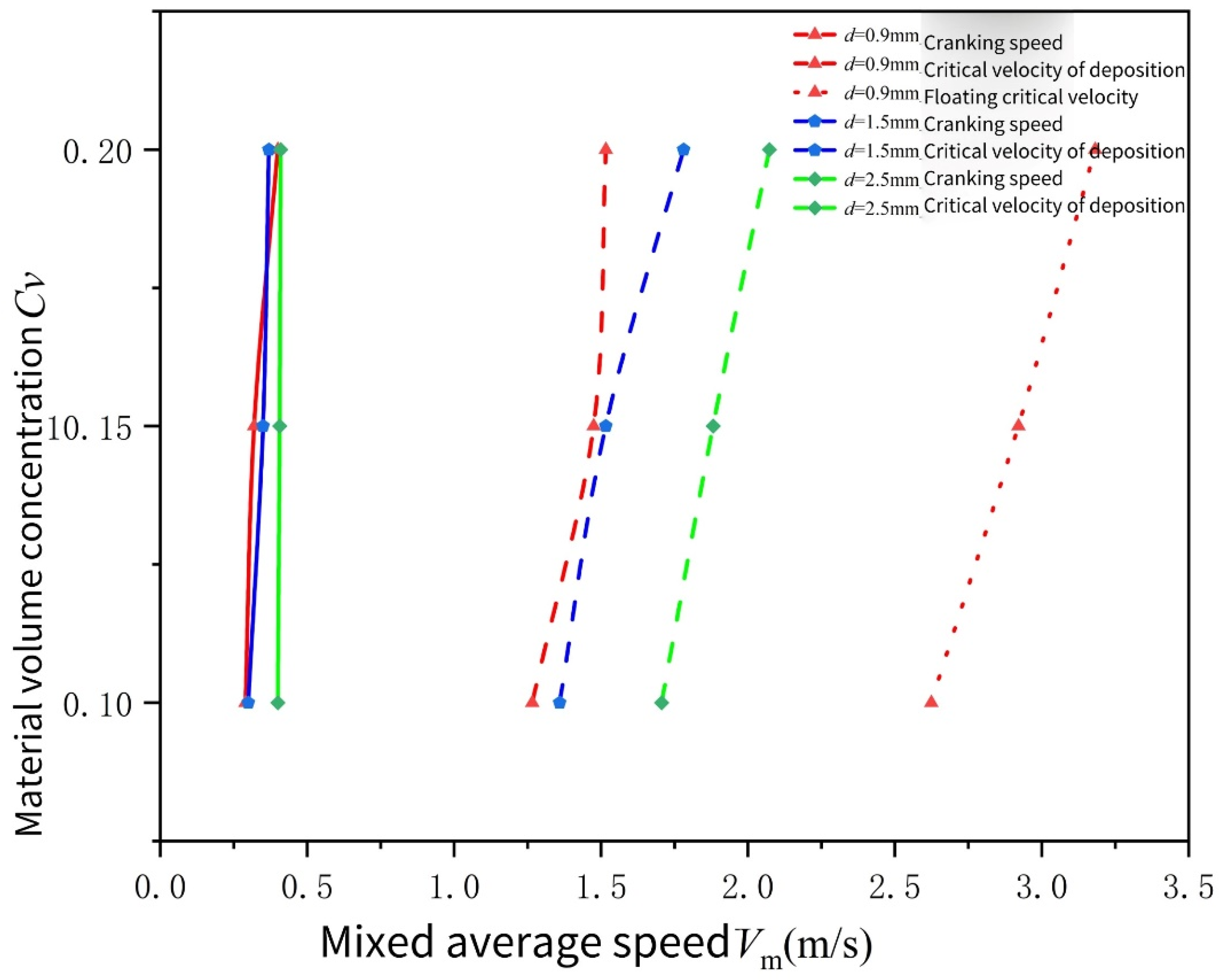

4.5. Statistical Analysis of Coarse Particle Flow Transitions

5. Conclusions

- (1)

- In horizontal circular pipe flow, the velocity distribution of each flow type has an overall symmetrical distribution, with the highest velocity in the central region, while the velocity of coarse particles in the upper and lower regions of the pipeline gradually decreases with an increasing distance from the centerline of the pipeline. There is a significant difference in the followability of particles with water flow, and particles near the centerline of the pipeline are more susceptible to the acceleration of water flow. The 0.9 mm diameter particles are more likely to complete the transition of the coarse particle group flow pattern.

- (2)

- The granular bed exhibits three main motion states: static sedimentation, displacement, and suspension under different operating conditions, with the static sedimentation layer accounting for a larger proportion in the low-speed region; The particles in the moving layer are tightly arranged and pushed forward as a whole through rolling or horizontal movement. The suspended moving layer mainly appears under high flow velocity conditions, and the particle distribution inside the pipe is relatively uniform. In addition, an increase in the material volume concentration and an increase in particle size will both cause the expansion of static sedimentary layers and delay the transition of flow patterns during translational motion. Therefore, when transferring dredged material via pipeline hydraulic conveyance, the concentration of dredged material should not be too high in order to avoid the emergence of an excessively thick sediment layer.

- (3)

- The range of particle starting speed variation is relatively small and always below 0.5 m/s. It is greatly affected by the average mixing speed, and the critical sedimentation speed is sensitive to changes in particle diameter and material volume concentration, showing a certain linear correlation as a whole. The transition of the coarse particle group flow pattern from the sedimentation bed type to translational motion is closely related to the particle diameter and material volume concentration. Coarse particle groups with a low material volume concentration and small particle diameter are more likely to complete the flow pattern transition. Therefore, when transferring dredged material via pipeline hydraulic conveyance, the water flow rate can be increased to achieve a reduction in the concentration of dredged material, thus avoiding blockage of the pipeline.

- (4)

- The range of the material particle size and the range of the maximum flow rate are limited in this study, and future research can further expand the range of the material particle size and the range of the maximum flow rate, as well as increase the number of experimental groups, so as to more comprehensively analyze the influence of relevant factors on the particle motion state. In view of the complexity of the pipeline arrangement in the actual dredging construction, future research can focus on exploring the mechanism of the influence of various factors on the movement and resistance characteristics of coarse particles in the pipeline under complex pipeline conditions. In addition, the influence of other factors such as pipe material and pipe geometry on the flow pattern and hydraulic gradient of the coarse particle population can also be studied in depth. It is recommended to combine numerical simulation methods to systematically analyze the motion characteristics of the coarse particle population under different parameter combinations, which will help optimize the conveying process, improve the conveying efficiency, and reduce energy consumption. The expansion of the above research directions can provide more comprehensive theoretical support and practical guidance for the theoretical research and engineering application of horizontal pipeline conveying of coarse particles.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bray, R.N.; Bates, A.D.; Land, J.M. Dredging: A Handbook for Engineers; Butterworth-Heinemann Ltd.: Oxford, UK, 1996. [Google Scholar]

- Manap, N.; Voulvoulis, N. Environmental management for dredging sediments—The requirement of developing nations. J. Environ. Manag. 2015, 147, 338–348. [Google Scholar] [CrossRef] [PubMed]

- Ting, X.; Zhang, X.; Miedema, S.A.; Chen, X. Study of the characteristics of the flow regimes and dynamics of coarse particles in pipeline transportation. Powder Technol. 2019, 347, 148–158. [Google Scholar] [CrossRef]

- Wasp, E.J.; Aude, T.C. Deposition Velocities, Transition Velocities, and Spatial Distribution of Solids in Slurry Pipelines. In Proceedings of the 1st International British Hydromechanics Research, Conventry, UK, 1–4 September 1970. [Google Scholar]

- Wasp, E.J.; Kenny, J.; Gandhi, R. Solid—Liquid flow: Slurry pipeline transportation. [Pumps, valves, mechanical equipment, economics]. Ser. Bulk Mater. Handl. 1977, 1. [Google Scholar]

- Gillies, R.G.; Shook, C.A.; Wilson, K.C. An improved two layer model for horizontal slurry pipeline flow. Can. J. Chem. Eng. 1991, 69, 173–178. [Google Scholar] [CrossRef]

- Wilson, K.C.; Addie, G.R. Coarse-particle pipeline transport: Effect of particle degradation on friction. Powder Technol. 1997, 94, 235–238. [Google Scholar] [CrossRef]

- Kaushal, D.R.; Tomita, Y. Solids concentration profiles and pressure drop in pipeline flow of multisized particulate slurries. Int. J. Multiph. Flow 2002, 28, 1697–1717. [Google Scholar] [CrossRef]

- Kaushal, D.R.; Tomita, Y. Prediction of Concentration Distribution in Pipeline Flow of Highly Concentrated Slurry. Part. Sci. Technol. 2013, 31, 28–34. [Google Scholar] [CrossRef]

- Falegnami, A.; Tomassi, A.; Gunella, C.; Amalfitano, S.; Corbelli, G.; Armonaite, K.; Fornaro, C.; Giorgi, L.; Pollini, A.; Caforio, A.; et al. Defining conceptual artefacts to manage and design simplicities in complex adaptive systems. Heliyon 2024, 10, e41033. [Google Scholar] [CrossRef] [PubMed]

- Miedema, S.A. Slurry Transport: Fundamentals, a Historical Overview and the Delft Head Loss a Limit Deposit Velocity Framework; Delft University of Technology: Delft, The Netherlands, 2016. [Google Scholar]

- Miedema, S.A. The heterogeneous to homogeneous transition for slurry flow in pipes. Ocean Eng. 2016, 123, 422–431. [Google Scholar] [CrossRef]

- Miedema, S.A. Slurry transport in inclined pipes. In Proceedings of the WEDA 2017 Dredging Summit & Expo, Vancouver, BC, Canada, 26–29 June 2017. [Google Scholar]

- Cao, B.; Zou, Y.; Xia, J. Experimental study on the behavior of coarse particles in two phases flow during water hammer. Adv. Water Sci. 2017, 28, 356–363. [Google Scholar] [CrossRef]

- Zhang, P.; Yang, Y.; Sun, J.; Huang, Z.; Wang, J.; Yang, Y. Acoustic analysis of particle dispersion state and prediction of solid concentration in horizontal hydraulic conveying. Chem. Eng. Sci. 2021, 245, 116973. [Google Scholar] [CrossRef]

- Vahidi-Nia, F.; Bayesteh, H.; Khodaparast, M. Effect of initial packing density, stress level and particle size ratio on the behavior of binary granular material: A micromechanical approach. Granul. Matter 2020, 22, 68. [Google Scholar] [CrossRef]

- Song, Z.; Wu, T.; Xu, F.; Li, R. A simple formula for predicting settling velocity of sediment particles. Water Sci. Eng. 2008, 1, 37–43. [Google Scholar] [CrossRef]

- Zhang, F.; Miska, S.; Yu, M.; Ozbayoglu, E. A unified transient solid-liquid two-phase flow model for cuttings transport- modelling part. J. Pet. Sci. Eng. 2018, 166, 146–156. [Google Scholar] [CrossRef]

- Thielicke, W.; Sonntag, R.J. Particle Image Velocimetry for MATLAB: Accuracy and enhanced algorithms in PIVlab. J. Open Res. Softw. 2021, 9, 12. [Google Scholar] [CrossRef]

- Thielicke, W.; Stamhuis, E.J. PIVlab—Towards User-friendly, Affordable and Accurate Digital Particle Image Velocimetry in MATLAB. J. Open Res. Softw. 2014, 2, e30. [Google Scholar] [CrossRef]

- Barmak, I.; Gelfgat, A.; Vitoshkin, H.; Ullmann, A.; Brauner, N. Stability of stratified two-phase flows in horizontal channels. Phys. Fluids 2016, 28, 044101. [Google Scholar] [CrossRef]

| Experimental Group Number | Average Particle Size d (mm) | Feed Concentration Cv | Range of Average Flow Velocity Variation Vm (m/s) |

|---|---|---|---|

| 1 | 0.9 | 10% | 0.49~4.00 |

| 2 | 0.9 | 15% | 0.49~4.00 |

| 3 | 0.9 | 20% | 0.49~4.00 |

| 4 | 1.5 | 10% | 0.56~4.00 |

| 5 | 1.5 | 15% | 0.56~4.00 |

| 6 | 1.5 | 20% | 0.56~4.00 |

| 7 | 2.5 | 10% | 0.64~4.00 |

| 8 | 2.5 | 15% | 0.64~4.00 |

| 9 | 2.5 | 20% | 0.64~4.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, S.; Wang, Y.; Jiang, P.; Xiong, T. Experimental Study on Horizontal Pipeline Transportation Characteristics of Coarse Particle. Appl. Sci. 2025, 15, 3388. https://doi.org/10.3390/app15063388

Lu S, Wang Y, Jiang P, Xiong T. Experimental Study on Horizontal Pipeline Transportation Characteristics of Coarse Particle. Applied Sciences. 2025; 15(6):3388. https://doi.org/10.3390/app15063388

Chicago/Turabian StyleLu, Songye, Yao Wang, Pan Jiang, and Ting Xiong. 2025. "Experimental Study on Horizontal Pipeline Transportation Characteristics of Coarse Particle" Applied Sciences 15, no. 6: 3388. https://doi.org/10.3390/app15063388

APA StyleLu, S., Wang, Y., Jiang, P., & Xiong, T. (2025). Experimental Study on Horizontal Pipeline Transportation Characteristics of Coarse Particle. Applied Sciences, 15(6), 3388. https://doi.org/10.3390/app15063388