Implementing an Industry 4.0 UWB-Based Real-Time Locating System for Optimized Tracking

Abstract

1. Introduction

2. Literature Review

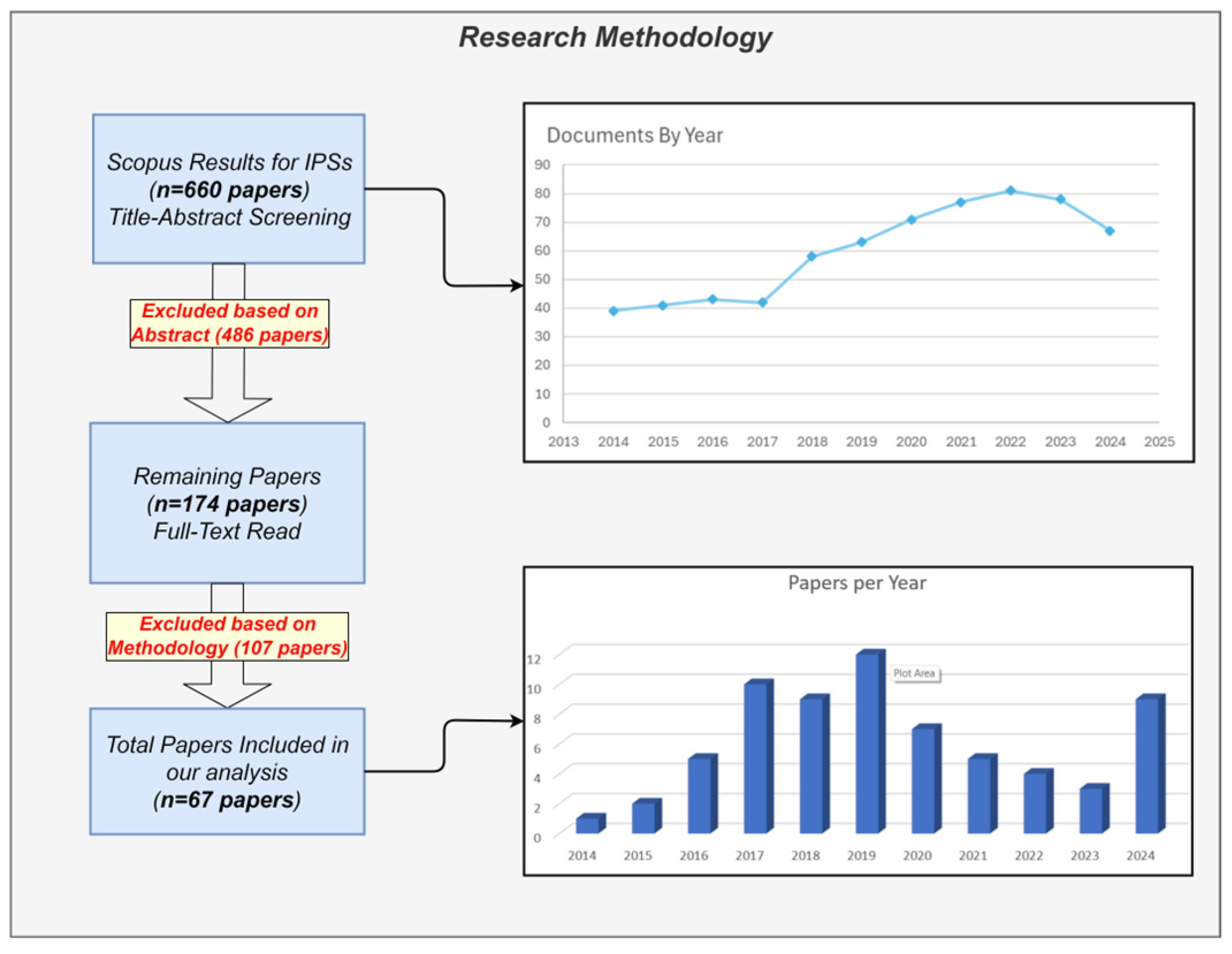

2.1. Research Methodology

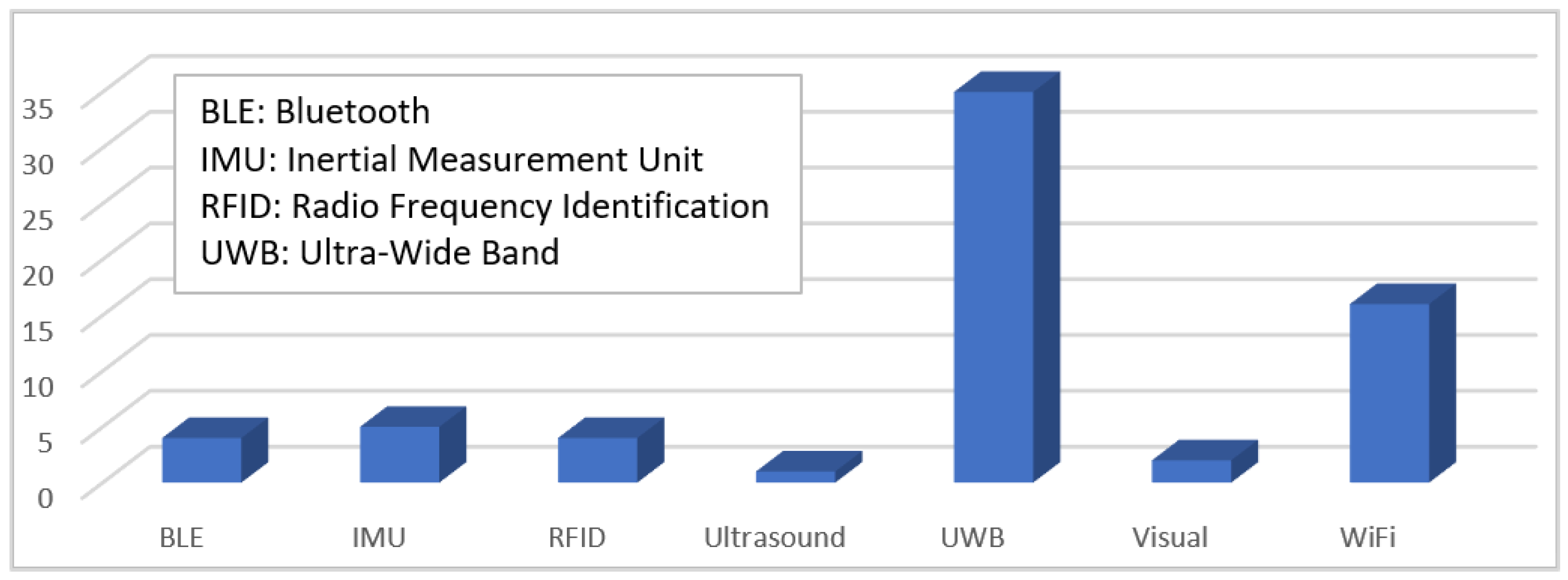

2.2. Related Works

2.3. Ultra-WideBand Technology

2.4. Categorization of Existing Research Efforts

3. Materials and Methods

3.1. Tracking Methods

- Angle of arrival (AoA). The AOA method estimates the position location by means of angular direction observations measured with respect to a reference axis using directional antennas or antenna arrays.

- Time difference of arrival (TDoA). The TDoA method locates a signal source from the different arrival times at the receivers. Once the signal is received at two reference points, the difference in the arrival time can be used to calculate the difference in distances between the target and the two reference points. This difference can be calculated using the equation ∆x = c × (∆t), where c is the speed of light and ∆t is the difference in arrival times at each reference point. To obtain a true Δt measurement, the transmitter and receiver must be synchronized. An implementation based on this technique with unsynchronized devices has been proposed [68], and it was able to calculate the position of the object with an increasing computational cost.

| Authors | Tracking Technology | Manuscript Content | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| UWB | BLΕ | Ultrasound | Wi-Fi | IMU | RFID | Visual Tracking | Review | Technology Comparison | System Architecture- Application | |

| Jimenez A.R., Seco F., 2016 [51] | √ | √ | ||||||||

| Gharat V., et al., 2017 [28] | √ | √ | √ | √ | ||||||

| Hyun J., et al, 2019 [65] | √ | √ | ||||||||

| Yao L., et al., 2017 [63] | √ | √ | ||||||||

| Yadar R., 2018 [32] | √ | √ | √ | √ | ||||||

| Athikulwongse K., et al., 2018 [69] | √ | √ | ||||||||

| Chen H., et al., 2017 [31] | √ | √ | ||||||||

| Jimenez A.R., et al., 2017 [52] | √ | √ | ||||||||

| Astafiev A., et al., 2019 [36] | √ | √ | √ | |||||||

| Karlsson F., et al., 2015 [40] | √ | √ | ||||||||

| Diallo Al., et al., 2019 [29] | √ | √ | ||||||||

| Jun Qi et al., 2017 [30] | √ | √ | ||||||||

| Duong N. S., et al., 2018 [34] | √ | √ | ||||||||

| Jeon J., et al., 2015 [37] | √ | √ | √ | |||||||

| Haryanto D., et al., 2018 [41] | √ | √ | ||||||||

| Woo S., et al., 2011 [38] | √ | √ | ||||||||

| Abbas M., et al., 2019 [39] | √ | |||||||||

| Alarifi A., et al., 2016 [70] | √ | √ | ||||||||

| Kunhoth J.., et al., 2020 [71] | √ | |||||||||

| Yassin A., et al., 2017 [72] | √ | |||||||||

| Oesterreich T.D, Osnabrück F.T., 2016 [4] | √ | |||||||||

| Kanan R., et al., 2018 [7] | √ | √ | ||||||||

| Zhao Z., et al., 2021 [6] | √ | |||||||||

| De Angelis G.., et al., 2016 [21] | √ | √ | ||||||||

| Ridolfi M., et al., 2018 [18] | √ | √ | ||||||||

| Kumler J., et al., 2017 [19] | √ | √ | ||||||||

| Yoon Paul K. et al., 2017 [73] | √ | √ | √ | |||||||

| Witrisal Klaus et al., 2016 [20] | √ | √ | √ | √ | √ | |||||

| Bharadwaj R., et al., 2017 [25] | √ | √ | ||||||||

| Yu J., et al., 2019 [23] | √ | √ | ||||||||

| Li S., et al., 2019 [14] | √ | √ | ||||||||

| Luo J., et al., 2019 [16] | √ | √ | √ | |||||||

| Zourmand A., et al., 2019 [13] | √ | √ | ||||||||

| Sadowski S., Spachos P., 2019 [11] | √ | √ | ||||||||

| Zhang W., et al., 2019 [15] | √ | √ | ||||||||

| Chen J., et al., 2019 [12] | √ | √ | ||||||||

| Hoang, M., et al., 2019 [17] | √ | √ | ||||||||

| Kianfar A. et al., 2020, [24] | √ | √ | ||||||||

| Pérez-Solano J., et al., 2020 [68] | √ | √ | ||||||||

| Grasso P., Innocente M., 2020 [74] | √ | √ | ||||||||

| Simedroni R. et al., 2020 [75] | √ | √ | ||||||||

| Guo S., et al., 2020 [22] | √ | √ | √ | |||||||

| Bing W., et al., 2018 [56] | √ | √ | ||||||||

| Schroeer G., 2018 [53] | √ | √ | ||||||||

| Martínez del Horno J.., et al., 2021 [76] | √ | √ | √ | |||||||

| Truong Q., et al., 2021 [77] | √ | √ | ||||||||

| Vleugels R., et al., 2021 [67] | √ | √ | √ | |||||||

| Hernánde, N., et al., 2021 [42] | √ | √ | ||||||||

| Chen, W., 2021 [78] | √ | √ | ||||||||

| Woods J., et al., 2024 [26] | √ | √ | ||||||||

| Shamsollahi D., et al., 2024 [9] | √ | √ | ||||||||

| Thota R., 2024 [10] | √ | √ | ||||||||

| Yuxuan Z., Manyi. W., 2022 [60] | √ | √ | ||||||||

| Kim J., et al., 2024 [62] | √ | √ | ||||||||

| Kim D. and Jae-Young Pyun J., 2024 [61] | √ | √ | ||||||||

| Ambrose A., et al., 2022 [55] | √ | √ | ||||||||

| Krummenauer A., et al., 2023 [47] | √ | √ | ||||||||

| Al-Khaddour M., et al., 2023 [58] | √ | √ | ||||||||

| Bendavid Y., et al., 2024 [27] | √ | √ | ||||||||

| Landaberea A., et al., 2022 [57] | √ | √ | ||||||||

| Landaberea A., et al., 2024 [8] | √ | √ | ||||||||

| Sinko S., et al., 2022 [79] | √ | √ | ||||||||

| Plangger J., et al., 2023 [59] | √ | √ | ||||||||

| Rana L. and Park J., 2024 [45] | √ | √ | ||||||||

| Horn B., 2024 [46] | √ | √ | ||||||||

| Orfanos M., et al., 2023 [44] | √ | √ | ||||||||

- 3.

- Time of arrival (ToA) or time of flight (ToF). Both methods estimate the position location of a tag by measuring the time that the signal needs to travel from the transmitter to the receiver. To use this technique, both transmitter and receiver must be synchronized.

- 4.

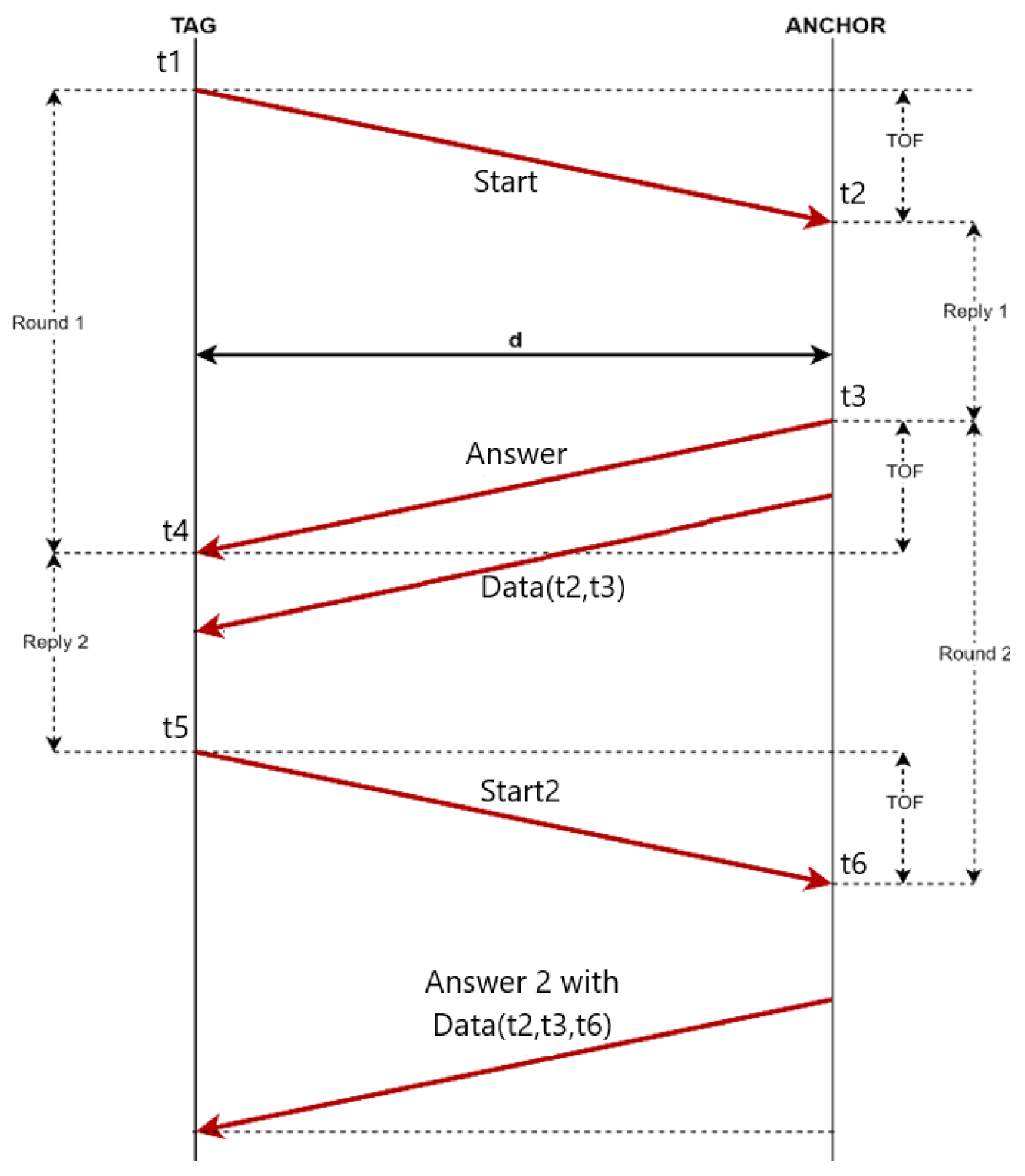

- Two-way ranging (TWR). The two-way ranging method determines the time of flight of the RF signal and then it calculates the distance between the nodes by multiplying the time parameter by the speed of light. Figure 3 depicts the TWR method. The tag sends a start signal to the anchor at t1. The anchor receives this beacon at a timestamp t2, and then sends an answer at t3, which is received at t4 by the tag. The timestamps t2 and t3 are then sent to a tag in a data frame [80]. Finally, the tag computes the travelling time of the signal both ways and obtains a distance estimation d, which is given by:where c denotes the speed of light (3 × 108 m/s).

- 5.

- Symmetrical double-sided two-way ranging (SDS-TWR). In symmetric double-sided two-way ranging, an additional cycle of sending and receiving signals is performed [80], leading to two additional timestamps, t5 and t6:

- 6.

- Near-field electromagnetic range (NFER). The NFER method refers to any radio technology employing the near-field properties of radio waves.

- 7.

- Received signal strength indication. RSSI is a term used to measure the relative quality of a received signal to a client device [76]. However, there is a direct proportion between the RSSI and the receiver–transmitter distance. This method matches the RSSI measurement to a receiver–transmitter distance. The formula for converting the RSSI measurement to distance is described below:

- r is the RSSI measured by the device,

- t is the RSSI measurement at 1 m,

- and A, B, and C are constants.

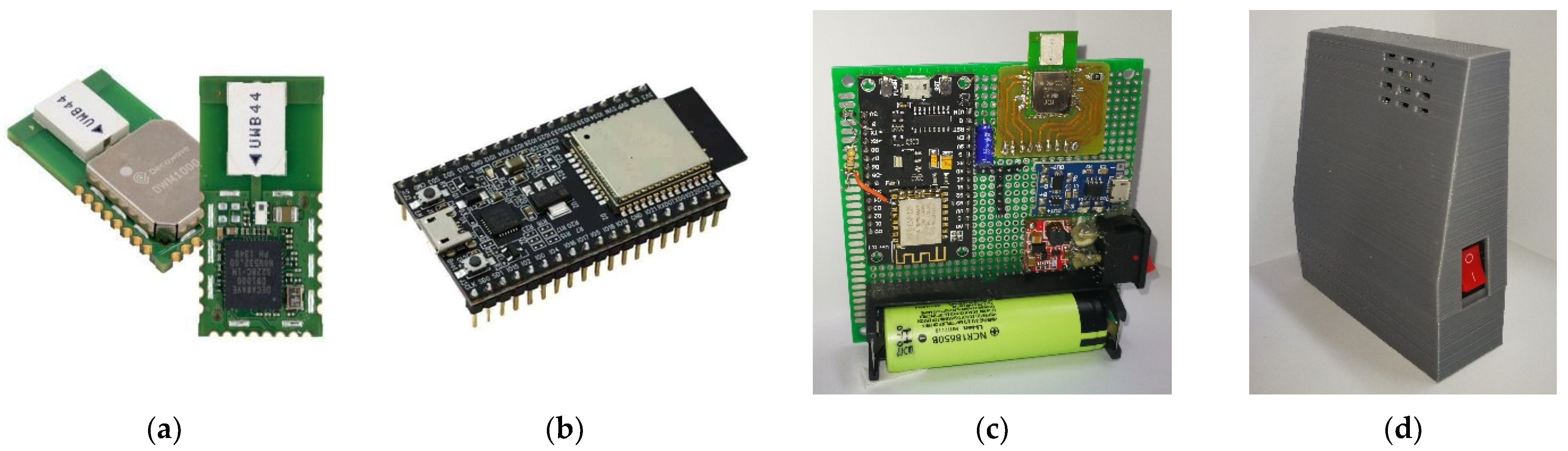

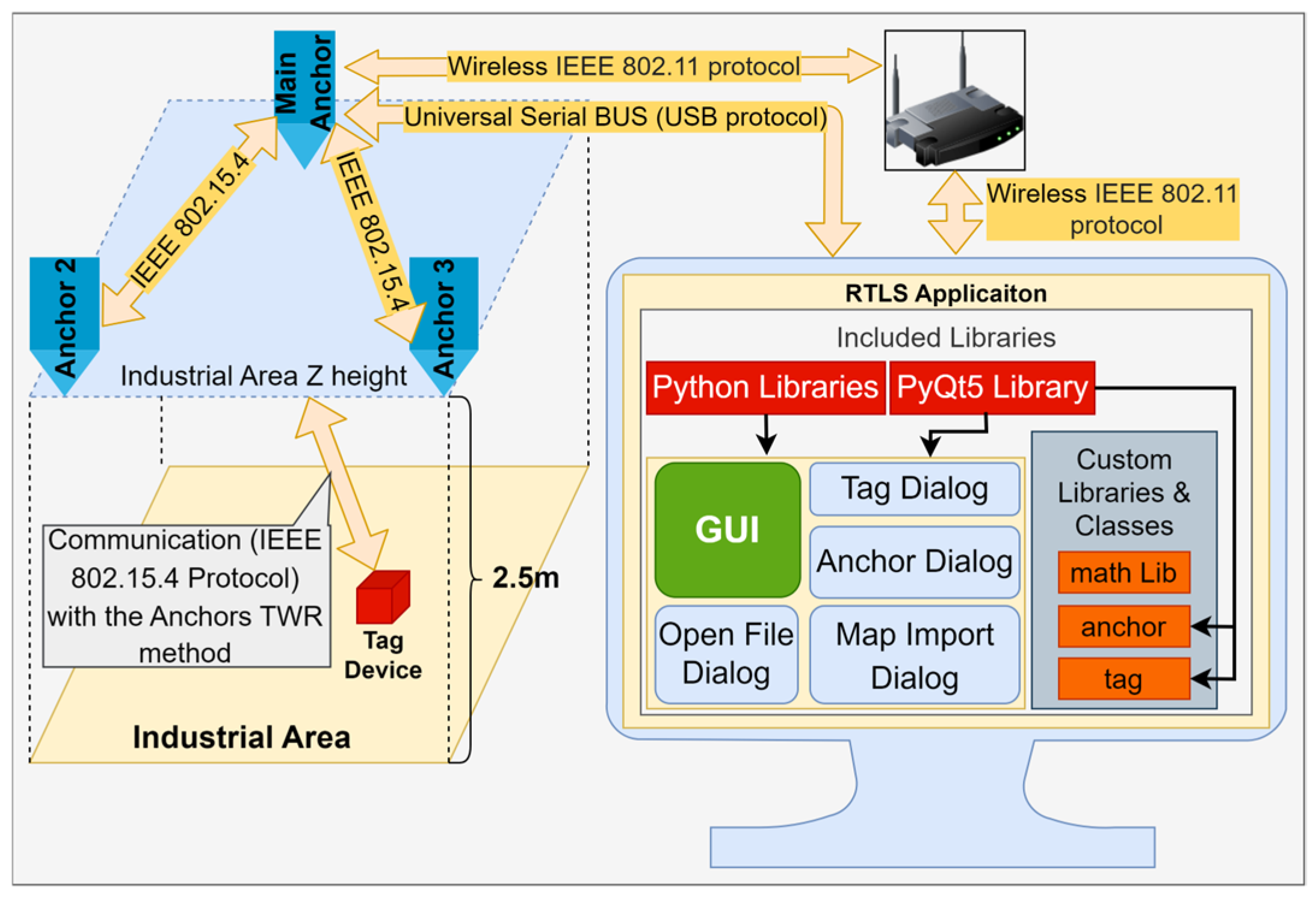

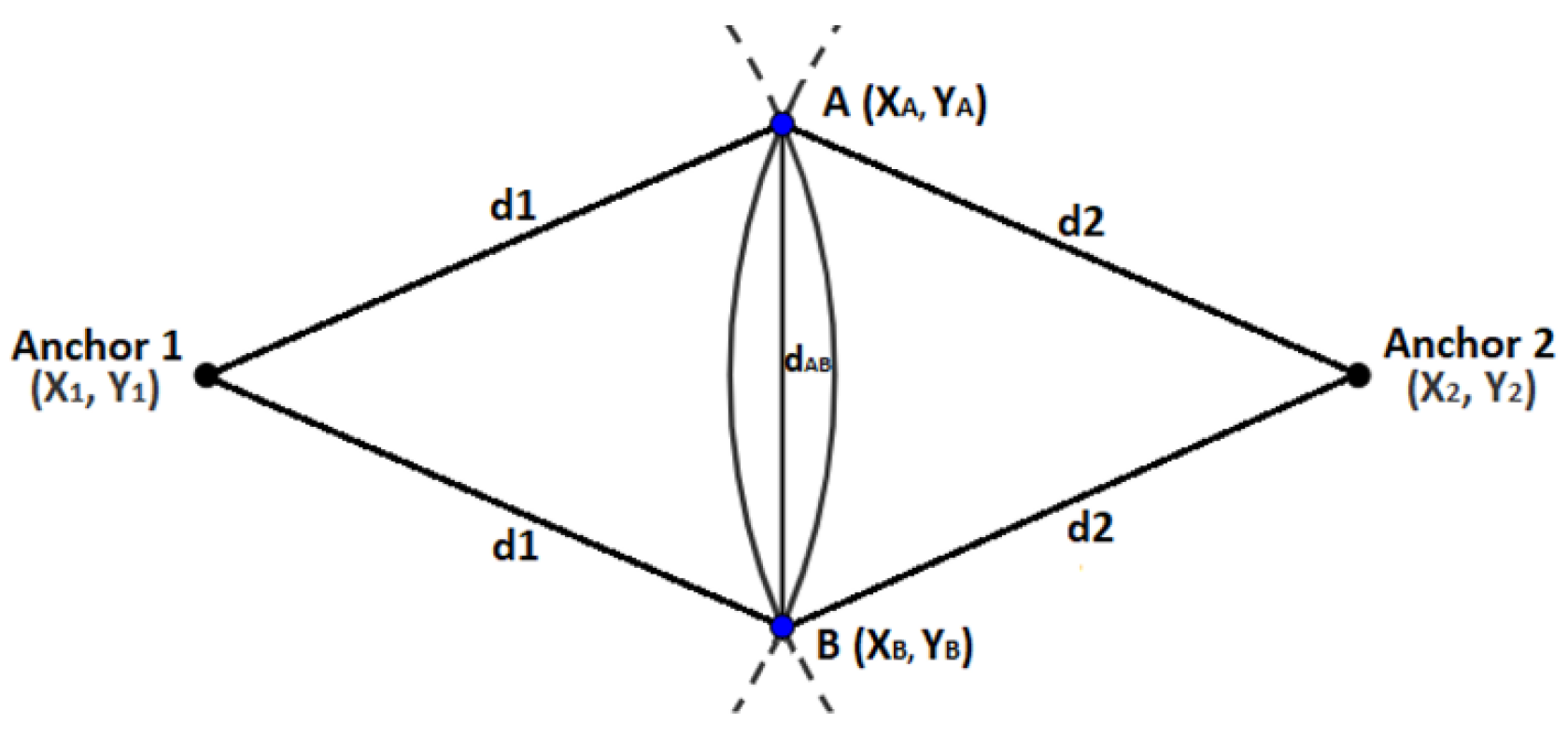

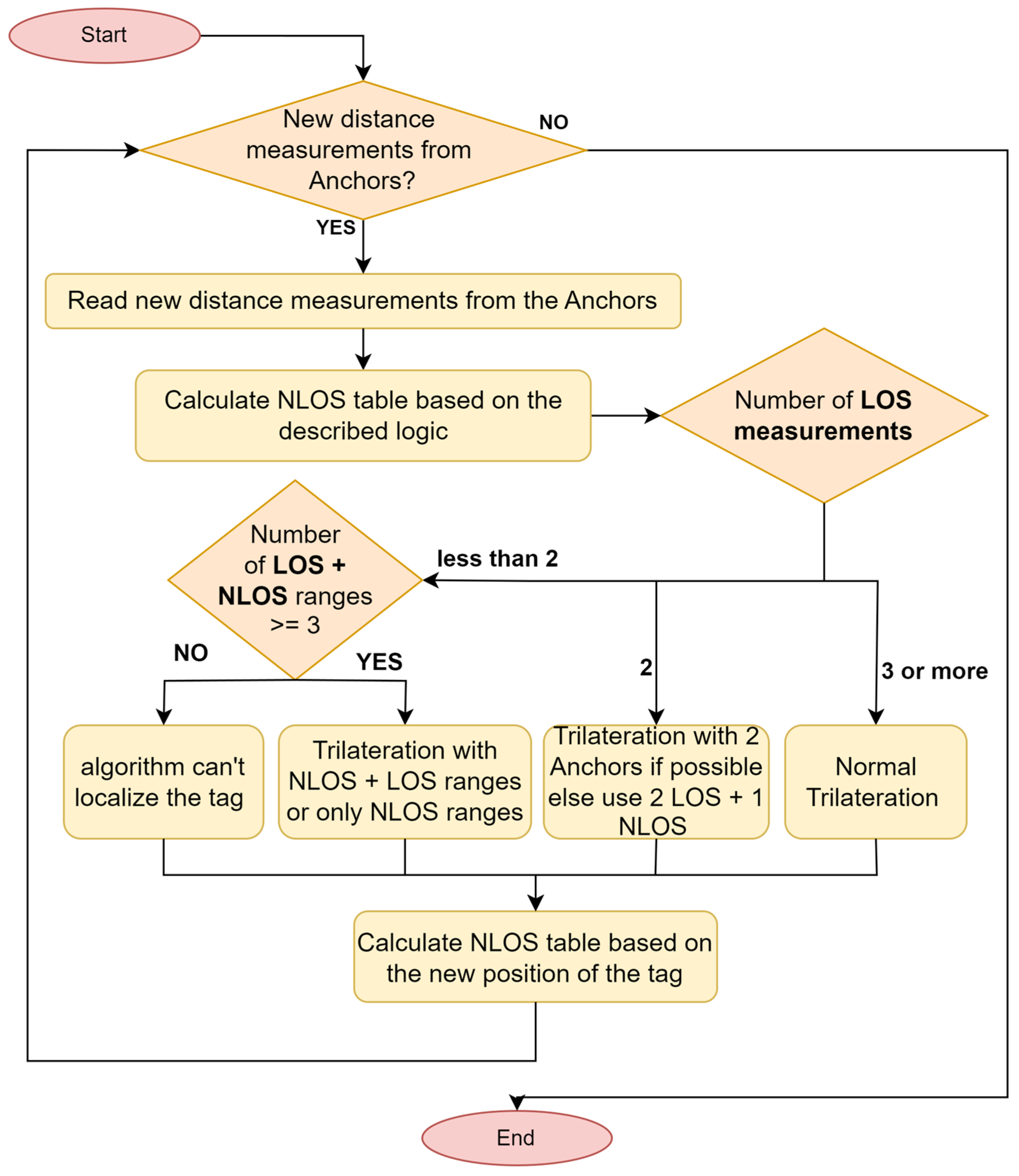

3.2. Proposed Real-Time Locating System

| Algorithm 1: System algorithm for NLOS minimization and tag position estimation |

| 1: rij,t1, rij,t2, NLOSij ⟵ 0 |

| 2: while (1) do: |

| 3: rij,t1 ⟵ rij,t2 |

| 4: read anchor’s data streams rij,t2 from USB/WiFi |

| 5: calculate new rij,t2, dtij and drij |

| 6: for i in Tags do: |

| 7: calculate newNLOSij for tag i based on Vmax speed |

| 8: numberOfLOSmeasurements = []; |

| 9: numberOfNLOSmeasurements = []; |

| 10: for j in Anchors do: |

| 11: if dr[i][j] > 0 and NLOS[i][j] = 0 and newNLOS[i][j] = 0 then |

| 12: numberOfLOSmeasurements.add(rij,t2); |

| 13: else |

| 14: numberOfNLOSmeasurements.add(rij,t2); |

| 15: end if |

| 16: end for |

| 17: if numberOfLOSmeasurements.size() > 3 then |

| 18: Tag i[x][y] ⟵ Normal_Trilateration(numberOfLOSmeasurements) |

| 19: else if numberOfLOSmeasurements.size() = 3 then |

| 20: Tag i[x][y] ⟵ Normal_Trilateration(numberOfLOSmeasurements) |

| 21: else if (numberOfLOSmeasurements.size() = 2 then |

| 22: pointA[x][y], pointB[x][y] ⟵ Find_2points_with_2_Anchors(Equation (9)) |

| 23: if Equation (10) is satisfied then |

| 24: Tag i[x][y] ⟵ closest of pointA and pointB |

| 25: end if |

| 26: else if numberOfLOSmeasurements.size() + numberOfNLOSmeasurements.size() >= 3 then |

| 27: Tag i[x][y] ⟵ Normal_Trilateration(LOS + NLOS) |

| 28: else |

| 29: Error;//can’t calculate position for tag i |

| 30: end if |

| 31: if new position for tag i was calculated then |

| 32: NLOSij = newNLOSij |

| 33: if distance from anchor j verifies the new position, then |

| 34: NLOS[i][j] ⟵ 0; |

| 35: end if |

| 36: end for |

| 37: plotTagsToMap(); |

| 38: end while |

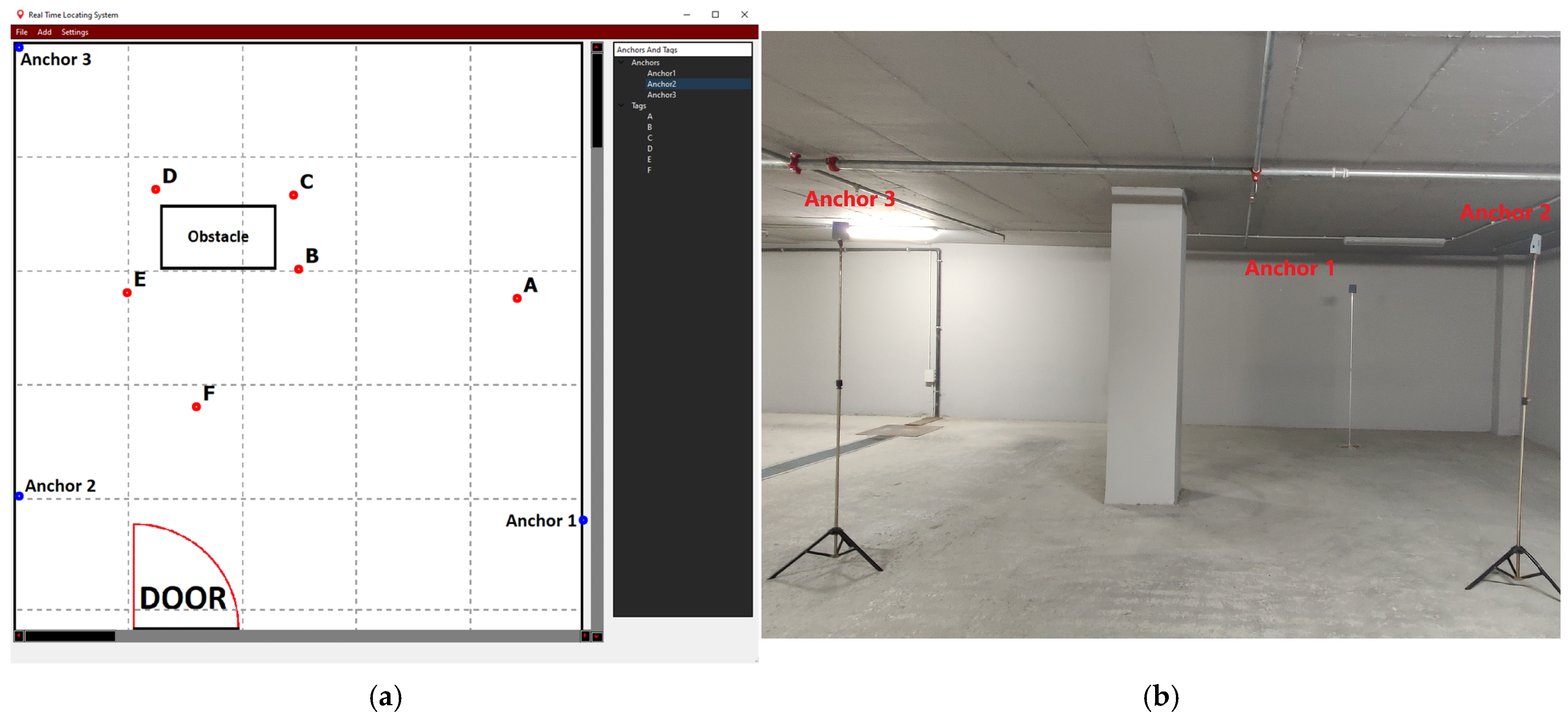

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AoA | Angle of arrival |

| BLE | Bluetooth |

| FTM | Fine-time measurement |

| GA | Genetic algorithm |

| GNSS | Global navigation satellite system |

| IMU | Inertial measurement unit |

| IoT | Internet of Things |

| IPS | Indoor positioning system |

| LIDAR | Laser imaging detection and ranging |

| LOS | Line-of-sight |

| NFER | Near-field electromagnetic range |

| NLOS | Non-line-of-sight |

| RFID | Radio frequency identification |

| RMSE | Root mean square error |

| RSSI | Received signal strength identification |

| RTLS | Real-time locating system |

| RTT | Round-trip time |

| SDS-TWR | Symmetrical double-sided two-way ranging |

| TDoA | Time difference of arrival |

| ToA | Time of arrival |

| ToF | Time-of-flight |

| TWR | Two-way ranging |

| UAV | Unmanned aerial vehicle |

| UWB | Ultra-wideband |

| VLC | Visible light communication |

| VNV | Variable noise variance Kalman filter |

References

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inf. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Sisinni, E.; Saifullah, A.; Han, S.; Jennehag, U.; Gidlund, M. Industrial Internet of Things: Challenges, Opportunities, and Directions. IEEE Trans. Ind. Inf. 2018, 14, 4724–4734. [Google Scholar] [CrossRef]

- Boyes, H.; Hallaq, B.; Cunningham, J.; Watson, T. The Industrial Internet of Things (IIoT): An Analysis Framework. Comput. Ind. 2018, 101, 1–12. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Teuteberg, F. Understanding the Implications of Digitisation and Automation in the Context of Industry 4.0: A Triangulation Approach and Elements of a Research Agenda for the Construction Industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the Current Status as Well as Future Prospects on Logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Zhao, Z.; Shen, L.; Yang, C.; Wu, W.; Zhang, M.; Huang, G.Q. IoT and Digital Twin Enabled Smart Tracking for Safety Management. Comput. Oper. Res. 2021, 128, 105183. [Google Scholar] [CrossRef]

- Kanan, R.; Elhassan, O.; Bensalem, R. An IoT-Based Autonomous System for Workers’ Safety in Construction Sites with Real-Time Alarming, Monitoring, and Positioning Strategies. Autom. Constr. 2018, 88, 73–86. [Google Scholar] [CrossRef]

- Ochoa-de-Eribe-Landaberea, A.; Zamora-Cadenas, L.; Velez, I. Untethered Ultra-Wideband-Based Real-Time Locating System for Road-Worker Safety. Sensors 2024, 24, 2391. [Google Scholar] [CrossRef]

- Shamsollahi, D.; Moselhi, O.; Khorasani, K. Data Integration Using Deep Learning and Real-Time Locating System (RTLS) for Automated Construction Progress Monitoring and Reporting. Autom. Constr. 2024, 168, 105778. [Google Scholar] [CrossRef]

- Thota, R.C.; Sara, S.M.; Sarwar Uddin, M.Y.; Bani-Yaghoub, M.; Sutkin, G. Accurate Estimation of Individual Transmission Rates Through Contact Analytics Using UWB Based Indoor Location Data. In Proceedings of the 2024 International Conference on Smart Applications, Communications and Networking, SmartNets 2024, Harrisonburg, VA, USA, 28–30 May 2024; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2024. [Google Scholar]

- Sadowski, S.; Spachos, P. Comparison of RSSI-Based Indoor Localization for Smart Buildings with Internet of Things. In Proceedings of the 2018 IEEE 9th Annual Information Technology, Electronics and Mobile Communication Conference, IEMCON 2018, Vancouver, BC, Canada, 1–3 November 2018; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2019; pp. 24–29. [Google Scholar]

- Chen, J.; Chen, H.; Luo, X. Collecting Building Occupancy Data of High Resolution Based on WiFi and BLE Network. Autom. Constr. 2019, 102, 183–194. [Google Scholar] [CrossRef]

- Zourmand, A.; Sheng, N.W.; Hing, A.L.K.; Rehman, M.A. Human Counting and Indoor Positioning System Using WiFi Technology. In Proceedings of the 2018 IEEE International Conference on Automatic Control and Intelligent Systems, I2CACIS 2018, Shah Alam, Malaysia, 20 October 2018; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2019; pp. 142–147. [Google Scholar]

- Li, S.; Hedley, M.; Bengston, K.; Humphrey, D.; Johnson, M.; Ni, W. Passive Localization of Standard WiFi Devices. IEEE Syst. J. 2019, 13, 3929–3932. [Google Scholar] [CrossRef]

- Zhang, W.; Hua, X.; Yu, K.; Qiu, W.; Zhang, S.; He, X. A Novel WiFi Indoor Positioning Strategy Based on Weighted Squared Euclidean Distance and Local Principal Gradient Direction. Sens. Rev. 2019, 39, 99–106. [Google Scholar] [CrossRef]

- Luo, J.; Zhang, Z.; Wang, C.; Liu, C.; Xiao, D. Indoor Multifloor Localization Method Based on WiFi Fingerprints and LDA. IEEE Trans. Ind. Inf. 2019, 15, 5225–5234. [Google Scholar] [CrossRef]

- Hoang, M.T.; Yuen, B.; Dong, X.; Lu, T.; Westendorp, R.; Reddy, K. Recurrent Neural Networks for Accurate RSSI Indoor Localization. IEEE Internet Things J. 2019, 6, 10639–10651. [Google Scholar] [CrossRef]

- Ridolfi, M.; Vandermeeren, S.; Defraye, J.; Steendam, H.; Gerlo, J.; De Clercq, D.; Hoebeke, J.; Poorter, E. De Experimental Evaluation of Uwb Indoor Positioning for Sport Postures. Sensors 2018, 18, 168. [Google Scholar] [CrossRef] [PubMed]

- Kulmer, J.; Hinteregger, S.; Grosswindhager, B.; Rath, M.; Bakr, M.S.; Leitinger, E.; Witrisal, K. Using DecaWave UWB Transceivers for High-Accuracy Multipath-Assisted Indoor Positioning. In Proceedings of the 2017 IEEE International Conference on Communications Workshops, ICC Workshops 2017, Paris, France, 21–25 May 2017; pp. 1239–1245. [Google Scholar] [CrossRef]

- Witrisal, K.; Hinteregger, S.; Kulmer, J.; Leitinger, E.; Meissner, P. High-Accuracy Positioning for Indoor Applications: RFID, UWB, 5G, and Beyond. In Proceedings of the 2016 IEEE International Conference on RFID, RFID 2016, Orlando, FL, USA, 3–5 May 2016. [Google Scholar] [CrossRef]

- De Angelis, G.; Moschitta, A.; Carbone, P. Positioning Techniques in Indoor Environments Based on Stochastic Modeling of UWB Round-Trip-Time Measurements. IEEE Trans. Intell. Transp. Syst. 2016, 17, 2272–2281. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, Y.; Gui, X.; Han, L. An Improved PDR/UWB Integrated System for Indoor Navigation Applications. IEEE Sens. J. 2020, 20, 8046–8061. [Google Scholar] [CrossRef]

- Yu, J.; Na, Z.; Liu, X.; Deng, Z. WiFi/PDR-Integrated Indoor Localization Using Unconstrained Smartphones. EURASIP J. Wirel. Commun. Netw. 2019, 2019, 41. [Google Scholar] [CrossRef]

- Kianfar, A.; Uth, F.; Baltes, R.; Clausen, E. Development of a Robust Ultra-Wideband Module for Underground Positioning and Collision Avoidance. Min. Metall. Explor. 2020, 37, 1821–1825. [Google Scholar] [CrossRef]

- Bharadwaj, R.; Swaisaenyakorn, S.; Parini, C.G.; Batchelor, J.C.; Alomainy, A. Impulse Radio Ultra-Wideband Communications for Localization and Tracking of Human Body and Limbs Movement for Healthcare Applications. IEEE Trans. Antennas Propag. 2017, 65, 7298–7309. [Google Scholar] [CrossRef]

- Woods, J.M.; Adcock, S.J.J. Validation of an Indoor Real-Time Location System for Tracking Sheep. Comput. Electron. Agric. 2024, 227, 109535. [Google Scholar] [CrossRef]

- Bendavid, Y.; Rostampour, S.; Berrabah, Y.; Bagheri, N.; Safkhani, M. The Rise of Passive RFID RTLS Solutions in Industry 5.0. Sensors 2024, 24, 1711. [Google Scholar] [CrossRef] [PubMed]

- Gharat, V.; Colin, E.; Baudoin, G.; Richard, D. Indoor Performance Analysis of LF-RFID Based Positioning System: Comparison with UHF-RFID and UWB. In Proceedings of the 2017 International Conference on Indoor Positioning and Indoor Navigation, IPIN 2017, Sapporo, Japan, 18–21 September 2017; pp. 1–8. [Google Scholar] [CrossRef]

- Diallo, A.; Lu, Z.; Zhao, X. Wireless Indoor Localization Using Passive RFID Tags. Procedia Comput. Sci. 2019, 155, 210–217. [Google Scholar] [CrossRef]

- Qi, J.; Liu, G.P. A Robust High-Accuracy Ultrasound Indoor Positioning System Based on a Wireless Sensor Network. Sensors 2017, 17, 2554. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Guan, W.; Li, S.; Wu, Y. Indoor High Precision Three-Dimensional Positioning System Based on Visible Light Communication Using Modified Genetic Algorithm. Opt. Commun. 2018, 413, 103–120. [Google Scholar] [CrossRef]

- Yadav, R.; Chugh, H.; Jain, V.; Baneriee, P. Indoor Navigation System Using Visual Positioning System with Augmented Reality. In Proceedings of the 2018 International Conference on Automation and Computational Engineering, ICACE 2018, Greater Noida, India, 3–4 October 2018; pp. 52–56. [Google Scholar] [CrossRef]

- Rodríguez-Araújo, J.; Rodríguez-Andina, J.J.; Fariña, J.; Chow, M.Y. Field-Programmable System-on-Chip for Localization of UGVs in an Indoor Ispace. IEEE Trans. Ind. Inf. 2014, 10, 1033–1043. [Google Scholar] [CrossRef]

- Duong, S.N.; Trinh, A.V.T.; Dinh, T.M. Bluetooth Low Energy Based Indoor Positioning on IOS Platform. In Proceedings of the 2018 IEEE 12th International Symposium on Embedded Multicore/Many-Core Systems-on-Chip, MCSoC 2018, Hanoi, Vietnam, 12–14 September 2018; pp. 57–63. [Google Scholar] [CrossRef]

- Pau, G.; Arena, F.; Gebremariam, Y.E.; You, I. Bluetooth5.1: An Analysis of Direction Finding Capability for High-Precision Location Services. Sensors 2021, 21, 3589. [Google Scholar] [CrossRef]

- Astafiev, A.V.; Zhiznyakov, A.L.; Privezentsev, D.G. Development of Indoor Positioning Algorithm Based on Bluetooth Low Energy Beacons for Building RTLS-Systems. In Proceedings of the 2019 International Russian Automation Conference, RusAutoCon 2019, Sochi, Russia, 8–14 September 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Jeon, J.S.; Kong, Y.; Nam, Y.; Yim, K. An Indoor Positioning System Using Bluetooth RSSI with an Accelerometer and a Barometer on a Smartphone. In Proceedings of the 2015 10th International Conference on Broadband and Wireless Computing, Communication and Applications, BWCCA 2015, Krakow, Poland, 4–6 November 2015; pp. 528–531. [Google Scholar] [CrossRef]

- Woo, S.; Jeong, S.; Mok, E.; Xia, L.; Choi, C.; Pyeon, M.; Heo, J. Application of WiFi-Based Indoor Positioning System for Labor Tracking at Construction Sites: A Case Study in Guangzhou MTR. Autom. Constr. 2011, 20, 3–13. [Google Scholar] [CrossRef]

- Abbas, M.; Elhamshary, M.; Rizk, H.; Torki, M.; Youssef, M. WiDeep: WiFi-Based Accurate and Robust Indoor Localization System Using Deep Learning. In Proceedings of the 2019 IEEE International Conference on Pervasive Computing and Communications, PerCom 2019, Kyoto, Japan, 11–15 March 2019. [Google Scholar] [CrossRef]

- Karlsson, F.; Karlsson, M.; Bernhardsson, B.; Tufvesson, F.; Persson, M. Sensor Fused Indoor Positioning Using Dual Band WiFi Signal Measurements. In Proceedings of the 2015 European Control Conference, ECC 2015, Linz, Austria, 15–17 July 2015; pp. 1669–1672. [Google Scholar] [CrossRef]

- Haryanto, D.K.; Karyono, K.; Hutagalung, S. The Comparison between Geo-Magnetism and WiFi for Indoor Positioning System for Public Places. In Proceedings of the 2018 International Conference on Robotics, Biomimetics, and Intelligent Computational Systems, Robionetics 2018, Bandung, Indonesia, 8–10 August 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Hernández, N.; Parra, I.; Corrales, H.; Izquierdo, R.; Ballardini, A.L.; Salinas, C.; García, I. WiFiNet: WiFi-Based Indoor Localisation Using CNNs. Expert. Syst. Appl. 2021, 177, 114906. [Google Scholar] [CrossRef]

- Park, K.M.; Lee, B.H.; Lee, E.; Kim, S.C.; Choi, J. GPS-Aided Automatic Site Survey Method for WiFi RTT-Based Positioning. IEEE Trans. Veh. Technol. 2023, 72, 13120–13129. [Google Scholar] [CrossRef]

- Orfanos, M.; Perakis, H.; Gikas, V.; Retscher, G.; Mpimis, T.; Spyropoulou, I.; Papathanasopoulou, V. Testing and Evaluation of Wi-Fi RTT Ranging Technology for Personal Mobility Applications. Sensors 2023, 23, 2829. [Google Scholar] [CrossRef] [PubMed]

- Rana, L.; Park, J.G. An Enhanced Indoor Positioning Method Based on RTT and RSS Measurements under LOS/NLOS Environment. IEEE Sens. J. 2024, 24, 31417–31430. [Google Scholar] [CrossRef]

- Horn, B.K.P. Round-Trip Time Ranging to Wi-Fi Access Points Beats GNSS Localization. Appl. Sci. 2024, 14, 7805. [Google Scholar] [CrossRef]

- Krummenauer, A.; Gomes, V.E.d.O.; Nardelli, V.C. Estimation of Measurement Uncertainty of the Real-Time Location System (RTLS) with Ultra-Wideband (UWB) Technology. Metrology 2023, 3, 113–130. [Google Scholar] [CrossRef]

- Qorvo DW1000. Available online: https://www.qorvo.com/products/p/DW1000 (accessed on 16 January 2025).

- Ubisense. Available online: https://ubisense.com (accessed on 17 January 2025).

- SEWIO. Available online: https://www.sewio.net (accessed on 16 January 2025).

- Jiménez, A.R.; Seco, F. Comparing Decawave and Bespoon UWB Location Systems: Indoor/Outdoor Performance Analysis. In Proceedings of the 2016 International Conference on Indoor Positioning and Indoor Navigation, IPIN 2016, Alcala de Henares, Spain, 4–7 October 2016. [Google Scholar] [CrossRef]

- Ruiz, A.R.J.; Granja, F.S. Comparing Ubisense, BeSpoon, and DecaWave UWB Location Systems: Indoor Performance Analysis. IEEE Trans. Instrum. Meas. 2017, 66, 2106–2117. [Google Scholar] [CrossRef]

- Schroeer, G. A Real-Time UWB Multi-Channel Indoor Positioning System for Industrial Scenarios. In Proceedings of the IPIN 2018—9th International Conference on Indoor Positioning and Indoor Navigation, Nantes, France, 24–27 September 2018; pp. 3–7. [Google Scholar] [CrossRef]

- OptiTrack. Available online: https://www.optitrack.com (accessed on 16 January 2025).

- Ambrose, A.; Savur, C.; Sahin, F. Low Cost Real Time Location Tracking with Ultra-Wideband. In Proceedings of the 2022 17th Annual System of Systems Engineering Conference, SOSE 2022, Rochester, NY, USA, 7–11 June 2022; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2022; pp. 445–450. [Google Scholar]

- Bing, W.; Yanyan, L.; Qingquan, L.; Yan, Z. A High-Precision Dynamic Indoor Localization Algorithm Based on UWB Technology. In Proceedings of the 5th IEEE Conference on Ubiquitous Positioning, Indoor Navigation and Location-Based Services, UPINLBS 2018, Wuhan, China, 22–23 March 2018; pp. 1–7. [Google Scholar] [CrossRef]

- Ochoa-De-eribe-landaberea, A.; Zamora-Cadenas, L.; Peñagaricano-Muñoa, O.; Velez, I. UWB and IMU-Based UAV’s Assistance System for Autonomous Landing on a Platform. Sensors 2022, 22, 2347. [Google Scholar] [CrossRef]

- Al-Khaddour, M.; Ali, M.; Yousef, M. Line-of-Sight Aware Accurate Collaborative Localization Based on Joint TDoA and AoA Measurements in UWB-MIMO Environment. Clust. Comput. 2024, 27, 7637–7655. [Google Scholar] [CrossRef]

- Plangger, J.; Govindasamy Ravichandran, H.; Rodin, S.C.; Atia, M. System Design and Performance Analysis of Indoor Real-Time Localization Using UWB Infrastructure. In Proceedings of the SysCon 2023—17th Annual IEEE International Systems Conference, Proceedings, Vancouver, BC, Canada, 17–20 April 2023; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2023. [Google Scholar]

- Zhao, Y.; Wang, M. The LOS/NLOS Classification Method Based on Deep Learning for the UWB Localization System in Coal Mines. Appl. Sci. 2022, 12, 6484. [Google Scholar] [CrossRef]

- Kim, D.H.; Pyun, J.Y. Enhanced UWB Ranging Utilizing Denoising Neural Network. IEEE Commun. Lett. 2024, 28, 1029–1033. [Google Scholar] [CrossRef]

- Kim, J.H.; An, H.G.; Komuro, N.; Kim, W.S. Bias and Deviation Map-Based Weighted Graph Search for NLOS Indoor RTLS Calibration. Electronics 2024, 13, 3993. [Google Scholar] [CrossRef]

- Yao, L.; Wu, Y.W.A.; Yao, L.; Liao, Z.Z. An Integrated IMU and UWB Sensor Based Indoor Positioning System. In Proceedings of the 2017 International Conference on Indoor Positioning and Indoor Navigation, IPIN 2017, Sapporo, Japan, 18–21 September 2017; pp. 1–8. [Google Scholar] [CrossRef]

- De Cock, C.; Joseph, W.; Martens, L.; Trogh, J.; Plets, D. Multi-Floor Indoor Pedestrian Dead Reckoning with a Backtracking Particle Filter and Viterbi-Based Floor Number Detection. Sensors 2021, 21, 4565. [Google Scholar] [CrossRef] [PubMed]

- Hyun, J.; Oh, T.; Lim, H.; Myung, H. UWB-Based Indoor Localization Using Ray-Tracing Algorithm. In Proceedings of the 2019 16th International Conference on Ubiquitous Robots, UR 2019, Jeju, Republic of Korea, 24–27 June 2019; pp. 98–101. [Google Scholar] [CrossRef]

- Vandermeeren, S.; Steendam, H. PDR/UWB Based Positioning of a Shopping Cart. IEEE Sens. J. 2021, 21, 10864–10878. [Google Scholar] [CrossRef]

- Vleugels, R.; Van Herbruggen, B.; Fontaine, J.; De Poorter, E. Ultra-Wideband Indoor Positioning and Imu-Based Activity Recognition for Ice Hockey Analytics. Sensors 2021, 21, 4650. [Google Scholar] [CrossRef]

- Pérez-Solano, J.J.; Ezpeleta, S.; Claver, J.M. Indoor Localization Using Time Difference of Arrival with UWB Signals and Unsynchronized Devices. Ad Hoc Netw. 2020, 99, 102067. [Google Scholar] [CrossRef]

- Athikulwongse, K.; Suwatthikul, C.; Chantaweesomboon, W. Impact of Altitude of Anchors on Performance of UWB Real-Time Locating System. In Proceedings of the 2018 International Conference on Embedded Systems and Intelligent Technology and International Conference on Information and Communication Technology for Embedded Systems, ICESIT-ICICTES 2018, Khon Kaen, Thailand, 7–9 May 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Alarifi, A.; Al-Salman, A.; Alsaleh, M.; Alnafessah, A.; Al-Hadhrami, S.; Al-Ammar, M.A.; Al-Khalifa, H.S. Ultra Wideband Indoor Positioning Technologies: Analysis and Recent Advances. Sensors 2016, 16, 707. [Google Scholar] [CrossRef] [PubMed]

- Kunhoth, J.; Karkar, A.G.; Al-Maadeed, S.; Al-Ali, A. Indoor Positioning and Wayfinding Systems: A Survey. Hum. Centric Comput. Inf. Sci. 2020, 10, 18. [Google Scholar] [CrossRef]

- Yassin, A.; Nasser, Y.; Awad, M.; Al-Dubai, A.; Liu, R.; Yuen, C.; Raulefs, R.; Aboutanios, E. Recent Advances in Indoor Localization: A Survey on Theoretical Approaches and Applications. IEEE Commun. Surv. Tutor. 2017, 19, 1327–1346. [Google Scholar] [CrossRef]

- Yoon, P.K.; Zihajehzadeh, S.; Kang, B.S.; Park, E.J. Robust Biomechanical Model-Based 3-D Indoor Localization and Tracking Method Using UWB and IMU. IEEE Sens. J. 2017, 17, 1084–1096. [Google Scholar] [CrossRef]

- Grasso, P.; Innocente, M.S. Theoretical Study of Signal and Geometrical Properties of Two-Dimensional UWB-Based Indoor Positioning Systems Using TDoA. In Proceedings of the 2020 6th International Conference on Mechatronics and Robotics Engineering, ICMRE 2020, Barcelona, Spain, 12–15 February 2020; pp. 130–134. [Google Scholar] [CrossRef]

- Simedroni, R.; Puschita, E.; Palade, T.; Dolea, P.; Codau, C.; Buta, R.; Pastrav, A. Indoor Positioning Using Decawave MDEK1001. In Proceedings of the 2020 International Workshop on Antenna Technology, iWAT 2020, Bucharest, Romania, 25–28 February 2020. [Google Scholar] [CrossRef]

- Martínez del Horno, M.; Orozco-Barbosa, L.; García-Varea, I. A Smartphone-Based Multimodal Indoor Tracking System. Inf. Fusion 2021, 76, 36–45. [Google Scholar] [CrossRef]

- Truong-Quang, V.; Ho-Sy, T. Maximum Convergence Algorithm for WiFi Based Indoor Positioning System. Int. J. Electr. Comput. Eng. 2021, 11, 4027–4036. [Google Scholar] [CrossRef]

- Chen, W. Personnel Precise Positioning System of Coal Mine Underground Based on UWB. J. Phys. Conf. Ser. 2021, 1920, 012115. [Google Scholar] [CrossRef]

- Šinko, S.; Marinič, E.; Poljanec, B.; Obrecht, M.; Gajšek, B. Performance-Oriented UWB RTLS Decision-Making Approach. Sustainability 2022, 14, 11456. [Google Scholar] [CrossRef]

- Pestourie, B.; Beroulle, V.; Fourty, N. Security Evaluation with an Indoor UWB Open Platform: Acknowledgment Attack Case Study. In Proceedings of the IEEE 30th Annual International Symposium on Personal, Indoor and Mobile Radio Communications (PIMRC): Track 3: Mobile and Wireless Networks, Istanbul, Turkey, 8–11 September 2019; IEEE: New York, NY, USA, 2019. ISBN 9781538681107. [Google Scholar]

- Mayer, P.; Magno, M.; Schnetzler, C.; Benini, L. EmbedUWB: Low Power Embedded High-Precision and Low Latency UWB Localization. In Proceedings of the 2019 IEEE 5th World Forum on Internet of Things (WF-IoT), Limerick, Ireland, 15–18 April 2019; Institute of Electrical and Electronics Engineers: New York, NY, USA, 2019; p. 814, ISBN 9781538649800. [Google Scholar]

- Silva, B.; Hancke, G.P. IR-UWB-Based Non-Line-of-Sight Identification in Harsh Environments: Principles and Challenges. IEEE Trans. Ind. Inf. 2016, 12, 1188–1195. [Google Scholar] [CrossRef]

| RTLS Technologies | Accuracy | LOS/NLOS Impact | Range | Complexity | Cost |

|---|---|---|---|---|---|

| RFID | Mid | - | Low | Low | Mid |

| Ultrasound | High | - | Low | Low | Mid |

| Visible Light | High | - | Mid | High | High |

| IMU | Mid | Low | High | High | Low |

| Bluetooth | Low | High | Mid | Low | Low |

| Image Recognition | High | - | Mid | High | High |

| Wi-Fi 2.4 GHz RSSI | Low | High | High | Low | Low |

| Wi-Fi 5 GHz RSSI | Low | High | High | Low | Low |

| Wi-Fi FTM RTT | Mid | Mid | High | Low | Low |

| Ultra-Wide Band | Mid | Low | High | Low | Mid |

| Point (X,Y) | Normal Trilateration Algorithm Error | Proposed RLTS System Error | ||||

|---|---|---|---|---|---|---|

| X RMSE | Y RMSE | Euclidean RMSE | X RMSE | Y RMSE | Euclidean RMSE | |

| A (4.40,3.00) (100 samples) | 0.071 | 0.068 | 0.098 | 0.060 | 0.074 | 0.095 |

| B (2.50,3.20) (100 samples) | 0.143 | 0.141 | 0.201 | 0.097 | 0.110 | 0.147 |

| C (2.40,3.80) (100 samples) | 0.147 | 0.136 | 0.201 | 0.118 | 0.126 | 0.173 |

| D (1.25,3.90) (100 samples) | 0.131 | 0.158 | 0.205 | 0.085 | 0.079 | 0.115 |

| E (1.00,3.00) (100 samples) | 0.085 | 0.112 | 0.140 | 0.070 | 0.066 | 0.096 |

| F (1.60,2.00) (100 samples) | 0.060 | 0.064 | 0.088 | 0.068 | 0.069 | 0.097 |

| Overall error (600 samples) | 0.112 | 0.118 | 0.163 | 0.086 | 0.090 | 0.124 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sidiropoulos, A.; Bechtsis, D.; Vlachos, D. Implementing an Industry 4.0 UWB-Based Real-Time Locating System for Optimized Tracking. Appl. Sci. 2025, 15, 2689. https://doi.org/10.3390/app15052689

Sidiropoulos A, Bechtsis D, Vlachos D. Implementing an Industry 4.0 UWB-Based Real-Time Locating System for Optimized Tracking. Applied Sciences. 2025; 15(5):2689. https://doi.org/10.3390/app15052689

Chicago/Turabian StyleSidiropoulos, Athanasios, Dimitrios Bechtsis, and Dimitrios Vlachos. 2025. "Implementing an Industry 4.0 UWB-Based Real-Time Locating System for Optimized Tracking" Applied Sciences 15, no. 5: 2689. https://doi.org/10.3390/app15052689

APA StyleSidiropoulos, A., Bechtsis, D., & Vlachos, D. (2025). Implementing an Industry 4.0 UWB-Based Real-Time Locating System for Optimized Tracking. Applied Sciences, 15(5), 2689. https://doi.org/10.3390/app15052689